Abstract

Shellac (S) and Aloe vera gel (AG) were used to develop edible surface coatings for shelf-life extension of tomato fruits. The coating was prepared by dissolving de-waxed and bleached shellac in an alkaline aqueous medium as such as well as in combination with AG. Incorporation of AG in shellac coating improved permeability characteristics of the coating film towards oxygen and carbon dioxide and water vapours. The coatings when applied to tomatoes delayed senescence which was characterized by restricted changes in respiration and ethylene synthesis rates during storage. Texture of the fruits when measured in terms of firmness showed restricted changes as compared to untreated control. Similar observations were also recorded in the case of instrumental colour (L*, a* and b* values). The developed coatings extended shelf-life of tomatoes by 10, 8 and 12 days in case of shellac (S), AG and composite coating (S + AG) coated fruits, respectively; when kept at ambient storage conditions (28 ± 2 °C).

Keywords: Shellac, Aloe vera, Coating, Shelf-life, Tomato

Introduction

The tropical countries have abundant resources of shellac and Aloe vera and efforts are being made for commercialization of the same in the form of edible surface coatings for improving the shelf life of fresh fruits and vegetables. Shellac is a resinous exudate from the insect Laccifer lacca inhabitant of tropical forests. Shellac is as such a purified product of lac and is a mixture of two resins secreted simultaneously by the specific insect. These resins are composed of a number of aliphatic polyhydroxy acids present in the form of lactones, lactides and inter esters (Goyal and Paltani 2003). Shellac is non-toxic and physiologically harmless and therefore, listed as GRAS (generally recognized as safe) substance by FDA (Okamoto and Ibanez 1986). Aloe vera gel is also a resinous substance extracted from the plant Aloe vera barbadensis L. Miller. The product has been widely used in several cosmetics and health foods. The applications of Aloe vera are multidimensional. The product has been described as a natures’ gift due to its being a vast resource of carbohydrates in the form of glucomannans, antioxidants and secondary metabolites with bio-preservative functionality (Chauhan et al. 2007). The extract has moisture conditioning (Martinez et al. 2006) and bio-preservative (Shupe 2003) properties, essential for formulating edible surface coatings.

The product has ample potential for use on confectionery and fruits. However, shellac as such gives a brittle and impervious coating. Shellac based coatings of high barrier and hydrophobic nature have been used as encapsulating agents for high potency sweeteners (Patel 1987). Kajuo et al. (2001) described a shellac coating for the prevention of oxidation of seeds and fruits. However, these coatings are of high barrier property with restricted coating consistency and could cause anaerobiosis when applied as a surface coating to extend the shelf life of fresh fruits and vegetables (Raju et al. 2010). Efforts have also been made to use shellac in an aqueous base for extending the shelf life of fresh commodities in cut form (Chauhan et al. 2011a). Thai Thi et al. (2002) observed development of anaerobiosis in mangoes due to the high barrier property of shellac. Attempts were made to improve the barrier properties of shellac formulations by incorporation of corn protein (Jinhe et al. 2003). Reports also exist with respect to beneficial effects of AG as edible surface coating on the keeping quality of sweet cherries (Martinez et al. 2006). Therefore, the present study was undertaken to develop a shellac composite coating based on aqueous extract of bleached and de-waxed shellac and AG along with requisite emulsifier and its evaluation for shelf-life extension of tomatoes.

Materials and methods

Coating preparation

The composite coating was prepared as per the procedure given by Chauhan et al. (2011a, b). De-waxed and bleached shellac was procured from Shellac Export Promotion Council, Kolkata, India, whereas, Aloe gel (AG) was obtained from fresh Aloe leaves procured locally by scraping the outer epidermis. The shellac coating was prepared by dissolving de-waxed and bleached shellac in alkaline aqueous medium (0.5 % ammonium hydroxide) at 95 °C and 3,000 rpm in a high-speed Virtis homogeniser (The Virtis Company, New York, NY), using oleic acid as emulsifier. The shellac coating and aloe gel were blended in equal proportions to get the composite coating. The shellac as well as composite coating had a total solids content of 3.75–4.0 %, whereas the aloe gel coating possessed a total solids content of 1.1–1.2 %. The surface coating with shellac alone was also prepared in a similar manner without incorporation of AG.

Raw material and coating application

Fully mature tomato fruits with initiation of colour break were washed with chlorinated water (100 ppm) and the surface moisture removed by placing the fruits in a cross flow cabinet at an air velocity of 2 m/s. The surface sanitized fruits (100 kg) were divided into four experimental blocks each consisting of 25 kg. The three blocks were subjected to surface coating i.e. composite coating (S + AG), shellac alone and Aloe gel and the experimental control was kept without coating. The individual coatings were carried out by dipping the fruits in the coating solution after necessary dilution for 5 min and then subjected to surface drying in the cross flow air cabinet at an air velocity of 2 m/s. The coated fruits along with the control were kept in vented cardboard boxes (2.5 kg/unit) under ambient temperature conditions (28 ± 4 °C, 65 ± 5 % RH) for physico-chemical and shelf life evaluation. The experiment was repeated thrice and the mean values of experimental replicates were considered.

Film permeability

The coatings were casted in the form of film on cellulose acetate film support and permeability towards O2, and CO2 measured by the method described by Hagenmaier and Shaw (1991). Water vapor permeability (WVTR) was measured using ASTM E96-80 ‘water method’ also known as the cup method as described in ASTM (1998).

Viscosity and pH of coating solution

The pH of samples was measured using a microprocessor based pH meter (Model CP931; Century Instruments Private Limited, Chandigarh, India). TSS values were measured using a hand-held refractometer (Model ERMA; Tokyo, Japan). Viscosity of the coating was measured using a Brookfield viscometer (Model RVDVI+, Brookfield Eng Labs Inc, Stoughton, USA).

Respiration and ethylene synthesis rate

Respiration rate was measured using a gas chromatograph (Model 8610 HT; Chemito India Pvt. Ltd., Chennai, India). Fruits were kept in respiration chambers (500 ml) for 1 h and 1 ml sample of head-space gas were removed and injected into a gas chromatograph using a gas-tight syringe. The oven temperature was programmed initially at 35 °C for 5 min, then to 225 °C with a rate of increase of 20 °C min−1. The injector and detector (TCD) temperatures were set at 180 °C and 200 °C; respectively; while the flow rate of the carrier gas (H2) was maintained at 30 ml min−1. Ethylene production rates were monitored using the same gas chromatograph and flame ionization detector (FID). The injector, oven and detector temperatures were set at 60°, 50° and 80 °C, respectively, with a carrier gas flow rate of 30 ml min−1.

Physiological loss in weight and firmness

Physiological losses in weight were measured by taking the weight of the fruits initially and during storage. Same fruits were taken each time for measurement. The results were expressed as the percentage loss of initial weight. Firmness of the fruits were measured using a texture analyzer (TAHDi, Stable Microsystems, UK) equipped with a 100 kg load cell. The analyzer was linked to a computer that recorded data via a software programme called Texture Expert (version 1.22, Stable Micro Systems, UK) by penetrating the fruits with a 2 mm diameter cylindrical rod at a speed of 0.5 mm/s with automatic return.

CIE colour values

Changes in the CIE colour values (L*, a*, b* values) were measured using D-65 illuminant and 100 observer. The equipment (MiniScan XE Plus, Model No. 45/0-S, Hunter Associates Laboratory, Inc., Reston, VA, USA) was calibrated using a white and black standard ceramic tiles and the readings were recorded with an inbuilt software (EasyMatch QC, Hunter Associates Laboratory, Inc., Reston, VA, USA).

Keeping quality and shelf life

The keeping quality and shelf-life of fruits were evaluated on the basis of sensory attributes in terms of visual sensory score and physiological loss in weight.

Statistical analysis

A total of nine replications were carried out for each measurement and the data obtained were analyzed statistically for analysis of variance (ANOVA) using completely randomized design (CRD) and least significant difference (LSD) at P < 0.05 using Statistica 7 software (StatSoft, Tulsa, OK, USA).

Results and discussion

Coating properties

The coatings developed from de-waxed and bleached shellac alone as well as along with Aloe vera gel (AG) had 3.75–4.0 % solids in aqueous medium and the coatings were found optimal for application on the selected fruit without excessive drip losses and drying time. Perez Gago et al. (2002) developed composite coating made up of shellac involving use of hydroxy propyl methyl cellulose and lipid moieties and found it to be useful in shelf life extension of mandarins; however, the lipid moiety of the coating was described to an extent of 20–60 % which could increase the drying time of the coating to a great extent. The low oxygen permeability of complex polysaccharides such as hydroxy propyl-methyl-cellulose resulted in development of anaerobiosis within the fruits. Whereas, the coating developed with shellac along with AG is edible and showed quick drying nature, transparency and optimal visco-elastic properties (Table 1). The inclusion of AG could enhance the moisture conditioning property of the coating besides improving the viscosity. Martinez et al. (2006) described application of Aloe vera on the surface of sweet cherries to obtain an extended shelf life. However, the coating properties were not described which are of utmost importance for the ultimate commercial use. In the present study, it was found that inclusion of AG as an ingredient in shellac based coating could improve the overall properties of the composite with emphasis on coating consistency, transparency and not affecting much the drying time. The intrinsic bio-preservative functionality of the composite coating rendered shelf stability. It was found that addition of AG significantly (P < 0.05) increased the WVTR, O2 and CO2 permeability rates in the developed composite coating without much affecting pH, drying time, viscosity and CIE colour values. It is also pertinent to note that the O2 and CO2 permeation rates are in the range of 1:2.5 which could be ideal to decrease the incidence of anaerobiosis within the tissues of the commodities. Use of oleic acid as an emulsifier and micro-dispersion of the coating with high speed blending under hot conditions could facilitate uniform dispersion of the coating without phase separation subsequently.

Table 1.

Physico-chemical properties of the edible coatings (Mean ± SD, n = 3)

| Parameter | Shellac | Aloe gel | Shellac + Aloe gel |

|---|---|---|---|

| Total solids (%) | 4.0 ± 0.1a | 1.0 ± 0.1b | 4 ± 0.1a |

| pH | 7.5 ± 0.1a | 5.7 ± 0.1b | 7.5 ± 0.1a |

| Viscosity (cp, at 30 °C) | 17.4 ± 0.1a | 9.8 ± 0.1b | 17.6 ± 0.1a |

| Drying time (min) | 4.1 ± 0.1b | 3.6 ± 0.1a | 5.0 ± 0.1c |

| OTR (cc/m2/day/atm, at 75 % RH and 30 °C) | 460 ± 10a | 1560 ± 25c | 650 ± 15b |

| CTR (cc/m2/day/atm, at 75 % RH and 30 °C) | 980 ± 30a | 1200 ± 4 °C | 1500 ± 30b |

| WVTR (g/m2/day/atm, at 75 % RH and 30 °C) | 5.6 ± 0.2a | 78.2 ± 1.4c | 9.2 ± 0.2b |

| L* | 4.15 ± 0.12a | 56.8 ± 0.16b | 4.19 ± 0.11a |

| a* | 2.13 ± 0.03a | −1.37 ± 0.01b | 2.08 ± 0.02a |

| b* | 0.32 ± 0.02a | 4.67 ± 0.03c | 0.45 ± 0.1b |

*Values with different superscript in same row differ significantly (P < 0.05)

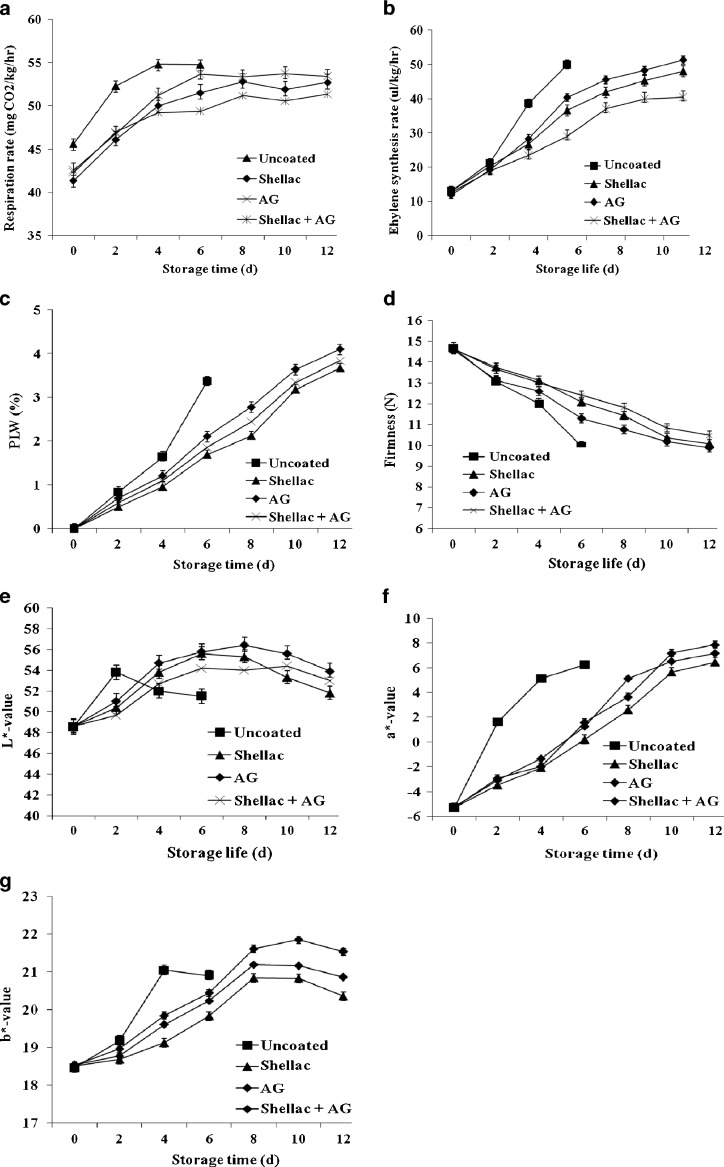

Respiration and ethylene synthesis

The respiratory behavior of shellac composite coated tomato fruits (Fig. 1) showed delayed attainment of respiratory climacteric and the respiratory magnitude was also found to be significantly (P < 0.05) lower as compared to uncoated ones. The delayed attainment of respiratory climacteric accompanied with a delayed color break was reported for tomatoes when coated with chitosan (El-Ghaouth et al. 1992) and sucrose polyesters (Kabir et al. 1995). However, certain coatings made up of cassava starch rendered better glossy appearance to tomato without significant retardation of ripening (Damasceno et al. 2003). The reports of shellac coatings on the retardation of tomato fruit senescence and related changes in respiration are scarce. The incidence of anaerobiosis has been the attention of centre for many workers with regards to the utility of shellac based coatings. Excessive contents of ethanol and other volatiles in the form of esters and aldehydes were extensively reported in the case of shellac coated tangerines (Hagenmaier and Shaw 2002). Apart from the nature of the coatings, the storage temperature was also found to play a crucial role. Saftener (1999) reported a transient storage temperature of 0 °C to retard the volatile formation in shellac coated apples. The ethanolic accumulation was also found to be dependent on concentration of shellac within the coating and tissue respiration (Alleyne and Hagenmaier 2002).

Fig. 1.

Changes in physico-chemical attributes during storage of tomatoes (LSD < 0.05, n = 3); a respiration rate (mg CO2/kg/h), b ethylene synthesis rate (μl/kg/h), c physiological loss in weight (%), d firmness (N), e L* value, f a* value, g b* value

The ethylene release pattern of coated tomato fruits showed a complimentary trend with respiratory pattern (Fig. 1). The composite coating showed restricted ethylene synthesis in the tomato fruits compared to those coated with shellac alone and the control samples without coating. This could be attribute to the reduction in metabolic rates of the fruits due to application of coating on the fruit surface restricting permeation of respiratory gases. However, the extent of variance between the composite and shellac alone was more pronounced in terms of extent of ethylene release compared with the variance observed between the two entities in terms of respiratory rates. The observation highlights the relative responses of ethylene release and respiratory rates towards anaerobiosis occurring in the case of fruits coated with shellac alone due to sub-optimal barrier properties.

Physiological loss in weight

One of the major objectives of surface coatings used during post harvest handling of fresh commodities has been to restrict surface shriveling and moisture loss. The coatings need to have moderate WVTR characteristics to facilitate optimal surface features without shriveling. The physiological loss in weight in the shellac coated tomato fruits (Fig. 1) was found to be lower as compared to those coated with shellac and AG as well as the ones without coating. However, the changes were found to be non-significant in the fruits coated with shellac alone as well as shellac and AG. Togrul and Arslan (2005) described shellac composite in combination with carboxy methyl cellulose and soybean oil which could restrict weight loss of apples during storage. Alleyne and Hagenmaier (2002) attributed the positive effects of shellac and candedila wax based composite on weight loss of coated fruits. The shellac composite making use of aqueous extract of shellac in combination with and AG showed beneficial effects in restricting the weight loss of tomato fruits at lower shellac concentrations. The same could be attributed to the moisture conditioning property of AG.

Firmness

Surface coatings were found to cause higher retention of tissue firmness and the positive effect was attributed to the restriction in metabolic activities associated with cell wall degrading enzymes. The shellac coating with or without AG showed significant (P < 0.05) retention in firmness of tomato fruits as compared to the uncoated ones (Fig. 1). Jinhe et al. (2002) described the preventive effect of shellac based coatings on the texture retention of apples during marketing at room temperature and attributed it to permeability properties of the coatings. However, the texture retention profile did not vary significantly between the composite and shellac alone coatings. The fruits coated with AG alone showed more loss of firmness during storage which may be attributed to less preventive effect of AG alone on ripening of tomato fruits as compared to other coatings.

CIE color values

One of the major drawbacks of shellac based coatings had been the whitening of the surface tissues of the fruits which could be detrimental for the commercial utility of the coating (Jinhe et al. 2002). The shellac coating containing AG showed no symptoms of whitening due to optimized formulation in an aqueous medium and restricted use of bleached and dewaxed shellac. The fruits appeared glossy and the coating upon drying was found transparent in nature. The colour coordinates showed a typical pattern for tomato fruits (Fig. 1). The coated fruits showed restricted rise in a* values showing delayed increase or development of reddish shade. Similarly, the b* values showed an increasing tendency for the tomato fruits with delay in the development of yellowness in the coated fruits (P < 0.05). The coated fruits showed a overall delayed process in the progression of colour coordinates highlighting retention of optimal colour characteristics. As such the progression of the colour break was found to be significantly (P < 0.05) slower in the composite coated fruits compared with shellac alone and the control samples.

Keeping quality and shelf life

The tomato fruits showed a shelf life of 9 and 12 days respectively for shellac alone and shellac with AG coated fruits against the shelf life of 6 days for uncoated fruits at ambient temperature (26–32 °C). The coating made up of shellac alone gave lesser shelf life due to excessive ethanol formation caused by anaerobiosis. The overall beneficial effects in terms of shelf life extension could be attributed to the multi functional nature including decreased tissue respiration, restricted weight loss and surface phyto-sanitation due to the bio-preservative functions of shellac as well as AG. The shellac alone coated samples also showed slight symptoms of white blushing of the skin which impeded the overall colour quality of the fruit yielding lower shelf life. The composite coating on the other hand showed no symptoms of white blushing of the fruit skin.

Conclusion

The developed composite coating based on aqueous extract of de-waxed and bleached shellac and AG (1:1 ratio) showed important commercial attributes such as glossiness, transparency, quick drying nature, visco-elastic properties and sound emulsion stability. The composite coating with optimal barrier properties towards O2, CO2 and water vapour effectively prevented anaerobiosis within tomato fruits. The composite coating could extend the shelf life of tomato fruits by 12 days under ambient conditions against 6 days in the case of uncoated ones.

Abbreviations

- S

Shellac

- AG

Aloe gel

- PLW

Physiological loss in weight

- RH

Relative humidity

- OTR

Oxygen transmission rate

- CTR

Carbon dioxide transmission rate

- WVTR

Water vapor transmission rate

References

- Alleyne V, Hagenmaier RD. Candelilla-shellac: an alternative formulation for coating apples. Hortic Sci. 2002;35:691–693. [Google Scholar]

- ASTM (1998) Standard test methods for water vapour transmission of materials. In: Annual book of ASTM standards, Weat Conshohocken: American Society for Testing and Materials, PA

- Chauhan OP, Raju PS, Khanum F, Bawa AS. Aloe vera—pharmaceutical and food applications. Ind Food Ind. 2007;26:43–51. [Google Scholar]

- Chauhan OP, Raju PS, Singh A, Bawa AS. Shellac and Aloe vera gel based surface coatings for maintaining keeping quality of apple slices. Food Chem. 2011;126:961–966. doi: 10.1016/j.foodchem.2010.11.095. [DOI] [Google Scholar]

- Chauhan OP, Raju PS, Dasgupta DK, Bawa AS (2011b) Coating composition of fruits and vegetables and method thereof. Indian Patent 246270

- Damasceno S, Vierira Sutil-de-Olivera P, Moro E, Macedo EK, Lopes MC, Vicentini NM. Application of cassava starch film effect in the tomato postharvest conservation. Ciencia-e-Tecnologia-de-Alimentos. 2003;23:377–380. doi: 10.1590/S0101-20612003000300014. [DOI] [Google Scholar]

- El-Ghaouth A, Ponnampalam R, Castaigne F, Arul J. Chitosan coating to extend the storage life of tomatoes. Hortic Sci. 1992;27:1016–1018. [Google Scholar]

- Goyal GK, Paltani IP. Shellac: most versatile edible coating material for food industry. Ind Food Ind. 2003;22:55–58. [Google Scholar]

- Hagenmaier RD, Shaw PE. Permeability of shellac coatings to gases and water vapour. J Agric Food Chem. 1991;39:825–829. doi: 10.1021/jf00005a001. [DOI] [Google Scholar]

- Hagenmaier RD, Shaw PE. Changes in volatile components of stored tangerines and other citrus fruits with different coatings. J Food Sci. 2002;67:1742–1745. doi: 10.1111/j.1365-2621.2002.tb08716.x. [DOI] [Google Scholar]

- Jinhe B, Hagenmaier RD, Elizabeth AB. Volatile response of four apple varieties with different coatings during marketing at room temperature. J Agric Food Chem. 2002;50:7660–7668. doi: 10.1021/jf020543n. [DOI] [PubMed] [Google Scholar]

- Jinhe B, Alleeyne V, Hagenmaier RD, Mattheis JP, Baldwin EA. Formulation of zein coatings for apples (Malus domestica Borkh) Postharvest Biol Technol. 2003;28:259–268. doi: 10.1016/S0925-5214(02)00182-5. [DOI] [Google Scholar]

- Kabir J, Ghosh B, Dutta Ray SK, Mitra SK. Post harvest use of edible coatings on shelf life of tomato. Ind Food Packer. 1995;49:25–28. [Google Scholar]

- Kajuo A, Toshihiko U, Tomoyoshi S, Tomonori T (2001) Method for preventing oxidation of seeds and fruits. European Patent No. JP 20011258515.

- Martinez RD, Alburquerque N, Valverde JM, Guillen F, Castillo S, Valero D, Serrano M. Postharvest sweet cherry quality and safety maintenance by Aloe vera treatment: a new edible coating. Postharvest Biol Technol. 2006;39:93–100. doi: 10.1016/j.postharvbio.2005.09.006. [DOI] [Google Scholar]

- Okamoto MY, Ibanez PS. Final report on the safety assessment of shellac. J Am Coll Toxicol. 1986;5:309–327. [Google Scholar]

- Patel MM (1987) Shellac encapsulant for high potency sweeteners in chewing gum. US Patent No. 4673577

- Perez Gago MB, Rojas C, Del Rio MA. Effect of lipid type and amount of edible hydroxypropyl methylcellulose-lipid composite coating used to protect postharvest quality of mandarins cv. fortune. J Food Sci. 2002;8:2903–2910. doi: 10.1111/j.1365-2621.2002.tb08836.x. [DOI] [Google Scholar]

- Raju PS, Chauhan OP, Bawa AS. Postharvest handling systems and storage of vegetables. In: Sinha NK, Jasim A, editors. Postharvest handling of vegetables. Iowa: Blackwell Publishing Limited; 2010. pp. 185–198. [Google Scholar]

- Saftener RA. The potential of fruit coating and film treatments for improving the storage and shelf life qualities of ‘Gala’ and ‘Golden delicious’ apples. J Am Soc Hortic Sci. 1999;124:682–689. [Google Scholar]

- Shupe K (2003) Antimicrobial agent isolated from Aloe vera. US Patent No. 6551631

- Thai Thi H, Ducamp MN, Lebrun M, Baldwin EA. Effect of different coating treatment on the quality of mango fruits. J Food Qual. 2002;25:471–486. doi: 10.1111/j.1745-4557.2002.tb01041.x. [DOI] [Google Scholar]

- Togrul H, Arslan N. Carboxymethyl cellulose from sugar beet pulp cellulose as a hydrophilic polymer in coating of apples. J Food Sci Technol. 2005;42:139–144. [Google Scholar]