Abstract

Electrohydrodynamic atomization (EHDA), also called electrospray technique, has been studied for more than one century. However, since 1990s it has begun to be used to produce and process micro-/nanostructured materials. Owing to the simplicity and flexibility in EHDA experimental setup, it has been successfully employed to generate particulate materials with controllable compositions, structures, sizes, morphologies, and shapes. EHDA has also been used to deposit micro- and nanoparticulate materials on surfaces in a well-controlled manner. All these attributes make EHDA a fascinating tool for preparing and assembling a wide range of micro- and nanostructured materials which have been exploited for use in pharmaceutics, food, and healthcare to name a few. Our goal is to review this field, which allows scientists and engineers to learn about the EHDA technique and how it might be used to create, process, and assemble micro-/nanoparticulate materials with unique and intriguing properties. We begin with a brief introduction to the mechanism and setup of EHDA technique. We then discuss issues critical to successful application of EHDA technique, including control of composition, size, shape, morphology, structure of particulate materials and their assembly. We also illustrate a few of the many potential applications of particulate materials, especially in the area of drug delivery and regenerative medicine. Next, we review the simulation and modeling of Taylor cone-jet formation for a single and co-axial nozzle. The mathematical modeling of particle transport and deposition is presented to provide a deeper understanding of the effective parameters in the preparation, collection and pattering processes. We conclude this article with a discussion on perspectives and future possibilities in this field.

Keywords: Electrohydrodynamic atomization, Micro-/nanoparticles, Fabrication, Processing, Drug delivery, Regenerative medicine, Modeling

1. Introduction

The phenomenon of electrohydrodynamic atomization (EHDA), also simply called electrospray, was firstly observed and recorded by William Gilbert in 1600 (Gilbert et al., 1600). In 1750, Jean-Antoine (Abbé) Nollet, a French Clergyman and physicist, reported the earliest observation on electrospray, more than two centuries before the terminology was generated, demonstrating water flowing from a container would aerosolize if the container was electrified and put close to electrical ground (Dumont and Cole, 2013). Around one century later, Lord Kelvin invented a setup composed of two liquid nozzles that were bridged to opposite collection reservoirs and demonstrated small differences in charging between water dripping from the nozzles instantly caused differences in kilovolt scale and electrospraying from the nozzles (Smith, 2000). In 1882, Lord Rayleigh theoretically evaluated the charge that a liquid droplet could carry to the greatest extent, known as the “Rayleigh limit”, which was confirmed experimentally 100 years later (Taylor, 1964; Gomez and Kang, 1994 and Duft et al., 2003). The first patent related to EHDA setup appeared in 1900 (Cooley, 1900). Zeleny conducted the electrospray experiment with ethanol and photographed a cone-jet in 1914 (Zeleny, 1917). In 1960’s, Taylor developed a mathematical description of the EHDA process, simulating the conical shape of the liquid phase in the presence of an electrical field that became known as Taylor cone later on (Taylor, 1966). In the 1980’s, Fenn and coworkers performed a series of studies that eventually made electrospray capable of introducing dissolved analytes into the gas phase for mass analysis (Fenn et al., 1989). John Bennett Fenn won the Nobel Prize in Chemistry in 2002 because of his contribution to electrospray ionization for analyzing biological macromolecules (Grayson, 2011).

EHDA is a well-practiced technique for generating very fine droplets with mono-dispersed size from a liquid under the influence of electrical forces. Though the applications of EHDA to many fields are numerous, including raindrops in thunderclouds, combustion, crop spraying, and electrospray ionization mass spectroscopy, this technique has started attracting a lot of attention since 1990s for producing and processing micro-/nanoparticulate materials in a rich variety of applications. In the present work, we begin with describing the basic setup and mechanism of EHDA, followed by a discussion of controlling composition, size, shape and secondary structure, collection, and deposition of micro-/nanoparticulate materials and their applications in the biomedical fields.

2. Electrohydrodynamic Atomization: Principles and Basic Setup

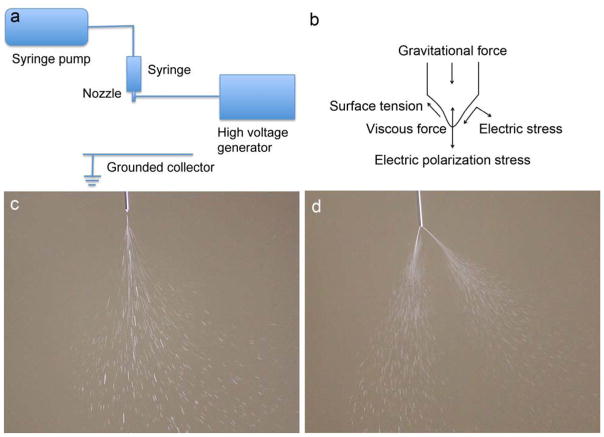

The basic setup for EHDA consists of several major components: a syringe pump, a syringe, a metal needle serving as nozzle, a high voltage power source and a grounded substrate serving as a collector (Fig. 1a). Some EHDA setups employ a closed chamber where air/nitrogen flow transfers particles toward collecting filters. The use of the chamber reduces the evaporation of solvents and facilitates formation of smaller particles with smoother surface morphology (Xie et al., 2006; Xie et al., 2008).

Fig. 1.

Schematic illustration of (a) basic setup of EHDA and (b) major forces on the spraying cone (reprinted from Hartman et al., 1999, with permission from Elsevier). Photographs showing (c) a single-cone spraying mode (also called stable cone-jet mode) and (d) a multiple-cone spraying mode.

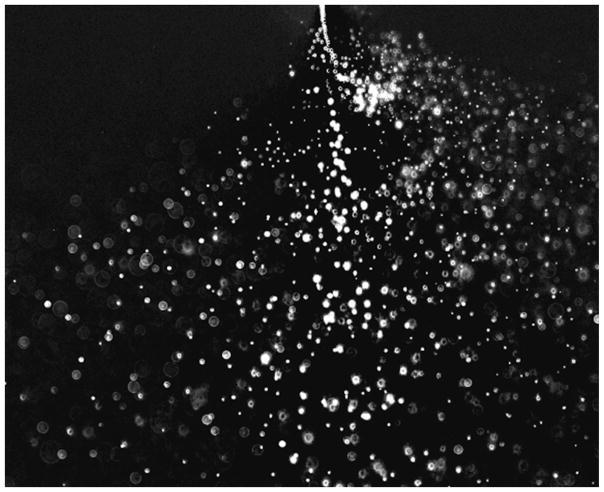

EHDA (electro refers to electric energy; hydrodynamic refers to fluid dynamics applied to liquids; and atomization refers to making bulk liquid into fine droplets) is a process where a liquid jet breaks up into fine droplets under influence of an external electrical field. Different spraying modes that are observed (e.g. dripping, microdripping, simple-jet, single cone spraying (stable cone-jet), and multiple cone spraying) are determined by the competition of the electric stress and the surface tension stress on the liquid-gas interface and by the kinetic energy of the liquid leaving the nozzle (Fig. 1b–d). Under the observation of the naked eye, the jet appears in a mist form. A high speed video camera image of a single cone spraying reveals that the jet breaks up into fine droplets near the tip of nozzle due to varicose instability or kink/whipping instability when the electric normal stress overcomes the surface tension stress (Fig. 2) (Hartman et al., 2000 and Camelot et al., 1999). Two videos are provided in the supplementary information showing both electrospraying and electrospinning jets. These video presentations provide complete illustration of jet breakup, droplet formation, and jet bending/whipping (Supplementary Information videos 1 and 2). After the droplets are emitted from the tip of the nozzle, they may undergo different scenarios: small droplet ejection, also called Rayleigh disintegration or Coulomb fission occurs; solvent evaporation increases the solute and charge concentrations; the reactive gas infiltrates the solution; and colloidal reactions occur within the solution (Salata, 2005). The maximum charge of a droplet is given by the equation (1a) (Rayleigh, 1882). Normally, the solute in the droplet solidifies and forms micro- or nanoparticulate materials after the solvent evaporates if the amount of charge carried by the droplet is under Rayleigh disintegration limit (Lr) expressed in equation (1b) (Rayleigh, 1882).

Fig. 2.

High-speed video camera image showing a single-cone spraying mode (reprinted from Xie et al., 2008, with permission from Elsevier).

| (1a) |

| (1b) |

where qR is the surface charge of a droplet, ε is the dielectric constant of the liquid, γ is the liquid surface tension and r is the droplet radius.

3. Criteria for EHDA

EHDA occurs as electric stress overcomes surface tension. Surface tension and electric conductivity of solvents play a critical role in EHDA. A liquid with surface tension higher than 50 × 10−3 N.m−1 cannot be atomized in air by electric forces (Smith, 1986). Therefore, organic solvents are often used in EHDA as they usually possess low surface tension. The selection of proper solvents to dissolve polymers for electrospraying is a critical step, since the surface morphology of generated particles is highly dependent on the solvent’s physicochemical properties. In general, electrospraying a polymer solution with a solvent with low vapor pressure and consequently high boiling temperature (e.g. N, N-dimethylformamide (DMF)) results in particles with smaller size and smoother surface morphology, however, it may also yield a bimodal size distribution due to weaker polymer chain entanglement. In contrast, solvents with high vapor pressure, low boiling temperature, and consequently faster evaporation rate (e.g. dichloromethane (DCM)) may result in the formation of textured and/or highly porous surfaces, and even hollow structures. In fact, the fast solvent evaporation rate reduces the time that polymer chains require to re-arrange within the droplet during rapid solidification (Bock et al., 2012).

Due to its high surface tension, EHDA of water or aqueous solutions may generate coronal discharge (e.g. electrical break down) in the air. Thus, inert gas environments (e.g. CO2, Ar, and N2) or vacuum is often required for EHDA of water (Tang et al., 1994). During EHDA process, charges are transferred/immobilized to the surface of cone and jet thus causing jet break-up. Herein, conductivity or dielectric constant of liquid also plays an important role. Previous studies showed the conductivity of liquids could range from 10−11 to 10−1 S.m−1 when the liquid was operated in the cone-jet mode (Smith, 1986 and Drozin, 1995). However, the conductivity with a range of 10−4 to 10−8 S.m−1 is generally considered for EHDA in this mode. In order to keep EHDA in the stable cone-jet mode, a minimum flow rate is known to scale as equation (2) when electrospraying low viscous liquids in the “high-conductivity” limit (Barrero and Loscertales, 2007).

| (2) |

where Qmin is the minimum flow rate, γ is the surface tension of the working liquid, ρ is the density of liquid, K is the conductivity of liquid, and εr is the permittivity of the working liquid. Most recently, Scheideler and Chen (2014) examined the minimum flow rate scaling of highly viscous systems and obtained equation (3).

| (3) |

where D is the diameter of spraying nozzle, and μ is the viscosity of fluid.

Previous studies also demonstrated that both DC and AC high voltages were suitable for EHDA (Borra et al., 1999b and Yeo et al., 2005).

4. Composition

It appears that EHDA can be used to fabricate and process particular materials without limiting the raw materials. Materials produced and processed by EHDA have been categorized as follows and summarized in Table 1.

Table 1.

List of materials produced and processed by EHDA

| Materials | Sizes | Solvents | References |

|---|---|---|---|

| Pharmaceutics/drugs | |||

| Aspirin | ≈ 6 μm | Ethanol | Li et al., 2006 |

| Methylparahydroxybenzoate | 1.58–4.55 μm | Ethanol | Ijsebaert et al., 2006 |

| Beclomethasone dipropionate | 1.5–4.5 μm | Ethanol | Ijsebaert et al., 2006 |

| Paclitaxel | ≈ 10 μm | Ethanol | unpublished |

| Carbamazepine | 0.32–1.75 μm | Methanol | Wang et al., 2011 |

| Indomethacin | 1.7 μm | Ethanol | Nystrom et al., 2011 |

| Piroxicam | 5.5 μm | Chloroform | Nystrom et al., 2011 |

| Budesonide | 4.9 μm | Chloroform | Nystrom et al., 2011 |

| Niflumic acid | 0.2–0.8 μm | Acetone/water | Ambrus et al., 2013 |

| Biological materials | |||

| Insulin | 110 nm | ethanol/water/HCl | Gomez et al., 1998 |

| BSA | 700 nm | ethanol/acetic acid | Cardoso et al., 2011 |

| Sucrose (C12H22O11) | 20 nm | Water | Morozov et al., 2011 |

| Sericin | 25–175 nm | DMSO | Hazeri et al., 2012 |

| Silk-elastin-like protein | 24 and 36 nm | ammonium acetate buffer | Anumolu et al., 2011 |

| DNAs | Water | Chen et al., 2000; Okubo et al., 2008 | |

| Cells | Abeyewickreme et al., 2009; Ng et al., 2011; Sahoo et al., 2012; Braghirolli et al., 2013 | ||

| Whole organism | Mongkoldhumrongkul et al., 2010; Clarke et al., 2008 | ||

| Natural polymers | |||

| Chitosan | 124 nm and ≈ 2.5 μm | Ethanol/acetic acid/water | Arya et al., 2009; Pancholi et al., 2009; Zhang and Kwakami, 2010 |

| Cellulose | ≈ 1 μm | Ethanol and butanone/DCM | Huang et al., 2012; Bodnar and Rosell-Llompart, 2013 |

| Alginate | 0.15 to 2 mm | Water | Moghadam et al., 2008; Xie and Wang, 2007; Tabeei et al., 2012; Park et al., 2012 |

| Synthetic polymers | |||

| PS | ≈ 0.75 – 5 | THF | Fantini et al., 2006 |

| PCL | 0.3 – 20 μm | DCM/chloroform/DMAc | Ding et al., 2005; Wu and Clark, 2007; Enayati et al., 2010; Bock et al., 2011 |

| PLGA | 0.06 – 15 μm | DCM/acetonitrile/TFE/DMSO/TEAF | Xie et al., 2006a; Xie et al., 2006b; Almeria et al., 2010; Almeria et al., 2014; Berkland et al., 2004 |

| PLA | 3.7 – 19 μm | 1-butanol/methylene chloride/1,2-dichloroethane-ethanol (DCE)/chloroform | Yeo et al., 2005; Xu et al., 2006; Ikeuchi et al., 2012 |

| Polymer/polymer blends | |||

| PLA/PLGA | ≈ 5 μm | DCM-DMSO | Xie et al., 2008 |

| PLGA/Pluronics | ≈ 1.4–1.6 μm | THF-DMF | Seth and Katti, 2012 |

| Drug/polymer | |||

| Taxol/PCL | 3–10 | DCM-Acetonitrile | Ding et al., 2005 |

| Paclitaxel/PLGA | 17–32 | DCM-Acetonitrile | Xie et al., 2006b; Naraharisetti et al., 2007; Ranganath et al., 2009a, b |

| Beclomethasone-dipropionate/PLA | 230–850nm | DCM-Ethanol | Valo et al., 2009 |

| Celecoxib/PLGA | 2–8 μm | Acetonitrile | Bohr et al., 2012 |

| Ketoprofen/ethyl cellulose | Ethanol aqueous | Huang et al., 2012 | |

| Piperine/p-coumaric acid-thiolated-chitosan | 2–5μm | Lactic acid | Pengpong et al., 2014 |

| Quercetin/PVP, SDS, sucralose | 1.3–1.8 μm | Dimethylacetamide-Ethanol | Li et al., 2014 |

| Griseofulvin/poly (methacrylic acid-co-methyl methacrylate) | 1 μm | Zhang et al., 2011 | |

| BSA/lysozyme/PLGA | ~20 μm | DCM-water | Xie et al., 2007 |

| Salbutamol-sulfate/PLA | 230–850nm | DCM-Ethanol | Valo et al., 2009 |

| BSA/PCL-PPE-EA | 2–4 μm | Water-DCM | Wu et al., 2010b |

| Ovalbumin/calcium alginate | 1.0–1.5 μm | Water | Sukasamran et al., 2013 |

| BSA/PDMS | 5–6 μm | Water-acetone | Pareta and Edirisinghe et al., 2006 |

| Budesonide/PLGA | ~3 μm | Acetonitrile | Lee et al., 2010c |

| Paclitaxel/suramin/PLLA/PLGA | 10–20 μm | DCM-Ethyl Acetate | Nie et al., 2010a,b |

| Doxorubicin/elastin-like polypeptide | 150–570nm | Water | Wu et al., 2009b |

| Imidazoquinoline/acetalated dextran or acetalated dextran/tween blends | ~2 μm | ||

| Trifluoroethanol/methanol/ethanol/1-propanol/1-b | Duong et al., 2013 | ||

| Irinotecan/acetalated dextran/PLGA | 8.4 μm | DMF | Rahmani et al., 2013 |

| Cisplatin/maleimide-PEG-PLGA | ~550nm | Ether/methanol | Bai and Liu, 2014 |

| Gemcitabine/folate-chitosan | 200–300nm | Xu et al., 2013 | |

| DNA | |||

| pCIKLux | Ethanol-water-ethanoic acid | Davies et al., 2005 | |

| Plasmid DNA/PEI | Wu et al., 2010a | ||

| Oblimerson sodium/Genasense/lipoplex | 100–2500 nm | PBS\ethanol | Wu et al., 2009a |

| pET30a-GFP plasmid/gold nanoparticles | 20–50 nm | water | Lee et al., 2011b |

| Adenovirus/alginate | <150 μm | Water | Park et al., 2012a |

| Food | |||

| Chocolate (fat, sugar, lecinthin) | Melt | Gorty and Barringer, 2011; Luo et al., 2012 | |

| Cocoa butter, coca butter equivalent, lauric butter | Melt | Marthina and Barringer, 2012 | |

| Zein-curcumin | 175–900 nm | Aqueous-ethanol | Gomez-Estaca et al., 2012 |

| Stearic acid-ethylcellulose-Maltol | 10–100 nm | Ethanol | Eltayeb et al., 2013 |

| Composites | |||

| Polystyrene/silica nanoparticles | 60–100 μm | water | Moon et al., 2004; Shen et al., 2010 |

| TiO2-PMMA | 0.25–1.87 μm | Diethylene glycol dimethyl ether | Yun et al., 2009 |

| CdSeS-poly(styrene-acrylate) | 500–1000nm | DMF | Sun et al., 2011 |

| PVA-MMT/Ag | ~ 4 μm | DMF/THF | Park et al., 2012; Park et al., 2011; Park et al., 2013 |

| Polystyrene-block-ethylene oxide-quantum dots/iron oxide | 36–38 nm | Water | Duong et al., 2014 |

| Metals | |||

| Sn-Bi | 5–50 nm | melt | Yu and Hu, 1997 |

| Au | 7.1 nm, 10.9 nm 14.9 nm | Water-methanol | Lengoro et al., 2002 |

| Pd | 4.3 nm | Water-methanol | Lengoro et al., 2002 |

| Al | 4–14 μm | Ether-ethanol | Wang et al., 2013 |

| Carbon | |||

| Carbon nanotubes | ~100 nm | Methanol | Jennerjohn et al., 2010; Kim et al., 2010; Wang et al., 2013 |

| Graphene | ~1 μm | Water | Tian et al., 2013 |

| Inorganic materials | |||

| TiO2 | 10 – 20 nm | Ethanol | Park et al., 1996; Wang et al., 2005; Terada et al., 2012 |

| TiO2/ZrOx | 110 nm 2–4 μm | 1-BuOH | Borra et al., 1999a; Camelot et al., 1999 |

| CeO2 | 24.6 and 29.9 nm | Ethanol/diethylene glycol butyl ether | Oh and Kim, 2007 |

| ZnS | 20–40 nm | Ethyl alcohol | Lenggoro et al., 2000 |

| Ce2O3/TiO2 | 80–500nm | Mou et al., 2013 | |

| BiFeO3 | Du et al., 2011 | ||

| Li4/3Ti5/3O4 | 10 nm | 2-propanol-acetic acid | Doi et al., 2009 |

| Nano-sized Hydroxyapatite | Li et al., 2007 | ||

| Gas | |||

| Microbubble (air) | <10 μm | Farook et al., 2007a, b; Pancholi et al., 2007; Farook et al., 2009 | |

Abbreviations: PLGA, Poly(lactic-co-glycolic acid); PLA, Polylactic acid; PCL, Poly(3-caprolactone); PHBV, Poly(3-hydroxybutyrate-co-3-hydroxyvalerate); TEAF: Triethyl ammonium formate

4.1. Natural polymers

Natural polymers are commonly non-toxic and environmentally responsive via degradation and remodeling via enzymes secreted by cells due to their intrinsic property. Many natural polymers have been processed into particulate materials using EHDA. Here, we illustrate several notable examples.

4.1.1. Chitosan

Chitosan is a linear, semi-crystalline natural polysaccharide composed of a randomly distributed (1→4)-2-acetamido-2-deoxy-β-D-glucan (N-acetyl D-glucosamine) and (1→4)-2-amino-2-deoxy-β-D-glucan (D-glucosamine) units, which can be readily obtained from the alkaline deacetylation of chitin. Chitosan is a polycation whose primary amino groups can be protonated at low pH (pKa~6.5) and exhibits remarkable antibacterial, mucoadhesive, analgesic, haemostatic, biocompatible, and biodegradable properties (Croisier and Jerome, 2013). Arya et al. (2009) reported the use of EHDA for the preparation of chitosan-based micro/nanospheres. They examined the influence of a series of parameters including applied voltage, needle size, concentrations of chitosan and acetic acid solutions, and the collecting distance on the particle formation. Similarly, Pancholi et al. (2009) examined the effects of viscosity and surface tension on particle diameter during electrospraying chitosan solutions. They demonstrated that chitosan particles with diameter of about 2.5 μm can be generated using a chitosan solution with a viscosity of around 80 mPa.s and the particle size can reduce to 500 nm when on drying. In another study, Zhang and Kawakami (2010) fabricated chitosan solid micro- and nanoparticles by electrospraying chitosan/acetic acid solution in one-step. It was found that the solution viscosity and conductivity played critical roles on electrospraying behavior, e.g. high viscosity and/or low conductivity can lead to stable electrospraying. By adding certain amount of ethanol to chitosan/acetic acid solution, they were able to obtain chitosan particles with diameter of 124 nm. In addition, researchers have demonstrated the encapsulation of various drugs in electrosprayed chitosan particles. Songsurgang et al. (2011) prepared doxorubicin (DOX)-loaded chitosan particles using tripolyphosphate (TPP) as a stabilizer during EHDA process. Under the optimized conditions, the size of DOX-chitosan particles obtained were around 300–570 nm in dry state or 530–870 nm in hydrated state for initial drug loadings of 0.25–1%. More recently, Choi et al. (2013) demonstrated the fabrication of bovine serum albumin (BSA)-loaded chitosan microspheres by electrospraying acetic acid solution containing chitosan and BSA into sodium carbonate solution. The sodium carbonate solution could render the microspheres insoluble and solidified through neutralization of chitosan acetate. The high encapsulation efficiency can be achieved owing to quick solidification of microspheres and the interactions between oppositely charged chitosan and BSA. In a different study, Gu et al. (2013) demonstrated the fabrication of pH responsive, mono-dispersed chitosan microspheres (256 ± 18 μm) containing glucose oxidase nanocapsules, and recombinant human insulin by a one-step electrospraying of an aqueous chitosan solution (2% w/v) into a receiving container containing 50 mL of 5% TPP with gentle agitation.

4.1.2. Cellulose

Ethyl cellulose (EC) is an inert and water-insoluble polysaccharide and its coatings are highly stable under storage. These properties make it a good candidate for sustained-release carriers. Huang et al. (2012) recently fabricated EC microparticles containing different amounts of a model drug ketoprofen (KET) for sustained release by electrospraying EC (15% w/v) and KET (50, 33, 20, 9% w/w) co-dissolved ethanol solution. The crystalline drug was in an amorphous state after encapsulation in EC particles and chemical interactions between KET and EC were noticed. In addition, with increasing the amount of EC content, the release rate of KET dropped. In a separated study, Bodnar and Rosell-Llompart (2013) examined the fabrication of EC particles by electrospraying EC in butanone and dichloromethane (DCM) at different humidity levels. They obtained various morphologies of particles including flatter, pancake-shaped, with a corrugated or dimpled wall, arising from primary droplets.

4.1.3. Alginate

Sodium alginate, the sodium salt of alginic acid, is obtained from brown marine algae. The sodium alginate solution with concentration of 1–3 w/v% is a non-Newtonian and viscous liquid. Electrospray of a highly viscous and non-Newtonian alginate solution was often in either pulsating jet model or dripping model. Alginate beads/microspheres are usually formed by electrospraying of sodium alginate solutions into an aqueous solution containing a crosslinking agent (e.g. CaCl2). Moghadam et al. (2008) produced mono-sized spherical alginate beads with size ranging from 0.57 to 2 mm by electrospraying high viscous alginate solution. Xie and Wang (2007) demonstrated the fabrication of uniform alginate microbeads having diameters ranging from 200 μm to 2 mm by performing electrospray in the dripping mode through an additional ring electrode. Tabeei et al. (2012) showed the use of a pulsating DC electric field for production of alginate beads in millimeter scale at a critical frequency could result in a narrow size distribution. In a separate work, Park et al. (2012a) examined different concentrations and flow rates for the production of alginate beads, indicating alginate beads with diameter less than 150 μm can be achieved using a low alginate concentration (<1.0 wt%) and a low flow rate (< 2 ml.h−1).

4.2. Synthetic polymers

Synthetic polymers have a number of advantages comparing to natural polymers as they can be tailored for the desired mechanical properties and the required degree of degradation. Furthermore, synthetic polymers are often in low cost and a more reliable source of raw materials. Fabrication of polymeric particles by EHDA shows the potential to eliminate the drawbacks associated with emulsion-based techniques and to generate micro- and nanoparticles with reproducible loadings.

4.2.1. Polystyrene

Polystyrene (PS) has been studied as a model polymer for producing micro- and nanoparticles using EHDA. Fantini et al. (2006) examined the effects of four different molecular weights of PS for production of micro- and nanoparticles, showing the low molecular weight PS easily led to non-fiber forming. They also found that the large quantity of solvent to be evaporated could result in irregular and rough beads when using the high molecular weight PS. In contrast, the lower amount of solvent to be evaporated when using the low molecular weight PS could result in formation of spheres with uniform dimensions and smooth surfaces. A different study showed electrospraying of off-the-shelf colloid PS nanospheres (360 nm and 720 nm) for the production of thick layers of tridimensional order (Coll et al., 2013).

4.2.2. Poly(ε-caprolactone) (PCL)/poly(lactide) (PLA)/poly(lactide-co-glycolide) (PLGA)

PCL/PLA/PLGA have been electrosprayed into nano- and microparticles for applications in drug delivery as they are FDA-approved, biocompatible and biodegradable polymers. PCL is biodegradable polyester with semi-crystalline structure and glass transition temperature around −60°C. However, hydrophobic nature of PCL would be the major constraint in the encapsulation of natural or synthetic macromolecules such as DNA, proteins, and peptides as well as hydrophilic small molecules (e.g. doxorubicin) (Woodruff and Hutmacher, 2010; Freiberg and Zhu, 2004). Ding et al. (2005) and Xie et al. (2006a) fabricated mono-dispersed PCL particles with diameters ranging from 1 to 32 μm by electrospraying a PCL and dichloromethane (DCM) solution using a glass chamber. Wu and Clark (2007) prepared PCL particles with a mean-size of 4 ± 0.3 μm and a porous microstructure by electrospraying a PCL and chloroform solution into an aqueous solution, regulating the evaporation rate of solvents during the fabrication process. Enayati et al. (2010) prepared PCL particles with diameters ranging from 300 nm to 4500 nm by jetting a solution in the presence of an electric field. They were able to control the size and size distribution of the fabricated particles by systematically adjusting the operating parameters. Bock et al. (2011) demonstrated the fabrication of relatively uniform-sized PCL microspheres with narrow size distributions and the average sizes of particles ranged from 10 to 20 μm. They also showed a high polymer concentration combined with a high feeding rate could ensure electrospraying in the semi-dilute entangled regime and result in the production of uniform sized and reproducible solid spheres and elimination of fiber formation and offspring droplets.

In another set of studies, Xie et al. (2006a, b) systematically examined the effect of parameters on PLGA particle formation by EHDA and demonstrated controlled morphologies (spherical, disintegrated, red blood cell-like, donut-like, porous, hollow) and sizes (255 nm to 15 μm). Almeria et al. (2010) further examined the fabrication of PLGA microparticles with different morphologies (spherical, elongated, and with one or multiple fibers attached to the particle core) and reported possible mechanisms. More recently, the same group reported the electrospray synthesis of monodisperse PLGA (M.W. 11–136 kDa) particles in a broad diameter rang (60 nm–2 μm) which was determined by main parameters including solution conductivity, flow rate and initial polymer volume fraction (Almeria and Gomez, 2014). However, the scale of flow rate used in this study was in microliter per hour and the production rate was low, which made this process less practical for applications. In a separate study, Berkland et al. (2004) obtained PLGA particles with sizes of 300 nm using flow-limited field-injection electrospraying (FFES) 5% w/v PLGA in acetonitrile at flow rate of 1 ml.h−1, indicating injection charge could be more efficient for inducing an ionic state in a solution of PLGA than the conventional electrospray setup.

PLA has properties similar to that of PLGA, but has more crystalline structure that is responsible for slower degradation. Therefore, it is an interesting candidate for long-term degradation and release applications (Nie et al., 2010). Yeo et al. (2005) fabricated PLA (M.W. 6000–16,000) particles (3.7 ± 1.9 μm) by AC electrospraying 5% w/v PLA dissolved in 20% 1-butanol and 80% methylene chloride mixture, demonstrating that the particles ejected possess neutral charge (unlike DC electrospray) and thus eliminating the chance of surface adsorption and destabilization of the encapsulated molecules because of electroporation and/or compound ionization. In another study, Xu et al. (2006) showed that 1,2-dichloroethane (DCE) was a more suitable solvent for electrospraying PLA than DCM. Ikeuchi et al. (2012) recently demonstrated the fabrication of PLA particles with high surface porosities due to phase separation by electrospraying 1% PLA chloroform solution containing 5% ethanol in a high humidity environment (90%).

4.3. Polymer blends

Polymer blends may provide an optimized combination of different activities. For example, natural polymers generally have poor mechanical properties but may present some biological functions. Synthetic polymers are usually mechanically stronger than natural polymers but lack biological functions. A mixture of natural and synthetic polymers could address this problem by integrating multiple desired properties, which can simultaneously have the superior physical properties and biological functions. However, few studies have examined the electrospraying of polymer blends. Xie et al. (2008b) prepared microparticles composed of PLA/PLGA blends. It was demonstrated that the microparticles composed of PLA/PLGA (30/70) blends could form core-shell structure due to phase-separation during the electrospraying process. In a different study, Seth and Katti (2012) reported the electrospraying of blends of Pluronics® with PLGA for simultaneous modulation of morphology from doughnut-shape to spherical shape and surface properties (e.g. surface charge, surface hydrophobicity, and surface chemistry) of PLGA microparticles.

4.4. Inorganic materials

Owing to their intriguing properties, many efforts have been devoted to the preparation of metal oxide particles in the 1–100 nm range. Nanoparticles made of metal oxides or compounds have been achieved by combining electrospray and sol-gel chemistry. Park and Burlitch (1992, 1996) prepared nanoparticles of anatase (TiO2) with sizes of 20 nm by pyrolyzing amorphous precursor particles generated by electrospraying a modified titanium alkoxide ethanol solution into a heated chamber. Wang et al. (2005) demonstrated a one-step synthesis of TiO2 nanoparticles having diameter of around 10 nm by electrospraying pyrolysis of three different organic precursors including titanium tetraisopropoxide and water-soluble titanium sources TC-300® and TC-400®. Similarly, Terada et al. (2012) fabricated TiO2 nano- and microparticles by electrospraying titanium (IV) bis(ammonium lactato) dihydroxide aqueous solutions followed by the pyrolysis at 300–500°C. In addition to the fabrication of TiO2 nanoparticles, electrospray has been used for processing TiO2 nanoparticles. Modesto-Lopez and Biswas (2010) examined the effect of electrical conductivity of nano-suspensions in the formation of TiO2 agglomerates and TiO2 films with electrospray. Similarly, Xi et al. (2011) fabricated polydispersed and nearly spherical TiO2 aggregates with 0.4–3 μm in diameter by electrospraying a colloidal dispersion of P25 TiO2 nanoparticles. The similar methodology has been reported for the fabrication or processing of other types of inorganic particles including ZrOx, CeO2, ZnS, BiFeO3, hydroxyapatite, Quantum dots, and Li4/3Ti5/3O4/CNT (Borra et al., 1999a; Camelot et al., 1999; Oh and Kim, 2007; Lenggoro et al., 2000; Li et al., 2007; Du et al., 2011; Jennerjohn et al., 2010 and Doi et al., 2009).

4.5. Composites

Incorporation of nanoparticles to polymeric matrices can enhance and/or render novel functionalities of composites due to the interaction between nanoparticles and polymer matrices. Moon et al. (2004) reported a one-step synthetic method for the preparation of colloidal aggregates and their inverse structures by electrospraying an aqueous colloidal suspension containing polystyrene beads and silica nanoparticles. Similar work has been reported for the generation of soft polymer spheres/silica crystal balls (Shen et al., 2010). Yun et al. (2009) fabricated nonagglomerated and monodispersed TiO2-poly(methyl methacrylate) (PMMA) composite microspheres with a mean diameter ranging from 0.25 to 1.87 μm using a combination of beads mill and electrospray techniques. Sun et al. (2011) fabricated quantum dot (CdSeS QDs)-encoded poly(styrene-acrylate) microspheres by electrospraying the mixture of polymer solution and quantum dots solution, providing many reliable codes for multiplex detection. In different studies, Park et al. (2011, 2012b, 2013) demonstrated the fabrication of PVA/MMT, PVA/Ag, and PVA/MMT/Ag composite particles using electrospray and explored the test of antibacterial activity against Staphylococcus aureus. In addition, a more recent study demonstrated the fabrication of micellar (polystyrene-block-ethylene oxide) nanocomposites containing quantum dots (QDs), superparamagnetic iron oxide nanoparticles (SPIONs) and their combination via co-axial electrospray (Duong et al., 2014).

4.6. Metals

EHDA has been used for the production and processing of metal particles. Yu and Hu (1997) fabricated Sn-Bi nanoparticles with sizes from around 5 to 50 nm by electrospraying a master alloy of Sn-60 wt pct Bi eutectic prepared by vacuum melting. Kandjani et al. (2010) prepared metal particles with various shapes including tear drop, tad pole, oval like, ligament, dumbbell and irregular/splat by electrospraying Sn (60%)/Pb (40%) alloy melt into a viscous medium - transformer oil. Other than fabrication of metal particles, electrospray was used for sizing metal particles. Lenggroro et al. (2002) showed that electrospray in conjunction with aerosol analyses (a differential mobility analyzer and a condensation nucleus/particle counter) can provide a means for sizing gold and palladium nanoparticles. Electrospray was also used to assemble metal particles. Wang et al. (2013a) generated a gel within a droplet via evaporation induced rapid aggregation of aluminum nanoparticles by co-axial electrospray, which contains a small mass fraction of nitrocellulose serving as an energetic binder and to adjust the particle size and morphology.

4.7. Carbon

Carbon nanotubes commonly tend to form bundles and are difficult to form aerosols in a well-controlled fashion because of their unique geometry and van der Waals forces. Jennerjohn et al. (2010) developed an approach for producing aerosols of carbon nanotubes in an occupationally relevant mass concentration-180 μg of nanotubes per cubic meter of the carrier gas using electrospray. A similar approach was carried out to disperse and aerosolize carbon nanofiber colloidal suspensions for in vitro and in vivo studies (Kim et al., 2010b and Wang and Pui 2013). In addition, 2D nanoscale graphene building blocks were integrated into 3D structures using electrospray-assisted self-assembly. Tian et al. (2013) fabricated erythrocyte-like grapheme microspheres in high quality and mass production capability by electrospraying graphene oxide suspension into a coagulation bath (e.g. CTAB solution) followed by hydrazine hydrate reduction.

4.8. Drugs

It is reported that more than 95% of new drug candidates are associated with limited bioavailability due to their large size, low solubility and high crystallinity. Electrospray has been used to fabricate various pharmaceutical particles to reduce the size, increase the solubility, and generate the amorphous form normally adopted to improve bioavailability and administration of such drugs. Ijsebaert et al. (2001) prepared methylparahydroxybenzoate (MPHB) and beclomethasone dipropionate (BDP) particles with desired sizes ranging from 1.58 μm to 4.55 μm for inhalation purposes by electrospraying MPHB and BDP ethanol solutions. In order to reduce the size and obtain a regular shape of aspirin powder for inhalation applications, Li et al. (2006) produced aspirin particles with sizes less than 10 μm by electrospraying a saturated solution of aspirin in ethanol. Nystrom et al. (2011) investigated the formation of indomethacin, piroxicam and budesonide particles (1.7–5.5 μm) by electrospraying them in ethanol and chloroform at reduced pressure. It was found that electrospraying of a high volatile solution in a reduced pressure could lead to generation of more amorphous particles than electrospraying in atmospheric pressure, which was most probably attributed to the fast solidification. Scholten et al. (2011) fabricated carbamazepine (CBZ) –microparticles (a poorly water-soluble drug) of different sizes and shapes by controlling jet formation and breakup, droplet evaporation and solidification during electrospraying solutions containing different amounts of CBZ in DCM. In a separate study, Wang et al. (2012) demonstrated the production of crystals of CBZ with sizes ranging from 320 ± 48 nm to 1756 ± 458 nm via EHDA followed by annealing at high temperatures. In order to reduce the size, electrospray crystallization was used for the production of submicron-sized niflumic acid (NIF) crystals (200 nm–800 nm), an anti-inflammatory drug, which is much smaller than the conventional NIF (around 80 μm) (Radacsi et al., 2012 and Ambrus et al., 2013). Fu et al. (2012) prepared pharmaceutical particles containing both budesonide and epigallocatechin gallate due to charge-enhanced coagulation via customized bipolar electrospray setup. Other than pure drug solutions, additives together with drugs were also electrosprayed to form particulate formulations. Kawakami (2012) employed electrospray to prepare particulate formulations of drugs/polymeric excipients such as CBZ/poly(vinyl pyrrolidone) and prednisolone (PDN)/Eudragit. It was found that the excess amount of CBZ readily forms a pure crystalline phase due to phase separation when the poly(vinyl pyrrolidone) excipient was loaded with larger than 40% CBZ. In contrast, excess PDN can retain the amorphous state for an even higher loading.

4.9. Biological materials

EHDA has also been used to fabricate protein and enzyme nanoparticles. Gomez et al. (1998) showed the possibility of generating relatively uniform and biologically active insulin nanoparticles with a mean diameter around 110 nm by electrospraying insulin in mixed solvents containing 89.1-9.9-1 ethanol-water-4% molar HCl by volume. Morozov (2011) designed a nano-aerosol generator with an opposite electrospraying of volatile solvents for neutralization. The prepared bovine serum albumin (BSA) nanoparticles had mean diameters from 80 ± 20 nm to 115 ± 15 nm. In addition, Morozov (2011) also showed the fabrication of alkaline phosphatase (an enzyme) nanoparticles using a customized bipolar electrospray setup. It was shown that enzymes aerosolized by bipolar electrospray could maintain their specific bioactivity. Anumolu et al. (2011) generated hollow silk-elastin-like protein polymeric nanoparticles (24.0 ± 1.2 nm and 36.0 ± 1.4 nm) and demonstrated precise control over their dimensions using a commercially available electrospray aerosol generator (TSI 3480) together with a differential mobility analyzer (DMA-TSI 3085). Hazeri et al. (2012) demonstrated the production of sericin nanoparticles with average particle sizes of 25–175 nm consisting of small crystallites and exhibiting a high moisture absorbance by electrospraying the sericin sponge in dimethyl sulfoxide.

EHDA has also been demonstrated as an intriguing approach for plasmid DNA delivery. Chen et al. (2000) examined the co-axial electrospraying of enhanced green fluorescent protein (GFP) plasmid for the delivery to African Green Monkey fibroblast cells. Okubo et al. (2008) showed that the charged water droplets generated from EHDA can produce temporary holes in cell membranes facilitating DNA transport into a living cell and the number of infected cells increased with increasing the applied voltage. In addition to biological molecules, living cells (immortalized cell line, primary cells, and stem cells) and organisms have been processed by EHDA. Ng et al. (2011) demonstrated the formation of functional cardiac tissues by electrospraying the three major cell types in the myocardium. Abeyewickreme et al. (2009) showed that the cellular viability and the pluripotency for mouse embryonic stem cells after electrospraying were indistinguishable when comparing with untreated cells. Sahoo et al. (2012) examined the effects of electrospraying process on the survival rate, growth, and multi-lineage differentiation potential of bone marrow stem cells (BMSCs). It was found that cells via electrospraying had a viability of approximately 88%, and their proliferation rate was similar to native BMSCs. Furthermore, BMSCs electrosprayed at 7.5 kV could differentiate into adipogenic, chondorgenic, and osteogenic lineages, indicating the retaining of their multipotency. Most recently, Braghirolli et al. (2013) also examined the survival rate, proliferation, DNA destruction, preservation of plasticity and the immunophenotypic profile of BMCS after electrospraying for 15–60 min. The study suggested that above 30 min of electrospraying caused DNA damage but the DNA was capable of repairing itself within 5 h. Mongkoldhumrongkul et al. (2010) demonstrated the non-parasitic nematode Caenorhabditis elegans – a well-characterized model organism subjected to electrospraying showed no modulation of the reproductive capability and no significant variations in stress-response biomarkers like heat shock proteins. The same research group also demonstrated electrospraying of multicellular organisms such as zebrafish embryos (Clarke and Jayasinghe, 2008). The results from these studies indicated that the electrospraying process did not influence the cellular mechanisms essential for the development of a multicellular organism. Therefore, EHDA is quite a mild approach that can maintain the bioactivity of the majority of proteins and other fragile biological materials.

5. Size

The size of droplets directly determines the size of particles in EHDA. A number of scaling laws have been created for predicting the size of the droplets generated by EHDA in the cone-jet mode. In earlier studies, De la Mora and Loscertales (1994) obtained scaling laws for regular fluid as shown in the equation (4).

| (4) |

where dj is the jet diameter, r* is a certain characteristic length, Q is the liquid flow rate, ε0 is vacuum permittivity, ε is the permittivity of liquid, K is the conductivity of liquid.

Ganan-Calvo et al. examined high viscosity fluids with regular conductivity and obtained the scaling laws (Ganan-Calvo et al., 1997). For liquids with high enough conductivities and viscosities, the droplet size is approximately given by equation (5).

| (5) |

| (6) |

| (7) |

Where d is the diameter of droplet, Q is the liquid flow rate, γ is surface tension of the gas-liquid interface, ε0 is vacuum permittivity, K is the conductivity of liquid, and ρ is the density of liquid. For liquids with low conductivities and viscosities, the droplet size is approximately given by equation (8).

| (8) |

Ganan-Calvo (1997) reported that the droplet diameter can be obtained through the equation (9).

| (9) |

Where d is the droplet size, ρ is the density of liquid, ε0 is vacuum permittivity, K is the conductivity of liquid, γ is surface tension of the gas-liquid interface, fb is the dimensionless radius of the jet at the breakup point (fb ≈ 0.60).

Hartman et al. (2000) reported the relationship between droplet size and variables in the cone-jet mode as the equations (10–12).

| (10) |

| (11) |

| (12) |

where d is the diameter of droplet, Q is the liquid flow rate, I is the current transferred through the jet, C is a constant, K is the conductivity of liquid, and ρ is the density of liquid.

Most recently, Ganan-Calvo et al. (2013) established the scaling laws for both the minimum flow rate obtained in the stable cone-jet mode of EHDA, and the droplet size achieved under that condition.

When viscous forces stall the jet emission before polarization forces, the jet diameter can be formulated as the following equation.

| (13) |

where and μ is the viscosity of liquid.

When polarization forces rise against the main driver first, the jet diameter can be formulated as the following equation.

| (14) |

Where

Table 2 represents a summary of scaling laws proposed for the calculation of droplet size and electrical current in EHDA.

Table 2.

Scaling laws for the prediction of droplet diameter in a single EHDA system

| Droplet diameter | Current | Dimensionless parameters | References | |||

|---|---|---|---|---|---|---|

|

when η ≫ 1 |

I=f(ε)(γQK/ε)1/2 |

(0.51 ≤ η ≤ 2.01) |

(de la Mora and Loscertales, 1994) | |||

|

when η ~ 1 |

||||||

|

| ||||||

|

when β ~ 1 |

|

|

(Gañán-Calvo., 1994) | |||

|

when β ≫ 1 |

|

|||||

|

| ||||||

|

|

|

|

(Gañán-Calvo, et al., 1997) | |||

|

|

Q0=γε0/ρK | |||||

|

|

|

I0=(ε0γ2/ρ)1/2 | ||||

|

|

|

|||||

|

| ||||||

| Dd=G(κ)r* | I = f(κ)(γKQ/κ)1/2 | κ = dielectric constant r* = (Qεε0/K)1/3 |

(Chen and Pui, 1997) | |||

| G(κ)=−10.9κ−6/5+4.08 κ−1/3 | f(κ) = −499−0.21κ+ 157κ1/6+336κ | |||||

|

| ||||||

|

|

|

Q0=ρK/γε0 | (Gañán-Calvo, 1997) | |||

|

| ||||||

|

|

|

|

(Gañán-Calvo, 1997) | |||

| kd: Constant; It depends on needle-to-electrode potential difference as well as on the needle radius. | k1: Constant; It depends on needle-to-electrode potential difference as well as on the needle radius. |

|

||||

|

| ||||||

|

|

I=(γKQ)1/2 | The velocity profile in the jet is assumed to be flat | (Hartman et al., 2000) | |||

|

| ||||||

|

|

I=(γKQ)1/2 | Inertia and electrostatic suction scaling *: and αp/(β−1)≫1 | (Gañán-Calvo, 2004) | |||

|

|

|

Inertia and polarization forces scaling: | ||||

|

|

I=(γKQ)1/2 | Viscous force and electrostatic suction scaling: and αμ/(β−1)4≫1 | ||||

|

|

|

Viscous force and polarization force scaling: | ||||

;β is the liquid polarity parameter.

By mass conservation, the droplet size is directly related to the particle size. One will be able to deduce equation (15) (Geerse, 2003) to relate final solid particle size (dp), initial droplet size (d), and weight fraction of solid material (w).

| (15) |

where ρs and ρp are the densities of the solvent and solid material.

So far, electrospray has been successfully applied to produce particles with sizes as small as around 10 nm. According to the scaling law, the flow rates applied were usually very low (in the scale of micro liter per hour) in order to achieve particles with sizes less than 100 nm.

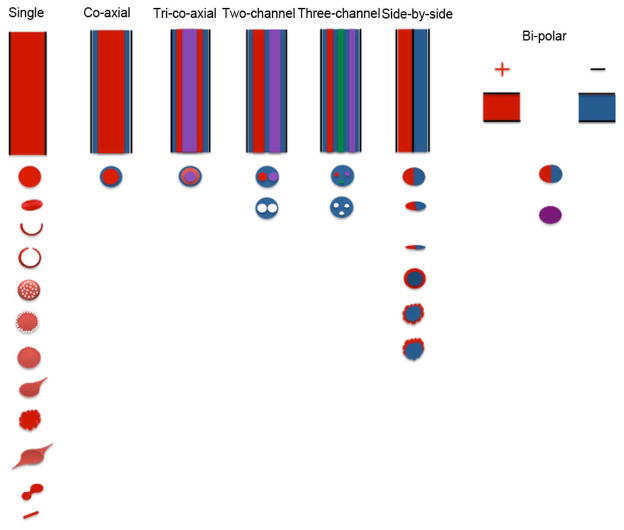

6. Morphology, Shape, and Secondary Structure

The consolidation mechanism for electrosprayed droplets could be similar to that of spray drying. The difference is that electrosprayed droplets are usually smaller and carry charges on the surface, resulting in enhancement of the evaporation rate of solvents in electrosprayed droplets. Electrospray has been demonstrated capable of generating particles with various morphologies, shapes and secondary structures. Figure 3 shows a schematic illustrating the possible morphologies, shapes and structures of particles that can be achieved using the different spraying nozzles. Almeria et al. (2010) extended a semi-empirical model that was originally developed to predict the transition from electrospray to electrospinning to evaluate the morphology of the particles generated by determining whether entanglements in the droplets are present in the Rayleigh limit (Shenov et al., 2005). However, this approach failed to predict detailed morphological features but only distinguish spherical from non-spherical particles. To validate the model, Almeria et al. (2010) demonstrated the production of PLGA particles with different morphologies including spherical, tailed, and elongated. In a different study, Doshi et al. (2009) prepared red blood cell-like PLGA particles using two approaches: directly electrospraying and 2-propanol treatment to PLGA microspheres generated by EHDA. Park et al. (2011) fabricate polyurethane particles with disk, torus (red blood cell like), and spherical shapes. Semi-spherical hollow structures of silica nanocomposites, PMMA, and polystyrene were also obtained using EHDA (Deotare and Kameoka, 2006; Liu and Kumar, 2005 and Lee et al., 2003). Chang et al. (2010a, b) demonstrated the fabrication of hollow and one-hole polymethylsilsesquioxane (PMSQ) microspheres with a controllable thickness by co-axial electrospraying PMSQ in the shell and perfluorohexane (PFH) in the core. In addition, polymeric particles with well-controlled porous structure can be produced by electrospray as well (Wu and Clark, 2007).

Fig. 3.

Schematic illustration of various electrospraying nozzles (top) and possible morphologies and structures (bottom) of particles achieved using these spraying nozzles. The configurations of the nozzle include single spraying nozzle, co-axial nozzle, tri-co-axial nozzle, multiple-channel nozzle, side-by-side nozzle, and bi-polar nozzle. By making use of these nozzles, particles obtained can be spherical, red-blood cell shaped, hollow, multicompartmental, core-shell, teardrop shaped, cup-shaped, porous, corrugated, and irregular shaped etc.

Loscertales et al. (2002) generated monodisperse capsules with diameters varying between 0.15 to 10 μm using steady coaxial electrospraying jets of immiscible liquids. Since then, various core-shell structured particles have been developed using the similar approach (Kzemi and Lahann, 2008; Xu et al., 2013a and Cao et al., 2014). The triple coaxial electrospraying device was also developed for the production of triple-layered structures in a single step process (Kim and Kim, 2010 and Labbaf et al., 2013). In separate studies, multi-chamber microspheres were generated by utilization of a modified co-axial electrospraying device called compound-fluidic electrospray (Chen et al., 2008 and Zhao and Jiang, 2009). In addition, Lahann’s group demonstrated the fabrication of biphasic Janus particles and triphasic nanocolloids with nanoscale anisotropy by making use of side-by-side electrospraying, (Roh et al, 2005; Roh et al., 2007; Roh et al., 2008; Bhaskar et al., 2008; Hwang et al., 2010; Lim et al., 2010; Yoshida et al., 2009 and Lahann, 2011). This approach can be extended to the fabrication of multicompartmental particles including side-by-side, pie-shaped, asymmetric, striped, and rosette compartment configurations (George and Braun, 2009). Bicompartmental particles of different shapes including discs, rods, and spheres were also demonstrated via side-by-side electrospray (Bhaskar et al., 2010). Kazemi and Lahann (2008) also demonstrated the fabrication of core-shell microparticulate structures via side-by-side electrospraying of miscible polymer solutions using the same setup. Alternatively, Janus particles can be produced by bi-polar electrospraying (Mou et al., 2013).

7. Particle Collection

Particles generated by electrospray were normally collected on the grounded substrate – a piece of aluminum foil in the laboratory. However, particles should be collected in a controllable way for practical applications. Ijsebaert et al. (2001) applied a gas flow to a glass chamber for inhalation purpose, demonstrating mass production rates ranging from 1.4–9.5 μg.l−1 air. Ding et al. (2005) used the similar setup for the production of PCL particles and they performed yield analysis for different operation and collection conditions. It was found that particles were deposited on the different parts including filter, inside wall, spray nozzle and ground needle and the total yield was less than 80%. After electrospraying, particles mainly endured electrical force (electrical field), drag force (air flow), columbic repulsive force (between particle), gravitational force (gravity) and buoyancy force (air). If particles were completely discharged, the particle trajectory can be easily controlled by the gas flow. Only a small fraction of particles were deposited on the filter, which could be due to incomplete discharge of particles. As a follow-up, the same group further improved the particle collection efficiency based on a modified setup (Rezvanpour et al., 2010). It was demonstrated that the particle collection efficiency was influenced by important factors presented in the following orders: solution flow rate, nitrogen flow rate, ring voltage, and nozzle voltage. The electric potential difference between nozzle and ring may also greatly influence the particle collection efficiency. The other factors affecting particle collection efficiency included durations of the process, polymeric materials, and electrical conductivities of solutions. The maximum collection efficiency can reach around 80% on the grounded aluminum collecting plate. They further performed the scaling analysis of this process for better control of pharmaceutical particle production (Rezvanpour et al., 2012). It was found that the electrical field and flow field forces played more important roles than the particle acceleration, gravitational and Saffman lift forces in their EHDA setup. An equation was also derived to describe the relation between a unique dimensionless group and the particle collection efficiency. They further investigated the effect of the auxiliary electric field formed by an additional flat plate connected to a high voltage supply and placed a few centimeters above the collecting plate on the particle collection efficiency (Rezvanpour and Wang, 2014). The collection efficiency can reach more than 90% in the optimized condition. In a different study, Grafahrend et al. (2010) developed a new and optimized electrospraying device consisting of the basic electrospray configuration, a spraying chamber, and a cyclone-type particle collector that can continuously produce 11.875 mg.h−1 monodisperse micro-sized particles with a yield of 79.2% while a basic electrospraying device allowed collection of only 34.7% of the generated particles.

8. Deposition

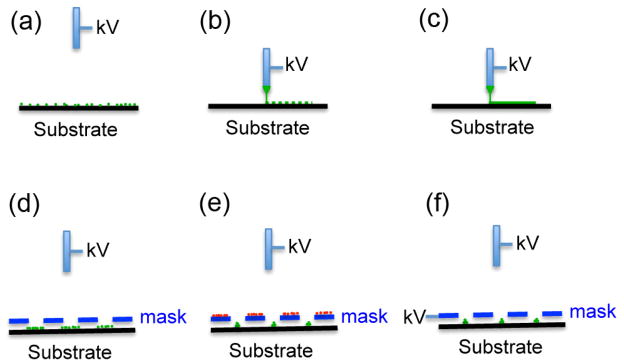

Based on the configurations, the types of electrospray deposition can be easily classified by traditional film/membrane deposition (Fig. 4a), droplet/particle placing (Fig. 4b), jet writing/printing (Fig. 4c), mask patterning (Fig. 4d), and electric field controlled deposition (Fig. 4, e and f). We highlight some of them in the following paragraphs.

Fig. 4.

Schematic illustrating different configurations of electrospray deposition. The pre-deposited ions on the mask are labeled in red (e). The deposited materials are labeled in green (a–f).

8.1. Direct jet writing (printing)

Electrospraying jet has been studied for printing or writing different materials on the surface for various applications. Chen et al. (2006) and Poon et al. (2008) showed “drop-and-place” particle deployment using a pulsed electrohydrodynamic jetting, demonstrating the capability of single particle manipulation and generation of linear colloidal crystal arrays. Samarasinghe et al. (2006) showed the deposition of gold nanoparticles to prepare conducting tracking on a table driven by a stepper motor using the electrohydrodynamic jet printing process. Lee et al. (2007) demonstrated the production of functional two-dimensional patterns of silver nanoparticles by making utilization of the silver nanocolloid jet that was generated in the cone-jet model of EHDA. Rahman et al. (2012) showed a fine-resolution patterning of copper nanoparticles on silicon substrate by electrohydrodynamic printing technology.

Park et al. (2007) demonstrated the printing of complex patterns of inks (e.g. insulating and conducting polymers, single-walled carbon nanotubes) by integrated computer-controlled electrohydrodynamic jet printer systems. The same group also demonstrated the formation of electrosprayed oligonucleotides nano-patterns for biosensing and nanomaterials assembly applications (Park et al., 2008). Galliker et al. (2012) demonstrated the direct printing of nanostructures by electrostatic autofocussing of ink nanodroplets and the generation of plasmonic nanoantennas with characteristic lengths as small as 50 nm. Korkut et al. (2008) showed the fabrication of polystyrene particle cluster arrays using an electrohydrodynamic printing system consisting of a motion system consisting of a rotary table and linear motor. Bodnar and Rosell-L lompart (2013) showed growth dynamics of ethyl cellulose granular films produced by electrospray deposition. Saywell et al. (2010) demonstrated the electrospray deposition of porphyrin polymers and oligomers on Au (111) surface, exhibiting a pattern of interdigitated chains from neighboring molecules. Electrohydrodynamic jetting has been used for depositing polymers and composites on different surfaces for biomedical applications (Ahmad et al., 2010 and Nithyanandan et al., 2013).

Morozov and Morozova (1999) showed the electrospray deposition of alkaline phosphatase (AP) to produce protein films with active biological functions. It was found that protein inactivation upon electrospray is mainly determined by voltage and current applied. The inactivation of electrosprayed proteins could also be attributed to the humidity and the presence of protective substances in solutions. Their most recent study showed that the inactivation of jack bean urease occurred when the enzyme solution (< 20 μg/ml) was electrosprayed at a current of 200 nA despite the low yield of the reactive oxygen species but the presence of 0.1 mM EDTA can retain the bioactivity of the electrosprayed urease (Kanev et al., 2014). Drop-on-demand patterning of bacterial cells on a nutrient-coated membrane and a raw silicon wafer in a straightforward, quick, and cost-effective manner was produced using electrohydrodynamic jet printing (Kim et al., 2009 and Kim et al., 2010).

8.2. Mask patterning

Morozov’s group showed the preparation of single- and multi-component microarrays of biologically active substances on any marginally conductive substrate (e.g. membrane, wet glass, semiconductor) using a dielectric mask (e.g. Teflon, mica, and nylon) with an array of holes during electrospray deposition (Morozov and Morozova, 1999; Avseenko et al., 2001; Aveseenko, 2002; Morozov, 2010). In this case, the electric field is a superposition of an attracting electric field projecting through the holes and a repelling electric field of the mask charged with some amount of the deposited electrosprayed particles. Therefore, at the beginning of experiment, particles could be deposited on the mask, resulting in loss of materials. Researchers further demonstrated the patterning of nano-sized hydroxyapatite and silicon-doped hydroxyapatite on both metallic (titanium) and non-metallic surfaces (glass) using a gold mesh mask during electrospray deposition (Li et al., 2008 and Munir et al., 2011). Similarly, Higashi et al. (2014) demonstrated the electrospray deposition of micropatterned silica nanoparticles through a stencil mask. They also showed the deposition of silver nanoparticles on the patterned silica nanoparticles, resulting in strong surface-enhanced Raman scattering effects. It was shown that the pattern can be provided with accuracy greater than 95% for patterns with line widths greater than 50 μm when using a 20 μm thick mask made of nickel.

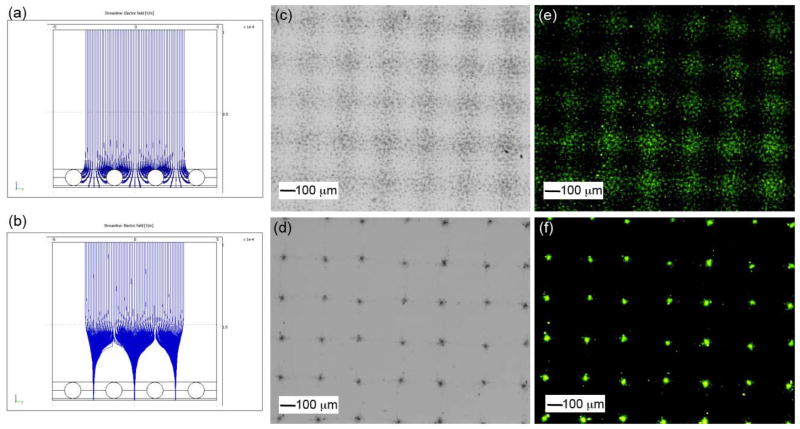

8.3. Electric field controlled deposition

Additional electric field has been used for the control of deposition of various materials during electrospray. Saf et al. (2004) demonstrated the fabrication of the thin films of functional organic materials by electrospray deposition to a moving target through a series of electrostatic lenses. Kim et al. (2006) developed an ion-induced parallel-focusing approach to pattern silver nanoparticles on both conducting (p-type silicon) and non-conducting (silica) surfaces through accumulating positive nitrogen ions generated by a corona discharger on the surface of the mask to form “focusing effect” similar to the electrostatic lens. In their following studies, they reported the parallel generation of nanoparticles (Ag, Cu, ZnO, PS) and protein (IgG) nanoarrays with 20–420 nm features as well as microarrays on various substrates (glass, PET film) using the same setup (Woo et al., 2011). They further demonstrated the generation of 3D assembly of nanoparticles with ordered arrays by extending electrospraying deposition time (Lee et al., 2011a). In a separate study, Xie et al. (2010) developed a simpler method to generate “electrostatic focusing effect” by directly applying a high voltage to the mask (Fig. 4). They demonstrated the fabrication of biodegradable and biocompatible polymeric particle patterns and subsequent formation of cell microarrays. The same group further developed a mathematic model to track the trajectories of particle and to better understand electrostatic focusing effect in the process of electrospray deposition on the substrate (Rezvanpour and Wang, 2011).

9. Applications

9.1. Pharmaceutical and food processing

Various pharmaceutics have been processed into micro- and nanoparticulate formulations using EHDA as mentioned above. In addition, EHDA technique has been used for food processing. Notable examples are as follows. Gorty and Barringer (2011) demonstrated that the electrospraying of chocolate a new approach allowing chocolate to be atomized due to the existence of an electric field can achieve a thin and even coating of chocolate. The same group also demonstrated confectionery coating (cocoa butter, coca butter equivalent, and lauric butter) using electrospray that offered greater and more complete coverage than non-electrospray coating (Marthina and Barringer, 2012). Luo et al. (2012) demonstrated the production of very fine, near-monodisperse chocolate particles by electrospraying chocolate suspensions. In a different study, Gomez-Estaca et al. (2012) examined the formation of zein nanoparticles and encapsulation of curcumin (a food coloring and active ingredient) in particles by EHDA. They further tested the performance of curcumin-loaded zein nanoparticles in semi-skimmed milk coloring, showing the potential of obtaining milk-based products with different shades and chromaticities through the addition of various amounts of curcumin-loaded zein nanoparticles. Additionally, Eltayeb et al. (2013) demonstrated the preparation of solid lipid nanoparticles (stearic acid (SA) and ethylcellulose (EC)) containing an active ingredient (Maltol) by electrospraying.

9.2. Drug/gene/virus delivery

EHDA is a promising technology for encapsulating both hydrophobic and hydrophilic drugs into polymeric particles (Bock et al., 2012). For hydrophobic drugs, they can be simply mixed with polymers and dissolved in organic solvents to form a solution that can be electrosprayed to form micro- and nanoparticles. Ding et al. (2005) and Xie et al. (2006a) demonstrated the encapsulation of paclitaxel– a hydrophobic drug in PCL and PLGA microparticles using electrospray, exhibiting sustained release of paclitaxel more than 30 days. Their subsequent study examined the performance of paclitaxel-loaded PLGA microparticles on the topical delivery of paclitaxel for the treatment of C6 glioma tumors inoculated subcutaneously in BALB/c nude mice (Naraharisetti et al., 2007). It was shown that microparticles with 20% drug loadings had good performance where the suppression of tumor growth was observed for about 10 days after the first administration. Comparing to other formulations (discs), microparticles generated by EHDA are normally more effective in suppressing tumor growth because of its inhibited burst release and the latter linearly sustained release. The same group developed a composite implant (calcium alginate beads) composed of paclitaxel-loaded PLGA microspheres embedded in alginate hydrogel matrix (Ranganath et al., 2009a, b). They further tested the implant using an intracranial U87 MG-luc2 glioblastoma model. The medium cross-linked calcium/alginate beads showed around 30 times higher anti-tumor growth activity and lower tumor proliferation index than sham and placebo controls after treatment for 41 days. In a different study, Valo et al. (2009) encapsulated beclomethasone-dipropionate a hydrophobic drug in PLA nanoparticles via electrospray in the stable cone-jet mode. Bohr et al. (2012) also fabricated celecoxib-loaded PLGA microparticles with diameters ranging from 2 to 8 μm for improving oral delivery where celecoxib is a hydrophobic, non-steroidal anti-inflammatory drug with a low aqueous solubility (≈ 5 μg/ml) and solubility-limited bioavailability. Ketoprofen (KET) a hydrophobic drug extensively used for treatment of inflammation, pain, or rheumatism was encapsulated in ethyl cellulose microparticles by electrospray (Huang et al., 2012). It was noted that the crystalline drug was transformed into an amorphous form in all the particles. More recently, Pengpong et al. (2014) encapsulated piperine a model hydrophobic drug in p-coumaric acid-thiolated-chitosan microparticles with an encapsulation efficiency of over 80%, exhibiting a sustained release of piperine up to 75% over 12 h between pH 1.2 and 6.4. In order to develop a fast-dissolving formulation for quercetin a poorly water-soluble drug, Li et al. (2014) prepared core-shell microparticles with PVP and quercetin in the core and PVP, SDS, and sucralose in the shell by co-axial electrospray. It was demonstrated that the rapid release, within one minute, of the incorporated quercetin from microparticles enhanced the permeation rates across the sublingual mucosa around 10 times faster than raw quercetin. Similarly, in order to improve oral absorption (e.g. solubility and bioavailability) of griseofulvin, which is an oral effective antifungal agent, Zhang et al. (2011) fabricated core-shell microparticles with griseofulvin in the core and poly(methacrylic acid-co-methyl methacrylate) (Eudragit L-100) in the shell using coaxial electrospray. This formulation showed much better dissolution and absorption behaviors, which could be due to the complete amorphization, smaller particle size, and improvement in dispersity.

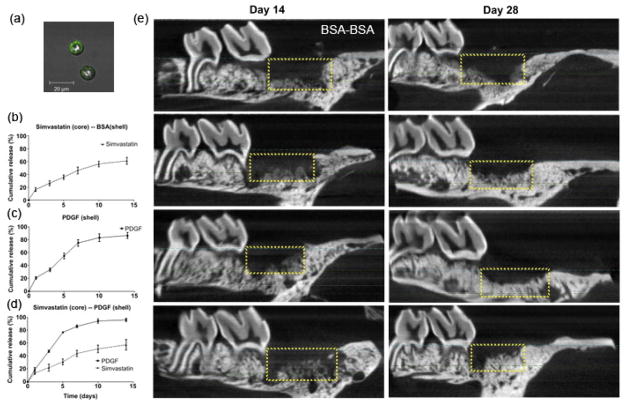

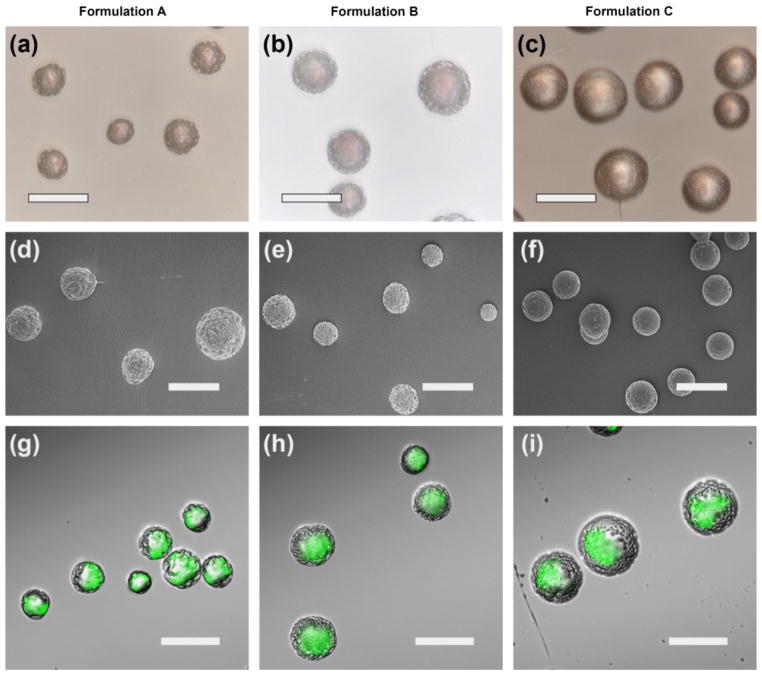

For hydrophilic drugs, they can firstly be dissolved in an aqueous solution and subsequently mixed with polymer organic solvent solution to form an emulsion that can be electrosprayed to form drug-loaded polymeric micro- and nanoparticles or core-shell particles with drug in the core and polymer in the shell. BSA and lysozyme were encapsulated in PLGA microparticles through electrospraying an emulsion solution for sustained delivery (Xie et al., 2007 and Wang et al., 2013b). Similarly, Valo et al. (2009) showed encapsulation of salbutamol-sulfate in PLA nanoparticles via electrospray. In a different study, Wu et al. (2010b) produced core-shell microspheres with BSA as the core and poly(ε-caprolactone-polyamino-ethyl ethylene phosphate) (PCL-PPE-EA) an amphiphilic biodegradable polymer as the shell using a one-step electrospraying technology. The protein release profiles exhibited constant release for more than 3 weeks without a significant initial burst. Alternatively, the encapsulation of hydrophilic drugs can be realized by electrospraying the water solution formed by co-dissolving hydrophilic drugs and water-soluble polymer followed by cross-linking and/or coating. Suksamran et al. (2013) prepared calcium alginate microparticles incorporating ovalbumin as a model antigen followed by methylated N-(4-N,N-dimethylaminocinnamyl) chitosan coating, demonstrating mucosal immune response after oral administration in vivo. In order to increase the encapsulation efficiency, protect the drugs from degradation, and prolong the release period, hydrophilic drugs can be encapsulated in the core of core-shell micro- and nanoparticles generated by coaxial electrospray. Pareta and Edirisinghe (2006) fabricated core-shell microspheres with starch and BSA in the core and polydimethylsiloxane (PDMS) in the shell using coaxial electrospray, which can avoid exposing the proteins to toxic organic solvents that cause denaturation. Similarly, Xie et al. (2008a) showed the incorporation of BSA/lysozyme in PLGA microparticles via coaxial electrospraying of aqueous solution in the core and polymer solution in the shell. In a separate study, Wang et al. (2013b) compared the release kinetics of protein-loaded microparticles fabricated by either electrospraying emulsion or coaxial electrospray. They found that microparticles prepared by coaxial electrospray showed a greater decrease in the initial burst release and a significantly higher loading efficiency than the particles prepared by the emulsion electrospray. Lee et al. (2010b) fabricated budesonide-loaded PLGA particles having sizes in the range from 165 nm to 1.2 μm by coaxial electrospray. The particles had two features: the drug release profile for particles less than 1 μm is mainly due to the penetration of water and drug diffusion and the core-shell structure greatly reduces the burst release of drugs at the initial stage. The same research group also reported the fabrication of tri-layered composite particles with encapsulation of various drugs in different layers using tri coaxial electrospray (Lee et al., 2011b). It was shown that tuning the layer thickness and material composition of layers can more efficiently control the release profiles of encapsulated drugs (Fig. 6).

Fig. 6.

(a) Schematic illustrating the co-axial and tri co-axial electrosprays and the corresponding microcapsules. The release profiles of PLGA-coated multidrug particles produced by co-axial electrospray (b) and tri co-axial electrospray (c) (reprinted from Lee et al., 2011b, with permission from Elsevier).

In addition to encapsulation of single drug, Nie et al. (2010a) prepared microspheres containing hydrophobic and hydrophilic drugs in the core and shell or vice versa via coaxial electrospray for sequential and concurrent release of different drugs. They subsequently fabricated core-shell PLLA-PLGA microparticles with encapsulation of paclitaxel and suramin in the core and shell or vice versa, which provided either a sequential release or parallel release (Nie et al., 2010b). They further tested the performance of microparticles in chemotherapy of U87 glioma a subcutaneous xenograft in BALB/c nude mice, demonstrating the higher dose of suramin released at the initial stage may efficiently suppress the tumor cell proliferation. In contrast, a subsequent sustained release of paclitaxel could enhance the apoptosis of tumor cells.

Other than traditional delivery systems, EHDA has been recently used to generate acid sensitive and targeted drug delivery systems. Wu et al. (2009b) showed the fabrication of doxorubicin-loaded elastin-like polypeptide (17.8 kD) nanoparticles by EHDA. Such particles showed pH-mediated release of doxorubicin. In a different study, Duong et al. (2013) demonstrated the encapsulation of the imidazoquinoline adjuvant resiquimod in microparticles made of acetalated dextran or acetalated dextran/tween blends that is acid responsive. It was shown that the drug released completely within 8 h under phagosomal condition and within 48 h under physiological condition because of the acid-responsive nature of acetalated dextran. The use of resiquimod-loaded particles can elicit much greater immune response in RAW macrophages than free drug. Further in vivo study suggested that intravenous injection of these microparticles into mice inoculated with Leishmania can significantly eliminate parasite load in the bone marrow versus controls. Rahmani et al. (2013) investigated the pH-responsive delivery of irinotecan from microparticles having two different compartments generated by side-by-side electrospray. Bai and Liu (2014) prepared cisplatin-loaded maleimide-PEG-PLGA particles using EHDA and subsequently conjugated with CD44 antibody. The resultant particles demonstrated a higher cell-killing outcome against ovarin cancer cells as compared to free form of cisplatin and particles without such antibody conjugation. The proposed antibody-functionalization strategy demonstrated a viable approach for producing particles with targeting ability in cancer therapy. Alternatively, Xu et al. (2013b) demonstrated the fabrication of core-shell nanoparticles with gemcitabine in the core and folate-chitosan in the shell for potential tumor-targeted, pH sensitive drug delivery by coaxial electrospray. The in vitro release profiles suggested a regulated burst release at the initial stage followed by a sustained release lasting for 3 days under neutral and acidic conditions, and the drug-releasing rate was higher under the acidic condition. In addition, the folate conjugated core–shell nanoparticles showed high particle uptake efficiency specifically by pancreatic cancer (BXPC3) cells, indicating the targeting potential.

EHDA was also reported for use in gene delivery. Davies et al. (2005) started investigating gene delivery using mice upon exposure to naked pCIKLux aerosols produced by EHDA though the efficiency was greatly compromised compared to the use of pDNA/PEI polyplexes (Koshikina et al., 2003). Wu et al. (2010a) demonstrated the production of plasmid DNA/polyethylenimine (PEI) polyplexes by coaxial electrospray. The delivery efficiency of these polyplexes was 2.6-fold higher than that generated by bulk mixing when the nitrogen to phosphate ratio (N/P) was 6.7. The same research group also prepared oligodeoxynucleotide G3139 (oblimerson sodium or Genasense)-loaded lipoplex nanoparticles that can efficiently deliver G3139 to K562 cells and downregulate the bcl-2 protein expression by 34 ± 6% and 57 ± 3% (Wu et al., 2009a). In a different study, Lee et al. (2011c) developed a method for delivering genes to microorganism Escherichia coli cells via electrospraying a mixture of pET30a-GFP plasmid and nano-sized gold particles. The momentum of gold nanoparticles attributed to the electric field can promote the delivery of DNA plasmids to microbial hosts and greatly enhance the transformation efficiency. In addition, Park et al. (2012a) fabricated calcium alginate beads for the delivery of adenovirus using EHDA, showing the high-efficiency transduction of cancer cells by the released adenovirus from the alginate beads.

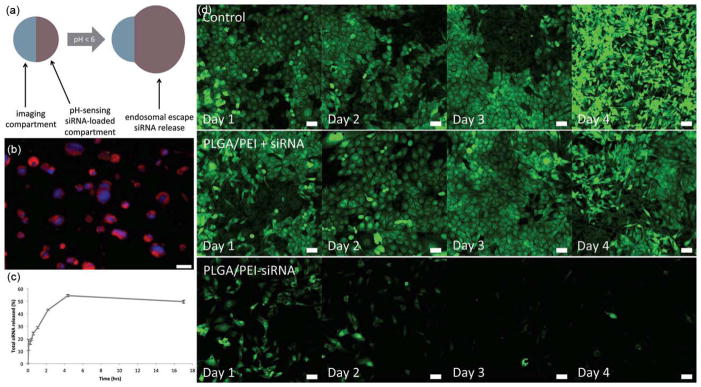

9.3. Imaging contrast agent

EHDA has been used to produce contrast agents for various imaging applications. The utilization of microbubbles as contrast agents for the delineation and perfusion of tissues evokes a great deal of interest in ultrasound imaging. Edirisinghe’s group first demonstrated the fabrication of microbubble suspensions containing uniform bubbles smaller than 10 μm in size based on co-axial electrospray (Farook et al., 2007a, b). The same research group further prepared phospholipid-coated microbubble suspensions with diameters of 3–7 μm (Pancholi et al., 2007 and Farook et al., 2009). They found these bubbles had high structural stability and their size remained almost the same for 160 min at room temperature. However, the mean bubble diameter decreased dramatically and then became stable at around 1–2 μm after 20 min under the human body temperature. Unfortunately, there is no report on in vivo studies of microbubbles generated by this technique. In separate studies, EHDA has been applied to encapsulate magnetic nanoparticles in polymeric materials for magnetic resonance imaging (MRI). Kim et al. (2013) encapsulated magnetic nanoparticles in polysorbate 80 by co-axial electrospraying of magnetic particles in hexane in the core and polysorbate 80 in the shell. Similarly, Gun et al. (2013) encapsulated superparamagnetic iron oxide nanoparticles within PLGA microspheres by co-axial electrospray, demonstrating the potential use as transverse relaxation contrast agents in MRI. In addition, particles fabricated by electrospray may present multimodalities for imaging and therapeutic applications. Hayashi et al. (2010) produced red blood cell-like particles having dual-modality including magnetic resonance and fluorescence imaging using EHDA. Low-temperature magnetic measurements confirmed the superparamagnetic behavior of the particles. The particles showed an obvious dark contrast in MRI and an effective fluorescence. In another study, Misra et al. (2012) fabricated multicompartmental particles encapsulated with gold nanostructures and siRNA having functions of both near infrared imaging and siRNA delivery (Fig. 7). Fig. 7a shows a schematic illustrating the bicompartmental particles with functions of both imaging and siRNA delivery. Fig. 7b shows a fluorescent image of bicompartmental particles. The blue and red colors indicate PLGA portion and a composite portion composed of PLGA/crosslinked PEI incorporated with rhodamine-labeled siRNA, respectively. Fig. 7c shows the release kinetics of siRNA from bicompartmental particles. Fig. 7d shows that the particles with dual functions were capable of silencing GFP production in 48 h. Si et al. (2012, 2013) also demonstrated the loading of drugs and imaging agents in PLGA microparticles, indicating the potential of co-axial electrospray for encapsulation of different drugs and imaging agents within microparticles for multimodal diagnosis and imaging-guided treatment.

Fig. 7.

Multicompartmental particles for combined imagine and siRNA delivery. (a) Bicompartmental particles illustrating different compartments with complimentary functions-imaging and siRNA delivery. (b) Fluorescent image of bicompartmental particles with blue fluorescent PLGA imaging compartment and a composite PLGA/crosslinked PEI compartment loaded with rhodamine-labeled siRNA. (c) siRNA release kinetics. (d) In vitro particles incubation experiments with MDA-MB-231/GFP breast cancer cells. Control: without treatment. PLGA/PEI+siRNA: particles and soluble siRNA. PLGA/PEI-siRNA: siRNA-loaded particles. Scale bar = 50 μm (reprinted from Misra et al., 2012. Copyright 2012 John Wiley & Sons, Inc.)

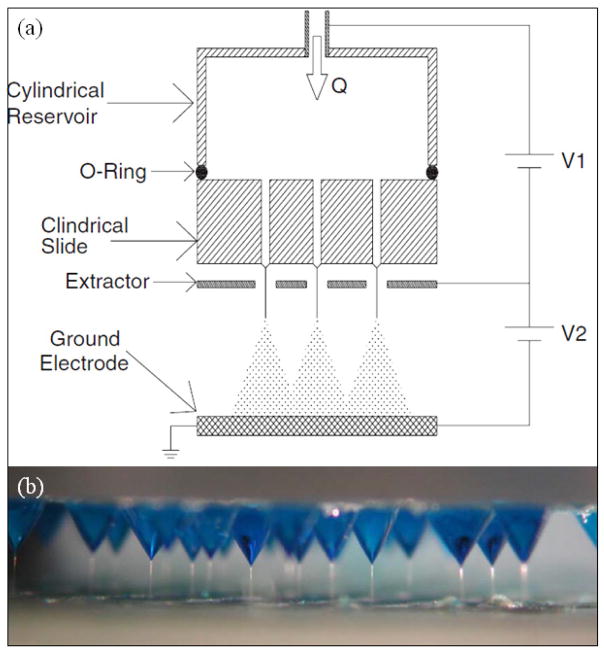

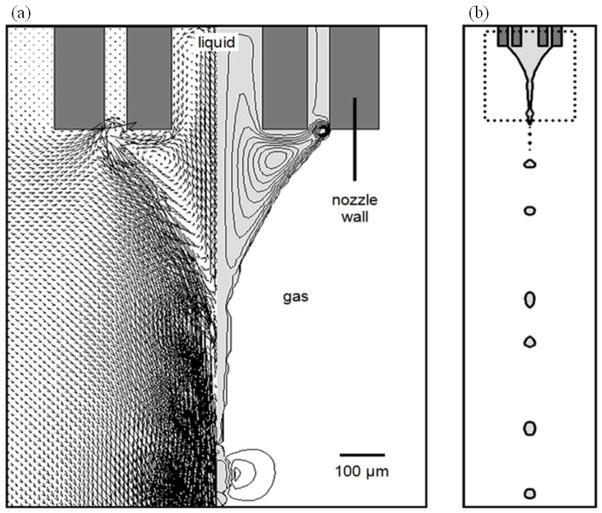

9.4. Cell/tissue encapsulation and regenerative medicine