Abstract

Onion powder has an extensive demand and wide application worldwide as flavour additive in convenience foods and medicinal products. Conventionally onion powder is prepared by hot air drying of onion slices followed by grinding. Convective air drying when used alone demands longer drying time and thus has a high expense of energy. As bulk of onion is water (82–87 %), removal of moisture prior to drying can reduce moisture loading on dryer and hence the energy consumption. Keeping this in view, onions were partially dewatered using centrifugal force before convective drying. The effect of partial mechanical dewatering and drying air temperature was studied on drying time, specific energy consumption and onion powder quality (colour and flavour). The combination process was also optimized to achieve increased drying rate and product quality comparable to products obtained using convective drying alone. Onions subjected to 60 % partial mechanical dewatering and hot air drying at 70 °C exhibited significantly (p ≤ 0.5) shortened drying time, decreased energy consumption and maintained colour and flavour of the dried product.

Keywords: Partial mechanical dewatering, Hot air drying, Optimization, Onion, Energy consumption, Quality

Introduction

In the world trade, dehydrated onions has been an important product as flavour additive in soups, sauces, salad dressings, meat products, packet and other processed foods and as products of medicinal value like nutraceuticals. Because of the better storage and easy to use properties, dehydrated onions are in wide demand in places like UK, Japan, Russia, Germany, Netherlands, Spain etc.. European Union alone requires dehydrated onions about 45,000 t per year (International Trade Center, Geneva).

Onions are generally dried from an initial moisture content of about 86 % (wet basis) to 7 % or less to reduce bulk handling, facilitate transportation and allow their use during off-season. The simplest, most economic and conventional method for dehydration of onion is hot air drying. The air drying method is indispensable even though certain problems like shrinkage, poor re hydration and unfavourable changes in colour, texture, flavour and nutritive value may occur (Kaymak-Ertekin and Gedik 2005; Revaskar et al. 2007). Moreover, hot air drying demands longer drying time thus a high expense of energy. To counter these disadvantages, drying methods viz. freeze drying, infrared drying, and vacuum drying alone or as multimode combination has been experimented (Kumar Parveen et al. 2005; Sharma et al. 2005; Pathare and Sharma 2006; Mongpraneet et al. 2002). The technologies improved the quality of end product but involve high processing cost. Osmo-convective drying is an economic alternative to hot air drying but use of osmotic agents adversely affects reconstitution and other properties of dried product (Lenart et al. 1993).

Improvement of hot air drying process is essential if further growth of the onion dehydration industry is envisaged. As bulk of onion is water (82–87 %), reduction of moisture using suitable mechanical means prior to conventional hot air drying can be a simple technique to reduce moisture loading on dryer and hence the energy consumption. Also it is well known fact that each 1 % reduction in feed moisture leads to 4 % less dryer energy input (BEE 2004; Masanet et al. 2008). EEBPP (1996) had reported that energy costs of a British Sugar factory was reduced by 40 times when wet beet pulp was mechanically dewatered prior to dehydration. Different methods of moisture removal are filtration, use of centrifugal force, gravity, mechanical compression, and high velocity air (ISU Extension 2005). Intervention of any one method of dewatering in onion drying process flow chart may have considerable effect on process economics besides yielding valuable products like onion powder and juice. In preliminary trials, two methods of moisture removal viz. screw press and centrifugal juicer were tested for removing moisture from onion. Screw press was ineffective and resulted in pasty material whereas centrifugal juicer was simple to use and effective in initial moisture removal producing a comparatively dried product which took less time to dry. Thus, the objective of the study was to investigate the effect of initial moisture removal using centrifugal force (mechanical dewatering) prior to hot air drying on drying time, energy consumption and colour and flavour (pyruvic acid content) of dried end product.

Material and methods

Materials and sample preparation

Onions (c.v. Punjab Red 06) were procured from vegetable farms of Punjab Agricultural University, Ludhiana. The onions were manually sorted to remove defective pieces and stored at ambient conditions (Temperature 35 °C, Relative Humidity 40 %) till their use in experiments. Onions were washed thoroughly before and after peeling. The surface moisture was removed using blotting paper. Whole lot of peeled onions was divided into three parts. One lot was subsequently sliced into 3 mm thick slices with the help of a stainless steel cutter. The thickness of onion slices was based on practice commonly employed by commercial manufacturers of dehydrated onion (Rapusas and Driscoll 1995). The remaining two lots were cut into four halves using stainless steel knife. The cut onions were subjected to crushing for partial moisture removal in a centrifugal juicer operated at two different levels of speed i.e.11,000 and 19,000 rpm which was measured using a tachometer. The two levels of rpm resulted in 30 % and 60 % dewatering of onion. The sliced onion samples were referred as 0 % dewatering. The ratio of juice extracted in centrifugal juicer to the initial weight of cut onions was expressed as percent dewatering. The centrifugal juicer used incorporated a discoidal rotating cutter plate as macerating device. The cutter plate was located near the base of a frusto-conical filter member disposed in a cylindrical working space. The frusto-conical side wall of the filter member was formed with small holes and narrow slits to permit juice to pass through. The pulp residues blocked by the filter member were dispensed outward from side.

Drying procedure

Samples were dried in tray dryer (Macro Scientific Works, Delhi, India). The dimensions of the drying chamber were height: 1.48 m, width: 1.02 m and depth: 1.12 m. The dryer consisted of stainless steel trays (800x400x30mm, temperature controller (0–300 °C), accuracy ± 1 °C) and a centrifugal fan for constant airflow of 1.2 m/s. The dryer was operated at ambient conditions i.e. 35 °C temperature and 40 % relative humidity. The drying was carried in thin layers with load density of 4 kg/m2 for each tray. The drying was performed at three different temperatures of 50 °C, 60 °C and 70 °C. Drying above 70 °C caused charring of dewatered onion pulp and drying below 50 °C took very long to dry resulting in bad odour. During drying, the weight loss of samples was measured at 1 h interval using an electronic weighing balance with an accuracy of ± 0.1 g which was placed near the tray dryer. The onions were dried till the ratio of raw material to dried product was approximately 9:1 i.e. moisture content in the range of 4 %–5 %. However at moisture content of 7 % temperature of dryer was lowered to 40 °C to reduce energy consumption and prevent discoloration of the end product (Fenwick and Hanley 1990). Dehydrated onion slices and pulp were then grinded using a laboratory grinder to make onion powder which was packed in polyethylene bags for further analyses.

Moisture content and drying rate

The moisture content of fresh onion was determined by the vacuum oven method (AOAC 1990) whereas that of onion powder was measured with infrared moisture analyzer (Kern and Sohn GmbH, Germany). Drying time (T) was noted as time taken to reach moisture content of 7 % (on wet basis). Drying rate (d) was the average value of moisture changes in the total drying time which were calculated using following expression

| 1 |

Where Xd and Xo are the moisture content on dry basis of dehydrated sample and the fresh sample respectively. In case of dewatered sample, Xo was the moisture content of dewatered pulp. Drying rate was expressed as g water/g drying solids min.

Specific energy consumption

Energy consumption was measured using a three phase energy meter (HPL – SOCOMEC, Gurgaon, India) fitted with tray drier with an accuracy of 0.01 kWh. Specific energy consumption expressed as kWh/kg was calculated by dividing total energy requirement obtained from energy meter with initial weight of undried product.

Colour and pyruvic acid content

Colour was measured using Hunter Lab Miniscan XE plus Colorimeter (HAL, USA, model 45 %-L). The instrument was calibrated with standard black and white tiles supplied with the equipment. The setup of the colorimeter was changed to colour scale. The colour of raw onion was measured directly from surface while undried dewatered onion pulp and powder were put in a petri dish for measurement. The nose cone of the colorimeter was so placed that it was in complete contact with the sample surface to prevent leakage of light emitted by the colorimeter. Average of four consecutive readings taken at different places was determined for each sample. The results were expressed as L, a and b respectively. In the Hunter scale, L measures lightness and varies from 100 for perfect white to zero for black, a is the degree of redness (+) and greenness (−), and b measures yellowness (+) and blueness (−).

Colour change (∆E) was defined using the Minolta equation as follows (subscript ‘o’ shows initial value of fresh onion whereas L, a, b represent the colour of onion powder):

| 2 |

Pyruyic acid content (PAC), measure for pungency of onion, was determined by Anthon and Barrett method using reagent 2, 4-dinitrophenylhydrazine (Anthon and Barrett 2003) which was a slight modification to the Schwimmer and Wetson (1961) method. The content was calculated on dry basis and expressed as micromole per 100 g solid.

Synthetic evaluation index

A Synthetic evaluation index (S) was developed as a single process indicator to mirror the effect of partial dewatering and hot air drying on drying rate, specific energy consumption and dried product quality. The index was composed of four response variables (Yi) namely pyruvic acid content (Y1), colour change (Y2), specific energy consumption (Y3) and drying rate (Y4). The degree of significance of these parameters was presumed on the basis of processor and consumer requirement as follows: pyruvic acid content (p) > colour change (∆E)> specific energy consumption (EC) > drying rate (d). Accordingly these four response variables were assigned weight coefficients k1, k2, k3, k4 at 0.4, 0.3, 0.2, and 0.1, respectively. Then synthetic evaluation index(S) (Liu 1998; Gowen et al. 2008) was calculated for each experimental condition using the equations below

| 3 |

Where

Statistical analysis

Statistical analysis was conducted using Statistica 6.0. The data was analyzed using one way ANOVA and Duncan’s multiple range test to detect the significant differences among treatments in colour and pyruvic acid content. The significance of difference was defined at p ≤ 0.05.

Results and discussion

Effect of partial mechanical dewatering on drying characteristics

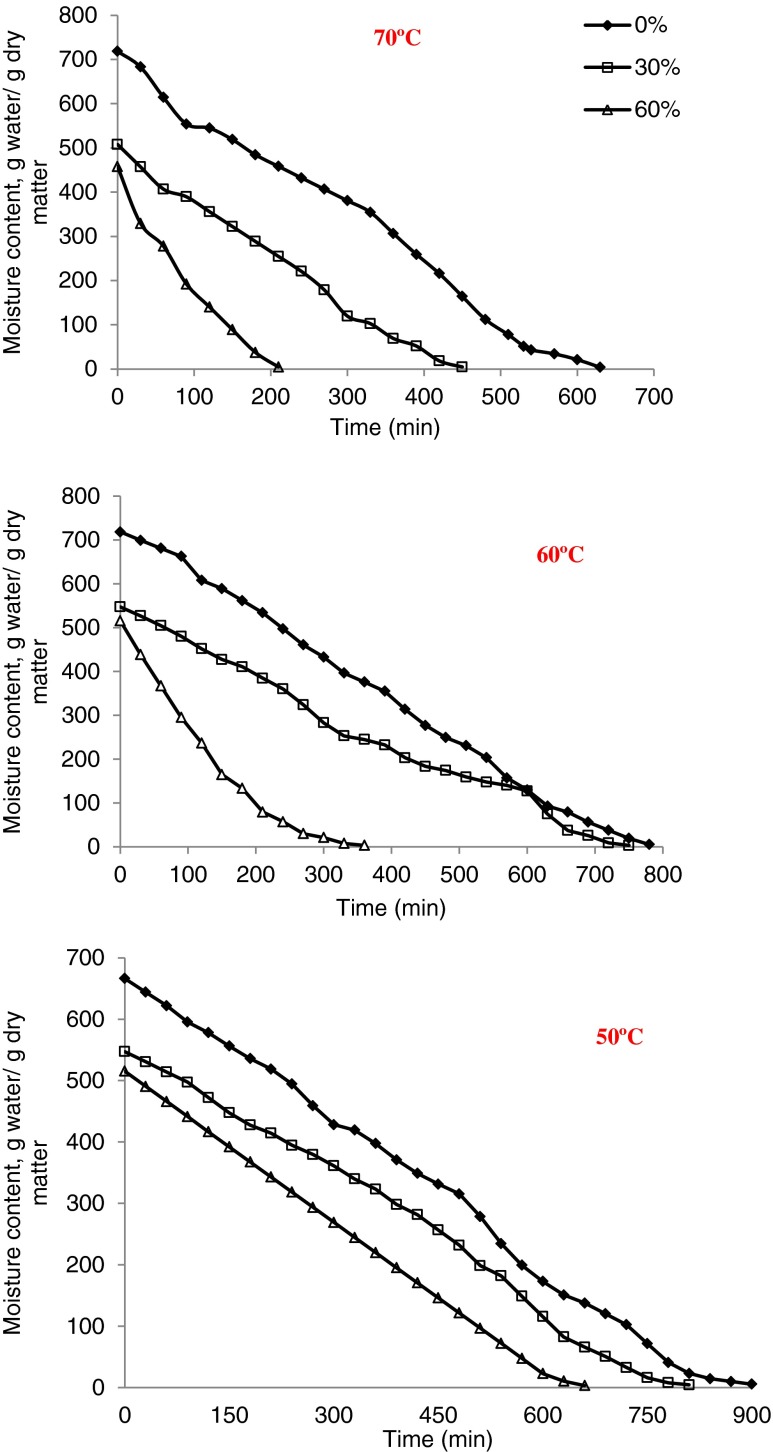

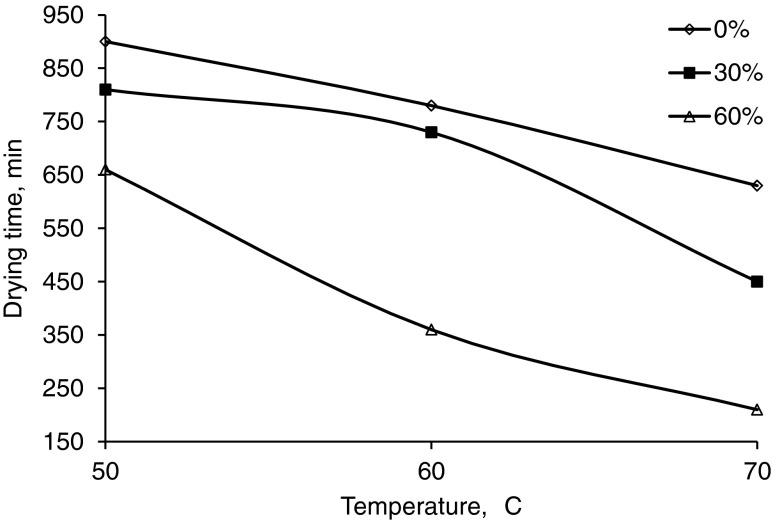

Effect of partial mechanical dewatering as pre-treatment of convective drying was investigated on drying time and moisture curves. At 70 °C, the 60 % dewatered pulp took 66.67 % less time to dry up to moisture content of 7 % (on wet basis). At 60 °C and 50 °C the decrease in drying time for 60 % dewatered pulp was 53.84 % and 26.67 % respectively compared to drying of control sample (3 mm slices, 0 % dewatering). The moisture content decreased at a much faster rate for dewatered samples (Fig. 1). Dewatered pulp has more surface area than slices (Mudahar et al. 1990; EEBPP 1996; Madamba and Bekki 2001; BEE 2004, Kumar Parveen et al. 2005; Arabhosseini et al. 2010; Aversa et al. 2010), which aided in higher heat and mass transfer rate for the samples to be dried. The results corroborate with earlier findings (Vergara et al. 1997; Sarsavadia et al. 1999; Revaskar et al. 2007) where osmotic dewatering prior to drying significantly affected the moisture curves. The drying temperature also affected total drying time (Fig. 2) due to acceleration of moisture migration and increase in air heat supply rate. At 60 % dewatering, longest drying time (210 min) and shortest drying time (900 min) was obtained at 70 °C and 50 °C respectively.

Fig. 1.

Moisture content of onion as a function of drying time for 70 °C, 60 °C and 50 °C and at 0 %, 30 % and 60 % levels of dewatering

Fig. 2.

Effect of mechanical dewatering (0 %, 30 % and 60 %) of onion on drying time

For most fruits and vegetables, drying takes place within both the constant and falling rate periods. Both the external factors and the internal mechanisms controlling the drying processes in the two main rate regimes are important in determining the overall drying rate of products (Gigler et al. 2000). The moisture content of the products as a function of drying time are presented in Fig. 1 for 50, 60 and 70 °C drying air temperatures and for different levels of dewatering, respectively. As evident from Fig. 1, all moisture curves had two stages. The moisture content rapidly reduced and then slowly decreased with increase in drying time (except for drying of 60 % dewatered samples at 50 °C).

Effect of partial mechanical dewatering on specific energy consumption

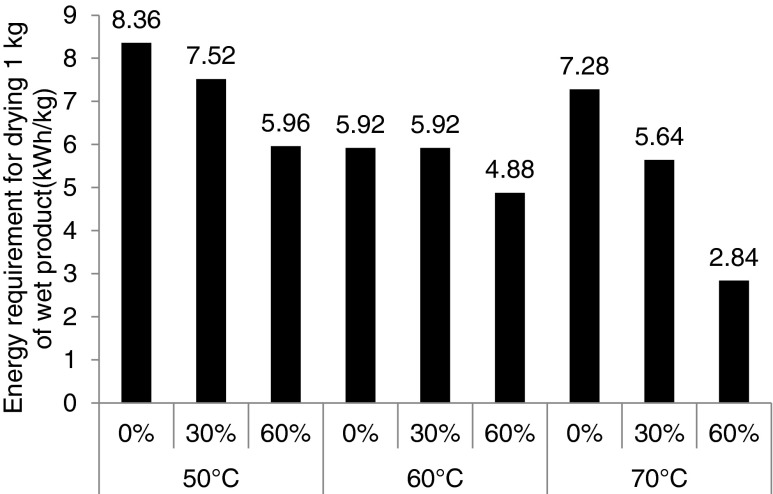

The lowest specific energy consumption of 2.84 kWh/kg was found at 70 °C and 60 % level of dewatering. This was 60.98 % less than energy consumed while drying control samples (3 mm slices, 0 % dewatering) at the same temperature. Also at 50 and 60 °C the energy consumption of 60 % dewatered pulp was less by 28.71 % and 37.84 % respectively as compared to control samples dried at same temperatures (Fig. 3). Thus mechanical dewatering prior to hot air drying had profoundly affected energy consumption. On similar lines, Revaskar et al. (2007) had also reported marginal decrease in energy consumption by drying pre-osmosed onion slices due to partial removal of water from the product before drying. Drying air temperature worked synergistically with the pre-dewatering treatment in reducing the energy consumption (Koyuncu et al. 2004).

Fig. 3.

Specific energy requirement for drying onion at 70 °C, 60 °C and 50 °C and 0 %, 30 % and 60 % levels of dewatering

Effect of partial mechanical dewatering on quality parameters

Drying time and temperature are the most important process parameters which affect sensory characteristics like colour and flavour of dried end product. Thermal damage to the product during drying is directly proportional to the drying time and temperature. In this study it had been observed that even though mechanical dewatering reduced initial levels of pyruvic acid content before drying but retention was more compared to conventional drying of slices due to reduced drying time (Table 1). The maximum retention rate of pyruvic acid content was 79.93 % for dewatered samples as compared to 61.2 % for control samples. This was attributed to reduced drying time which directly affected the flavour retention of dried onion (Prabhanjan et al. 1995; Maskan 2001; Kumar Parveen et al. 2005; Hu et al. 2006).

Table 1.

Effect of drying method on pyruvic acid content, colour values (L,a,b) and colour change (∆E) of onion powder

| Treatment combination | Pyruvic acid content (μmole/g solid) | L | a | b | ∆E | |

|---|---|---|---|---|---|---|

| Percent dewatering (%) | Temperature (°C) | |||||

| 0 | 70 | 13.3 ± 0.28c,d | 61.5 ± 1.36b,c | 5.3 ± 0.20g,h | 10.2 ± 1.16b,c,d,e | 19.4a |

| 30 | 70 | 13.7 ± 0.16c,d | 60.8 ± 2.41b,c | 7.8 ± 0.55e | 8.2 ± 0.38d,e,f | 7.5c |

| 60* | 70 | 10.9 ± 0.44d,e,f,g | 63.6 ± 1.29b,c | 9.9 ± 0.60c | 4.6 ± 0.26g,h | 5.7c |

| 0 | 60 | 11.7 ± 0.15d,e,f | 53.3 ± 1.27d | 5.6 ± 0.28g,h | 8.1 ± 0.13e,f | 14.4b |

| 30 | 60 | 8.6 ± 0.29g,h,i,j | 68.1 ± 0.76a | 6.5 ± 0.16f | 14.9 ± 0.85a | 17.3a |

| 60 | 60 | 9.4 ± 0.18f,g,h,i | 70.7 ± 1.73a | 4.4 ± 0.12i | 14.3 ± 0.36a | 14.2b |

| 0 | 50 | 12.4 ± 0.25c,d,e,f | 52.9 ± 0.96d | 4.8 ± 0.18h,i | 11.7 ± 0.60b,c,d | 17.9a |

| 30 | 50 | 7.4 ± 0.19h,i,j | 68.6 ± 1.36a | 9.3 ± 0.18d | 10.5 ± 1.66b,c,d | 15.2b |

| 60 | 50 | 7.9 ± 0.22g,h,i,j | 63.8 ± 0.43b,c | 11.0 ± 0.04b | 8.5 ± 0.40c,d,e,f | 5.3c |

| Raw onion | 21.8 ± 2.64a | 54.9 ± 1.98d | 16.4 ± 3.62a | 4.0 ± 3.68h | – | |

| Fresh onion pulp (30 % dewatering) | 17.2 ± 1.86b | 54.1 ± 0.76d | 5.7 ± 0.55g,h | 3.5 ± 0.26h | – | |

| Fresh onion pulp (60 % dewatering) | 16.9 ± 1.90b | 59.4 ± 1.22c | 7.4 ± 0.33e | 5.8 ± 0.16g | – | |

Different letters in the same column indicate a significant difference (p ≤ 0.05). (n = 3)

*60 % dewatering and70°C is treatment no. 9 in the orthogonal test

Product colour needs to be maintained during drying and higher L values are desirable in the dried products (Doymaz et al. 2006). Onion powder prepared by grinding dried onion slices were significantly darker (lower L value), less red (lower a value) and more yellow (higher b value) when compared to powder samples obtained from dewatered pulp (Table 1). Fresh onion was more red (higher ‘a’ value) and less yellow (lower ‘b’ value) than dewatered pulp and powder. The colour change (∆E) was minimum in case of dewatered samples dried at 50 °C and 70 °C. This was due to reduced drying time which reduced the intensity of Maillard browning reactions thus minimizing the colour damage (Krokida and Maroulis 1999).

Evaluation of optimal drying condition

Drying temperature is the most important drying process parameters affecting quality of dried end product. Thus, drying air temperature (50 °C, 60 °C and 70 °C) and degree of mechanical dewatering (0 %, 30 %, 60 %) were considered as factors in an orthogonal design of two factors at three levels(L9 (23) to optimize combination of partial mechanical dewatering and hot air drying process for making onion powder. The combination of 60 % dewatering and drying using hot air at 70 °C exhibited the highest synthetic evaluation index of 0.813. This combination required significantly less drying time (188 min) in the whole drying process as compared to 0 % dewatered samples i.e. 3 mm slices (524 min) at the same temperature. This resulted in lower specific energy consumption. Also the foresaid combination had 64.45 % retention of pyruvic acid content and minimum colour change. Mechanical partial dewatering prior to hot air drying greatly reduced the drying time by reducing moisture loads on the dryer and also ensured a good product quality. Polar difference analyses revealed that drying temperature was more significant process parameter than level of dewatering (Table 2). The next combination with second highest value of synthetic evaluation index of 0.783 was combination of 30 % dewatering and 70 °C drying temperature thus further emphasizing the role of temperature in the process.

Table 2.

Testing values and synthetic evaluation index at the design of L9 (23) orthogonal array

| Temperature(°C) | %dewatering | Y1(μmol/g solid) | Y2 | Y3(kWh/kg) | Y4(g/g min) | S |

|---|---|---|---|---|---|---|

| 50 | 0 | 12.380 | 17.94 | 8.36 | 0.734 | 0.349 |

| 50 | 30 | 7.400 | 15.25 | 7.52 | 0.692 | 0.119 |

| 50 | 60 | 7.920 | 5.28 | 5.96 | 0.801 | 0.427 |

| 60 | 0 | 11.720 | 14.40 | 5.92 | 0.914 | 0.483 |

| 60 | 30 | 8.611 | 17.34 | 4.88 | 0.748 | 0.251 |

| 60 | 60 | 9.408 | 14.22 | 3.68 | 1.538 | 0.465 |

| 70 | 0 | 13.330 | 19.45 | 7.28 | 1.134 | 0.443 |

| 70 | 30 | 13.740 | 7.51 | 5.64 | 1.118 | 0.780 |

| 70 | 60 | 10.930 | 5.74 | 2.84 | 2.159 | 0.813 |

| 0.299 | 0.425 | |||||

| 0.400 | 0.384 | |||||

| 0.679 | 0.568 | |||||

| 0.380 | 0.185 |

aA1, A2, A3 are the average values of total evaluation related with the same factor at three levels, respectively

bR = Aimax-Aimin, i = 1,2,3

Conclusions

Effect of mechanical dewatering prior to hot air drying was investigated on drying time, specific energy consumption, flavour and colour of dried product. The combination of 60 % dewatering and drying using hot air at 70 °C was found to be optimal in terms of product flavour, colour change, drying rate and specific energy consumption. At 70 °C, the 60 % dewatered pulp took 66.67 % less time to dry up to moisture content of 7 % (on wet basis), as compared to drying of 3 mm slices. The reduced drying time ensured good quality onion powder with less colour change and better retention of pyruvic acid. Moreover mechanical dewatering does not require a major equipment investment. Thus the mechanical dewatering and hot air drying could be taken as less energy intensive for manufacture of good quality onion powder.

Acknowledgments

Financial support received from Indian Council of Agricultural Research (ICAR) and facilities provided by Central Institute of Post Harvest Engineering and Technology (CIPHET) for this research are gratefully acknowledged.

References

- Anthon GE, Barrett DM. Modified method for the determination of pyruvic acid with DNPH in the assessment of onion pungency. J Sci Food Agric. 2003;83:1210–1213. doi: 10.1002/jsfa.1525. [DOI] [Google Scholar]

- AOAC (1990) Official Methods of Analysis (15th edition). Association of Official Analytical Chemists, Arlington

- Arabhosseini A, Padhye S, Huisman W, Boxtel A, Müller J. Effect of drying on the color of Tarragon (Artemisiadracunculus L.) leaves. Food Bioprocess Tech. 2010;4:1281–1287. doi: 10.1007/s11947-009-0305-9. [DOI] [Google Scholar]

- Aversa M, Curcio S, Calabrò V, Iorio G. Experimental evaluation of quality parameters during drying of carrot samples. Food Bioprocess Tech. 2010;5:128–129. [Google Scholar]

- Bureau of Energy Efficiency (BEE) (2004) Best practice manual: dryers. New Delhi, India. http://www.energymanagertraining.com/bee_draft_codes/best_practices_manual-DRYERS.pdf. Accessed 22 August 2009

- Doymaz I, Tugrul N, Pala M. Drying characteristics of dill and parsley leaves. J Food Eng. 2006;77:559–565. doi: 10.1016/j.jfoodeng.2005.06.070. [DOI] [Google Scholar]

- Energy Efficiency Best Practice Programme (EEBPP) (1996) Rotary drying in the food and drink industry, good practice guide, pp 149. Carbon Trust. www.energystar.gov/ia/business/industry/Food-Guide.pdf. Accessed 22 August 2009

- Fenwick RG, Hanley AB. Processing of Alliums: Use in food manufacture. In: Brewster JL, Rabinowitch HD, editors. Onions and allied crops: biochemistry, food science and minor crops. Boca Raton: CRC press; 1990. pp. 74–88. [Google Scholar]

- Gigler JK, Loon WKP, An Seres I, Meerdink G, Coumans WJ. Drying characteristics of willow chips and stems. J Agric Eng Res. 2000;77(4):391–400. doi: 10.1006/jaer.2000.0590. [DOI] [Google Scholar]

- Gowen AA, Abu-Ghannam N, Frias J, Oliveira J. Modeling dehydration and rehydration of cooked soybeans subjected to combined microwave–hot-air drying. Innov Food Sci Emerg Technol. 2008;9:129–137. doi: 10.1016/j.ifset.2007.06.009. [DOI] [Google Scholar]

- Hu QG, Zhang M, Mujumdar AS, Xiao GN, Jin-cai S. Drying of edamames by hot air and vacuum microwave combination. J Food Eng. 2006;77(4):977–982. doi: 10.1016/j.jfoodeng.2005.08.025. [DOI] [Google Scholar]

- Iowa State University (ISU) Energy-related best practices: a sourcebook for the food industry. Ames: Iowa State University Extension Program; 2005. [Google Scholar]

- Kaymak-Ertekin F, Gedik A (2005) Kinetic modelling of quality deterioration in onions during drying and storage. J Food Eng 68:443–453

- Koyuncu T, Serdar U, Tosun I. Drying characteristics and energy requirement for dehydration of chestnuts (Castanea sativa Mill.) J Food Eng. 2004;62:165–168. doi: 10.1016/S0260-8774(03)00228-0. [DOI] [Google Scholar]

- Krokida MK, Maroulis ZB. Effect of microwave drying on some quality properties of dehydrated products. Dry Technol. 1999;17:449–466. doi: 10.1080/07373939908917545. [DOI] [Google Scholar]

- Kumar Parveen DG, Hebbar HU, Sukumar D, Ramesh MN. Infrared and hot-air drying of onions. J Food Process Preserv. 2005;29:132–150. doi: 10.1111/j.1745-4549.2005.00019.x. [DOI] [Google Scholar]

- Lenart A, Iwaniuk B, Lewicki PP (1993) Water transfer during rehydration of dewatered apple, pumpkin and carrot. In: Properties of water in foods. Warsaw Agricultural University Press, pp 118–129

- Liu K. Food research and data analysis. Beijing: Chinese Light Industry; 1998. [Google Scholar]

- Madamba PS, Bekki E. Optimization of the vacuum dehydration of carrot (Daucus carota, L.) strips. American Society of Agricultural Engineers (ASAE) Annual Convention (ASAE Paper no: 2001–6065) Sacramento: Sacramento Convention Center; 2001. [Google Scholar]

- Masanet E, Worrell E, Graus W, Galitsky C. Energy efficiency improvement and cost saving opportunities for the fruit and vegetable processing industry: an ENERGY STAR® guide for energy and plant managers. Berkeley: Environmental Energy Technologies Division, University of California; 2008. [Google Scholar]

- Maskan M (2001) Kinetics of colour change of kiwifruits during hot air and microwave drying. J Food Eng 48:169–175

- Mongpraneet S, Abe T, Tsurusaki T. Accelerated drying of Welsh onion by far infrared radiation under vacuum conditions. J Food Eng. 2002;55:147–156. doi: 10.1016/S0260-8774(02)00058-4. [DOI] [Google Scholar]

- Mudahar GS, Toledo RT, Jen JJ. A response surface methodology approach to optimize the potato dehydration process. J Food Process Preserv. 1990;14:93–106. doi: 10.1111/j.1745-4549.1990.tb00831.x. [DOI] [Google Scholar]

- Pathare PB, Sharma GP. Effective moisture diffusivity of onion slices undergoing infrared convective drying. Biosyst Eng. 2006;93(3):285–291. doi: 10.1016/j.biosystemseng.2005.12.010. [DOI] [Google Scholar]

- Prabhanjan DG, Ramaswamy HS, Raghavan GSV (1995) Microwave assisted convective air drying of thin layer carrots. J Food Eng 25:283–293

- Rapusas RS, Driscoll RH. The thin layer drying characteristics of white onion slices. Dry Technol. 1995;13:1905–1931. doi: 10.1080/07373939508917056. [DOI] [Google Scholar]

- Revaskar V, Sharma GP, Verma RC, Jain SK, Chahar VK. Drying behaviour and energy requirement for dehydration of white onion slices. Int J Food Eng. 2007;3(5):14. doi: 10.2202/1556-3758.1077. [DOI] [Google Scholar]

- Sarsavadia PN, Sawhney RL, Pangavhane DR, Singh SP (1999) Drying behaviour of brined onion slices. J Food Eng 40:219–226

- Schwimmer S, Wetson WJ. Enzymatic development of pyruvic acid in onions as a measure of pungency. J Agric Food Chem. 1961;9:301–304. doi: 10.1021/jf60116a018. [DOI] [Google Scholar]

- Sharma GP, Verma RC, Pathare P. Mathematical modeling of infrared radiation thin layer drying of onion slices. J Food Eng. 2005;71:282–286. doi: 10.1016/j.jfoodeng.2005.02.010. [DOI] [Google Scholar]

- Vergara F, Amezaga E, Barcenas ME, Welti J. Analysis of the drying processes of osmotically dehydrated apple using the characteristic curve model. Dry Technol. 1997;15:949–963. doi: 10.1080/07373939708917270. [DOI] [Google Scholar]