Purpose

The vesicle extrusion method is used for preparing small (e.g. 100 nm diameter) monodisperse (uniform-sized) vesicles. Polycarbonate track-etched membranes with pores generally ranging from 50 nm to 200 nm in diameter and a hand-held mini-extruder are used for such a procedure. Extrusion through small (100 nm in diameter or smaller) pores also ensures that the vesicle population is predominantly unilamellar.

Theory

The vesicle extrusion method takes advantage of the fact that when vesicles are forced through membrane pores smaller than their diameters, they break down into smaller vesicles closer to the pore size. Vesicle extrusion has also been used as a laboratory method to induce protocell division [1].

Equipment

Hand-held mini-extruder (http://www.ncnr.nist.gov/userlab/pdf/E134extruder.pdf)

Two gas-tight syringes (often come with extruder)

pH meter

1.5 ml Eppendorf tubes

Materials

Polycarbonate track-etched membranes, either 13 or 25 mm in diameter (http://www.whatman.com/NucleporeTrackEtchedMembranes.aspx)

10 mm Filter Supports (http://avantilipids.com/index.php?option=com_content&view=article&id=522&Itemid=293&catnumber=610014)

1-palmitoyl-2-oleoyl-sn-glycero-3-phosphocholine (POPC)

(or any phospholipid of choice)

Oleic acid (or any fatty acid of choice)

LissamineTMrhodamine B 1,2-dihexadecanoyl-sn-glycero-3-phosphoethanolamine (Rh-DHPE) (for fluorescent membrane labeling, if desired)

Bicine (or other buffer of choice, except borate or phosphate buffer, which produces leaky fatty acid vesicles)

8-hydroxypyrene-1,3,6-trisulfonic acid trisodium salt (HPTS, or other water-soluble fluorescent dye of choice)

NaOH

Chloroform

Methanol

Deionized water

Solutions & buffers

| Preparation | ||

| Na-bicine buffer (200 mM), 2 mM HPTS, pH 8.5 | ||

| Component | Stock | Amount |

|

| ||

| Na-bicine | 1 M | 1 ml |

|

| ||

| HPTS | 100 mM | 0.1 ml |

|

| ||

| Add water to 5 ml | ||

| Step 1 | ||

| Na-bicine buffer (200 mM), pH 8.5 | ||

| Component | Stock | Amount |

|

| ||

| Na-bicine | 1 M | 1 ml |

|

| ||

| Add water to 5 ml | ||

Protocol

Duration

|

| |

| Preparation | about 1 day |

|

| |

| Protocol | about 50 minutes |

|

| |

Preparation: Prepare vesicles by suspending lipid(s) in a buffer solution. (For details, see the “Preparation of fatty acid or phospholipid vesicles by thin-film rehydration” protocol)

Caution: If using photosensitive lipids, avoid light by wrapping aluminum foil around the flask containing the vesicles. Avoid oxygen by flushing the container with argon or nitrogen gas.

Step 1 Title

Assemble the extrusion apparatus

Overview: Assemble the extrusion apparatus with the polycarbonate track-etched membranes and filter supports (see Fig. 1)

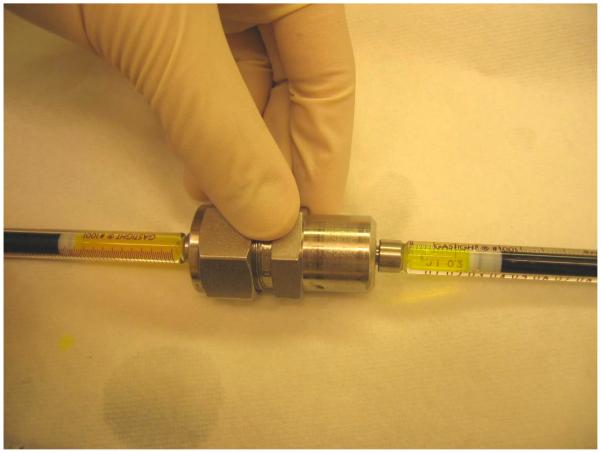

Fig 1.

Hand-held mini-extruder with two gas-tight syringes.

Duration: 5 min

1.1: Pre-wet the polycarbonate track-etched membranes of choice (e.g., with 100 nm diameter pores) and the filter supports.

Tip: Rinse the extruder parts with water before assembly.

Tip: When pre-wetting the polycarbonate track-etched membranes and filter supports, rapidly dip the membranes or filter supports into the same buffer used for preparing vesicles.

1.2: Put one filter support on each side of the two internal membrane support (white plastic parts), with the pre-wetted polycarbonate track-etched membrane on top. Assemble the rest of the parts (see Fig. 2 and Fig. 3).

Fig 2.

Assembly of the extrusion apparatus. On each internal membrane support (white plastic part with a black O-ring) there is a filter support, with a polycarbonate track-etched membrane on top.

Fig 3.

Assembly of the internal membrane support parts with filter support and polycarbonate track-etched membrane in the middle.

Tip: One can choose to double the polycarbonate track-etched membrane to prevent membrane rupture, especially when using high pressure for extrusion.

Step 2 Title

Load the gas-tight syringes

Overview: Load the gas-tight syringes with vesicle sample.

Duration: 5 min

2.1: Rinse the syringes with water and then the same buffer used for preparing vesicles.

2.2: Load one of the gas-tight syringes with the vesicle sample at a volume between 0.5 to 1 ml.

Step 3 Title

Extrusion to yield monodisperse vesicles

Overview: Force the vesicles in the two gas-tight syringes back and forth through the hand-held mini-extruder 11 times.

Duration: 10 min

3.1: Lock the gas-tight syringes in place on the hand-held mini-extruder.

3.2: Slowly push one syringe, so that all the solution in it goes through the hand-held mini-extruder to the other side, into the other syringe (see Fig. 4).

Fig 4.

Slowly push one syringe (left), so that all the solution in it goes through the hand-held mini-extruder to the other side, into the other syringe (right).

Tip: For larger pore sizes (> 100 nm), slowly push the syringe at a constant rate of 1 mL/min. Extrusion at higher flow rates may lead to excessive vesicle disruption [1].

3.3: Push from the other side using the other syringe. Repeat this 11 times through the filter, and collect the final product vesicles.

Tip: Make sure tha thet final product vesicles are collected from the non-starter syringe.

10. References

Source article(s) used to create this protocol

- Hope MJ, Bally MB, Webb G, Cullis PR. Production of large unilamellar vesicles by a rapid extrusion procedure. Characterization of size distribution, trapped volume and ability to maintain a membrane potential. Biochimica et Biophysica Acta (BBA)–Biomembranes. 1985 Jan 10;812(1):55–65. doi: 10.1016/0005-2736(85)90521-8. [DOI] [PubMed] [Google Scholar]

- Chen IA, Roberts RW, Szostak JW. The emergence of competition between model protocells. Science. 2004 Sep 3;305(5689):1474–6. doi: 10.1126/science.1100757. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hanczyc MM, Fujikawa SM, Szostak JW. Experimental models of primitive cellular compartments: encapsulation, growth, and division. Science. 2003 Oct 24;302(5645):618–22. doi: 10.1126/science.1089904. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [1].Hanczyc MM, Fujikawa SM, Szostak JW. Experimental models of primitive cellular compartments: encapsulation, growth, and division. Science. 2003 Oct 24;302(5645):618–22. doi: 10.1126/science.1089904. [DOI] [PMC free article] [PubMed] [Google Scholar]