Abstract

Objective:

This study compared the cutting capacity of carbide burs sterilized with microwaves and traditional sterilization methods.

Material and Methods:

Sixty burs were divided into 5 groups according to the sterilization methods: dry heat (G1), autoclave (G2), microwave irradiation (G3), glutaraldehyde (G4) or control – no sterilization (G5). The burs were used to cut glass plates in a cutting machine set for twelve 2.5-min periods and, after each period, they were sterilized (except G5) following the protocol established for each group. The cutting capacity of the burs was determined by a weight-loss method. Data were analyzed statistically by Kruskal-Wallis and Dunn's test.

Results:

The means of the cutting amount performed by each group after the 12 periods were G1 = 0.2167 ± 0.0627 g; G2 = 0.2077 ± 0.0231 g; G3 = 0.1980 ± 0.0326 g; G4 = 0.1203 ± 0.0459 g; G5 = 0.2642 ± 0.0359 g. There were statistically significant differences among the groups (p<0.05); only dry heat sterilization was similar to the control.

Conclusion:

Sterilization by dry heat was the method that least affected the cutting capacity of the carbide burs and microwave sterilization was not better than traditional sterilization methods.

Keywords: Sterilization, Dental instruments, Infection control, Microwaves

INTRODUCTION

Dental burs have been identified as a source of crosscontamination between patient and dental personnel12,13. They may become heavily contaminated with necrotic tissues, saliva, blood and potential pathogens during use. However, it is difficult to proceed the pre-cleaning and sterilization of burs because of their complex architecture12.

It is desirable that disinfection and sterilization do not affect the instruments during their processing. However, questions have been raised about the effects of different sterilization methods on the microscopic characteristics, durability and strength of dental instruments, especially burs3,7,8,19,23,27, which can have their sharpness and ability to effectively cut tooth structure altered33. While sterilization and disinfection procedures are vital to guarantee the safety of dental treatment20, these procedures may generate alterations in the characteristics and performance of the burs3,8,23,27. Therefore, in order to associate a safe procedure with the least possible structural alterations in burs, the effects and limitations of each sterilization method must be known.

The most common sterilization methods are dry heat, autoclaving and immersion in chemical solutions20. All these methods have advantages and disadvantages. Dry heat sterilization can be used on package itens with no risk of rust or corrosion, leaving the instruments dry upon completion41. However, it requires a longer sterilizing cycle being time consuming24 and the cycle could be interrupted if the oven door is opened before the its end. Autoclaving is one of the most effective and safe methods, but it may result in corrosion of steel items25,35 in addition to being time consuming and expensive5. Chemical sterilization is achieved after a prolonged sterilization time, and may be unable to penetrate bacteria that are physically sequestered and impregnated within the material, or may be inactivated by tissue debris38.

Increasing interest in the use of the microwave oven as a sterilization method has been observed. It has been suggested as a practical physical sterilization method9,38 that is as effective as autoclaving2,9,38. The low cost, speed and simplicity of disinfection and sterilization by microwaves34 have encouraged research to be conducted in several areas. Although research has been conducted with regard to the sterilization of dental instruments and materials5, there are few publications32,38 about the effects of microwave sterilization on burs. Thus, it is necessary to compare the effect of different sterilization methods on the cutting capacity of carbide burs. The aim of this study was to compare the cutting capacity of carbide burs after sterilization by dry heat, autoclave, microwave irradiation, and glutaraldehyde. The null hypothesis was that the sterilization methods cause no significant difference in the cutting capacity of the tested burs.

MATERIAL AND METHODS

A total of 65 new, cylindrical, cross-cut, no. 57 carbide burs from the same manufacturer (S.S. White, S.S. White Burs Inc., Lakewood, NJ, USA) were examined. The burs were evaluated with a stereoscopic magnifying glass (Citoval, Carl Zeiss, Jena, Germany) in order to discard those with imperfections. Five burs were excluded and the remaining 60 burs were used to carry out the cutting procedures on square (30 x 30 x 10 mm) glass plates10,16,31 (Cebrace, Cia Brasileira de Cristal, Jacareí, SP, Brazil).

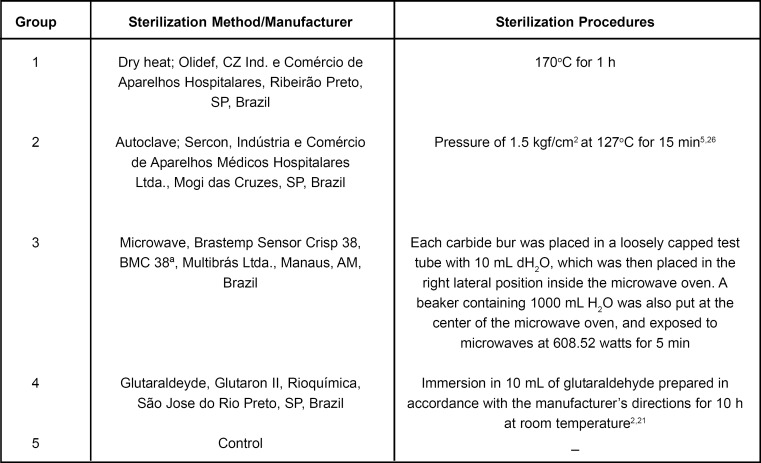

The burs were randomly divided into 5 groups (b=12) according to the sterilization method (Figure 1). One group of 12 burs was not subjected to any sterilization method and served as a control.

FIGURE 1. Experimental groups and sterilization characteristics. dH2O = distilled water.

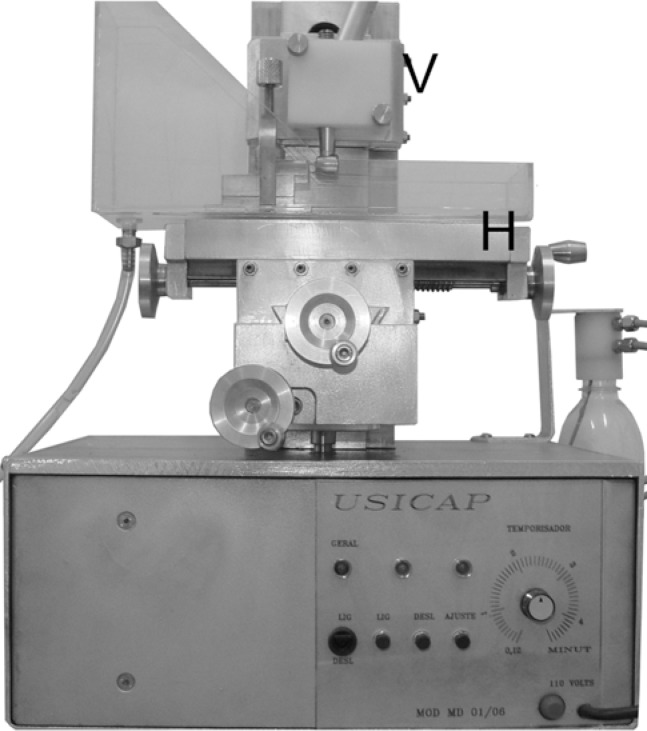

A high-reliability cutting machine (Figure 2), with accessory timing and controlling features that allow standardized cutting, was used in this experiment. On this machine, a movable platform (V) that held the handpiece (605 Extratorque; Kavo do Brasil Indústria e Comércio Ltda, Joinville, SC, Brazil) could automatically be placed under a predetermined load (0.68N)17–18 on the square glass plates, which were attached to other platform (H). When the machine was switched on, the platform V was automatically moved up and down, making it possible to cut the glass intermittently. The high speed turbine was also activated automatically, maintaining a constant speed (350,000 rpm), air pressure (2.2 bar) and water cooling (25 mL/min)11.

FIGURE 2. Cutting machine: V - Vertical platform; H - Horizontal platform.

Each carbide bur was subjected to a total of 30 min of use divided into twelve 2.5-min periods. After each period, except for the last one, the burs were cleaned with a nylon brush under running water (40 s), dried with an air stream, and then sterilized individually according to the experimental group.

A weight-loss method21–22,36 was used to measure the amount of glass cutting performed by the carbide burs. Immediately before cutting, each glass plate was weighed on a digital balance (Sartorius-Werke, Sartorius AG, Göettingen, Germany) accurate to 0.0001 g. After each 2.5 min of cutting, the glass was cleaned with air stream (40 s), dried, and reweighed.

The difference between the initial and final weight of the glass determined the quantity of cut performed by each bur after each 2.5-min cut period. Then, the sum of the cutting amount performed by each bur after 30 min of use and the mean of the cutting amount of each group was calculated, thereby determining indirectly, the cutting efficiency.

Data were statistically analyzed using the software Bioestat 4.0. Data sets did not fit the normal curve, exhibiting heteroscedasticity. Thus, the groups were compared by the non-parametric Kruskal-Wallis and Dunn's tests (α = 0.05).

RESULTS

The mean glass cutting amount recorded in each group was: G1 = 0.2167 ± 0.0627 g; G2 = 0.2077 ± 0.0231 g; G3 = 0.1980 ± 0.0326 g; G4 = 0.1203 ± 0.0459 g; G5 = 0.2642 ± 0.0359 g. The statistical analysis showed that some of the sterilization methods evaluated in this study affected the performance of the carbide burs (p<0.05).

Compared to the control, the burs that were autoclaved, microwave irradiated and treated with chemical solution showed a statistically significant decrease (p<0.05) in their cutting capacity. Burs treated with dry heat did not differ significantly (p>0.05) from the non-treated control burs. Burs sterilized by chemical solution showed the lowest cutting capacity. The mean glass cutting amount produced by G2 and G3 were statistically similar to that of G1 (p>0.05), but were significantly lower (p<0.05) than that of the control group. No significant differences (p>0.05) were seen between microwave sterilization and autoclave and also between microwave and glutaraldehyde.

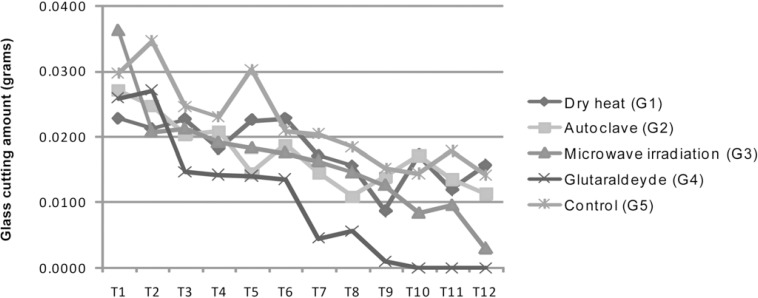

The changes in glass cutting amount after each 2.5-min cut period for each group are shown in Figure 3. All burs showed a decrease on the cutting capacity. The burs subjected to dry heat or autoclaving and the non-treated burs presented a nonuniform decrease of their cutting capacity with the presence of peak different from the microwaved and chemically sterilized burs, which had a gradual and continuous cutting capacity decrease. G1, G2 and G3 showed a decrease of the cutting capacity already after the first sterilization cycle and, among them, microwave irradiation promoted the the greatest decrease. Sterilization with glutaraldehyde (G4) reduced the cutting capacity of the burs by more than 50% after 3 cycles, while for the other methods a reduction of 50% occurred after 7 cycles.

FIGURE 3. Changes in glass cutting amount after each 2.5-min cut period for each group.

Fifteen burs broke during the experiment: one bur in G2, two burs in G3 and twelve burs in G4, in which no burs withstood more than 9 cycles of use and 8 sterilizations. Most of them broke at the weld and few burs fractured along the carbide head. There were no breakages of the stainless steel shafts.

DISCUSSION

In the present study, one chemical and three physical sterilization methods were investigated with respect to their influence on carbide bur cutting capacity. When the burs were sterilized by dry heat, no significant decrease in the cutting capacity was observed compared to no sterilization. A possible explanation for this may be that sterilization by dry heat occurs by means of dehydrating the microorganisms and is obtained in a dry environment24. This environment preserves the integrity of stainless steel instruments because it does not induce steel oxidation and corrosion24–25, and could even improve some of the properties, such as fracture strength, in different types of burs8. According to Miller25 (2002), steel instruments do not corrode when they are put into the oven under dry conditions. In a study evaluating the influence of the sterilization process on the geometry of carbide burs, McLundie23 (1974) showed that dry heat causes only a slight increase in the number of cracks visible on the cutting blade surfaces, which could even improve the cutting capacity because of the increase in contact area between the bur and the substrate4. These may be the reasons for the lack of significant decrease in the cutting capacity of the dry heat sterilized carbide burs.

Different reasons for the loss of carbide bur cutting capacity are listed in the literature. Some are related to the cutting head composition, blade dulling28, manufacturing process, quality control16, and cutting blade fractures due to the metal high hard22,27,30,37. Other reasons are specially associated with the geometric alterations caused by the microstructural alterations induced by oxidation or corrosion of the steel during certain sterilization processes3.

The two other physical sterilization methods investigated in this study, autoclaving and microwaving, showed a negative influence on the performance of the carbide burs. The sterilization by autoclave is based on microorganism denaturation, achieved by the action of both heat and humidity9,14,24,35. Although the autoclave caused little visible surface deterioration in the geometrical characteristics23, the loss of cutting capacity shown by the autoclaved burs may be explained by corrosion of the burs that may have dulled their cutting edges35. While the carbide tungsten of the burs has a protective layer on its surface, the shank and the solder joint have greater amount of basic metals (e.g.: Fe). When subjected to high temperature under wet conditions, these metals create an electrolytic medium that result in the passivation of the protective layer favoring the corrosion phenomenon.

In the present study, the carbide burs were immersed in distilled water during the microwave irradiation and a decrease in the cutting capacity of these burs was observed. According to some authors, microorganism inhibition depends on the energy absorbed and/or heat transferred40, and is severely compromised in the absence of water2,18,40. Since the microwaves cause the water molecules to vibrate, producing friction that results water heating2,17–18, a condition similar to that of autoclave sterilization was established (heat and humidity). According to Miller25 (2002), irrespective of the process used to achieve sterilization, corrosion will occur more quickly in an autoclave or in any other environment involving water and heat.

The use of a chemical solution to sterilize the carbide burs caused the greatest alterations in their structure. Although the chemically sterilized burs produced mean glass cutting amount similar to that obtained after microwave sterilization, all the burs broke at the weld. According to McLundie23 (1974), burs immersed in a chemical solution may show various degrees of attack, but apparently less damage to the blade surfaces. A possible explanation for these results might be the potentially corrosive action of glutaraldehyde present in the chemical solution. Moreover, carbide burs weaken when they are immersed in an electrolyte because macroscopic galvanic coupling is formed between different sections of the burs3.

The influence of sterilization on rotary instruments remains unclear and a consensus has not yet been reached26. Reports concerning effects of autoclave and dry cycles on these instruments focus mainly on the mechanical properties, fracture strength and cutting efficiency. In addition to carbide burs, the diamond burs and rotary NiTi file are among the most studied rotary instruments.

Even considering that the comparisons to the results of published studies are difficult due to the use of different types of substrates and different parameters, the effects of sterilization were considered deleterious when Chung, et al.7 (2006) verify that the diamond burs had their cutting capacity progressively reduced after the first sterilization cycle. According to Guerekics, et al.13 (1991), although there were no significant differences among the cutting capacity of diamond burs after sterilization in chemical agent, autoclave, dry heat; or chemiclave, there are differences in the cutting capacity of individual diamond instruments. According to Borges, et al.6 (1999) among the problems encountered by the repeated sterilization of diamond instruments that may decrease their cutting effectiveness are the diamond particle loss caused by the effects on the matrix that binds diamond particles to the shank.

With respect to the rotary NiTi files, both autoclave and dry heat sterilization methods are the most frequently evaluated. Valois, et al.39 (2008) reported that autoclave was able to increase the irregularities and the roughness of rotary NiTi files wich was associated with the impairment of the cutting capacity and fracture of rotary Ni-Ti files during clinical use. As found in this study, autoclave had a cumulative effect on structure of the metal, which can result in surface corrosion after an excessive number of cycles. Similarly, Rapisarda, et al.29 (1999) verified that the sterilization of rotary NiTi files by autoclave produced an increase in Ni-Ti oxides in the near surface layer which could be the cause of the experienced 20% reduction in cutting ability after 7 cycles of sterilization and further reduction by up to 50% after 14 cycles. Regarding to the dry heat use, debris, pitting, metal strips and deep milling marks were observed by Alexandrou, et al.1 (2006) after 11 sterilization cycles. These defects could be responsible for a low cutting efficiency and may compromise the corrosion resistance of rotary NiTi files.

Considering the undesirable effects of the sterilization procedures, burs manufacturers have introduced single- patient-use burs as a partial solution to dentist's concerns regarding infection control. However, most professionals state that they use the burs until perceiving the instruments had lost their cutting efficiency. According to Hauptman, et al.15 (2006), if manufacturers adopt a rule providing sterilized burs, which is common for disposable burs, it will increase their functional usage time by around 10%.

One of the limitations of this in vitro study is that the cutting substrate used does not reproduce the characteristics of dental structure or restorative materials encountered under clinical conditions. However, it is indicated by the American Dental Association for tests that evaluate the durability and capacity of carbide burs because it has the same hardness throughout its entire surface. Although the dry heat sterilization results were the same as those of the control, this study was incapable of detecting differences among the influence of the physical sterilization methods on the cutting capacity of carbide burs. Furthermore, the results of this study should be interpreted with caution because the use of microwave is not still recognized by any standards as a sterilization method and may not encourage some clinicians to consider off-label use of these devices in clinical practice. However, microwave sterilization and comparison among dry heat, autoclave and microwave irradiation should be subject of further investigations.

CONCLUSIONS

In conclusion, the null hypothesis was rejected because the cutting capacity of the carbide burs was less affected by dry heat. Microwave sterilization was not better than traditional sterilization methods regarding the reduction of carbide bur cutting efficiency.

ACKNOWLEDGEMENTS

The partial financial support by PROAP, CAPES and FAPESP is gratefully acknowledged.

REFERENCES

- 1.Alexandrou G, Chrissafis K, Vasiliadis L, Pavlidou E, Polychroniadis EK. Effect of heat sterilization on surface characteristics and microstructure of Mani NRT rotary nickel-titanium instruments. Int Endod J. 2006;39(10):770–778. doi: 10.1111/j.1365-2591.2006.01147.x. [DOI] [PubMed] [Google Scholar]

- 2.Banik S, Bandyopadhyay S, Ganguly S. Bioeffects of microwave—a brief review. Bioresour Technol. 2003;87(2):155–159. doi: 10.1016/s0960-8524(02)00169-4. [DOI] [PubMed] [Google Scholar]

- 3.Bapna MS, Mueller HJ. Corrosion of dental burs in sterilizing and disinfecting solutions. J Prosthet Dent. 1988;59(4):503–511. doi: 10.1016/0022-3913(88)90051-0. [DOI] [PubMed] [Google Scholar]

- 4.Berman MH. Cutting efficiency in complete coverage preparation. J Am Dent Assoc. 1969;79(5):1160–1167. doi: 10.14219/jada.archive.1969.0063. [DOI] [PubMed] [Google Scholar]

- 5.Border BG, Rice-Spearman L. Microwaves in the laboratory: effective decontamination. Clin Lab Sci. 1999;12(3):156–160. [PubMed] [Google Scholar]

- 6.Borges CF, Magne P, Pfender E, Heberlein J. Dental diamond burs made with a new technology. J Prosthet Dent. 1999;82(1):73–79. doi: 10.1016/s0022-3913(99)70130-7. [DOI] [PubMed] [Google Scholar]

- 7.Chung EM, Sung EC, Wu B, Caputo AA. Comparing cutting efficiencies of diamond burs using a high-speed electric handpiece. Gen Dent. 2006;54(4):254–257. [PubMed] [Google Scholar]

- 8.Cooley RL, Marshall TD, Young JM, Huddleston AM. Effect of sterilization on the strength and cutting efficiency of twist drills. Quintessence Int. 1990;21(11):919–923. [PubMed] [Google Scholar]

- 9.Cottone JA, Tererhalmy GT, Molinari JA. Practical infection control in dentistry. Philadelphia: Lea & Febiger; 1991. [Google Scholar]

- 10.Eames WB, Nale JL. A comparison of cutting efficiency of air-driven fissure burs. J Am Dent Assoc. 1973;86(2):412–415. doi: 10.14219/jada.archive.1973.0083. [DOI] [PubMed] [Google Scholar]

- 11.Ercoli C, Rotella M, Funkenbusch PD, Russell S, Feng C. In vitro comparison of the cutting efficiency and temperature production of 10 different rotary cutting instruments. Part I: Turbine. J Prosthet Dent. 2009;101(4):248–261. doi: 10.1016/S0022-3913(09)60049-4. [DOI] [PubMed] [Google Scholar]

- 12.Gordon BL, Burke FJT, Bagg J, Marlborough HS, McHugh ES. Systematic review of adherence to infection control guidelines in dentistry. J Dent. 2001;29(8):509–516. doi: 10.1016/s0300-5712(01)00043-4. [DOI] [PubMed] [Google Scholar]

- 13.Gureckis KM, Burgess JO, Schwartz RS. Cutting effectiveness of diamond instruments subjected to cyclic sterilization methods. J Prosthet Dent. 1991;66(6):721–726. doi: 10.1016/0022-3913(91)90402-i. [DOI] [PubMed] [Google Scholar]

- 14.Hastreiter RJ, Molinari JA, Falken MC, Roesch MH, Gleason MJ, Merchant VA. Effectiveness of dental office instrument sterilization procedures. J Am Dent Assoc. 1991;122(10):51–56. doi: 10.14219/jada.archive.1991.0291. [DOI] [PubMed] [Google Scholar]

- 15.Hauptman JM, Golberg MB, Rewkowski CA. The sterility of dental burs directly from the manufacturer. J Esthet Restor Dent. 2006;18(5):268–271. doi: 10.1111/j.1708-8240.2006.00035.x. [DOI] [PubMed] [Google Scholar]

- 16.Henry EE, Peyton FA. The relationship between design and cutting efficiency of dental burs. J Dent Res. 1955;33(2):281–292. doi: 10.1177/00220345540330021501. [DOI] [PubMed] [Google Scholar]

- 17.Hume WR, Makinson OF. Sterilizing dental instruments: evaluation of lubricating oils and microwave radiation. Oper Dent. 1978;3(3):93–96. [PubMed] [Google Scholar]

- 18.Jeng DK, Kaczmarek KA, Woodworth AG, Balasky G. Mechanism of microwave sterilization in the dry state. Appl Environ Microbiol. 1987;53(9):2133–2137. doi: 10.1128/aem.53.9.2133-2137.1987. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Johnson GK, Perry FU, Pelleu GB. Effect of four anticorrosive dips on the cutting efficiency of dental carbide burs. J Am Dent Assoc. 1987;114(5):648–650. doi: 10.14219/jada.archive.1987.0154. [DOI] [PubMed] [Google Scholar]

- 20.Kohn WG, Harte JA, Malvitz DM, Collins SA, Cleveland JL, Eklund KJ. Guidelines for infection control in dental health care settings – 2003. J Am Dent Assoc. 2004;135(1):33–47. doi: 10.14219/jada.archive.2004.0019. [DOI] [PubMed] [Google Scholar]

- 21.Lloyd BA, Rich JA, Brown WS. Effect of cooling techniques on temperature control and cutting rate for high-speed dental drills. J Dent Res. 1978;57(5-6):675–684. doi: 10.1177/00220345780570050201. [DOI] [PubMed] [Google Scholar]

- 22.Luebke NH, Chan KC, Bramson JB. The cutting effectiveness of carbide fissure burs on teeth. J Prosthet Dent. 1980;43(1):42–45. doi: 10.1016/0022-3913(80)90351-0. [DOI] [PubMed] [Google Scholar]

- 23.McLundie AC. The effects of various methods of sterilization and disinfection on tungsten-carbide burs. Br Dent J. 1974;37(2):49–55. doi: 10.1038/sj.bdj.4803238. [DOI] [PubMed] [Google Scholar]

- 24.Miller CH. Cleaning, sterilization and disinfection: basics of microbial killing for infection control. J Am Dent. 1993;124(1):48–56. doi: 10.14219/jada.archive.1993.0022. [DOI] [PubMed] [Google Scholar]

- 25.Miller CH. Tips on preparing instruments for sterilization. Am J Dent. 2002;15(1):66–66. [PubMed] [Google Scholar]

- 26.Parashos P, Messer HH. Rotary NiTi instrument fracture and its consequences. J Endod. 2006;32(11):1031–1043. doi: 10.1016/j.joen.2006.06.008. Review. [DOI] [PubMed] [Google Scholar]

- 27.Patterson CJW, McLundie AC. The effect of ultrasonic cleaning and autoclaving on tungsten carbide burs. Br Dent J. 1988;164(20):113–115. doi: 10.1038/sj.bdj.4806368. [DOI] [PubMed] [Google Scholar]

- 28.Pines MS, Schulman A. Characterization of wear of tungsten carbide burs. J Am Dent Assoc. 1979;99(5):831–833. doi: 10.14219/jada.archive.1979.0403. [DOI] [PubMed] [Google Scholar]

- 29.Rapisarda E, Bonaccorso A, Tripi TR, Condorelli GG. Effect of sterilization on the cutting efficiency of rotary nickel-titanium endodontic files. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 1999;88(3):343–347. doi: 10.1016/s1079-2104(99)70040-5. [DOI] [PubMed] [Google Scholar]

- 30.Reisbick MH, Bunshah RF. Wear characteristics of burs. J Dent Res. 1973;52(5):1138–1146. doi: 10.1177/00220345730520052301. [DOI] [PubMed] [Google Scholar]

- 31.Reports of Councils and Bureaus. Revised American Dental Association Specification n° 23 for dental excavating burs. J Am Dent Assoc. 1975;90(2):459–468. doi: 10.14219/jada.archive.1975.0068. [DOI] [PubMed] [Google Scholar]

- 32.Rizzo R. Gli effetti della sterilizzazione com microonde sulle frese diamantate. Minerva Stomatol. 1993;42:93–96. [PubMed] [Google Scholar]

- 33.Roberson TM, Heymann HO, Swift EJ. Sturdevant's art & science of operative dentistry. St. Louis: Mosby; 2002. [Google Scholar]

- 34.Rohrer MD, Bulard RA. Microwave sterilization. J Am Dent Assoc. 1985;110(2):194–198. doi: 10.14219/jada.archive.1985.0250. [DOI] [PubMed] [Google Scholar]

- 35.Savage NW, Walsh LJ. The use of autoclaves in the dental surgery. Aust Dent J. 1995;40(3):197–200. doi: 10.1111/j.1834-7819.1995.tb05637.x. [DOI] [PubMed] [Google Scholar]

- 36.Semmelman JO, Kulp PR, Kurlansik L. Cutting studies at air-turbine speeds. J Dent Res. 1961;40(3):404–410. [Google Scholar]

- 37.Tanaka N, Taira M, Wakasa K, Shintani H, Yamaki M. Cutting effectiveness and wear of carbide burs on eight machinable ceramics and bovine dentin. Dent Mater. 1991;7(4):247–253. doi: 10.1016/S0109-5641(05)80023-5. [DOI] [PubMed] [Google Scholar]

- 38.Tate WH, Goldschmidt MC, Ward MT, Grant RL. Disinfection and sterilization of composite polishing instruments. Am J Dent. 1995;8(5):270–272. [PubMed] [Google Scholar]

- 39.Valois CR, Silva LP, Azevedo RB. Multiple autoclave cycles affect the surface of rotary nickel-titanium files: an atomic force microscopy study. J Endod. 2008;34(7):859–862. doi: 10.1016/j.joen.2008.02.028. [DOI] [PubMed] [Google Scholar]

- 40.Vela GR, Wu JF. Mechanism of lethal action of 2450 Mhz radiation on microorganisms. Appl Environ Microbiol. 1979;37(3):550–553. doi: 10.1128/aem.37.3.550-553.1979. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Woods R. Sterilization: Part 1. Instrument preparation. FDI World. 1996;5(2):7–10. [PubMed] [Google Scholar]