Abstract

An experiment was conducted to evaluate and standardize the protocol for enhancing recovery of oil and quality from cold pressed wild apricot kernels by using various enzymes. Wild apricot kernels were ground into powder in a grinder. Different lots of 3 kg powdered kernel were prepared and treated with different concentrations of enzyme solutions viz. Pectazyme (Pectinase), Mashzyme (Cellulase) and Pectazyme + Mashzyme. Kernel powder mixed with enzyme solutions were kept for 2 h at 50(±2) °C temperature for enzymatic treatment before its use for oil extraction through oil expeller. Results indicate that use of enzymes resulted in enhancement of oil recovery by 9.00–14.22 %. Maximum oil recovery was observed at 0.3–0.4 % enzyme concentration for both the enzymes individually, as well as in combination. All the three enzymatic treatments resulted in increasing oil yield. However, with 0.3 % (Pectazyme + Mashzyme) combination, maximum oil recovery of 47.33 % could be observed against were 33.11 % in control. The oil content left (wasted) in the cake and residue were reduced from 11.67 and 11.60 % to 7.31 and 2.72 % respectively, thus showing a high increase in efficiency of oil recovery from wild apricot kernels. Quality characteristics indicate that the oil quality was not adversely affected by enzymatic treatment. It was concluded treatment of powdered wild apricot kernels with 0.3 % (Pectazyme + Mashzyme) combination was highly effective in increasing oil recovery by 14.22 % without adversely affecting the quality and thus may be commercially used by the industry for reducing wastage of highly precious oil in the cake.

Keywords: Wild apricot, Pectazyme, Mashzyme, Iodine value, Saponification value, Acid value, Refractive index

Introduction

Edible oil production is a separate sector of the food processing industry. There are several species of plants in the world whose oil can be utilized for human consumption for edible and non-edible purposes. Though around 40 oilseeds are known, only around a dozen oilseeds crops have become commercially important including ten seed crops and three tree crops. These oil seed crops (mostly annual) of commercial importance are groundnut, rapeseed-mustard, sesame, soybean, sunflower, cottonseed, safflower, niger, castor and linseed. The three major tree oil crops are palm, olive and coconut. Besides these, the kernels of some other tree crops i.e. apricot, almond, walnut, hazelnut, peach can also be utilized for oil extraction purposes for edible and non-edible uses. The oils of tree fruits and kernels are also becoming popular very fast for various foods, pharmaceutical and cosmetic industries (Nagaraj 2009; Sharma et al. 2011).

Large scale requirement and local shortages of oils for various edible and non-edible uses have prompted the identification of many new sources of oil during the last few decades. Most of these oilseeds and their products have wide utility in the specialty oils sector and are mostly used for non-edible purposes. Soap and detergents, paint and varnish, lubricants, pesticides and medicines, cosmetics, bio-diesel fuel industry are the major consumers of these oilseeds. All the oil crops will gain greater attention in future as they are renewable and biodegradable in nature (Sharma et al. 2011).

Wild apricot kernel is a good source of edible oil containing high unsaturated fatty acids. Apricot oil is also used as a substitute of almond oil in national and international markets. Stone fruit kernel oil can be extracted using various methods viz. manual grinding and pressing, oil press (power ghani), solvent extraction, oil expeller and table oil expeller. Use of oil press (power ghani) has been practiced for oil extraction from stone fruit kernels. Apricot kernels are reported to contain 40 to 47 % oil but only 35 % is extractable by cold pressing. Rest about 12 % is wasted in the cake (Sharma et al. 2011).

Improvement of the extractability of vegetable oils from enzymatically treated fruits and seeds, and optimization of hydrolysis time and characterization of resulting products have been reported for olives (Alba Mendoza et al. 1990), coconut (Cintra MacGlone et al. 1986), rape seed (Sousulski et al. 1988; Sarkar et al. 1998), and soybean (Fullbrook 1983). Enzymatic hydrolysis has been shown to be a useful option for pre-treatment. Pre-treatment with enzymes release extra oil for extraction enhancing the oil availability and recovery (Kashyap et al. 1997). Enhanced oil recovery in enzyme aided extraction has been suggested to be due to the bio-degradation of cell walls and hydrolysis of complex lipoproteins and lipopolysaccharides into simpler molecules releasing extra oil which was otherwise non-extractable (Srivastava et al. 2004). Enzymes to enhance extractability of the oilseeds vary in efficiency, but formulations with mixed activities have proved to be very effective (Sousulski et al. 1988; Dominguez et al. 1994; Sharma et al. 2007). The use of enzyme significantly improve the oil recovery and had no adverse effect on the nutritive and pharmaceutical quality of the oil and it was more resistant to auto oxidation as observed by sensory score (Sharma et al. 2007). Prolonged enzymatic treatment for upto 120 h increased the oil yield from grape seed to 163 % (Passos et al. 2009). Besides extraction of oils, enzymes have also been reported to be used in extraction of various bioactives and non-caloric sweeteners from plant sources (Puri et al. 2012a, b).

The recovery from wild apricot fruit kernels may be enhanced by making use of different enzymes, thus increasing efficiency of extraction. The use of enzymes for enhancing extraction of oil from olive, coconut, oilseeds etc. has been reported in the literature but that in wild apricot is scanty in literature. Enzyme and enzymes formulations are supposed to degrade the walls of oil bearing cells and break the colloidal system in wild apricot kernel powder, thereby releasing more oil. Therefore, the present investigation was undertaken for evaluating the effect of different enzymes for enhancing oil recovery by cold pressing and its effects on oil quality. Use of enzymes is presumed to enhance efficiency of the operation and reduce wastage of oil in the spent cake.

Materials and methods

Experiment was conducted at Postharvest Technology Laboratory, Department of Horticulture, G.B. Pant University of Agriculture and Technology, Hill Campus, Ranichauri, Tehri-Garhwal, Uttarakhand, India during January, 2010 to June, 2011. Fruits of wild apricot were harvested from local areas of district Tehri-Garhwal, Uttarakhand at full maturity stage. Pulp and seeds were separated in a pulper. Seeds were washed in water and dried in Sun to remove surface moisture. Seeds were broken in mechanical decorticator (5 HP motor, 80–100 kgh−1 capacity, procured from Sardar Engineering Company, Kanpur, UP, India). The mixture of broken shell and kernels was dipped in 20 % common salt (NaCl) solution. Kernels floating on the surface (due to difference in specific gravity) were collected and washed in running water for removing the adhering salt and shade dried (Sharma et al. 2011). Dried kernels were ground to powder in a spice grinder (Sandeep Instruments and Chemicals, New Delhi) and passed through sieve (5.5 mm mesh dia.) of the grinder to obtain find powder.

Enzyme preparation

Two enzymes namely pectinase (Pectazyme), cellulase (Mashzyme) and combination pectinase + cellulase, (P + C) were used at 0.1, 0.2, 0.3, 0.4, 0.5, 0.6 and 0.7 % concentration. Different concentrations of enzyme solutions were prepared by dissolving weighed quantities of commercial powdered enzyme GRAS (Generally Recognized as Safe) formulation (65000 Apple Juice Digective Units AJDU) procured from M/s Advanced Enzymes, Thane, Maharashtra, India into known quantity (150 ml) of hot 50(±2) °C water.

Enzyme treatment and oil extraction

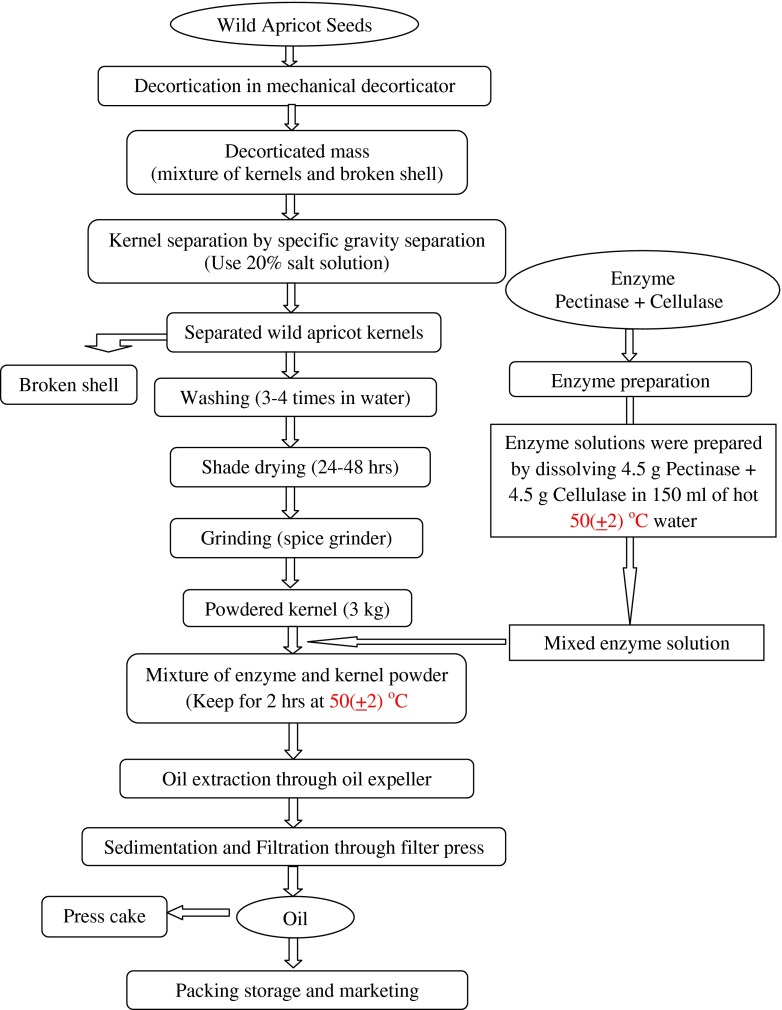

Lots of 3 kg powdered kernel were prepared and treated with different concentrations of enzyme solutions viz. Pectazyme, Mashzyme and combination (Pectazyme + Mashzyme) followed by thorough mixing in wild apricot kernel powder. The kernel powder mixed with enzyme solutions were kept for 2 h at 50(±2) °C temperature for enzymatic treatment before its use for oil extraction through oil expeller (Sardar Engineering Company, Kanpur, UP, India). Untreated (no enzymatic treatment) kernel powder was defined as control. The best enzyme concentration was determined on the basis of% increase in oil recovery over control (no enzyme) treatment (Fig. 1). The experiment was carried out in three replicates.

Fig. 1.

Protocol for enhanced extraction of apricot kernel oil by using enzymes

Quality analysis

The specific gravity of oil was measured using specific gravity bottles according to the standard method (Ranganna 1997). The refractive index of oil was determined using Abbe’s refractometer (Model Advance Research Inst. Co., New Delhi) by placing 2–3 drop of oil sample on the prism. During the process the temperature of oil was maintained at 40 °C by holding the oil samples in water bath (AOAC 1995). Acid value of apricot kernel oils was estimated by titrating a known weight of sample (5 g) with addition of 50 ml alcohol against 0.1 N NaOH solution using phenolphthalein as an indicator (AOAC 1995). Iodine value of apricot kernel oil was estimated according to (Wijs Procedure). Saponification value of apricot kernel oil was estimated according to the standard method (AOAC 1995).

Statistical analysis

Wild apricot oil extracted by best enzymatic treatment along with control was evaluated for quality characteristic. The quality parameters of wild apricot kernels oil were analyzed statistically by Completely Randomized Design (CRD) described by Cochran and Cox (1967)

Results and discussion

Effect of pectinase

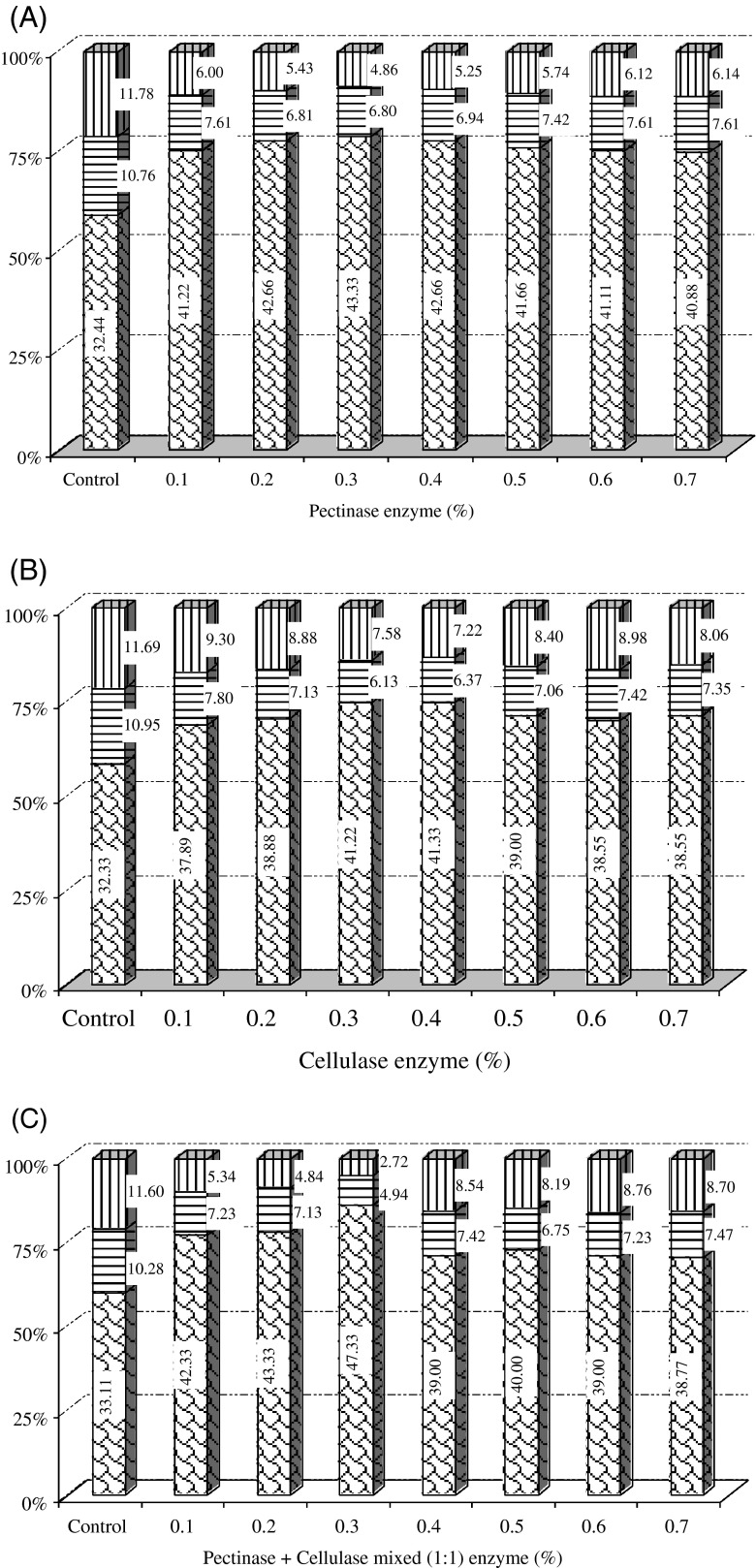

Treatment of wild apricot kernel with pectinase brought about significant increase in oil yield upto 0.3 % concentration (Table 1). Pectinase treatment @ 0.3 % resulted in maximum oil recovery (43.33 %) thereby accounting for 10.89 % increase in oil recovery over control (32.44 %). However, beyond 0.3 % pectinase concentration the oil recovery decreased steadily upto 0.7 % concentration. Enzyme at higher concentrations than required might form some emulsion of oil and water during the process of oil extraction, thus making the release of oil difficult from the material. The press cake obtained after oil extraction was found to be maximum (1.60 kg) in control i.e. without enzyme treatment and minimum (1.52 kg) in pectinase concentration of 0.3 %. The quantity of cake was reduced with corresponding increase in oil recovery. The wastage of oil in the cake was maximum (10.76 % wet basis, 12.18 % dry basis) in control (without enzyme) and minimum (6.80 % wet basis, 7.37 % dry basis) in pectinase (0.3 %) treated samples (Fig. 2). However, a small amount of oil was also wasted in the residue. The proportion of residue obtained after oil extraction was found to be maximum (441.7 g) in control/without enzyme and minimum (182.3 g) in pectinase enzyme (0.3 %) treated samples. The% oil content in residue was found to be maximum (11.78 %) in control (without enzyme) and minimum (4.86 %) in those obtained from pectinase (0.3 %) enzyme treatment.

Table 1.

Effect of pectinase treatment on oil recovery and quality parameters during extraction from 3 kg wild apricot kernels

| Parameter | Control | Enzyme concentration (%) | CD 0.05 | SE | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | ||||

| Volume of oil obtained (ml) | 973.3 | 1230 | 1280 | 1300 | 1280 | 1250 | 1230 | 1220 | 26.90 | 12.69 |

| Wt of cake obtained (kg) | 1.60 | 1.56 | 1.52 | 1.52 | 1.53 | 1.54 | 1.54 | 1.55 | 0.01 | 0.005 |

| Wt of residue (g) | 441.7 | 225.3 | 204.0 | 182.3 | 197.0 | 215.7 | 229.7 | 230.7 | 24.81 | 11.70 |

| Oil recovery from kernel% (v/w) | 32.44 | 41.22 | 42.66 | 43.33 | 42.66 | 41.66 | 41.11 | 40.88 | 0.89 | 0.42 |

| % increase in oil recovery over control | – | 8.78 | 10.22 | 10.89 | 10.22 | 9.22 | 8.67 | 8.44 | – | – |

| Oil recovery from cake (%) wet basis (w/w) | 10.76 | 7.61 | 6.81 | 6.80 | 6.94 | 7.42 | 7.61 | 7.61 | 0.38 | 0.18 |

| Oil recovery from cake (%) dry basis (w/w) | 12.18 | 8.37 | 7.39 | 7.37 | 7.53 | 8.20 | 8.47 | 8.92 | 0.43 | 0.2 |

| Oil content in residue% (w/w) | 11.78 | 6.00 | 5.43 | 4.86 | 5.25 | 5.74 | 6.12 | 6.14 | 0.66 | 0.31 |

| Iodine value (g I2/100 g) | 101.2 | 95.08 | 94.58 | 94.07 | 93.56 | 93.05 | 93.05 | 92.04 | 0.08 | 0.4 |

| Acid value (mg KOH/g) | 3.73 | 3.93 | 4.10 | 4.18 | 4.38 | 4.55 | 4.85 | 5.08 | 0.01 | 0.08 |

| Saponification value (mg KOH/g) | 191.1 | 191.1 | 189.8 | 187.9 | 187.9 | 187.3 | 186.1 | 186.1 | 1.86 | 0.88 |

| Refractive Index 40 °C | 1.471 | 1.471 | 1.470 | 1.470 | 1.470 | 1.469 | 1.469 | 1.469 | NS | 0.0004 |

CD critical difference, SE standard error (n = 3)

Fig. 2.

Efficiency of oil extraction as affected by a Pectinase enzyme, b Cellulase enzyme and c Pectinase + Cellulase mixed (1:1) enzyme treatments (n = 3)

As far as quality is concerned, iodine value refers to the extent of unsaturation, i.e. the presence of double bonds in the oil. Decrease in iodine value is a measure of quality changes during product preparation and storage. The long chain fatty acids found in fats have a low saponification value because they have a relatively fewer number of carboxylic functional groups per unit mass of the fat as compared to short chain fatty acids

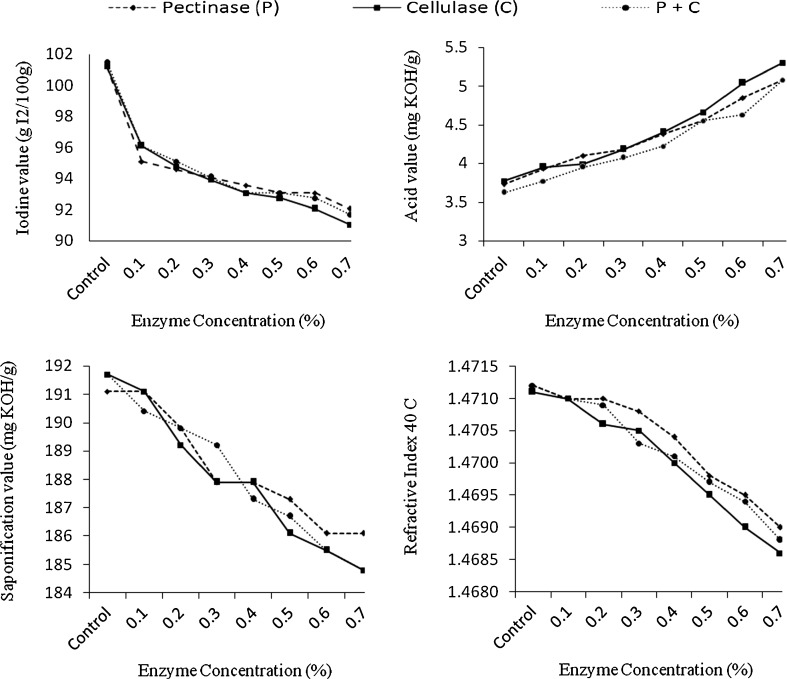

The iodine value (IV) and saponification value (SV) of oil decreased with the increase in enzyme concentration (Fig. 3). The iodine value of wild apricot kernel oil was found to be 101.2 g I2/100 g in control and 92.04–95.08 g I2/100 g in different concentrations of pectinase. The saponification value was found to be 191.1 mg KOH/g in control and 186.1–191.1 mg KOH/g in different concentration of pectinase. According to PFA specification the iodine value range for almond oil was 90–109 g I2/100 g and saponification value was 186–195 mg KOH/g. Thus wild apricot kernel oil extracted either without enzyme treatment or with enzymatic treatment at different concentration exhibited IV and SV within the prescribed range for almond oil. However, the acid value of wild apricot kernel oil increased with the increase in enzyme concentration and was found to be 3.73 mg KOH/g in control and 3.93–5.08 mg KOH/g in different concentrations of pectinase. No significant effect of enzyme concentration was found on refractive index (RI) of apricot kernel oil.

Fig. 3.

Effect of a Pectinase enzyme, b Cellulase enzyme and c Pectinase + Cellulase mixed (1:1) enzyme treatments on quality of apricot oil (n = 3)

Effect of cellulase

The enzyme cellulase brought about significant increase in oil yield up to the concentration of 0.4 % (Table 2). Cellulase concentration of 0.4 % resulted in maximum oil recovery (41.33 %) thereby accounting for 9 % increase in oil recovery over control (32.33 %). However, in other concentration of cellulase (below or above 0.4 %) the oil recovery ranged between 37.89 and 41.22 %. Increasing cellulase concentration beyond 0.4 % did not bring about any significant increase in the oil recovery from treated kernels. The press cake obtained after oil extraction was found to be maximum (1.60 kg) in control/without enzyme and minimum (1.50 kg) in cellulase concentration of 0.3 and 0.4 %. The quantity of cake was reduced corresponding to increase in oil recovery. Oil recovery from cake was maximum (10.95 % wet basis, 12.37 % dry basis) in control (without enzyme) and minimum (6.13 % wet basis, 6.51 % dry basis) in cellulase concentration of 0.4 % (Fig. 2). However, small amount of oil was wasted in the form of residue. The proportion of residue obtained after oil extraction found to be maximum (438.3 g) in control/without enzyme and minimum (217.7 g) in cellulase concentration 0.3 %. The% oil content in residue was found to be maximum (11.69 %) in control (without enzyme) and minimum (7.22 %) in cellulase concentration of 0.4 %. Overall the values for 0.3 and 0.4 % cellulase concentration were statistically at par with each other for most of the parameters.

Table 2.

Effect of cellulase treatment on oil recovery and quality parameters during extraction from 3 kg wild apricot kernels

| Parameter | Control | Enzyme concentration (%) | CD 0.05 | SE | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | ||||

| Volume of oil obtained (ml) | 970.0 | 1.14 | 1.16 | 1.23 | 1.24 | 1.17 | 1.15 | 1.15 | 56.97 | 26.87 |

| Wt of cake obtained (kg) | 1.60 | 1.52 | 1.51 | 1.49 | 1.50 | 1.53 | 1.52 | 1.52 | 0.02 | 0.01 |

| Wt of residue (g) | 438.3 | 349.0 | 333.3 | 217.7 | 271.0 | 315.3 | 337.0 | 340.0 | 72.92 | 34.40 |

| Oil recovery from kernel% (v/w) | 32.33 | 37.89 | 38.88 | 41.22 | 41.33 | 39.00 | 38.55 | 38.55 | 1.86 | 0.88 |

| % increase in oil recovery over control | – | 5.56 | 6.55 | 8.89 | 9.00 | 6.67 | 6.22 | 6.22 | ||

| Oil recovery from cake (%) wet basis (w/w) | 10.95 | 7.80 | 7.13 | 6.13 | 6.37 | 7.06 | 7.42 | 7.35 | 1.16 | 0.54 |

| Oil recovery from cake (%) dry basis (w/w) | 12.37 | 8.56 | 7.67 | 6.51 | 6.74 | 7.82 | 8.02 | 7.91 | 0.43 | 0.66 |

| Oil content in residue% (w/w) | 11.69 | 9.30 | 8.88 | 7.58 | 7.22 | 8.40 | 8.98 | 8.06 | 0.90 | 0.42 |

| Iodine value (g I2/100 g) | 101.20 | 96.10 | 94.75 | 93.90 | 93.05 | 92.72 | 92.04 | 91.02 | 0.1 | 0.47 |

| Acid value (mg KOH/g) | 3.77 | 3.95 | 3.99 | 4.18 | 4.40 | 4.66 | 5.04 | 5.30 | 0.02 | 0.09 |

| Saponification value (mg KOH/g) | 191.7 | 191.1 | 189.2 | 187.9 | 187.9 | 186.1 | 185.5 | 184.8 | 1.74 | 0.82 |

| Refractive Index 40 °C | 1.471 | 1.471 | 1.470 | 1.470 | 1.470 | 1.469 | 1.469 | 1.468 | NS | 0.0004 |

CD critical difference, SE standard error (n = 3)

The iodine value (IV) and saponification value (SV) of oil decreased with the increase in cellulase enzyme concentration (Fig. 3). The iodine value of wild apricot kernel oil was found to be 101.2 g I2/100 g in control and 91.04–96.10 g I2/100 g in different concentration of cellulase. The saponification value of oil was 191.7 mg KOH/g in control and 184.8–191.1 mg KOH/g in different concentration of cellulase. However, the acid value of wild apricot kernel oil increased with the increase in enzyme concentration. The acid value of wild apricot kernel oil was found to be 3.77 mg KOH/g in control and 3.95–5.30 mg KOH/g in different concentration of cellulase. No significant effect of enzyme concentration was observed on refractive index of oil.

Effect of mixed enzyme formulation

The enzyme mixture brought about significant increase in oil yield (Table 3) up to concentration of 0.3 % resulting in maximum oil recovery (47.33 %) thereby accounting for 14.22 % increase in oil recovery over control (33.11 %). However, in other concentration of pectinase + cellulase (below or above 0.3 %) the oil recovery ranged between 38.77 and 43.33 %. Increasing enzyme concentration beyond 0.3 % did not bring about any further increase in oil recovery from treated kernels. The press cake obtained after oil extraction found to be maximum (1.58 kg) in control/without enzyme and minimum (1.49 kg) in mixed enzyme concentration of 0.3 %. The quantity of cake was reduced corresponding to increase in oil recovery. Oil recovery from cake was maximum (10.28 % wet basis, 11.67 % dry basis) in control (without enzyme) and minimum (4.94 % wet basis, 7.31 % dry basis) in pectinase + cellulase concentration of 0.3 % (Fig. 2). However, small amount of oil was also wasted in the form of residue. The proportion of residue obtained after oil extraction found to be maximum (435.0 g) in control/without enzyme and minimum (102.3 g) in mixed enzyme concentration of 0.3 %. The% oil content in residue found to be maximum (11.60 %) in control (without enzyme) and minimum (2.72 %) in pectinase + cellulase concentration of 0.3 %.

Table 3.

Effect of mixed enzyme formulation on oil recovery and quality parameters during extraction from 3 kg wild apricot kernels

| Parameter | Control | Enzyme concentration (%) | CD 0.05 | SE | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | ||||

| Volume of oil obtained (ml) | 993.3 | 1.27 | 1.30 | 1.42 | 1.17 | 1.20 | 1.17 | 1.16 | 60.47 | 28.52 |

| Wt of cake obtained (kg) | 1.59 | 1.54 | 1.53 | 1.49 | 1.52 | 1.50 | 1.51 | 1.52 | 0.003 | 0.01 |

| Wt of residue (g) | 435.0 | 200.7 | 181.7 | 102.3 | 320.7 | 307.3 | 328.7 | 326.3 | 33.26 | 15.69 |

| Oil recovery from kernel% (v/w) | 33.11 | 42.33 | 43.33 | 47.33 | 39.00 | 40.00 | 39.00 | 38.77 | 2.01 | 0.95 |

| % increase in oil recovery over control | – | 9.22 | 10.22 | 14.22 | 5.89 | 6.89 | 5.89 | 5.66 | ||

| Oil recovery from cake (%) wet basis (w/w) | 10.28 | 7.23 | 7.13 | 4.94 | 7.42 | 6.75 | 7.23 | 7.47 | 1.25 | 0.59 |

| Oil recovery from cake (%) dry basis (w/w) | 11.67 | 7.85 | 7.67 | 7.31 | 7.82 | 7.18 | 7.63 | 7.95 | 1.55 | 0.73 |

| Oil content in residue% (w/w) | 11.60 | 5.34 | 4.84 | 2.72 | 8.54 | 8.19 | 8.76 | 8.70 | 0.88 | 0.41 |

| Iodine value (g I2/100 g) | 101.5 | 96.10 | 95.08 | 94.07 | 93.05 | 93.05 | 92.72 | 91.70 | 0.1 | 0.44 |

| Acid value (mg KOH/g) | 3.62 | 3.77 | 3.95 | 4.07 | 4.22 | 4.55 | 4.63 | 5.08 | 0.01 | 0.07 |

| Saponification value (mg KOH/g) | 191.7 | 190.4 | 189.8 | 189.2 | 187.3 | 186.7 | 185.5 | 184.8 | 1.47 | 0.69 |

| Refractive Index 40 °C | 1.471 | 1.471 | 1.471 | 1.470 | 1.470 | 1.470 | 1.469 | 1.469 | NS | 0.0004 |

CD critical difference, SE standard error (n = 3)

The iodine value (IV) and saponification value (SV) of oil decreased with the increase in mixed enzyme concentration (Fig. 3). The iodine value of wild apricot kernel oil was found to be 101.5 g I2/100 g in control and 91.70–96.10 g I2/100 g in different concentrations of mixed enzyme. The saponification value of oil was 191.7 mg KOH/g in control and 184.8–190.4 mg KOH/g in different concentrations of pectinase + cellulase. However, the acid value of wild apricot kernel oil increased with the increase in enzyme concentration. The acid value of wild apricot kernel oil was found to be 3.62 mg KOH/g in control and 3.77–5.00 mg KOH/g in different concentrations of mixed enzyme formulation. No significant effect of enzyme concentration was observed on refractive index of apricot kernel oil.

Use of enzymes increased oil recovery from the apricot kernels upto a level of 0.3 % enzyme concentration, individually or with mixed formulations of enzymes. The enhancement of oil recovery was probably due to better release of oil from the cells as a result of biodegradation of cell wall on enzyme application. Increase in oil yield from olive by use of enzymes has been reported by various workers (Dominguez et al. 1994; Ranalli et al. 1998; Ranalli et al. 2001; Sharma et al. 2007). The quantity of cake was reduced as per increase in oil recovery when kernel was treated by enzymes which is obvious as more the oil recovery lesser will be the quantity of cake obtained. Similar finding were also reported by Dominguez et al. (1994) and Ranalli et al. (2001). Some processing factors affecting palm kernel oil yield recovery in a hot-water extraction system have been detailed by Obetta and Onwualu (2007). Gandh et al. (2005) reported the possibility of using some alternative solvents like n-propanol, isopropyl alcohol, ethanol and n-hexane in place of of n-hexane for the extraction of peanut oil.

However, small amount of oil was also wasted in the residue. Although, there was an increase in oil yield due to application of enzymes but the increasing trend stopped after a particular level (0.3–0.4 % enzyme concentration). Increase in enzyme concentration beyond this level did not bring about any further increase in oil yield rather the oil yield declined to some extent in various treatments. Excessive use of enzyme might have formed some emulsion of oil and water during the process of oil extraction, thus making the release of oil drops more and more difficult. This oil is trapped in the cake and is generally obtained in the residue (Dominguez et al. 1994 and Ranalli et al. 2001). Further, reduction in oil recovery is also reported if enzymatic treatment applied for longer time i.e. more than 60 min. in case of olive (Sharma et al. 2007).

The iodine value (IV) and saponification value (SV) of oil decreased with the increase in enzyme concentration. Sharma et al. (2007) reported that the overall quality parameters such as free fatty acids, peroxide value, saponification value and iodine value were in general not much affected by the actions exerted by the enzyme used for oil extraction. According to Prevention of Food Adulteration (PFA) Act 1954 specification the iodine value range for almond oil was 90–109 g I2/100 g and saponification value was 186–195 mg KOH/g. Thus wild apricot kernel oil exhibited IV and SV within the prescribed range for almond oil. However, the acid value of wild apricot kernel oil increased with the increase in enzyme concentration. No significant effect of enzyme concentrations was recorded on refractive index (RI) of oil.

Sharma et al. (2007) reported that the cake obtained after oil extraction at laboratory and commercial scale were 32.0 and 29.6 % in control and 30.4 and 27.4 % respectively in cellulase 0.08 % treatment. Further, the oil content in cake were maximum (9.7 and 5.6 %) in control and less (8.4 and 3.1 %) when cellulase 0.08 % was used. Similar finding were also reported by Dominguez et al. (1994) and Ranalli et al. (2001). Sharma et al. (2007) reported that in olive fruits the pectinase + cellulase concentration 0.05 % in both laboratory and commercial scale resulted in maximum oil recovery (9.9 % and 11.7 % respectively) thereby accounting for 11.0 and 13.3 % increase in oil recovery over control (8.9 % and 10.4 %).

Conclusively it emerges that the use of enzymes significantly improved the oil recovery from apricot kernels and had no adverse effect on the nutritive quality of the oil and it was more resistant to auto oxidation. Enzymes to enhance extractability of oil from wild apricot kernels, vary in efficiency, but formulations with mixed activities have proved to be very effective. The use of mixed enzyme formulation containing pectinase + cellulase (1:1) @ 0.3 % resulted in 47.33 % oil yield which was 14.22 % more than that obtained without enzymes. The use of enzymes also did not have any adverse implication on the quality of apricot oil obtained.

Contributor Information

Tejpal Singh Bisht, Email: tejpalbisht23@gmail.com.

Satish Kumar Sharma, Email: drsatish10@yahoo.com.

References

- Alba Mendoza J, Ruiz Gomez A, Hidalgo Casado F. Utilization de enzymes en la extraction del aceite de olive. Aliment Equipos Technol. 1990;9:63–71. [Google Scholar]

- AOAC (1995) Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Washington DC

- Cintra MacGlone O, Lopez Munguia Canales A, Vermon Carter J. Coconut oil extraction by a new enzymatic process. J Food Sci. 1986;51:695–697. doi: 10.1111/j.1365-2621.1986.tb13914.x. [DOI] [Google Scholar]

- Dominguez H, Nunez MJ, Lema JM. Enzymatic pretreatment to enhance oil extraction from fruits and oilseeds- a review. Food Chem. 1994;49:271–286. doi: 10.1016/0308-8146(94)90172-4. [DOI] [Google Scholar]

- Fullbrook PD. The use of enzymes in the processing of oilseeds. J Am Oil Chem Soc. 1983;74:1543–1547. [Google Scholar]

- Gandh AP, Joshi KC, Krishna J, Parihar VS, Srivastav DC, Raghunadh P, Kawalkar J, Jain SK, Tripathi RN. Studies on alternative solvents for the extraction of peanut oil. J Food Sci Technol. 2005;42(4):352–355. [Google Scholar]

- Kashyap MC, Agrawal YC, Sarkar BC, Singh BPN. Response surface analysis of enzyme aided extraction of soyabean for enhanced oil recovery. J Food Sci Technol. 1997;34:386–390. [Google Scholar]

- Nagaraj G. Oilseeds - properties, processing, products and procedures. New Delhi: New India Pub. Agency; 2009. [Google Scholar]

- Obetta SE, Onwualu AP. Some processing factors affecting palm kernel oil yield recovery in a hot-water extraction system. J Food Sci Technol. 2007;44(4):397–399. [Google Scholar]

- Passos CP, Yilmaz S, Silva CM, Coimbra MA. Enhancement of grapeseed oil extraction using cellwall degrading enzyme cocktail. Food Chem. 2009;115(1):48–53. doi: 10.1016/j.foodchem.2008.11.064. [DOI] [Google Scholar]

- Puri M, Sharma D, Barrow CJ. Enzyme assisted extraction of bioactives from plants. Trends Biotechnol. 2012;30(1):37–44. doi: 10.1016/j.tibtech.2011.06.014. [DOI] [PubMed] [Google Scholar]

- Puri M, Sharma D, Barrow CJ, Tiwary AK. Optimisation of novel method for the extraction of steviosides from Stevia rebaudiana leaves. Food Chem. 2012;132:1113–1120. doi: 10.1016/j.foodchem.2011.11.063. [DOI] [PubMed] [Google Scholar]

- Ranganna S (1997) Handbook of analysis and quality control for fruits and vegetable products 2nd edn. Tata McGraw Hill Publication Co. Ltd. New Delhi, India, p 1112

- Ranalli A, De Mattia G, Ferrante ML. The characteristics of percolation olive oils produced with a new processing enzyme aid. Int J Food Sci Technol. 1998;33:247–258. doi: 10.1046/j.1365-2621.1998.00147.x. [DOI] [Google Scholar]

- Ranalli A, Malfatti A, Cabras P. Composition and quality of pressed virgin olive oil extracted with a new processing aid. J Food Sci. 2001;66:592–603. doi: 10.1111/j.1365-2621.2001.tb04607.x. [DOI] [Google Scholar]

- Sarkar BC, Singh BPN, Agrawal YC, Gupta DK. Optimization of enzyme pretreatment of rapeseed for enhanced oil recovery. J Food Sci Technol. 1998;35:183–186. [Google Scholar]

- Sharma R, Kaushal BB, Sharma PC. Development of cost effective commercial method for enhancing yield and quality of olive oil. J Food Sci Technol. 2007;44(2):133–137. [Google Scholar]

- Sharma SK, Gupta A, Sharma R, Verma AK, Sati RC, Juyal SB. Fruit kernel and oilseed processing waste management. In: Joshi VK, Sharma SK, editors. Food processing waste management -treatment and utilization technology. New Delhi: New India Pub. Agency; 2011. pp. 257–293. [Google Scholar]

- Sousulski K, Sousulski FW, Coxworth E. Carbohydrate hydrolysis of canola to enhanced oil extraction with hexane. J Am Oil Chem Soc. 1988;65:357–361. doi: 10.1007/BF02663076. [DOI] [Google Scholar]

- Srivastava B, Agrawal YC, Sarker BC, Kushwaha YPS, Singh BPN. Effect of enzyme extract on rapeseed microstructure and oil recovery. J Food Sci Technol. 2004;41(1):88–91. [Google Scholar]