Abstract

The purpose of this study was to evaluate the individual contraction force during polymerization of a composite resin (Z-250), a flowable composite (Filtek Flow, FF) and a resin-modified glass ionomer cement (Vitrebond, VB), and the transmission of Z-250 composite resin polymerization contraction force through different thicknesses of FF and VB. The experiment setup consisted of two identical parallel steel plates connected to a universal testing machine. One was fixed to a transversal base and the other to the equipment's cross head. The evaluated materials were inserted into a 1-mm space between the steel plates or between the inferior steel plate and a previously polymerized layer of an intermediate material (either FF or VB) adhered to the upper steel plate. The composite resin was light-cured with a halogen lamp with light intensity of 500 mW/cm2 for 60 s. A force/time graph was obtained for each sample for up to 120 s. Seven groups of 10 specimens each were evaluated: G1: Z-250; G2: FF; G3: VB; G4: Z-250 through a 0.5-mm layer of FF; G5: Z-250 through a 1-mm layer of FF; G6: Z-250 through a 0.5-mm of VB; G7: Z-250 through a 1-mm layer of VB. They were averaged and compared using one-way ANOVA and Tukey test at a = 0.05. The obtained contraction forces were: G1: 6.3N ± 0.2N; G2: 9.8 ± 0.2N; G3: 1.8 ± 0.2N; G4: 6.8N ± 0.2N; G5: 6.9N ± 0.3N; G6: 4.0N ± 0.4N and G7: 2.8N ± 0.4N. The use of VB as an intermediate layer promoted a significant decrease in polymerization contraction force values of the restorative system, regardless of material thickness. The use of FF as an intermediate layer promoted an increase in polymerization contraction force values with both material thicknesses.

Keywords: Polymerization contraction, Contraction force, Composite, Composite flow, Resin-modified glass ionomer

INTRODUCTION

Composite resin shrinks during the polymerization process that transforms a viscous liquid into a solid material3. This contraction is due to the presence of an organic matrix, often a mixture of Bis-GMA, TEGDMA and other small monomer molecules that have to approach to each other establishing a polymer chain during polymerization. The use of small molecules decreases the organic matrix viscosity12. Therefore, low viscosity composites must have a higher percentage of small molecules in their organic matrix or less inorganic filler content. Consequently, low viscosity composites experience a great volumetric contraction during polymerization12. This group of materials includes flowable composite resins which were suggested to be used as intermediate materials4,20. The supposed advantage of these materials when used as an intermediate layer is related to their low modulus of elasticity, which leads to a higher deformation12,21. They absorb stress when the composite resin shrinks over them and transmit the contraction force through adjacent structures. Stress absorption is a function of material's thickness and modulus of elasticity. For a given elastic modulus, a thicker layer will absorb more stress20. The observation that a composite resin restoration that used unfilled resin as an intermediate layer showed less microleakage than conventional composite restoration encourages the indication of these flowable composites for this purpose9.

Resin-modified glass ionomer cement (RMGIC) was developed by Mitra14 (1991). This material permits photoactivation of the glass ionomer and makes the sandwich technique easier and faster.22 Several studies have proven that composite resin restorations lined with glass ionomer lead to less microleakage or better marginal adaptation than without lining2,6,8,10,11,14,21 There were many explanations for the reason why a material with lower bond strength promoted less infiltration, however Kemp-Scholte and Davidson9 (1990) were the only authors to measure the effect of using RMGIC as an intermediate layer as a function of stress absorption10.

The use of an intermediate material leads to many variables in the restoration. One is the modification of the configuration factor of the cavity that will be filled with a composite resin. Although this is an advantage of this technique, it is not exclusive for glass ionomer cements, in the sense that the first increment (whether flowable or low-viscous composite resin) in an incremental technique can be considered an "intermediate material" for a second increment. Kemp-Scholte and Davidson10 (1990) demonstrated stress absorption by RMGIC and stated that the solution of the leakage problem could be found in the increased flexibility of the restorative system. Therefore materials with low modulus of elasticity should be adequate to be used as intermediate layers. RMGIC has lower modulus of elasticity 19 when compared to flowable composites12.

The aim of this study was to verify the hypothesis that low modulus of elasticity materials used as intermediate layers could absorb part of the composite resin polymerization contraction force.

MATERIAL AND METHODS

The tested materials were: Hybrid Z-250 composite resin (3M/ESPE, St. Paul, MN, USA), Filtek Flow flowable composite (FF) (3M/ESPE) and Vitrebond (VB) resin-modified glass ionomer cement.

The following groups had the polymerization contraction force evaluated: G1: Z-250 (1 mm thickness); G2: FF (1 mm thickness); G3: VB (1 mm thickness); G4: Z-250 through a 0.5-mm layer of FF; G5: Z-250 through a 1-mm layer of FF; G6: Z-250 through a 0.5-mm of VB; G7: Z-250 through a 1mm layer of VB.

The experiment setup consisted of two identical rectangular (6 x 2mm), opposed, parallel steel plates. The upper plate was connected to a 10 kg load cell on the crosshead while the lower plate was fixed to the transversal base of a universal testing machine (EMIC-DL-500; São José dos Pinhais, PR, Brazil). Both steel plates were sandblasted to promote adhesion of the composite resin during the test15,17. For evaluation of polymerization contraction force of the composite resin Z-250, FF and VB (G1 - G3), 1-mm thick layer of the materials were inserted between steel plates and light-cured for 60 seconds. Contraction force recording began simultaneously with material's light activation and continued for a period of 120 seconds. For the other groups (G4 - G7), the procedure was done as follows: the lower base surface was isolated with a Teflon strip. The upper plate was moved upwards to create a space of either 0.5 or 1 mm to be filled with the intermediate materials. FF or VB were inserted into the predetermined spaces between the plates and photoactivated for 20 or 30 seconds respectively. Irradiation was done from one side using a conventional halogen lamp curing unit (Spectrum, Dentsply-Caulk, Milford, Canada) performing 500 mW/cm2. Then, the plates were moved away from each other and the Teflon strip was removed. Immediately after light-curing the intermediate material, the upper plate was fixed leaving a 1mm space between the "liner" and the lower plate. The Z-250 composite resin was inserted into this space and light-cured for 60 seconds. A 6-mm-diameter light tip was applied as close as possible to each specimen's wider (6mm) surface allowing light to cross the 2-mm thick layer of material. Contraction force recording began simultaneously with Z-250 light activation and continued for a period of 120 seconds.

For all groups, the configuration factor of the simulated restorations was 1.5 and the volume of the Z-250 composite resin sample was 12 mm3. During the test, the upper plate fixed to the cross-head was not allowed to move. As a consequence of the material polymerization contraction force, the load cell underwent a deformation that was transformed in force (N). In groups G4 to G7, the polymerization contraction force had to cross the intermediate materials before reaching the upper plate and the load cell. This setup provided continuous recording of contraction forces during polymerization, even after light-activation had finished. A force/time graph was obtained for each sample. The values of the 120-second period were recorded.

Ten samples were tested for each group. They were averaged and compared using one-way ANOVA followed by Tukey test at a = 0.05.

RESULTS

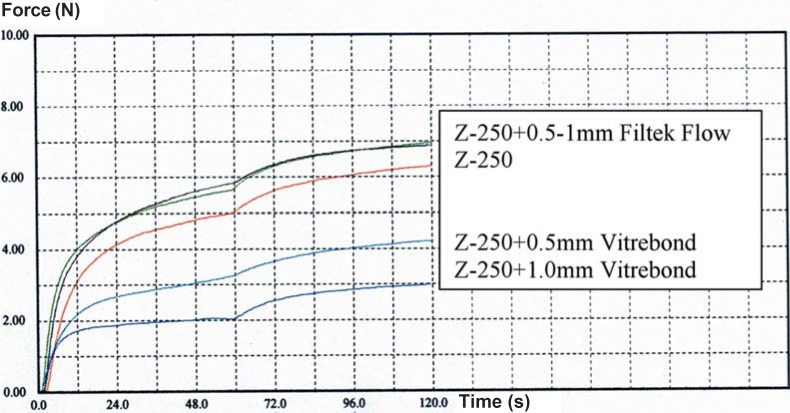

The results showed significant differences between the force values recorded for Z-250 with or without intermediate materials (p<0.05) (Table 1). Z-250 specimens used without intermediate materials showed a polymerization contraction force of 6.321±0.2618N (Table 1). When Z-250 was used with flowable composite as an intermediate material, the restorative system showed significantly higher polymerization contraction force values than the control group (G1) regardless of its thickness (Figure 1). A 0.5-mm-thick FF layer promoted a mean value of 6.8±0.2 N and a 1-mm-thick FF layer promoted a mean value of 6.9±0.3N (Table 1). Although the arithmetic mean was higher for the 1mm thickness layer, they did not differ significantly from each other (Figure 1).

TABLE 1. Means (±SD) and statistical analysis of the polymerization contraction forces of the composite resin with or without intermediate materials.

| Groups | Means (N) (±SD) |

|---|---|

| Z-250 | 6.3(±0.2)c |

| Z-250 + 0.5 mm FF | 6.8(±0.2)d |

| Z-250 + 1.0 mm FF | 6.9(±0.3)d |

| Z-250 + 0.5mm VB | 4.0(±0.4) b |

| Z-250 + 1.0mm VB | 2.8(±0.4)a |

n = 10; Different letters indicate statistically significant difference at 5%.

FIGURE 1. Force/time graph obtained for Z-250 composite resin without intermediate layer, with 0.5-mm-thick and 1-mm-thick Filtek Flow layer and with 0.5-mm-thick and 1-mm-thick Vitrebond layer.

When Z-250 was used with VB as intermediate material, polymerization contraction force values dropped significantly (Figure 1). A 0.5-mm-thick VB layer promoted a mean value of 4.0±0.4 N. This value was significantly lower than that of the control group (G1) and the groups with flowable composite as intermediate materials (Table 1). The 1-mm-thick VB layer promoted a mean value of 2.8±0.4 N. This value was significantly lower than those of other tested conditions (p<0.05) (Table 2).

TABLE 2. Means (±SD) and statistical analysis of polymerization contraction forces of Z-250 composite resin, Filtek Flow flowable composite and Vitrebond resin-modifed glass ionomer cement.

| Groups | Means (N) (±SD) |

|---|---|

| Z-250 | 6.3(±0.2)b |

| Filtek Flow | 9.8(±0.2)c |

| Vitrebond | 1.8(±0.2)a |

n = 10; Different letters indicate statistically significant difference at 5%.

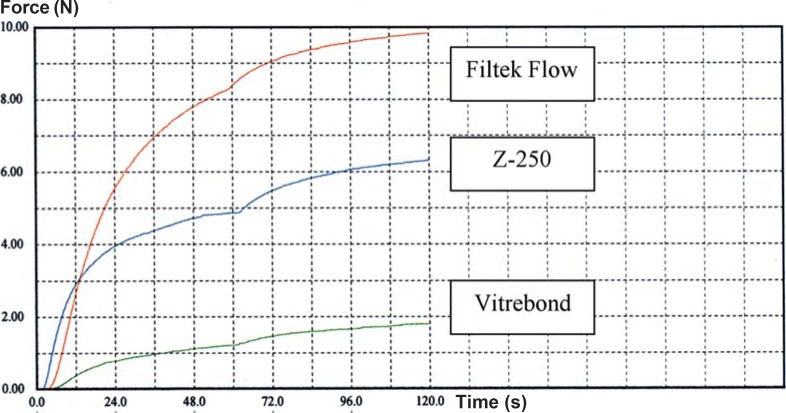

Additionally, FF and VB polymerization contraction forces (9.8±0.2 N and 1.8±0.2 N, respectively) were compared to that of Z-250 (6.3±0.2 N) (Figure 2). VB polymerization contraction force was significantly lower than those of Z-250 and FF. Z-250 polymerization contraction force was significantly lower than that of FF (p<0.05) (Table 2).

FIGURE 2. Force/time graph obtained for Z-250 resin composite, Filtek Flow flowable composite and Vitrebond resin-modified glass ionomer cement.

DISCUSSION

Polymerization contraction force was determined for Z-250 individually or combined with a flowable composite or resin-modified glass ionomer cement as intermediate materials. None of the specimens presented loss of adhesion to the steel plates, during the test, otherwise the force/time graph would register a spontaneous decrease of the force values. The results (Table 1) showed that the restorative system that used VB as intermediate material registered significantly lower values and that these values decreased significantly as the VB layer thickness increased from 0.5 mm to 1 mm (p<0.05). Although it represents an interesting finding, unfortunately, it is very difficult to control the liner thickness clinically. Kemp-Scholte and Davidson9 (1990) showed a stress relief that varied from 18% to 50% when a 0.15-mm-layer of VB was applied underneath a 5-mm-layer of P-10, a chemically activated composite resin. Although our study used intermediate layers of different thicknesses and a photoactivated composite resin (Z-250), results were in agreement with this previous study. The lower values found with the 1-mm-thick VB layer in relation to the 0.5-mm-thick layer were in agreement with Unterbrink and Liebenberg20 (1999), who stated that for a given modulus, a thicker layer will absorb more stress.

VB RMGIC was polymerized just before the composite resin was inserted and polymerized. Although VB presents a double setting reaction, the photoactivated reaction is responsible for the initial setting and properties. Volume and factor configuration of the Z-250 composite resin was maintained constant for all groups. A probable explanation for the lower values of polymerization contraction force in this restorative system could be that VB absorbed part of the forces that were generated and transmitted from Z-250. This absorption could be responsible for the decrease of the mean values in the order of 35.5% (4.0 N) and 55.5% (2.8 N) for layer thickness of 0.5 mm and 1 mm, respectively, in relation to Z-250 (6.3N). Dauvillier, et al.6 (2000) demonstrated that, during setting, the modulus of elasticity of glass ionomer increases slower than that of composite resin. RMGIC had probably a greater capacity of stress absorption during the first minutes after mixing, as shown in the present study.

Although flowable composites are considered composite resins with low modulus of elasticity20, and hence a release in the developed contraction forces of Z-250 associated with it could be expected, this was not observed. Our results showed that, regardless of the thickness, FF caused an increase in the contraction forces, which reached values that were significantly higher than those produced by Z-250 alone and by Z-250 associated with VB (Table 1). Polymerization contraction and modulus of elasticity have to be assessed dynamically when polymerization contraction force of a restorative system is evaluated. In the case of composite with low filler content such as flowable composite it presents low modulus of elasticity and high polymerization shrinkage. Furthermore, to investigate the effect of the modulus of composite on the polymerization shrinkage force, the instrument with zero or very low compliance should be used. In this study a 10 kg load cell having compliance to measure contraction force was used. In these cases, composite shrinkage is major determinant factor on shrinkage force.

In our methodology, intermediate material has been polymerized before the test began. Just after its polymerization, composite resin was applied and polymerized. The test and the composite light-activation began simultaneously. Labella, et al.12 (1999), stated that the higher shrinkage of flowable composites over that of hybrids may indicate a potential for higher interfacial stresses. Although flowable composite light-activation had finished before the test began, this material continued generating contraction forces for at least 2 minutes, as the present study showed. An increase of generated force during the whole 120-second period for G2 was shown. This means that at the moment the test started, the computer recorded the resultant force values of the interaction between Z-250 and FF. We have to take into account that flowable composite with a low modulus of elasticity should absorb some stress from Z-250. Therefore, the values observed for these groups with flowable composite (G4 and G5) could be seen as the result of the polymerization contraction force of Z-250 without the force absorbed by FF(depending on its modulus of elasticity at that moment), added to FF residual polymerization contraction force generated during the test period. Residual polymerization contraction force of FF was so great that it hindered the beneficial effect of a low modulus of elasticity15 and promoted significantly higher force values than did Z-250 used as a single material. Therefore, if the resultant polymerization contraction force did not decrease, microleakage would be expected to be similar or higher than resin restorations without flowable composite liner. Hagge, et al.8 (2001), found that the flowable composite Revolution (SDS Kerr) used as an intermediate material was not able to reduce microleakage in a composite resin restoration. In their study, Fuji II LC (Fuji Japan) showed significantly lower microleakage than both resin groups. Beznos5 (2001), showed that RMGIC or flowable composite could not significantly reduce the marginal leakage of composite restorations, but the author noted that there was a clear tendency for poorer results with the use of flowable composite.

In the present study, there was no significant difference between the 0.5-mm or 1-mm-thick FF layer used as intermediate material. The increase in layer thickness leads to a greater volume of the material, a greater volumetric contraction and corresponding contraction force, but it leads to an increase in the absorption capacity as well. The values showed again the interaction between these two factors, where a difference in layer thickness from 0.5 mm to 1 mm promoted no significant difference in polymerization contraction force of the two groups. Malmström, et al.13 (2002), found no significant difference in microleakage for composite restorations with an intermediate layer of 0.5 or 1 mm of flowable composite. These results are in accordance with the present observations of contraction force values and their potential for microleakage.

VB RMGIC is considered a low modulus of elasticity material and, unlike the flowable composite resin, it generated a low polymerization contraction force (1.8N). This property allowed that the stress absorption capacity of this material due to its low modulus of elasticity could be expressed as a decrease in the polymerization contraction force of the restorative system, as shown in G6 (4.0N) and G7 (2.8N) (Figure 1). This fact could explain in part the reason why other studies had demonstrated a better marginal adaptation,2,11 less microleakage2,8 and lower cusp deflection1 in composite restorations that used glass ionomer as an intermediate material.

The use of a flowable composite as an intermediate material due to its capacity of stress absorption should be questioned because of the residual polymerization contraction force at the moment that the restorative composite resin is polymerized over it. Nevertheless, it is important to mention that instead of curing from the top down, this study used a cross sectional lateral photocuring approach in order to accommodate the non-transmissible steel plates mounted in the tested machine. As a result, the intensity of light used to cure the composite layer was equivalent to that reaching the pre-cured liner layer. This differs from the clinical situation where placement of a composite layer over the liner significantly attenuates the light intensity that reaches the liner when irradiating from the top down. Therefore, the approach used here is likely to magnify the secondary curing contribution of the liner layer to the overall stress. Other studies addressing this relation and other properties of these materials should be done since there are studies showing that flowable composites used as intermediate layers can decrease the leakage of composite restorations16.

CONCLUSIONS

Based on the findings that VB was able to absorb part of the polymerization contraction force of Z-250, its use as an intermediate layer under composite resin restorations could be recommended in situations where the composite resin polymerization contraction force is not controllable or predictable.

ACKNOWLEDGEMENT

This study was partially supported by grants from CAPES – Brazil.

REFERENCES

- 1.Alomari QD, Reinhardt JW, Boyer DB. Efect of liners on cusp deflection and gap formation in composite restorations. Oper Dent. 2001;26:406–411. [PubMed] [Google Scholar]

- 2.Anderson-Wenckert IE, Van Dijken JWV, Hörstedt P. Modified class II open sandwich restorations: evaluation of interfacial adaptation and influence of different restorative techniques. Eur J Oral Sci. 2002;110:270–275. doi: 10.1034/j.1600-0447.2002.11210.x. [DOI] [PubMed] [Google Scholar]

- 3.Bausch JR, De Lange K, Davidson CL, Peters A, De Gee AJ. Clinical significance of polymerization shrinkage of composite resins. J Prosthet Dent. 1982;48:59–67. doi: 10.1016/0022-3913(82)90048-8. [DOI] [PubMed] [Google Scholar]

- 4.Bayne S C, Thompson J Y, Swift E J, Stamatiades P, Wilkerson M. A characterization of first generation flowable composites. J Amer Dent Assoc. 1998;129:567–577. doi: 10.14219/jada.archive.1998.0274. [DOI] [PubMed] [Google Scholar]

- 5.Beznos C. Microleakage at the cervical margin of composite class II cavities with different restorative techniques. Oper Dent. 2001;26:60–69. [PubMed] [Google Scholar]

- 6.Dauvillier BS, Feilzer AJ, De Gee AJ, Davidson CL. Viscoelastic parameters of dental restorative materials during setting. J Dent Res. 2000;79:818–823. doi: 10.1177/00220345000790030601. [DOI] [PubMed] [Google Scholar]

- 7.Dietrich Th, Lösche AC, Lösche GM, Roulet JF. Marginal adaptation of direct composite and sandwich restorations in class II cavities with cervical margins in dentine. J Dent. 1999;27:119–128. doi: 10.1016/s0300-5712(98)00035-9. [DOI] [PubMed] [Google Scholar]

- 8.Hagge MS, Lindemuth JS, Mason JF, Simon JF. Effect of four intermediate layer treatments on microleakage of class II composite restorations. Gener Dent. 2001:489–495. [PubMed] [Google Scholar]

- 9.Kemp-Scholte Ch M, Davidson CL. Marginal integrity related to bond strength and strain capacity of composite resin restorative systems. J Prosthet Dent. 1990;64:658–664. doi: 10.1016/0022-3913(90)90291-j. [DOI] [PubMed] [Google Scholar]

- 10.Kemp-Scholte ChM, Davidson CL. Complete marginal seal of class v resin composite restorations affected by increased flexibility. J Dent Res. 1990;69:1240–1243. doi: 10.1177/00220345900690060301. [DOI] [PubMed] [Google Scholar]

- 11.Krejci I, Lutz F, Krejci D. The influence of different base materials on marginal adaptation and wear of conventional class II composite resin restorations. Oper Dent. 1988;19:191–198. [PubMed] [Google Scholar]

- 12.Labella R, Lambrechts P, Van Meerbeek B, Vanherle G. Polymerization shrinkage and elasticity of flowable composites and filled adhesives. Dent Mater. 1999;15:128–137. doi: 10.1016/s0109-5641(99)00022-6. [DOI] [PubMed] [Google Scholar]

- 13.Malmström H, Schlueter M, Roach T, Moss ME. Effect of thickness of flowable resins on marginal leakage in class II composite restorations. Oper Dent. 2002;27:373–380. [PubMed] [Google Scholar]

- 14.Mitra SB. Adhesion of dentin and physical properties of a light cured glass ionomer liner/base. J Dent Res. 1991;70:72–74. doi: 10.1177/00220345910700011201. [DOI] [PubMed] [Google Scholar]

- 15.Mondelli RFL, Ishikiriama SK, Valeretto TM, Franco EB, Ishikiriama A, Mondelli J. Força de contraçâo de polimerização de materiais de forramento e resina composta. Rev Assoc Paul Cir Dent. 2006;60:61–66. [Google Scholar]

- 16.Payne JH., IV The marginal seal of class II restorations: flowable composite resin compared to injectable glass ionomer. J Clin Ped Dent. 1999;23:123–130. [PubMed] [Google Scholar]

- 17.Pereira RA, Amarante PA, Castaòeda-Espinosa JC. Avaliação de contração de polimerização de resinas compostas: microhiìbrida, nanopartiìculas e ormocer. Rev Ibero Am Odont Est & Dent JBD. 2005;4:181–187. [Google Scholar]

- 18.Prati C. Early marginal microleakage in class II resin composite restorations. Dent Mater. 1989;5:392–398. doi: 10.1016/0109-5641(89)90107-3. [DOI] [PubMed] [Google Scholar]

- 19.Tam LE, Mc Comb D, Pulver F. Physical properties of proprietary light-cured lining materials. Oper Dent. 1991;16:210–217. [PubMed] [Google Scholar]

- 20.Unterbrink G L, Liebenberg H. Flowable resin composites as "filled adhesives": Literature review and clinical recommendations. Quintessence Int. 1999;30:249–257. [PubMed] [Google Scholar]

- 21.Van Meerbeek B, Lambrechts P, Inokoshi S, Braem M, Vanherle G. Factors affecting adhesion to mineralized tissues. Oper Dent. 1992;(Suppl. 5):111–124. [PubMed] [Google Scholar]