Abstract

This review article summarizes the last few decades of research on nickel hydroxide, an important material in physics and chemistry, that has many applications in engineering including, significantly, batteries. First, the structures of the two known polymorphs, denoted as α-Ni(OH)2 and β-Ni(OH)2, are described. The various types of disorder, which are frequently present in nickel hydroxide materials, are discussed including hydration, stacking fault disorder, mechanical stresses and the incorporation of ionic impurities. Several related materials are discussed, including intercalated α-derivatives and basic nickel salts. Next, a number of methods to prepare, or synthesize, nickel hydroxides are summarized, including chemical precipitation, electrochemical precipitation, sol–gel synthesis, chemical ageing, hydrothermal and solvothermal synthesis, electrochemical oxidation, microwave-assisted synthesis, and sonochemical methods. Finally, the known physical properties of the nickel hydroxides are reviewed, including their magnetic, vibrational, optical, electrical and mechanical properties. The last section in this paper is intended to serve as a summary of both the potentially useful properties of these materials and the methods for the identification and characterization of ‘unknown’ nickel hydroxide-based samples.

Keywords: nickel hydroxide, structure, synthesis, properties

1. Introduction

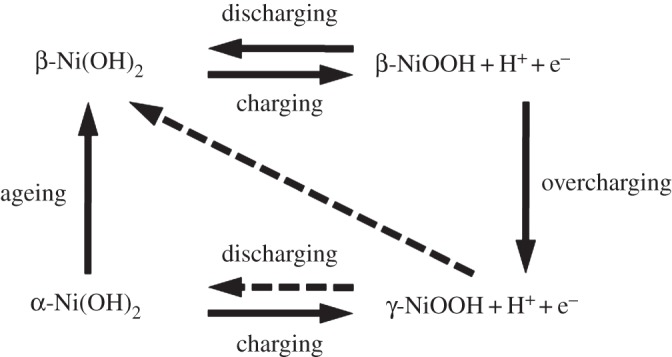

When we began to write this review on nickel hydroxides, we considered what information about these industrially significant materials would provide the most benefit to the scientific community. It has been 33 years since Oliva et al.'s monumental review [1]. The work covered in that review had its origins in the 1950s and 1960s when there was an interest in the water/hydroxyl/oxy–hydroxy content of thin/bulk nickel oxide films, leading to concepts such as bound water, water of composition, structural water and adsorbed water, and their importance for corrosion and battery performance. However, this was long before suitable analysis/measurement techniques were available. The advances made in the last number of years have been most significant and has led to the point where we know a lot more today. From the thousands of literature results that a simple search on the Internet for ‘nickel hydroxide’ turns up, it is obvious that these are important materials. However, this vast body of literature can quickly become overwhelming and confusing, especially to new students or researchers who are just beginning to work with nickel hydroxides and who may not yet be familiar with all the experimental techniques discussed in the literature. Moreover, nickel hydroxide materials find diverse applications in the fields of chemistry, physics and engineering. Since the first half of the twentieth century, nickel hydroxide has been used as an electrode material for battery technologies (e.g. [2,3]). Nickel hydroxides are also important components of the surface layers that form either electrochemically or by the corrosion of nickel metal and nickel-based alloys. In the late 1900s, research into nickel hydroxides was principally focused on these two areas. In the late 1960s, Bode et al. proposed a simple scheme to explain the reported behaviour of the electrochemical oxidation of nickel hydroxides to nickel(III) oxyhydroxide and the subsequent reduction back to nickel(II) hydroxide [4]. Their scheme involves two phases of nickel hydroxide, α- and β-Ni(OH)2, and two phases of the oxidized material, β- and γ-NiOOH (figure 1). Although the complete picture is somewhat more nuanced, the original scheme, sometimes with one or two more arrows added (such as the -Ni(OH)2 transition in figure 1), remains a good overall description of the processes that occur at nickel hydroxide battery electrodes.

Figure 1.

A general scheme of the chemical and electrochemical processes that occur at a nickel hydroxide battery electrode [1,4]. Copyright this work.

Today, nickel-based batteries are ubiquitous, including nickel–cadmium (NiCd) and nickel metal hydride (NiMH) technologies [5,6]. Recently, McBreen reviewed the applications of nickel hydroxides in modern battery technologies [6]. But nickel hydroxides are no longer limited to laboratories investigating batteries and corrosion processes. Today, these materials are involved in a diversity of practical applications, which include photocatalysis (e.g. [7–9]), electrocatalysis and electrosynthesis (e.g. [10–12]), supercapacitors (e.g. [13–18]), electrochromic devices (e.g. [12,19–21]), electrochemical sensors (e.g. [22–25]) and more. Decades of work has determined a much more complete description of the nickel hydroxides than the simple two-phase model shown above. There have been numerous advances in the preparation and characterization of nickel hydroxide materials. Nanotechnology has become widespread and complex morphologies that once defied imagination, such as nanoflowers and nanoribbons, are prepared and described on a regular basis. There are now literally hundreds of reported ways to synthesize nickel hydroxide materials, including newer methods such as microwave-assisted synthesis and sonochemistry.

This all amounts to an exciting and deeply interesting material that has a very rich history. However, this also means that understanding all the nuances of its structures and properties can be challenging. Moreover, finding an appropriate method to prepare nickel hydroxide with particular chemical or physical properties and at a suitable scale can be an overwhelming task. Therefore, in this review, we provide an up-to-date guide to nickel hydroxide materials and their modern applications. This review is aimed at an interdisciplinary audience and does not assume a strong background in any one field. We begin with a discussion of the different structures of nickel hydroxide, including the various types of structural disorder that the material tends to adopt (§2). Next, we organize the synthesis of nickel hydroxides into its most common methods, with some discussion of when to use each approach (§3). Finally, the physical properties and analytical characterization of nickel hydroxides are summarized and assessed (§4).

2. Structures

(a). The two fundamental crystal forms

Bode et al. [4] first identified the two known pseudopolymorphs of Ni(OH)2, denoted as α- and β-Ni(OH)2. The β-phase material (figure 2), which is isostructural with brucite, Mg(OH)2 [28], occurs naturally as the mineral theophrastite [29,30]. Note that the a- and b-axes in figure 2 are not orthogonal because this material has trigonal symmetry. Therefore, the angle between these axes, γ, is 120°. For a full explanation of unit cell symmetry and crystallographic notation, see [31]. The unit cell parameters, measured by X-ray diffraction (XRD) [26,28] and neutron diffraction [26,27], are listed in table 1. A sample XRD pattern is shown in figure 3 and the XRD parameters are summarized in table 2.

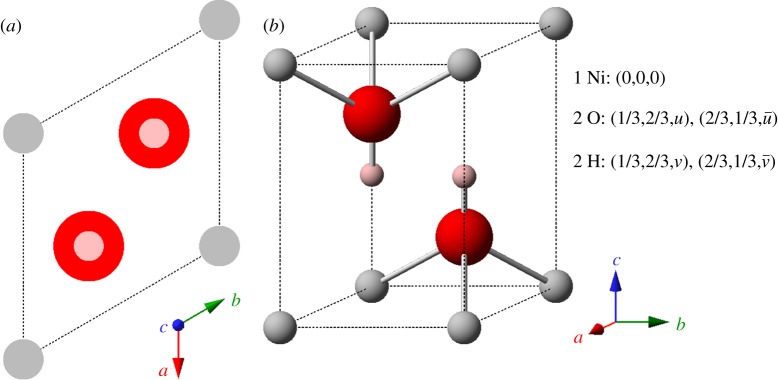

Figure 2.

The crystal structure of β-Ni(OH)2 represented by (a) unit cell projection and (b) ball-and-stick unit cell (u=0.24 and v=0.47 [26]; or u=0.2221 and v=0.4275 [27]). Medium size (grey) spheres, Ni2+; large (red) spheres, O2−; small (pink) spheres, H+. Unit cell parameters are listed in table 1. Copyright this work. (Online version in colour.)

Table 1.

Unit cell parameters for the two fundamental phases of Ni(OH)2.

| β-Ni(OH)2 | β-Ni(OD)2 | α-Ni(OH)2⋅xH2O | ||

|---|---|---|---|---|

| [28] | [27] | [32] | ||

| space group | ml/No. 164 | lm/No. 162a | ||

| α=β | 90° | 90° | ||

| γ | 120° | 120° | ||

| a=b | 3.126 Å | 3.126 Å | dbNi−Ni | 3.08 Å |

| c | 4.605 Å | 4.593 Å | 8.0 Åc,d | |

aThe space group is for the idealized structure shown in figure 4. However, the H2O molecules do not actually occupy fixed lattice points and α-Ni(OH)2 materials are always turbostratic. Therefore, this is only a representative symmetry.

bThe a-parameter of α-Ni(OH)2 depends on the definition of the unit cell. The Ni–Ni spacing, however, may be directly compared to the a-parameter of β-Ni(OH)2.

cThe c-parameter may vary from this value if there are anionic impurities incorporated into the interlayer space.

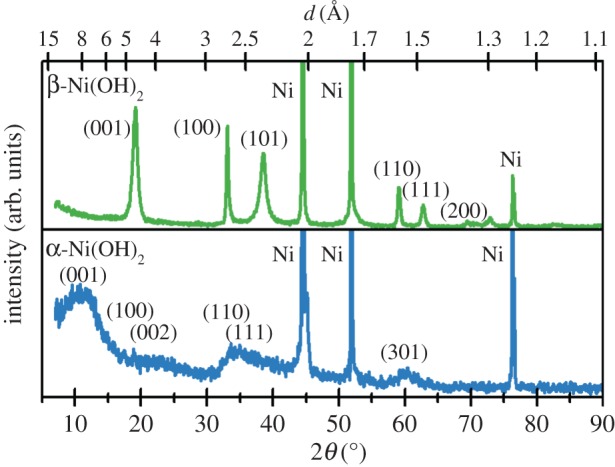

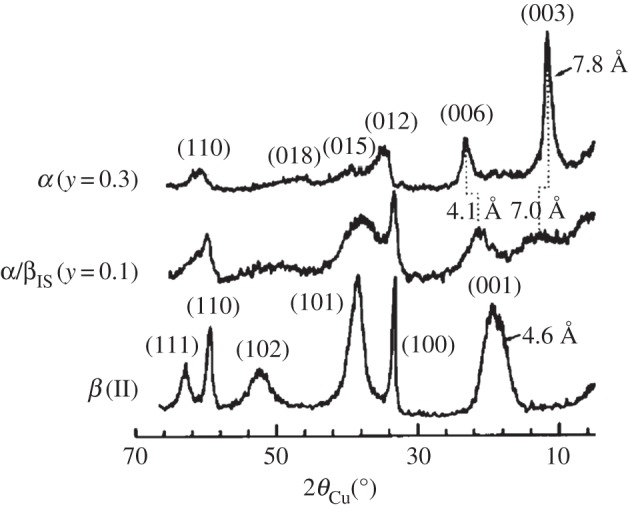

Figure 3.

X-ray diffraction patterns of Ni(OH)2 films on Ni substrates collected using a Cu Kα X-ray source. Upper: β-Ni(OH)2 with stacking fault disorder (βsf) displays selective line broadening of the peaks that involve the crystallographic c-axis. Lower: α-Ni(OH)2 has low XRD intensities owing to high general structural disorder. Copyright this work. (Online version in colour.)

Table 2.

X-ray diffraction parameters of β-Ni(OH)2 calculated using the lattice parameters reported by McEwen [28]. Diffraction angles are listed for Cu Kα (λ=1.542 Å) and Co Kα (λ=1.789 Å) X-ray sources.

| Miller indices (hkl) | d(Å) | 2θCuKα(°) | 2θCoKα(°) | broadened by stacking faults |

|---|---|---|---|---|

| (001) | 4.605 | 19.3 | 22.4 | • |

| (100) | 2.707 | 33.1 | 38.6 | |

| (101) | 2.334 | 38.6 | 45.1 | • |

| (110) | 1.563 | 59.1 | 69.8 | |

| (111) | 1.480 | 62.8 | 74.4 | • |

| (200) | 1.354 | 69.4 | 82.7 | |

| (201) | 1.299 | 72.8 | 87.1 | • |

| (202) | 1.167 | 82.7 | 100.1 | • |

| (113) | 1.095 | 89.5 | 109.5 | • |

The α-Ni(OH)2⋅xH2O polymorph of nickel hydroxide consists of layers of β-Ni(OH)2, oriented parallel to the crystallographic ab-plane, intercalated by water molecules (figure 4) [4]. The degree of hydration varies within the range 0.41≤x≤0.7 [28,35]. Although the material is intrinsically hydrated, the water molecules are typically omitted from the written formula, i.e. the material is denoted α-Ni(OH)2. Note that the representation of α-Ni(OH)2 in figure 4 is not strictly correct or, at the very least, is somewhat misleading [1,28,36]. The intercalated water molecules do not occupy fixed sites, but rather they have some freedom to rotate and translate within the ab-plane. If the water molecules were close-packed with the hydroxide ions, as originally proposed by Bode et al. [4], the c-parameter would be approximately 7.6 Å. Actually, c≥7.8 Å, and water acts as an ‘amorphous glue’ that holds together the Ni(OH)2 layers [28]. As a result, adjacent layers have little, or no, tendency to orient relative to one another. This random layer orientation motif is known as a ‘turbostratic’ structure [28,37].

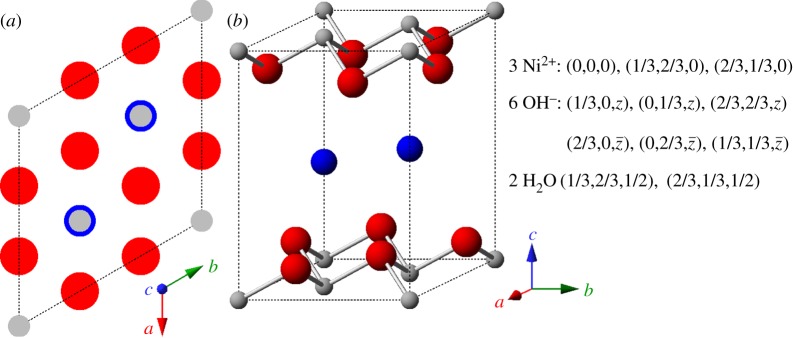

Figure 4.

The idealized crystal structure of α-Ni(OH)2⋅xH2O represented by (a) unit cell projection and (b) ball-and-stick unit cell for x=0.67 (actual value varies, 0.41≤x≤0.7). Small (grey) spheres, Ni2+; large (red) spheres, OH−; medium size (blue) spheres, H2O. Unit cell parameters are listed in table 1. Copyright this work. (Online version in colour.)

Extended X-ray absorption fine structure (EXAFS) measurements show that there is a 0.05 Å contraction in the Ni–Ni distance, dNi−Ni, in α-Ni(OH)2 relative to β-Ni(OH)2 [32]. Therefore, the unit cell parameters for the idealized stoichiometry (3 Ni : 2 H2O) shown in figure 4 are a=b=5.335 Åand c=8.0 Å. Note that the a-parameter depends on the way in which the unit cell is defined, which in turn, is determined by the degree of hydration. dNi−Ni, however, may be compared directly with the a-parameter of β-Ni(OH)2 (table 1). Furthermore, the c-parameter is greater if the interlayer space contains anionic impurities (see §2b(iii)). A representative XRD pattern is shown in figure 3 and the XRD parameters are listed in table 3.

Table 3.

X-ray diffraction parameters of α-Ni(OH)2 calculated using the unit cell shown in figure 4 and the lattice parameters reported by Pandya et al. [32]. Fewer significant digits are provided for peaks involving the crystallographic c-axis [(001), (111), etc.]. Diffraction angles are listed for Cu Kα (λ=1.542 Å) and Co Kα (λ=1.789 Å) X-ray sources.

| Miller indices (hkl) | d (Å) | 2θCuKα(°) | 2θCoKα(°) |

|---|---|---|---|

| (001)a | 8.0 | 11.1 | 12.8 |

| (100) | 4.62 | 19.2 | 22.3 |

| (002) | 4.0 | 22.2 | 25.8 |

| (110) | 2.67 | 33.6 | 39.2 |

| (111) | 2.5 | 35.5 | 41.4 |

| (200) | 2.31 | 39.0 | 45.6 |

| (004) | 2.0 | 45.3 | 53.1 |

| (210) | 1.75 | 52.4 | 61.6 |

| (301) | 1.5 | 61.3 | 72.5 |

aWe have used the unit cell definition and Miller indices reported by Bode et al. and McEwen, in which the intersheet distance, dIS=c[4,28]. However, some authors use a different unit cell definition, such that dIS=c/3 (e.g. [33,34]). In these sources, the Miller indices also vary by a factor of three (e.g. where we report (001), they would report (003), etc.).

(b). Structural disorder

In addition to the two fundamental phases of nickel hydroxide, there are several possible types of structural disorder, including the incorporation of foreign ions, variable hydration and crystal defects including stacking faults [38]. Numerous methods have been used to denote the structural disorder, including adopting labels such as αam, α*, α′, IS and βbc [1,39–41], in part, because the nature of the disorder was not always fully understood. However, it is now possible to establish a less ambiguous method to identify and communicate nickel hydroxide structures. Quite simply, we recommend that the parent structure is first identified, followed by the observed type, or types, of disorder. For example, some βbc samples have since been identified as β-Ni(OH)2 with stacking fault disorder [34,38]. Such clearly defined short-hand notations may be useful, provided they actually are clearly defined. In this example, one could write βsf, where sf = stacking fault disorder.

The effects of structural disorder can have very important practical consequences. For example, well-crystallized β-Ni(OH)2 has lower electrochemical activity than disordered β-Ni(OH)2 materials [6]. However, the relationship between structural disorder and the measured properties is not always clear. The substitution of nickel sites with cobalt atoms improves the proton conductivity of β-Ni(OH)2. It is unclear, however, whether this is attributable to increased proton vacancies [42] or to increased stacking fault disorder, which is also known to affect the electrochemical activity of nickel hydroxide electrodes [43–45]. Therefore, it is important that all possible forms of disorder should be identified. These are briefly reviewed below.

(i). Hydration

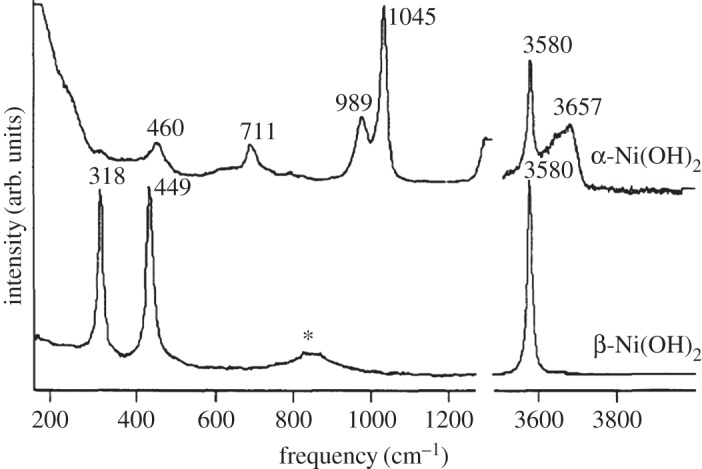

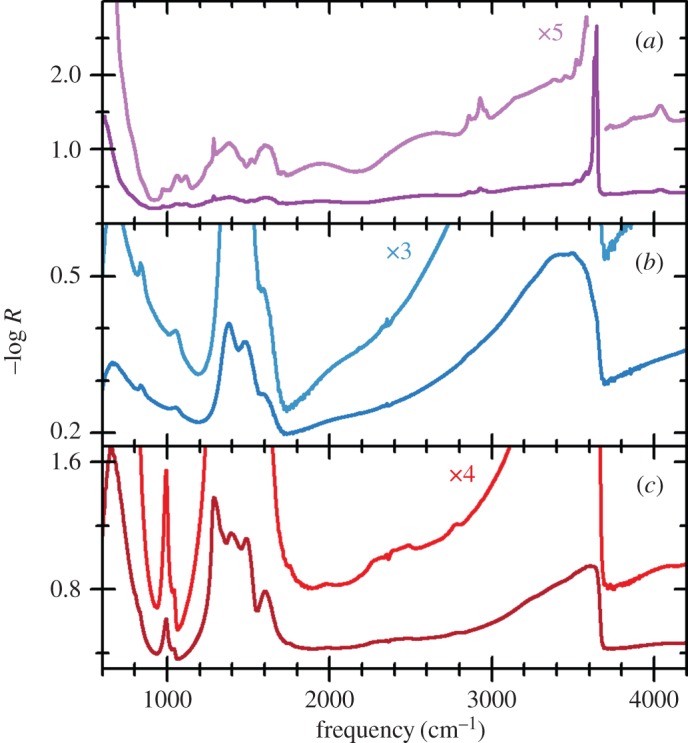

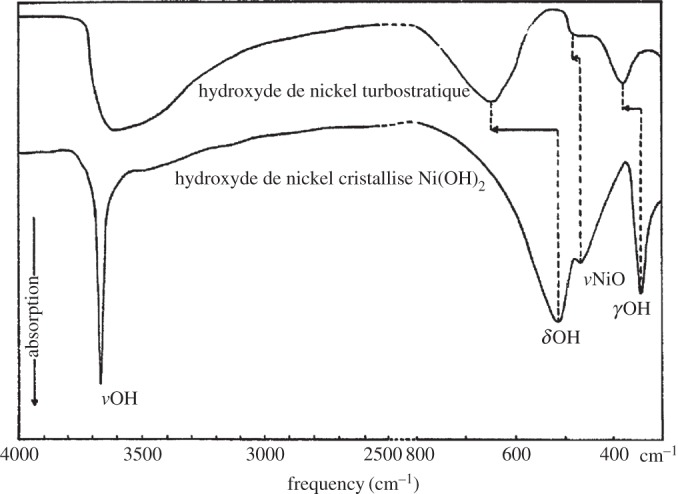

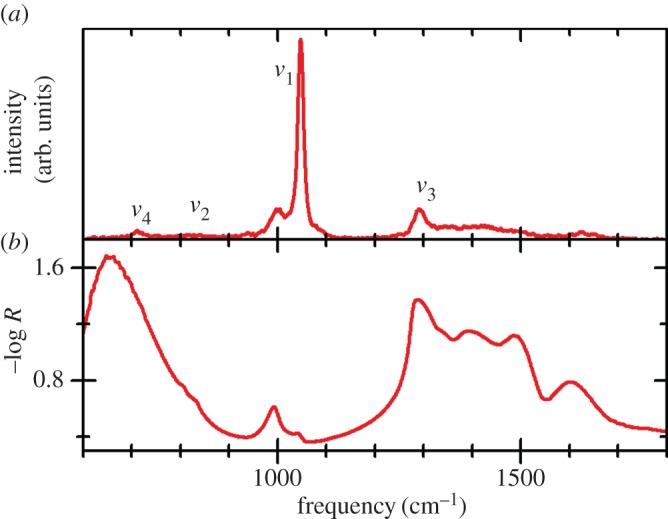

Hydrated β-Ni(OH)2 materials are very important for electrochemical applications. The hydrated, electrochemically active form of the material has been given the representation [Ni(H2O)x](OH)2, where 0.1≤x≤0.4 [46,47]. The water molecules are weakly associated with the nickel cations and do not form hydrogen bonds with the lattice hydroxide [6,47–49]. One way to assess the amount of hydration is through thermogravimetric analysis or thermal gravimetric analysis (TGA) that involves the measurement of a sample's mass as its temperature, T, is slowly increased (ΔT/Δt is fixed and the sample mass is plotted against T) or as a function of time (T is fixed and mass is plotted against time). This method is very useful for hydrated materials because the removal of water may be measured as a sample's temperature is increased [50,51]. For β-Ni(OH)2, TGA has shown that surface water may be removed at relatively low temperatures, T≈80–90°C, and that the incorporated water can be fully removed at high temperatures, T≈160°C [35,46,47,52–54]. Thermal dehydration decreases the charge capacity of β-Ni(OH)2 battery electrodes by approximately 10–14% [47,49]. The presence of incorporated water can also increase the interlayer spacing by Δc≈0.1 Å[27], although because the role of stacking faults (see §2b(ii)) in these measurements is unknown, this expansion may not be wholly attributable to hydration effects. Incorporated water may be conclusively detected by the presence of additional O−H libration (bending) modes in the Raman and IR spectra [27,38,48,49,52] (see §4b).

α-Ni(OH)2⋅xH2O materials are always hydrated because water is intrinsic to their structure. TGA measurements show that the interlayer water in α-Ni(OH)2 is only removed at very high temperatures, T≈240–300°C [35,46,55]. The removal of the interlayer water may occur together with the removal of water from the decomposition of the hydroxide to NiO [46]. This is quite different from the TGA behaviour of β-Ni(OH)2 materials, which shows a dehydration process at T≈160°C from incorporated water, followed by a very broad feature at 170°C<T<525°C from decomposition to NiO [47]. Moreover, the mass loss of α-Ni(OH)2 from dehydration is significantly greater than that of the β-phase. The ‘pure’ material is generally reported within the range 0.41≤x≤0.7 [28,35], although the exact degree of hydration is quite variable and sometimes lies outside this range. The incorporation of foreign anions into the region between Ni(OH)2 layers strongly affects hydration (see §2b(iii)). In addition to the water limited to within this interlayer region, it has been suggested that water may associate with the lattice Ni, similar to what is observed for hydrated β-Ni(OH)2 materials [46,48]. TGA measurements show that a small amount of weakly bound water may be removed at approximately 110°C. This has been attributed to water adsorbed on the surface, but could also originate from bulk hydration of the Ni atoms [35]. EXAFS evidence that α-Ni(OH)2 materials can have Ni–O coordination numbers greater than six supports this possibility [32].

(ii). Stacking fault disorder

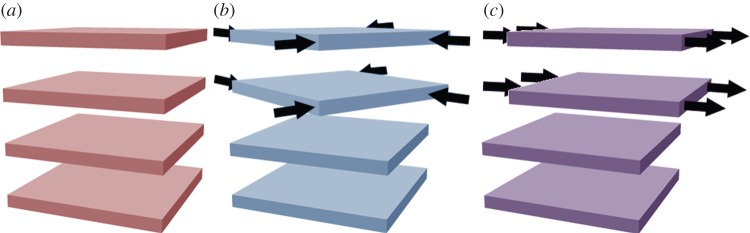

Stacking faults, which are common in layered double hydroxides (LDHs) [56], may be understood by examining the unit cell of β-Ni(OH)2 (figure 2). There is strong ionic bonding between Ni2+, O2− and H+ ions within each Ni(OH)2 sheet, whereas the interactions between adjacent layers are relatively weak. Therefore, Ni(OH)2 materials consist of several ‘stacked’ layers. Consequently, in addition to the aligned thermodynamic product, illustrated in figure 5a, one can propose three additional stacking motifs. The first arises from rotation about the c-axis by 60° (figure 5b), the second from translation within the ab-plane (figure 5c), and the last from both rotation and translation. One may alternatively consider stacking fault disorder by examining the oxygen anion stacking sequence, which is ideally AC AC AC AC, etc. In the presence of a stacking fault, this sequence is altered, e.g. to AC BA CB AC, etc. [57]. For more information on stacking fault disorder in nickel hydroxides, the reader is referred to Tessier et al. [45] or, for a detailed and general discussion of stacking fault disorder, Sebastian & Krishna [58]. Stacking faults cause selective line broadening in XRD patterns, because the disorder is only along the direction of the crystallographic c-axis (i.e. order within the ab-plane is unaffected by stacking faults) [43,45,57]. The relationship between stacking fault frequency and powder XRD peak widths and intensities has been simulated computationally [44,59]. Stacking faults in β-Ni(OH)2 materials also cause additional O−H stretching modes in their Raman and infrared (IR) spectra (see §4) [38]. One can therefore estimate the relative frequency of stacking fault disorders between two samples from the relative peak intensities in the Raman or IR spectra. However, spectral differences arising from the different stacking fault motifs, e.g. translation (figure 5b) versus rotation (figure 5c), have not been reported. It is meaningless to discuss stacking faults in α-Ni(OH)2 because of its turbostratic structure (the layer orientation is always random).

Figure 5.

Schematic of stacking fault disorder between two adjacent layers. (a) No stacking faults are present and adjacent layers are aligned. (b) Rotation about the crystallographic c-axis. (c) Translation within the ab-plane. Copyright this work. (Online version in colour.)

(iii). Ionic substitution and foreign ion incorporation

Substitutional point defects involve the substitution of a lattice atom (or polyatomic ion) with another. Numerous cationic substitutions of nickel hydroxides have been prepared from bivalent metal cations and are given the general formula Ni1−xMx(OH)2, where M is the substituted metal atom. Substitution may be minor; for example, reagent impurities led to the preparation of Ni1−xCax(OH)2, x≤0.02 in [38]. More extensive cationic substitution may also occur, especially if there are isostructural materials. For example, solid solutions of β-Ni(OH)2 and Mg(OH)2 (brucite) of any composition are possible and have been used to correlate the vibrational modes of the two materials [60].

β-Ni(OH)2 materials have been prepared with cationic substitutions of the lattice Ni with Mg [60,61], Al [16], Ca [38,61], Co [42,43,52,61–64], Cu [61], Zn [61,65,66] and Cd [42,64]. All of these materials maintain the space group of the parent β-phase material, although generally with slightly modified unit cell parameters. For example, the interplanar spacing, c, decreases with increasing Co content [63]. This may not purely result from the different cationic radii, as the preparation of these substituted materials is often accompanied by other structural changes, such as decreased stacking fault disorder [43].

α-Ni(OH)2 materials have been prepared with cationic substitutions of the lattice Ni with Al [16,67–75], Mn [76,77], Fe [78,79], Co [14,69,74,75,80–82], Cu [67,83], Zn [65,66,70,84,85], Y [86] and Yb [87]. In some of these examples, the bivalent Ni2+ cation is replaced with a trivalent species (e.g. Fe3+). Therefore, the resulting materials must be hydroxide-rich, proton-deficient or there is a corresponding degree of anionic incorporation, which is further discussed below, to maintain charge balance (e.g. carbonate anions in [79]).

Ni(OH)2 materials can be isotopically enriched by treatment with D2O, which is another form of cationic substitution. Deuterated materials have been used for crystallographic studies (β-Ni(OD)2 [27] and α-Ni(OD)2 [88]) and to definitively identify the O−H and O−D stretching modes in IR spectra (β-Ni(OH)2/β-Ni(OD)2 [49,88,89] and α-Ni(OH)2/α-Ni(OD)2 [88]).

Foreign anions are commonly incorporated into α-Ni(OH)2. During precipitation from a nickel(II) salt, it is quite common for some of the counterions to be incorporated into the structure (see §3 for the methods of nickel hydroxide synthesis). The amount incorporated can be considerable and the resultant material is represented by the general formula α-Ni(OH)2−xAyBz ⋅ nH2O, where A and B are monovalent and divalent anions, respectively, and x=y+2z [90]. Because Ni(NO3)2 is widely used as a precursor to prepare nickel hydroxide materials, the most common foreign anion is nitrate [1,91], although chloride, sulfate, carbonate, cyanate, acetate, succinate, glutarate and adipate anions have also been reported [38,90,92,93]. The incorporated anions may either occupy lattice hydroxide sites or they may sit within the interlayer region [38,94]. The former tends to be less stable, probably owing to mechanical stresses from the size mismatch. By contrast, anions in the intercalation region tend to be more stable and have very similar spectroscopic properties to the free solution species. In the field of intercalation chemistry, the thickness of the interlayer space is known as the ‘gallery height’ [95].The presence of foreign ions in the interlayer space can increase the gallery height and, consequently, the interlayer spacing. For example, the interlayer spacing of α-Ni(OH)2 containing nitrate or carbonate is typically 7.8 Å ≤c≤8.2 Å , whereas the spacing of α-Ni(OH)2 that contains the larger anion adipate [] has been reported as high as c=13.2 Å. This is a 65% expansion from the parent structure [33,90]. The increased gallery height is presumably accompanied by the incorporation of additional water.

The incorporation of foreign anions into β-Ni(OH)2 materials is far less common because adjacent layers are close-packed. Furthermore, foreign anions are quickly removed during the preparation of β-Ni(OH)2 by chemical ageing, i.e. the conversion of α- to β-Ni(OH)2 (see §3d) [38,94].

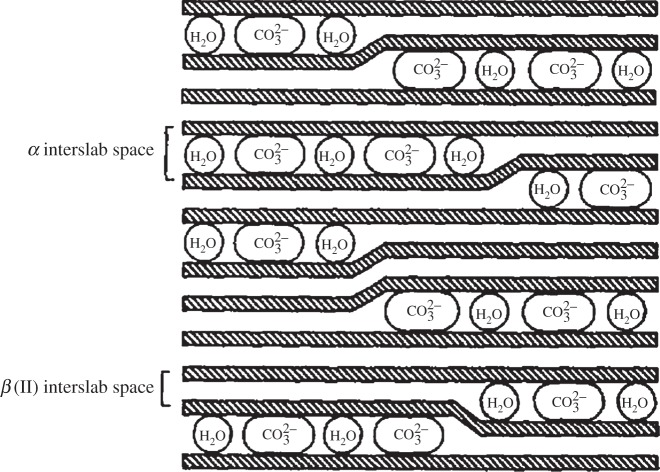

(iv). α/β-Interstratification

One can consider a single grain or crystal of nickel hydroxide in which some of the layers are separated by intercalated water (α), whereas the rest are not (β). Such materials have been described as ‘interstratified phases consisting of α- and β-type structural motifs’ and not simple mixtures of α- and β-Ni(OH)2 crystals [33,41,96,97]. Rather, the presence of interstratification allows α- and β-Ni(OH)2 domains to coexist within a single crystal. This material, which we denote α/βIS-Ni(OH)2, is illustrated in figure 6. These domains may hypothetically be very large or as little as a single layer. Generally, the measured XRD pattern of materials containing primarily one phase (i.e. when the interstratification is minimal), is quite similar to that of the pure material. However, for mixed samples such as the α/βIS-Ni(OH)2 shown pictorially in figure 6, the diffraction lines appear shifted and broadened. This is because the long-range structural order required for diffraction measurements is diminished in interstratified materials. If each layer is solely α- or β-phase, the disorder is only oriented along the c-axis and the (hkl), l≠0, XRD lines will be selectively broadened or even absent from the measured pattern [59,97]. However, it is also possible to have both phases within a single layer, as shown in figure 6, in which case the structural disorder will be more generalized. The variation of the diffraction peak widths and relative intensity versus the diffraction angle in interstratified layered structures has been examined theoretically and experimentally for various compositions and structural motifs [59,96,98]. A sample diffraction pattern shown in figure 7.

Figure 6.

Schematic of α/β-interstratification, in which both phases coexist within a single crystal. In this example, the α-Ni(OH)2 contains intercalated carbonate anion impurities. Adapted from [96], copyright 1994, with permission from Elsevier.

Figure 7.

XRD patterns collected from α-Ni0.7Mn0.3(OH)2, α/βIS-Ni0.9Mn0.1(OH)2, and β-Ni(OH)2 using a Cu Kα X-ray. The α- and α/βIS-phase materials contained intercalated carbonate anions (figure 6). Adapted from [96], copyright 1994, with permission from Elsevier.

It should be noted that vibrational spectra collected from interstratified materials contain the characteristic O−H internal stretching modes of both the α- and β-phase materials (see §4b) [33,41,96]. Moreover, it is possible to have interstratification and other types of structural disorder, such as the mixed metal, carbonate-intercalated α/βIS-Ni0.9Mn0.1(OH)2 materials reported in Guerlou-Demourgues et al. [96] or the carbonate-intercalated α/βIS-Ni1−xCox(OH)2 in [33]. Guerlou-Demourgues et al. suggested that the small amount of carbonate in their samples was insufficient to homogeneously distribute within the interlayer space, which caused segregation, as represented in figure 6.

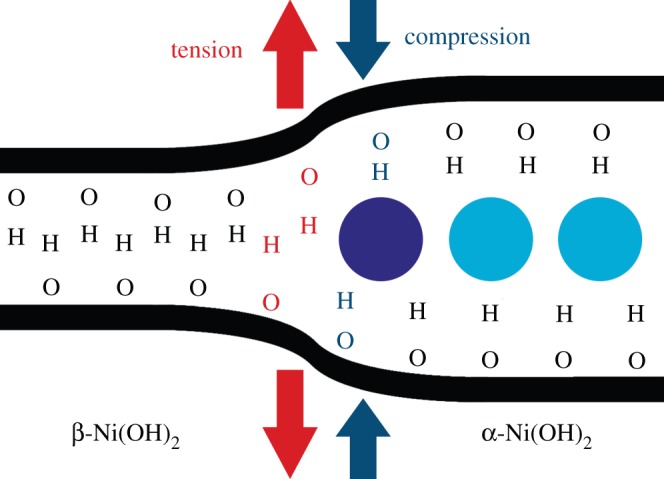

(v). Internal mechanical stress

There are several causes of internal mechanical stress. For example, the insertion of large polyatomic anions, such as nitrate, into the lattice sites or the intercalation space of α-Ni(OH)2 is expected to introduce mechanical stress. Internal stress occurs during the chemical ageing of α- to β-Ni(OH)2 because of the changing unit cell c-parameter (8.0–4.6 Å), which causes compressive and tensile forces along the c-direction of the α- and β-phases, respectively [94]. Mechanical stress is also reported for dried nickel hydroxide films. The lattice vibrational modes are shifted when the films are visibly cracked, showing that the removal of water changes the density of the materials and causes internal stresses [38]. Mechanical stress also occurs during the redox cycling of nickel hydroxide electrodes in batteries, because of the differences in densities of nickel hydroxide and nickel oxyhydroxide [1,99].

(c). α-Derivative structures

In addition to α-Ni(OH)2, there are several related materials that may not truly belong to the α-Ni(OH)2 phase. Nevertheless, they are often given the ‘α’ label because of certain structural similarities. For example, Nevravathi et al. [82] used the term ‘surfactant-intercalated α-nickel hydroxide’ to designate a material composed of single sheets of Ni(OH)2 separated by intercalated dodecyl sulfate. This term clearly indicates that the surfactant molecules are between the nickel hydroxide sheets. However, one may argue that the ‘α’ label should be reserved for materials that are composed of brucite-like nickel hydroxide intercalated with water molecules (i.e. α-Ni(OH)2⋅xH2O). Essentially, this suggests two possible interpretations of the ‘α’ label: (i) brucite-like Ni(OH)2 sheets with intercalated water or (ii) brucite-like Ni(OH)2 sheets with any intercalated species. With the crystallographic and historic perspectives in mind, we shall choose the first of these over the latter. Therefore, we now introduce the term ‘α-derivative structures’ for brucite-like Ni(OH)2 sheets with any intercalated species other than water. This new term is quite broad and may be considered a class of materials, rather than an individual crystallographic phase. These materials may be generally described as partially ordered layered structures, as the individual Ni(OH)2 layers are well ordered, whereas there is disorder in the intercalation space. This is also true for α-Ni(OH)2 itself. Several examples of these α-derivative structures are provided below.

(i). Surfactant-intercalated α-derivative structures

α-Ni(OH)2-like materials in which the intercalated water is replaced with surfactant molecules have been prepared using cetyltrimethylammonium bromide [100], dodecyl sulfate [82,92,100–106], dodecylbenzene sulfonate [103], p-aminobenzoate [18] and Tween 80 [100]. The polar or ionic regions of the surfactant molecules interact with the Ni(OH)2 sheets and the non-polar regions fill the interlayer space. Therefore, the interlayer space is hydrophobic and water is consequently excluded from the region. Note that these materials are fundamentally different from the α-Ni(OH)2 materials with incorporated foreign anions described in §2b(iii). Those previous examples are hydrated structures that are closely related to the ideal parent α-phase, whereas these surfactant-intercalated α-derivative materials do not contain water.

(ii). Exfoliated α-derivatives

The individual layers of α-Ni(OH)2 may be separated, i.e. exfoliated, to produce a colloidal suspension. The exfoliation of layered structures, in general, such as perovskites, hydroxyl double salts and LDHs, has been studied in more detail [107]. Just as the properties of graphene are wholly different than those of graphite, the properties of exfoliated nickel hydroxide can be quite different from those of either α- or β-Ni(OH)2 [102].

Generally, there are two exfoliation methods. In the first, the interlayer region is rendered organophilic via surfactant intercalation, as described above. Then, the use of an organic solvent spontaneously exfoliates the material [107]. For example, a dodecyl sulfate-intercalated α-derivative may be exfoliated by the addition of formamide [102] or 1-butanol [82]. In the second method, exfoliated α-derivatives are prepared in an aqueous solution. An intercalated α-derivative is prepared with an amphoteric molecule, which is any chemical species that has both acidic and basic functional groups. For example, p-aminobenzoic acid has a carboxylic acid group and a basic amine group. At high pH, this species is anionic and may be incorporated into the interlayer space to produce a p-aminobenzoate-intercalated α-derivative. When the pH is decreased, the molecule becomes a zwitterion. Zwitterions are electrically neutral molecules that contain regions of positive (–NH) and negative (–CO) charge. The result is that the material becomes unstable and Coulombic repulsion between adjacent, positively charged amine groups drives exfoliation of the material [108].

The colloidal sheets maintain the octahedral coordination of the Ni cations. However, as they are no longer stacked sheets of Ni(OH)2, they cannot correctly be designated as α- or β-phase materials. Rather, we recommend the term ‘exfoliated α-derivative,’ to describe the preparation of the material. It is also noteworthy that changing the solution conditions of the suspension may result in reformation of the surfactant-intercalated α-derivative [82].

(iii). Basic nickel salts

Several basic salts of nickel exist that are related to the nickel hydroxides [34]. In particular, nickel hydroxynitrates (NHNs) may be prepared from Ni(NO3)2 and include Ni2(OH)3(NO3) [109], Ni3(OH)4(NO3)2 [110], and Ni(OH)(NO3) [111]. These materials, which can be hydrated, have the general formula Ni(OH)2−x(NO3)x⋅nH2O, the same given to nitrate-containing α-Ni(OH)2 [34]. NHNs have trigonal symmetry and the nitrate anions are directly bonded to the Ni cations [34], which is also true for some α-Ni(OH)2 samples [38]. However, NHNs may be prepared as anhydrous materials, which is fundamentally different from α-Ni(OH)2 [34]. One may wonder, then, what differences exist between these two related materials. First, the interlayer spacing is consistently less in NHNs (typically, cNHN<7.6 Å) than in α-Ni(OH)2 (cα≥7.8 Å). Second, NHN materials have considerably sharper diffraction peaks [34], because adjacent layers in NHNs are close-packed. This is in contrast to the broad diffraction peaks that arise from the turbostratic α-Ni(OH)2 structure [1,28]. Therefore, the main difference between nitrate-containing α-Ni(OH)2 and hydrated NHN is the relative spacing and alignment of the adjacent layers.

Other basic salts of nickel include nullaginite [Ni2(OH)2CO3] [112], paraotwayite [Ni(OH)2−x(SO4,CO3)0.5x, x≈0.5] [113] and otwayite [(Ni,Mg)2(OH)2CO3⋅H2O] [114]. The unit cell symmetries of these three minerals (monoclinic, orthorhombic and monoclinic, respectively) are different from those of the NHNs, α-Ni(OH)2 and β-Ni(OH)2 (all trigonal).

3. Synthesis

Countless methods to prepare nickel hydroxide materials exist. As a result, finding a method to prepare a sample with appropriate properties can be a time-consuming and overwhelming task. Desired properties may include the phase (α or β), crystallinity (stacking fault disorder, purity, etc.), product morphology (porosity, nanostructure, etc.) and general form (bulk powder, thin film on a metallic substrate, etc.). Therefore, this portion of the review is intended to serve as a guide to direct the reader toward appropriate references by outlining some of the more widely used methods that are available. By no means is this summary comprehensive or exhaustive, as the compilation of all the different published methods is simply outside the scope of a simple review article. Rather, examples have been selected for their popularity, for their ease, or to represent the diversity of published methods.

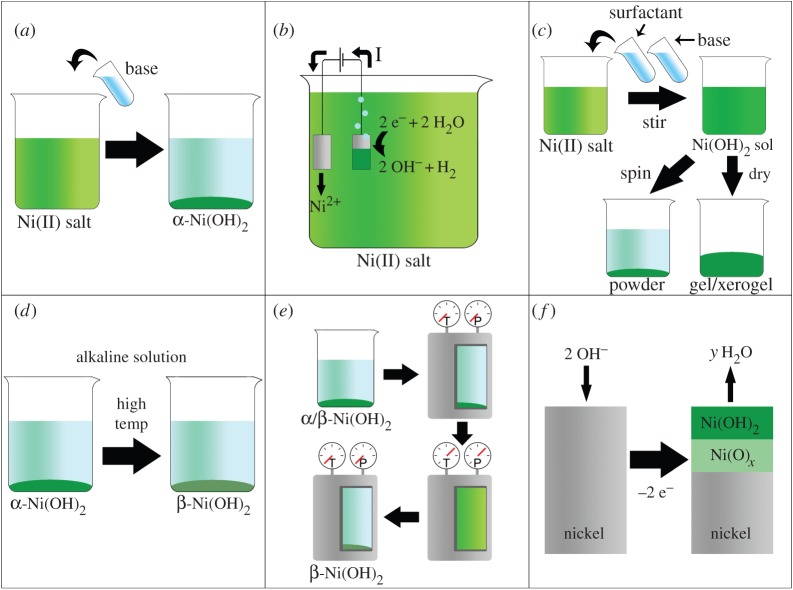

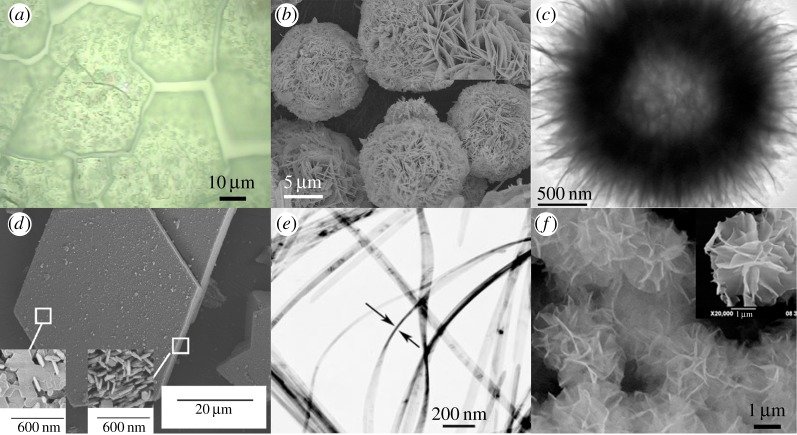

In general, α-Ni(OH)2 may be prepared in bulk quantities by chemical precipitation or as a thin layer on a high surface area substrate by impregnation-precipitation (§3a). α-Ni(OH)2 may be deposited as a thin layer on a conductive substrate by electrochemical precipitation (§3b). A wide variety of porous and micro-/nanoscale structured materials may be prepared by sol–gel synthesis, as a bulk material or deposited onto a substrate by spin- or dip-coating (α or β, §3c). High-purity β-Ni(OH)2 materials may be produced by chemically ageing α-Ni(OH)2 (§3d) or purchased as a powder from a commercial supplier. Bulk quantities of micro- or nanostructured α- or β-Ni(OH)2 may be produced by hydrothermal or solvothermal synthesis (§3e). Nickel hydroxides are common components of corrosion deposits and electrochemically formed surface layers on nickel metal and nickel-based alloys (§3f). These six synthetic methods are schematically represented in figure 8. Finally, several less common methods, including microwave-assisted, sonochemical and solid-state synthesis, are briefly presented (§3g). Examples of six possible morphologies for α- and β-Ni(OH)2 prepared by various synthetic methods are shown in figure 9.

Figure 8.

Six methods to prepare Ni(OH)2. (a) The basification of an aqueous nickel(II) salt solution (e.g. addition of KOH(aq) to NiCl2(aq)). (b) Electrochemical precipitation onto a conductive substrate. The reduction of water produces hydroxide anions at the cathode surface, which react with the nickel(II) cations in solution. In this example, the anode material is a Ni sheet. (c) Sol–gel methods. A solution of a nickel(II) salt and a surfactant (e.g. sodium dodecylsulfate) is basified to form a Ni(OH)2 sol. The sol is treated (e.g. by centrifugation or evaporation) to produce a gel. (d) Chemical ageing converts α-Ni(OH)2 to β-Ni(OH)2. This is typically performed in concentrated alkaline media at high temperatures but also proceeds slowly in room temperature water. (e) The hydrothermal method. α/β-Ni(OH)2 precursor is dissolved in a pressure vessel at high temperatures. The temperature is subsequently decreased and β-Ni(OH)2 precipitates. (f) α/β-Ni(OH)2 surface layers form on nickel and nickel-based alloys as corrosion products or electrochemically formed surface layers, often underlaid by non-stoichiometric nickel oxide. Reproduced with permission from [115]. (Online version in colour.)

Figure 9.

Representative images of the morphologies discussed in this review: (a) Light micrograph of an electrochemically precipitated α-Ni(OH)2 film. The surface visibly cracked when the film was dried. Adapted with permission from [38]. (b) SEM image of β-Ni(OH)2 nanoflowers prepared by hydrothermal synthesis. Inset: high magnification shows the nanoflowers are composed of nanosheets. Adapted by permission from [22]. (c) TEM image of a ‘dandelion-like’ hollow β-Ni(OH)2 microsphere prepared by a sol–gel method. Reprinted with permission from [116], © 2009 American Chemical Society. (d) SEM of an ‘unusually large β-Ni(OH)2 ‘pseudo-single crystal’ prepared by a chemical precipitation method. Inset: high magnification of the particle basal plane and an edge. Reprinted with permission from [117], © 2011 American Chemical Society. (e) TEM image of α-Ni(OH)2 nanoribbons prepared by hydrothermal synthesis. Ribbons are 10–20 nm thick. Adapted with permission from [118]. © 2008 WILEY-VCH Verlag GmbH & Co. (f) SEM image of β-Ni(OH)2 nanoflowers prepared by microwave-assisted hydrothermal synthesis. Inset: high magnification of a single nanoflower. Reprinted from [119], © 2010, with permission from The Society of Powder Technology. (Online version in colour.)

Keen-eyed readers will notice that some of the product phases and descriptions do not exactly match those in the original articles. This is because, to the best of our ability, we have made efforts to re-evaluate crystallographic and spectroscopic results using the most recently available interpretations and assignments. It is not that we believe or wish to imply that previous researchers made errors. Rather, the community's understanding of some experimental results (e.g. vibrational mode assignments) has improved with time and one may now better understand decades-old experimental results. For example, selective line broadening in XRD patterns is now understood to usually arise from stacking fault disorder, rather than particle size effects [43].

(a). Chemical precipitation

The chemical precipitation of Ni(OH)2 is a one-step method, in which a basic solution (NaOH, NH3, etc.) is added, typically dropwise, to a nickel(II) salt solution (Ni(NO3)2, NiCl2, etc.), or vice versa. At sufficiently high pH, the hydroxide anion concentration exceeds the solubility limit and Ni(OH)2 forms as a precipitate

| 3.1 |

The phase and the crystallinity of the product are determined by the solution concentrations, the nickel(II) salt used, the base solution used (NaOH, NH4OH, etc.), the temperature and the pH of the solution during precipitation [40,120]. In general, precipitation at room temperature favours the formation of α-Ni(OH)2 and precipitation at elevated temperatures produces mixed-phase α/β- or pure β-Ni(OH)2 materials [35]. It has been suggested that the precipitation process always produces α-Ni(OH)2 initially, but that the initial product rapidly chemically ages (sometimes referred to as ‘ripening’) at high temperatures to the more crystalline β-phase [121]. Chemical ageing, the spontaneous transformation from α to β, is further discussed in §3d. The formation of pure β-Ni(OH)2 by chemical precipitation generally requires temperatures near or above the boiling point of water. These high temperature and pressure methods are described in §3e, which discusses hydrothermal synthesis. Precipitation at high temperatures in ambient pressure may be performed if very concentrated alkaline solutions are used (e.g. β-Ni(OH)2 was precipitated by reflux at 170°C in 63–75% (w/w) NaOH(aq) [122]). The choice of the nickel(II) salt and the basification agent also affects the product structure. For example, the basification of Ni(NO3)2 with urea at 90°C yields α-Ni(OH)2 precipitate, despite the high temperature [121]. This is presumably because of the incorporation of nitrate and cyanate anions into the interlayer space during precipitation. Through careful control of the experimental conditions, it is also possible to control the crystallite size. For example, figure 9d shows a large hexagonal β-Ni(OH)2 crystal prepared by Gourrier et al. [117].

Mixed hydroxides (e.g. Ni1−xMnx(OH)2), which may be used in NiCd or NiMH battery anodes, are easily prepared by chemical precipitation [6]. This is a common step in the synthesis of materials for Li-ion battery electrodes (e.g. LiNi1−xMnxO2) [77,123,124]. More complex mixed hydroxides, such as core–shell Ni1−xMnx(OH)2 spherical nanoparticles, where x varies as a function of the particle radius, may be prepared by gradually changing the composition of the precipitation solution [125]. Several representative precipitation methods are listed in table 4.

Table 4.

Representative methods from the literature for chemical precipitation of bulk Ni(OH)2 materials.

| Ni(II) salt | base | other reagents | product phase | comments | refs. |

|---|---|---|---|---|---|

| Ni(NO3)2 | NaOH | α-Ni(OH)2 | article discusses the effect of solution pH | [40] | |

| Ni(NO3)2 | KOH | α-Ni(OH)2 | [126] | ||

| Ni(NO3)2 | KOH | α-Ni(OH)2 | T=22°C | [35] | |

| contains some β-Ni(OH)2 | |||||

| Ni(NO3)2 | KOH | β-Ni(OH)2 | T=90°C | [35] | |

| stacking fault disorder | |||||

| contains some α-Ni(OH)2 | |||||

| Ni(NO3)2 | NH4OH | α-Ni(OH)2 | [127] | ||

| Ni(NO3)2 | NaOH | Na2CO3 | α-Ni(OH)2 | product contains Zn2+ | [84] |

| Zn(NO3)2 | |||||

| Ni(NO3)2 | KOH | sodium citrate | α/β-Ni(OH)2 | [126] | |

| NiCl2 | NH4OH | β-Ni(OH)2 | dried at 100°C for 12 h | [128] | |

| stacking fault and hydration disorder | |||||

| NiCl2 | NH4OH | graphene | β-Ni(OH)2 | dried at 100°C for 12 h | [128] |

| stacking fault, hydration and general disorder | |||||

| contains some α-Ni(OH)2 | |||||

| NiCl2 | NH4OH | CoCl2 | α/β-Ni(OH)2 | dried at 100°C for 12 h | [128] |

| product contains Co | |||||

| stacking fault, hydration and general disorder | |||||

| NiCl2 | NH4OH | Al2(SO4)3 | α-Ni(OH)2 | dried at 100°C for 12 h | [128] |

| product contains Al | |||||

| hydration and general disorder | |||||

| NiCl2 | NH4OH | Al2(SO4)3 | α-Ni(OH)2 | dried at 100°C for 12 h | [128] |

| CoCl2 | product contains Co and Al | ||||

| hydration and general disorder | |||||

| NiSO4 | NaOH | α-Ni(OH)2 | [129] | ||

| NiSO4 | NaOH | Fe2(SO4)3 | α/β-Ni(OH)2 | mostly, the α-phase material is produced | [79] |

| Na2CO3 | |||||

| product contains Fe3+ and CO | |||||

| NiSO4 | NaOH | β-Ni(OH)2 | T=20°C, dried at 60°C | [43] | |

| stacking fault and general disorder | |||||

| Ni(NO3)2 | NaOH | α/β-Ni(OH)2 | T=60°C | [101] | |

| product contains NO | |||||

| Ni(NO3)2 | OC(NH2)2 | α-Ni(OH)2 | T=70–90°C | [121] | |

| product contains OCN− and CO | |||||

| Ni(NO3)2 | Na2O2 | β-Ni(OH)2 | yields ‘coral-like’ nanoporous materials | [130] | |

| stacking fault disorder | |||||

| NiSO4 | NaOH | β-Ni(OH)2 | T=70°C, dried at 120°C | [43] | |

| stacking fault and some general disorder | |||||

| NiSO4 | NaOH | α/β-Ni(OH)2 | T=60°C | [101] | |

| product contains SO | |||||

| NiSO4 | NaOH | NH4OH | α/β-Ni(OH)2 | T=60°C | [131] |

| article discusses the effect of solution pH | |||||

| stacking fault disorder | |||||

| Ni(ClO4)2 | NaOH | β-Ni(OH)2 | stir at 110≤T≤170°C for 24 h | [122] | |

| yields hexagonal crystals (≤0.1 mm) | |||||

| Ni(ClO4)2 | NaOH | β-Ni(OH)2 | stir at T=140°C for 24 h, remove mother liquor, add water, then stir at T=170°C for 24 h | [117] | |

| yields hexagonal crystals (approx. 50 μm) |

The impregnation-precipitation method is used to prepare high surface area materials, commonly for battery anodes. A porous or highly textured conductive substrate is first impregnated by immersion in a nickel(II) salt solution. The substrate is then immersed in an alkaline solution to elicit the precipitation of Ni(OH)2. By repeating this cycle, one may obtain the desired electrode loading, i.e. the desired Ni(OH)2 layer thickness [39]. The deposited Ni(OH)2 maintains the morphology of the substrate [39,132]. This method has also been called ‘dip-coating’ [132], a term that also refers to other techniques. Battery electrodes are also prepared by the suspension-impregnation method, in which an Ni(OH)2 suspension is deposited onto a porous substrate [6,72,133–135]. Ni(OH)2 may also be deposited onto a substrate by slow precipitation from a single solution [16,136].

(b). Electrochemical precipitation

A thin layer of α-, α/β- or β-Ni(OH)2 may be deposited on a conductive substrate by electrochemical precipitation (cathodic electrodeposition, electro-precipitation, etc.). An example of electrochemically precipitated α-Ni(OH)2 is shown in figure 9a. In this process, shown schematically in figure 8b, the substrate is placed in a nickel(II) salt solution and is held at a negative potential to elicit a cathodic current from the reduction of water

| 3.2 |

If the solution contains nickel(II) nitrate, the reduction of nitrate anions may contribute to the production of the hydroxide anions [28]. Because Ni(OH)2 has very low solubility, chemical precipitation immediately occurs at the electrode (substrate) surface

| 3.3 |

The structure of the product (phase, crystallinity, etc.) is heavily dependent on the nature of the nickel(II) salt solution (concentration, counterion) and the cathodic current density employed. It is emphasized that only the formation of hydroxide is electrochemical. The precipitation step is identical to the chemical precipitation methods described in §3a. During this process, the oxidation state of the nickel ions does not change. Hence, this method is dissimilar to the oxidation of nickel metal or a nickel-based alloy, which is discussed in §3f.

At low Ni(NO3)2 concentrations, the Faradaic efficiency of the deposition is nearly 100%, e.g. [Ni(NO3)2]<0.2 M at 0.5 mA cm−2 [91]. That is, approximately 1 mol of Ni(OH)2 is produced for every 2 mol of hydroxide produced at the electrode surface. At higher concentrations, the deposition efficiency can be much lower, e.g. 20% in 1 M Ni(NO3)2 at 0.5 mA cm−2. This inefficiency in concentrated solutions is attributed to the formation of soluble species, such as [NiOH]+ or [Ni4(OH)4]4+, that diffuse away from the substrate.

In general, deposition currents on the order of a few mA cm−2 yield α-Ni(OH)2, whereas larger currents produce mixed α/β-phase materials [28,137]. However, it is difficult to predict the product phase or crystallinity because of the joint effects of salt concentration, deposition current, temperature, etc. (e.g. cf. [13,138]). Even the nature of the substrate has an influence; for example, deposition onto Fe is more facile than on Ni or Pt electrodes [137]. Several representative electrochemical precipitation methods are listed in table 5.

Table 5.

Representative methods from the literature for electrochemical precipitation of Ni(OH)2 films onto electrically conducting substrates. Depositions are performed galvanostatically (at constant current), except where noted.

| Ni(II) salt and reagents | conc. (mol L−1) | current density (mA cm−2) | deposition time min | temp. (°C) | substrate | product phase | comments | refs |

|---|---|---|---|---|---|---|---|---|

| Ni(NO3)2 | 0.1 | -2.5 | 10 | 22 | nickel sheet | α-Ni(OH)2 | product contains NO | [38] |

| Ni(NO3)2 | 0.005 | -0.1 | 60 | 25 | stainless steel sheet (316L) | α-Ni(OH)2 | product contains NO | [13] |

| produces nanoparticles (approx. 5 nm) | ||||||||

| Ni(NO3)2 | 0.005 | -2.0 | 30 | 40 | stainless steel sheet (316L) | β-Ni(OH)2 | stacking fault disorder and very hydrated | [138] |

| produces nanoparticles (approx. 100 nm) | ||||||||

| NiCl2 | 0.1 | -2.5 | 10 | 22 | nickel sheet | α-Ni(OH)2 | product contains Cl− | [38] |

| NiCl2 | 0.005 | -1.0 | —a | 10 | stainless steel sheet (316L) | β-Ni(OH)2 | stacking fault disorder and very hydrated | [139] |

| produces nanoparticles (less than 5 nm) | ||||||||

| NiSO4 | 0.1 | -2.5 | 2 | 22 | nickel sheet | α-Ni(OH)2 | very highly disordered material | [38] |

| product contains SO | ||||||||

| NiCl2 | 0.01 | -1.0 | 12.5 | 70 | graphite sheet | β-NixCo1−x(OH)2 | x=0.32 | [14] |

| CoCl2 | 0.02 | product contains some α-phase material | ||||||

| NaNO3 | 0.06 | |||||||

| Ni(NO3)2 | 0.3 | -6.25 | 30 | 25 | nickel sheet | α-Ni(OH)2 | product is highly disordered | [35] |

| KNO2 | 0.1 | unclear what the role KNO2 or KNO3 serve | ||||||

| KNO3 | 0.1 | |||||||

| NiCl2 | 0.01 | -1.0 | 12.5 | 70 | graphite sheet | α-Ni(OH)2 | NaNO3 is used to increase solution conductivity | [14] |

| NaNO3 | 0.06 | |||||||

| Ni(NO3)2 | 1.8 | −0.7 VbSCE | — | — | titanium sheet | α-Ni(OH)2 | Mix Brij 56 and aqueous solution, 50% (w/w) | [140] |

| NaNO3 | 0.075 | remove surfactant template at 100°C for 1.5 h | ||||||

| Brij 56 | pure | hexagonal pore array, dp=2.5 nm, dp−p=7.0 nm | ||||||

| Ni(NO3)2 | 0.01 | −1.1 VbAg/AgCl | 1–100 s | 25 | boron-doped diamond | — | nanoparticle size determined by deposition time | [141] |

| (1 s, d=12±3 nm; 15 s, d=39±9 nm) | ||||||||

| longer times result in agglomerates |

a ‘—’ Indicates experimental details that were not provided.

bDeposition performed potentiostatically (at constant potential).

(c). Sol–gel synthesis

The sol–gel method encompasses several related synthetic procedures. These always begin with the preparation of a sol, followed by treatment of the sol to prepare a gel. A sol is a colloidal suspension of very small particles, with a dimension, in at least one direction, between 1 nm and 1 μm, in a liquid [142]. The term ‘gel’ includes several related substances: (i) covalent polymer networks; (ii) polymer networks formed through physical aggregation; (iii) polymer networks formed through glassy junction points (e.g. gels based on block copolymers); (iv) lamellar structures (e.g. soap gels, phospholipids, clays); or (v) particulate disordered structures (e.g. particles with large geometrical anisotropy, such as in V2O5 gels) [142]. Sol–gel synthesis methods vary by how the sol is prepared and how it is treated to produce the gel.

A Ni(OH)2 sol may be prepared from chemically precipitated powder by repeatedly washing it with water [143,144]. This produces a suspension of nanoparticles. A gel may then be formed by network growth as an array of these discrete colloidal particles (e.g. by centrifuging the suspension as shown in figure 8c) [145]. Alternatively, one may form an interconnected, three-dimensional network by the simultaneous hydrolysis and polycondensation of an organometallic precursor. Metal alkoxide precursors are quite common [145]. For example, metathesis (ion exchange) may be used to prepare nickel ethoxide [146]

| 3.4 |

The hydrolysis of the metal alkoxide produces nickel hydroxide

| 3.5 |

The gelation can begin before the hydrolysis is complete (i.e. the sol and the gel steps can be concurrent). The product may be aged and dried under ambient atmosphere to produce a xerogel with high porosity and high specific surface area. Alternatively, the gel may be supercritically dried to produce an aerogel [146]. Aerogels have extremely high porosity and specific surface area [145]. NHN aerogels, which are related to α-Ni(OH)2 (see §2c(iii)), may also be prepared [147].

Sol–gel methods may be used to prepare α- and β-Ni(OH)2 with a variety of densities and porosities either as a bulk solid or a thin film on a substrate. An example of hollow microspheres of β-Ni(OH)2 prepared by Zhang & Zeng using a sol–gel method is shown in figure 9c. Representative sol–gel methods for preparing α- and β-Ni(OH)2 materials are listed in table 6.

Table 6.

Representative methods from the literature for sol–gel preparation of Ni(OH)2 materials. a-PEO, amorphous polyethylene oxide; CTAB, cetyltrimethyl ammonium bromide; DEA, diethanolamine; EDA, 1,2-ethanediamine; FTO, fluorine-doped tin oxide; OAc, [O2CCH3]− (acetate); OEt, [OCH2CH3]− (ethoxide); PVA, polyvinyl alcohol; SDS, sodium dodecylsulfate.

| Ni(II) salt | solvent(s) and reagents | method | product phase | comments | refs |

|---|---|---|---|---|---|

| NiCl2 | OC(NH2)2 | stir reactants at room temperature for 2 h | α-Ni(OH)2 | product contains some β-Ni(OH)2 | [148] |

| SDS | heat at 80°C for 6 h | yields nanoparticle (approx. 250 nm) xerogel | |||

| H2O | centrifuge to obtain product | product is mesoporous (dpore=3.6 nm) | |||

| dry overnight at 100°C | |||||

| NiCl2 | NaOEt | stir NiCl2, NaOEt and HOEt at 70–80°C for 3–5 h | α-Ni(OH)2 | dried with supercritical CO2 to yield an aerogel | [146] |

| HOEt | add aqueous NH4OH to obtain a sol | ||||

| NH4OH | leave overnight to obtain a hydrogel | ||||

| H2O | |||||

| NiCl2 | ethylene glycol | stir NiCl2 in ethylene glycol and n-butanol 30 min | α-Ni(OH)2 | film contains NiO | [21] |

| n-butanol | add HOAc and reflux at 70°C for 3 h | yields nanoparticle (d∼30 nm) xerogel | |||

| HOAc | add H2O and a-PEO/DEA then reflux for 1 h | ||||

| H2O | cool to room temperature to obtain sol | ||||

| a-PEO | dip-coat onto SnO2 glass | ||||

| DEA | dry at 100°C for 10–30 min | ||||

| NiCl2 | EtOH | stir NiCl2 with water and EtOH | β-Ni(OH)2 | stacking fault disorder | [149] |

| N2H4 | stir N2H4 and NaOH in water | yields clusters of nanoparticles (d∼65 nm) | |||

| NaOH | add second solution to first dropwise until pH≈10 | ||||

| centrifuge the sol to obtain a gel (powder) | |||||

| Ni(NO3)2 | H2O | stir Ni(NO3) and NH4OH, in water | β-Ni(OH)2 | Some stacking fault disorder | [150] |

| NH4OH | stir 1 h at 70°C | yields nanoparticle (d = 50–80 nm) xerogel | |||

| centrifuge, rinse and dry at 80°C for 12 h | |||||

| Ni(NO3)2 | H2O | stir Ni(NO3), NH4OH and PEG-400 in water | β-Ni(OH)2 | stacking fault disorder | [150] |

| NH4OH | stir 1 h at 70°C | yields nanoflakes (d=20–60 nm) and needles (d=10–20 nm, l=100–200 nm) | |||

| PEG-400 | centrifuge, rinse and dry at 80°C for 12 h | ||||

| Ni(NO3)2 | H2O | stir Ni(NO3), NH4OH and Tween-80 in water | β-Ni(OH)2 | stacking fault and hydration disorder | [150] |

| NH4OH | stir 1 h at 70°C | low crystallinity | |||

| Tween-80 | centrifuge, rinse and dry at 80°C for 12 h | yields needles (d∼10 nm, l≈100 nm) | |||

| Ni(NO3)2 | OC(NH2)2H2O | stir Ni(NO3)2 and urea in water | α-Ni(OH)2 | very low crystallinity | [151] |

| H2O | add maleic acid and stir 10 min to obtain sol | yields nanoparticle (d∼500 nm) xerogel | |||

| maleic acid | heat at 100°C for 24 h | product is mesoporous (dpore=16 nm) | |||

| centrifuge to obtain product | |||||

| Ni(NO3)2 | NaOH | stir Ni(NO3)2, NaOH and EDA in water | β-Ni(OH)2 | yields hollow, ‘dandelion-like’ microspheres | [116] |

| H2O | Dry at 100°C for 0–3 h | (d∼5 μm) composed of nanosheets | |||

| EDA | hydration disorder | ||||

| NiSO4 | H2O | combine NiSO4 and NaOH solutions | β-Ni(OH)2 | stacking fault disorder | [152] |

| NaOH | centrifuge the sol to obtain a gel and dry at 80°C | yields nanoparticle (d∼10 nm) xerogel | |||

| NiSO4 | H2O | stir all reagents except KOH in water | β-Ni(OH)2 | high surface area, mesoporous xerogel | [153] |

| sodium citrate | add KOH solution dropwise | ||||

| NaOAc | centrifuge, rinse and dry at 80°C | ||||

| KOH | |||||

| NiSO4 | CTAB | dissolve NiSO4 in CTAB, butanol, cyclohexane | α/β-Ni(OH)2 | mostly, the α-phase materials is produced | [154] |

| n-butanol | add NaOH solution dropwise | product contains SO | |||

| cyclohexane | transfer to ice water | ||||

| NaOH | centrifuge, rinse and dry | ||||

| NiSO4 | H2O | combine Ni(II) and LiOH solutions | α-Ni(OH)2 | film contains SO and CO foreign anions | [155] |

| LiOH | wash precipitate with water | ||||

| HOAc | acidify with acetic acid | ||||

| formamide | stir with formamide, glycerol, PVA | ||||

| glycerol | wet substrate with Teloksid A-30 | ||||

| PVA | dip-coat onto Pt, CdTe or Si substrate | ||||

| Teloksid A-30 | |||||

| Ni(OAc)2 | H2O | stir Ni(OAc)2 and water for 2 days | β-Ni(OH)2 | film may contain OAc− foreign anions | [156] |

| dip-coat onto Ni foil substrate | hydration disorder | ||||

| film was dried to yield NiO xerogels | |||||

| Ni(OAc)2 | glycerine | stir all reagents except water | unknown | clear gelatinous mass | [143] |

| KOH | let stand several days | ||||

| HOEt | dilute with water then partially dry | ||||

| H2O | |||||

| Ni(OAc)2 | glycerine | stir reagents | α-Ni(OH)2 | Ref. also prepared Ni1−xCox(OH)2, 0≤x≤0.5 | [157] |

| KOH | spin- or dip-coat onto FTO glass | ||||

| n-butanol | |||||

| Ni(OAc)2 | glycerine | spread sol onto glass, quartz, FTO- or Pt-coated Si substrate α-Ni(OH)2 | α-Ni(OH)2 | yields nanoparticles (d<10 nm) | [158] |

| KOH | dry under vacuum then remove glycerine at 240°C | ||||

| n-butanol |

(d). Chemical ageing

It has long been known that α-Ni(OH)2 spontaneously transforms to β-Ni(OH)2 in aqueous KOH [4]. This process is widely referred to as chemical ageing, or simply ageing, and is typically performed at high temperatures (e.g. 70–80°C) in concentrated alkaline media (e.g. 5 M, 30% KOH) [1,159]. The ageing process has also been studied at room temperature (22–25°C) in the mother liquor after chemical precipitation [160], in concentrated alkaline solutions [35,85] and in pure water [94,161]. These studies support the widespread belief that ageing occurs faster at higher temperatures. Furthermore, one may conclude by comparing [35,85,94] that ageing proceeds faster in concentrated alkaline media (7 M–8 M KOH, 25°C) than in pure water (18.2 MΩ cm, 22°C). β-Ni(OH)2 that is newly formed from α-Ni(OH)2 usually has stacking fault disorder. Through further chemical ageing, the stacking faults are slowly removed and the overall crystallinity increases [35,85,120,162]. Tessier et al. [85] found that chemically ageing β-Ni1−xZnx(OH)2 both increases the structural order and gradually leaches the Zn from the material. It is noted that β-Ni(OH)2 with superior crystallinity may be prepared by hydrothermal recrystallization ([43], see §3e) or via the formation and subsequent decomposition of Ni(NH3)6(OH)2 ([35], see §3f).

Chemical ageing has long been proposed to occur via a dissolution-precipitation mechanism. At sufficiently high pH, this process may be facilitated by [Ni(OH)3]− ions [1,85,121]. As a result, chemical ageing has also been referred to as ‘ripening’, in that the unstable α-Ni(OH)2 particles slowly dissolve and the thermodynamically favoured β-Ni(OH)2 particles slowly grow. This is somewhat analogous to Ostwald ripening in solids and sols, for example, in which a dissolution-precipitation process leads to the formation of larger particle sizes. However, the solubility of Ni(OH)2 is very low in neutral and slightly alkaline media (7<pH<14), which would make such a mechanism improbable under milder conditions. In particular, this mechanism does not explain the spontaneous transformation of α- to β-Ni(OH)2 in pure water at room temperature [94,161]. Chemical ageing may alternatively be considered analogous to a zipper with hydroxide as the teeth, supported on nickel backbones (figure 10) [94]. The water molecule next to the α/β-boundary (dark blue circle) blocks the opposing hydroxyl groups from ‘zipping’ into place, analogous to the zipper's slider (i.e. the part one pulls to operate a zipper). As the water is removed, the molecules move stochastically (to the right in figure 10), which allows the hydroxide ‘teeth’ to interdigitate (i.e. to zip closed). The ageing process actually involves stacked, two-dimensional sheets of Ni(OH)2 and, hence, a full representation of the process would be considerably more complex. Nevertheless, this simple model provides informative predictions. The process is apparently mass-transfer limited, which may explain why ageing is faster at higher temperatures [94]. Moreover, it predicts an additional water vibrational mode, corresponding to the ‘slider’ molecule, and red- and blue-shifts of the β- and α-phase O−H stretching modes from tensile and compressive forces, respectively (figure 10). These have all been observed in the Raman spectra of partially aged samples [94]. However, this model suffers the major setback that it does not explain the observed kinetic effect of using an alkaline ageing solution. Therefore, it is possible that the two pathways compete kinetically, with dissolution-precipitation favoured in concentrated alkaline solutions and the ‘zipper’ model favoured in lower pH conditions. The rate of both mechanisms is predicted to increase at elevated temperatures.

Figure 10.

Representative schematic of the boundary between the α- and β-Ni(OH)2 phases during chemical ageing showing the mechanical forces near the α/β boundary. These forces correspond to observed blue- and red-shifts in the frequencies of various lines in the Raman spectra of partially aged samples. Figure reproduced with permission from [94]. (Online version in colour.)

Chemical ageing also removes intercalated species, such as nitrate or chloride anions, from the interlayer region. Raman spectroscopy measurements show that the removal of intercalated nitrate anions is much faster than the dehydration process [94,159]. This may be due to mechanical stresses from the size mismatch of the incorporated nitrate anions.

The term ‘ageing’ also refers to the transformation of α-Ni(OH)2 electrode materials to β-Ni(OH)2 via prolonged electrochemical cycling between Ni(OH)2 and NiOOH [71,85,163–167]. In the field of rechargeable battery anodes, this transformation is often accompanied by decreased electrode conductivity and charge capacity [6]. In order to obtain more consistent charge–discharge cycling, commercial batteries use β-Ni(OH)2 anodes [6].

(e). Hydrothermal and solvothermal synthesis

Hydrothermal (aqueous) and solvothermal (non-aqueous) synthesis methods are represented in figure 8d. The precursor materials and the solvent are placed in a pressure vessel and then the reaction mixture is heated. Typical reaction temperatures for Ni(OH)2 synthesis are 150–200°C, well above the boiling point of water. Because the vessel has a fixed volume, as the solution is heated, the pressure increases. Therefore, the boiling point increases and the solution remains liquid at such high temperatures that the precursors fully dissolve [168]. The scale of this method is limited by the size of the pressure vessel. In the laboratory, this is usually in the range of hundreds of millilitres to a few litres. Larger pressure vessels, on the order of hundreds of litres, are commonly used for industrial applications. Therefore, hydrothermal and solvothermal methods may be used for large-scale production of Ni(OH)2 materials.

In general, the thermodynamic product, β-Ni(OH)2, tends to form at the high temperatures used in hydrothermal synthesis. However, it is possible to produce α-Ni(OH)2 materials by introducing an intercalation agent into the reaction mixture [169], by using a non-aqueous solution [170], by limiting the reaction time or by using a low reaction temperature [118]. For example, the addition of urea to a reaction mixture results in the formation of NH3-intercalated α-Ni(OH)2 [169].

Hydrothermal and solvothermal syntheses may be used to produce Ni(OH)2 nanoscale materials with unique morphologies. For example, one may prepare micrometre-scale ‘nanoflower’ aggregates composed of nanosheets (figure 9b) [17,22,170]. The morphology is maintained when the nanoflowers are calcinated, to form NiO [22], or chemically aged, to form crystalline β-Ni(OH)2 [17]. However, prolonged ageing can flatten the nanoflowers. One can also produce ‘nanoribbons’ or ‘nanobelts’ (figure 9e). Several representative literature methods are summarized in table 7.

Table 7.

Representative methods from the literature for hydrothermal and solvothermal preparation of Ni(OH)2 materials. CG, cyanoguanidine; CNT, carbon nanotube; CTAB, cetyltrimethyl ammonium bromide; DEG, diethylene glycol; EG, ethylene glycol; GO, graphene oxide; OAc, acetate (H3CCO); PSS, sodium poly(4-styrenesulfonate).

| precursors | solvent | temperature (°C) | time h | product phase | comments | refs |

|---|---|---|---|---|---|---|

| α-Ni(OH)2 | H2O | 150–200 | —a | β-Ni(OH)2 | very crystalline product | [43] |

| α-Ni(OH)2 | H2O | 200 | — | β-Ni(OH)2 | yields ‘non-porous, hexagonal thin platelets’ | [127] |

| Ni(NO3)2 | H2O | 180 | 18 | β-Ni(OH)2 | yields nanoflowers (dflower≈10–15 μm) composed of nanosheets approximately 15 nm thick some stacking fault disorder | [22] |

| CG | ||||||

| NiCl2 | H2O | 180 | 6 | β-Ni(OH)2 | hollow microspheres (d≈2 μm) | [171] |

| PSS | ||||||

| NH4OH | ||||||

| further treatment yields ‘hollow microspheres wrapped in graphene oxide’ | ||||||

| NiOAc | H2O | 200 | 5–30 | β-Ni(OH)2 | nanosheets (d≈200–300 nm, h≈12–20 nm) | [172] |

| NH4OH | ||||||

| 5 h: hexagonal sheets; 30 h: round sheets | ||||||

| good crystallinity (some stacking fault disorder) | ||||||

| NiSO4 | H2O | 120–200 | 24 | α/β-Ni(OH)2 | studied the effect of reactant ratio and temp. on product morphology and phase | [118] |

| NaOH | ||||||

| α- ‘nanobelts’/nanoribbons (d=10–20 nm) or nanowires (d=20–30 nm, l=1–3 μm) | ||||||

| β- hexagonal or rectangular ‘nanoplates’/ nanosheets | ||||||

| Ni(NO3)2 | H2O | 120 | 1.7 | α-Ni(OH)2 | contains intercalated NH3 | [169] |

| OC(NH2)2 | ‘Fibrillar’ nanoscale morphology | |||||

| Ni(NO3)2 | H2O | 200 | 24 | β-Ni(OH)2 | nanosheets (d≈100–120 nm) | [173] |

| NH4OH | CH3OH | stacking fault and hydration disorder | ||||

| NiOAc | H2O | 200 | 1–10.5 | α/β-Ni(OH)2 | nanosheets and nanoflowers | [170] |

| EG | α-Ni(OH)2 forms at shorter times and higher EG concentrations | |||||

| crystallinity increases with reaction time stacking fault disorder | ||||||

| NiCl2 | EG | 170 | 1–4 | β-Ni(OH)2 | porous network of nanoparticles | [174] |

| CTAB | ||||||

| NaBH4 | ||||||

| particle and pore sizes depend on temp and time | ||||||

| product contains Ni metal and β-Ni(OH)2 | ||||||

| highly disordered material | ||||||

| Ni foam | H2O | 150 | 6 | β-Ni(OH)2 | nanoflakes form on the Ni foam substrate | [175] |

| H2O2 | ||||||

| NaOH | ||||||

| stacking fault disorder | ||||||

| NiCl2 | DEG | 180 | 10 | α-Ni(OH)2 | yields nanoflowers (dflower≈400 nm) | [17] |

| NaOAc | ||||||

| may be prepared with GO and CNTs | ||||||

| α-Ni(OH)2 nanoflowers | H2O | 180 | 1 | β-Ni(OH)2 | maintains nanoflower morphology | [17] |

| (from prev. method) | ||||||

| stacking fault disorder | ||||||

| 10 | β-Ni(OH)2 | nanoflowers become flattened | ||||

| less stacking fault disorder than after 1 h |

a ‘—’ Indicates experimental details that were not provided.

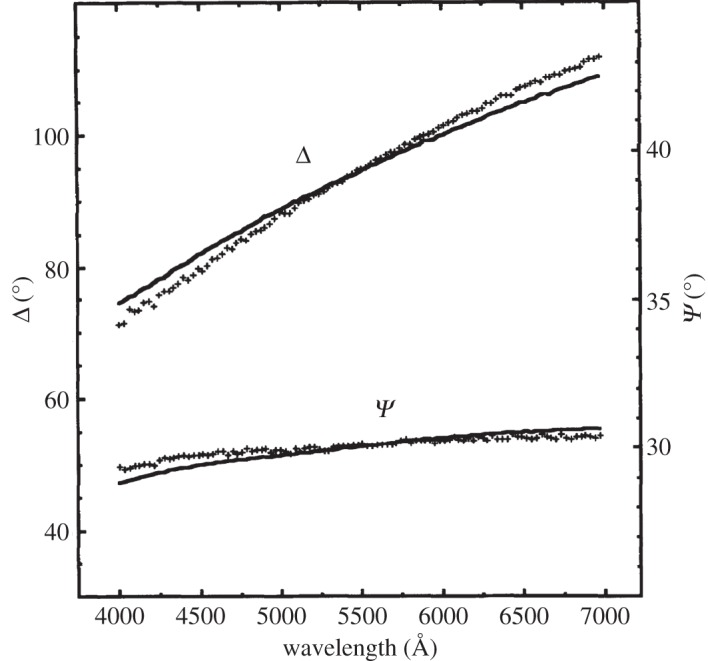

(f). Surface layers on nickel

An air-formed oxide layer, 6–8 Åthick, rapidly forms on Ni metal that has been mechanically or electro-polished. Ellipsometry measurements [176] and angle-resolved X-ray photoelectron spectroscopy (XPS) [177] show that this is a bilayer, with a Ni(OH)2 layer underlaid by NiO. The underlayer is non-stoichiometric NiOx, x≥1, with approximately 2% lattice parameter expansion [178]. On the basis of the XPS peak shapes and positions, the hydroxide layer is assessed to be α-Ni(OH)2 [179]. Ni(OH)2 is also a common component of the passive layers and corrosion deposits on Ni metal [176,180,181] and Ni-containing alloys [182,183] that form in alkaline (e.g. [176]) and neutral media (e.g. [183]).

Ni(OH)2 also forms electrochemically on Ni electrodes in alkaline media, which has importance for the development of Ni-based electrocatalysts [23,105,179,184–187]. Consequently, the surface electrochemistry has been extensively studied using atomic force microscopy [188], ellipsometry [181,189–191], IR spectroscopy [192], Raman spectroscopy [166,193,194], UV–Vis spectroscopy [192,195], voltammetry [179,185,196–201], X-ray scattering [176], XPS [179,202] and gravimetry with an electrochemical quartz crystal microbalance [203,204]. During a forward voltammetric sweep, a surface bilayer of α-Ni(OH)2 underlaid by NiOx forms initially [179]. This corresponds to a voltammetric peak at approximately 0.3 V versus the reversible hydrogen electrode (RHE). At higher potentials, the surface layer thickens and some β-Ni(OH)2 forms. It is unknown whether the β-Ni(OH)2 is formed electrochemically or by the ageing of the α-Ni(OH)2. The relative amount of β-Ni(OH)2 tends to be greater at slower potential scan rates.

The voltammetric peak at approximately 0.3 V versus RHE has been used to estimate the surface area of nickel electrodes [197]. The method approximates that the peak corresponds to the formation of a monolayer consisting entirely of α-Ni(OH)2. Recently, this method has been refined by adding an oxalate salt to the electrolyte, which is proposed to limit the surface hydroxide to a single layer [205]. Moreover, to avoid the problem of the concurrent formation of NiOx, this new method instead measures the Ni(OH)2/NiOOH redox pair.

(g). Other preparation methods

Several remaining methods to prepare Ni(OH)2 materials that do not fall neatly into the six previous categories are briefly presented here. Presently, these methods represent only a small portion of the vast literature on Ni(OH)2 materials. However, their adoption and usage may well increase with time. As with the methods in §§3a–3e, each method uses a nickel source, already in the nickel(II) oxidation state, and a source of hydroxide anions.

(i). Electrodialysis

The electrodialysis method is related to electrochemical precipitation. The method uses a two-electrode electrochemical cell with two compartments that are separated by an anionic membrane. When a current is applied, Ni2+ cations are generated by the oxidative dissolution of the Ni metal anode and OH− anions are produced by the reduction of water molecules at the cathode. The Ni(OH)2 deposits onto the anode side of the membrane [206]. The product is a mixture of α- and β-Ni(OH)2 [162]. The α-phase component contains incorporated anions and the β-phase component has considerable stacking fault disorder.

(ii). Microwave-assisted synthesis

Ni(OH)2 may be prepared by microwave-assisted synthesis, in which a microwave oven is used to heat a solution more homogeneously than conventional heating [93,119,121,207,208]. Microwave-assisted methods produce very uniform nanoparticle shapes and narrow size distributions, but otherwise mirror the results of homogeneous precipitation or hydrothermal synthesis. For example, Soler-Illia et al. [121] used microwave heating and aged α-Ni(OH)2 samples at 150°C, in a pressure vessel, to produce β-Ni(OH)2. Microwave heating may be used to produce unique nanoscale morphology. For example, Ni(NO3)2 and urea dissolved in water and ethanol and heated in a microwave oven at 90°C for 15 min produces nanoflowers (d=0.7–1.0 μm) composed of nanoflakes [93]. The flakes are, in turn, composed of nanocrystals d=2–3 nm). In another example, a Ni(NO3)2, urea, NH4OH and PEG-20 000 solution placed in a pressure vessel and heated in a microwave oven at 160°C for 30 min produces nanoflowers (d=2.5–4.0 μm) composed of nanosheets 10–20 nm thick and 0.2–1.5 μm wide (figure 9f) [119]. The XRD pattern contains peaks from β-Ni(OH)2. Several other peaks show a material with c=6.2 Å , which may be ascribed to an NHN component (see §2c(iii)) on the basis of the d-spacing (cα≥7.8 Å, cNHN≤7.6 Å) and the absence of any clear α-Ni(OH)2 modes in the Fourier-transform infrared spectroscopy (FTIR) spectra.

(iii). Sonochemistry

Sonochemical methods, which use the application of powerful ultrasound radiation (20 kHz–10 MHz) to drive chemical reactions, may be used to prepare Ni(OH)2 materials with unique nanostructures [55,67,83,87,209]. In general, sonochemistry has significant advantages for the preparation amorphous products, the insertion of nanoscale materials into mesoporous materials, the deposition of nanoparticles on ceramic and polymeric surfaces, and the formation of proteinaceous micro- and nanospheres [210]. For example, the application of 20 kHz ultrasound to a solution of Ni(NO3)2 and urea produces very disordered, nanoscale α-Ni(OH)2 fibres of approximately 200 nm long and 15 nm wide [55]. The application of 20 kHz ultrasound at a lower power to a solution of Ni(NO3)2 and NH4OH produces nanoparticles of nitrate-intercalated α-Ni(OH)2 (d≈5 nm) [209]. One may similarly prepare α-Ni1−x−yCoxCdy(OH)2 by adding Co(NO3)2 and/or Cd(NO3)2 to the reaction flask during the synthesis.

(iv). Solid-state synthesis

Liu & Yu [211] report a two-step solid-state method for preparing β-Ni(OH)2 at room temperature. First, Ni(CH3CO2) (nickel acetate) and H2C2O4 (oxalic acid) are ground together in a 1 : 1 molar ratio with a mortar. The resulting NiC2O4 (nickel oxalate) is similarly ground together with NaOH in a 1 : 2 molar ratio. The green powder is rinsed with water and dried at 80°C to obtain β-Ni(OH)2 with stacking fault and general structural disorder. The product is composed of clusters of nanoscale fibres (d=3–9 nm, l=10–50 nm).

(v). Purification by ‘recrystallization’

Barnard et al. [35] report a unique method of β-Ni(OH)2 purification. A Ni(OH)2 precursor is dissolved in an 8 M NH3 aqueous solution. This resulting blue solution of Ni(NH3)6(OH)2 is then added to concentrated H2SO4 and stored in a desiccator for several days. The NH3 is gradually removed from the material and green, glassy flakes of β-Ni(OH)2 are left behind. The authors describe their process as recrystallization, although it does not fit the conventional meaning of the term. Barnard et al.'s method yields very high purity, highly crystalline β-Ni(OH)2 with minimal stacking fault disorder. However, a slightly more crystalline product may be prepared by hydrothermal recrystallization [43].

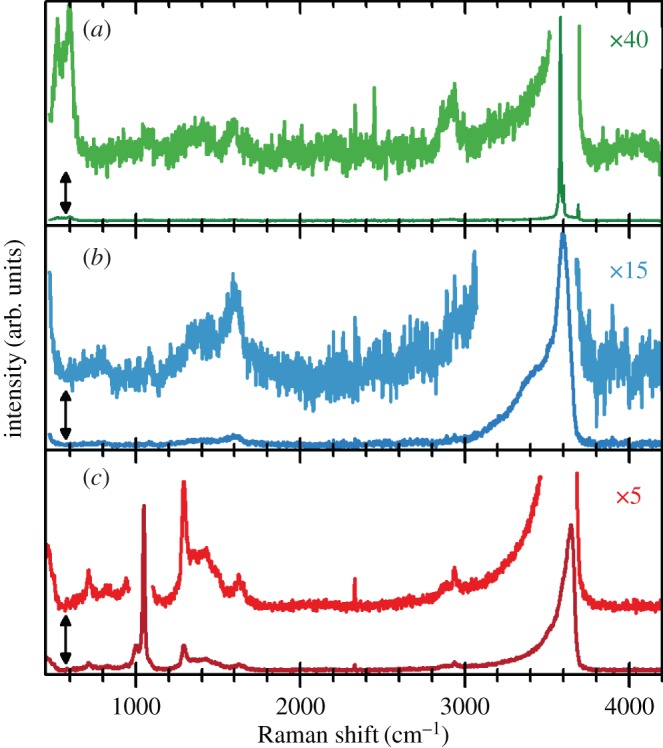

4. Physical properties and analytical characterization

So far, this review has focused primarily on the chemical and structural properties of the various forms of nickel hydroxide. However, this material system possesses many interesting physical properties, such as in electricity and magnetism, that have potential applications and others, such as vibrational and optical spectroscopy, including XPS, that can be very useful in characterizing nickel hydroxide materials for research and developmental investigations. In this section, we provide an overview of the large amount of work on the physical properties of Ni(OH)2. We also highlight how this knowledge can be usefully applied in characterizing ‘unknown’ materials. In general, we find that vibrational spectroscopy is perhaps the quickest and simplest method for the identification and characterization of α- and β-Ni(OH)2, either as bulk materials or thin films. Moreover, it is evident that the stable β form of Ni(OH)2 is by now well characterized, but that α-Ni(OH)2 still requires a lot more work. Such characterization work is made particularly difficult by the multitudinous forms of α-Ni(OH)2, owing to its inherent turbostratic disorder, its tendency to incorporate variable amounts of water and/or impurities and its poor long-term stability.

(a). Magnetic properties

(i). Bulk magnetic properties

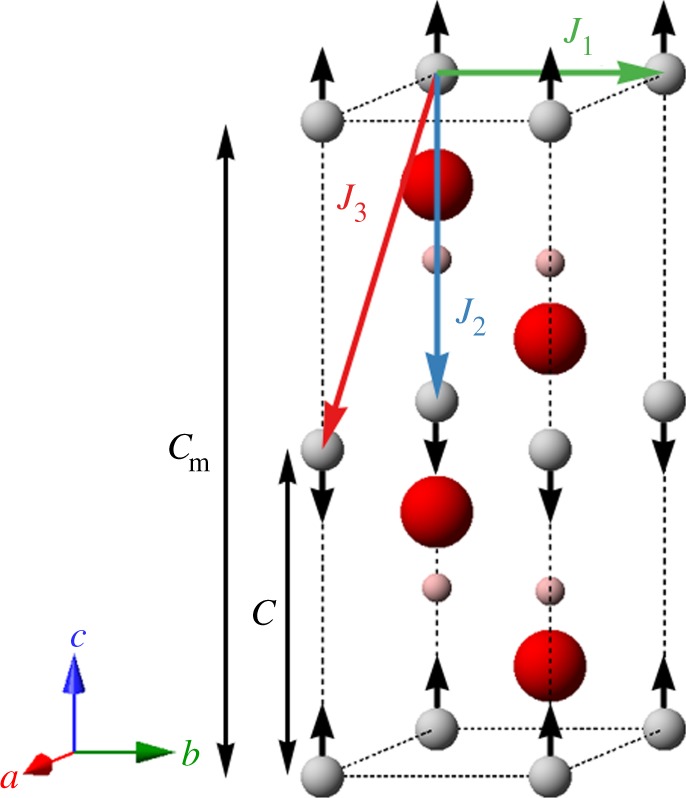

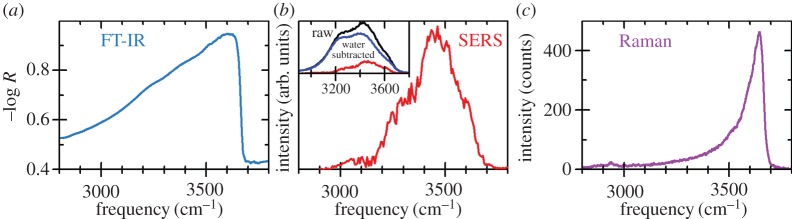

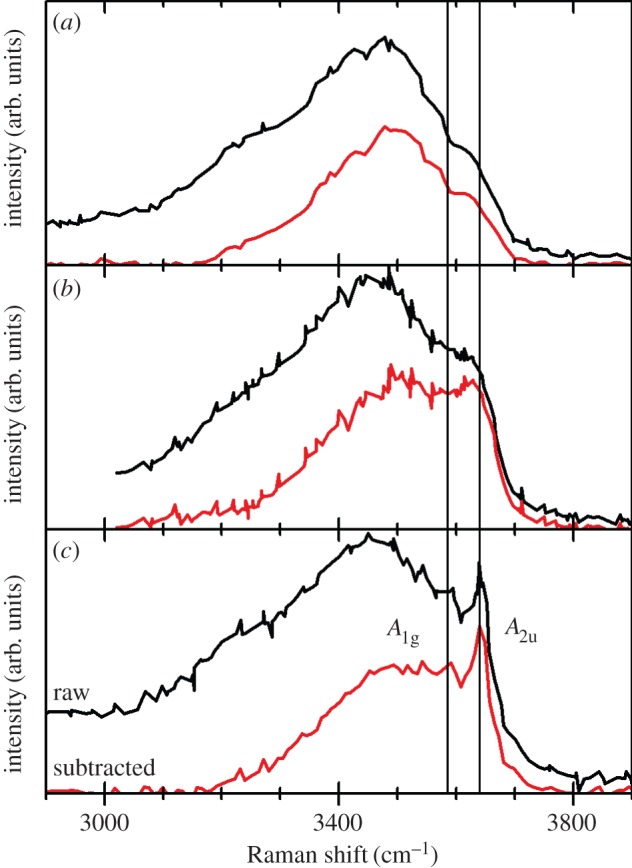

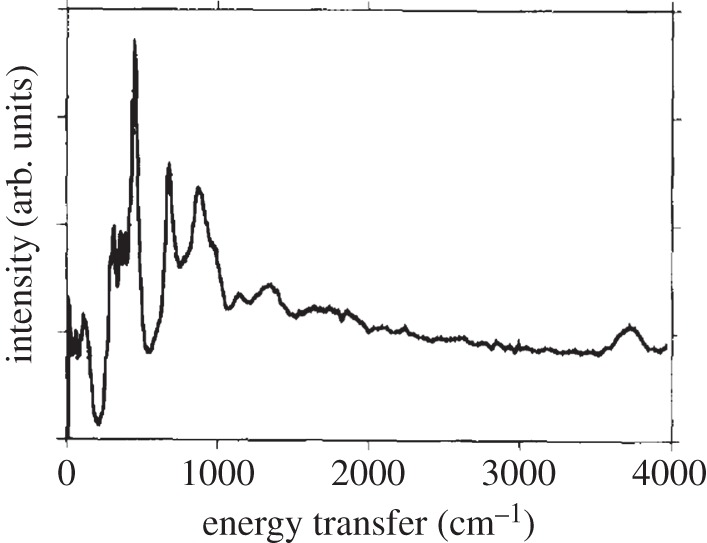

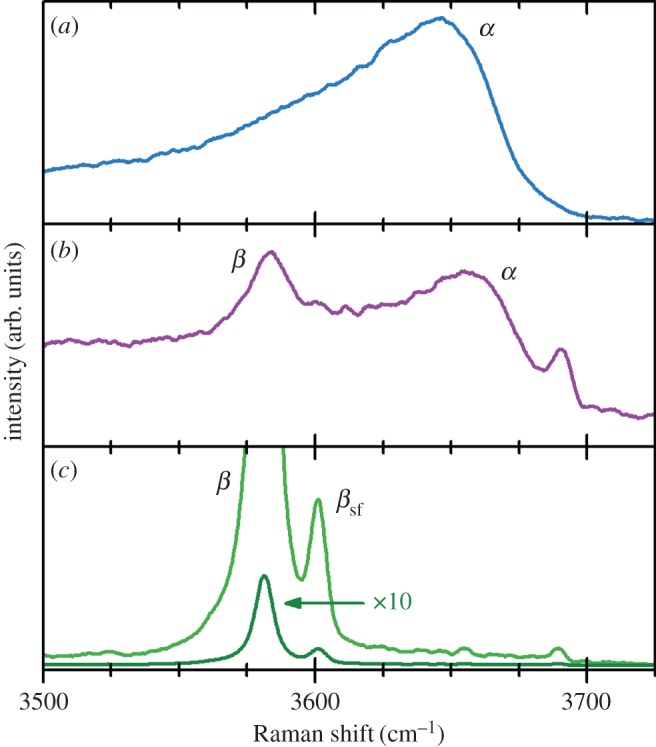

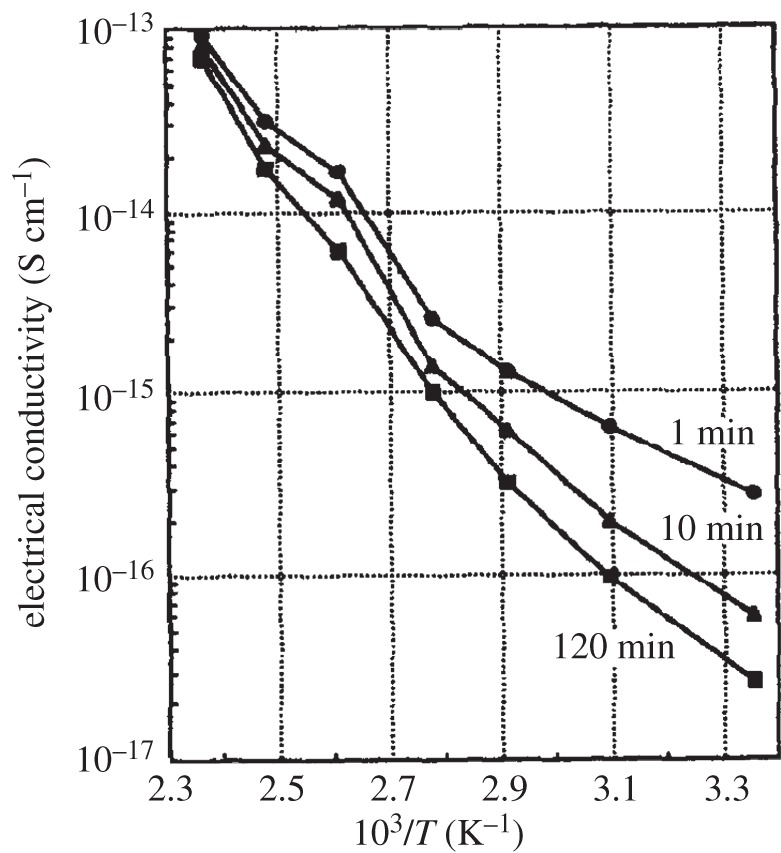

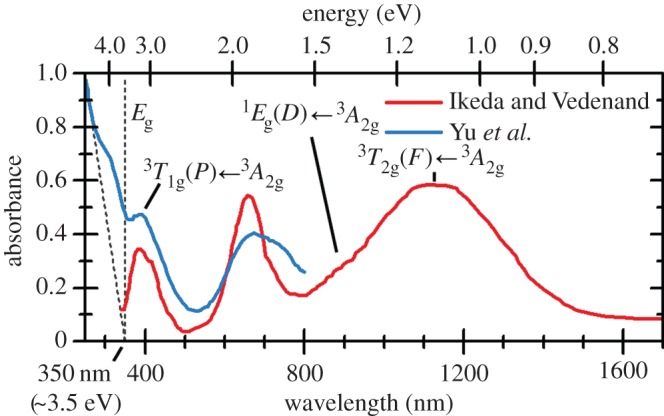

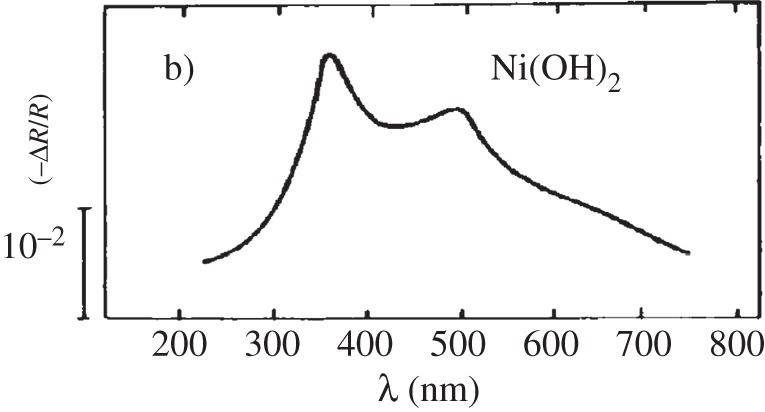

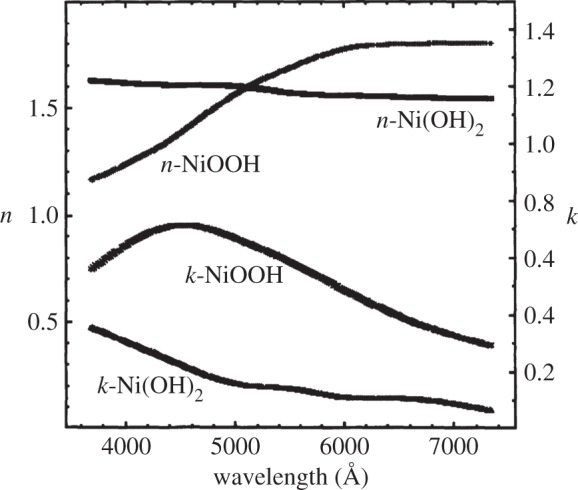

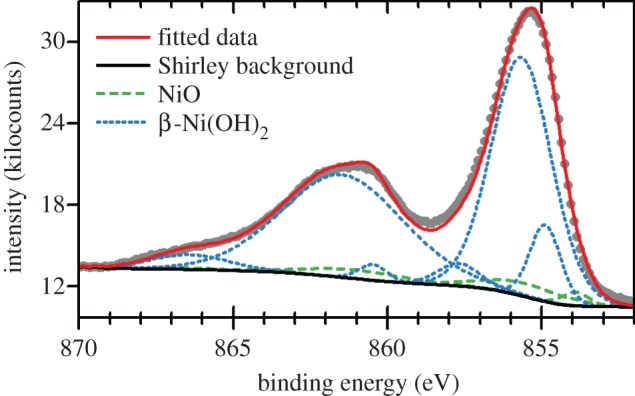

Compounds containing Ni2+ ions typically exhibit magnetism owing to the particular electronic properties of the transition metal ions. The layered structure of Ni(OH)2, and β-Ni(OH)2 in particular, is analogous or identical to that of many transition metal halides including for example NiCl2, all of which exhibit ferromagnetism within their layers of metal ions in the crystallographic a–b plane, with their parallel electron spins aligned either along or perpendicular to the crystallographic c-axis, but overall they form antiferromagnets with the spins in one layer pointing in the opposite direction to those in the adjacent layers [212]. This type of layered-structure magnetism is classified as being metamagnetic, because the external magnetic field-induced transition to the paramagnetic phase can occur without the existence of an intermediate spin-flop phase.