Abstract

Meat and meat products are generally recognized as good sources of high biological value proteins, fat-soluble vitamins, minerals, trace elements and bioactive compounds. Changes in socioeconomic factors in recent years have increased the consumer’s preference for ready to eat foods including meat products. The processing of meat and meat products leads to generation of many functional compounds beneficial to human health but most of those foods are rich in fat, added salts but deficient in complex carbohydrates like dietary fiber and pose a health hazard that somehow is proved to be a predisposing factor for cardiovascular diseases, colon cancer, obesity including diabetes mellitus. With increasing consciousness among consumers about their nutrition and well being, there is a growing concern over nutritional diseases of affluence. Therefore an increase in dietary fiber inclusion in daily diet has been recommended. For adults, the recommended acceptable intakes of dietary fiber are 28–36 g/day, 70–80 % of which must be insoluble fiber. The insoluble fraction of dietary fiber has been related to intestinal regulation whereas soluble fiber is associated with decrease in cholesterol level and absorption of intestinal glucose. So incorporation of dietary fibers from different sources in meat products would help to enhance their desirability. Dietary fiber sources are generally agricultural byproducts that are comparatively cheap and incorporation in meat products reduces its overall cost. Whole grains and cereal brans are the rich source of insoluble fiber and pectins, gums, starch and other storage polysaccharides have high content of the soluble fraction. With this background, the effect of various dietary fibers on the quality attributes of meat and meat products with its physiological role has been reviewed here.

Keywords: Meat, Dietary fiber, Physico-chemical properties, Sensory quality

Introduction

While food has long been used to improve health, our knowledge of health is now being used to improve foods (Fergus 2004). So a promising approach in improving health care is zeroing on to produce a healthier food supply as preventive health care strategy (Decker and Park 2010).

Meat has a great potential for delivering important nutrients like quality proteins and some essential fat-soluble vitamins and minerals of high degree of bioavailability as compared to other foodstuffs (Chan 2004; Biesalski 2005) and further processing of meat and meat products leads to generation of many compounds beneficial to human health (Saiga et al. 2003; Vercruysse et al. 2005) but recently a negative campaign about the possible health hazards by meat consumption (Verma and Banerjee 2010; Biswas et al. 2011) and understanding of relationship between nutrition and health has resulted in the development of concept of functional foods (Bhat and Bhat 2011) including meat products. It contains the technologically developed ingredients with a specific health benefit (Roberfroid 2002; Alzamora et al. 2005; Niva 2007). Epidemiological research has demonstrated the relationship between diet deficient in dietary fiber and other complex carbohydrates and increase of a number of chronic diseases, including colon cancer, obesity and cardiovascular diseases (WHO/FAO 2003). The direct relationship between energy dense diet and range of diseases (Best 1991; Kaeferstein and Clugston 1995; Beecher 1999) has emphasized the search of components that can be regarded as a marker of healthy diet.

Most of meat foods are rich in fat and protein but deficient in complex carbohydrates like dietary fiber (Sanchez-Zapata et al. 2010) and its incorporation in the meat products from health point of view have been further emphasized a lot. Various types of fibers have been studied alone or in combination for the formulation of low fat meat products (Desmond et al. 1998a; Mansour and Khalil 1999) and meat emulsions (Claus and Hunt 1991; Chang and Carpenter 1997). The effect of dietary fiber on the quality attributes of meat and its physiological role has been reviewed as under:

-

Dietary fiber

The term dietary fiber was first used in 1953 by Eben Hipsley to describe the unavailable carbohydrate content in foods, which lowered the rates of pregnancy toxaemia (Hipsley 1953). Previously the analytical term ‘crude fiber’ was used for components that escaped acid and alkali extractions (Trowell 1976; Mehta and Kaur 1992). Spiller et al. (1978) used the term ‘plantix’ for fiber and Trowell et al. (1985) defined dietary fiber as “sum of polysaccharides and lignin not digested by human gastrointestinal tract.” The conflict between what to define as dietary fiber and its analysis has made its definition in classification a little tough for public health agencies and food industries (Buttriss and Stokes 2008; McCleary 2008). According to American Association of Cereal Chemists, dietary fiber is the remanant of edible part of plants that escaped digestion and absorption in small intestine (Asp 1987; AACC 2001). The components that constitute dietary fiber are listed in the Table 1.

-

System of classification

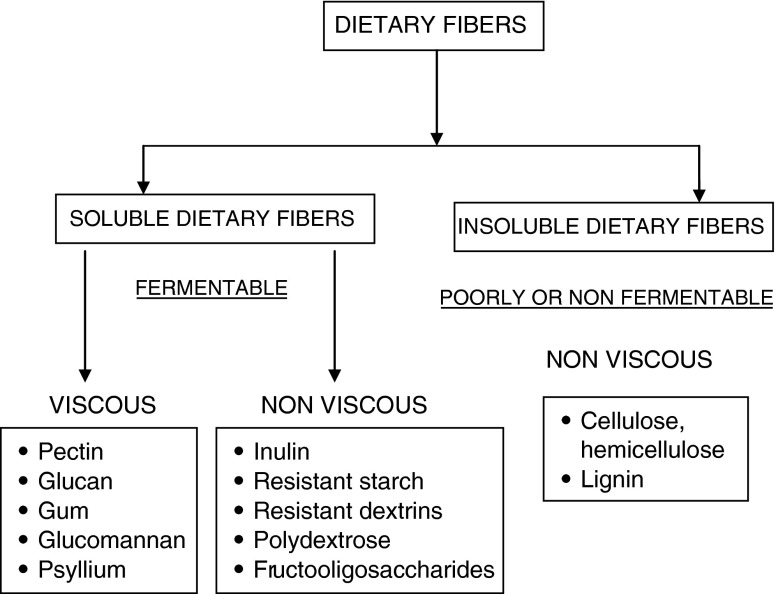

Dietary fiber can be classified by many possible ways, such as, on the basis of sources from which they are derived and that can be further categorized into plant polysaccharides, animal polysaccharides or synthetic sources. On the basis of the structure, they can be classified into linear or non linear polysaccharides. But the most widely accepted and used system of classification is on the basis of solubility and/or the fermentation behavior in an invitro system using an enzyme component which simulates that of human alimentary canal. According to their water solubility, dietary fiber is conventionally classified into insoluble dietary fiber (IDF)/less fermented fiber and soluble dietary fiber (SDF)/well fermented fibers. Insoluble fiber consists of cellulose, part of hemicellulose and lignin and soluble fiber consists of pentosans, pectins, gums and mucilage (Esposito et al. 2005; Chawla and Patil 2010). Welsh et al. (1994) and Slavin et al. (1997) concluded that the whole grains are the major source of insoluble dietary fiber and Van Soest (1976) reported that maximum amount of hemicellulose in diet is contributed by bran and husks. The classification of dietary fiber based on solubility is shown in Table 2 and according to chemical properties has been classified in Fig. 1.- Cellulose: Cellulose is a linear chain of β (1 → 4) linked glucose monomers and is the structural component of cell walls in green plants and vegetables. It is water insoluble and inert to digestive enzymes in the small intestine. However, it can go through microbial fermentation to a certain degree in the large intestine in turn producing short chain fatty acids. Basically, cellulose can be divided into two groups: Crystalline and amorphous. The crystalline component, which is made up of intra and intermolecular non covalent hydrogen bonds, make cellulose insoluble in water. It is also responsible for its great mechanical strength and resistance to microbial degradation and makes up a large portion of cellulose. On the other hand, the amorphous portion is readily hydrolysed and makes up a little (10–15 %) portion of total cellulose (Aspinall 1970).

- Hemicellulose: It consists of chain of β (1 → 4) linked glucose monomers similar to that of cellulose but they are smaller in size, usually branched and contain variety of sugar moieties like xylose, mannose and arabinose (Kay 1982).

- Resistant starches (RS): Any starch not digested in the small intestine is known as resistant starch. It behaves like soluble fiber without sacrificing palatability and mouth feel. RS has been classified into four basic types - Type 1 (RS1) is made up of starch granules surrounded by an indigestible plant matrix. Type 2 (RS2) occurs in its natural form such as in an uncooked potato and high amylose maize. Type 3 (RS3) are crystallized starches made by unique cooking and cooling processes. Type 4 (RS4) is a starch chemically modified by esterification, crosslinking, or transglycosylation and is not found in nature. The cross-linked RS4 is found to elicit a greater glucose lowering effect than the more commonly tested RS2 (Haub et al. 2010).

- Lignin: It is a polymer containing the oxygenated phenylpropane units including the coniferyl, sinapyl and p-coumaryl alcohols that have undergone a complex dehydrogenative polymerization (Schubert 1956; Theander and Aman 1979). It is very inert in nature and has a greater resistance power than any other naturally occurring polymer (Dhingra et al. 2012).

- Pectin: Pectin is a linear polymer of galacturonic acid connected with α (1 → 4) bonds. It is a water soluble polysaccharide that bypasses enzymatic digestion of the small intestine but is easily degraded by the microflora of the colon. At commercial level, these are typically used in food applications which require a gelling or a thickening agent. Inside the GI tract, pectin maintains this ability to form a gel or thicken a solution. Due to this gelling behavior, it is linked to many beneficial effects on health including dumping syndrome (Lawaetz et al. 1983), improved cholesterol and lipid metabolism (Brown et al. 1999) and diabetes prevention and control (Jenkins et al. 1977).

-

Recommended dietary allowances (RDA) for dietary fiber

The dietary fiber has been recognized as an important part of the complete diet and it is believed that a fiber intake of 30–40 g/day is desirable. Out of it, half should be derived from cereal bran and other half from fruits and vegetables (Nayak et al. 2000). The amount of dietary fiber provided by cereals depends on the source and the degree of processing. For example, the content of fiber in refined wheat flour is 2.5 g/100 g while in unrefined flour, it is 12 g/100 g which is around five times higher than former. The insoluble fraction of dietary fiber gets removed at large during refining process (Rodriguez et al. 2006).

The recommendations regarding the intake of dietary fiber are not same in all countries. The difference is due to the variable eating habits, lifestyles and the degree of processing of various food products consumed in different countries (Bemiller 2004). An average Indian diet contains about 6–8.5 g of crude fiber (Mehta and Kaur 1992). Some International Committee recommendations for the total dietary fiber intake in diet per day has been presented in Table 3.

-

Physiological role and health benefits of dietary fiber

Dietary fiber plays a significant role in prevention of several diseases and maintenance of health. The mechanism by which each fiber exerts a protective action in the body varies with the type and composition of that fiber.-

Dietary fiber as a restraint for prevention of risk of cardiovascular diseasesDietary fiber acts as a protective agent against cardiovascular diseases. They exert this action by acting as reducing agent of hyperlipidemia and hypocholesterolemia (Bosaeus et al. 1986; Arjmandi et al. 1997; Chau et al. 2004; Kendall et al. 2009). The exact mechanism by which dietary fibers lower serum LDL cholesterol levels is not known. Evidence suggests that they may interfere with lipid and/or bile acid metabolism. Dietary fiber from coconut is rich in uronic acid, glucomannans and galactomannans which are metabolized by microflora of large intestine and produce short chain fatty acids such as acetates, propionate and butyrate that contribute to lowering serum cholesterol levels (Trinidad et al. 2006; Theuwissen and Mensink 2008). Similarly dietary fiber from other sources such as oat bran, guar gum (Fahrenbach et al. 1965), psyllium (Garvin et al. 1965) have also been found to lower the serum cholesterol levels.Other suggested mechanisms include inhibition of hepatic lipoprotein production and cholesterol synthesis, delayed absorption of macro nutrients leading to increased insulin sensitivity and formation of protective membrane by dietary fibers around lipid droplet that prevent the action of lipase (Mun et al. 2006; Lunn and Buttriss 2007). It has also been suggested that dietary fiber has a capacity to bind bile acids and metabolites of cholesterol which play an important role in digestion and absorption of lipids in small intestine. This leads to lower serum cholesterol concentration by interrupting entero hepatic circulation (Eastwood 1992). The fiber polysaccharides affect the absorption of lipids, as they can be strong inhibitors of pancreatic lipase that participates in lipid metabolism (Dunaif and Schneeman 1981). On the other hand they decrease the level of total cholesterol and low-density lipoproteins in plasma by dilution and excretion of bile acids (Gallaher et al. 1992) and by decreasing absorption of biliary cholesterol (Marlett et al. 1994).

-

Improvement in gastrointestinal healthThe fiber can bind a large amount of water resulting in an increase in stool weight (Madar and Odes 1990; Cummings 1993; Kurasawa et al. 2000; Lefebvre and Thebaudin 2002). Increased stool bulk reduces colonic transit time which prevents constipation and production of carcinogenic and genotoxic compounds (Gibson 2004). Dietary fiber plays an important role in maintenance of gastrointestinal immunity. In particular, the fermentable fiber diet result in an increased T-cell mitogen response and increased activity of gut associated lymphoid tissue (GALT) (Field et al. 1999). The fermentation of dietary fiber in large intestine by gut microflora results in increased level of short chain fatty acids which are believed to be important for promoting the health of colonic epithelium (Topping and Clifton 2001). Also, it results in lowering of colonic pH, which inhibits the potentially harmful bacteria and promote the growth of favorable lactic acid microflora (Grasten et al. 2003).

-

Role of fiber in preventing cancerRelationship between dietary fiber and colon cancer, despite its complexity, are quite well documented. Dietary fiber imparts anticarcinogenic and antitumerogenic effects either by reducing the production of carcinogenic substances in colon (Rumney and Rowland 1995) or by increasing faecal bulk that ultimately decreases effective interactions between intestinal mucosa and cancer risk agents present in faeces (Armstrong and Doll 1975; Harris and Ferguson 1993). Dietary fiber might reduce the risk of colorectal cancer by enhanced fermentation in large intestine leading to productions of high levels of short chain fatty acids (Sharma et al. 2008). The butyric acid is reported to promote cell differentiation and inhibit the production of secondary bile acids by reducing luminal pH resulting in reduction of risk of malignant changes in cell (Potter 1999).

-

Fiber and diabetes mellitusThe risk of Type 2 diabetes mellitus is inversely correlated with intake of diets with high fiber content (Chandali et al. 2000; Schulze et al. 2004). The reduction in plasma glucose concentration as a result of consumption of various fiber sources may be due to several events. The fiber has ability to lower post-prandial glucose peak, which leads to decreased insulin demands and protects the over exhaustion of the pancreas. The ingested fibers slow gastric emptying by forming a gel matrix as a result of their high water holding capacity (Wursch and Pi-Sunyer 1997). This gel matrix may thicken small intestinal contents and decrease the contact between food and digestive enzymes (Jenkins et al. 1978). In addition, the fibers could alter the contractile movements in gastro intestinal tracts and thereby decrease the transport of glucose to the absorptive surface (Edwards et al. 1998; Mälkki 2001).

-

Fiber as an effective tool for weight managementA number of researches have also examined the potential of dietary fiber as satiety agent and a contributor to weight management (Sharma et al. 2008; Mikusova et al. 2009). Dietary fiber intake may increase the mobilization and use of fat depots as a direct result of reduction in insulin secretion (Tapsell 2004). The diets rich in fiber lead to slowing down in gastric emptying resulting in slower rate of nutrient absorption (Behall 1997; Brennan 2005). The high fiber diet also reduces the energy density of overall diet.

-

-

Functional properties of dietary fiber in meat products

Utilization and incorporation of dietary fiber in meat products are gaining importance day by day. The suitability of fiber incorporation in meat products is increasing because of the numerous functional properties like water retention, lubrication, ability to decrease cooking loss, texture modification and neutral flavor (Jimenez-Colomenero 1996; Akoh 1998). Dietary fibers isolated from various plant sources, dehydrated fruits, vegetables and cereal fibers have been used in the food industry and has shown the promising results (Viuda-Martos et al. 2010). However, the fruit and vegetable fiber has found to have better oil binding capacity which is of significant importance in emulsion based products (Rodriguez et al. 2006). The hydration and oil binding properties of dietary fiber are related to their chemical structure, pH, ionic strength and particle size (Fleury and Lahaye 1991) (Table 4). Both of these properties in turn, affect the possibility about the use of various fibers as ingredients in meat products. For example, dietary fiber with high oil holding capacity allows the stabilization of fat in emulsion based products whereas, the dietary fibers with high water holding capacity can be used as a functional ingredient to avoid synaeresis and to modify the viscosity and texture of some formulated foods (Grigelmo-Miguel and Martina-Belloso 1999). Various fiber sources like oat, sugar beet, soy, pea, psyllium etc. have been tried in formulation of some meat products such as patties and sausages (Andres 1986; Przybyla 1988; Chan and Wypyszyk 1988; Trout et al. 1992; Duxbury 1993; Keeton 1994; Mauro and Wang 1997; Confrades et al. 2000). Fiber is also being used as an extender, binder and fat replacer in manufacturing various meat products (Gelroth and Ranhotra 2001; Modi et al. 2009a; Viuda-Martos et al. 2010). A comprehensive list of different fiber sources utlilized in formulation of various meat products has been presented in Table 5.

-

Effect of fiber addition on physico-chemical properties of meat products

Inherent functional properties of fiber has a profound effect on physicochemical properties. Fiber addition in meat results in decreasing cooking loss, alteration in pH and an increase in emulsion stability. The higher emulsion stability resulting in a higher cooking yield of emulsion based meat products is important from technological as well as economical point of view. The change in pH on addition of dietary fiber source largely depends upon the pH of the fiber source added. Grigelmo-Miguel et al. (1999) used two different peach dietary fiber suspensions (17 and 29 %) to obtain low fat high dietary fiber frankfurters. They found that viscosity of meat batters increased with dietary fiber content and the added dietary fiber was effective in retaining water in the product. There was also a reduction in pH value of the frankfurters incorporated with peach dietary fiber and it further decreased as level of incorporation increased. A similar trend of decrease in pH value was also recorded by Alesson-Carbonell et al. (2004) who reported that when lemon albdeo was added in non fermented dry cured sausages, pH decreased due to acidic nature of the albedo owing to the organic acids present in raw albedo. Addition of dried orange fibre at 10, 15 and 20 g/kg level in dry cured fermented sausage decreased pH during curing process. With increasing concentration of fibre, pH decreased progressively (Fernandez-Lopez et al. 2007). On the contrary, Fernandez-Gines et al. (2004) observed that the pH of bologna sausage containing raw albedo did not differ from that of control. The pH of raw lemon albedo (4.53) increased to 5.02 on cooking. They suggested that cooking favours the leaching out of organic acids present in albedo that increased its pH. As cooking process itself increases meat pH, probably due to the breaking down of the cellular buffer and release of free fat, they suggested that lemon albedo decreased the pH, but the cooking process reversed this effect. Goat meat patties having kinnow rind powder extract had lower pH (6.02) as compared to control (6.23). It was attributed to acidic pH of extracts by Devatkal et al. (2010).

Apart from a pH lowering effect, the major advantage of dietary fiber from citrus fruits is that they contain higher proportion of soluble dietary fiber (33 %) as compared to conventional alternative sources of fiber like cereals (7 %) (Grigelmo-Miguel and Martina-Belloso 1999; Gorinstein et al. 2001; Fernández-López et al. 2004). An increase in pH with the incorporation of dietary fiber has been reported by Rao and Reddy (2000) in chicken loaves added with Bengal and Black gram flour. Rye bran was incorporated at four different levels viz. 5, 10, 15 and 20 % and results revealed that the pH increased significantly (p ≤ 0.05) at 10 % level as compared to control (Yilmaz 2004). Similar increase in pH value was again reported in meatballs incorporated with wheat bran at 5, 10, 15 and 20 % levels and the highest pH was obtained with addition of 20 % wheat bran (Yilmaz 2005). Talukdar and Sharma(2010) incorporated wheat bran and oat bran at 5, 10 and 15 % levels in chicken meat patties. They reported an increase in pH of emulsion as well as cooked product on incorporation of wheat bran.

Another important physicochemical property of meat products is Water Holding Capacity (WHC), Emulsion Stability (ES) and Cooking yield. WHC is the ability of meat to hold fast its own or added water during processing. Good WHC is essential as it provides desirable characteristics to meat products. Fiber is suitable for addition to meat products and has been used previously in cooked meat products to increase the WHC (Confrades et al. 2000). This in turn affects emulsion stability and cooking yield of the final product. A higher WHC is responsible for a high value of both ES and cooking yield. Chang and Carpenter (1997) incorporated oat bran with a view to reduce fat in frankfurters. With an increased oat bran level, more water was retained in frankfurters. Hughes et al. (1997) investigated the effects of fat level (5, 12 and 30 %), carrageenan and oat fibre on the hydration/binding properties of frankfurters. Decreasing the fat content from 30 % to 5 % significantly increased cook loss and decreased water holding capacity and emulsion stability. Addition of 2 % oat fiber reduced the total expressible fluid from 9.6 to 7.6 % and from 4.8 to 4.3 % in frankfurters having 5 and 12 % targeted fat, respectively. They concluded that addition of carrageenan or oat fibre reduced cooking loss and increased both water holding capacity and emulsion stability.

Anderson and Berry (2000) examined the properties of lower fat (10 and 14 %) ground beef patties containing inner pea fiber and revealed that it had improved the cooking yield and tenderness. Rao and Reddy (2000) also used 20 % Bengal Gram Flour (BGGF) and 20 % Black Gram Flour (BGF) in chicken loaves and found that addition of these two fiber sources resulted in significant (p ≤ 0.01) reduction of cooking losses and Extract Release Volume (ERV) whereas a higher value for emulsion stability and pH value was recorded. The cooking yields on addition of high absorption or bleached oat fiber upto 3 % level in light bologna and fat free frankfurters were increased (Steenblock et al. 2001). Kumar and Sharma (2004) observed that cooking yield, moisture retention and dimensional parameters of low fat ground pork patties increased (p ≤ 0.05) with increasing levels (4, 7 and 10 %) of barley flour as fiber source. Lin and Lin (2004) also found that addition of Bacterial cellulose (Nata.) in Chinese-style meatball increased the water holding capacity of raw meatballs than control but pattern was reversed after cooking because cooking losses of Nata-containing products were higher than that of control. Turhan et al. (2005) concluded that addition of hazel nut pellicle fiber increased the cooking yield and thickness of beef burgers. Similarly, Serdaroglu et al. (2005) used blackeye bean flour, chickpea flour, lentil flour and rusk in meatballs. They also observed that cooking yield was improved on incorporation with bean flour and lentil flour. But on contrary, Morin et al. (2004) found an increase in cooking loss on addition of carboxy methylcellulose in breakfast sausages than control samples. Also, Modi et al. (2009c) reported that inclusion of oat flour and carrageenan resulted a significant increase in cooking yield of fried meat kofta.

Vural et al. (2004) and Javidipour et al. (2005) utilized sugar beet fiber and reported a significant increase in water holding capacity and total dietary fiber content of frankfurters and Turkish- type salami, respectively. The emulsion pH, emulsion stability and cooking yield was increased on incorporation of rice bran at different levels in meat batters (Choi et al. 2007). The addition of dietary fibers from pea and wheat improved the water binding capacity including cooking yield and decreased the shrinkage in beef burgers (Besbes et al. 2008). Pinero et al. (2008) evaluated the effect of adding oat fiber source of β-glucan in low fat (<10 %) beef patties as compared to 20 % fat (control) patties and they observed significant (p ≤ 0.05) improvements in cooking yield, fat retention and moisture content in fiber added patties as compared to control. But Singh et al. (2008) found that chicken nuggets prepared with roasted pea flour up to 10 % levels had a non-significant rise in cooking yield.

Two types of lemon albedo (raw and dehydrated) at 5 different concentrations (0, 2.5, 5, 7.5 and 10 %) were used by Saricoban et al. (2008) to evaluate their effect on functional properties of emulsions. Its addition increased the emulsion capacity with highest value in 5 % albedo added emulsions. A similar trend was followed in emulsion stability values. Emulsion viscosity values were positively correlated with an increase in albedo concentration and highest value was obtained at 10 % level while there was no change in flow properties of emulsions but an increase in pseudoplasticity was reported.

The use of Bambara Groundnut Seed Flour (BGSF) significantly (p ≤ 0.05) increased the pH of cooked patties from 6.16 to 6.23 and it significantly (p ≤ 0.05) reduced the shrinkage of cooked patties from 9.13 to 6.76 %, while percentage cooking yield, moisture retention and fat retention increased significantly (p ≤ 0.05) with increasing BGSF levels from 79.1 to 87.2 %, 67.5 to 78.05 % and 73.51 to 88.34 %, respectively in beef patties (Alakali et al. 2010). Prinyawiwatkul et al. (1997) and Naveena et al. (2006) also reported an increase in cooking yields in chicken nuggets and chicken patties incorporated with cowpea and/or peanut flour and ragi millet flour, respectively. An increase in cooking yield and a significant decrease in shrinkage of buffalo meat burger incorporated with different decorticated legume flours has been observed by Modi et al. (2003)

-

Effect of dietary fiber addition on proximate composition of meat products

Fiber addition in meat products can result in a change in overall composition of the final products. This has led to the emergence of novel sources of fibers, being offering new opportunities in their use in the industries (Guillon and Champ 2000). Chang and Carpenter (1997) worked on the addition of hydrated oat bran in frankfurters and found that moisture content and carbohydrate level increased with a subsequent increasing level of water and oat bran. However, moisture and fat content were decreased with increasing levels of oat bran. Similarly, Dawkins et al. (1999) utilized oat bran at 15, 20, 35 and 50 % levels in chevon patties and reported that moisture, protein and fat content were decreased and ash and total dietary fibre (TDF) were increased with increasing levels of oat bran, but Mansour and Khalil (1999) reported an increase in moisture, protein, ash and carbohydrate content in cooked and uncooked beef burgers with hydrated wheat fiber (1:1). They explained that the decrease in fat content was due to the fact that wheat fiber was used as a fat replacer. With increasing amounts of oat bran (5, 10, 15 and 20 % levels), the moisture and fat content decreased while protein and ash content increased (Yilmaz and Daglioglu 2003). Yilmaz (2004) reported a decrease in moisture and fat content but an increase in protein and ash content with an increasing amount of rye bran addition in low fat meatballs. Huang et al. (2005) found that use of rice bran in kung-wan, an emulsified pork meatball decreased protein and fat contents of meatballs, and in contrast, carbohydrate content significantly increased with increasing amount of rice bran. Yilmaz (2005) determined a decrement in fat and moisture content but an increment in protein and ash percent with increasing level of wheat bran viz. 5, 10, 15 and 20 % in low fat meatball but Saricoban et al. (2009) reported that addition of wheat bran decreased protein and increased fat per cent of cooked beef patties.

Serdaroglu (2006) used three concentrations of oat flour viz 0, 2 and 4 % (v/w) in beef patties and reported that addition of oat flour resulted in a decrease in moisture content in raw patties but an increase in cooked patties. The addition of oat flour did not change the protein, fat and ash content of raw or cooked patties. Yasarlar et al. (2007) added cereals bran at 5, 10, 15 and 20 % in meatballs and recorded that moisture and fat content gradually decreased with rise in added wheat and oat bran but protein, ash and dietary fiber increased as level of wheat and oat bran increased. Choi et al. (2008 and 2009) reported an increase in ash content with addition of rice bran fiber to emulsion type sausages and low fat meat emulsions, respectively. Bilek and Turhan (2009) added flax seed flour at 3, 6, 9, 12 and 15 % concentration in beef patties and observed that with an increasing level of flax seed flour, fat and ash content increased while moisture and protein content decreased. Kenawi et al. (2009) studied the effect of mung bean powder and/or low fat soy flour on proximate composition of buffalo meat patties. Low fat soy flour or mung bean powder at a level of 10 % reduced the moisture and fat content whereas increased the fiber and protein contents.

Low fat and high fibre mutton kofta was developed by Modi et al. (2009b) using minced meat and optimized quantities of wheat flour, oat flour and carrageenan. Inclusion of oat flour and carrageenan significantly lowered fat content and increased moisture, protein, ash and carbohydrate percentage in treated products as compared to control, but Dzudie et al. (2002) and Naveena et al. (2006) reported lower protein content in beef patties and chicken patties formulated with different levels of common bean flour and ragi millet flour, respectively. The moisture content of raw beef patties incorporated with Bambara Groundnut Seed Flour (BGSF) decreased but its addition resulted in significant increase in moisture content of cooked patties. The protein content gradually decreased and ash content increased with an increase in concentration of BGSF (Alakali et al. 2010). Choi et al. (2010) recorded the moisture, protein, fat and ash content of uncooked meat batter formulations with varying grape seed oil and rice bran fiber levels. They found that protein, fat and ash content of treatment with 20 % pork back fat and 2 % rice bran fiber was higher than treatment with only 20 % pork back fat. However, the moisture content was lower than in former. Similarly, addition of the dietary fibers (wheat fiber, oat fiber and inulin) resulted in significantly lower moisture content than control in Chinese-style sausages (Huang et al. 2011). The experimental and control groups did not exhibit significant differences in crude fat and protein contents but the crude fiber content increased with added dietary fiber while Szczepaniak et al. (2005) reported that comminuted sausages with different levels viz. 7.5 and 10 % of wheat fiber and oat fiber resulted in lower fat contents in comparison to control sausages while protein content did not differ significantly.

-

Effect of dietary fiber on sensory properties of meat products

Palatability of meat products is a complex trait which depends on aroma and flavour, colour, appearance, tenderness and juiciness. Out of all the above parameters, flavor and texture are given more weightage by the consumer. According to Risivik (1994), tender and juicy meat is generally preferred by the consumers. The addition of pea cotyledon fiber in low fat (10 and 14 %) beef patties resulted in improved tenderness without any negative effect on juiciness or beef flavor intensity (Anderson and Berry 2000). Sanjeewa et al. (2008) reported that addition of chickpea flour (made from kabuli and desi chickpeas) at 2.5 and 5 % levels in low fat pork bologna had no detrimental effect on sensory properties. They further explained that sensory scores for cohesiveness, firmness and graininess increased and juiciness decreased in chickpea flour added bologna as compared to control. Shand (2000) used hull-less waxy barley and normal starch barley in ultra low fat pork bologna sausages and concluded that hull-less waxy barley at 4 % level had better sensory properties than normal starch barley.

The sensory properties of low fat (6 %) dry fermented sausages at 3 % of incorporation of wheat and oat fibers were significantly affected as compared to control (Garcia et al. 2002). Lemon albedo addition in bologna sausages caused an increase in hardness and decrease in juiciness perception (Fernandez-Gines et al. 2004). This decrease was higher in bolognas with added raw albedo than cooked albedo. Kumar and Sharma (2004) developed low fat ground pork patties with three levels of barley flour (4, 7 and 10 %) and concluded that 4 % barley flour incorporation had higher (p ≤ 0.05) flavor and texture scores than 7 and 10 % levels. Turhan et al. (2005) reported that increasing levels of hazelnut pellicle resulted in decreased appearance and color, flavor and juiciness scores as compared to control in low fat beef burgers. But addition of jobs-tears (Coix lacryma-jobi), wheat groats (Triticum spp), Chinese wolfberry (Lycium chinensis), green pea (Pisum sativum) and celluloses did not alter the flavor acceptability of the frankfurters and no significant effect was observed in juiciness and hardness acceptability (Chen and Chi 2008). Eim et al. (2008) suggested that addition of carrot dietary fiber to sobrassada modified the organoleptic properties depending upon the concentration. All the sensory attributes were declined when the level of added dietary fiber was greater than 3 %. The sensory characteristics of cooked beef patties formulated with Bambara Groundnut Flour did not differ significantly up to 5 % level of inclusion but at 7.5 % level, a significant decrease in appearance, flavor, tenderness and overall acceptability was noticed by Alakali et al. (2010).

According to Kenawi et al. (2009) the product containing 5 % of both low fat soy flour and mung bean powder had the highest values for colour, taste, odour, juiciness and overall acceptability. Addition of low fat soy flour and mung bean powder increased the juiciness of patties as compared to control. On the contrary, Modi et al. (2009c) observed that inclusion of carrageenan and oat flour resulted in lowering of juiciness in fried meat kofta. Verma et al. (2009) incorporated various dietary fiber sources like pea hull flour, apple pulp, gram hull flour and bottle gourd in different combinations in low fat chicken nuggets. There were differences in different quality attributes among control and treated products but organoleptically latter were comparable to former. Yilmaz and Gegel (2009) reported that sensory scores of veal meatballs with 10, 15 and 20 % added inulin were less acceptable than control due to hardness, low juiciness and low flavor intensity. Viuda-Martos et al. (2010) also reported a decrease in juiciness and increase in hardness perception on sensory analysis of mortadellas added with orange dietary fiber. Global appearance, saltiness, fatness and acid taste were not affected by orange dietary fiber.

-

Fiber and textural properties of meat products

Texture, appearance and flavour are the three major components of food acceptability. Though there is no alternative of human perception for texture, Instron Texture Analyzer is popularly used. Other instruments commonly used for texture analysis of food products are Warner Bratzler shear press and Kramer Shear apparatus. Desmond et al. (1998b) investigated the effects of addition of tapioca starch, oat fiber and whey protein in low fat beef burgers. They found that Warner-Bratzler and Kramer shear force were negatively influenced by addition of above fiber sources. Lin and Lin (2004) reported that addition of bacterial cellulose (Nata.) in Chinese style meatball resulted in detrimental effect on textural attributes. The values for hardness, cohesiveness, springiness, chewiness and shear force showed a decreasing pattern with an increasing level of Nata incorporation.

An increase in hardness value of mortadella, a spanish cooked meat product incorporated with inulin was reported by Garcia et al. (2006). Inulin in powdered form increased hardness at 2.5 % level while in gel it affected hardness at 7.5 %. Kaack et al. (2006) studied the functionality of three new enzymatically extracted fibres as ingredients in pig liver pate prepared using reduced amount of pig fat with dry potato pulp and a commercial potato fiber (Potex) as references. Dry potato pulp, potex and two of the new enzymatically extracted fiber 1 and 2 with high contents of cellulose and lignin resulted in increased hardness, deformation energy and gumminess with a detrimental effect on texture while fiber 3 with low content of soluble non starch polyasaccharides (SNSP) resulted in better textural properties.

The hardness of pork sausage samples gradually decreased with the increasing addition of hydrated oatmeal (Yang et al. 2007). However, the springiness did not differ significantly amongst samples but gumminess and chewiness decreased with increasing levels of added hydrated oatmeal. A healthy and low fat fish sausage containing dietary fiber from swelite (a dietary fiber obtained from inner pea) and fibruline (a dietary fiber obtained from chicory root) was developed by Cardoso et al. (2008). They also replaced the different levels of pork meat by hake mince. The addition of swelite favored greater gel strength and hardness. High fibruline sausages were less cohesive and chewable than pork fat sausages (control), but also exhibited greater gel strength. Lee et al. (2008) determined the effect of addition of kimchi powder on textural properties of the breakfast sausages. Treatment containing 2 % kimchi powder had a higher hardness, gumminess and chewiness as compared to control. Similar increases in above textural parameters have been reported for frankfurters and bologna due to addition of soy fiber, plasma protein and other types of fiber (Confrades et al. 2000; Colmenero et al. 2005).

Saricoban et al. (2009) adopted a three-factor Box-Behnken design for studying the simultaneous effects of processing variables such as fat (10–30 %), wheat bran (5–15 %) and NaCl (0–2 %) on physico-chemical, textural and sensory properties of cooked beef patties. They found that addition of wheat bran increased hardness and gumminess but decreased springiness, resilience and cohesiveness with out influencing adhesiveness of the cooked beef patties.

The addition of orange dietary fiber in mortadellas also led to a significant increase in hardness and a decrease in springiness and chewiness as compared to control products (Viuda-Martos et al. 2010) but the cohesiveness was not affected by addition of orange dietary fiber. Choi et al. (2011) studied the addition of rice bran fiber on the textural properties of heat induced gel and found that hardness was significantly lower in gels with added rice bran fiber than the control samples. Similarly, springiness, cohesiveness, gumminess and chewiness were lower in all samples with added rice bran fiber relative to control.

Wan Rosli et al. (2011) studied the textural properties of chicken patties formulated with different levels of grey oyster mushroom (Pleurotus sajor-caju) at 0, 25 or 50 % as fiber source and fat replacer. They found that hardness of chicken patties decreased proportionally with the increasing level of oyster mushroom. Also, the cohesiveness, gumminess and chewiness of oyster mushroom based patties had lower values than control while springiness was higher than control chicken patties.

-

Quality characteristics of fiber rich meat products during storage

Maintaining stability and superior quality of a meat product during storage period is of utmost importance. Addition of various fiber sources in meat products have been found to influence the storage quality in various ways. Prasad et al. (2011) reported that oat flour had better inhibition of oxymyoglobin oxidation when added in chicken kofta as compared to control. The product was also found to be microbiologically safe and sensorily acceptable during the 15 days of storage. The oat flour in chicken kofta was found to have a synergistic effect as a fat replacer and natural antioxidant. The antioxidant activity of oat flour has been found due to high concentration of phenolic and tocol antioxidants (Duve and White 1991; Emmons et al. 1999). Similarly, Modi et al. (2003) has observed that the buffalo meat burger containing roasted flours registered lower TBA values which signifies lower lipid oxidation than control. The burgers were found to be organoleptically acceptable after storage at −16 + 2 °C for 4 months. Alvarez et al. (2011) found that the antioxidant activity of rice bran added frankfurters was preserved till 14 days of storage showing an efficient protection against lipid oxidation. On the contrary, Choi et al. (2010) found a higher lipid oxidation in rice bran supplemented frankfurters.

During storage the change in pH of meat products is an interesting phenomenon. Modi et al. (2009a) had reported a decrease in pH of fried mutton kofta added with oat flour during storage period for 6 weeks. But an increased alkalinity resulting in higher pH was observed in rice bran fiber added pork salt soluble meat proteins in a model system (Choi et al. 2011). Similar findings were observed by Verma et al. (2009) in storage of chicken nuggets with high fiber ingredients.

Table 1.

Components of dietary fiber

| Fiber components | Principal groupings | Fiber sources |

|---|---|---|

| Non starch polysaccharides and oligosaccharides | Cellulose | Cellulose plants (vegetable, sugar beet, various brans) |

| Hemicellulose | Arabinogalactans, β-glucans, arabinoxylans glucuronoxylans, xyloglucans, galactomannans, pectic substances | |

| Polyfructoses | Inulin, oligofructans | |

| Gums and mucilages | Seed extracts (galactomannans – guar and locust bean gum), tree exudates (gum acacia, gum karaya, gum tragacanth), algal polysaccharides (alginates, agar carrageenan), psyllium | |

| Carbohydrate analogues | Pectins | Fruits, vegetables, legumes, potato, sugar beets |

| Resistant starches and maltodextrins | Various plants such as maize, pea, potato | |

| Chemical synthesis | Polydextrose, lactulose, cellulose derivatives | |

| Enzymatic synthesis | Neosugar or short chain, guar hydrolyzate fructooligosaccharides, levan, xanthan gum, transgalactooligosaccharides, oligofructose, xylooligosaccharide, curdlan | |

| Lignin | Lignin | Woody plants |

| Substances associated with non starch polysaccharides | Waxes, cutin, Suberin | Plant fibers |

| Animal origin fibers | Chitin, chitosan, collagen, chondroitin | Fungi, yeasts, invertebrates |

(Tungland and Meyer 2002)

Table 2.

Classification of dietary fiber based on solubility

| Class | Examples |

|---|---|

| Insoluble | Cellulose |

| Soluble (only in hot water) | Agars, amylose, aligns, kappa-type carrageenans (in the presence of K+ or Ca2+), gelan, konjac, mannan, locust bean gum, low methoxyl pectins, granular starches and starch derivatives |

| Soluble (in water at room temperature but insoluble in hot water) | Curdlan, hydroxylpropylcelluloses, hydroxylpropylmethylcelluloses and methylcelluloses |

| Soluble (in water at room temperature and hot water) | Alginates, amylopectins, carboxymethylcelluloses, dextrins, iota type carrageenans, guar gum, gum Arabic, high methoxyl pectins, polydextrose and xanthan gum |

(Source: BeMiller 2001)

Fig. 1.

Classification of dietary fibers according to chemical properties

Table 3.

Some International Committee Recommendations regarding RDA for total dietary fiber intake

| Source | Recommendation (g/day) |

|---|---|

| National Cancer Institute | 20–30 |

| USDA and USFDA | 38 for men and 26 for women |

| National Academy of Sciences (USA) | 30–38 for men and 21–26 for women |

| UK Department of Health | 18 (expressed as Non starch polysachharide) |

| German Department of Health | 30 |

Table 4.

Water and oil holding capacity (WHC) of some dietary fiber (CHO) sources

| Sources of dietary fiber | WHC (g water/g) | OHC (g oil/g) | References |

|---|---|---|---|

| Sugarbeet fiber | 26.5–35.4 | – | Bertin et al. (1988) |

| Carrot dietary fiber | 18.6 | 5.5 | Eim et al. (2008) |

| Date dietary fiber concentrate | 15.6 | 9.75 | Elleuch et al. (2008) |

| Peach dietary fiber concentrate | 12.1 | 1.09 | Grigelmo-Miguel et al. (1999) |

| Orange dietary fiber concentrate | 7.3 | 1.27 | Grigelmo-Miguel et al. (1999) |

| Defatted rice bran | 4.89 | 4.54 | Abdul-Hamid and Luan 2000 |

| Wheat bran | 2.8–3.6 | 1.2–5 | Caprez et al. 1986 |

Table 5.

Various fiber sources utilized for formulation of fiber rich meat products

| Type/source of fiber | Type of meat product | References |

|---|---|---|

| High soluble fiber sources | ||

| Fructo-oligosaccherides | • Sausages | Caceres et al. 2004 |

| Inulin | • Sausages | Mendoza et al. 2001; McDonagh et al. 2005; Huang et al. 2011 |

| • Mortadella | Garcia et al. 2006 | |

| • Veal meatballs | Yilmaz and Gegel 2009 | |

| Carrageenan | • Mutton kofta | Modi et al. 2009c |

| Konjac flour | • Frankfurters | Lin and Huang 2003 |

| Carboxy methyl cellulose | • Sausages | Morin et al. 2004 |

| Legumes (hulls and flours) | • Beef patties | Muller and Redden 1995; Alakali et al. 2010 |

| • Meat Balls | Serdaroglu et al. 2005 | |

| • Buffalo Meat Burgers | Modi et al. 2003 | |

| • Chicken nuggets | Prinyawiwatkul et al. 1997; Singh et al. 2008; | |

| • Camel meat patties | Al-Khalifa and Atia 1997 | |

| • Beef burgers | Turhan et al. 2005; Besbes et al. 2008 | |

| • Goat meat patties | Gujral et al. 2002 | |

| • Chicken loaves | Rao and Reddy 2000 | |

| • Buffalo meat patties | Kenawi et al. 2009 | |

| Cereals and bran | ||

| Oat bran | • Meat balls | Yilmaz and Daglioglu 2003; Yasarlar et al. 2007 |

| • Pork sausages | Desmond and Troy 2003 | |

| Oat flour | • Beef patties | Serdaroglu 2006 |

| • Mutton kofta | Modi et al. 2009c | |

| • Chicken kofta | Prasad et al. 2011 | |

| Wheat bran | • Meat Balls | Yilmaz 2005 |

| • Beef patties | Saricoban et al. 2009 | |

| • Chicken patties | Talukdar and Sharma 2010 | |

| Rice bran | • Pork meatball | Huang et al. 2005 |

| • Meat batter, sausages and emulsions | Choi et al. 2007, 2008, 2009, 2010 | |

| • Frankfurters | Alvarez et al. 2011 | |

| Rye bran | • Meat balls | Yilmaz 2004 |

| Barley | • Bologna | Shand 2000 |

| • Pork patties | Kumar and Sharma 2004 | |

| Ragi millet | • Chicken patties | Naveena et al. 2006 |

| Fruits, vegetables and their by-products | ||

| Apple pulp | • Chicken nuggets | Verma et al. 2009 |

| • Fermented sausages | Garcia et al. 2002 | |

| Lemon albedo | • Sausages | Fernandez-Gines et al. 2004; Aleson-Carbonell et al. 2005 |

| Orange | • Fermented sausages | Garcia et al. 2002; Fernandez-Lopez et al. 2008 |

| • Bologna | Viuda-Martos et al. 2010 | |

| Kinnow | • Goat meat patties | Devatkal et al. 2010 |

| Peach dietary fiber | • Frankfurters | Grigelmo-Miguel and Martina-Belloso 1999 |

| • Fermented sausages | Garcia et al. 2002 | |

| Carrot dietary fiber | • Sobrassada | Eim et al. 2008 |

| • Chicken nuggets | Bhosale et al. 2011 | |

| Sugarbeet fiber | • Frankfurters | Ozboy-Ozbas et al. 2003; Vural et al. 2004 |

| • Turkish type Salami | Javidipour et al. 2005 | |

| Oyster mushroon | • Chicken patties | Wan Rosli et al. 2011 |

Challenges and future potential of fiber rich meat products

The suitability of dietary fiber incorporation in meat products is increasing because of its numerous functional properties like water retention, emulsion stability, lubrication, texture modification and neutral flavor. Various fiber sources like oat, rice, sugar beet, soy, pea, psyllium etc. have been tried in formulation of some meat products such as patties and sausages for development of nutritionally balanced diet. Fiber is also being used as a fat replacer in manufacturing of various meat products. Other than the nutritional properties, dietary fiber is now used in meat products for technological up gradation like improvement in cooking yields, rheological properties, reducing formulation costs and enhancing the palatability and texture of meat products. The dietary fiber rich meat products are considered clinically better than traditional meat products. But the real challenge actually lies in effective development and marketing of these functional meat products. Even from the consumer perspective, the trust on the composition and desired outcome of fiber rich meat products on regular consumption has to be widely studied. The development of meat products enriched with fiber is indeed a novel area. A lot of work is still left to unfold the real potential of those components which are scarcely used in diet or are now eliminated from diet due to change in food habits.

References

- AACC The definition of dietary fiber. AACC report. Cereal Foods World. 2001;46:112–126. [Google Scholar]

- Abdul-Hamid A, Luan YS. Functional properties of dietary fibre from defatted rice bran. Food Chem. 2000;68:15–19. [Google Scholar]

- Akoh CC. Fat replacers. Food Technol. 1998;52(3):47–53. [Google Scholar]

- Alakali JS, Irtwange SV, Mzer MT. Quality evaluation of beef patties formulated with Bambara groundnut (Vigna subterranean L.) seed flour. Meat Sci. 2010;85:215–223. doi: 10.1016/j.meatsci.2009.12.027. [DOI] [PubMed] [Google Scholar]

- Aleson-Carbonell L, Fernandez-Lopez J, Perez-Alvarez JA, Kuri V. Functional and sensory effects of fibre rich ingredients on breakfast fresh sausages manufacture. Food Sci Technol Int. 2005;11:89–97. [Google Scholar]

- Alesson-Carbonell L, Fernandez-Lopez J, Sendra E, Sayas Barbera E, Perez-Alvarez JA. Quality characteristics of non-fermented dry cured sausage formulated with lemon albedo. J Sci Food Agric. 2004;84:2077–2084. [Google Scholar]

- Al-Khalifa A, Atia M. Effect of soy hull and fat on camel meat patties. Alex Sci Exch. 1997;18:303–311. [Google Scholar]

- Alvarez D, Delles RM, Xiang YL, Castillo M, Payne FA, Laencina J. Influence of canola olive oils, rice bran and walnut on functionality and emulsion stability of frankfurters. J Food Sci Technol. 2011;44:1435–1442. [Google Scholar]

- Alzamora SM, Salvatori D, Tapia S, Copez-Malo MA, Welti-Chanes J, Fito P. Novel functional foods from vegetable matrices impregnated with biologically active compounds. J Food Eng. 2005;67:205–214. [Google Scholar]

- Anderson ET, Berry BW. Sensory, shear and cooking properties of low-fat beef patties made with inner pea fibre. J Food Sci. 2000;65(5):805–810. [Google Scholar]

- Andres C. Multifunctional fiber provides nutrition, texture and increased functionality. Food Process. 1986;47(13):39–40. [Google Scholar]

- Arjmandi BH, Sohn E, Juma S, Murthy SR, Daggy BP. Native and partially hydrolyzed psyllium have comparable effects on cholesterol metabolism in rats. J Nutr. 1997;127:463–469. doi: 10.1093/jn/127.3.463. [DOI] [PubMed] [Google Scholar]

- Armstrong B, Doll R. Environmental factors and cancer incidence and mortality in different countries. Int J Cancer. 1975;15:617–631. doi: 10.1002/ijc.2910150411. [DOI] [PubMed] [Google Scholar]

- Asp N-G. Definition and analysis of dietary fiber. Scand J Gastroenterol. 1987;22(129):16–20. doi: 10.3109/00365528709095845. [DOI] [PubMed] [Google Scholar]

- Aspinall GO. Polysaccharides. Oxford: Pergamon Press; 1970. pp. 130–144. [Google Scholar]

- Beecher GR. Phytonutrients role in metabolism: effects on resistance to degenerative processes. Nutr Rev. 1999;57:3–6. doi: 10.1111/j.1753-4887.1999.tb01800.x. [DOI] [PubMed] [Google Scholar]

- Behall KM. Dietary fiber: nutritional lessons for macronutrient substitutes. In: Anderson GH, Rolls BJ, Steffen DG, editors. Nutritional implications of macronutrient substitutes. New York: New York Academy of Science; 1997. pp. 142–154. [DOI] [PubMed] [Google Scholar]

- BeMiller JN. Classification, structure and chemistry of polysaccharides of food. In: Cho SS, Dreher ML, editors. Handbook of dietary fibre. New York: Marcel Dekker, Inc.; 2001. pp. 603–611. [Google Scholar]

- BeMiller JN. Dietary fiber intake, disease prevention, and health promotion: an overview with emphasis on evidence from epidemiology. In: Van-der Kamp JM, Asp NG, Miller J, Schaafsma G, editors. Dietary fiber. The Netherlands: Wageningen Academic Publishers; 2004. pp. 143–164. [Google Scholar]

- Bertin C, Roman X, Thibault JF. Structure and properties of sugarbeet fibers. J Sci Food Agric. 1988;44:15–29. [Google Scholar]

- Besbes S, Attia H, Deroanne C, Makni S, Blecker C. Partial replacement of meat by pea fiber: effect on the chemical composition, cooking characteristics and sensory properties of beef burgers. J Food Qual. 2008;31:480–489. [Google Scholar]

- Best D. Whatever happened to fiber. Prepared Foods. 1991;160:54–56. [Google Scholar]

- Bhat ZF, Bhat H. Functional meat products: a review. Int J Meat Sci. 2011;1(1):1–14. [Google Scholar]

- Bhosale SS, Biswas AK, Sahoo J, Chatli MK, Sharma DK, Sikka SS. Quality evaluation of functional chicken nuggets incorporated with ground carrot and mashed sweet potato. Food Sci Technol Int. 2011;17(3):233–239. doi: 10.1177/1082013210382339. [DOI] [PubMed] [Google Scholar]

- Biesalski HK. Meat as a component of a healthy diet – are there any risks or benefits if meat is avoided in the diet? Meat Sci. 2005;70:509–524. doi: 10.1016/j.meatsci.2004.07.017. [DOI] [PubMed] [Google Scholar]

- Bilek AE, Turhan S. Enhancement of the nutritional status of beef patties by adding flax seed flour. Meat Sci. 2009;82:472–477. doi: 10.1016/j.meatsci.2009.03.002. [DOI] [PubMed] [Google Scholar]

- Biswas AK, Kumar V, Bhosle S, Sahoo J, Chatli MK. Dietary fibers as functional ingredients in meat products and their role in human health. Int J Livest Prod. 2011;2(4):45–54. [Google Scholar]

- Bosaeus I, Carlsson NG, Sandberg AS, Anderson H. Effect of wheat bran and pectin on bile acid and cholesterol excretion in ileostomy patients. Hum Nutr Clin Nutr. 1986;40:429–440. [PubMed] [Google Scholar]

- Brennan CS. Dietary fibre, glycaemic response, and diabetes. Mol Nutr Food Res. 2005;49:560–570. doi: 10.1002/mnfr.200500025. [DOI] [PubMed] [Google Scholar]

- Brown L, Rosner B, Willett WW, Sacks FM. Cholesterol-lowering effects of dietary fiber: a meta-analysis. Am J Clin Nutr. 1999;69:30–42. doi: 10.1093/ajcn/69.1.30. [DOI] [PubMed] [Google Scholar]

- Buttriss JL, Stokes CS. Dietary fibre and health: an overview. Nutr Bull. 2008;33:186–200. [Google Scholar]

- Caceres E, Garcia ML, Toro J, Selgas MD. The effect of fructooligosacharides on the sensory characteristics of cooked sausages. Meat Sci. 2004;68:87–96. doi: 10.1016/j.meatsci.2004.02.008. [DOI] [PubMed] [Google Scholar]

- Caprez A, Arrigoni E, Amado R, Neukom H. Influence of different types of thermal treatment on the chemical composition and physical properties of wheat bran. J Cereal Sci. 1986;4:233–239. [Google Scholar]

- Cardoso C, Mendes R, Nunes ML. Development of a healthy low-fat fish sausage containing dietary fibre. Int J Food Sci Technol. 2008;43(2):276–283. [Google Scholar]

- Chan W (2004) Macronutrients in meat. In: Jensen WK, Devine C, Dikeman M (eds) Encyclopedia of meat sciences. Elsevier Academic Press, Oxford, pp 614–618

- Chan JK, Wypyszyk V. A forgotten natural dietary fiber: psyllium mucilloid. Cereal Foods World. 1988;33:919–922. [Google Scholar]

- Chandali M, Garg A, Lutjohann D, Von Bergmann K, Grundy SM, Brinkley LJ. Beneficial effects of high dietary fiber intake in patients with type 2 diabetes mellitus. N Engl J Med. 2000;342:1392–1398. doi: 10.1056/NEJM200005113421903. [DOI] [PubMed] [Google Scholar]

- Chang HC, Carpenter JA. Optimizing quality of frankfurters containing qat bran and added water. J Food Sci. 1997;62(1):194–197. [Google Scholar]

- Chau CF, Huang YL, Lin CY. Investigation of the cholesterol-lowering action of insoluble fiber derived from the peel of Citrus sinensis L. cv. Liucheng. Food Chem. 2004;87(3):361–366. [Google Scholar]

- Chawla R, Patil GR. Soluble dietary fiber. Comp Rev Food Sci F. 2010;9:178–196. [Google Scholar]

- Chen WS, Chi SP. Physicochemical properties and sensory evaluation of frankfurter containing different cereal crops, Chinese wolfberry, green pea and celluloses. J Agric Assoc Taiwan. 2008;9(3):243–253. [Google Scholar]

- Choi YS, Jeong JY, Choi JH, Han DJ, Kim HY, Lee MA, et al. Quality characteristics of meat batters containing dietary fiber extracted from rice bran. J Korean Soc Food Sci Anim Res. 2007;27(3):228–234. [Google Scholar]

- Choi YS, Jeong JY, Choi JH, Han DJ, Kim HY, Lee MA, et al. Effects of dietary fiber from rice bran on the quality characteristics of emulsion type sausages. J Korean Soc Food Sci Anim Res. 2008;28(1):14–20. [Google Scholar]

- Choi YS, Choi JH, Han DJ, Kim HY, Lee MA, Kim HW, Jeong JY, Kim CJ. Characteristics of low fat meat emulsion systems with pork fat replaced by vegetable oils and rice bran fibers. Meat Sci. 2009;82(2):266–271. doi: 10.1016/j.meatsci.2009.01.019. [DOI] [PubMed] [Google Scholar]

- Choi YS, Choi JH, Han DJ, Kim HY, Lee MA, Kim HW, Lee JW, Chung HJ, Kim CJ. Optimization of replacing pork back fat with grape seed oil and rice bran fiber for reduced-fat meat emulsion systems. Meat Sci. 2010;84(1):212–218. doi: 10.1016/j.meatsci.2009.08.048. [DOI] [PubMed] [Google Scholar]

- Choi YS, Choi JH, Han DJ, Kim HY, Lee MA, Kim HW, Jeong JY, Kim CJ. Effects of rice bran fiber on heat induced gel prepared with pork salt soluble meat proteins in model system. Meat Sci. 2011;88:59–66. doi: 10.1016/j.meatsci.2010.12.003. [DOI] [PubMed] [Google Scholar]

- Claus JR, Hunt MC. Low fat, high added water bologna formulated with texture- modifying ingredients. J Food Sci. 1991;56:643–647. [Google Scholar]

- Colmenero FJ, Ayo MJ, Carballo J. Physicochemical properties of low sodium frankfurter with added walnut: effect of transglutaminase combined with caseinate, KCl and dietary fiber as salt replacers. Meat Sci. 2005;69(4):781–788. doi: 10.1016/j.meatsci.2004.11.011. [DOI] [PubMed] [Google Scholar]

- Confrades S, Guerra MA, Carballo J, Ferna’ndez-Marti’n F, Jime’nez-Colmenero F. Plasma protein and soy fiber content effect on bologna sausage properties as influenced by fat level. J Food Sci. 2000;65(2):281–287. [Google Scholar]

- Cummings JH. The effect of dietary fiber on faecal weight and composition. In: Spiller GA, editor. Handbook of dietary fibre in human nutrition. Boca Raton: CRC Press; 1993. p. 263. [Google Scholar]

- Dawkins NL, Phelps O, Mcmillan KW, Forrester IT. Composition and physicochemical properties of chevon meat patties containing oat bran. J Food Sci. 1999;64(4):597–600. [Google Scholar]

- Decker EA, Park Y. Healthier meat products as functional foods. Meat Sci. 2010;86(1):49–55. doi: 10.1016/j.meatsci.2010.04.021. [DOI] [PubMed] [Google Scholar]

- Desmond EM, Troy DJ. Sensory and physical characteristics of pork sausages manufactured with dietary fibres. Irish J Agric Food Res. 2003;42(1):161. [Google Scholar]

- Desmond E, Troy DJ, Buckley J. Comparative studies on non-meat ingredients used in the manufacture of low-fat burgers. J Muscle Foods. 1998;9:221–241. [Google Scholar]

- Desmond E, Troy DJ, Buckley J. The effects of tapioca starch, oat fiber and whey protein on the physical and sensory properties of low-fat beef burgers. Lebensm Wiss Technol. 1998;31:653–657. [Google Scholar]

- Devatkal SK, Narsaiah K, Borah A. Anti-oxidant effects of extracts of kinnow rind, pomegranate rind and seed powders in cooked goat meat patties. Meat Sci. 2010;85(1):155–159. doi: 10.1016/j.meatsci.2009.12.019. [DOI] [PubMed] [Google Scholar]

- Dhingra D, Michael M, Rajput H, Patil RT. Dietary fibre in foods: a review. J Food Sci Technol. 2012;49(3):255–266. doi: 10.1007/s13197-011-0365-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dunaif G, Schneeman BO. The effect of dietary fiber on human pancreatic enzyme activity in vitro. Am J Clin Nutr. 1981;34:1034–1035. doi: 10.1093/ajcn/34.6.1034. [DOI] [PubMed] [Google Scholar]

- Duve KJ, White PJ. Extraction and identification of antioxidants in oats. J Oil Chem Soc. 1991;68(6):365–370. [Google Scholar]

- Duxbury DD. Fiber: form follows function. Food Process. 1993;54(3):44–54. [Google Scholar]

- Dzudie T, Scher J, Hardy J. Common bean flour as an extender in beef sausages. J Food Eng. 2002;52:143–147. [Google Scholar]

- Eastwood MA. The physiological effect of dietary fiber: an update. Annu Rev Nutr. 1992;12:19–35. doi: 10.1146/annurev.nu.12.070192.000315. [DOI] [PubMed] [Google Scholar]

- Edwards CA, Hepburn IC, Segal I, Hassan H, Vorster E, Oosthuizen W, Kruger S. Colonic fermentation capacity in young children from South African populations of low and high cancer risk. In: Guillon F, Amado R, editors. Functional properties of non-digestible carbohydrates. Brussels: EU Commission DGX11; 1998. pp. 222–224. [Google Scholar]

- Eim VS, Small S, Rossello C, Femenia A. Effect of addition of carrot dietary fibre on the ripening process of a dry fermented sausage (Sobressada) Meat Sci. 2008;80:173–182. doi: 10.1016/j.meatsci.2007.11.017. [DOI] [PubMed] [Google Scholar]

- Elleuch M, Besbes S, Roiseux O, Blecker C, Deroanne C, Attia H. Date flesh: chemical composition and characteristics of the dietary fibre. Food Chem. 2008;111:676–682. [Google Scholar]

- Emmons CL, Peterson DM, Paul GL. Antioxidant capacity of oat (Avena sativa L.) extracts. 2. In vitro antioxidant activity and contents of phenolic and tocol antioxidants. J Agric Food Chem. 1999;47(12):4894–4898. doi: 10.1021/jf990530i. [DOI] [PubMed] [Google Scholar]

- Esposito F, Arlotti G, Bonifati AM, Napolitano A, Vitale D, Vincenzo F. Antioxidant activity and dietary fiber in durum wheat bran by-products. Food Res Int. 2005;38:1167–1173. [Google Scholar]

- Fahrenbach MJ, Riccardi BA, Saunders JC, Lourie IN, Heider JG. Comparative effetcs of guar gum and pectin on human serum cholesterol levels. Circulation. 1965;31:11. [Google Scholar]

- Fergus C. Functional foods: opportunities and challenges. Food Technol. 2004;58(12):35–40. [Google Scholar]

- Fernandez-Gines JM, Fernandez-Lopez J, Sayas-Barbera ME, Sendra E, Perez Alvarez JA. Lemon albedo as a new source of dietary fibre: application to bologna sausage. Meat Sci. 2004;67:7–13. doi: 10.1016/j.meatsci.2003.08.017. [DOI] [PubMed] [Google Scholar]

- Fernández-López J, Fernández-Ginés JM, Alerón-Carbonell L, Sayas-Barberá E, Sendra E, Pérez-Álvarez JA (2004) Application of functional citrus by-products to meat products. Trends Food Sci Technol 15:176–85

- Fernandez-Lopez J, Viuda-Martos M, Sendra E, Sayas-Barbera E, Navarro C, Perez Alvarez JA. Orange fiber as potential functional ingredient for dry cured sausages. Eur Food Res Technol. 2007;226:1–6. [Google Scholar]

- Fernandez-Lopez J, Sendra E, Sayas-Barbera E, Navarro C, Perez- Alvarez JA. Physico-chemical and microbiological profiles of “salchichon” (Spanish dry – fermented sausage) enriched with orange fiber. Meat Sci. 2008;80:410–417. doi: 10.1016/j.meatsci.2008.01.010. [DOI] [PubMed] [Google Scholar]

- Field CJ, McBurney MI, Massimino S, Hayek MG, Sunvold GD. The fermentable fiber content of the diet alters the function and composition of canine gut associated lymphoid tissue. Vet Immunol Immunopathol. 1999;72:325–341. doi: 10.1016/s0165-2427(99)00148-8. [DOI] [PubMed] [Google Scholar]

- Fleury N, Lahaye M. Chemical and physico-chemical characterization of fibres from Laminaria digitata (Kombu breton): a physiological approach. J Sci Food Agric. 1991;55:389–400. [Google Scholar]

- Gallaher DD, Locket PL, Gallaher CM. Bile acid metabolism in rats fed two levels of corn levels and brans of oat, rye and barley and sugar beet fiber. J Nutr. 1992;122:473–481. doi: 10.1093/jn/122.3.473. [DOI] [PubMed] [Google Scholar]

- Garcia ML, Dominguez R, Garlvez MD, Casas C, Selgas MD. Utilization of cereal and fruit fibers in low-fat dry fermented sausage. Meat Sci. 2002;60:227–236. doi: 10.1016/s0309-1740(01)00125-5. [DOI] [PubMed] [Google Scholar]

- Garcia ML, Caceres E, Selgas MD. Effect of inulin on the textural and sensory properties of mortadella, a spanish cooked meat product. Int J Food Sci Technol. 2006;41:1207–1215. [Google Scholar]

- Garvin JE, Forman DT, Eiseman WR, Phillips CR. Lowering of human serum cholesterol by an oral hydrophilic colloid. Proc Soc Exp Biol Med. 1965;120:744–746. doi: 10.3181/00379727-120-30643. [DOI] [PubMed] [Google Scholar]

- Gelroth J, Ranhotra GS. Food uses of fiber. In: Sussan-Sungsoo C, Dreher ML, editors. Hand book of dietary fibres. New York: Marcel Dekker-Inc; 2001. pp. 435–451. [Google Scholar]

- Gibson GR. Fibre and effects on probiotics (the prebiotic concept) Clin Nutr Suppl. 2004;1:25–31. [Google Scholar]

- Gorinstein S, Martίn-Belloso O, Park YS, Haruenkit R, Lojek A, Ciz M, Caspi A, Libman I, Trakhtenberg S (2001) Comparison of some biochemical characteristics of different citrus fruits. Food Chem 74:309–315

- Grasten S, Liukonnen K-H, Chrevatidis A, Nezami H, Poutanen K, Mykkanen H. Effects of wheat pentosan and inulin on the metabolic activity of fecal microbiota and on bowel function in healthy humans. Nutr Res. 2003;23:1503–1514. [Google Scholar]

- Grigelmo-Miguel N, Martina-Belloso O. Characterization of dietary fibre from orange juice extraction. Food Res Int. 1999;131:355–361. [Google Scholar]

- Grigelmo-Miguel N, Abadias-Seros MI, Martin-Belloso O. Characterisation of low-fat high-density fibre frankfurters. Meat Sci. 1999;52(3):247–256. doi: 10.1016/s0309-1740(98)00173-9. [DOI] [PubMed] [Google Scholar]

- Guillon F, Champ M. Structural and physical properties of dietary fibers and consequences of processing on human physiology. Food Res Int. 2000;33:233–245. [Google Scholar]

- Gujral HS, Kaur A, Singh N, Sodhi SN. Effects of liquid whole egg, fat and textured soy protein on the textural and cooking properties of raw and baked patties from goat meat. J Food Eng. 2002;53:377–385. [Google Scholar]

- Harris PJ, Ferguson LR. Dietary fibre: its composition and role in protection against colorectal cancer. Mutat Res. 1993;290:97–110. doi: 10.1016/0027-5107(93)90037-g. [DOI] [PubMed] [Google Scholar]

- Haub MD, Hubach KL, Al-Tamimi EK (2010) Different types of resistant starch elicit difference glucose responses in humans. J Nutr Metab Article ID 230501 [DOI] [PMC free article] [PubMed]

- Hipsley EH. Dietary fiber and pregnancy toxaemia. Br Med J. 1953;2:420–442. doi: 10.1136/bmj.2.4833.420. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Huang SC, Shiau CY, Liu TE, Chu CL, Hwang DF. Effects of rice bran on sensory and physico chemical properties of emulsified pork meatballs. Meat Sci. 2005;70:613–619. doi: 10.1016/j.meatsci.2005.02.009. [DOI] [PubMed] [Google Scholar]

- Huang SC, Tsai YF, Chen CM. Effects of wheat fiber, oat fiber and inulin on sensory and physico-chemical properties of Chinese-style sausages. Asian-Aust J Anim Sci. 2011;24(6):875–880. [Google Scholar]

- Hughes E, Calfrades S, Troy DJ. Effect of fat level, oat fiber and carrageenan on frankfurters with 5, 12 or 30 % fat. Meat Sci. 1997;45(3):273–281. doi: 10.1016/s0309-1740(96)00109-x. [DOI] [PubMed] [Google Scholar]

- Javidipour I, Vural H, Ozbas OO, Tekin A. Effect of interestified vegetable oils and sugar beet fibre on the quality of Turkish-type salami. Int J Food Sci Technol. 2005;40(2):177–185. [Google Scholar]

- Jenkins DJA, Leeds AR, Gassull MA, Cochet B, Alberti KGMM. Decrease in postprandial insulin and glucose concentrations by guar and pectin. Ann Intern Med. 1977;86:20–23. doi: 10.7326/0003-4819-86-1-20. [DOI] [PubMed] [Google Scholar]

- Jenkins DJA, Wolever TMS, Leeds AR, Gassull MA, Haisman P, Dilawari J, Goff DV, Metz GL, Alberti KGMM. Dietary fibres, fibre analogues, and glucose tolerance: importance of viscosity. Br Med J. 1978;1:1392–1394. doi: 10.1136/bmj.1.6124.1392. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Jimenez-Colomenero F. Technologies for developing low fat meat products. Trends Food Sci Technol. 1996;7:41–48. [Google Scholar]

- Kaack K, Laerke HN, Meyer AS. Liver pate enriched with dietary fibre extracted from potato fibre as fat substitutes. Eur Food Res Technol. 2006;223(2):267–272. [Google Scholar]

- Kaeferstein FK, Clugston GA. Human health problems related to meat production and consumption. Fleischwirtschaft. 1995;75:889–892. [Google Scholar]

- Kay RM. Dietary fibre. J Lipid Res. 1982;23:221–242. [PubMed] [Google Scholar]

- Keeton JT. Low fat meat products - technological problems with processing. Meat Sci. 1994;36:261–276. doi: 10.1016/0309-1740(94)90045-0. [DOI] [PubMed] [Google Scholar]

- Kenawi MA, Abdelsalam SA, El-Sherif SA. The effect of mung bean powder, and/or low fat soy flour as meat extender on the chemical, physical and sensory quality of buffalo meat product. Biotechnol Anim Husb. 2009;25(5–6):327–337. [Google Scholar]

- Kendall CW, Esfahani A, Jenkins DJA. The link between dietary fiber and human health. Food Hydrocoll. 2009;24(1):42–48. [Google Scholar]

- Kumar M, Sharma BD. Quality and storage stability of low-fat pork patties containing barley flour as fat substitute. J Food Sci Technol. 2004;41(5):496–502. [Google Scholar]

- Kurasawa S, Hack VS, Marlett JA. Plant residue and bacteria as basis for increased stool weight accompanying consumption of higher dietary fibre diets. J Am Coll Nutr. 2000;19:426–433. doi: 10.1080/07315724.2000.10718942. [DOI] [PubMed] [Google Scholar]

- Lawaetz O, Blackburn AM, Bloom SR, Aritas Y, Ralphs DNL. Effect of pectin on gastric emptying and gut hormone release in the dumping syndrome. Scand J Gastroenterol. 1983;18:327–336. doi: 10.3109/00365528309181602. [DOI] [PubMed] [Google Scholar]

- Lee MA, Han DJ, Jeong JY, Choi JH, Choi YS, Ki HY, Paik HD, Kim CJ. Effect of kimchi powder level and drying methods on quality characteristics of breakfast sausage. Meat Sci. 2008;80:708–714. doi: 10.1016/j.meatsci.2008.03.010. [DOI] [PubMed] [Google Scholar]

- Lefebvre AC, Thebaudin J. Fibras extraidas de las hortalizas. In: Tirilly Y, Bourgeois C, editors. Tecnologia de las hortalizas. Spain: Acribia/Zaragoza; 2002. pp. 459–481. [Google Scholar]

- Lin KW, Huang HY. Konjac/gellan gum mixed gels improve the quality of reduced-fat frankfurters. Meat Sci. 2003;65(2):749–755. doi: 10.1016/S0309-1740(02)00277-2. [DOI] [PubMed] [Google Scholar]

- Lin KW, Lin HY. Quality characteristics of Chinese-style meatball containing bacterial cellulose (Nata.) J Food Sci. 2004;69(3):107–111. [Google Scholar]

- Lunn J, Buttriss JL. Carbohydrates and dietary fibre. Nutr Bull. 2007;32(1):21–64. [Google Scholar]

- Madar Z, Odes HS. Dietary fibre in metabolic diseases. In: Paoletti R, editor. Dietary fibre research. Basel: Karger; 1990. pp. 1–65. [Google Scholar]

- Mälkki Y. Oat fiber. Production, composition, physicochemical properties, physiological effects, safety, and food applications. In: Cho SS, Dreher ML, editors. Handbook of dietary fiber. New York: Marcel Dekker, Inc; 2001. pp. 497–517. [Google Scholar]

- Mansour EH, Khalil AH. Characteristics of low fat beef burgers as influenced by various types of wheat fibers. J Sci Food Agric. 1999;79:493–498. [Google Scholar]

- Marlett JA, Hosing KB, Vellendorf NW, Shinnick FL, Hack VS, Story JA. Mechanism of serum cholesterol reduction by oat bran. Hepatol. 1994;20:1450–1457. doi: 10.1002/hep.1840200612. [DOI] [PubMed] [Google Scholar]

- Mauro DJ, Wang YJ. Breakfast food ingredients. Cereal Foods World. 1997;42:440–443. [Google Scholar]

- McCleary BV. Measurement of dietary fibre components: the importance of enzyme purity, activity and specificity. In: McCleary BV, Prosky L, editors. Advanced dietary fibre technology. Oxford: Blackwell Science Ltd; 2008. pp. 89–105. [Google Scholar]

- McDonagh C, Troy D, Desmond E, McDermott H. Nutritional enhancement of meat products with dietary fibers. Project RMIS No. 4957. Ashtown: The National Food Centre; 2005. [Google Scholar]

- Mehta K, Kaur A. Reviews: dietary fiber. Int J Diabetes Dev Ctries. 1992;12:12–18. [Google Scholar]

- Mendoza E, Garcia ML, Casas C, Selgas MD. Inulin as fat substitute in low fat, dry fermented sausages. Meat Sci. 2001;57:387–393. doi: 10.1016/s0309-1740(00)00116-9. [DOI] [PubMed] [Google Scholar]

- Mikusova L, Sturdik E, Mosovska S, Brindzova L, Mikulajova A. Proceedings of 4th International dietary fibre conference. Vienna: Intl Assoc for Cereal Science and Technology; 2009. Development of new bakery products with high dietary fibre content and antioxidant activity for obesity prevention; p. 185. [Google Scholar]

- Modi VK, Mahendrakar NS, Narsimha Rao D, Sachindra NM. Quality of buffalo meat burger containing legume flour as binders. Meat Sci. 2003;66:143–149. doi: 10.1016/S0309-1740(03)00078-0. [DOI] [PubMed] [Google Scholar]

- Modi VK, Yashoda KP, Bhaska N, Mahendrakar NS. Effect of carrageenan and oat flour on storage characteristics of fried mutton kofta. J Food Process Preserv. 2009;33(6):763–776. [Google Scholar]

- Modi VK, Yashoda KP, Mahendrakar NS. Low-fat mutton kofta prepared by using carrageenan as fat replacer: quality changes in cooked product during storage. J Food Sci Technol. 2009;46:316–319. [Google Scholar]

- Modi VK, Yashoda KP, Naveen SK. Effect of carrageenan and oat flour on quality characteristics of meat kofta. Int J Food Prop. 2009;12:228–242. [Google Scholar]

- Morin LA, Temelli F, McMllen L. Interaction between meat proteins and barley Hordeurm spp. β-glucan within a reduced-fat breakfast sausage system. Meat Sci. 2004;68:419–430. doi: 10.1016/j.meatsci.2004.04.009. [DOI] [PubMed] [Google Scholar]

- Muller G, Redden VR (1995) Sensory and functional evaluation of ground beef patties extended with milling grade culinary beans. Bridging 2000 and beyond. Proc Joint Aust NZ Inst Food Sci Technol Conf, Auckland, New Zealand, 15-19th May, p 52

- Mun S, Decker EA, Park Y, Weiss J, McClements DJ. Influence of interfacial composition onin vitrodigestibility of emulsified lipids: potential mechanism for chitosan’s ability to inhibit fat digestion. Food Biophys. 2006;1(1):21–29. [Google Scholar]

- Naveena BM, Muthukumar M, Sen AR, Babaji Y, Murthy TRK. Quality characteristics and storage stability of chicken patties formulated with finger millet flour (Eleusina coracana) J Muscle Foods. 2006;17:92–104. [Google Scholar]

- Nayak SK, Pattnaik P, Mohanty AK. Dietary fiber: a low-calorie dairy adjunct. Indian Food Ind. 2000;19(4):268–274. [Google Scholar]

- Niva M. All foods affect health: understandings of functional foods and healthy eating among health oriented Finns. Appetite. 2007;48:384–393. doi: 10.1016/j.appet.2006.10.006. [DOI] [PubMed] [Google Scholar]

- Ozboy-Ozbas O, Vural H, Javidipour I. Effects of sugarbeet fiber on the quality of frankfurters. Zucker Ind. 2003;128:171–175. doi: 10.1016/j.meatsci.2003.09.006. [DOI] [PubMed] [Google Scholar]

- Pinero MP, Parrak Leidenz NH, deMoreno LA, Ferrer M, Araujo S, Barboza Y. Effect of oat’s soluble fiber (β-glucan) as a fat replacer on physical, chemical, microbiological and sensory properties of low fat beef patties. Meat Sci. 2008;80:675–680. doi: 10.1016/j.meatsci.2008.03.006. [DOI] [PubMed] [Google Scholar]

- Potter JD. Colorectal cancer: molecules and populations. J Natl Cancer Inst. 1999;91:916–932. doi: 10.1093/jnci/91.11.916. [DOI] [PubMed] [Google Scholar]

- Prasad B, Rashmi MD, Yashoda KP, Modi VK. Effect of casein and oat flour on physicochemical and oxidative processes of cooked chicken kofta. J Food Process Preserv. 2011;35(3):359–368. [Google Scholar]

- Prinyawiwatkul W, McWatters KH, Beuchat LR, Philips RD. Physicochemical and sensory properties of chicken nuggets extended with fermented cowpea and peanut flours. J Agric Food Chem. 1997;45:1891–1899. [Google Scholar]

- Przybyla AE. Formulating fiber into foods. Food Eng. 1988;60(10):77–88. [Google Scholar]

- Rao BJ, Reddy KP. Influence of binders and refrigerated storage on quality of chicken meat loaves. Indian J Poult Sci. 2000;35(3):302–305. [Google Scholar]

- Risivik E. Sensory properties and preferences. Meat Sci. 1994;36:6777. doi: 10.1016/0309-1740(94)90034-5. [DOI] [PubMed] [Google Scholar]

- Roberfroid MB. Global view on functional foods: European perspectives. Br J Nutr. 2002;88:5133–5138. doi: 10.1079/BJN2002677. [DOI] [PubMed] [Google Scholar]

- Rodriguez R, Jimenez A, Fernández-Bolaños J, Guillen R, Heredia A. Dietary fibre from vegetable products as source of functional ingredients. Trends Food Sci Technol. 2006;17(1):3–15. [Google Scholar]