Abstract

Whey is a nutritious by product of some traditional Indian processed milk products and it needs to be utilized in an effective way in order to reduce environmental hazards associated with its untreated disposal. Low calorie watermelon beverage appears to be a simple, attractive and economic method of whey disposal. The experiment was designed by Central Composite Rotatable Design of Responce Surface Methodology. Three independent variables whey, Innova ® fiber and sucralose were chosen at five levels within the respective ranges of 40–60 %, 2.0–5.0 % and 0.01–0.03 %. The effect of the variables on flavour, mouthfeel, after-taste, viscosity, total soluble solids (all to be maximized) and sedimentation (to be minimized) was observed. These three were the independent variables whose effect on flavour, mouthfeel, after-taste, viscosity, total soluble solids (all to be maximized) and sedimentation (to be minimized) were evaluated. Quadratic model fitted well to all dependent variables. The R2 values for flavour, mouthfeel, aftertaste, viscosity, sedimentation and TSS were 95.57, 98.71, 95.50, 97.87, 99.26 and 98.17 %, respectively. Response surface methodology was used to optimize the level of processing parameters. Maximum scores for flavour (7.46), mouthfeel (7.49), after-taste (7.72), viscosity (13.55 cp) and total soluble solid (15.34°Brix) and minimum score for sedimentation (1.55 ml/10 ml) were obtained when the formulation contained 51.46 % whey, 3.84 % Innova® fiber and 0.021 % sucralose.

Keywords: Whey, Watermelon juice, Sucralose, Dietary fiber

Introduction

Watermelon is one of the abundant and cheap fruits that are available in India. It is available throughout the year, though production is highest in the summer. Watermelon production contributes to 6–7 % of overall fruit production in the world (Reddy et al. 2008). This fruit is a rich natural source of lycopene, a compound responsible for its red colour (Perkins-Veazie et al. 2001). Intake of lycopene containing-products has been associated with a reduced incidence of coronary heart disease and some types of cancer (Giovannucci 2002). The fruit also contains small amounts of phenolics but low in vitamin C content compared to other fruits (Gil et al. 2006).

India is the largest producer of milk in the world, produced 117 million tons in 2010 (FAO 2010). A large share of the production is utilized for making some traditional Indian processed milk products. Whey is the byproduct in the manufacture of most of these products. The high biological oxygen demand (BOD) of whey (3–5 × 105 ppm (Hofer 1995)) will lead to its disposal into waterways and sewages to cause serious environmental problems. The growing concern over pollution has compelled the dairy industry to discontinue dumping of whey into rivers, streams and municipal sewage system without proper treatment, which is a costly affair. The other alternative is to divert whey for the production of value-added products in order to utilize its nutrients.

Back in the 16th century during the Italian Renaisance, two prevalent sayings clearly identified the benefits of whey: ‘Shi vuol viver sano e lesto keve Scotta e cena presto’ translating to ‘If you want to live a healthy and active life, drink whey and dine early’ and ‘allevato Con la Scotta it dottore e in bancarotta’ meaning ‘if everyone were raised on whey, doctors would be bankrupt’ (Berry 2002).

Whey and whey derived products besides being excellent nutritional ingredients, have wide-ranging and excellent functional characteristics supplying flavor, texture, colour and overall acceptability in a variety of food. Whey-based fruit beverages hold good promise in the value added nutritious food products basket. Orange and grapefruit juices are very compatible with acid whey (Holsinger et al. 1974). Mango, banana, pineapple, guava and strawberry flavors also have good acceptability in blends with whey (Singh et al. 1994). In India, some attempts have been made for utilization of whey through whey protein concentrates and whey beverages. However, the potential of whey has not been fully exploited (Murdia et al. 2005).

People today are very calorie-conscious and look for foods with low calorific value. Several studies have consistently reported that people are concerned with weight and its health related implications, and for that most individuals are making a concerted effort to either maintain or lose weight. Contemporary processed food products are incorporating various artificial sweeteners which are low in calorie content instead of high calorie sugar (Chattopadhyay et al. 2011). These low calorie sweeteners impart sweetness to foods and are used to partially or totally replace sucrose. Sucralose possesses unparallel advantages in relation to the other low-calorie sweeteners for use in nutritive products. It exhibits 600 times of sucrose sweetness with no aftertaste, good storage stability at low pH, high temperature stability, and no bulking properties (Mendonca et al. 2005).

Recent interest in fiber, particularly soluble dietary fiber (SDF), has prompted researchers to explore the outcomes of incorporating of fiber in various food systems (Chakraborty et al. 2010). Well-documented studies now accept that dietary fiber plays a significant role in the prevention of several diseases. Diets with a high content SDF have a positive effect on health; since its consumption is related to decreased incidence of several types of cancer (Jimenez-Escribano et al. 2001). The cholesterol lowering effect of SDF in specific foods has been established in animal (Ranhotra et al. 1987) and human clinical studies (Anderson and Tietyen-Clark 1986). A major problems involved in incorporating dietary fibers into a food system is the negative effect it has on functional properties of the food (Brenna and Samyue 2004). The present study was conceived with the objective of preparing a whey-based low-calorie high-fiber watermelon beverage. A systematic investigation was conducted on how different levels of whey, artificial sweetener and dietary fiber influence the sensory (juice flavour, mouthfeel and after-taste) and physical (viscosity, sedimentation and total soluble solids) properties.

Materials and methods

Watermelon juice preparation

Fresh watermelon of ‘crimson sweet’ variety was procured from the local market. Watermelon juice was extracted with the help of an enzyme (Masazyme, Advance Biochemical, Mumbai, India). The juice was clarified using a muslin cloth and was concentrated to 20°Brix.

Whey

Whey was produced in the laboratory as a byproduct of paneer production by the method of Sachdeva and Singh (1988). The composition of whey thus obtained was: total solid 6.3 %, lactose 5.12 %, whey protein 0.43 %, fat 0.10 % and ash 0.5 %.

Artificial sweetener

Sucralose, an intense sweetener, was procured from Unicolloids, Mumbai, India.

Soluble dietary fiber (SDF)

Spray dried Innova® guar fibre was obtained from Drytech Processes, Mumbai, India.

Other additives

Watermelon flavour was obtained from Cargil Pvt. Ltd, Bangalore, India, Raspberry red powder (IH 7804) supplied by Bush Boake Allen Ltd. Chennai, India, was used as a colouring agent. Malic acid (S.D. Fine Chemicals Ltd., Mumbai, India) was used for maintaining the pH of watermelon juice at 3.8 in order to prevent microbial contamination.

Preparation of beverage

Concentrated watermelon juice was blended with freshly prepared pasteurized and neutralized whey (40–60 %). Innova® fiber (2–5 %), sucralose (0.01–0.03 %) and 0.01 % xanthan gum were added to the blend and kept for 30 min at room temperature for hydration and stabilization. The mixture was blended with an electric blender, while simultaneously adding 0.5 % flavour, 0.10 % potassium meta bisulphite (KMS) and 0.75 % of a 10 % solution of colour. The pH was reduced to 3.8 using malic acid. Finally, the prepared beverage was pasteurized at 80 °C for 10 min and filled in sterilized glass bottles before storage at refrigerated temperature.

Experimental design

Response Surface Methodology (RSM) which involves design of experiments, selection of levels of variables in experimental runs, fitting mathematical models and finally selecting the levels of variables by optimizing the response (Khuri and Cornell 1987) was employed in the study. A Central Composite Rotatable Design (CCRD) was used to design the experiments comprising three variables with five levels each (Table 1). A total of 20 experiments were conducted of which five were at centre point to calculate the repeatability of the method. As a prerequisite of RSM, the input variables were coded using the following equations,

| 1 |

| 2 |

| 3 |

Table 1.

Experimental design matrix and attributes scores of high fiber and low calorie whey based watermelon beverage

| Run | Independent variables | Dependent variables | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Whey % | Innova % | Sucralose % | Flavour | Mouthfeel | Aftertaste | Viscosity cp | Sedimentation | TSSa °Brix | |

| X1(x1) | X2(x2) | X3(x3) | Y1 | Y2 | Y3 | Y4 | ml/10 ml Y5 | Y6 | |

| 1 | 50(0) | 3.5(0) | 0.02(0) | 7.4 | 7.5 | 7.8 | 14 | 1.6 | 15.1 |

| 2 | 60(+1) | 5(+1) | 0.03(+1) | 6.3 | 6.7 | 6.8 | 15 | 2.43 | 12.11 |

| 3 | 40(−1) | 2(−1) | 0.03(+1) | 6.5 | 6.8 | 6.4 | 9 | 0.79 | 16.51 |

| 4 | 50(0) | 3.5(0) | 0.02(0) | 7.1 | 7.5 | 7.4 | 14 | 1.6 | 14.8 |

| 5 | 50(0) | 3.5(0) | 0.02(0) | 7.6 | 7.4 | 7.7 | 13 | 1.4 | 14.4 |

| 6 | 40(−1) | 2(−1) | 0.01(−1) | 7.2 | 6.05 | 6.4 | 9 | 0.52 | 13.17 |

| 7 | 50(0) | 3.5(0) | 0.02(0) | 7.5 | 7.4 | 7.6 | 13 | 1.5 | 14.8 |

| 8 | 40(−1) | 5(+1) | 0.01(−1) | 7.4 | 6.5 | 6.5 | 15 | 1.9 | 17.4 |

| 9 | 50(0) | 3.5(0) | 0.04(+1.68) | 5.9 | 7.2 | 5.8 | 13 | 1.8 | 15.8 |

| 10 | 33.18(−1.68) | 3.5(0) | 0.02(0) | 8.1 | 7.4 | 7.7 | 12 | 1.21 | 18.01 |

| 11 | 66.81(+1.68) | 3.5(0) | 0.02(0) | 5.79 | 6.4 | 7.1 | 8 | 1.94 | 10.4 |

| 12 | 60(+1) | 2(−1) | 0.03(+1) | 6.2 | 5.7 | 6.5 | 7 | 1.2 | 11.5 |

| 13 | 60(+1) | 5(+1) | 0.01(−1) | 5.52 | 5.98 | 6.03 | 13 | 2.25 | 13.48 |

| 14 | 50(0) | 3.5(0) | 0.00(−1.68) | 5.7 | 5.8 | 5.7 | 12 | 1.5 | 16.0 |

| 15 | 60(+1) | 2(−1) | 0.01(−1) | 5.8 | 5.5 | 6.82 | 7 | 0.77 | 11.1 |

| 16 | 50(0) | 3.5(0) | 0.02(0) | 7.6 | 7.3 | 7.7 | 12 | 1.4 | 15.5 |

| 17 | 40(−1) | 5(+1) | 0.03(+1) | 6.7 | 7.54 | 7.7 | 16 | 2 | 17.8 |

| 18 | 50(0) | 3.5(0) | 0.02(0) | 7.4 | 7.2 | 8 | 13 | 1.5 | 15.3 |

| 19 | 50(0) | 0.98(−1.68) | 0.02(0) | 6.8 | 5.2 | 7.2 | 7 | 0.051 | 13.3 |

| 20 | 50(0) | 6.02(+1.68) | 0.02(0) | 6.2 | 6.6 | 7 | 17 | 2.4 | 16.3 |

a TSS Total soluble solid

The design was employed for systematic investigation of how different levels of whey, dietary fiber and artificial sweetener influence the sensory (juice flavour, mouthfeel and after-taste) and physical properties (viscosity, sedimentation and total soluble solids).

Statistical analysis

The experimental data was analysed for their statistical reliability and were used for obtaining the optimum values for the processing variables. Commercial statistical software, Design Expert 7.1.3 (Stat-Ease Inc., Minneapolis, MN) was used for multifactor analysis of variance to assess the fitness of the models. The variance for each factor assessed was partitioned into linear, quadratic and interactive components and was represented using the second order polynomial equation for three factors

| 4 |

where Y is the response, X is coded independent variable and b are regression coefficients.

Response surfaces of the fitted models were plotted as a function of variables while keeping the other variables at the optimum level. Numerical optimization of data was also carried out using same software.

Sensory evaluation

The freshly manufactured beverage was evaluated for its sensory attributes by a panel of 10 members. The attributes evaluated were flavour, mouthfeel and after-taste. For each sample, panelists scored their liking of these characteristics using the nine-point hedonic scale (1- dislike extremely, 2 - dislike very much, 3 - dislike moderately, 4 - dislike slightly, 5 - neither like nor dislike, 6 - like slightly, 7 - like moderately, 8 - like very much and 9 - like extremely).

Physical analysis

Viscosity was measured using Brookfield viscometer (DV-II+Pro, Brookfield Engineering Laboratory, Inc., Middleboro, USA) at 100 rpm with spherical spindle LV-2. Sedimentation was assessed using BIS method (BIS 1981), with slight modification using REMI centrifuge. TSS was determined using Atago digital refractometer (Model RP-101, Tokyo, Japan) at 20 °C with a scale ranging 0–45°Brix.

Results and discussion

Experimental design and statistical analysis

The experimental sensory responses as a function of whey concentration (X1), Innova® fiber (X2) and sucralose (X3) for producing high fiber and low calorie whey based watermelon beverage are summarized in Table 1 with coded variable levels. The scores of flavor, mouthfeel, after-taste, viscosity, sedimentation and TSS were within the ranges of 5.52–8.10, 5.20–7.54, 5.7–8.0, 7–17 cp, 0.051–2.43 ml/10 ml and 10.4–18.01°Brix, respectively. The effect of different variables on these attributes represented statistically by the regression analysis of the data is shown in Table 2. Model analysis, which included checking the validity of the model with the help of various relevant statistical aids, such as F-value, coefficient of determination (R2) and coefficient of variation (CV) revealed that the models was statistically adequate (Chakraborty et al. 2011). The results indicated that the models for all dependent variables were adequate with their satisfactory levels of coefficient of determination (R2) from 95.57 % to 99.26 % and all models were significant at p < 0.05. The F-value of lack-of-fit for all models implies that the lack of fit is not significant relative to the pure error. Coefficient of variation (CV) indicates the relative dispersion of the experimental points from the prediction of the model. It is desirable to have a CV of less than 10 %. In the present investigation, CV for flavour, mouthfeel, after-taste, viscosity, sedimentation and TSS were 3.34, 1.77, 2.96, 5.19, 4.89 and 3.99 %, respectively.

Table 2.

Analysis of regression and variance of the second order polynomial models for dependent variables

| Source | Flavour | Mouthfeel | Aftertaste | Viscosity | Sedimentation | TSS |

|---|---|---|---|---|---|---|

| Regression | ||||||

| Model | 7.43* | 7.38* | 7.70* | 13.16* | 1.5* | 15.01* |

| X1 | −0.57* | −0.34* | −0.14*** | −1.00* | 0.19* | −2.16* |

| X2 | 0.057 | 0.36* | 0.042 | 3.20* | 0.67* | 1.02* |

| X3 | 0.008 | 0.37* | 0.13*** | 0.34 | 0.10* | 0.23 |

| X1*X2 | −0.072** | 0.036 | −0.24** | 0.13 | 0.015 | 0.32 |

| X1*X3 | 0.32 | −0.11*** | −0.09 | 0.13 | 0.03 | 0.59*** |

| X2*X3 | 0.048 | 0.10*** | 0.29** | 0.38 | −0.05 | 0.59*** |

| X21 | −0.15** | −0.17* | −0.12 | −1.12* | 0.02** | −0.44*** |

| X22 | −0.30* | −0.53* | −0.22** | −0.42** | −0.09* | −0.27** |

| X23 | −0.55* | −0.32* | −0.70* | −0.24 | 0.05*** | 0.16 |

| ANOVA | ||||||

| R2, % | 95.57 | 98.71 | 95.50 | 97.87 | 99.26 | 98.17 |

| Adj R2, % | 91.58 | 97.54 | 91.44 | 95.96 | 98.60 | 96.52 |

| Pred R2, % | 75.45 | 93.95 | 78.71 | 93.40 | 97.79 | 89.65 |

| Adequate precision | 16.58 | 28.00 | 15.04 | 24.62 | 45.95 | 26.92 |

| Std. dev. | 0.23 | 0.12 | 0.20 | 0.61 | 0.07 | 0.50 |

| Mean | 6.74 | 6.68 | 6.99 | 11.95 | 1.48 | 14.34 |

| Coefficient of variation, % | 3.34 | 1.77 | 2.96 | 5.19 | 4.89 | 3.49 |

| PRESS | 2.81 | 0.65 | 2.02 | 11.94 | 0.15 | 14.19 |

| Lake of fit | 0.2447NS | 0.4751NS | 0.4428NS | 0.8591NS | 0.8693NS | 0.1065NS |

X1 = Whey; X2 = Innova® fibre; X3 = Sucralose

NS Non significant

*Significant at 0.001 level, **Significant at 0.01 level, ***Significant at 0.05 level

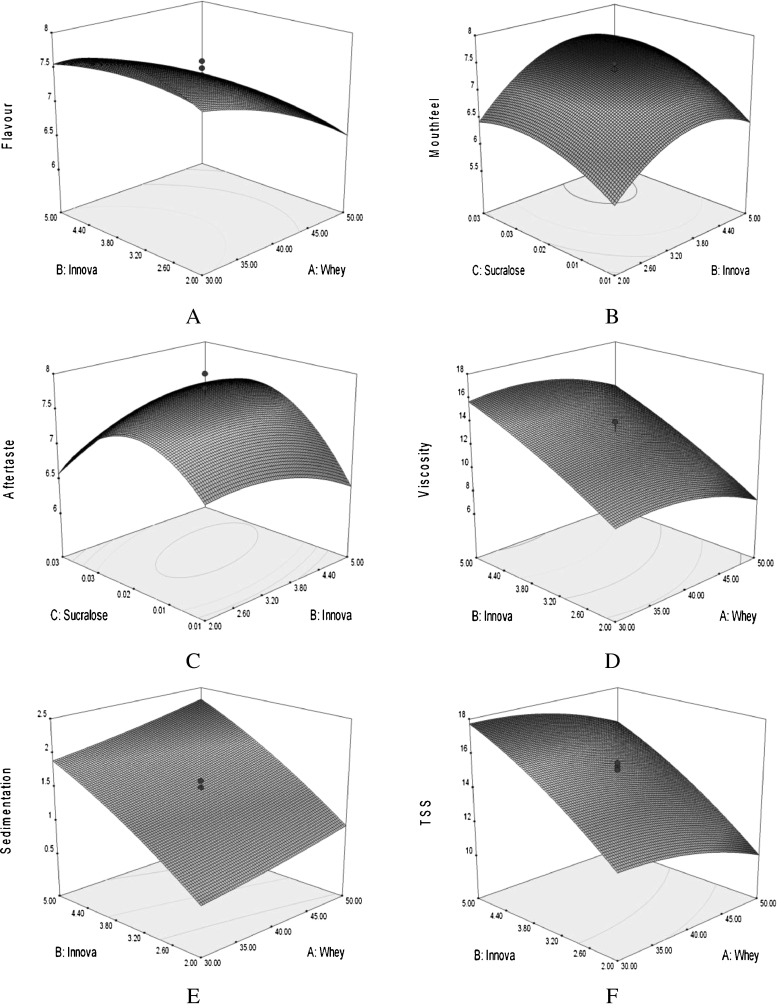

Flavour

From Table 2, it is evident that flavour depends on the whey concentration as its linear (p < 0.001) as well as quadratic (p < 0.01) effects are significantly negative on flavour. The flavour scores decreased with increase in quantity of whey. This is because the blends contain low total solids in the beverage as the level of whey increased and also owing to the strong flavour of whey. Innova® fiber showed negative effect on its quadratic (p < 0.001) level. The surface diagram for flavour (Fig. 1a) in the current study also shows that Innova® fiber improves the flavour up to a particular level. Effect of sucralose was also significant (p < 0.001) at quadratic level and its effect was negative. Higher concentration of the sweetener decreased the flavour score of product. The interaction of whey concentration with Innova® fiber was significantly effective at p < 0.01 and its effect was negative on flavour score.

Fig. 1.

Response surface plots for different parameters as a function of whey concentration, innova® fiber and sucralose

Branger et al. (1999) reported similar results in grape whey beverage where flavour, sweetness, sourness and astringency decreased with addition of whey concentration while cheesiness and saltiness of the blends increased when the whey concentration was increased. This was because of higher levels of soluble solids and titratable acidity (10.5 % and 1.22 % citric) and higher astringency in grapefruit juices than whey (6.2 % and 0.54 % lactic).

Mouthfeel

Figure 1b shows the surface diagram of the independent variables on the mouthfeel. From Table 2, it is evident that mouthfeel depends on the whey concentration as its linear and quadratic effect was negative at p < 0.001. Innova® fiber showed significant (p < 0.01) positive effect at linear level where as at quadratic level showed a significant (p < 0.001) negative effect. Hence overall effect was curvilinear in nature. Sucralose also showed a significant (p < 0.001) effect at linear and quadratic level but its effect was positive at linear level and negative at quadratic level. The interaction of whey concentration and sucralose on mouthfeel was significant (p < 0.05) and negative, whereas the interaction of Innova® fiber and sucralose was significant (p < 0.05) and positive (Fig. 1b).

Carbohydrates have been used to improve mouthfeel of low calorie beverages. Mouthfeel perception was also impacted by the interaction between pH and flavour system in the beverage (O’ Carroll 2001). Hollowood et al. (2002) reported that the addition of gum and polydextrose to diet beverages would decrease in the free water available in solution and may result increased mouthfeel. Stamp (1990) found that if sucrose is replaced by high intensity sweeteners, the bulking properties provided to food by sucrose are diminished. Since, the high potency sweetener replaced only the sweet taste of the sugar and lowered its bulk, the samples were perceived to have a watery mouthfeel. Kappes et al. (2006) also reported that body and mouth coating were significantly lower in diet cola flavoured beverages in comparison to regular cola flavoured carbonated beverages.

After-taste

Table 2 illustrates that at linear level whey concentration and sucralose levels affect the after-taste significantly (p < 0.05) with respective negative and positive effects. Innova® fiber (p < 0.01) and sucralose (p < 0.001) in quadratic levels showed significant effect on after-taste. The negative sign of partial coefficient indicates increases in score of after-taste with a decrease in Innova® fiber and sucralose. Sweet after-taste was highest at the 0.02 % sucralose level and then decreased gradually to the bitter after-taste. The interaction of whey concentration with Innova® fiber had significant (p < 0.01) negative effect while there was positive significant (p < 0.01) interaction between Innova® fiber and sucralose on after-taste (Fig. 1c).

Sweet taste of artificial sweetener is accompanied by a bitter off-taste (Helgren et al. 1955) that increase with concentration, when the bitterness predominates and the artificial sweeteners no longer evokes the sweet taste. Carbohydrate gums can change the sensory properties in the product. Sweet taste decreased as viscosity of sodium saccharine solution increased using CMC (Arabie and Moskowitz 1971).

Viscosity

The regression coefficient and the probability of factors influencing the response at linear, quadratic and interactive level are illustrated in Table 2. It is evident that whey had negative effect on viscosity at linear and quadratic level at a highly significant level (p < 0.001). The linear effect of Innova® fiber on viscosity was positive (p < 0.001) while quadratic effect was negative (p < 0.01). From the Fig. 1d, it was clear that for the highest level of Innova® fiber (6.02 %), the viscosity was maximum. This increase could be explained by the interactions of the dietary fiber and liquid phase of the beverage. Dietary fiber, being highly hygroscopic, would bind water and form a gel-like network that, in addition to the other components, would modify the rheology of the beverage. The interactions between all independent variables were found to be non-significant.

Dietary fibers that form viscous solutions are usually used as thickening agents to increase the viscosity in food systems. Water soluble dietary fiber components i.e. β-glucans, pectin and plant gums form colloidal solutions, contributing to higher viscosity. As dietary fiber present in food, they act as a thickness and stablizers. Decreasing the ratio of dissociated to non-dissociated acid groups by lowering the pH rendered pectin molecules reducing in hydrophilic portions, contributing to great tendency to form gels which paid a major role in increasing the viscosity of guava juice (Kaul et al. 2009). Sarah et al. (2006), also reported that the addition of potato fibers had a unique reducing effect on the K-value, which was opposite to the effect seen in the other juices and in water.

Sedimentation

Table 2 reveals that sedimentation depended on levels of whey, Innova® fiber and sucralose. There was a significant increase in sedimentation with an increase whey proportion for linear (p < 0.001) as well as quadratic (p < 0.01) levels (Fig. 1e). Dietary fiber showed positive significance at linear level (p < 0.001) whereas at quadratic level (p < 0.001) the effect was negative. Sedimentation also increased significantly with sucralose at linear (p < 0.001) and quadratic (p < 0.05) levels. Its effect was negative at linear and positive at quadratic level. Hence, overall effect was curvilinear in nature. The effect at all interactive levels were non-significant.

Particulate matters present in fruit whey beverage may settle down forming sediments. This could be attributed to the mechanical and thermal treatment of fruit beverage which causes the formation of aggregates containing protein, fat and lactose as well as inorganic salts of varying composition. Depending on their size, specific density and electrical charge, these aggregates may either sediment or clump on the surface. Aggregates of a certain size give the sensory feeling of a ‘chalky’ or ‘sandy’ mouthfeel (Hostettler and Imhoff 1963). Interaction between components of whey and fruit (pectin, tannins, starch) results in sedimentation reported by Devkota (1991). Beverages made from dietary fiber comprising of a high amount of soluble fiber exhibited and improved the dispersability and reduced rate of sedimentation. The dietary fiber composition consists of granulate particles coated with modified starch (Klaus 1995).

Total soluble solid (TSS)

Whey had a significant negative effect at linear (p < 0.001) and quadratic (p < 0.05) levels on TSS, as evinced in Table 2. In other word, TSS content is inversely proportional to whey concentration. Innova® fiber also significantly affected TSS at linear level (p < 0.001) in a positive manner. Innova® fiber, being a soluble carbohydrate caused an increment in the total solids by incorporation of additional solids in the beverage. The direct effect of the fiber on soluble solids content of the beverage was due to its partial solubility in water. Interaction effect between whey and sucrlose as well as Innova® fiber and sucralose significantly (p < 0.05) decreased the TSS (Fig. 1f) as whey concentration increased. Ingale et al. (2009) reported similar results with their findings that TSS of beverage gradually increased with increases in the level of custard apple pulp. As the fruit pulp levels increases i.e. 10, 15 and 20 %, the TSS of the beverages was 11.3, 11.7 and 12.2 %, respectively. Mittal and Bajwa (2011) also observed that in low calorie milk drinks, sugar replacement with sucralose considerably decreased TSS while addition of inulin fiber increased it.

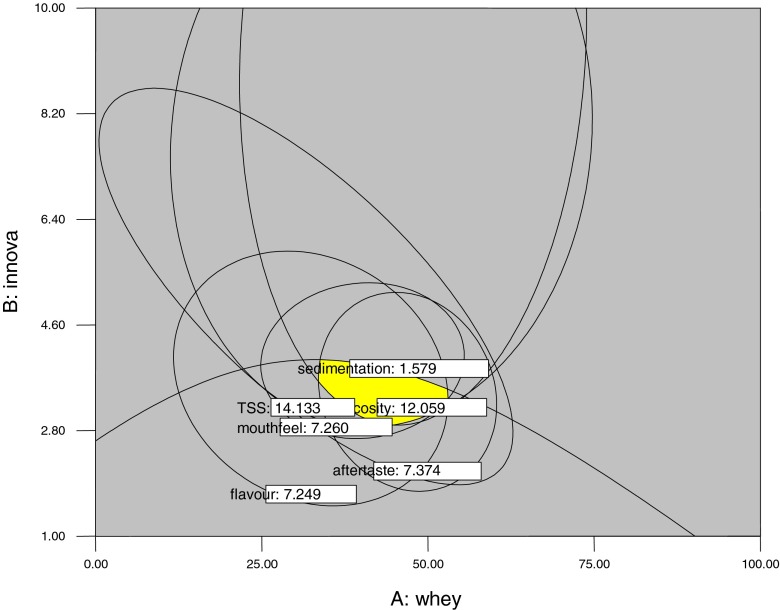

Optimization of product formulation and model validation

RSM was used to study the optimum conditions of the factors that affect the sensory and physical properties of high fiber and low calorie whey based watermelon beverages. Superimposing all the plots, the identification of a region which satisfied all constraints is shown in Fig. 2. In order to arrive at the optimum condition for high fibre and low calorie whey based watermelon beverages made with whey, Innova® fibre and sucralose, Design-Expert version 7.1.3 (2009) software was used while the desired goals for each variable and response were chosen as summarized in Table 3. Numerical optimization was carried out for this study. Table 4 shows the software-generated optimum condition for independent variables with predicted values of responses, which were 51.46 % whey, 3.84 % Innova® fibre and 0.021 % sucralose for achieving the highest scores of flavour (7.46), mouthfeel (7.49), after-taste (7.72), viscosity (13.55cp), TSS (15.34°Brix) and lowest score of sedimentation (1.55 ml/10 ml). The final product was made with this formulation and compared with that of predicted values as demonstrated in Table 4. It can be inferred from the results of the t-test that there was no significant difference between the predicted and experimental values of responses. It is, therefore, confirmed that the selected combination is the best combination one in the term of sensory and physical responses delineated at beginning of the study.

Fig. 2.

Superimposed diagram for optimum condition as a function

Table 3.

Optimization parameter in the response optimizer for high fiber and low calorie whey based watermelon beverage

| Responses | Goal | Lower limit | Upper limit | Importance |

|---|---|---|---|---|

| Whey(%) | Maximize | 40 | 60 | 4 |

| Innova® fiber(%) | Is In Range | 2 | 5 | 3 |

| Sucralose(%) | Is In Range | 0.01 | 0.03 | 3 |

| Flavour | Maximize | 5.52 | 8.1 | 4 |

| Mouthfeel | Maximize | 5.2 | 7.54 | 4 |

| Aftertaste | Maximize | 5.7 | 8 | 4 |

| Viscosity(cp) | Maximize | 7 | 17 | 3 |

| Sedimentation(ml/10 ml) | Minimize | 0.051 | 2.43 | 3 |

| TSS(°Brix) | Maximize | 9.2 | 18.01 | 3 |

Lower and upper weights values were 1 for all variables

Table 4.

Optimized level of process parameter for high fiber and low calorie whey based watermelon beverage

| Attributes | Predicted value | Experimental valuea | % deviation | tcal |

|---|---|---|---|---|

| Flavour | 7.46 | 7.21 | −3.36 | −1.78 |

| Mouthfeel | 7.49 | 7.43 | −0.80 | −0.50 |

| Aftertaste | 7.72 | 7.4 | −2.9 | −1.047 |

| Viscosity | 13.55 | 13.96 | 3.0 | 1.78 |

| Sedimentation | 1.55 | 1.54 | −1.30 | −0.969 |

| TSS | 15.34 | 15.29 | 0.85 | −0.21 |

Ho: μo = μ1, tcal < t table at p < 0.1, ‘Ho’ was accepted

aMean of five replications

Conclusion

The present investigation demonstrated the feasibility of using whey, an under-utilized dairy by-product normally thrown into the gutters, for development of whey based fruit beverage. The CCRD based experimental design was found to be very useful for the development of high fiber and low calorie whey based watermelon beverage. The result showed that the formulation contain 51.46 % whey, 3.84 % Innova® fiber and 0.21 % sucralose was the most effective formulation to achieve the desirable flavour, mouthfeel, aftertaste, overall acceptability and TSS and highest reduction in sedimentation and viscosity.

References

- Anderson JW, Tietyen-Clark J. Dietary fibre: hyperlipidemia, hypertension, and coronary heart disease. Am J Gastroenterol. 1986;81:907. [PubMed] [Google Scholar]

- Arabie P, Moskowitz HR. The effects of the viscosity upon perceived sweetness. Percept Psychophys. 1971;9:410–412. doi: 10.3758/BF03210240. [DOI] [Google Scholar]

- Berry D. Whey proteins role. J Dairy Food. 2002;103(10):38–46. [Google Scholar]

- BIS . ISI handbook of food analysis. IS: SP: 18 part XI dairy products. New Delhi: Bureau of Indian Standards; 1981. [Google Scholar]

- Branger EB, Sims CA, Schmidt RH, Keefe SFO, Cornell JA. Sensory characteristics of cottage cheese whey and grapefruit juice blends and changes during processing. J Food Sci. 1999;64(1):180–184. doi: 10.1111/j.1365-2621.1999.tb09887.x. [DOI] [Google Scholar]

- Brenna CS, Samyue E. Evaluation of starch degradation and textural characteristics of dietary fiber enriched biscuits. Int J Food Prop. 2004;7:647–657. doi: 10.1081/JFP-200033070. [DOI] [Google Scholar]

- Chakraborty SK, Kumbhar BK, Chakraborty S, Yadav P, Sharma HP. Colour characteristics and overall acceptability of fibre enriched biscuits: a response surface approach. Int J Food Eng. 2010;6(6):6. doi: 10.2202/1556-3758.1925. [DOI] [Google Scholar]

- Chakraborty SK, Kumbhar BK, Chakraborty S, Yadav P. Influence of processing parameters on textural characteristics and overall acceptability of millet enriched biscuits using response surface methodology. J Food Sci Technol. 2011;48(2):167–174. doi: 10.1007/s13197-010-0164-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chattopadhyay S, Raychaudhuri U, Chakraborty R. Artificial sweeteners – a review. J Food Sci Technol. 2011 doi: 10.1007/s13197-011-0571-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Devkota K (1991) Protein-pectin interactions in cottage cheese whey. M.Sc. thesis, University of Alberta, Canada 202 p

- FAO (2010) http://faostat.fao.org/site/569/Default.aspx?PageID=569#ancor accessed on January 13, 2011

- Gil MI, Aguayo E, Kaer AA. Quality changes and nutrient retention in fresh-cut versus whole fruits during storage. J Agric Food Chem. 2006;54:4284–4296. doi: 10.1021/jf060303y. [DOI] [PubMed] [Google Scholar]

- Giovannucci E. A review of epidemiologic studies of tomatoes, lycopene, and prostate cancer. Exp Biol Med (Maywood) 2002;227(10):852–859. doi: 10.1177/153537020222701003. [DOI] [PubMed] [Google Scholar]

- Helgren FJ, Lynch MJ, Kirchmeyer FJ. A taste panel study of saccharin off-taste. J Am Pharm Assoc. 1955;44:353–355. doi: 10.1002/jps.3030440613. [DOI] [PubMed] [Google Scholar]

- Hofer A. Whey a by-product or a source of valuable milk constituents. DMZ Milchwirtschaft. 1995;116:124–126. [Google Scholar]

- Hollowood TA, Linforth RST, Taylor AJ. The effect of viscosity on the perception of flavour. Chem Senses. 2002;27:583–591. doi: 10.1093/chemse/27.7.583. [DOI] [PubMed] [Google Scholar]

- Holsinger VH, Posati LP, DeVilbiss ED. Whey beverages: a review. J Dairy Sci. 1974;57:849–858. doi: 10.3168/jds.S0022-0302(74)84976-3. [DOI] [PubMed] [Google Scholar]

- Hostettler VH, Imhoff K. Studies on sedimentation and formation of a mealy-chalky texture of UHT steam injected milk. Milchwissenschafft. 1963;18(1):2–6. [Google Scholar]

- Ingale MP, Ranveer RC, Nagargole KD. Development of whey based custard apple (Annona Squamosa L.) beverage. Beverage Food World. 2009;36(12):4344. [Google Scholar]

- Jimenez-Escribano A, Rincin M, Pulido R, Saura-Calixto F. Guava fruits as a new source of antioxidant dietry fiber. J Agric Food Chem. 2001;49:5489–5493. doi: 10.1021/jf010147p. [DOI] [PubMed] [Google Scholar]

- Kappes SM, Schmidt SJ, Lee SY. Descriptive analysis of cola and lemon/lime carbonated beverages. J Food Sci. 2006;71(8):S583–S590. doi: 10.1111/j.1750-3841.2006.00162.x. [DOI] [Google Scholar]

- Kaul RK, Gupta N, Sharma I, Gupta V. Dietary fibres: a review. Beverage Food World. 2009;36(7):23–27. [Google Scholar]

- Khuri AI, Cornell JA. Response surfaces: designs and analyses. New York: Marcel Dekker publication; 1987. [Google Scholar]

- Klaus K (1995) Dietary supplement based on soluble dietary fibers. http://www.wipo.int/patentscope/search/en/WO1995006417

- Mendonca CRB, Zambiazi RC, Gularte MA, Granada GG. Sensory characteristics of light peach compote adjusted with sucralose and acesulfame-K. Cienc Tecnologia Alimentos. 2005;25(3):401–407. doi: 10.1590/S0101-20612005000300002. [DOI] [Google Scholar]

- Mittal S, Bajwa U. Effect of fat and sugar substitution on the quality characteristics of low calorie milk drinks. J Food Sci Technol. 2011 doi: 10.1007/s13197-010-0216-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Murdia LK, Paliwal S, Wadhwani R. Waste management in dairy industry-current practices. Indian Dairyman. 2005;57(5):30. [Google Scholar]

- O’ Carroll P (2001) Sweetener trends. World Food Ingred J Pract Food Technol 34–60

- Perkins-Veazie P, Collins JK, Pair SD, Roberts W. Lycopene content differs among red-fleshed watermelon cultivars. J Sci Food Agric. 2001;81(10):983–987. doi: 10.1002/jsfa.880. [DOI] [Google Scholar]

- Ranhotra G, Gelroth J, Bright P. Effect of source of fibre in bread based diets on blood and liver lipids in rats. J Food Sci. 1987;52:1420. doi: 10.1111/j.1365-2621.1987.tb14097.x. [DOI] [Google Scholar]

- Reddy LV, Reddy YHK, Reddy LPA, Reddy OVS. Wine production by novel yeast biocatalyst prepared by immobilization on watermelon (Citrullus vulgaris) rind pieces and characterization of volatile compounds. Proc Biochem. 2008;43(7):748–752. doi: 10.1016/j.procbio.2008.02.020. [DOI] [Google Scholar]

- Sachdeva S, Singh S. Optimization processing parameters in manufacture of paneer. J Food Sci Tehnol. 1988;25(3):142–145. [Google Scholar]

- Sarah L, Mason LD, Anne S, Meyer Viscosity of enzymatically-extracted potato fibres in fruit juices. Annu Trans Nordic Rheology Soc. 2006;14:1–2. [Google Scholar]

- Singh S, Ladkani BG, Kumar A, Mathur BN. Development of whey based beverages. Indian J Dairy Sci. 1994;47:586–590. [Google Scholar]

- Stamp JA. Sorting out the alternative sweeteners. Cereal Food World. 1990;35:395–400. [Google Scholar]