Abstract

The investigation was undertaken to study the effect of acidulants on the recovery of milk constituents and composition of Mozzarella pre-cheese and physical, chemical and sensory characteristics and texture profile analysis (TPA) of processed cheese prepared there from. The pre-cheese was made by direct acidification technique using citric, acetic and lactic acid and processed with 1 % tri-sodium citrate. The acidulants significantly (p < 0.05) affected the fat and protein recoveries and chemical composition of pre-cheese. These also had a significant (p < 0.05) effect on chemical constituents (moisture, protein, fat on dry basis and moisture in non-fat substances), sensory characteristics, physical properties (expressible serum, fat leakage and meltability) and TPA (hardness, fracturability, adhesiveness, elasticity, gumminess and chewiness) of processed cheese.

Keywords: Mozzarella pre-cheese, Processed cheese, Acidulant, Composition, Sensory, Texture profile analysis

Introduction

Cheese is a widely consumed fermented dairy product world over. It is now becoming popular in India too with the estimated per annum growth rate of about 10–12 % in terms of volume and 16–17 % in monetary terms. Around 60 % of the Indian market is dominated by processed cheese and 30 % by cheese spreads (MOFPI 2013). It has high food and nutritive value (De 1980). Processed cheese is produced by blending shredded natural cheese of different types and degrees of maturity with emulsifying agents and by heating the blend with constant agitation until a homogeneous mass is obtained. In addition to natural cheese, other dairy and non-dairy ingredients may be included in the blend (Caric and Kalab 1993). Processed cheese is often criticied for its small range of flavors, which is far narrower than the range for unprocessed cheeses and normally very mild. Processed cheeses are normally very smooth and medium-firm; also lack the range of textures available in unprocessed cheeses.

Acidification is one of the most important stages in cheese manufacture which has a bearing in assuring the desirable cheese curd characteristics. Direct acidification technique for manufacture of cheese has gained considerable commercial interest as it does not rely on starter performance. The manufacture of Mozzarella cheese using this technique has been attempted by many workers (Schafer and Olson 1975; Demott 1983; Singh and Ladkani 1984; Najafi et al. 2006). Different types of acids have been used for preparation of Mozzarella cheese. Breene et al. (1964) used lactic, acetic or hydrochloric acid; Quarne et al. (1968) used hydrochloric, phosphoric and lactic acids; Keller et al. (1974) used phosphoric, acetic, hydrochloric, malic, or citric acids; Patel et al. (1985) used lactic acid whereas Dave et al. (2003) used glucono-δ-lactone. Najafi et al. (2006) used lactic and citric acid to attain pH levels of 5.3, 5.6 and 5.8 to make Mozzarella cheese. The type of acid used affected the solid-not-fat recovery whereas it had no effect on fat recovery (Quarne et al. 1968). It also affected the curd characteristics, rate of curd formation, coagulation of milk from rennet action (Breene et al. 1964; Ernstrom 1965), moisture content, mineral retention, rheological properties of cheese (Keller et al. 1974) and yield and elasticity (Najafi et al. 2006). Keller et al. (1974) found that more hardness and least moisture content of Mozzarella cheese was produced by using phosphoric acid while Mozzarella cheese produced using citric and lactic acid had the high moisture content and was softer.

The flavour compounds present in ripened/mature cheese are ammonia, various amines, methional, H2S, phenylacetic acid, aldehydes, primary and secondary alcohols and their esters, short chain fatty acids and related compounds (Walstra et al. 1999). Hard cheese, to be used for manufacturing processed cheese, requires ripening/maturing of 3 to 12 months or more to develop a typical flavour and texture. It is time consuming, labour intensive, involves space for ripening and adds to temperature maintenance cost of ripening process. On the other hand Mozzarella cheese is dryer, less flavorful, and has a rubbery texture. The flavor is delicate and slightly sour, with a milk-like freshness. The longer the cheese ages, the softer and more sour it becomes. In order to impart specific flavor, several flavoring agents, salts, spices and herbs could be incorporated (Seth et al. 2009). During manufacture of processed cheese, heating of natural cheese results in separation of fat from protein and processing destroys both the curd granule junctions and the fat globule membranes. Under the effect of melting salts, high heat and vigorous stirring, the relatively insoluble protein matrix of natural cheese is converted into a smooth and homogenous mass of partially solubilized proteins (mostly casein) of processed cheese. The emulsifying properties of the cheese proteins, which would deteriorate on heating, are restored as the result of their reactions with the melting salts and consequently, fat becomes emulsified into small globules (Caric and Kalab 1993). Therefore, addition of melting salt can play important role in emulsification of fat leading to improved quality of high fat product.

Using Mozzarella pre-cheese as a base for process cheese manufacture results in a product with no or very little cheese flavour of its own that could be further blended with desirable flavouring agents to get a product suitable to Indian palate (Seth et al. 2009). A range of emulsifying salts and their blends have been used to provide a variety of textural, slicing and melting properties to processed cheeses (Rayan et al. 1980; Gupta et al. 1984; Swenson et al. 2000; Awad et al. 2002). The work on manufacture of processed cheese from Mozzarella pre-cheese is scanty. A series of experiments were conducted to transform Mozzarella pre-cheese in to process cheese to shorten the method of process cheese manufacture and it’s blending with spices and herbs to suit Indian palate. Taking into consideration the effect of coagulant acids on the properties of cheese, the present investigation was undertaken to study the effect of different acidulants on physico-chemical properties of processed cheese prepared from Mozzarella pre-cheese in presence of a melting salt, tri-sodium citrate (TSC).

Materials and methods

Pre-cheese manufacture

Standardized buffalo milk (fat 4.5 %, total solids 13.65 %) was pasteurized at 71 °C for 15 s, cooled to 30 °C, pH lowered to 5.6 by direct acidification using 5 % solution of citric/acetic/lactic acid, renneted (@ 1 g/100 l of milk), coagulum cut into cubes, stirred, pH adjusted to 5.2, curd cooked up to 40 °C for 20 min, whey drained and finally pre-cheese was collected.

Processed cheese manufacture

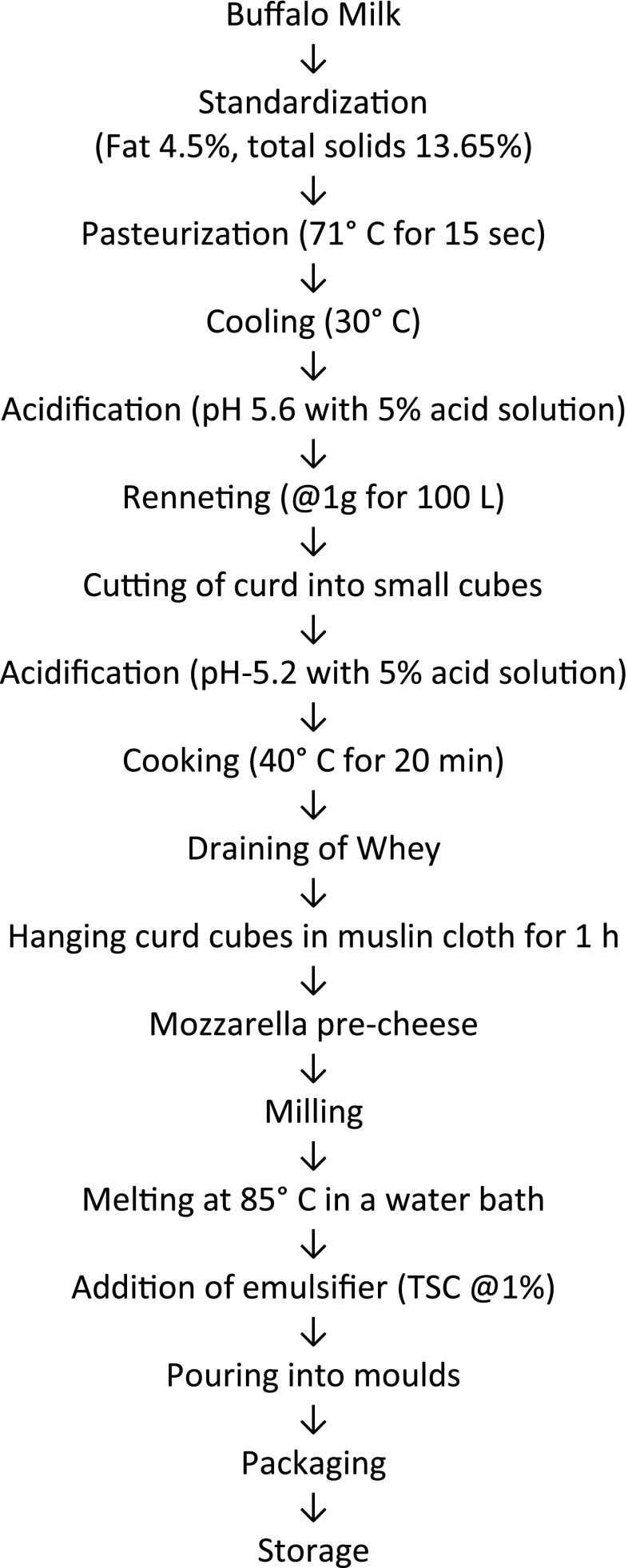

Pre-cheese was grated and allowed to melt with 1 % TSC and 1 % sodium chloride in a boiling water bath. Melted cheese was poured into moulds and allowed to cool at room temperature to obtain sliceable processed cheese. TSC was added to facilitate melting of pre-cheese and its conversion to processed cheese. Flow diagram of manufacture of pre and processed cheese is presented in Fig. 1.

Fig. 1.

Process of preparation of Mozzarella processed cheese

Yield and recoveries

Yield was calculated from weight of cheese divided by weight of milk and multiplied by 100. Theoretical yield was calculated using Van Slyke and Price formula as modified by Barbano (Rudan et al. 1999). Fat and protein recoveries were calculated from the weight (yield) of each product multiplied by its percentage of fat/protein/total solids content and then divided by the total weight/percentage of fat/protein/total solids present in the original milk and multiplied by 100. Yield, dry weight yield and theoretical yield (Van Slyke and Price as modified by Barbano) was estimated for pre-cheeses by using following formula:

Chemical analysis

Moisture, protein, ash, acidity in milk, pre-cheese and processed cheese were determined by AOAC (2000) procedures. Calcium was estimated by titrimetric method of Ranganna (2003).

Physical properties

Expressible serum

The method as described by Guo and Kindstedt (1995) with some modifications was followed. The amount of expressible serum for pre-cheese and processed Mozzarella cheeses was obtained by centrifuging the 5 g grated cheese at 10,000 × g for 40 min at 37 °C. The centrifuged tubes were then refrigerated to solidify fat. Thereafter, fat layer was punctured to drain serum in a dry dish and its weight expressed as percent.

Meltability

The Schreiber melt test was performed on processed Mozzarella cheese samples using the modified method from Muthukumarappan et al. (1999). Samples were cut in the form of discs with 32 mm diameter and 7 mm height, discs of equal weights were randomly selected and placed on aluminum plates, covered with a glass Petri plate, were tempered at room temperature for 30 min. The average weight of the discs was approx. 8 g. Tempered samples were then heated in oven at 100 °C for 5 min. The meltability of processed cheese was determined by measuring the final diameter of the cheese discs at 4 different locations after they reached room temperature and the average value was reported as meltability.

Melt time

The modified method of Guinee et al. (2002) was used to determine the melt time of pre-cheeses by recording the time taken in melting 100 g of pre-cheese over hot water bath.

Fat leakage

Fat leakage was determined by method of Breene et al. (1964) with the following modifications. Discs of 1.8 cm in diameter and 0.5 mm in height were cut weighing approx. 5 g; melted on filter paper in oven at 100 °C for 5 min. The area of oil ring was expressed as fat leakage.

Sensory analysis

Mozzarella processed cheese samples were evaluated for appearance, body and texture and flavour by a semi-trained panel of six judges using 9-point hedonic scale and assigned scores from liked extremely (9) to disliked extremely (1) (Larmond 1982). The overall acceptability was estimated by taking mean of all the three attributes.

Texture profile analysis

Stable Micro System Texture Analyzer (Model TA-HDi England) was used to determine texture by measuring gram force required to compress a piece of size 1.5 cm3 using following settings Pre-test speed: 1.00 mm/s, Test speed: 1.00 mm/s, Post-test speed:1.00 mm/s, Distance 2: 15 %, Distance: 30 %, Force: 100 g, Time: 3.00 s, Count: 5.00, Load cell: 25 Kg, Probe: P-75 (Flat, Diameter 75 mm).

Statistical analysis

The data collected from the studies was subjected to analysis of variance (ANOVA) using CPCS1 software developed by Deptt. of Mathematics, Statistics and Physics, P.A.U., Ludhiana.

Results and discussion

Physico-chemical characteristics of milk

The physico-chemical characteristics of milk used for manufacturing Mozzarella processed cheese are presented in Table 1. The milk contained 4.5 % fat, 13.65 % total solids, 3.75 % protein, 3.12 % casein, 0.12 % calcium and 0.70 % ash.

Table 1.

Physico–chemical characteristics of milk used for Mozzarella processed cheese manufacture

| Component, % | |

|---|---|

| Fat | 4.5 ± 0.07 |

| Total solids | 13.7 ± 0.03 |

| Protein | 3.8 ± 0.10 |

| Casein | 3.1 ± 0.01 |

| Calcium | 0.12 ± 0.01 |

| Ash | 0.70 ± 0.05 |

| pH | 6.8 ± 0.03 |

| Acidity (as lactic acid) | 0.13 ± 0.03 |

n = 6

Yield, fat and protein recoveries of pre-cheese

Theoretical yield, yield and dry weight yield of pre-cheese did not differ appreciably with the acidulant (Table 2). Fat (99.2 %) and protein (89.45 %) recoveries were highest in pre-cheeses made from lactic acid and acetic acid, respectively. The high fat recovery and low protein recovery in cheese made with lactic acid was due to more losses of protein in whey than fat. Quarne et al. (1968) and Keller et al. (1974) found that fat recovery in Pizza cheese was not affected by the type of acidulant used in direct acidification procedure but the yield of cheese with various acidulants differed significantly. Mona et al. (2011) stated coagulant type as one factor affecting cheese yield amongst many other factors causing differences in cheese yield.

Table 2.

Effect of acidulants on yield and recovery of milk constituents in pre-cheese

| Parameter | Citric acid | Acetic acid | Lactic acid | CD (5 %) |

|---|---|---|---|---|

| Pre-cheese yield | ||||

| Theoretical yield,% | 13.96 | 13.66 | 15.13 | NS |

| Yield,% | 15.12 | 15.80 | 15.65 | NS |

| Dry weight yield,% | 7.88 | 8.01 | 7.30 | NS |

| Recovery | ||||

| Fat,% | 93.54b | 98.80a | 99.20a | 1.998 |

| Protein,% | 84.23b | 89.45a | 74.66c | 1.999 |

Values with different superscripts (a, b and c) in a row differ significantly

n = 3, CD critical difference

NS non-significant

Chemical composition of pre-cheese

The effect of different acidulants on composition of pre-cheese is shown in Table 3. The acidulant had significant (p < 0.05) effect on fat on dry weight basis (FDB), protein, protein on dry weight basis (PDB), moisture and moisture in non-fat substances (MNFS) contents of Mozzarella pre-cheeses. Acetic sample had maximum protein (21.23 %) and minimum moisture content (47.01 %) whereas lactic sample had minimum protein (17.89 %) and maximum moisture content (50.12 %). The MNFS content was also higher than other samples due to higher moisture retention by lactic samples. Lactic samples also had higher FDB than other samples.

Table 3.

Effect of acidulants on chemical composition of Mozzarella pre-cheese

| Component, % | Citric acid | Acetic acid | Lactic acid | CD (5 %) |

|---|---|---|---|---|

| Moisture | 48.1ab | 47.0b | 50.1a | 1.998 |

| Fat | 27.8 | 28.1 | 28.6 | NS |

| Fat on dry basis | 53.7b | 53.1b | 57.2a | 1.999 |

| Protein | 20.9ab | 21.2a | 17.9b | 2.903 |

| Protein on dry basis | 40.3a | 40.1a | 35.9b | 1.998 |

| Moisture in non-fat substances | 66.7b | 65.4b | 70.1a | 1.998 |

| Moisture: protein (ratio) | 2.3 | 2.2 | 2.8 | NS |

| Ash | 1.9 | 2.0 | 1.9 | NS |

| Acidity (as lactic acid) | 0.48 | 0.48 | 0.48 | NS |

Values with different superscripts (a, b and c) in a row differ significantly

n = 3, CD critical difference

NS non-significant

Chemical composition of processed cheese

The composition of processed cheese showed a significant (p < 0.05) difference in moisture content, fat on dry basis (FDB), protein and protein on dry basis (PDB) between the cheeses prepared using three types of acidulants (Table 4). Due to high moisture retention a significantly (p < 0.05) high MNFS and moisture to protein (M:P) ratio in cheese made with lactic acid was recorded. Acidity, fat, ash, Ca and calcium as % of protein were not affected by variation in type of acidulant. Shehata et al. (1966, 1967) found that the type of acid used to acidify milk to pH 5.6 before coagulation with rennet in direct acidification procedure had a significant effect on the composition and characteristics of Blue and Pizza cheese.

Table 4.

Effect of acidulants and melting salt on chemical composition of Mozzarella processed cheese

| Components, % | Control | TSC | CD (5 %) | ||||

|---|---|---|---|---|---|---|---|

| Citric acid | Acetic acid | Lactic acid | Citric acid | Acetic acid | Lactic acid | ||

| Moisture | 38.2cl | 37.6cdl | 42.4al | 37.4cdl | 36.9dl | 40.5bl | A = 1.258, M = 1.027, A × M = NS |

| Fat | 33.2 | 33.8 | 33.9 | 33.7 | 34.0 | 34.1 | A = NS, M = NS, A × M = NS |

| Fat on dry basis | 53.7c | 54.1c | 58.9a | 53.8c | 53.8c | 57.4b | A = 1.258, M = NS, A × M = NS |

| Protein | 23.7a | 23.9a | 19.8b | 23.5a | 23.7a | 19.6b | A = 1.258, M = NS, A × M = NS |

| Protein on dry basis | 38.4a | 38.2a | 34.3b | 37.6a | 37.5a | 33.0c | A = 1.258, M = NS, A × M = NS |

| Moisture in non-fat substances | 57.1cl | 56.7cdl | 64.2al | 56.4cdl | 55.9dm | 61.5bm | A = 1.258, M = 1.027, A × M = NS |

| Moisture: protein (ratio) | 1.6 | 1.6 | 2.1 | 1.6 | 1.6 | 2.1 | A = NS, M = NS, A × M = NS |

| Ash | 2.9 | 3.0 | 2.9 | 3.9 | 3.9 | 3.9 | A = NS, M = NS, A × M = NS |

| Acidity (as lactic acid) | 0.48 | 0.48 | 0.48 | 0.44 | 0.44 | 0.44 | A = NS, M = NS, A × M = NS |

| Ca | 0.40 | 0.43 | 0.50 | 0.40 | 0.43 | 0.49 | A = NS, M = NS, A × M = NS |

| Ca (% of P) | 1.7 | 1.8 | 2.5 | 1.7 | 1.8 | 2.6 | A = NS, M = NS, A × M = NS |

Values with different superscripts (a, b, c and d) in a row differ significantly with respect to acidulant

Values with different superscripts (l and m) in a row differ significantly with respect to melting salt

n = 3 NS non significant; CD critical difference

A acidulant, M melting salt, TSC tri-sodium citrate

Addition of 1 % TSC (melting salt) resulted in a significant (p < 0.05) decrease in moisture content of processed cheese leading to decrease in MNFS content. Inclusion of TSC had a non-significant effect on fat, FDB, protein, PDB, Moisture: protein (M: P), ash, acidity, Ca and Ca as % of protein.

Sensory characteristics

The appearance scores differed significantly (p < 0.05) for processed cheese prepared using different acidulants (Table 5). Citric sample obtained higher appearance score (8.00) than other two acid samples. A greenish tinge and oozing of fat on the surface of cheese made with acetic and lactic acid caused inferior rating of these. According to Walstra et al. (1999) the colour of cheese is affected by the amount of intact casein micelles; therefore, higher amount of intact casein micelle leads to more scattering of light resulting in whiter appearance.

Table 5.

Effect of acidulants and melting salt on sensory characteristics of Mozzarella processed cheese

| Type of acidulant | Appearance | Body and texture | Flavour | Overall acceptability | ||||

|---|---|---|---|---|---|---|---|---|

| Control | TSC | Control | TSC | Control | TSC | Control | TSC | |

| Citric acid | 8.0l | 8.5l | 8.0l | 8.5l | 8.0l | 8.5l | 8.0al | 8.5al |

| Acetic acid | 6.5m | 7.0m | 6.5m | 7.0m | 6.5m | 6.5m | 6.5bm | 6.83bm |

| Lactic acid | 6.5m | 7.0m | 6.0m | 6.5m | 7.0m | 7.0m | 6.5bm | 6.83bm |

n = 6

Values with different superscripts (a, b, c, d) in a row differ significantly with respect to melting salt

Values with different superscripts (l, m, n) in a column differ significantly with respect to acidulant

TSC tri-sodium citrate

*Significant (p < 0.05)

The body and texture scores differed significantly (p < 0.05) for different acidulants. Citric acid samples obtained highest score (8.00) followed by acetic (6.50) and lactic acid (6.00) samples for body and texture. Citric samples were softer and showed less oozing of fat as compared to acetic and lactic samples. The flavour scores also differed significantly (p < 0.05). The citric sample had a richer and smoother flavour as compared to lactic sample due to lower fat losses during processing and transformation in to processed cheese. The flavour score was lowest for acetic sample as it possessed an odour of acetic acid. The overall acceptability scores also differed significantly (p < 0.05). The overall acceptability score was highest for citric samples. Addition of 1 % TSC non-significantly increased the scores for appearance, body and texture, flavor and overall acceptability. According to Metzger et al. (2001b) the post melt chewiness and whiteness of low fat mozzarella cheese were affected by milk pre-acidification. The largest level of calcium reduction and modification in post melt whiteness occurred in pH 5.8 citric treatment.

Effect on physical properties of processed cheese

Expressible serum

It is the indirect way of determining the water holding capacity of cheese. The expressible serum of cheese prepared using three acidulants was significantly (p < 0.05) different for pre-cheese and processed cheese without (control) and with 1 % TSC (Table 6). The cheeses made using lactic acid had maximum value of expressible serum followed by citric and acetic samples. High moisture to protein ratio (M:P) was responsible for higher expressible serum, indicating higher water holding capacity of the proteins in lactic samples. The findings are in accordance with Metzger et al. (2001a) who observed that pre-acidification with citric acid decreased the amount of expressible serum more than pre-acidification with acetic acid The differences in the amount of expressible serum between acid treatments may be related to the differences in the binding affinity of calcium for the acid types that affect the casein matrix and the amount of casein soluble in water phase of cheese (Metzger et al. 2001a). Milk pre-acidification may decrease the amount of expressible serum due to casein solubilization and formation of casein gel in the water phase of the cheese. Expressible serum decreased significantly (p < 0.05) when pre-cheese was processed with TSC. This signifies that non-expressible serum i.e. water holding capacity of proteins increased by processing with TSC. This was due to change in structure of proteins during heat processing in presence of melting salt. Type of acidulant and processing of pre-cheese with melting salt showed a significant (p < 0.05) interaction indicating that each one affected the protein structure in a different way. Higher concentration of solubilized casein have been attributed to a decrease in the amount of expressible serum (Guo and Kindstedt 1995)

Table 6.

Effect of acidulant and melting salt on physical properties of Mozzarella processed cheese

| Type of acidulant | Expressible serum, % | Meltability, cm | Melt time, min | Fat leakage, cm2 | |||||

|---|---|---|---|---|---|---|---|---|---|

| Pre-cheese | Control | TSC | Control | TSC | Control | TSC | Control | TSC | |

| Citric acid | 26.6al | 1.3bl | 1.1bl | 4.9 | 5.1 | 15m | 14m | 10.1 | 9.5 |

| Acetic acid | 25.2am | 1.2bl | 1.0bl | 3.6 | 3.9 | 17l | 16l | 10.2 | 9.7 |

| Lactic acid | 24.0an | 1.5bl | 1.2bl | 3.8 | 4.1 | 16lm | 15lm | 10.3 | 9.7 |

n = 3

Values with different superscripts in a row (a and b) and in a column (l, m and n) differ significantly

*Significant (p < 0.05)

Meltability

Cheese meltability is defined as the ease and extent at which cheese will flow upon heating. It is an important functional property especially for cheese used in foods consumed after heating (Altan et al. 2005). The meltability of cheese samples prepared with different acidulants did not differ significantly. This may be due to the fact that pre-acidification pH was same in all the three acidulants. Therefore, there was not much difference in calcium content of cheese samples prepared with different acidulants. Even, inclusion of 1 % TSC did not have significant effect on meltability indicating that concentration of melting salt may require alteration to achieve a product with higher meltability (Table 6). Keller et al. (1974) reported that meltability of Mozzarella cheeses was affected significantly by the type of acid and pH at coagulation. Though pH affects the properties of milk and casein miscelles by affecting the extent and nature of protein interactions, yet it is difficult to separate the effect of pH from that of changes in total and soluble calcium content, moisture content, extent and pattern of proteolysis and their interactions (Pastorino et al. 2003). It is generally accepted that reduced calcium cheese has higher meltability. Caseins are better able to emulsify fat in curd with reduced calcium (McMahon et al. 1993), resulting in higher melting, a desirable characteristic in Mozzarella cheese. The combined action of proteolysis by residual coagulant and reduction in calcium content has been shown to improve meltability of Mozzarella cheeses (Fife et al. 1996). It has also been observed that TSC chelated Ca from colloidal calcium phosphate and dispersed casein; the citrate-Ca complex remained trapped within the process cheese matrix (Shirashoji et al. 2006). Swenson et al. (2000) observed that use of TSC in fat-free cheese spreads produced properties closest to those of a full-fat reference cheese and provided high meltability. Increasing the amount of TSC or disodium phosphate from 0.5 to 3 % resulted in increased firmness, decreased melt, and decreased spreadability. High degree of firmness for cheese spreads was explained by an increase in amount of protein-protein interaction facilitated by greater calcium sequestering abilities of emulsifying salts/polyphosphate containing ingredient (Swenson et al. 2000).

Melt time

Melt test measures the ability of cheese particles to flow past one another when heated (Fife et al. 1996). The melt time varied significantly (p < 0.05) with acidulant for samples without melting salt (control) and with melting salt (Table 6). Control samples of acetic cheese had highest melt time (17 min) whereas that of citric had lowest (15 min). Variation in Protein content was responsible for difference in melt time. Reduction in melt time could be important for cheese processing industry as it can save time and reduce the power consumption thus helping to economize the process of manufacture. Addition of 1 % TSC to control samples during processing did not result in a significant difference in melt time. Cheeses with smaller protein aggregate and a more hydrated protein matrix had a better melt (Paulson et al. 1998).

Fat leakage

Fat leakage/oiling off is a heat related property and is affected by heating temperature and time. Heating causes the cheese to melt and release fat and therefore alter the original structure. Melted fat may coalesce and result in separation of fat from the protein matrix. This causes the undesirable effect of oiling-off or fat leakage (Gunasekaran and Ak 2003). Therefore fat leakage becomes important parameter if cheese is to be consumed after heat treatment. Effect of acidulant and TSC on fat leakage of processed cheese is shown in Table 6. The fat leakage of samples was not affected significantly either with acidulant or TSC. This was due to the fact that fat content did not differ both with acidulant or TSC. Addition of melting salt to control samples decreased fat leakage but the decrease was non-significant. The findings are in agreement with Jian-Qiang et al. (2011) as they did not find significant difference in fat and free oil contents when using acids such as citric, lactic, acetic, phosphoric and hydrochloric. It is based on the fact that well emulsified fat has lower tendency to exude and coalesce from cheese upon melting (Joshi et al. 2003)

Texture profile analysis

The textural parameters of cheese samples made with different acidulants are tabulated in Table 7. Hardness/firmness is the resistance to deformation (Guinee et al. 2002). Hardness of control and TSC samples was significantly (p < 0.05) different for various acidulants. Hardness values of control and samples with TSC ranged from 1,580 to 5,454 g and 1,650 to 6,600 g, respectively. Acetic cheese samples had maximum hardness whereas citric cheese had minimum hardness. Variation in firmness was related to the concentration of casein in the matrix. As the concentration of casein increased, the intra and inter-strand linkages became more numerous and matrix more difficult to deform (Jong 1976, 1978; Chen et al. 1979; Prentice et al. 1993). Addition of TSC in control samples lead to significant (p < 0.05) increase in hardness. Gupta et al. (1984) found that addition of melting salt to processed cheese increased its firmness. A significant interaction was noted between acidulant and TSC. As such well emulsified cheeses were found to be firmest and most sliceable (Awad et al. 2002).

Table 7.

Effect of acidulants and melting salt on Texture Profile Analysis (TPA) of Mozzarella processed cheese

| Parameters | Control | TSC | CD (5 %) | ||||

|---|---|---|---|---|---|---|---|

| Citric acid | Acetic acid | Lactic acid | Citric acid | Acetic acid | Lactic acid | ||

| Hardness, g | 1580cm | 5454am | 1659bm | 1658cl | 6600al | 2525bl | A = 52.639, H = 42.979, A × H = 74.442 |

| Fracturability, g | 2.3a | 1.6b | 0.3c | 2.5a | 2.6b | 1.1c | A = 0.894, F = NS, A × F = NS |

| Cohesiveness | 0.03 | 0.06 | 0.04 | 0.05 | 0.07 | 0.04 | A = NS, C = NS, A × C = NS |

| Adhesiveness, gs | 20.2am | 15.8bl | 12.8cm | 26.8al | 16.5bl | 19.0cl | A = 9.593, A = 7.833, A × A = NS |

| Elasticity | 0.25bm | 0.26am | 0.21cm | 0.26al | 0.27al | 0.23bl | A = 0.013, E = 0.010, A × E = NS |

| Gumminess | 52.2bl | 338.1am | 63.0cm | 79.6bl | 442.2al | 124.3bl | A = 59.330, G = 48.443, A × G = 83.906 |

| Chewiness, g | 13.0bl | 88.6am | 13.5bm | 20.9cl | 120.7al | 28.6bl | A = 1.258, C = 1.027, A × C = NS |

| Resilience | 0.33a | 0.36a | 0.22b | 0.34b | 0.40a | 0.23c | A = 0.052, R = NS, A × R = NS |

Values with different superscripts (a, b and c) in a row differ significantly with respect to acidulant

Values with different superscripts (l, m and n) in a row differ significantly with respect to melting salt

A acidulant, H hardness, F fracturability, C cohesiveness, A adhesiveness, E elasticity, G gumminess, C chewiness, R resilience

n = 3, NS non significant; CD critical difference

Fracturability is the tendency of cheese to fracture into pieces when stress is applied (Visser 1991; Fox et al. 2000). Fractrability values showed a significant (p < 0.05) difference with type of acidulant and presence of TSC. Control samples made with citric, acetic and lactic acid had 2.3, 1.6 and 0.3 g fracturability values, respectively, while samples with TSC had values 2.5, 2.6 and 1.1 g respectively. Low fracturability was because of low protein and high moisture content (Table 7) (Guinee et al. 2002, Creamer and Olson 1982). Adhesiveness, elasticity, guminess and chewiness values were significantly (p < 0.05) different with the acidulant. Adhesiveness and elasticity are related to concentration of casein (Ma et al. 1997) and moisture content (Visser 1991). Lower protein and high moisture content of lactic samples were responsible for lower values of elasticity (0.214 and 0. 230) and high values of adhesiveness (20.24 gs and 26.8 gs) for control samples and samples with melting salt. Adhesiveness and elasticity increased significantly (p < 0.05) when melting salt was added to control samples. Guminess and chewiness are related to hardness, cohesiveness and elasticity. Guminess and chewiness increased significantly (p < 0.05) with the addition of TSC. The acidulants and melting salt addition had a significant (p < 0.05) effect on guminess and chewiness. Resilience indicates the stability of the product, higher the value, higher is the stability of the product. The acidulants had a significant effect on resilience. High resilience value of 0.360 and 0.400 and low resilience values of 0.219 and 0.229 were observed for acetic and lactic samples, respectively. Stability of the cheese structure depends on the protein matrix, therefore high protein content of acetic samples might be responsible for high resilience values. Changes in functionality of cheese were as a result of change in pH, proteolysis, protein bound water and free oil in cheese (Jana and Mandal 2011) Earlier Rayan et al. (1980) and Fukushima and Deman (1970) attributed textural attributes of full fat process cheese to the amount of protein interaction and calcium sequestering abilities of emulsifying salts. The essential role of emulsifying salts in the manufacture of processed cheese is to supplement emulsifying capability of cheese proteins (Awad et al. 2002). The changes in ability to absorb water have also been shown to play a major role in the textural performance of various foods (Fennema 1985) and may have influences on the texture of process cheeses. Overall, it was stated that the influence of pH on cheese texture may function through a number of mechanisms (Swenson et al. 2000)

Conclusion

On the basis of sensory characteristics, physical properties and texture profile analysis of processed cheese made from Mozzarella pre-cheese using three acidulants, citric samples were found to rate superior. Although the acetic acid samples showed more recovery of fat and protein but they were hard and possessed acetic flavour. On the other hand lactic acid samples showed lower protein recovery and had high moisture content. Citric sample had softer texture, medium protein and fat recovery, good sensory characteristics and medium level of water holding capacity. Citric samples also had minimum melt time out of the three acids tested.

References

- Altan A, Turhan M, Gunasekaran S. Comparison of covered and uncovered Schreiber test for cheese meltability evaluation. J Dairy Sci. 2005;88:857–861. doi: 10.3168/jds.S0022-0302(05)72751-X. [DOI] [PubMed] [Google Scholar]

- AOAC . Official methods of analysis. 16. Washington: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Awad RA, Abdeil-hamid LB, El-Shabrawy SA, Singh RK. Texture and microstructure of block type processed cheese with formulated emulsifying salt mixtures. Lebensm-Wiss u-Technol. 2002;35:54–61. doi: 10.1006/fstl.2001.0828. [DOI] [Google Scholar]

- Breene WM, Price WV, Ernstrom CA. Manufacture of pizza cheese without starter. J Dairy Sci. 1964;47:1173–1179. doi: 10.3168/jds.S0022-0302(64)88877-9. [DOI] [Google Scholar]

- Caric M, Kalab M (1993) Cheese: chemistry, physics and microbiology. Processed cheese products. In: Fox PF (ed) Vol 2. Aspen publication, pp 480–84

- Chen AH, Larkin JW, Clark CJ, Irwin WE. Textural analysis of cheese. J Dairy Sci. 1979;62:901–905. doi: 10.3168/jds.S0022-0302(79)83346-9. [DOI] [Google Scholar]

- Creamer LK, Olson NF. Rheological evaluation of maturing cheddar cheese. J Food Sci. 1982;47:631–635. doi: 10.1111/j.1365-2621.1982.tb10138.x. [DOI] [Google Scholar]

- Dave RI, Donald JM, Craig JO, Jeffery RB. Influence of coagulant level on proteolysis and functionality of Mozzarella cheese made using direct acidification. J Dairy Sci. 2003;86:114–126. doi: 10.3168/jds.S0022-0302(03)73590-5. [DOI] [PubMed] [Google Scholar]

- De S. Outlines of dairy technology. Delhi: Oxford University Press; 1980. pp. 226–228. [Google Scholar]

- Demott BJ. Recovery of milk constituents in a Mozzarella–like product manufactured from non fat dried milk and cream by direct acidification at 4 and 35 °C. J Dairy Sci. 1983;66:1–6. doi: 10.3168/jds.S0022-0302(83)82118-3. [DOI] [Google Scholar]

- Ernstrom CA. Mechanized pizza cheese making by means of a continuous direct acidification method. Mfd Milk Prod J. 1965;57:7–11. [Google Scholar]

- Fennema OR. Food chemistry. 2. New York: Marcel Dekker Inc; 1985. p. 991. [Google Scholar]

- Fife RL, Macmahon DJ, Oberg CJ. Functionality of low fat Mozzarella cheese. J Dairy Sci. 1996;79:1903–1910. doi: 10.3168/jds.S0022-0302(96)76559-1. [DOI] [Google Scholar]

- Fox PF, Guniee TP, Cogan T, Mcsweeney PLH. Fundamentals of cheese science. Gaithersburg: Aspen Publishers, Inc; 2000. pp. 305–340. [Google Scholar]

- Fukushima M, DeMan JM (1970) Effect of processing salts on some rheological properties of process cheese. 18th Int Dairy Congr, Sydney Oct 12–16, (cited by Swenson et al. 2000)

- Guinee TP, Feeney EP, Auty MAE, Fox PF. Effect of pH and calcium concentration on some textural and functional properties of mozzarella cheese. J Dairy Sci. 2002;85:1655–1669. doi: 10.3168/jds.S0022-0302(02)74238-0. [DOI] [PubMed] [Google Scholar]

- Gunasekaran S, Ak MM. Cheese rheology and texture. Boca Raton: CRC Press; 2003. p. 243. [Google Scholar]

- Guo MR, Kindstedt PS. Age-related changes in the water phase of mozzarella cheese. J Dairy Sci. 1995;78:2099–2107. doi: 10.3168/jds.S0022-0302(95)76836-9. [DOI] [Google Scholar]

- Gupta SK, Karahdian C, Linday RC. Effect of emulsifier salts on textural and flavour properties of processed cheese. J Dairy Sci. 1984;67:764–778. doi: 10.3168/jds.S0022-0302(84)81367-3. [DOI] [Google Scholar]

- Jana A, Mandal PK. Manufacturing and quality of mozzarella cheese: a review. Int J Dairy Sci. 2011;6:199–226. doi: 10.3923/ijds.2011.199.226. [DOI] [Google Scholar]

- Jian-Qiang Z, Hui-Fang S, Li-qin Z. Effects of acidifying agent on the functional properties of pizza cheese. Packag Food Mach. 2011;29:1–4. [Google Scholar]

- Jong L. Protein breakdown in soft cheese and relationship to consistency of ‘Noordholbndase Mashanger’ cheese. Neth Milk Dairy J. 1976;30:242–253. [Google Scholar]

- Jong L. The influence of moisture content on the consistency and protein breakdown of cheese. Neth Milk Dairy J. 1978;32:1–4. [Google Scholar]

- Joshi NS, Muthukumarappan K, Dave RI. Understanding the role of calcium in functionality of part skim mozzarella cheese. J Dairy Sci. 2003;86:1918–1926. doi: 10.3168/jds.S0022-0302(03)73778-3. [DOI] [PubMed] [Google Scholar]

- Keller B, Olson NF, Richardson T. Mineral retention and rheological properties of mozzarella cheese made by direct acidification. J Dairy Sci. 1974;57:174–179. doi: 10.3168/jds.S0022-0302(74)84856-3. [DOI] [Google Scholar]

- Larmond E. Laboratory methods for sensory evaluation of food. Publication No 1637. Ottawa: Department of Agriculture; 1982. [Google Scholar]

- Ma I, Drake GV, Barbosa-Canovas GV, Swanson BG. Rheology of full-fat cheddar cheeses as related to type of fat mimetic. J Food Sci. 1997;62:748–752. doi: 10.1111/j.1365-2621.1997.tb15449.x. [DOI] [Google Scholar]

- McMahon DJ, Oberg CJ, Mc Manus W. Functionality of Mozzarella cheese. Aust J Dairy Technol. 1993;11:99–104. [Google Scholar]

- Metzger LE, Barbano DM, Rudan MA, Kindstedt PS. Effect of milk preacidification on low fat mozzarella cheese II. Chemical and functional properties during storage. J Dairy Sci. 2001;84:1348–1356. doi: 10.3168/jds.S0022-0302(01)70165-8. [DOI] [PubMed] [Google Scholar]

- Metzger LE, Barbano DM, Rudan MA, Kindstedt PS. Effect of milk preacidification on low fat mozzarella cheese III. Post melt chewiness and whiteness. J Dairy Sci. 2001;84:1357–1366. doi: 10.3168/jds.S0022-0302(01)70166-X. [DOI] [PubMed] [Google Scholar]

- MOFPI (2013) Ministry of food processing industry. http://mofpi.nic.in/ContentPage.aspx?CategoryId=145, accessed July 5, 2013

- Mona AM, El-Gawad A, Nawal SA. Cheese yield as affected by some parameters. Review. Acta Sci Pol Technol Aliment. 2011;10:131–153. [Google Scholar]

- Muthukumarappan K, Wang YC, Gunasekaran S. Estimating softening point of cheeses. J Dairy Sci. 1999;82:2280–2286. doi: 10.3168/jds.S0022-0302(99)75476-7. [DOI] [Google Scholar]

- Najafi MBH, Asianfar H, Ghoddosi HB. Study on physico-chemical, rheological and sensory properties of Mozzarella cheese by direct acidification. Am Eurasian J Agric Environ Sci. 2006;1:268–272. [Google Scholar]

- Pastorino AJ, Hansen CJ, McMahon DJ. Effect of pH on the chemical composition and structure-function relationships of Cheddar Cheese. J Dairy Sci. 2003;86:2751–2760. doi: 10.3168/jds.S0022-0302(03)73871-5. [DOI] [PubMed] [Google Scholar]

- Patel GC, Vyas SH, Upadhyay GU. Evaluation of mozzarella cheese made from buffalo milk using direct acidification technique. Indian J Dairy Sci. 1985;39:394–403. [Google Scholar]

- Paulson BM, McMahaon DJ, Oberg CJ. Influence of sodium chloride on appearance, functionality and protein arrangements in non fat Mozzarella cheese. J Dairy Sci. 1998;81:2053–2064. doi: 10.3168/jds.S0022-0302(98)75780-7. [DOI] [Google Scholar]

- Prentice JH, Langley KR, Marshall RJ. Cheese rheology. In: Fox PF, editor. Cheese: chemistry, physics and microbiology. 2. London: Chapman Hall; 1993. pp. p303–p340. [Google Scholar]

- Quarne EL, Larson WR, Olson NF. Recovery of milk solids in direct acidification and traditional procedures of manufacturing pizza cheese. J Dairy Sci. 1968;52:527–533. doi: 10.3168/jds.S0022-0302(68)87023-7. [DOI] [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. New Delhi: Tata McGraw-Hill Publishing; 2003. p. 123. [Google Scholar]

- Rayan A, Kalab M, Ernstrom CA (1980) Microstructure and rheology of pasteurized process cheese. Scanning Electron Microscopy No. 3, 635–643 (Cited by Awad et al. 2002)

- Rudan MA, Barbano DM, Yun JJ, Kindstedt PS. Effect of fat reduction on chemical composition, proteolysis, functionality and yield of Mozzarella cheese. J Dairy Sci. 1999;82:661–672. doi: 10.3168/jds.S0022-0302(99)75282-3. [DOI] [PubMed] [Google Scholar]

- Schafer HW, Olson NF. Characteristics of Mozzarella cheese made by direct acidification from ultra-high-temperature processed milk. J Dairy Sci. 1975;58:494–501. doi: 10.3168/jds.S0022-0302(75)84596-6. [DOI] [Google Scholar]

- Seth K, Bajwa U, Sandhu KS (2009) Processed Mozzarella cheese: effect of spices and herbs on the physico-chemical, sensory and textural characteristics. Proc National workshop on spices and aromatic plants, PAU, Ludhiana, Feb 04–05, pp 181–188

- Shehata AE, Meena I, Olson NF. Manufacture of blue cheese by direct acidification methods. J Dairy Sci. 1966;49:1025–1028. doi: 10.3168/jds.S0022-0302(66)88007-4. [DOI] [Google Scholar]

- Shehata AE, Meena I, Olson NF, Richardson T. Effect of type of acid used in direct acidification procedures on moisture, firmness and calcium levels of cheese. J Dairy Sci. 1967;50:824–827. doi: 10.3168/jds.S0022-0302(67)87529-5. [DOI] [Google Scholar]

- Shirashoji N, Jaeggi N, Lucey JA. Effect of trisodium citrate concentration and cooking time on the physicochemical properties of pasteurized process cheese. J Dairy Sci. 2006;89:15–28. doi: 10.3168/jds.S0022-0302(06)72065-3. [DOI] [PubMed] [Google Scholar]

- Singh S, Ladkani BC (1984) Annual Report, NDRI, Karnal, p 82

- Swenson BJ, Wendorff WL, Lindsay RC. Effects of ingredients on the functionality of fat-free process cheese spreads. J Food Sci. 2000;65:822–825. doi: 10.1111/j.1365-2621.2000.tb13594.x. [DOI] [Google Scholar]

- Visser J (1991) Factors affecting the rheological and fracture properties of hard and semi-hard cheese. Bulletin 268. Int Dairy Fed. Brussels, Belgium, pp 49–61

- Walstra P, Geurts TJ, Noomen A, Jellema A, Van Boekel MAJS, editors. Dairy technology. Cheese ripening and properties. USA: Marcel Dekker; 1999. p. 617. [Google Scholar]