Abstract

Some of the strongest electromagnetic fields (EMF) are found in the workplace. A European Directive sets limits to workers’ exposure to EMF. This review summarizes its origin and contents and compares magnetic field exposure levels in high-risk workplaces with the limits set in the revised Directive. Pubmed, Scopus, grey literature databases, and websites of organizations involved in occupational exposure measurements were searched. The focus was on EMF with frequencies up to 10 MHz, which can cause stimulation of the nervous system. Selected studies had to provide individual maximum exposure levels at the workplace, either in terms of the external magnetic field strength or flux density or as induced electric field strength or current density. Indicative action levels and the corresponding exposure limit values for magnetic fields in the revised European Directive will be higher than those in the previous version. Nevertheless, magnetic flux densities in excess of the action levels for peripheral nerve stimulation are reported for workers involved in welding, induction heating, transcranial magnetic stimulation, and magnetic resonance imaging (MRI). The corresponding health effects exposure limit values for the electric fields in the worker’s body can be exceeded for welding and MRI, but calculations for induction heating and transcranial magnetic stimulation are lacking. Since the revised European Directive conditionally exempts MRI-related activities from the exposure limits, measures to reduce exposure may be necessary for welding, induction heating, and transcranial nerve stimulation. Since such measures can be complicated, there is a clear need for exposure databases for different workplace scenarios with significant EMF exposure and guidance on good practices.

Keywords: electromagnetic fields, legislation, occupational exposure, peripheral nervous system

INTRODUCTION

Electromagnetic fields (EMF) can affect the human body via two main mechanisms. For frequencies up to 10 MHz, time-varying electric fields are induced in the body, which may affect the electrical properties of living cells and alter their function (Reilly, 1998). For frequencies >100kHz, the induced electric fields generate an oscillating current, which transfers energy to the body and may increase local or whole-body temperature (Challis, 2005). The International Commission on Non-Ionizing Radiation Protection (ICNIRP) has recommended basic restrictions for occupational exposure below which no adverse effects should occur in healthy, adult workers. The basic restrictions for exposure of the general public are two to five times lower than those for workers to account for variations in vulnerability due to age and health status. For frequencies between 1 Hz and 10 MHz, the basic restrictions are set in terms of the induced electric field strength in the body to prevent perceptible stimulation of nerve fibres, which may become painful at higher intensities. Between 1 and 400 Hz a second, lower basic restriction is also set to prevent the induction of magnetophosphenes in the retina, which may cause a startle reaction and affect worker safety. For frequencies between 100kHz and 10 GHz, basic restrictions are set in terms of the specific absorption rate to prevent whole-body heat stress and excessive localized tissue heating. For frequencies between 10 and 300 GHz, ICNIRP sets basic restrictions in terms of power density to prevent excessive heating in tissue at or near the body surface. Since the induced electric field and specific absorption rate cannot be measured directly, ICNIRP has also set reference levels in terms of the strength of the EMF outside the body. According to ICNIRP, worker exposure below the reference levels guarantees that the basic restrictions are not exceeded. When the reference levels are exceeded, additional assessments, which may include calculations, are necessary to establish whether the basic restrictions are exceeded (ICNIRP, 1998, 2010).

Some of the strongest human-made sources of EMF can be found in the workplace. In 2004, the Council and Parliament of the European Union therefore adopted Directive 2004/40/EC, which sets general rules for the obligations of employers in protecting workers against the risks of EMF (European Parliament and Council, 2004). This Directive also contains annexes in which the basic restrictions in the 1998 ICNIRP recommendations are used as binding limits for worker exposure. The terminology differs from that of ICNIRP: basic restrictions are called ‘exposure limit values’ and reference levels are called ‘action values’. Concerns were expressed that the limits in the Directive would make some activities of hospital workers involving magnetic resonance imaging (MRI) impossible (Keevil et al., 2005; European Society of Radiology, 2007). Indeed, subsequent exposure measurements established that the action values and exposure limit values in the Directive could be exceeded for some hospital workers’ tasks near MRI equipment (Capstick et al., 2007; Chadwick, 2007; Stam, 2008). Since ICNIRP had also announced that its guidelines for static magnetic fields and for EMF with frequencies up to 10 MHz were to be updated, the European Commission, European Parliament and Council of the European Union subsequently followed due procedure to revise the Directive. The final revised Directive was adopted by the Parliament and Council on 26 June 2013 and published in the Official Journal of the European Union (European Parliament and Council, 2013).

For static magnetic fields, which were omitted from the 2004 Directive, the 2013 Directive sets exposure limit values, which are identical to those in the most recent ICNIRP guidelines (ICNIRP, 2009). For electrical stimulation effects (frequencies up to 10 MHz), the exposure limit values and action values (now called ‘action levels’) are based on the 2010 ICNIRP guidelines. For heating effects (frequencies >100kHz), they are still based on the 1998 ICNIRP guidelines. The main difference between the limits in the 2004 Directive and in the 2013 Directive is the introduction of two tiers of exposure limit values and action levels for low frequencies. For magnetic fields with frequencies between 1 and 400 Hz, ICNIRP provides reference levels only for the basic restrictions related to effects on the ‘central nervous system in the head’ (magnetophosphenes). These are called ‘low action levels’ in the revised Directive and correspond to the sensory effects (magnetophosphenes) exposure limit values. The ‘high action levels’ between 1 and 400 Hz are derived from ICNIRP basic restrictions for ‘all tissues of head and body’ based on nerve stimulation, using the same conversion factor (45V/m/T) and safety factor (3) that ICNIRP uses for frequencies between 400 Hz and 10 MHz (ICNIRP, 2010). The revised Directive calls these basic restrictions ‘health effects exposure limit values’. Unlike ICNIRP, the revised Directive also has separate action levels for exposures of limbs, which are three times higher than the action levels for the whole body (including head and trunk). This is because the smaller diameter of the limbs means that the same external magnetic flux density induces a lower internal electric field strength. For external electric fields, separate high and low action levels are provided between 25 Hz and 10 MHz for workplaces with or without adequate measures to prevent spark discharges.

The second major change compared with Directive 2004/40/EC concerns an article on derogations (Article 10). Worker exposure related to the installation, testing, use, development, maintenance of or research related to MRI equipment used for patients in the health sector may exceed the exposure limit values in the annexes of the revised Directive. The conditions are that derogation is only applied in duly justified circumstances and that all state-of-the-art technical and organizational protection measures have been applied and workers are still protected against adverse health effects and safety risks, among others by following the manufacturer’s instructions for safe use. Personnel working in operational military installations or involved in military activities may apply a system equivalent to or more specific than that in the annexes of the revised Directive, such as the system in NATO standards. Finally, member states may allow, as long as duly justified circumstances apply, exposure limit values to be temporarily exceeded in other employment sectors where all technical and organizational measures have been applied and workers are still protected against adverse health effects and safety risks. Member states have to inform the European Commission of any derogations other than that for MRI in their implementation report (European Parliament and Council, 2013).

Earlier assessments have already established that the action values and exposure limit values in Directive 2004/40/EC can be exceeded under some circumstances for workers near equipment for resistance welding, induction heating, electrolysis, broadcasting antennas, and MRI (Bolte and Pruppers, 2006; Decat et al., 2006; Capstick et al., 2007; Chadwick, 2007; Broeckx et al., 2008). Since most of these ‘problem-sources’ emit EMF with frequencies <10 MHz and since the limits for radiofrequency sources have not changed since 2004, the present review only presents an analysis of worker exposure for low frequency sources (1 Hz to 10 MHz). This review focuses on ambient magnetic fields in the workplace. Although ambient electric fields can also induce electric fields in the body, for low frequency fields the induced field strength is orders of magnitude lower than that caused by magnetic fields from the same source. The main risks associated with ambient electric fields in the workplace are indirect, i.e. contact currents and spark discharges from objects or persons charged by the field (Reilly, 1998). The results give an indication of the degree to which the action levels and exposure limit values in the revised Directive may be exceeded in working environments with high exposures and where measures to reduce exposure may be necessary.

METHODS

Literature search and selection

The web-based scientific literature databases Pubmed (http://www.ncbi.nlm.nih.gov/pubmed/) and Scopus (http://www.scopus.com/) were searched up to October 2012 with combinations of the following search units: (electromagnetic OR magnetic) AND field*; occupational OR worker*; medical OR hospital OR clinical OR (healthcare); mri OR (magnetic resonance); induction OR oven* OR heating OR heater* OR furnace*; welding OR welder*; electrolysis OR electrochemical; electrical OR electricity OR generator OR (power plant). A search for grey literature in Dutch, English, French, and German was also conducted with various combinations of the above key words in Picarta (http://picarta.pica.nl/), OpenGrey (http://www.opengrey.eu/), the National Technical Information Service (http://www.ntis.gov/) database, and on the websites of the following organizations: Allgemeine Unfallsversicherungsanstalt (Austria); Bayerisches Landesamt für Arbeitsschutz, Arbeitsmedizin und Sicherheitstechnik (Germany); Deutsche Gesetzliche Unfallsversicherung (Germany); Hauptverband der Gewerbliche Berufsgenossenschaften (Germany); Health Protection Agency (UK); Health and Safety Executive (UK); Institut Nationale de Recherche et de Sécurité (France); DNV-KEMA (Netherlands); National Institute for Occupational Safety and Health (USA); Vlaamse Instelling voor Technologisch Onderzoek (Belgium). Only publicly available measurement reports were used.

Full publications with results of measurement of magnetic fields in the workplace, or calculation of the resulting induced electric fields or currents in the body, were selected for further analysis. For comparison with limits based on electrical stimulation effects (frequencies between 1 Hz and 10 MHz), instantaneous individual exposure values should be used (ICNIRP, 2010). Therefore, only those publications listing individual maximum exposure values at specific frequencies were used. Other publications, which list time-averaged or frequency-averaged exposures or group averages only, were not used since these make it impossible to compare maximum individual exposures to the action levels (based on ICNIRP reference levels) or exposure limit values (based on ICNIRP basic restrictions). No date limit was set on the publication year, since some of the older devices may still be in use and it is not clear that the strength of the EMF that newer devices generate is necessarily lower. An overview of the publications from which exposure data were extracted is given in Table 1.

Table 1.

| Figure | Workplace | References |

|---|---|---|

| 1A | Welding | Lovsund and Oberg, 1982; Ortendahl and Högstedt, 1988; Stuchly and Lecuyer, 1989; Szuba, 1993; Allen et al., 1994; Moss and Booher, 1996; Skyberg et al., 2001; Bayerisches Landesamt Für Arbeitsschutz, 2002; Cooper, 2002; Dasdag et al., 2002; Sakurazawa et al., 2003; Vereinigung der Metall-Berufsgenossenschaften, 2003; Nadeem et al., 2004; Melton, 2005; Herrault and Donato, 2006; Broeckx et al., 2008; Molla-Djafari et al., 2008; Börner, 2009; Sharifian et al., 2009; Yamaguchi-Sekino et al., 2011. |

| 1B | Induction heating | Neubauer et al., n.d.; Lovsund and Oberg, 1982; Stuchly and Lecuyer, 1985; Conover et al., 1986; Andreuccetti et al., 1988; Tubbs et al., 1992; Moss and Booher, 1993; Allen et al., 1994; Moss and Mattorano, 1994a; Moss and Mattorano, 1995; Neubauer et al., 1998; Tuschl et al., 2000; Bayerisches Landesamt Für Arbeitsschutz, 2002; Cooper, 2002; Floderus et al., 2002; Börner, 2003; Vereinigung der Metall-Berufsgenossenschaften, 2003; Jonker and Venhuizen, 2005; Decat et al., 2006; Tapp et al., 2006; Hanna et al., 2011. |

| 1C | Electricity supply | Anderson and Phillips, 1984; Tubbs and Moss, 1993; Allen et al., 1994; Tepper et al., 1996; Molla-Djafari et al., 1998; Bayerisches Landesamt Für Arbeitsschutz, 2002; Berufsgenossenschaftliches Institut für Arbeitsschutz, 2003; Sakurazawa et al., 2003; Helhel and Ozen, 2008; Bednarek, 2010; Fard et al., 2011; Korpinen et al., 2011; Souques et al., 2011; Safigianni et al., 2012. |

| 1D | Hospital | Moss and Booher, 1994; Paul et al., 1994; Bullough et al., 1996; Li et al., 2000; Karlström et al., 2006; Capstick et al., 2007; Chadwick, 2007; Riches et al., 2007; Fuentes et al., 2008; Glover and Bowtell, 2008; Maccà et al., 2008; Kännälä et al., 2009; de Vocht et al., 2009; Wilén et al., 2010; Groebner et al., 2011. |

| 2A | Welding | Nadeem et al., 2004; Broeckx et al., 2008; Molla-Djafari et al., 2008; Börner, 2009; Canova et al., 2010; Dughiero and Forzan, 2010; Yamaguchi-Sekino et al., 2011. |

| 2B | Electricity supply | Dawson et al., 1999, 2002; Helhel and Ozen, 2008. |

| 2C | MRI | Capstick et al., 2007; Crozier et al., 2007a,b; Li et al., 2007; Trakic et al., 2008; Wang et al., 2008; Ilvonen and Laakso, 2009; Chiampi and Zilberti, 2011; Hartwig et al., 2011. |

Data analysis and presentation

For consistency, all magnetic field measurements are presented as magnetic flux density. Where only the magnetic field strength was available, the magnetic flux density was calculated by multiplying with the magnetic permeability for air and water of 4π ·10–7 H m−1. Exposure at the main frequency component with highest exposure was used, even though higher harmonics may also contribute to exposure. Where action levels are exceeded, this should be seen as an indication that there are potential issues with exposure levels for higher harmonics and that the frequency-summated exposure may be even higher. For non-sinusoidal fields, the maximum value for magnetic flux density is listed at a frequency of 1/(2·t), where t is the phase duration (ICNIRP, 2003). Where peak values were measured, they have been converted to root-mean-square (rms) values for easier comparison with the action levels. Where no mention of peak or rms values was made in the publication, rms values were assumed. Since no sources with frequencies >1 MHz were found, all frequency axes are cut off at that frequency.

The highest value of magnetic flux density measured at the actual workplace was used as an indicator of maximum exposure to the source. When this was not available, the highest value measured at a distance of 20cm from the source was used in accordance with EMF assessment procedures in European Standards (see for example: European Committee for Electrotechnical Standardization, 2008). The ICNIRP reference levels on which the action levels in the annexes to the revised Directive are based have been determined for exposure conditions where the variation in the magnetic flux density over the space occupied by the body is relatively small. However, the low frequency sources discussed in this review are often relatively close to the body and the magnetic field distribution will usually be non-uniform. In these cases, the maximum flux density in the space occupied by the worker’s body will give a safe but conservative exposure assessment (ICNIRP, 2010). When measurements were made at multiple heights from the floor, 1.75 m (approximate head height) was chosen or, if unavailable, the lower height closest to 1.75 m. Although the revised Directive offers higher action levels for limbs-only exposure, most of the publications did not contain sufficient information to determine whether the maximum flux densities listed were limited to the limbs. It was therefore presumed that all measured flux densities could involve head or trunk exposure.

In studies where induced electric fields were calculated using tissue voxel models, 1% thresholded maximum values were used to avoid the artificially high maximum values associated with possible edge singularities in the induced fields (numerical staircase errors) (Dawson et al., 2002; Crozier et al., 2007b). Where only current densities were listed, these were converted to induced electric field strength through dividing by the appropriate tissue conductivity from the Italian National Research Council online database of dielectric properties of body tissues (http://niremf.ifac.cnr.it/tissprop/). For movement-induced electric fields, the conductivities at 10 Hz (the lowest frequency listed in the database) were used. The actual simulated frequency used for movement-induced electric field was usually 1 Hz and this was also assumed where no information on movement time or frequency was given. In one case, the frequency was calculated from the duration of the movement associated with the maximum induced electric field (Hartwig et al., 2011). For electric fields induced by the switched magnetic fields of the gradient coils, the conductivities at 1000 Hz, the simulated gradient frequency, were used. For other workplace sources, the actual source frequency was used. A differentiation could usually be made as to whether the voxel areas with maximum electric field strength or current density were located in the central nervous system or in peripheral tissues. However, the latter does not necessarily indicate limbs exposure but may also be located in the head or trunk. For the central nervous system, the average conductivity of grey matter and white matter was used. For peripheral tissue voxels, where tissue type was not specified, the conductivity of muscle tissue (which is close to the average body conductivity) was used.

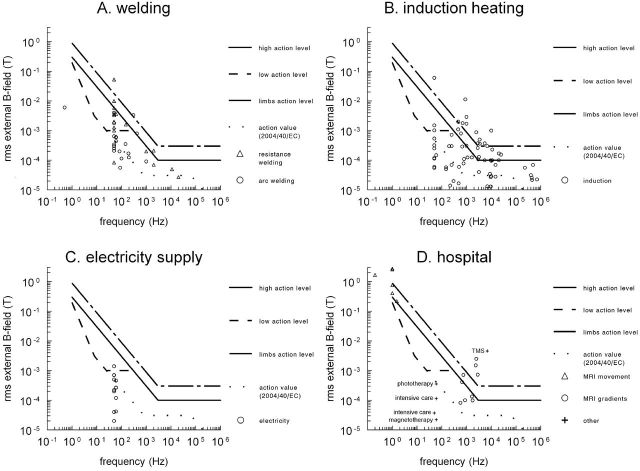

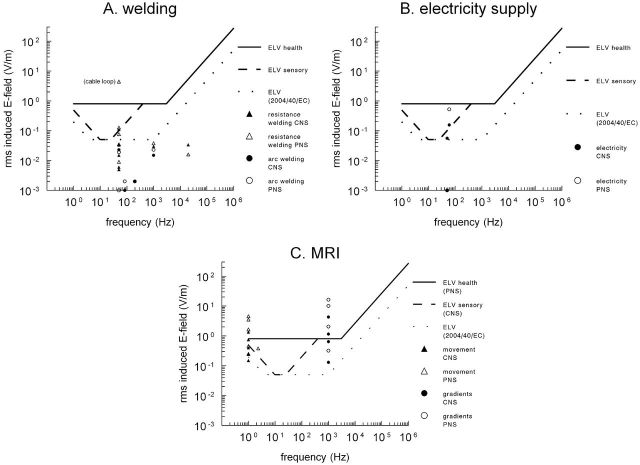

RESULTS

The two main types of welding processes that generate considerable magnetic fields are arc welding and resistance welding (Man and Shahidan, 2008). In arc welding, the main sources of magnetic fields are the electrode, which is often hand-held, and the cable, which is sometimes draped over the shoulder for support or to reduce drag on the electrode. In resistance welding, including spot welding, the main sources for magnetic fields are the two electrodes between which the workpiece is placed. Frequencies for both types of welding process vary from 0 Hz (direct current) to the kHz range (Melton, 2005). Most of the maximum flux densities measured at the workplace of welders are below the high action level in the revised Directive, although the majority of these flux densities would have exceeded the action values in the 2004 Directive (Fig. 1A). Of the five publications in Fig. 1A that report maximum flux densities higher than the high action level, two report flux densities that also exceed the limbs action level. Unfortunately, most of the publications analysed provide insufficient information to determine whether the highest exposures were likely to be limbs only. The highest reported flux density (0.053 T at 50 Hz) concerned a situation where the welding cable was worn directly on the welder’s body (Börner, 2009). For those publications where the induced current or electric field were calculated for various welding practices, all of the calculated values for central nervous system exposure are below the sensory effects exposure limit values (Fig. 2A). All but one of the calculated values for peripheral exposure are considerably below the health effects exposure limit values. The one situation where the health effects exposure limit values are exceeded concerned a situation where the welding cable formed a loop directly on the welder’s body (Börner, 2009).

1.

Maximum magnetic flux density measured at the workplace or at a standardized distance to the source for workers involved in welding (A), induction heating (B), the electricity supply sector (C), and hospital work, including MRI (D). TMS, transcranial magnetic stimulation. See Table 1 for details of the data sources.

2.

Maximum induced electric field calculated at the workplace for workers involved in welding (A), the electricity supply sector (B), and near equipment for MRI (C). CNS, central nervous system; ELV, exposure limit value; PNS, peripheral nervous system. See Table 1 for details of the data sources.

In induction heating, alternating magnetic fields induce eddy currents in electrically conducting materials, resulting in melting, bonding, welding, surface hardening, annealing, tempering, brazing or drying. Low frequency fields tend to be used for uniform heating and higher frequencies (up to 10 MHz) for surface heating (Allen et al., 1994). Induction cookers in professional kitchens can also generate magnetic fields. At a frequency of 20kHz, the flux density of the magnetic fields they generate can exceed the low action level and low exposure limit value but are unlikely to exceed the high action level and high exposure limit value (Guldiman and Meier, 2012). For industrial induction heaters, however, one third of the reported maximum flux densities measured at the workplace exceed the high action level in the revised Directive (Fig. 1B). Approximately half of these flux densities also exceed the limbs action level. With one exception, induction heaters where worker exposure exceeds the high action level operated in the range of 300 Hz to 30kHz. Unfortunately, no publications were found with calculations of the currents or electric fields induced in the worker’s body by magnetic fields of induction heaters. It therefore remains to be seen whether the exposure limit values in the revised Directive may be exceeded.

Workers in the electricity supply sector are exposed to EMF from a variety of sources, including power lines, cables, busbars, transformers, and capacitors, particularly during inspection or maintenance work (Korpinen et al., 2011). The maximum power frequency magnetic field flux densities to which electricity workers can be exposed are relatively modest. They can be higher than the low action level in the revised Directive but do not exceed the high action level (Fig. 1C). Although there are relatively few publications with calculations of the induced current or electric field in the body of electricity supply workers, these show that the sensory effects exposure limit value may be exceeded, but the health effects exposure limit vale is not (Fig. 2B). Although the present paper concentrates on external magnetic fields and the electric fields they induce in the body, the external electric field is a more important potential problem in the electricity supply sector. The maximum electric field strength reported at the workplace can be as high as 47 kV m–1, which exceeds the relevant high action level in the revised Directive (Korpinen et al., 2009).

In electrolysis plants, rectified direct currents are transported by busbars and then passed through electrolyte solutions to form solid metals or gasses. Since the rectifying process is not perfect, the busbar current not only generates a static magnetic field, but also an alternating current ‘ripple’ at the power frequency and its higher harmonics (Moen et al., 1996). The maximum reported flux density of the static magnetic field at the workplace is 0.16 T, which is considerably lower than the corresponding exposure limit value of 2 T in the revised Directive (Moss and Stephenson, 1989). Very few public records were available that report measurements of the alternating current ripple and these find a maximum magnetic flux density of up to 1.4 mT at 60 Hz (Moss and Booher, 1994; Moss and Mattorano, 1994b; Moen et al., 1996). This flux density exceeds the low action level, but not the high action level in the revised Directive.

The strongest magnetic fields to which hospital workers can be exposed are generated by equipment for MRI. It is important to stress that the action levels and exposure limit values in the annexes to the revised Directive do not apply to MRI workers. The following observations are offered merely by way of comparison with other sources of magnetic fields at the workplace and indicate why the European Commission thought it necessary to propose an exemption.

The static field is continually present, while the gradient fields (frequencies in the kHz range) and radiofrequency fields (frequencies in the MHz range) are only generated during a scanning procedure (Shellock, 2000; Nyenhuis et al., 2001; Schenck, 2001). The flux density of the static magnetic field varies with distance from the scanner, so that movement in the static field generates time-varying electric fields and currents in the worker’s body. The maximum magnetic flux density related to workers’ movement near MRI scanners, integrated from the change in flux density over time, may exceed both the high action level and the limbs action level in the revised Directive (Fig. 1D). The calculated induced electric field at a movement-related frequency of 1 Hz may also exceed the health effects exposure limit values in some scenarios, at the anatomical locations of both the central and peripheral nervous system (Fig. 2C). For the MRI gradient fields, at the equivalent frequencies calculated from the relevant rise times, both the high action levels and limbs action levels may be exceeded at the worker position (Fig. 1D). The calculated induced electric field at a standardized equivalent frequency of 1000 Hz may exceed the health effects exposure limit value (Fig. 2C).

There are other sources of magnetic fields to which hospital workers may be exposed where the limits in the annexes of the revised Directive do apply. The strongest of these is the coil used for transcranial magnetic stimulation, which the worker usually holds in hand above the brain region of interest (Najib et al., 2011). At a standardized distance of 20cm from the coil, the magnetic flux density can exceed both the high action level and limbs action level in the revised Directive (Fig. 1D) (Karlström et al., 2006). Other sources of time-varying magnetic fields in the hospital environment operate mostly at power frequency and generate magnetic flux densities that do not exceed the low action level in the revised Directive. These include equipment for magnetotherapy, phototherapy, and in intensive care units (Fig. 1D). Measurements in a pharmacy found power frequency magnetic flux densities at the workplace that were 500 times lower than the low action levels (Li et al., 2000).

DISCUSSION

The present analysis shows that the high action levels for magnetic fields in the revised European Directive on worker exposure to EMF can be exceeded at workplaces near welding equipment, induction furnaces, and medical equipment for MRI and transcranial magnetic stimulation. Only in the cases of MRI scanners and a welding cable worn on the worker’s body has it been demonstrated that the health effects exposure limit values in the revised Directive can be exceeded. However, these calculations do not yet appear to have been published for induction furnaces and coils used for transcranial magnetic stimulation. On the basis of Article 10 of the revised Directive, exposure due to MRI equipment for patients in the health sector is not subject to the exposure limit values in the annexes of the revised Directive. For the other sources mentioned, the revised Directive gives employers two options when the action levels are exceeded. Firstly, they can take measures to reduce exposure below the action levels. If this option were taken, exposure reduction measures would potentially have to be taken at some workplaces with welding equipment, induction furnaces, or devices for transcranial magnetic stimulation. Alternatively, they can seek expert advice on the calculated induced electric field in relation to the exposure limit values. The problem here is that there is a discrepancy between the relatively high number of cases in which the action levels are exceeded and the relatively low number of cases in which the exposure limit values are exceeded. There is a considerable potential for unnecessary effort and cost, since the necessary calculations and computer simulations can be generally only be performed by experts in numerical dosimetry (Mair, 2008; Hansson Mild et al., 2009). There is clearly a need for databases or other information sources with ready-made assessments of typical exposure situations in the problem sectors for which the dosimetry of the induced electric fields has already been performed. The intended Practical Guide to accompany the revised EMF Directive may partially serve that purpose (European Parliament and Council, 2013).

There are several limitations to the present analysis of the exposure literature. Only the maximum magnetic flux densities at the workplace per frequency per publication are listed as an indication of a worst-case scenario. This does not mean that these flux densities are representative of the majority of exposures, nor that they always represent good working practice. On the other hand, the measurements and calculations listed here have only been performed in a limited set of workplaces and in a limited set of locations within a workplace. Therefore, it cannot be excluded that higher exposures are possible in specific workplaces or locations not covered by these publications. As an example, there is a particularly high variability in manual welding with regard to the shape and position of the workpiece, the cable layout, and the equipment setting (Mair, 2008). Since some of the exposure measurements were conducted at a standardized distance of 20cm to the source, it is possible that the real workplace exposure for those sources can be higher. It is also possible that workers will be exposed to EMF from multiple devices or sources at the same time in a particular workplace, again potentially leading to higher exposure.

A comparison with the limits in the revised Directive was only made for the main frequency of the source in question. Although this will usually account for a large percentage of the exposure, other frequency components may contribute to the total exposure particularly when ICNIRP’s frequency summation method is used (ICNIRP, 2010). The revised Directive favours the weighted peak filtering method, also described in the ICNIRP guidelines, but allows alternative methods if they give approximately comparable results (European Parliament and Council, 2013). The problem is that different methods for dealing with non-sinusoidal or pulsed EMF often do not give equivalent results. Likewise, there are different ways of assessing the induced electric fields, depending on body models, calculation algorithms, and averaging methods, potentially leading to diverging decisions on whether the exposure limit values may be exceeded (Mair, 2008). Wider-ranging assessments may be necessary, especially in the high exposure environments analysed in the present paper.

Another major limitation is that measurement uncertainty was not taken into account when comparing the measured values with the action levels. This information is not always available in the source publications and the revised Directive does not specify how to deal with measurement uncertainty when applying the limits in the annexes. It merely states (Article 4.3) that exposure assessment shall take into account the measurement or calculation uncertainties determined in accordance with relevant good practice and that further guidance will be provided in the European Commission’s non-binding practical guide to accompany the revised Directive (European Parliament and Council, 2013). Accounting for measurement or calculation uncertainty can be done in different ways (shared risk approach, additive approach, or a mixture of these models), with different consequences for the number of workplaces where measures must be taken. Further specification or guidance on uncertainty management is therefore no trivial matter (Chadwick, 2008; Hansson Mild et al., 2009).

When measures are taken to reduce exposure, the amount of effort and cost involved can vary per source. For welding, the EMF sources are often small, mobile, and hand-held. Access restriction may not be an option, but the cable can be mechanically suspended to increase the distance from the welder’s body (Melton, 2005). For large induction furnaces, it is easier in theory to restrict access to the immediate vicinity of the furnace. In practice, it may sometimes be easier to reduce the need for worker access in the design stage, by mechanizing procedures such as loading, unloading, and stirring. For smaller induction coils, such as those used to pre-heat metal pipes for welding, it may be possible to apply electromagnetic shielding (Gabriel and Lau, 1999; European Agency for Safety and Health at Work, 2009). The exposure limit values in the Annexes to the revised Directive do not apply to MRI workers, provided that all possible technical and organizational measures have been taken and workers are still protected against adverse health effects and safety risks. Since the level of protection can vary from hospital to hospital (Stam, 2008), guidance on protection measures on a national or European level would be useful. An example on a national level is already available (Ministry for Social Affairs and Employment, 2008). For transcranial magnetic stimulation, worker exposure can be reduced relatively easily by mounting the coil on a mechanical arm close to the patient (Karlström et al., 2006). The other low frequency medical devices listed in the present review do not appear to pose any EMF-related risk. However, there is a wide range of novel medical techniques involving EMF for which exposure measurements are not yet available (Stam and Bijwaard, 2011). There is clearly a need for a broader risk assessment in the medical sector.

FUNDING

A project grant (Z/110007) from the Ministry of Social Affairs and Employment, the Netherlands .

ACKNOWLEDGEMENTS

The author is not involved in legal testimony or consultancy related to the material in the paper, has no financial or other recent or expected relationships with a body that could appear to influence what is in the paper, and has no financial interest in products or companies producing products discussed in the paper. Part of the data were presented in at the BIOEM 2013 meeting in Thessaloniki, Greece, June 2013.

REFERENCES

- Allen SG, Blackwell RP, Chadwick PJ, et al. (1994). Review of occupational exposure to optical radiation and electric and magnetic fields with regard to the proposed CEC physical agents directive. Chilton, UK: National Radiological Protection Board. [Google Scholar]

- Anderson FJ, Phillips BG. (1984). Electric field strengths and magnetic flux densities around electric power generating and distribution facilities in Alberta. Edmonton, Canada: Alberta Workers’ Health, Safety & Compensation. [Google Scholar]

- Andreuccetti D, Bini M, Ignesti A, et al. (1988). Analysis of electric and magnetic fields leaking from induction heaters. Bioelectromagnetics; 9: 373–9. [DOI] [PubMed] [Google Scholar]

- Bayerisches Landesamt Für Arbeitsschutz. (2002). Elektromagnetische Felder an Arbeitsplatz. Ergebnisse einer Messreihe des LfAS. München, Germany: Bayerisches Landesamt Für Arbeitsschutz, Arbeitsmedizin und Sicherheitstechnik. [Google Scholar]

- Bednarek K. (2010). Electromagnetic action of heavy-current equipment operating with power frequency. Int J Occup Saf Ergon; 16: 357–68. [DOI] [PubMed] [Google Scholar]

- Berufsgenossenschaftliches Institut für Arbeitsschutz. (2003). Elektromagnetische Felder in Anlagen der Energietechnik. Sankt Augustin, Germany: Hauptverband der Gewerblichen Berufsgenossenschaften. [Google Scholar]

- Bolte JFB, Pruppers MJM. (2006). Electromagnetic fields in the working environment. The Hague, The Netherlands: Ministry of Social Affairs and Employment. [Google Scholar]

- Börner F. (2003). Elektromagnetische Felder an Anlagen, Machinen und Geräten. Sankt Augustin, Germany: Hauptverband der Gewerblichen Berufsgenossenschaften. [Google Scholar]

- Börner F. (2009). Elektromagnetische Felder an handgeführten Punktscheisszangen. Sankt Augustin, Germany: Instut für Arbeitzschutz der Deutsche Gesetzliche Unfallsversicherung. [Google Scholar]

- Broeckx K, Decat G, Deckx L, et al. (2008). Meten en evalueren van de blootstelling van lassers aan elektromagnetische velden in het kader van de nieuwe Europese EMF-Richtlijn 2004/40/EC. Gent, Belgium: Belgisch Instituut voor Lastechniek. [Google Scholar]

- Bullough J, Rea MS, Stevens RG. (1996). Light and magnetic fields in a neonatal intensive care unit. Bioelectromagnetics; 17: 396–405. [DOI] [PubMed] [Google Scholar]

- Canova A, Freschi F, Repetto M. (2010). Evaluation of workers exposure to magnetic fields. Eur Phys J Appl Phys; 52: 23311. [Google Scholar]

- Capstick M, McRobbie M, Hand J, et al. (2007). An investigation into occupational exposure to electromagnetic fields for personnel working with and around medical magnetic resonance imaging equipment. Report VT/2007/017. Brussels, Belgium: European Commission. [Google Scholar]

- Chadwick P. (2007). Assessment of electromagnetic fields around magnetic resonance imaging (MRI) equipment. Sudbury, UK: Health and Safety Executive. [Google Scholar]

- Chadwick P. (2008). Assessment of uncertainties relating to electromagnetic fields (EMF) measurement and computation. London, UK: Health and Safety Executive. [Google Scholar]

- Challis LJ. (2005). Mechanisms for interaction between RF fields and biological tissue. Bioelectromagnetics; Suppl 7: S98–S106. [DOI] [PubMed] [Google Scholar]

- Chiampi M, Zilberti L. (2011). Induction of electric field in human bodies moving near MRI: an efficient BEM computational procedure. IEEE Trans Biomed Eng; 58: 2787–93. [DOI] [PubMed] [Google Scholar]

- Conover DL, Murray WE, Lary JM, et al. (1986). Magnetic field measurements near RF induction heaters. Bioelectromagnetics; 7: 83–90. [DOI] [PubMed] [Google Scholar]

- Cooper TG. (2002). Occupational exposure to the electric and magnetic fields in the context of the ICNIRP guidelines. Chilton, UK: Health Protection Agency. [Google Scholar]

- Crozier S, Trakic A, Wang H, et al. (2007a) Numerical study of currents in workers induced by body-motion around high-ultrahigh field MRI magnets. J Magn Reson Imaging; 26: 1261–77. [DOI] [PubMed] [Google Scholar]

- Crozier S, Wang H, Trakic A, et al. (2007b) Exposure of workers to pulsed gradients in MRI. J Magn Reson Imaging; 26: 1236–54. [DOI] [PubMed] [Google Scholar]

- Dasdag S, Sert C, Akdag Z, et al. (2002). Effects of extremely low frequency electromagnetic fields on hematologic and immunologic parameters in welders. Arch Med Res; 33: 29–32. [DOI] [PubMed] [Google Scholar]

- Dawson TW, Caputa K, Stuchly MA. (1999). Numerical evaluation of 60 Hz magnetic induction in the human body in complex occupational environments. Phys Med Biol; 44: 1025–40. [DOI] [PubMed] [Google Scholar]

- Dawson TW, Caputa K, Stuchly MA. (2002). Magnetic field exposures for UK live-line workers. Phys Med Biol; 47: 995–1012. [DOI] [PubMed] [Google Scholar]

- Decat G, Deckx L, Meynen G, et al. ; European Parliament and of the Council. (2006). Magnetic fields of induction heaters in the framework of directive 2004/40/EC of the European Parliament and of the Council. Int J Occup Saf Ergon; 12: 169–76. [DOI] [PubMed] [Google Scholar]

- de Vocht F, Muller F, Engels H, et al. (2009). Personal exposure to static and time-varying magnetic fields during MRI system test procedures. J Magn Reson Imaging; 30: 1223–8. [DOI] [PubMed] [Google Scholar]

- Dughiero F, Forzan M. (2010). A numerical evaluation of electromagnetic fields exposure on real human body models until 100 kHz. COMPEL; 29: 1552–61. [Google Scholar]

- European Agency for Safety and Health at Work. (2009). Assessment, elimination and substantial reduction of occupational risks. Luxembourg: Office for Official Publications of the European Communities. [Google Scholar]

- European Committee for Electrotechnical Standardization. (2008). European Standard EN 50444: basic standard for the evaluation of human exposure to electromagnetic fields from equipment for arc welding and allied processes. Brussels, Belgium: CENELEC. [Google Scholar]

- European Parliament and Council. (2004). Directive 2004/40/EC of the European Parliament and of the Council of 29 April 2004 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (electromagnetic fields). Official J Eur Union; L184: 1–9. [Google Scholar]

- European Parliament and Council. (2013). Directive 2013/35/EU of the European Parliament and of the Council of 26 June 2013 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (electromagnetic fields) (20th individual Directive within the meaning of Article 16(1) of Directive 89/391/EEC) and repealing Directive 2004/40/EC. Official Journal of the European Union; L179: 1–21. [Google Scholar]

- European Society of Radiology. (2007). Position on the EU Physical Agents (EMF) Directive 2004/40/EC. Vienna, Austria: European Society of Radiology. [Google Scholar]

- Fard MS, Nasiri P, Monazzam MR. (2011). Measurement of the magnetic fields of high-voltage substations (230kV) in Tehran (Iran) and comparison with the ACGIH threshold limit values. Radiat Prot Dosimetry; 145: 421–5. [DOI] [PubMed] [Google Scholar]

- Floderus B, Stenlund C, Carlgren F. (2002). Occupational exposures to high frequency electromagnetic fields in the intermediate range (>300 Hz-10 MHz). Bioelectromagnetics; 23: 568–77. [DOI] [PubMed] [Google Scholar]

- Fuentes MA, Trakic A, Wilson SJ, et al. (2008). Analysis and measurements of magnetic field exposures for healthcare workers in selected MR environments. IEEE Trans Biomed Eng; 55: 1355–64. [DOI] [PubMed] [Google Scholar]

- Gabriel C, Lau R. (1999). Assessment and management of the exposure of workers to electromagnetic fields in the workplace. London, UK: Health and Safety Executive. [Google Scholar]

- Glover PM, Bowtell R. (2008). Measurement of electric fields induced in a human subject due to natural movements in static magnetic fields or exposure to alternating magnetic field gradients. Phys Med Biol; 53: 361–73. [DOI] [PubMed] [Google Scholar]

- Groebner J, Umathum R, Bock M, et al. (2011). MR safety: simultaneous B0, dF/dt, and dB/dt measurements on MR-workers up to 7 T. MAGMA; 24: 315–22. [DOI] [PubMed] [Google Scholar]

- Guldiman R, Meier M. (2012). Magnetfeld-Expositionen durch professionelle Induktionskochherde. Bern, Switzerland: Bundesamt für Gesundheit. [Google Scholar]

- Hanna S, Motai Y, Varhue W, et al. (2011). Measurement evaluations of static and low frequency magnetic fields in the near field region. Measurement; 44: 1412–21. [Google Scholar]

- Hansson Mild K, Alanko T, Decat G, et al. (2009). Exposure of workers to electromagnetic fields. A review of open questions on exposure assessment techniques. Int J Occup Saf Ergon; 15: 3–33. [DOI] [PubMed] [Google Scholar]

- Hartwig V, Vanello N, Giovannetti G, et al. (2011). A novel tool for estimation of magnetic resonance occupational exposure to spatially varying magnetic fields. MAGMA; 24: 323–30. [DOI] [PubMed] [Google Scholar]

- Helhel S, Ozen S. (2008). Assessment of occupational exposure to magnetic fields in high-voltage substations (154/34.5kV). Radiat Prot Dosimetry; 128: 464–70. [DOI] [PubMed] [Google Scholar]

- Herrault J, Donato P. (2006). Soudage par résistance - cartographie du champ magnétique et prévention. Paris, France: Institut National de Recherche et de Sécurité. [Google Scholar]

- ICNIRP. (1998). Guidelines for limiting exposure to time-varying electric, magnetic, and electromagnetic fields (up to 300 GHz). Health Phys; 74: 494–522. [PubMed] [Google Scholar]

- ICNIRP. (2003). Guidance on determining compliance of exposure to pulsed and complex non-sinusoidal waveforms below 100kHz with ICNIRP guidelines. Health Phys; 84: 383–7. [DOI] [PubMed] [Google Scholar]

- ICNIRP. (2009). Guidelines on limits of exposure to static magnetic fields. Health Phys; 96: 504–14. [DOI] [PubMed] [Google Scholar]

- ICNIRP. (2010). Guidelines for limiting exposure to time-varying electric and magnetic fields (1 Hz to 100kHz). Health Phys; 99: 818–36. [DOI] [PubMed] [Google Scholar]

- Jonker HT, Venhuizen R. (2005). Samenvatting EM veldsterkte metingen KEMA Quality 1995–2005 in relatie tot volksgezondheidsaspecten. Arnhem, The Netherlands: KEMA. [Google Scholar]

- Ilvonen S, Laakso I. (2009) Computational estimation of magnetically induced electric fields in a rotating head. Phys Med Biol; 54: 341–51. [DOI] [PubMed] [Google Scholar]

- Kännälä S, Toivo T, Alanko T, et al. (2009). Occupational exposure measurements of static and pulsed gradient magnetic fields in the vicinity of MRI scanners. Phys Med Biol; 54: 2243–57. [DOI] [PubMed] [Google Scholar]

- Karlström EF, Lundström R, Stensson O, et al. (2006). Therapeutic staff exposure to magnetic field pulses during TMS/rTMS treatments. Bioelectromagnetics; 27: 156–8. [DOI] [PubMed] [Google Scholar]

- Keevil SF, Gedroyc W, Gowland P, et al. (2005). Electromagnetic field exposure limitation and the future of MRI. Br J Radiol; 78: 973. [DOI] [PubMed] [Google Scholar]

- Korpinen L, Kuisti H, Pääkkönen R, et al. (2011). Occupational exposure to electric and magnetic fields while working at switching and transforming stations of 110kV. Ann Occup Hyg; 55: 526–36. [DOI] [PubMed] [Google Scholar]

- Korpinen LH, Elovaara JA, Kuisti HA. (2009). Evaluation of current densities and total contact currents in occupational exposure at 400kV substations and power lines. Bioelectromagnetics; 30: 231–40. [DOI] [PubMed] [Google Scholar]

- Li CY, Lin RS, Wu CH, et al. (2000). Occupational exposures of pharmacists and pharmaceutical assistants to 60 Hz magnetic fields. Ind Health; 38: 413–9. [DOI] [PubMed] [Google Scholar]

- Li Y, Hand JW, Wills T, et al. (2007). Numerically-simulated induced electric field and current density within a human model located close to a z-gradient coil. J Magn Reson Imaging; 26: 1286–95. [DOI] [PubMed] [Google Scholar]

- Lovsund P, Oberg PA. (1982). ELF magnetic fields in electrosteel and welding industries. Radio Sci; 17: 35S–8S. [Google Scholar]

- Maccà I, Scapellato ML, Carrieri M, et al. (2008). Occupational exposure to electromagnetic fields in physiotherapy departments. Radiat Prot Dosimetry; 128: 180–90. [DOI] [PubMed] [Google Scholar]

- Mair P. (2008). Electromagnetic fields in welding applications. Weld World; 52: 381–8. [Google Scholar]

- Man AK, Shahidan R. (2008). Variations in occupational exposure to magnetic fields among welders in Malaysia. Radiat Prot Dosimetry; 128: 444–8. [DOI] [PubMed] [Google Scholar]

- Melton GB. (2005). Measurement and analysis of magnetic fields from welding processes. Sudbury, UK: Health and Safety Executive. [Google Scholar]

- Ministry for Social Affairs and Employment (2008). Using MRI safely. Practical rules for employees. The Hague, The Netherlands: Ministry for Social Affairs and Employment. [Google Scholar]

- Moen BE, Drabløs PA, Pedersen S, et al. (1996). Absence of relation between sick leave caused by musculoskeletal disorders and exposure to magnetic fields in an aluminum plant. Bioelectromagnetics; 17: 37–43. [DOI] [PubMed] [Google Scholar]

- Molla-Djafari H, Tabitsch G, Neubauer G, et al. (2008). Belastung von Schweissern durch elektromagnetische Felder am Arbeitsplatz. Vienna, Austria: Allgemeine Unfallsversicherungsanstalt. [Google Scholar]

- Molla-Djafari H, Winker N, Neubauer G, et al. (1998). Messung und sicherheitstechnische Beurteilung der elektrischen und magnetischen Felder im Bereich von Kraft- und Umspannwerken. Vienna, Austria: Allgemeine Unfallversicherungsanstalt. [Google Scholar]

- Moss CE, Booher D. (1993). Health hazard evaluation report 91-0140-2352. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Moss EC, Booher D. (1994). Health hazard evaluation report No. 93-1120-2429. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Moss CE, Booher D. (1996). Health hazard evaluation report 93-0667-2585. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Moss CE, Mattorano D. (1994a) Health hazard evaluation report 93-1034-2447. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Moss CE, Mattorano D. (1994b) Health hazard evaluation report 93-1038-2432. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Moss CE, Mattorano D. (1995). Health hazard evaluation report 92-0306-2465. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Moss CE, Stephenson RL. (1989). Health hazard evaluation report 88-229-1985. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Nadeem M, Hamnerius Y, Mild KH, et al. (2004). Magnetic field from spot welding equipment–is the basic restriction exceeded? Bioelectromagnetics; 25: 278–84. [DOI] [PubMed] [Google Scholar]

- Najib U, Bashir S, Edwards D, et al. (2011). Transcranial brain stimulation: clinical applications and future directions. Neurosurg Clin N Am; 22: 233–51, ix. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Neubauer G, Garn H, Brusl H, et al. (n.d.) Untersuchungen von Arbeitsplätzen in hochfrequenten Feldern. Vienna, Austria: Allgemeine Unfallsversicherungsanstalt. [Google Scholar]

- Neubauer G, Molla-Djafari H, Pühringer KD, et al. (1998). Messung und sicherheitstechnische Beurteilung der elektromagnetische Felder im Bereich von Induktionsöfen. Vienna, Austria: Allgemeine Unfallsversicherungsanstalt. [Google Scholar]

- Nyenhuis JA, Bourland JD, Kildishev AV, et al. (2001). Health effects and safety of intense gradient fields. In Shellock FG, editor. Magnetic resonance procedures: health effects and safety. Boca Raton, FL: CRC Press. [Google Scholar]

- Ortendahl TW, Högstedt P. (1988). Magnetic field effects on dental amalgam in divers welding and cutting electrically underwater. Undersea Biomed Res; 15: 429–41. [PubMed] [Google Scholar]

- Paul M, Hammond SK, Abdollahzadeh S. (1994). Power frequency magnetic field exposures among nurses in a neonatal intensive care unit and a normal newborn nursery. Bioelectromagnetics; 15: 519–29. [DOI] [PubMed] [Google Scholar]

- Reilly JP. (1998). Applied bioelectricity. New York, NY: Springer. [Google Scholar]

- Riches SF, Collins DJ, Charles-Edwards GD, et al. (2007). Measurements of occupational exposure to switched gradient and spatially-varying magnetic fields in areas adjacent to 1.5 T clinical MRI systems. J Magn Reson Imaging; 26: 1346–52. [DOI] [PubMed] [Google Scholar]

- Safigianni AS, Spyridopoulos AI, Kanas VL. (2012). Electric and magnetic field measurements in a high voltage center. Ann Occup Hyg; 56: 18–24. [DOI] [PubMed] [Google Scholar]

- Sakurazawa H, Iwasaki A, Higashi T, et al. (2003). Assessment of exposure to magnetic fields in occupational settings. J Occup Health; 45: 104–10. [DOI] [PubMed] [Google Scholar]

- Schenck JF. (2001). Health effects and safety of static magnetic fields. In Shellock FG, ed. Magnetic resonance procedures: health effects and safety. Boca Raton, FL: CRC Press. [Google Scholar]

- Sharifian A, Gharavi M, Pasalar P, et al. (2009). Effect of extremely low frequency magnetic field on antioxidant activity in plasma and red blood cells in spot welders. Int Arch Occup Environ Health; 82: 259–66. [DOI] [PubMed] [Google Scholar]

- Shellock FG. (2000). Radiofrequency energy-induced heating during MR procedures: a review. J Magn Reson Imaging; 12: 30–6. [DOI] [PubMed] [Google Scholar]

- Skyberg K, Hansteen IL, Vistnes AI. (2001). Chromosomal aberrations in lymphocytes of employees in transformer and generator production exposed to electromagnetic fields and mineral oil. Bioelectromagnetics; 22: 150–60. [DOI] [PubMed] [Google Scholar]

- Souques M, Magne I, Lambrozo J. (2011). Implantable cardioverter defibrillator and 50-Hz electric and magnetic fields exposure in the workplace. Int Arch Occup Environ Health; 84: 1–6. [DOI] [PubMed] [Google Scholar]

- Stam R. (2008). The EMF Directive and protection of MRI workers. Bilthoven, The Netherlands: National Institute for Public Health and the Environment. [Google Scholar]

- Stam R, Bijwaard H. (2011). Recent developments in medical techniques involving ionising or non-ionising radiation. Bilthoven, The Netherlands: National Institute for Public Health and the Environment. [Google Scholar]

- Stuchly MA, Lecuyer DW. (1985). Induction heating and operator exposure to electromagnetic fields. Health Phys; 49: 693–700. [DOI] [PubMed] [Google Scholar]

- Stuchly MA, Lecuyer DW. (1989). Exposure to electromagnetic fields in arc welding. Health Phys; 56: 297–302. [DOI] [PubMed] [Google Scholar]

- Szuba M. (1993). Identification of the magnetic fields generated by welding machines. Bioelectrochem Bioenerg; 30: 265–71. [Google Scholar]

- Tapp L, Ewers L, Durgam S. (2006). Health hazard evaluation report 2006-0155-3072. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Tepper A, Mattorano D, Moss CE. (1996). Health hazard evaluation report 96-0006-2604. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Trakic A, Wang H, Liu F, et al. (2008). Minimizing the induced fields in MRI occupational workers by lowering the imager. Concepts Magn Reson Part B (Magn Reson Engineering); 33B: 39–54. [Google Scholar]

- Tubbs RL, Moss CE. (1993). Health hazard evaluation report 92-0243-2377. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Tubbs RL, Moss CE, Fleeger A. (1992). Health hazard evaluation report 89-364-2202. Atlanta, GA: National Institute for Occupational Safety and Health. [Google Scholar]

- Tuschl H, Neubauer G, Schmid G, et al. (2000). Occupational exposure to static, ELF, VF and VLF magnetic fields and immune parameters. Int J Occup Med Environ Health; 13: 39–50. [PubMed] [Google Scholar]

- Vereinigung der Metall-Berufsgenossenschaften (2003). BGI 839 - Elektromagnetische Felder in Metallbetrieben. Sank Augustin, Germany: Hauptverband der Berufsgenossenschaften. [Google Scholar]

- Wang H, Trakic A, Liu F, et al. (2008). Numerical field evaluation of healthcare workers when bending towards high-field MRI magnets. Magn Reson Med; 59: 410–22. [DOI] [PubMed] [Google Scholar]

- Wilén J, Hauksson J, Mild KH. (2010). Modification of pulse sequences reduces occupational exposure from MRI switched gradient fields: Preliminary results. Bioelectromagnetics; 31: 85–7. [DOI] [PubMed] [Google Scholar]

- Yamaguchi-Sekino S, Ojima J, Sekino M, et al. (2011). Measuring exposed magnetic fields of welders in working time. Ind Health; 49: 274–9. [DOI] [PubMed] [Google Scholar]