Abstract

Screw pressing performance of whole and dehulled flaxseed at different seed moisture (6.4 to 11.1 % d.b.) and press head temperature (80–120 °C) was investigated. Oil recovery, residual oil, press rate and sediment content and some important physico-chemical characteristics were determined at six different levels (50, 60, 70, 80, 90 and 100 %) of dehulled flaxseed. Oil recovery decreased with increasing moisture content as well as press head temperature. Press rate was found maximum for 100 % dehulled flaxseed while minimum for 50 % dehulled flaxseed at 6.4 % moisture content. Colour of oil samples was found affected both with the level of dehulled flaxseed and press head temperature. Free fatty acids content of oil ranged from 1.07 % to 2.70 % and lower at 80 °C press head temperature. Oil and cake temperatures ranged from 53.10 °C to 65.95 °C and 69.15 to 103.75 °C, respectively. The α-linolenic acid content of different oil samples obtained at 80 °C was in the range of 53.34 ± 0.95 to 54.21 ± 1.04 %. In view of maximum oil recovery (82.9 % d.b.), lower FFA content, and oil and cake temperature, 7:3 ratio of dehulled and whole flaxseed having 6.4 % d.b. moisture content and 80 °C press head temperature may be considered for screw pressing of flaxseed.

Keywords: Screw pressing, Dehulled flaxseed, Press head temperature, Oil recovery, α-linolenic acid content

Introduction

India ranks first in respect of acreage accounting for 23.8 % of the world area and third in flaxseed production contributing 10.2 % of the world production (FAO 2004; Singh et al. 2011a). Flaxseed (referred as linseed) is a unique oilseed, which posses many health benefits due to high α-linolenic acid content (ALA, an omega-3 fatty acid) and lignans. Omega-3 fatty acids have anti-inflammatory, anti-thrombotic, and anti-arrhythmic properties (Simopoulos 1999). The α-linolenic acid in flaxseed can reduce the risk of cardiovascular disease (CVD) osteoporosis, rheumatoid arthritis, and cancer (Adlercreutz 2007; Kettler 2001; Spence et al. 2003; Clark et al. 2000; Prasad et al. 1998). Flaxseed contains about 35 to 45 % oil rich in α-linolenic acid, which is mainly present in embryo portion of the seed (Zheng et al. 2003). The α-linolenic acid content in flaxseed oil varied between 45 % and 52 % (Bhatty 1995; Singh et al. 2011b, Mridula et al. 2011a, b).

The main aim of oil extraction process is to obtain high oil recovery and good quality meal for its further utilization in food and feed. Solvent extraction and mechanical pressing are two important methods for oil extraction. Solvent oil extraction is the most efficient method and is able to extract over 98 % oil (Yoyock et al. 1988). However, it is costlier, dangerous and flammable (Bargale et al. 1999; Ajibola et al. 2002). Mechanical pressing using hydraulic press, screw press and rolling press is technically less extensive and used for high oil bearing materials to extract most of the oil prior to solvent extraction of the remaining oil from the cake (Bamgboye and Adejumo 2007). The mechanical pressing of oilseeds recovers 86–92 % of oil in two passes (Singh and Bargale 2000).

The recovery of oil during mechanical extraction is influenced by a number of factors mainly appropriate pre-treatment of the oilseeds viz. cracking, dehulling, moisture conditioning, etc. (Fils 2000). The moisture content of the oilseed is also important in screw pressing and studied for a range of oil bearing materials (Singh et al. 2002; Zheng et al. 2003; Singh and Bargale 1990). Zheng et al. (2003) reported the inverse relationship between seed moisture content (6.1 to 11.6 %) and oil recovery (70.1–85.7 %). Singh and Bargale (1990) observed that moisture adjustment and soaking pre-treatment of flaxseed can influence the oil recovery significantly in screw pressing. Higher moisture content increased the plasticity and thereby reduced the level of compression and contributed to poor oil recovery. Moisture also acts as a lubricant in the barrel; therefore, higher moisture content resulted in insufficient friction during pressing Singh and Bargale (1990).

Traditionally, flaxseed is processed for oil extraction without been dehulled prior to oil extraction that results in poor quality of oil due to gum residue in the oil fraction (Zheng et al. 2003; Zhang et al. 2009). Dehulling of oilseeds is important to obtain the good quality edible oil, to improve the flavour, to increase the protein content of the meal for food purposes (Mridula et al. 2011a, b; Mridula et al. 2012; Pohjanheimo et al. 2006; Kangas et al. 2006). During the dehulling process, a major part of the fibre and certain pigments are removed, which otherwise pass into the meal during the screw pressing and deteriorate its quality. However, the dehulled flaxseed may not be readily pressed using a process configured for pressing of whole flaxseed because of high oil and low fibre content that result in a softer material and low friction.

Omega-3 fatty acids are sensitive to high temperature, light and oxygen, hence flaxseed oil is required to be extracted at lower temperature if intended for edible purposes. For cold pressed oil, oil temperature should be less than 50 °C (Panfilis et al. 1998) or less than or equal to 70 °C (Singh and Bargale 2000) when exiting the screw press. In view of this, the present investigations were undertaken to study the effect of moisture conditioning, dehulling, press head temperature and some physico-chemical attributes on screw pressing performance of flaxseed.

Material and methods

Flaxseed (cv. Shikha) was procured from Chandra Shekhar Azad University of Agriculture and Technology, Kanpur for this experiment. Seeds were stored at 5 °C and equilibrated overnight in sealed plastic bags to room temperature before use. The flaxseed was dehulled in the laboratory model rice polisher (STE–08, Cadence Electronics Systems, Ambala, Haryana, India) at 2,000 rpm of the rotor (Barnwal et al. 2010) and 60s residence times. The hull was separated using a batch type laboratory aspirator (6726, M/s Osaw Industrial Products Pvt Ltd, Ambala, Haryana, India). The dehulled flaxseed was sieved using the ASTM Nr 20 sieve to separate the powder from the mixture of the dehulled flaxseed. The dehulled flaxseed with different proportion of whole flaxseed in duplicate were prepared and conditioned to the desired moisture content for screw pressing.

Moisture conditioning of flaxseed

The moisture content of whole and dehulled flaxseed was determined by hot air oven method at 105 °C for the period until the constant weight reached (AOAC 2000) and reported in terms of dry basis (d.b.) throughout the manuscript. The samples (whole flaxseed or samples with dehulled and whole flaxseed) were conditioned for different moisture content (6, 8 and 10 % wb). To achieve the higher moisture content than that present in the seed, the calculated amount of distilled water was sprinkled over seed and mixed thoroughly by hand and stored in sealable bags at 5 °C in refrigerator for 24 h. The desired quantity of distilled water to be added, or moisture to be evaporated (seed to be dried), was calculated using following formula (Chakraverty 1988):

where, Wm is moisture to be added or removed (g), W1 is initial weight of the seed at M1(g), ΔM = M2 − M1 (for M2 > M1) and ΔM = M1 − M2 (for M1 > M2), M1 is initial moisture content (wb) and M2 is final or desired moisture content (wb).

Oil expression

A Komet screw press (model CA59G, Komet IBG Monforts GmbH, Monchengladbach, Germany) was used to press the flaxseed samples in a single pass. Samples were fed from the hopper to the press on demand by gravity. The length of the screw shaft was 140 mm, screw diameter 30 mm and pitch 15 mm. The die at the meal discharge end of the screw press had an inside diameter of 8 mm. An electrical resistance heating ring was attached around the press head that preheated the press head to the desired temperature (80–120 ± 3 °C) for 30 min before the press operation. In order to achieve the steady flow of oil and cake before pressing the actual samples, whole flaxseed about 1 kg was pressed for 20–30 min. After assuming the steady operation, duplicate samples of flaxseed (whole flaxseed or dehulled or mixture of dehulled and whole flaxseed) were fed to the press hopper sequentially in the order of increasing moisture content. Samples with different moisture content were pressed at 80 °C. In order to study the effect of press head temperatures on screw pressing performance of whole and dehulled flaxseed, samples were pressed at three different temperatures i.e. 80, 100 and 120 °C using standardized moisture content which was obtained as 6 %. The oil and cake samples obtained were considered for determining the important physico-chemical characteristics.

During screw pressing of whole and dehulled flaxseed in the oil expeller, the flaxseed oil and cake temperatures were measured by using a digital multi-thermometer (least count = 0.1 °C, range = −50 to +150 °C) by placing the measuring probe of the thermometer at the oil just coming below barrel and cake nearest to press head (just coming out of the screw press), respectively. After pressing, crude oil and cake was collected and the sample collection time was recorded using a stopwatch. The crude oil and cake samples were weighed after pressing. The press rate was calculated using following expression:

Residual oil content

The residual oil content in the cake was determined by following the standard procedure (AOAC 2000).

Sediment content of oil

The sediment content is the dry solid weight per unit weight of unfiltered crude oil. Crude oil obtained after screw pressing contained some solid particles which settled at the bottom of the flasks. These particles were removed from the crude oil to get actual weight of the oil of different samples. The crude oil was filtered using the previously weighed filter paper. The filtered solid was rinsed with warm hexane and allowed to dry in oven at 50 °C. After drying, the filter paper along with dry solids was weighed and the amount of sediment content was calculated by the difference. The hexane was removed from the crude oil by evaporation process.

Oil recovery

Oil recovery (OR) is the ratio of oil weight in the product oil to the original oil present in the seed that was pressed. Oil recovery was calculated using following expression (Zheng et al. 2003).

Physico-chemical characteristics of flaxseed oil

Free fatty acid (FFA) Content in flaxseed oil was determined following the standard procedure (Ranganna 2008). Colour (L, a, b values) of flaxseed oil, after 12 h of oil extraction was measured using Tintometer. Chroma value was computed by using the standard formula (Hernandez et al. 2008). The omega-3 in terms of α-linolenic acid content of oil samples, obtained from 6 % seed moisture content and 80 °C press head temperature was determined using gas liquid chromatography by converting fatty acids into methyl/ethyl esters and comparing with a set of standard esters (Appleqvist 1968).

Statistical analysis

Two-way analysis of variance (ANOVA) was carried out using LSD AgRes software to test the effect of moisture content, pressing temperature and level of dehulled flaxseed on dependent variables i.e. oil recovery, residual oil, press rate and sediment content. The regression analysis, calculation of average values and SD were performed using MS Excel 2003.

Results and discussion

Oil recovery

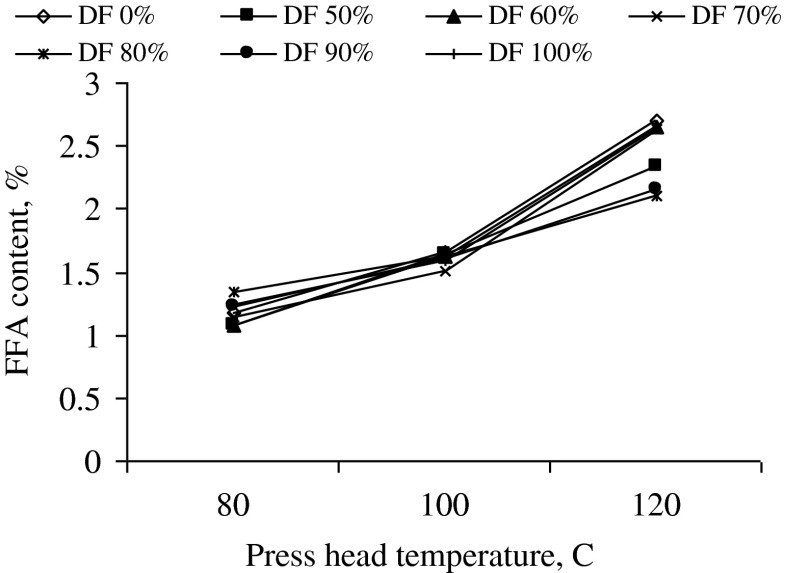

Effect of moisture content and different level of dehulled flaxseed on various oil expelling parameters is presented in Fig. 1(a–d). The oil content in the whole and dehulled flaxseed samples was 39.91 and 52.14 %, respectively. The present study revealed that oil recovery decreased with increasing moisture content of the flaxseed samples from 6.4 % to 11.1 % d.b. The oil recovery from different studied flaxseed samples at 6.4, 8.7 and 11.1 % moisture content was ranged from 73.69 % to 82.91 %, 64.91 % to 73.23 % and 62.63 % to 69.01 % d.b., respectively. Similar findings have been reported for cooked and uncooked crambe seed in 3.6 to 9.2 % d.b moisture content (Singh et al. 2002), whole and dehulled flaxseed in 6.6 to 11.1 % d.b. moisture content (Zheng et al. 2003), whole flaxseed in 6.1 to 12.1 % d.b. moisture content (Singh et al. 2010) and flaked and cooked soybean in 8.1 to 13.6 % moisture content (Khan and Hanna 1983). In the present study, the pressing of dehulled flaxseed could not be performed successfully below the 6 % moisture content due to plugging of the screw press, however the trend indicated that oil recovery may be enhanced even at lower moisture content. The proportion of whole and dehulled flaxseed with different moisture content also influenced the oil recovery in this study (Table 1). The comparison by mean LSD showed that the samples with 60 and 70 % dehulled flaxseed and 6.4 % seed moisture content resulted in the maximum oil recovery and also at par. The oil recovery of the whole flaxseed and sample with 90 % dehulled flaxseed was at par with minimum oil recovery at 100 % dehulled flaxseed sample. This showed that low fibre content in the samples reduced oil recovery. Zheng et al. (2003) also reported a low oil recovery in dehulled flaxseed than whole flaxseed. Inverse relationship between moisture content and oil recovery (p < 0.05) was observed in this study (Fig 1d).

Fig. 1.

Effect of moisture content and different level of dehulled flaxseed on oil expelling parameters (a, b, c & d)

Table 1.

Analysis of variance for different oil expelling parameters of whole and dehulled flaxseed at different moisture content

| Oil expelling parameters | df | SS | MS | F-value | p-value | |

|---|---|---|---|---|---|---|

| Oil recovery | F | 6 | 282.45 | 47.07 | 44.03** | 0.000 |

| M | 2 | 1326.05 | 663.02 | 620.09** | 0.000 | |

| FM | 12 | 26.15 | 2.18 | 2.04ns | 0.116 | |

| Residual oil | F | 6 | 466.39 | 77.73 | 114.10** | 0.000 |

| M | 2 | 767.64 | 383.82 | 563.40** | 0.000 | |

| FM | 12 | 30.41 | 2.53 | 3.72** | 0.016 | |

| Press rate | F | 6 | 3.102 | 0.517 | 38.71** | 0.000 |

| M | 2 | 0.687 | 0.344 | 25.73** | 0.000 | |

| FM | 12 | 0.530 | 0.044 | 3.31* | 0.024 | |

| Sediment content | F | 6 | 14.94 | 2.49 | 7.23** | 0.002 |

| M | 2 | 44.46 | 22.23 | 64.49** | 0.000 | |

| FM | 12 | 30.24 | 2.52 | 7.31** | 0.001 | |

F- Level of dehulled Flaxseed; M-moisture content; FM-F ×M; ns-not significant; *significant at p ≤ 0.05; **significant at p ≤ 0.01

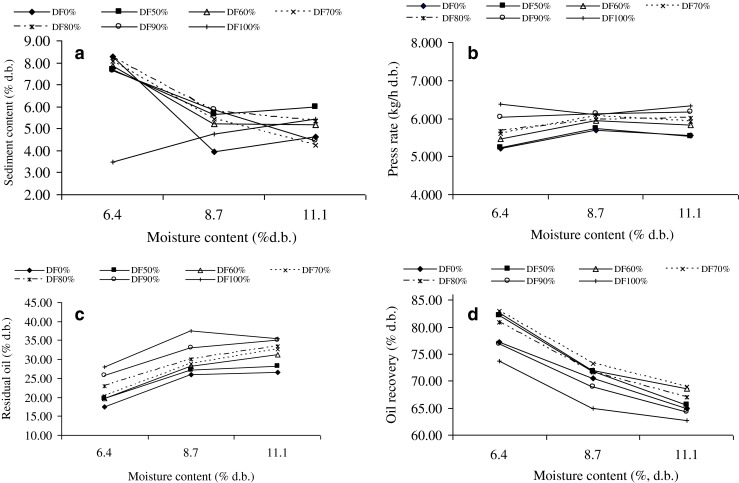

The oil recovery of flaxseed at different press head temperature ranged from 71.76 % to 82.91 % d.b., which was significantly affected by both with the level of dehulled flaxseed and also press head temperature of the screw press (Table 2). Mean comparison by LSD showed that the oil recovery from the samples with 50, 60 and 70 % dehulled flaxseed, pressed at different press head temperatures was statistically similar. The minimum oil recovery was obtained from the sample with 100 % dehulled flaxseed (p < 0.05). Results showed a reducing trend in the oil recovery with increasing level of press head temperature (Fig. 2). The oil recovery from the samples pressed at 100 and 120 °C was statistically similar and significantly lower than 80 °C press head temperature. Felycia et al. (2008) also reported decrease in the oil yield of Neem seeds at increased heating temperature. Faborode and Favier (1996) stated that the increase of temperature might reduce the water content of the seeds. The low level of water may not be able to crack the cells walls of the seeds to ooze out the oil, and thus resulted in the decreased oil yield. However, Baryeh (2001) found the increased oil yield of palm oil with increase in heating temperature from 50 °C to 100 °C. These studies showed that oil yield is not dependant only on press head temperature but also on quality and moisture content of oilseed and screw configuration of the screw press.

Table 2.

Analysis of variance for different oil expelling parameters of whole and dehulled flaxseed at different press head temperatures

| Oil expelling parameters | df | SS | MS | F-value | p-value | |

|---|---|---|---|---|---|---|

| Oil recovery | F | 6 | 281.65 | 46.94 | 37.72** | 0.000 |

| T | 2 | 50.67 | 25.33 | 20.36** | 0.000 | |

| FT | 12 | 32.17 | 2.68 | 2.15 ns | 0.099 | |

| Residual oil | F | 6 | 423.85 | 70.64 | 193.51** | 0.000 |

| T | 2 | 22.53 | 11.25 | 30.87** | 0.000 | |

| FT | 12 | 4.44 | 0.37 | 1.01 ns | 0.491 | |

| Press rate | F | 6 | 2.262 | 0.377 | 43.63** | 0.000 |

| T | 2 | 7.240 | 3.620 | 418.99** | 0.000 | |

| FT | 12 | 0.718 | 0.060 | 6.93** | 0.001 | |

| Sediment content | F | 6 | 92.59 | 15.43 | 65.33** | 0.000 |

| T | 2 | 2.74 | 1.37 | 5.79** | 0.017 | |

| FT | 12 | 5.79 | 0.48 | 2.04 ns | 0.115 | |

F- Level of dehulled Flaxseed; T-press head temperature; FT-F ×T; ns-not significant; *significant at p ≤ 0.05; **significant at p ≤ 0.01

Fig. 2.

Effect of press head temperature and different level of dehulled flaxseed on oil expelling parameters (a, b, c & d)

Residual oil

Analysis of variance showed that the level of dehulled flaxseed and the moisture content of the samples significantly affected the residual oil content (Table 1). The residual oil in cake ranged from 17.48 % to 28.01 %, 25.97 % to 37.46 % and 26.54 % to 35.58 % d.b. at 6.4, 8.7 and 11.1 % d.b. moisture content, respectively. The comparison of the results of oil recovery and residual oil (Fig. 1c and d) showed that the increased oil recovery resulted in the decreased residual oil in cake. The residual oil content in cake increased with increasing moisture content and was maximum at 11.1 % moisture content. The residual oil in cake was minimum in the whole flaxseed sample while maximum in 100 % dehulled flaxseed. Previous studies had also indicated the decreased residual oil in cake with decreasing moisture content for pressing of uncooked sunflower seed with 6 to 14 % moisture range (Singh et al. 1984); for cooked and uncooked crambe seed with 3.6 to 9.2 % moisture range (Singh et al. 2002); for dehulled and whole omega flaxseed with 7.7 to 9.7 % and 9 to 15.3 % moisture range, respectively (Zheng et al. 2003); and for moisture conditioned, steam treated and enzyme treated whole flaxseed with 6.5 to 13.8 % d.b. moisture range (Singh et al. 2010). This trend might be due to higher frictional resistance offered by lower moisture of seed in the screw barrel during the pressing of flaxseed. Hoffmann (1989) and Reuber (1992) had also viewed that lower seed moisture increases friction, whereas higher moisture content acts as a lubricant during seed pressing. Residual oil content in the resultant cake was also influenced by the press head temperature with significantly minimum residual oil at 80 °C (Table 2).

Press rate

Press rate was found in the range of 5.2 to 6.38, 5.68 to 6.1 and 5.55 to 6.32 kg/h (d.b.), respectively at 6.4, 8.7 and 11.1 % (d.b.) moisture content. Press rate for the 100 % dehulled flaxseed sample was maximum whereas minimum for sample with 50 % dehulled flaxseed (p < 0.05). The press rate of whole flaxseed and sample with 50 % dehulled flaxseed was found statistically similar. Low fibre content in dehulled flaxseed might have caused low resistance inside the screw barrel and hence high press rate was observed for samples with dehulled flaxseed. Press rate for whole flaxseed and sample with different level of dehulled flaxseed was lower at 6.4 % d.b. moisture content than 8.7 and 11.1 % d.b. (Table 1). Singh et al. (2002) reported decreased press rate from 5.8 kg/h to 5.2 kg/h and 6.1 kg/h to 5.2 kg/h for cooked and uncooked crambe seeds, respectively with decrease in moisture content from 9.2 % to 3.6 d.b. However, Singh et al. (2010) observed a slight increase in press rate with increase in moisture content from 6.5 % to 13.8 % d.b. of pre-treated whole flaxseed. Similar results have also been observed in the present study. The press rate was also influenced by the press head temperature with minimum at 80 °C (Table 2).

Sediment content

The sediment content of samples with different level of dehulled flaxseed at 6.4 and 8.7 % and 11.1 % d.b. varied from 3.49 to 8.27, 3.93 to 5.86 and 4.23 to 5.98% d.b, respectively. Both, moisture content and level of dehulled flaxseed in sample affected the sediment content significantly (Table 1). Minimum sediment content was observed in the oil sample obtained from 100 % dehulled flaxseed sample. The sediment content in th crude oil obtained from the sample with 6.4 % moisture content was higher than 8.7 and 11.1 % seed moisture. However, Singh et al. (2010) did not observe any significant effect of moisture content of pretreated whole flaxseed on sediment content in crude oil. The sediment content was also influenced by the press head temperature with significantly minimum at 120 °C (Table 2).

Oil and cake temperatures

Omega-3 is sensitive to high temperature; hence it is required to press the flaxseed at low press head temperature to extract the quality edible oil. Shukla (2003) had also indicated that low oil temperature may protect omega-3 fatty acids during pressing of dehulled flaxseed. The temperature of flaxseed oil in this study, obtained by pressing at 80–120 °C press head temperature was ranged from 53.10 °C to 65.95 °C (Fig. 3a). Oil temperature was significantly affected both with the level of dehulled flaxseed in the sample and at higher press head temperature but at 80 °C, the oil temperature of all the samples was at par.

Fig. 3.

Effect of press head temperature and different level of dehulled flaxseed on oil and cake temperatures (a–b)

The higher cake temperature may deteriorate the quality of oil particularly the omega-3 present in the residual oil (Zheng et al. 2005), hence it is desired to minimize the cake temperature by pressing the oilseed at appropriate temperature. The cake temperature in this study was in the range of 69.15 to 106.70 °C (Fig. 3b), which was also found affected with the press head temperature but the level of dehulled flaxseed in the sample did not brought any significant impact on cake temperature. As found in case of oil temperature, mean comparison by LSD showed the minimum cake temperature in the cake samples obtained by pressing of flaxseed at 80 °C and maximum at 120 °C. Increased cake temperature had also been observed by Zheng et al. (2005) with increasing press head temperature at 6.3 % moisture content of flaxseed.

Physico-chemical charaterisctics

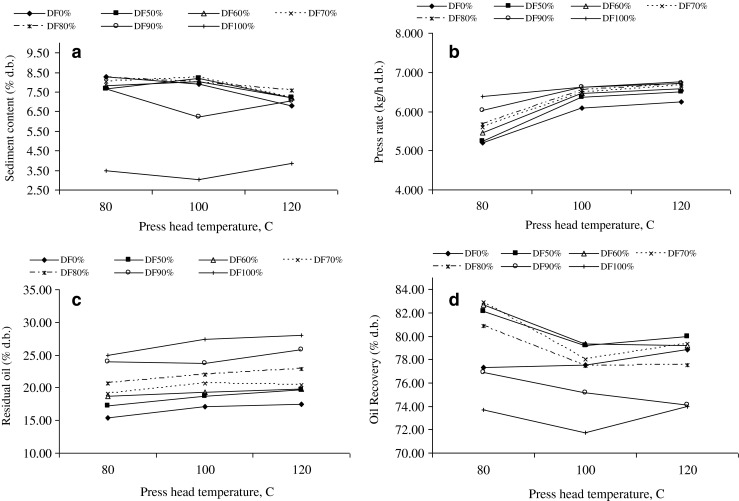

FFA content in the flaxseed oil was found in the range of 1.07 to 2.70 % (Fig. 4) with significantly minimum FFA content in the oil obtained by pressing the flaxseed at 80 °C. In case of all the oil samples obtained from different proportions of whole and dehulled flaxseed and pressed at 120 °C press head temperature, the FFA content was found maximum and more than 2 % which is undesirable for edible purposes (Nagaraj 2009). This showed that dehulled flaxseed should not be pressed at ≥120 °C press head temperature of screw press.

Fig. 4.

Effect of press head temperature and different level of dehulled flaxseed on FFA content in oil

The colour (L, a, b and chroma) of the flaxseed oil is presented in Fig. 5. L and a values of oil were found affected both with the level of dehulled flaxseed and press head temperature while b value and chroma of oil was affected only with the level of dehulled flaxseed. The flaxseed oil obtained at 120 °C press head temperature showed the higher a values (p < 0.05).

Fig. 5.

Effect of dehulled flaxseed and press head temperature on colour of flaxseed oil

The omega-3 in terms of α-linolenic acid content of different oil samples was in the range of 53.34 ± 0.95 to 54.21 ± 1.04 % (% fatty acids). Though a slight variation was observed in the α-linolenic acid content in different flaxseed oil samples but it was not affected with the different level of dehulled flaxseed (p > 0.05).

Conclusions

The seed moisture, proportion of dehulled flaxseed and press head temperatures affected the oil expelling parameters significantly. The oil recovery was found decreased while residual content in cake increased with increasing moisture content of flaxseed. The maximum oil recovery 82.9 % d.b. was observed from the samples with 7:3 ratio of dehulled and whole flaxseed having 6.4 % d.b. moisture content and pressed at 80 °C temperature. Colour of oil samples was found affected both with the level of dehulled flaxseed and press head temperature. Different level of dehulled flaxseed and at 80 °C press head temperature did not brought any significant difference on the oil and cake temperatures. Similarly, FFA content in flaxseed oil was also unaffected with the level of dehulled flaxseed while the lower press head temperature i.e. 80 °C resulted in lower FFA content, which was in the range of 1.07 to 1.31 %. The α-linolenic acid content of different oil samples was in the range of 53.34 ± 0.95 to 54.21 ± 1.04 %.

Acknowledgments

Financial assistance received from Department of Science and Technology (DST), Govt. of India, New Delhi, India for this study is duly acknowledged.

References

- Ajibola OO, Okunade DA, Owolarafe OK. Oil point pressure of soybean seed. J Food Process Eng. 2002;25:407–416. doi: 10.1111/j.1745-4530.2002.tb00574.x. [DOI] [Google Scholar]

- Adlercreutz H. Lignans and human health. Crit Rev Clin Lab Sci. 2007;44(5):483–525. doi: 10.1080/10408360701612942. [DOI] [PubMed] [Google Scholar]

- AOAC . Official methods of analysis. 17. Washington: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Appleqvist LA. Rapid methods of lipid extraction and fatty acid esters preparation for seed and leaf tissue with special remarks on preventing the accumulation of lipid contaminants. Ark Kenci. 1968;28:351–370. [Google Scholar]

- Bamgboye AI, Adejumo AOD. Development of a sunflower oil expeller. Agric Eng Int CIGR E J. 2007;9:1–6. [Google Scholar]

- Bargale PC, Ford RJ, Sosulki FW, Wulfsohn D, Irudayaraj J. Mechanical oil expression from extruded soybean samples. J Am Oil Chem Soc. 1999;76:223–229. doi: 10.1007/s11746-999-0222-0. [DOI] [Google Scholar]

- Barnwal P, Singh KK, Mridula D, Kumar R, Rehal J. Effect of moisture content and residence time on dehulling of flaxseed. J Food Sci Technol. 2010;47(6):662–667. doi: 10.1007/s13197-010-0113-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Baryeh EA. Effect of palm oil processing parameters on yield. J Food Eng. 2001;48:1–6. doi: 10.1016/S0260-8774(00)00137-0. [DOI] [Google Scholar]

- Bhatty RS. Nutritional composition of whole flaxseed and flaxseed meal. In: Cunnane SC, Thompson LH, editors. Flaxseed in human nutrition. Champaign: AOCS Press; 1995. pp. 22–45. [Google Scholar]

- Chakraverty A. Post-harvest technology of cereals, pulses and oilseeds. New Delhi: Oxford and IBH publ Co Pvt Ltd; 1988. [Google Scholar]

- Clark WF, Muir AD, Westcott ND, Parbtani A. A novel treatment for lupus nephritis: lignan precursor derived from flax. Lupus. 2000;9:429–436. doi: 10.1191/096120300678828622. [DOI] [PubMed] [Google Scholar]

- Faborode MO, Favier JF. Identification and significance of the oil-point in seed-oil expression. J Agr Eng Res. 1996;65:335–375. doi: 10.1006/jaer.1996.0107. [DOI] [Google Scholar]

- FAO Production Year book (2004) http://www.fao.org/ag/aga/agap/frg/AFRIS/DATA/508. htm accessed 31.03.04

- Felycia ES, Budijanto GM, Prasetyo RI, Indraswati N. Effects of pre-treatment condition on the yield and quality of Neem oil obtained by mechanical; pressing. ARPN J Eng Appl Sci. 2008;3(5):45–49. [Google Scholar]

- Fils JM. The production of oils. In: Hamm W, Hamilton RJ, editors. Edible oil processing. Sheffield: Sheffield Academic Press; 2000. pp. 47–78. [Google Scholar]

- Hernandez LF, Larsen AO, Lindstrom LI, Iriarte LB (2008) Physiological maturity in sunflower—correspondence between the quantitative and the visual definition. Proceedings of the 17th International Sunflower Conference Cordoba, June 8–12, Spain, p 337–340 (http://www.criba.edu.ar/morfologiavegetal/producfiles/ papers/17ISC-PhysMat.pdf)

- Hoffmann G. The chemistry and technology of edible oils and fats and their high-fat products. New York: Academic; 1989. pp. 63–68. [Google Scholar]

- Kangas N, Niehaus M, Hall CA III (2006) Utilization of flaxseed gum in dairy foods. In: Proceedings of the 61st Flax Institute of the U.S. Carter JF (Ed.). North Dakota State University, Fargo, ND. p 205–212

- Kettler DB. Can manipulation of ratios of essential fatty acids shows the rapid rate of post menopausal bone loss? Alternative Med Rev. 2001;6(1):61–77. [PubMed] [Google Scholar]

- Khan LM, Hanna MA. Expression of oil from oilseeds—a review. J Agr Eng Res. 1983;28:495–503. doi: 10.1016/0021-8634(83)90113-0. [DOI] [Google Scholar]

- Mridula D, Singh KK, Barnwal P. Development of omega-3 rich energy bar with flaxseed. J Food Sci Tech. 2011 doi: 10.1007/s13197-011-0425-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mridula D, Daljeet K, Nagra SS, Barnwal P, Gurumayum S, Singh KK. Growth performance, carcass traits and meat quality in broilers, fed flaxseed meal. Asian Australas J Anim Sci. 2011;24(12):1729–1735. doi: 10.5713/ajas.2011.11141. [DOI] [Google Scholar]

- Mridula D, Barnwal P, Gurumayum S, Singh KK. Effect of chemical pre-treatment on dehulling parameters of flaxseed (cv. Garima) J Food Sci Tech. 2012 doi: 10.1007/s13197-012-0699-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nagaraj G. Oilseeds-properties, processing, products and procedures. New Delhi: New India Publishing Agency; 2009. [Google Scholar]

- Panfilis FD, Toschi TG, Lercker G. Quality control for cold-pressed oils. Informatics. 1998;9:212–221. [Google Scholar]

- Pohjanheimo TA, Hakala MA, Tahvonen RL, Salminen SJ, Kallio HP. Flaxseed in breed making: effects on sensory quality, aging, and composition of bakery products. J Food Sci. 2006;71:S343–S348. doi: 10.1111/j.1750-3841.2006.00005.x. [DOI] [Google Scholar]

- Prasad K, Mantha SV, Muir AD, Westcott ND. Reduction of hyper cholesterolemic atherosclerosis by CDC-flaxseed with very low alphalinolenic acid. Atherosclerosis. 1998;136:367–375. doi: 10.1016/S0021-9150(97)00239-6. [DOI] [PubMed] [Google Scholar]

- Ranganna S. Hanbook of analysis and quality control for fruit and vegetable products 2nd edn. New Delhi: The MaGraw-Hill Publishing Company Limited; 2008. [Google Scholar]

- Reuber M (1992) New technologies for processing crambe abyssinica. M.S. Thesis, Iowa State University, Ames

- Shukla VKS. A designer oil for better health. Int New Fats Oils Relat Mater. 2003;14(6):340–341. [Google Scholar]

- Simopoulos AP. Essential fatty acids in health and chronic disease. Am J Clin Nutr. 1999;70(3):560–569. doi: 10.1093/ajcn/70.3.560s. [DOI] [PubMed] [Google Scholar]

- Singh J, Bargale PC. Mechanical expression of oil from linseed. J Oilseed Res. 1990;7:106–110. [Google Scholar]

- Singh J, Bargale PC. Development of a small capacity double stage compression screw press oil expression. J Food Eng. 2000;43:75–82. doi: 10.1016/S0260-8774(99)00134-X. [DOI] [Google Scholar]

- Singh KK, Jhamb SA, Kumar R. Effect of pretreatments on performance of screw pressing for flaxseed. J Food Process Eng. 2010 [Google Scholar]

- Singh KK, Mridula D, Rehal J, Barnwal P. Flaxseed: a potential source of food, feed and fibre. Crit Rev Food Sci Nutr. 2011;51:210–222. doi: 10.1080/10408390903537241. [DOI] [PubMed] [Google Scholar]

- Singh KK, Mridula D, Barnwal P, Rehal J. Selected engineering and biochemical properties of 11 flaxseed varieties. Food Bioproc Technol. 2011 [Google Scholar]

- Singh KK, Wiesenborn DP, Tostenson K, Kangas N. Influence of moisture content and cooking on screw pressing of crambe seed. J Am Oil Chem Soc. 2002;79:165–170. doi: 10.1007/s11746-002-0452-3. [DOI] [Google Scholar]

- Singh MS, Farsai A, Stewart LE, Douglass LW. Development of mathematical models to predict sunflower oil expression. Trans ASAE. 1984;27:1190–1194. doi: 10.13031/2013.32944. [DOI] [Google Scholar]

- Spence JD, Thornton T, Muir AD, Westcott ND. The effect of flax seed cultivars with differing content of alpha-linolenic acid and lignans on responses to mental stress. J Am Coll Nutr. 2003;22:494–501. doi: 10.1080/07315724.2003.10719327. [DOI] [PubMed] [Google Scholar]

- Yoyock JY, Lombia G, Owonubi JJ. Crop science and production in warm climates. General edition. London: Macmillan Intermediate Agricultural Series; 1988. [Google Scholar]

- Zhang W, Xu S, Wang Z, Yang R, Lu R. Demucilaging and dehulling flaxseed with a wet process. LWT--Food Sci Technol. 2009;42:1193–1198. doi: 10.1016/j.lwt.2009.01.001. [DOI] [Google Scholar]

- Zheng Y, Wiesnborn DP, Tostenson K, Kangas N. Characterization of preparation parameters for improved screw pressing of crambe seed. Trans ASAE. 2003;45:1029–1035. [Google Scholar]

- Zheng Y, Wiesnborn DP, Tostenson K, Kangas N. Energy analysis in the screw pressing of whole and dehulled flaxseed. J Food Eng. 2005;66(2):193–202. doi: 10.1016/j.jfoodeng.2004.03.005. [DOI] [Google Scholar]