Abstract

Fruits and vegetables are extensively processed and the residues are often discarded. However, due to their rich composition, they could be used to minimize food waste. This study aimed to develop food products based on the solid residue generated from the manufacture of an isotonic beverage. This beverage was produced based on integral exploitation of several fruits and vegetables: orange, passion fruit, watermelon, lettuce, courgette, carrot, spinach, mint, taro, cucumber and rocket. The remaining residue was processed into flour and its functional properties were evaluated. The fruit and vegetable residue (FVR) flour was incorporated with different levels (20 to 35 %) into biscuits and cereal bars. The proximate composition, microbiological stability until 90 days and consumer acceptance were analyzed. The FVR flour presented a higher water holding capacity than oil holding capacity, respectively 7.43 and 1.91 g g−1 of flour, probably associated with its high levels of carbohydrates (53 %) and fibres (21.5 %). Biscuits enriched with 35 % of FVR flour presented significantly higher fibre, ranging from 57 % to 118 % and mineral contents, from 25 % to 37 % than when only 20 % was added. Cereal bars presented about 75 % of fibres and variable mineral contents between 14 % and 37 %. The incorporation of FVR did not change the fat content. The microbiological examinations are within acceptable limits according to international regulation. The incorporation of FVR flour did not impair consumer acceptance, the sensory attributes averaged around 6. The chemical, microbiological and sensorial results of the designed products attested for an alternative towards applying and reducing agro-industrial wastes.

Keywords: Biscuits, By-products, Cereal bars, Food development, Integral exploitation, Proximate composition

Introduction

Nowadays, food industry is marked by the high volume of waste produced. According to the recent research conducted by FAO, about 1.3 billion tons of food has been wasted worldwide per year, which represents one-third of the total food industry production (Gustavsson et al. 2011). The largest amount of loss is verified by fruits and vegetables, representing 0.5 billion tons. In developing countries, fruit and vegetable losses are severe at the agricultural stage but are mainly explained by the processing step, which accounts for 25 % of losses (Gustavsson et al. 2011).

Over the past two decades, the literature have discussed the problem of waste generated by the food industry and the possibility of re-use them not only for animal feed or organic fertilization but also as raw-material for novel food products (Zaror 1992; Laufenberg et al. 2003; Ayala-Zavala et al. 2010). Hence, there is a pressing need for improving the use of fruit and vegetable through the integral exploitation of these species, thus minimizing the food waste production and creating new food sources (Ayala-Zavala et al. 2010; Laufenberg et al. 2003; Ayala-Zavala et al. 2011; Sun-Waterhouse 2011).

Fruits and vegetables are extensively processed for the beverage manufacture generating a large amount of residue which is frequently discarded, causing disposal problems. Classically, the outer layers and extremities of fruits and vegetables are removed during processing, mainly by peeling and pressing; they comprise essentially stalks, peels, seeds and crashed pulp which still contain large amounts of bioactive molecules and biopolymers, resulting in a considerable nutritional loss (Ayala-Zavala et al. 2010; Sousa et al. 2011; Figuerola et al. 2005; Schieber et al. 2001). Since these materials are naturally susceptible to microbiological degradation, their further exploitation remains limited (Schieber et al. 2001; Carle and Schieber 2006). In this way, the drying and its subsequent transformation into flour can be a viable alternative to storage and use as bread-making raw material.

Recovery processes for fruit and vegetable residues (FVR) and extraction of bioactive compounds applied as food additives (i.e. anti-browning, antimicrobial, flavouring, colorants) have been extensively developed (as reviewed by Ayala-Zavala et al. 2011; Sun-Waterhouse 2011). Furthermore, recent studies have shown functional food ingredients extracted from FVR, since they are rich in dietary fibres and antioxidants compounds (Sun-Waterhouse et al. 2010; Nilnakara et al. 2009; Aziz et al. 2011, 2012; Sun-Waterhouse et al. 2009).

The application of FVR from food processing as raw material for the development of new food products have demonstrated commercial significance, considering worldwide interest in sustainable development of the food industry, reduction of food wastes and also the development of new functional foods (Silva et al. 2009; Yagci and Gogus 2009; Ajila et al. 2010; Canett-Romero et al. 2004; Rosales Soto et al. 2012).

The consumer trends concern nutritious, healthy and natural food (Betoret et al. 2011). Fruit and vegetable blends present numerous advantages, such as flavour and nutritional added-value (Sun-Waterhouse 2011). Blended beverage has appeared as a good option of nutritionally improved product with good sensory acceptance (Bhardwaj and Pandey 2011; Dominguez-Perles et al. 2011; Martins et al. 2011).

Based on the most recent analysis of personal food consumption in Brazil (IBGE 2008) that investigated the foodstuff consumption per capita and preference of the consumer, we have recently proposed an isotonic beverage manufacture based on integral exploitation of several fruits and vegetables species (Martins et al. 2011). The designed isotonic beverage showed a good sensory acceptance and a microbiological stability. Some of the fruits and vegetables used are known to produce a large amount of waste (e.g. watermelon, passion fruit, orange, taro), mainly because when processed they are not fully exploited. Despite the efforts to minimize the waste generation through the full utilization of the raw material, the amount of solid residue generated remained high. In this context, the main idea of this work was to develop sustaining and functional food products based on the residue generated from the isotonic beverage production. This residue was processed into flour (FVR) and incorporated with different levels into biscuits and cereal bars. The aims of this study were i) to evaluate the functional properties of the FVR flour, ii) the proximate composition, iii) the microbiological stability and iv) the consumer acceptability of the FVR flour and of the developed products.

Materials and methods

Plant materials

In this study, the following species of fruits were used: Selecta orange (Citrus sinensis), passion fruit (Passiflora edulis) and watermelon (Citrullus lanatus). The following species of vegetables were used: lettuce (Lactuca sativa), courgette (Cucúrbita pepo), carrot (Daucus carota), spinach (Spinacea oleracea), mint (Mentha s.p.), taro (Colocasia esculenta), cucumber (Cucumis sativus) and rocket (Eruca sativa). All species were purchased from a local supermarket (Rio de Janeiro, Brazil) and were taken to the laboratory for immediate use. Fruits and vegetables were properly washed in flowing water, after they were sanitized for 30 min in a bath containing 200 ppm of sodium hypochlorite (NaClO) before rinsing in flowing water again.

Isotonic beverage preparation

Preliminary tests with different proportions of the fruits and vegetable species were performed and accompanied by sensory analysis. After preliminary tests, the final formulation of the concentrated juice contained 50 % vegetables (approximately 2 % mint and rocket; 5.5 % lettuce, spinach and taro; 8.5 % cucumber and courgette and 13 % carrot) and fruits (11 % orange; 19 % passion fruit and 22 % watermelon). Whole fruits and vegetables were cut into pieces, weighed and processed by using a centrifugal Juicer (Phillips Wallita, Brazil). The concentrated juice was kept at −18 °C in plastic bags after pasteurization (60 °C for 60 min).

The adjustments of carbohydrate (method 925.46) and sodium (method 960.29) contents were performed in quadruplicate on the freshly concentrated juice (AOAC 1984). The upper limit of carbohydrate concentration was established around 8 % (w/v) and the interval of sodium content 460–1,150 mg L−1 based on the suitable concentration for functional isotonic drinks (Brouns and Kovacs 1997). Finally, the isotonic beverage was prepared by addition of water in the proportion 1: 2 of frozen concentrated juice, natural green colour (chlorophyll), mint flavour, xanthan gum (0.3 %, w/w) and sodium citrate (0.1 %, w/w) as previously reported (Martins et al. 2011).

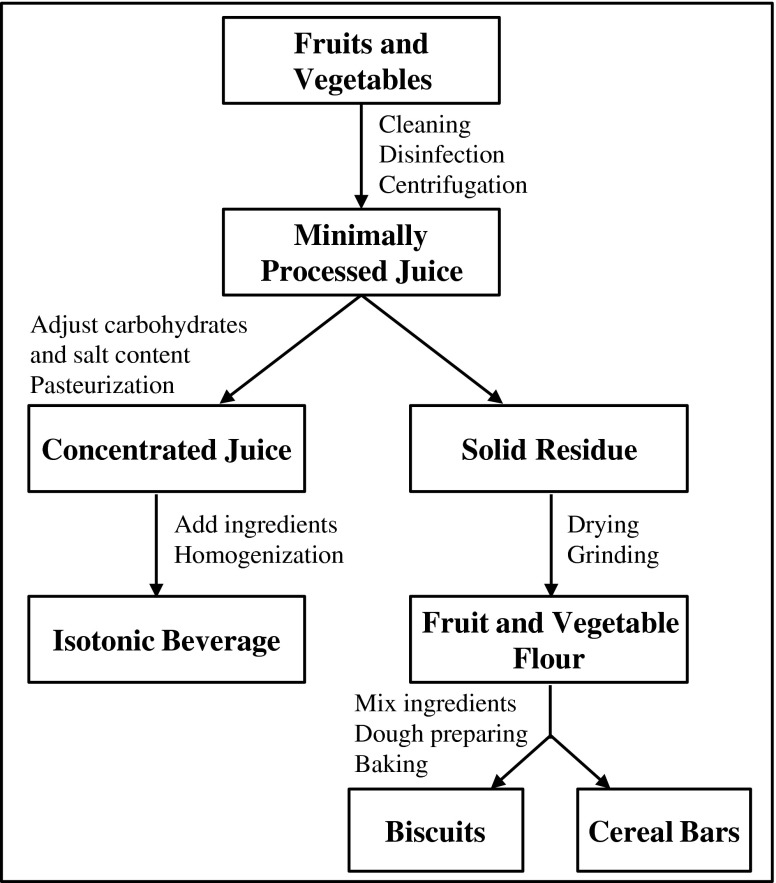

FVR flour processing

After the production of the concentrated juice, the remaining solid residue (FVR) was immediately processed into flour. The FVR was dried in a drying oven with air renewal and circulation (Marconi, model MA035, Brazil) at 65 °C for 6 h. Then, the dehydrated residue was ground using a food processor for 5 min and dried out for 1 h at 90 °C before grinding once more for 1 min. Flour samples were stored at room temperature (RT) in aluminized aseptic bags until further analysis. The flow diagram of the FVR flour production is showed in the Fig. 1.

Fig. 1.

Flow diagram for the isotonic beverage, fruit and vegetable residue flour, biscuit and cereal bars production

The flour yield was determined in three different lots by the relationship between the mass of the solid residue after processing of fresh fruits and vegetables and the mass of the dried flour. The granulometry of FVR flour was determined by sieving 100 g of sample during 10 min on a sieve shaker with the mesh Tyler opening from 40 to 170.

Biscuit preparation

Biscuits were produced from three blend formulations: salty (B1), bittersweet (B2) and sweet (B3) formulation (Table 1). The blends were prepared by mixing wheat flour (WF) with FVR flour in the proportions of 80:20 for the salty and 65:35 for the sweet biscuits. The ingredients were mixed thoroughly in a kitchen aid mixer. The dough was then placed on a cutting board, rolled out until uniform thickness and textures. Biscuits were weighed and cut into desired shape and size. The shaped dough pieces were then baked at 180 °C for 40 min. Once baked, the biscuits were allowed to cool, packaged in aluminized aseptic bags, sealed and stored in cool and dry place.

Table 1.

Formulation of biscuits and cereal bars added with fruit and vegetable residue flour

| Ingredients (g Kg−1) | Biscuit formulations | Cereal bar formulations | ||||

|---|---|---|---|---|---|---|

| Salty | Bittersweet | Sweet | Salty | Sweet | ||

| B1 | B2 | B3 | C1 | C2 | C3 | |

| Fruit and vegetable flour | 120 | 110 | 90 | 150 | 200 | 200 |

| Wheat flour | 480 | 210 | 170 | – | – | – |

| Rice flour | – | – | – | 150 | 200 | – |

| Oat flakes | – | – | – | 150 | 200 | 380 |

| Linseeds | – | – | – | 30 | 30 | 20 |

| Sucrose syrup | – | – | – | – | 330 | 350 |

| Egg white | – | – | – | 320 | – | – |

| Olive oil | 91 | 80 | 60 | 160 | – | – |

| Water | 280 | 270 | 250 | – | – | – |

| Brown sugar | – | 120 | 260 | – | 20 | 35 |

| Cocoa powder | – | 210 | 170 | – | 20 | 15 |

| Condiments | 26 | 1 | 1 | 40 | – | – |

Cereal bars preparation

Three blends of cereal bars varying in composition were prepared: salty (C1) and two sweet (C2 and C3) formulations (Table 1). The samples were prepared by mixing the wet ingredients, heating the sucrose syrup (only for sweet formulations) to boiling temperature and thoroughly blending with the premixed dry ingredients. The resultant mixture was weighed, pressed into rectangular bars (30 mm × 100 mm × 10 mm) and allowed to cool at RT for 6 h. The salty moulded bars were baked at 160 °C for 10 min and cooled at RT. Finally, the cereal bars were packaged in aluminized aseptic bags, sealed and stored in cool and dry place.

Functional and physico-chemical analysis of FVR flour

Solubility, water and oil holding capacities

The solubility, water holding (WHC) and oil holding (OHC) capacities were determined in four replicates based on the standard method proposed by Anderson (1982) with slight modifications. FVR flour (1 g) was accurately weighed into previously tared 15 mL Falcon tubes. Next, 10 mL of distilled water (or vegetal oil) was pipetted into the tubes containing the samples. The suspensions were stirred at RT and centrifuged (1,500 × g 30 min). The supernatants were dried to a constant weight at 105 °C. The residue obtained represented the amount of flour granules solubilised in water (g of dry weight per 100 g of FVR, dry basis). After centrifugation, each tube was weighed then the WHC and OHC were calculated as g water or oil per g of dry sample, respectively.

Total titratable acidity

The total titratable acidity (TTA) was determined in four replicates in freshly prepared FVR flour and during its storage until 120 days. Five grams was homogenized with 30 mL of 95 % ethyl alcohol and the corresponding TTA was performed by titrating against 0.1 M NaOH using bromothymol blue indicator (Gonçalves 2009). The results were calculated as citric acid equivalent and were expressed as g Kg−1 of FVR flour.

Proximate composition analysis

The proximate composition of the FVR flour, biscuits and cereal bars was analyzed. The moisture, ash, crude fat, crude fibre and protein (N × 6.25) contents were determined according the standard methods (AOAC 1984). Crude fibre content was determined by acid and further alkaline digestion (90 °C for 1 h) on a fibre digester (Marconi, MA-444, Brazil). The content of available carbohydrates was determined by difference from the protein, fat, moisture, ash and crude fibre contents. Caloric values were computed using the Atwater general factor system: carbohydrate (4 Kcal g−1), lipid (9 Kcal g−1) and protein (4 Kcal g−1). All experiments were performed on four replicates.

Evaluation of microbiological stability

The microbial stability of FVR flour, biscuits and cereal bars was evaluated attending to the specifications of the International standards CODEX Alimentarius (CAC/GL 21–1997) (CAC 1997). The microbiological stability of the FVR flour, biscuits and cereal bars was evaluated in duplicate at 0, 30 and 90 days by analyzing the total viable aerobic mesophilic bacteria, Escherichia coli, Bacillus cereus, Staphylococcus aureus, yeast and mold counts and also the verification of the presence of Salmonella sp, coliforms at 35 °C and 45 °C (Downes and Ito 2001; ICMSF 1986). The maximum accepted levels followed the Brazilian regulations (RDC nº12) of food microbiological standards (Brasil 2001). This legislation establishes microbiological standards, based on the CODEX Alimentarius, separated by category; the categories considered were fruit and vegetable products, flour and baking products.

Consumer acceptability

A total of 100 consumers were recruited from Nutrition School to evaluated the cereal bars and 90 for evaluation of biscuits. These consumers consisted of both genders between the ages of 17 and 68. Biscuits and 1/3 of bar samples were presented on odourless white plastic plates at RT with three-digit random number codes. These samples were rated for overall acceptability, appearance, colour, taste and texture. Evaluations were conducted using a nine-point hedonic scale to determine the degree of liking (9 = like extremely, 5 = neither like nor dislike, 1 = dislike extremely) according to Stone and Sidel (1992). The purchase intent was measured on a five-point scale (from 5 = definitely would buy to 1 = definitely would not buy).

Statistical analysis

All results were statistically examined by using one-way analysis of variance (ANOVA) and significant differences were determined using Tukey’s test at a significance level of p < 0.05, performed using the software Assistat (7.5 beta, 2010). Three lots of FVR flour were studied and all analyses in this study were performed in four independent replicates.

Results and discussion

The composite flour (FVR) was produced from the solid residue based on the entire exploitation of several fruits and vegetables after the isotonic preparation. The total weight of this residue was approximately 1 kg, after processing it was reduced by approximately 100 g of flour. Therefore, the FVR flour production provided a 10 % yield. The processed flour presented a maximum particle size of 75 μm, being completely retained on the first mesh.

Physico-chemical analysis

Solubility, water and oil holding capacity of FVR flour

The water holding capacity (7.43 g/g flour) of FVR was higher than oil holding capacity (1.91 g/g flour) (Table 2). This difference may be related to the main composition of the residue of fruits and vegetables, rich in monosaccharide and polysaccharides and their derivatives, such as pectin, which have in their chemical structure many available hydrophilic groups to connect the water molecule through hydrogen bonds. Both, WHC and OHC are important functional properties that have been widely studied in food, as they are associated with food quality. The WHC of FVR flour was higher than those from the mango kernel processed flour, rice flour, soy flour and dietary fibres of cereals bran and comparable to the apple fibre, i.e. 1.9, 2.4, 4.8–6.7, 2.1–5, 9.4 g of water/g of dry matter, respectively (Arogba 1997; Heywood et al. 2002; Silva and Ascheri 2009; Chen et al. 1988). The OHC of FVR resembled the values from mango kernel processed flour and commercial preparations of dietary fibres (i.e. 0.9 and 1.29 g of oil/g of dry matter) (Abdul-Hamid and Luan 2000; Arogba 1997). Another important functional property is the solubility in water. This relates to the amount of soluble solids in the sample. The percentage of water solubility of FVR flour (17.3 %) was superior to that found in rice flour (1.1 %) and similar to sweet potato flour (16.6 %) (Silva and Ascheri 2009; Borba et al. 2005). Fruit-based flour has been appointed as suitable for incorporation in dough and pastry products due to the exhibited functional properties (Arogba 1997; Aziz et al. 2012).

Table 2.

Functional properties of the fruit and vegetable residue (FVR) flour

| Water holding capacity (WHC) (g water/g FVR flour) | 7.43 ± 1.25 |

| Oil holding capacity (OHC) (g oil/g FVR flour) | 1.91 ± 0.40 |

| Solubility (%, d.b.) | 17.27 ± 0.52 |

Values are means ± standard deviation (n = 4)

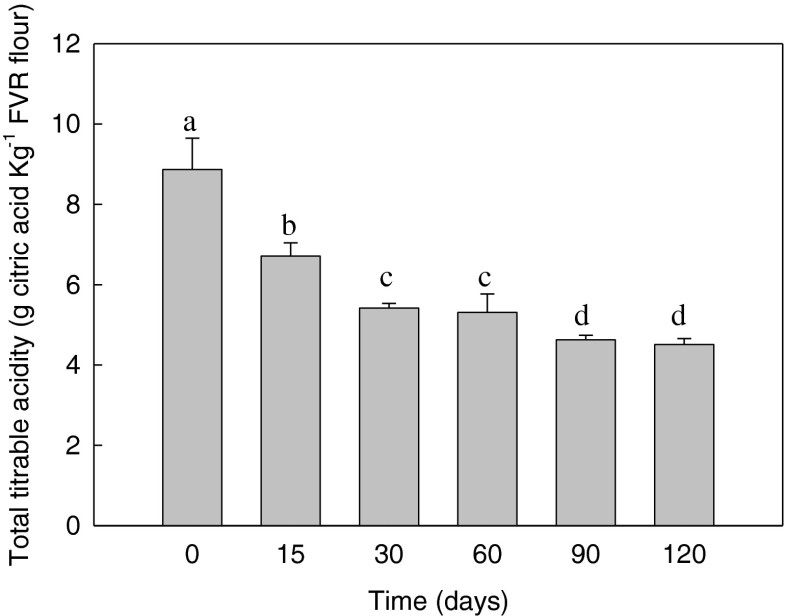

Changes in the total titratable acidity of fruit and vegetable residue flour

The acidity determination can provide important data to assess the conservation state of the product, since a decomposition process by hydrolysis or oxidation, often changes the sensory and nutritional characteristics of the product. The results of the changes in the acidity of FVR flour during its storage showed a progressive decrease in the TTA until 120 days (Fig. 2). After 90 days, the TTA level decreased significantly by 50 %, from 8.87 ± 0.78 g citric acid Kg−1 FVR to 4.63 ± 0.11 g citric acid Kg−1 FVR and remained stable until 120 days. These results are in agreement with our unpublished results showing a significantly decrease in the TTA in FVR-based biscuits storage until 90 days (data not published). Similar levels of TTA (7–10 g citric acid Kg−1) were observed for the blend of wheat and mango kernel flour and manufactured biscuits (Arogba 1999). However, no information is available in the literature concerning the evolution of TTA during storage. The importance of the TTA decrease could be related to the control of microorganism growth, since this parameter is accompanied of a pH increase and a raise of the total soluble solids. Considering that the FVR flour was produced from whole plants, including peels and seeds, the decrease in the TTA can be explained by the continuous metabolic changes of organic acids into carbon dioxide and water. Moreover, high levels of reducing substances, such as tannins, polyphenols and carotenoids, have been described to be present in fruit and vegetable by-products (Ajila et al. 2007; Ayala-Zavala et al. 2010).

Fig. 2.

Changes in the titratable acidity during the storage of the fruit and vegetable residue flour. Vertical bars indicate average and standard deviation (n = 4) and different letters show significantly difference (p < 0.05)

Proximate composition

The proximate composition of FVR flour indicated low humidity and high levels of available carbohydrates, fibres, proteins, ash and lipids (Table 3). The high concentration of carbohydrates, proteins and lipids gave a caloric value of 296 kcal per 100 g. The high concentration of carbohydrates and fibres resulted from the main components of the FVR flour: peels and seeds, which are rich in starch, cellulose, hemicelluloses, lignin, pectin and other biopolymers. In the same way, these components were responsible by the high mineral concentration. Crude fibre and mineral contents were approximately eight-fold higher and the fat content four-fold higher than that in WF (Arogba 1999; Madruga and Camara 2000). The low moisture content found in FVR flour has a positive influence on storage stability, textural quality, chemical and biochemical reactions. Moreover, the incorporation of FVR in bakery products improved dietary fibre and functional properties (Ajila et al. 2008). The composition results indicated valuable features for the elaboration of bakery products rich in fibres and minerals and also presenting a considerable energetic value.

Table 3.

Proximate composition of biscuits and cereal bars added with fruit and vegetable residue flour

| Fractions (g Kg−1 d.b.) | Fruit and vegetable flour | Biscuit formulations | Cereal bar formulations | ||||

|---|---|---|---|---|---|---|---|

| Salty | Bittersweet | Sweet | Salty | Sweet | |||

| B1 | B2 | B3 | C1 | C2 | C3 | ||

| Moisture | 58.8 ± 4.88 | 52.4 ± 3.83a | 53.9 ± 4.59a | 175.1 ± 2.18b | 136.2 ± 3.32b | 274.6 ± 23.22a | 293.6 ± 9.57a |

| Ash | 49.3 ± 4.07 | 25.1 ± 0.64a | 36.7 ± 1.89b | 35.0 ± 1.84b | 32.7 ± 1.10a | 14.0 ± 1.22c | 18.1 ± 1.78b |

| Protein | 95.2 ± 16.81 | 48.6 ± 1.84a | 102.9 ± 5.17b | 65.8 ± 3.84c | 143.2 ± 1.41a | 73.9 ± 1.08b | 41.3 ± 2.12c |

| Fat | 50.9 ± 5.04 | 115.7 ± 1.68a | 97.9 ± 2.91b | 97.5 ± 2.91b | 132.2 ± 3.82a | 19.3 ± 1.10c | 28.6 ± 0.97b |

| Crude Fibre | 215.2 ± 16.07 | 57.1 ± 10.41a | 117.5 ± 13.41b | 83.7 ± 6.01c | 72.2 ± 5.87a | 75.5 ± 3.86a | 78.7 ± 1.64a |

| Available carbohydrate | 530.6 | 701.1 | 591.5 | 542.9 | 483.5 | 542.7 | 539.7 |

| Calories (kcal per 100 g) | 296 | 404 | 365 | 331 | 370 | 264 | 258 |

Values are means ± standard deviations (n = 4). For each product, mean values followed by different letters within the same line differ significantly (p < 0.05). Refer to Table 1 for biscuit and cereal bar formulations

The proximate composition of the developed products is showed in the Table 3. The moisture content of the sweet biscuit (B3) was significantly higher than the others, due to the sugar addition in this formulation, since it is a very hygroscopic ingredient and given that similar amounts of water were used in all formulations. Contrary to expectations, due to the water holding capacity of fibres, the moisture content did not increased when the amount of FVR flour increased (compare B1 and B2 formulations, which presented respectively 20 % and 35 % of FRV). This result is in agreement with Canett-Romero et al. (2004), who showed no differences in the moisture content of cookies added of different proportions of deseeded grape pomace. The protein, ash and fibre contents observed in the B2 and B3 biscuits, were significantly higher than in the B1, since the formers presented a higher (35 %) level of FVR flour than B1 (20 %). The mineral content can also be explained by the presence of cocoa powder in these formulations. The addition of FVR flour do not contributed to a higher fat content, since the B1 formulation presented the highest fat content. It was rather associated to the olive oil used in this formulation. The highest carbohydrate content of B1 samples was attributed to the additional proportion of WF (25 %).

Sweet cereal bars (C2 and C3) showed significantly higher moisture contents than the salty bar (C1), which was baked while the sweet bars just rested at RT. In addition, the moisture content increased when the total amount of flour (FVR, rice and oat flakes) increased, it can be attributed to the water holding capacity of the present fibres. Despite the high water content, cereal bars showed a good microbiological stability until 30 days. Crude fibre and available carbohydrate contents did not differ in relation to the level of FVR addition, showing the cereal contribution. The fibre and protein contents were similar to those found in fruit-based snack bars (Silva et al. 2009; Sun-Waterhouse et al. 2010). Similarly to biscuit samples, the highest fat content of the salty bar was related to the presence of olive oil, whereas sweet samples presented a very low fat content.

The increment of FVR flour in all formulations developed promoted a significantly improvement in the fibre fractions when compared to similar commercial products (data not shown).

Microbiological tests

All food products designed with the fruit and vegetable flour were complied with the CODEX Alimentarius standards and were negative for Salmonella sp., coliforms (at 35 °C and 45 °C) and Escherichia coli (<0.3 MPN g−1). All samples met the standard set for specific counting of each category according to Brazilian standard regulation.

The evolution of microbiological profile of the samples during storage until 90 days was also analyzed. Excepted for the sweet cereal bars (C2 and C3), that after 30 days presented visible growth of molds and yeasts being consequently discarded, all samples met the standard set for specific recommendations of Brazilian standard regulation for each category and did not present exceeding microbiological limits or degradation symptoms for 0, 30 and 90 days. The growth of molds and yeast in the sweet cereal bars after 30 days of storage is related to the high moisture content found in these samples (Table 3). For the conservation of these products additional studies, changing the packaging or the processing and adding preservatives should be carried out. Salty cereal bars and also FRV flour and biscuit samples presented a regular profile in the molds and yeast counts ranging from 100 CFU g−1 for salty bars and 30 CFU g−1 for FRV flour in the time zero. During the storage period all samples presented counts inferior to 10 CFU g−1.

For all samples analysed, the microbiological examination for Staphylococcus aureus was minimal (<0.3 MPN g−1) and are within acceptable limits (<100 MPN g−1, for vegetables dehydrated, dried or freeze-dried; <500 MPN g−1, for cookies and biscuits). The counting of Bacillus cereus ranged from <10 to 20 CFU g−1 being within the legal standards for cereal bars.

Because microorganisms play significant role in the determination of shelf lives of food products, we investigated the level of viable aerobic mesophilic bacteria. The results, expressed as log CFU g−1, ranged from 4.15, 4.59 to 4.90 for the FVR flour, respectively after 0, 30 and 90 days of storage. The counting for biscuits and cereal bars samples were in the same range but decreased during the storage (4.04 to 1.48 and 3.72 to 1.30, respectively for biscuits and bars after 0 and 90 days). Despite of some elevated values and a slightly increasing profile mainly in the FVR flour, this parameter cannot be used to dispose of the samples, since there is no standard value specified for the presence of these microorganisms in food products. Therefore, these numbers have only an informative purpose.

Evaluation of consumer acceptability

The FVR flour was obtained from the solid residue generated in the isotonic beverage process. The consumer acceptance of this beverage was previous studied and showed a good sensory acceptance, averaging around 7 for the general appearance (Martins et al. 2011).

The consumer acceptance of biscuits did not differ significantly (p < 0.05) between the salty (B1) and sweet (B3) formulations (Table 4). For this reason the sensory evaluation of the bittersweet formulation (B2) was not performed. The evaluation of the consumer acceptance was also performed after 0, 30 and 90 days of storage (data not shown). Although without significant differences, the global rate of acceptance increased after the storage period, probably due to an improvement of texture. All attributes presented higher rates for sweet than salty biscuits. Accordingly, the sweet biscuit presented a higher purchase potential of 3.4, with approximately 50 % of consumers appointing between “definitely” and “probably would buy”, than the salty biscuit with a score of 3.1, where only about 30 % selected these options.

Table 4.

Sensory quality of biscuits (n = 90) and cereal bars (n = 100) containing fruit and vegetable residue flour

| Sensory attribute | Biscuit formulations | Cereal bars formulations | |||

|---|---|---|---|---|---|

| Salty | Sweet | Salty | Sweet | ||

| B1 | B3 | C1 | C2 | C3 | |

| Appearance | 4.7 ± 0.38a | 5.6 ± 0.48a | 6.3 ± 0.14a | 6.3 ± 0.16a | 6.6 ± 0.15a |

| Taste | 5.2 ± 0.33a | 5.6 ± 0.44a | 7.0 ± 0.13a | 6.2 ± 0.18b | 6.8 ± 0.18a |

| Colour | 5.3 ± 0.35a | 6.2 ± 0.33a | 6.2 ± 0.16a | 6.4 ± 0.16a | 6.7 ± 0.14a |

| Texture | 5.5 ± 0.40a | 5.8 ± 0.40a | 6.8 ± 0.13a | 6.8 ± 0.17a | 7.2 ± 0.16a |

| Overall acceptance | 5.5 ± 0.24a | 5.8 ± 0.38a | 6.7 ± 0.10a | 6.3 ± 0.17a | 6.6 ± 0.14a |

Values are means ± standard errors. For each product, mean values followed by different letters within the same line differ significantly (p < 0.05). Refer to Table 1 for biscuit and cereal bar formulations

The consumer acceptance of cereal bar formulations did not significantly differ (p < 0.05), only taste attribute of the sweet sample (C2) differed negatively from the other samples. It could be attributed to the lower sugar content and the higher cereal content within its formulation, impacting negatively to the flavour and texture. Although without significant difference, the sweet sample (C3) averaged slightly better for colour, appearance and texture and the salty sample (C1) obtained the highest rate for taste. The salty bar (C1) presented also the greatest purchase potential of 3.9, with 73 % of consumers indicated “certainly would buy” or “probably would buy”. This result may be attributed to the originality of this product, differing from the commercial types in the market. The sweet bars obtained lower purchase intention, with 3.6 and 3.7 for C2 and C3 respectively, but still showing the preponderance of the purchase intention of about 60 %.

Taking all results together, incorporation of FVR flour in the different formulations did not significantly impacted consumer acceptance (p > 0.05). The sensory attributes averaged around 6 (“liked slightly”), demonstrating that the FVR-containing products did not have particularly high consumer ratings. Similar findings were reported by Ajila et al. (2008) for biscuits substituted in 20 % with mango peel powder and by Noor Aziah and Komathi (2009) in a composite flour crackers produced with unripe mango pulp and peel. Moreover, Kumari and Grewal (2007) showed that incorporation of carrot pomace up to 20 % into biscuit formulations did not change the sensory attributes.

Conclusion

This study reported a feasible and sustainable food processing without waste generation. Results showed that the high fibre, protein and mineral contents and also the WHC and OHC of the FVR flour are potentially suitable for use in food applications as a new low-calorie and functional raw material. The designed products presented high fibre content, reasonable consumer acceptance and were microbiologically stable. This research promotes the reducing food waste since whole plant tissues have been used leading to the maximum exploitation of food raw materials.

Acknowledgments

The authors thank the Brazilian funding institute CAPES (Coordination for the Improvement of Higher Education Personnel) for the financial support.

Abbreviations

- FVR

Fruit and vegetable residue

- OHC

Oil holding capacity

- TTA

Total titratable acidity

- WHC

Water holding capacity

- WF

Wheat flour

References

- Abdul-Hamid A, Luan SY. Functional properties of dietary fibre prepared from defatted rice bran. Food Chem. 2000;68:15–19. doi: 10.1016/S0308-8146(99)00145-4. [DOI] [Google Scholar]

- Ajila CM, Naidu KA, Bhat SG, Rao UP. Bioactive compounds and antioxidant potential of mango peel extract. Food Chem. 2007;105:982–988. doi: 10.1016/j.foodchem.2007.04.052. [DOI] [Google Scholar]

- Ajila CM, Leelavathi K, Rao U. Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J Cereal Sci. 2008;48:319–326. doi: 10.1016/j.jcs.2007.10.001. [DOI] [Google Scholar]

- Ajila CM, Aalami M, Leelavathi K, Rao U. Mango peel powder: A potential source of antioxidant and dietary fiber in macaroni preparations. Innov Food Sci Emerg Technol. 2010;11:219–224. doi: 10.1016/j.ifset.2009.10.004. [DOI] [Google Scholar]

- Anderson RA. Water absorption and solubility and amylograph characteristics of roll-cooked small grain products. Cereal Chem. 1982;59:265–269. [Google Scholar]

- AOAC . Official methods of analysis. 14. Washington DC: Association of Official Analytical Chemists; 1984. [PubMed] [Google Scholar]

- Arogba SS. Physical, chemical and functional properties of nigerian mango (mangifera indica) kernel and its processed flour. J Sci Food Agric. 1997;73:321–328. doi: 10.1002/(SICI)1097-0010(199703)73:3<321::AID-JSFA722>3.0.CO;2-4. [DOI] [Google Scholar]

- Arogba SS. The performance of processed mango (mangifera indica) kernel flour in a model food system. Bioresour Technol. 1999;70:277–281. doi: 10.1016/S0960-8524(99)00028-0. [DOI] [Google Scholar]

- Ayala-Zavala JF, Rosas-Domínguez C, Vega-Vega V, González-Aguilar GA. Antioxidant enrichment and antimicrobial protection of fresh-cut fruits using their own by-products: Looking for integral exploitation. J Food Sci. 2010;75:175–181. doi: 10.1111/j.1750-3841.2010.01792.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ayala-Zavala JF, Vega-Vega V, Rosas-Dominguez C, Palafox-Carlos H, Villa-Rodriguez JA, Siddiqui MW, Davila-Avina JE, Gonzalez-Aguilar GA. Agro-industrial potential of exotic fruit byproducts as a source of food additives. Food Res Int. 2011;44:1866–1874. doi: 10.1016/j.foodres.2011.02.021. [DOI] [Google Scholar]

- Aziz NAA, Ho L-H, Azahari B, Bhat R, Cheng L-H, Ibrahim MNM. Chemical and functional properties of the native banana (musa acuminata x balbisiana colla cv. Awak) pseudo-stem and pseudo-stem tender core flours. Food Chem. 2011;128:748–753. doi: 10.1016/j.foodchem.2011.03.100. [DOI] [Google Scholar]

- Aziz NAA, Wong LM, Bhat R, Cheng LH. Evaluation of processed green and ripe mango peel and pulp flours (mangifera indica var. Chokanan) in terms of chemical composition, antioxidant compounds and functional properties. J Sci Food Agric. 2012;92:557–563. doi: 10.1002/jsfa.4606. [DOI] [PubMed] [Google Scholar]

- Betoret E, Betoret N, Vidal D, Fito P. Functional foods development: Trends and technologies. Trends Food Sci Technol. 2011;22:498–508. doi: 10.1016/j.tifs.2011.05.004. [DOI] [Google Scholar]

- Bhardwaj RL, Pandey S. Juice blends- a way of utilization of under-utilized fruits, vegetables, and spices: A review. Crit Rev Food Sci Nutr. 2011;51:563–570. doi: 10.1080/10408391003710654. [DOI] [PubMed] [Google Scholar]

- Borba AM, Sarmento SBS, Leonel M. Effect of extrusion parameters on sweet potato extrudates. Cienc Tecnol Aliment. 2005;25:835–843. doi: 10.1590/S0101-20612005000400034. [DOI] [Google Scholar]

- Brasil (2001) Regulamento técnico sobre os padrões microbiológicos para alimentos—rdc nº 12, de 2 de janeiro de 2001. Agência Nacional de Vigilância Sanitária

- Brouns F, Kovacs E. Functional drinks for athletes. Trends Food Sci Technol. 1997;8:414–421. doi: 10.1016/S0924-2244(97)01098-4. [DOI] [Google Scholar]

- CAC (1997) Principles for the establishment and application of microbiological criteria for foods, vol 1B. Codex alimentarius commission. Joint FAO/WHO Food Standards Programme, Codex Committee on Food Hygiene

- Canett-Romero R, Ledesma-Osuna AI, Robles-Sánchez RM, Morales-Castro R, León-Martínez L, León-Gálvez R. Characterization of cookies made with deseeded grape pomace. Arch Latinoam Nutr. 2004;54:93–99. [PubMed] [Google Scholar]

- Carle R, Schieber A. Functional food components obtained from waste of carrot and apple juice production. Gewinn Funct Lebensm Restst Karottensaft. 2006;53:348–352. [Google Scholar]

- Chen H, Rubenthaler GL, Leung HK, Baranowski JD. Chemical, physical, and baking properties of apple fiber compared with wheat and oat bran. Cereal Chem. 1988;65:244–247. [Google Scholar]

- Dominguez-Perles R, Moreno DA, Carvajal M, Garcia-Viguera C. Composition and antioxidant capacity of a novel beverage produced with green tea and minimally-processed byproducts of broccoli. Innov Food Sci Emerg Technol. 2011;12:361–368. doi: 10.1016/j.ifset.2011.04.005. [DOI] [Google Scholar]

- Downes FP, Ito K. Compendium of methods for the microbiological examination of foods. 4. Washington, DC: American Public Health Association; 2001. [Google Scholar]

- Figuerola F, Hurtado ML, Estevez AM, Chiffelle I, Asenjo F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chem. 2005;91:395–401. doi: 10.1016/j.foodchem.2004.04.036. [DOI] [Google Scholar]

- Gonçalves ECBA. Análise de alimentos: Uma visão química da nutrição. 2. São Paulo: Varela; 2009. [Google Scholar]

- Gustavsson J, Cederberg C, Sonesson U, Van Otterdijk RAM. Global food losses and food waste: Extent, causes and prevention. Rome: Food and Agriculture Organization of the United Nations (FAO); 2011. [Google Scholar]

- Heywood AA, Myers DJ, Bailey TB, Johnson LA. Functional properties of low-fat soy flour produced by an extrusion-expelling system. Am Oil Chem Soc. 2002;79:1249–1253. doi: 10.1007/s11746-002-0635-y. [DOI] [Google Scholar]

- ICMSF . Microorganisms in foods. Sampling for microbiological analysis: Principles and specific applications. International commission on microbiological specifications for foods. London: Blackie Academic & Professional; 1986. [Google Scholar]

- Kumari S, Grewal RB. Nutritional evaluation and utilization of carrot pomace powder for preparation of high fiber biscuits. J Food Sci Technol. 2007;44:56–58. [Google Scholar]

- Laufenberg G, Kunz B, Nystroem M. Transformation of vegetable waste into value added products: (a) the upgrading concept; (b) practical implementations. Bioresour Technol. 2003;87:167–198. doi: 10.1016/S0960-8524(02)00167-0. [DOI] [PubMed] [Google Scholar]

- Madruga MS, Camara FS. The chemical composition of “Multimistura” As a food supplement. Food Chem. 2000;68:41–44. doi: 10.1016/S0308-8146(99)00152-1. [DOI] [Google Scholar]

- Martins RC, Chiapetta SC, Paula FD, Gonçalves ECBA. Evaluation isotonic drink fruit and vegetables shelf life in 30 days. Braz J Food Nutr. 2011;22:623–629. [Google Scholar]

- Nilnakara S, Chiewchan N, Devahastin S. Production of antioxidant dietary fibre powder from cabbage outer leaves. Food Bioprod Process. 2009;87:301–307. doi: 10.1016/j.fbp.2008.12.004. [DOI] [Google Scholar]

- Noor Aziah A, Komathi CA. Acceptability attributes of crackers made from different types of composite flour. Int Food Res J. 2009;16:479–482. [Google Scholar]

- Pesquisa de orçamentos familiares - aquisição alimentar domiciliar per capita brasil e grandes regiões (2008) Instituto Brasileiro de Geografia e Estatística. http://www.ibge.gov.br/home/estatistica/populacao/condicaodevida/pof/default.shtm. Accessed 19 February 2013

- Rosales Soto MU, Brown K, Ross CF. Antioxidant activity and consumer acceptance of grape seed flour-containing food products. Int J Food Sci Technol. 2012;47:592–602. doi: 10.1111/j.1365-2621.2011.02882.x. [DOI] [Google Scholar]

- Schieber A, Stintzing FC, Carle R. By-products of plant food processing as a source of functional compounds - recent developments. Trends Food Sci Technol. 2001;12:401–413. doi: 10.1016/S0924-2244(02)00012-2. [DOI] [Google Scholar]

- Silva RF, Ascheri JLR. Extrusion of broken rice for use as food ingredient. Braz J Food Technol. 2009;12:190–199. doi: 10.4260/bjft2009800900012. [DOI] [Google Scholar]

- Silva IQ, Oliveira BCF, Lopes AS, Pena RS. Cereal bar with the industrial residue of passion fruit. Braz J Food Nutr. 2009;20:321–329. [Google Scholar]

- Sousa MSB, Vieira LM, Da Silva MJM, De Lima A. Nutritional characterization and antioxidant compounds in pulp residues of tropical fruits. Cienc Agrotecnol. 2011;35:554–559. doi: 10.1590/S1413-70542011000300017. [DOI] [Google Scholar]

- Stone H, Sidel JL. Sensory evaluation practices. 2. San Diego: Academic; 1992. [Google Scholar]

- Sun-Waterhouse D. The development of fruit-based functional foods targeting the health and wellness market: A review. Int J Food Sci Technol. 2011;46:899–920. doi: 10.1111/j.1365-2621.2010.02499.x. [DOI] [Google Scholar]

- Sun-Waterhouse D, Wen I, Wibisono R, Melton LD, Wadhwa S. Evaluation of the extraction efficiency for polyphenol extracts from by-products of green kiwifruit juicing. Int J Food Sci Technol. 2009;44:2644–2652. doi: 10.1111/j.1365-2621.2009.02097.x. [DOI] [Google Scholar]

- Sun-Waterhouse D, Teoh A, Massarotto C, Wibisono R, Wadhwa S. Comparative analysis of fruit-based functional snack bars. Food Chem. 2010;119:1369–1379. doi: 10.1016/j.foodchem.2009.09.016. [DOI] [Google Scholar]

- Yagci S, Gogus F. Development of extruded snack from food by-products: A response surface analysis. J Food Process Eng. 2009;32:565–586. doi: 10.1111/j.1745-4530.2007.00232.x. [DOI] [Google Scholar]

- Zaror CA. Controlling the environmental impact of the food industry: An integral approach. Food Control. 1992;3:190–199. doi: 10.1016/0956-7135(92)90130-3. [DOI] [Google Scholar]