Abstract

Fish burgers from catla (Catla catla) were assessed for proximate, chemical, microbiological and sensory quality changes over 17 days of refrigerated storage at 4 (±1) °C. The changes in proximate analysis of fish burgers were found to be significant at P < 0.01. The values of peroxide value, free fatty acid, thiobarbutric acid and total volatile base nitrogen at the end of storage increased significantly at P < 0.01 were determined as 4.98 (±0.22) meqO2/kg of fat, 0.94 (±0.01)% of oleic acid, 0.58 (± 0.02) mg MA/kg of sample and 4.78 (±0.02) mg/100 g of sample respectively. Total plate count and psychrophilic bacterial counts increased significantly (P < 0.01) during refrigerated storage. Staphylococcus aureus, Faecal streptococci, Escherichia coli, Salmonella, Vibrio, yeast and molds were found absent. According to sensory scores, the fish burgers have a shelf life of 15 days. A negative correlation was observed between storage period and overall acceptability scores.

Keywords: Catla, Fish burger, Chemical quality, Sensory, Shelf life

Introduction

Freshwater fish production in India increased from 0.89 million tons in 1980–81 to 5.70 MMT during the year 2010–2011 (Annual report of Animal Husbandry 2012). Among the freshwater fish produced in India, the major carps of India (Catla catla, Labeo rohita and Cirrhinus mrigala) and Chinese carps (Cyprinus carpio, Ctenopharyngodon idella and Hypophthalmicthys molitrix) form a major component of Indian aquaculture, with a market share of over 90 %. They can be easily cultured in low – input technology systems because of their herbivorous feeding habit (Sehgal and Sehgal 2003). This increase in fish production agrees with an increase in the consuming of fish meat as an alternative or substitute for livestock meat, since fish is considered as a healthy food with a good source of animal protein than the livestock.

Processing and value addition to carps is the need of the hour to sustain carp culture and to make it more profitable. The demand for ready to eat and/or ready to cook products are gradually growing because of their convenience (Yerlikaya et al. 2005). Burgers are simple and a cost effective means of converting carps into convenience products. The main parameters which affect the shelf life of the stored fish products are the production form, features of packing material, storage temperature, packing process and machines that are used (Baygar et al. 2008). There is a growing interest in producing ready-made seafood products such as fish burgers and several studies have been conducted to investigate the quality changes of such products.

The aim of present study is to develop ready to eat fish burger from Catla (Catla catla) and to find out the shelf life and the type of deterioration that occurs during the refrigerated storage using proximate, biochemical, microbiological and organoleptic assessments.

Material and methods

Catla (Catla catla) harvested from freshwater culture ponds of Muthukur of Nellore district were iced in the ratio of 1:1 and transported to laboratory within 20 min. The average length and weight of Catla used in the present study was 35.83 (±2.27) cm and 625.01 (±30.74) g respectively. The fish were later dressed to remove head and viscera. Meat was separated from dressed fish using rotary type deboner (Safe World, Malaysia). The deboned fish meat was minced using a mincer (Sirman, Italy) to obtain uniform size meat particles. The fresh minced meat obtained from catla was used to prepare fish burgers. Other ingredients used were procured from the local markets.

Each fish burger was a mean 25 g weight and composed of 72.72 % fish mince, 1.22 % salt, 1.50 % sugar, 4.36 % corn flour, 0.29 % ginger, 0.14 % pepper, 7.27 % onion, 1.69 % green chilly, 2.32 % bread crumbs, 4.72 % potatoes, 0.14 % sodium tripolyphosphate, 3.63 % chilled water. After the batter application, it was covered with conventional breading crumbs and then pre-fried at 180 °C for 30 s. The products were later cooled and six fish burgers were packed in each HDPE pouches, sealed, labeled and stored at 4(± 1) °C for quality evaluation. The analyses were done on the every alternate day up to 17 days. The samples were drawn randomly for analyses and were performed in triplicate for biochemical and duplicate for microbiological parameters.

Moisture, fat, protein and ash were analyzed as per AOAC “(2000)”. Total volatile base nitrogen (TVBN) was determined by the micro diffusion method of Conway “(1962)”. Thiobarbituric acid value (TBA) was assessed by the method of Tarladgis et al. “(1960)”, peroxide value (PV) and free fatty acid (FFA) were estimated according to Jacobs “(1958)” and Olley and Lovern “(1960)” respectively.

All the microbial analysis were enumerated as per the procedures described in APHA “(1992)”. The microbial count was estimated by spread plate technique. 25 g of the sample was weighed aseptically and diluted with 225 ml of physiological saline solution to obtain 10−1 dilution. Samples were homogenized using stomacher (Lab-Med, England). Preparation of sample and serial dilutions were done near the flame in a horizontal laminar flow apparatus that was presterilized by ultraviolet radiation observing all possible aseptic precautions. Serial dilutions were done by transferring 1 ml of supernatant (diluted sample) with sterile pipettes into 9 ml of sterile physiological saline tubes.

Total plate count (TPC), Staphylococcus aureus, Escherichia coli and Faecal streptococci was determined by spread plate method using Soyabean Casein Agar medium, Baird Parker Agar, Tergitol 7 Agar and Kenner Faecal streptococcus Agar respectively and were incubated at 37 °C for 24 to 48 h. Psychrophilic bacteria was determined using Nutrient Agar and plates were incubated at 4(±1) °C for 1 week. Salmonella and Vibrio were analyzed by streaking method using Brilliant green Agar and Thiosulphate Citrate Bile salt Sucrose mediums. For molds, Potato Dextrose Agar Medium was used.

Sensory characteristics of the fish burgers were evaluated by selected panel members of the institute who have experience in evaluation of similar products, on a ten-point scale (IS: 6273[II] 1971; Vijayan 1984). Scores were assigned with ‘1’ being the least and ‘10’ being the highest for attributes. The characteristics covered under the taste panel were appearance, colour, flavor, taste, texture and overall acceptability. The products were deep fried in refined sunflower oil until they were cooked before being presented to the panelists. Scores 10, 9, 8, 7, 6, 5, 4, 3, 2, 1 were taken for excellent, like extremely, like very much, like moderately, like slightly, neither like nor dislike, dislike slightly, dislike moderately, dislike very much and dislike extremely respectively for each of the sensory characteristics. The observations were converted to equivalent numerical scores and a sensory score of 4 was taken as the borderline of overall acceptability.

The SPSS (Statistical Package for Social Sciences) 19 (IBM 2010) statistical package was used for analysis of the experimental results. Sufficient numbers of samples were carried out for each analysis. The results were expressed as mean ± standard deviation (SD). The correlation coefficients between the parameters were carried out using the same software. One way ANOVA was performed by the Duncan test to find the significance difference between storage days.

Result and discussion

The yield of mince was 37.3 % from the whole catla and the initial moisture, protein, fat and ash content of catla mince were found to be 78.65 (±0.72) %, 16.64 (±0.34) %, 2.23 (±0.08) % and 1.05 (±0.03) % respectively. The raw mince yield and proximate composition of catla is compared to the other freshwater fishes (Arekere 1993; Siddaiah et al. 2001; Sehgal et al. 2010 and Elyasi et al. 2010).

Proximate composition

The proximate composition of the product is given in Table 1. The moisture content in fish burgers decreased significantly at 0.05 % level (P < 0.05) from 55.08 % to 52.42 %. An increase in the fat and ash content has been observed from 12.18 to 16.01 % and 2.18 to 2.48 % respectively (P < 0.01). The increase in fat can be attributed to the decrease in moisture content as they are inversely proportional. Similar observation was found by the Ucak et al. (2011) during the refrigeration storage of mackerel fish burgers for 15 days. During storage, crude protein decreased significantly at (P < 0.01). The decrease can be attributed to the leaching out of the water soluble nitrogenous components, during storage along with moisture. The ash content in the product was higher than the fresh fish mince, due to the addition of the ingredients during the preparation of fish burgers. The remaining percentage of the proximate composition is thought to be due to carbohydrates (Tokur et al. 2006). Sayar (2001) observed 15.2 % carbohydrates in fish fingers and attributed to the coating materials which contain carbohydrate rich ingredients such as flour, starch, bread crumbs, potatoes, etc.

Table 1.

Changes in the proximate composition of fish burgers during refrigerated storage

| Storage period (Days) | Fish burger | |||

|---|---|---|---|---|

| Moisture | Crude protein | Crude fat | Ash | |

| 0 | 55.08 ± 1.88c | 18.11 ± 0.01f | 12.18 ± 0.07a | 2.18 ± 0.17a |

| 1 | 54.82 ± 1.24bc | 18.02 ± 0.01f | 12.50 ± 0.09b | 2.21 ± 0.08a |

| 3 | 54.17 ± 2.43ab | 17.91 ± 0.42f | 13.24 ± 0.09c | 2.23 ± 0.08a |

| 5 | 53.77 ± 1.84ab | 17.65 ± 0.05e | 13.83 ± 0.05d | 2.30 ± 0.17ab |

| 7 | 53.79 ± 1.04ab | 17.43 ± 0.04d | 14.09 ± 0.05e | 2.24 ± 0.06ab |

| 9 | 53.24 ± 1.62ab | 17.20 ± 0.00c | 14.79 ± 0.00f | 2.32 ± 0.09ab |

| 11 | 53.83 ± 0.55ab | 16.87 ± 0.60b | 14.44 ± 0.07g | 2.41 ± 0.02ab |

| 13 | 52.9 ± 1.38a | 16.63 ± 0.03a | 15.43 ± 0.14h | 2.59 ± 0.09b |

| 15 | 52.78 ± 0.89a | 16.41 ± 0.01a | 15.83 ± 0.08i | 2.53 ± 0.05ab |

| 17 | 52.42 ± 1.42ab | 16.11 ± 0.02a | 16.01 ± 0.06j | 2.48 ± 0.04ab |

Each value is represented as the mean ± SD of n = 3

abcdefMeans followed by the same superscript with in a column are not significantly different (P > 0.01)

Chemical analysis

The changes in pH, PV, FFA, TBA and TVB-N values of catla burgers during refrigerated storage are shown in Table 2. The pH values of fish burgers decreased significantly (P < 0.01) from 6.78 to 6.15. This could be caused due to the fermentation of potato and bread ingredients and due to the addition of spices. A similar observation was made by the Metin et al. (2002) in rainbow trout fish burgers during the refrigerated storage. The PV was 4.62 meqO2/kg in fresh sample, but increased to 7.28 meqO2/kg and then decreased to 4.98 meqO2/kg at the 17th days. The decrease of the PV at the end of the storage may occur owing to decomposition of hydro peroxides into secondary oxidation products. The FFA and TBA content increased significantly (P < 0.01) from 0.22 % of oleic acid to 0.94 % of oleic acid and from 0.25 to 0.58 mg malonaldehyde/kg of meat for fish burgers. A similar trend was also observed by the Yerlikaya et al. (2005) during the refrigerated studies of fish patties from anchovy and Ucak et al. (2011). Increase in FFA results from the enzymatic hydrolysis of esterified lipids (Hwang and Regenstein 1993). Kose et al. (2009) reported that TBA values in whiting burgers increased from 0.21 to 1.66 mg malonaldehyde/kg of meat, 0.23 to 1.79 mg malonaldehyde/kg of meat and 0.44 to 2.87 mg malonaldehyde/kg of meat prepared from unwashed mince products, washed mince products and precooked mince products, respectively. A similar increase in the TBA was observed by Taskaya et al. (2003) in fish burger.

Table 2.

Changes in the Chemical quality of fish burger during refrigerated storage

| Storage period (Days) | Fish burger | ||||

|---|---|---|---|---|---|

| pH | PV (meqO2/kg of fat) | FFA (% of oleic acid) | TBA (mg MA/kg of sample) | TVBN (mg/100 g of sample) | |

| 0 | 6.78 ± 0.00h | 4.62 ± 0.12a | 0.22 ± 0.01a | 0.25 ± 0.01a | 2.02 ± 0.01a |

| 1 | 6.74 ± 0.00g | 5.59 ± 0.21bc | 0.27 ± 0.01b | 0.33 ± 0.01b | 2.58 ± 0.04b |

| 3 | 6.70 ± 0.01f | 6.93 ± 0.21ef | 0.32 ± 0.01c | 0.36 ± 0.01bc | 3.24 ± 0.02c |

| 5 | 6.66 ± 0.01e | 7.28 ± 0.12g | 0.47 ± 0.01d | 0.36 ± 0.01c | 3.58 ± 0.02d |

| 7 | 6.60 ± 0.01d | 6.48 ± 0.12f | 0.55 ± 0.00e | 0.41 ± 0.02d | 3.67 ± 0.03d |

| 9 | 6.58 ± 0.00d | 6.26 ± 0.21de | 0.64 ± 0.01f | 0.42 ± 0.02d | 3.83 ± 0.02e |

| 11 | 6.52 ± 0.01c | 6.13 ± 0.21cd | 0.70 ± 0.01g | 0.48 ± 0.01e | 4.10 ± 0.03f |

| 13 | 6.42 ± 0.01b | 5.66 ± 0.23c | 0.78 ± 0.01h | 0.54 ± 0.01f | 4.30 ± 0.03g |

| 15 | 6.36 ± 0.01a | 5.06 ± 0.21ab | 0.83 ± 0.01i | 0.55 ± 0.01f | 4.50 ± 0.04h |

| 17 | 6.15 ± 0.01a | 4.98 ± 0.22ab | 0.94 ± 0.01j | 0.58 ± 0.02e | 4.78 ± 0.02i |

Each value is represented as the mean ± SD of n = 3

abcdefghMeans followed by the same superscript with in a column are not significantly different (P > 0.01)

Total volatile base nitrogen is known as a product of bacterial spoilage and endogenous enzymes action and its content is often used as an index to assess the keeping quality and shelf life of products (EEC 1995). TVBN content in the fish burgers stored at 4(± 1) °C increased significantly (P < 0.01) during the refrigerated storage period. Metin et al. (2002) observed increase in TVBN value from 10.98 to 19.66 mg/100 g in fish burger stored at refrigerated temperature.

Acceptability limits for the different freshness parameters of fish burger are given in Table 5.

Table 5.

Acceptable limits for different freshness parameters in fish burger stored at refrigerated temperature

| Parameters products | PV (meqO2/kg of fat) | FFA (% of oleic acid) | TBA (mg MA/kg of meat) | TVBN (mg/100 g of sample) |

|---|---|---|---|---|

| Fish burger | 0.34 | 0.94 | 0.55 | 4.60 |

Microbiological analysis

The changes in the total plate count (TPC) during storage were enumerated and the results are presented in Table 3. TPC analyses of fish products did not exceed the maximum levels (7 Log. cfu/g of meat) of microbiological criteria for fresh and frozen fish given by the ICMSF (1978). A steady increase in TPC was observed during refrigerated storage from the initial value of 4.06 × 102 cfu/g to 7.38 × 104 cfu/g. The psychrophilic bacteria count of fish burger were initially 3.2 × 102 cfu/g which reached 5.76 × 104 cfu/g of sample at the end of the storage period. Taskaya et al. (2003) observed an increase from the initial count of 4.04 Log. cfu/g to 8.91 Log. cfu/g in fish burger stored at refrigerated temperature over a period of 21 days. Kilinc (2007) observed increase in total viable count from 5.7 × 102 cfu/g of meat to 1.6 × 106 cfu/g of meat in fish patties from anchovies at the end of 5 days. Baygar et al. (2008) observed a significant increase in the total mesophilic bacterial count in rainbow trout meat balls during storage. Joseph et al. (1984) observed a significant increase in total plate count in fish cutlets during storage at 4 °C. Salmonella spp., Vibrio spp., Staphylococcus aureus, Faecal streptococci, Escherichia coli, yeast and molds were not detected in fish burger during the entire period of refrigerated temperature. This was also found in many studies (Taskaya et al. 2003; Kilinc 2007 and Baygar et al. 2008).

Table 3.

Changes in the Microbial quality of fish burger during refrigerated storage

| Storage period (Days) | Fish Burger | |

|---|---|---|

| TPC (cfu/g of meat) | Psychrophilic count (cfu/g of meat) | |

| 0 | 4.06 × 102 (2.60) | 3.20 × 102 (2.50) |

| 1 | 6.88 × 102 (2.83) | 5.84 × 102 (2.76) |

| 3 | 1.09 × 103 (3.03) | 9.54 × 102 (2.97) |

| 5 | 1.62 × 102 (3.20) | 1.38 × 103 (3.13) |

| 7 | 4.78 × 103 (3.67) | 4.18 × 103 (3.62) |

| 9 | 8.66 × 103 (3.93) | 7.70 × 103 (3.88) |

| 11 | 1.17 × 104 (4.06) | 1.46 × 104 (4.01) |

| 13 | 2.44 × 104 (4.38) | 1.56 × 104 (4.19) |

| 15 | 5.52 × 104 (4.74) | 4.90 × 104 (4.69) |

| 17 | 7.38 × 104 (4.89) | 5.76 × 104 (4.79) |

Each value is represented as mean of two estimates

Figures in the parenthesis indicates Log. psychrophilic count

Cfu colony forming units

Sensory analysis

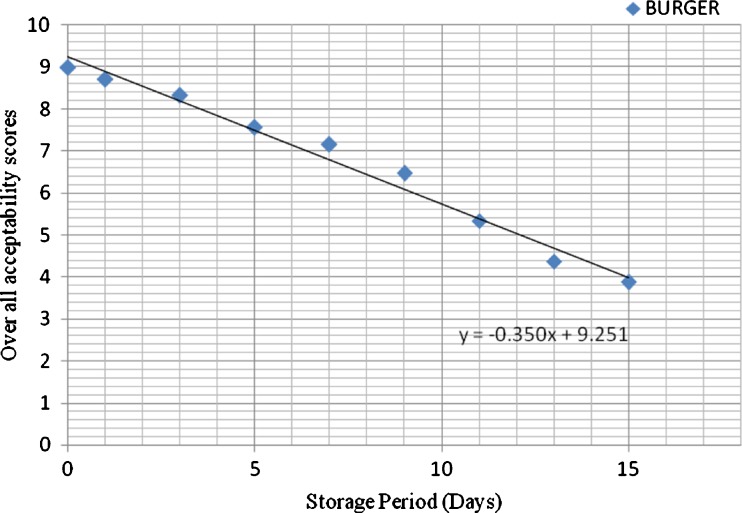

Sensory quality changes and overall acceptability of fish burger are given in Table 4 and 5. The appearance, texture, odor and flavor of the fish burger started decreasing at a significant level of 1 % level. According to the results of overall sensory evaluation, fish burgers were acceptable up to 15 days. Yerlikaya et al. (2005) reported the limit of acceptability for anchovy patties in refrigerated storage for 6 days. Turhan et al. (2001) determined the shelf life of refrigerated raw anchovy (E. encrasicholus) patties for 6 days at 4 °C. Taskaya et al. (2003) reported that fish burger made from rainbow trout was not microbiologically good and should be consumed before 9 days of the storage. The above mentioned studies showed the very similar results with the present study. A negative correlation was observed between storage time and sensory score (−0.991) and the corresponding regression equation is y = 9.25 – 0.35 × (Fig. 1 and Table 6).

Table 4.

Changes in the overall acceptability scores of fish burger during refrigerated storage

| Storage period (Days) | Overall acceptability scores |

|---|---|

| 0 | 8.99 ± 0.17i |

| 1 | 8.71 ± 0.13h |

| 3 | 8.33 ± 0.20g |

| 5 | 7.57 ± 0.15f |

| 7 | 7.16 ± 0.29e |

| 9 | 6.47 ± 0.28d |

| 11 | 5.34 ± 0.29c |

| 13 | 4.73 ± 0.15b |

| 15 | 3.88 ± 0.28a |

| 17 | 2.64 ± 0.18d |

Each value is represented as mean ± SD of n = 7

abcdefghiMeans followed by the same superscript with in a column are not significantly different (P > 0.01)

Fig. 1.

Regression equation of storage period on overall acceptability scores of catla fish burgers during refrigerated storage. Plot of linear regression with time

Table 6.

Correlation coefficient and regression equations for mean overall acceptability scores during storage period and shelf life of products stored at refrigerated temperature

| Products | Regression equation | Correlation coefficient | Shelf-life (Days) |

|---|---|---|---|

| Fish burger | y = 9.25 – 0.35 x | − 0.991a | 15 days |

aSignificance at 1 % level

Conclusion

Quality changes of fish burgers prepared from fresh Catla catla were studied during the storage at 4 °C for 17 days. It was found that burgers prepared from 72.72 % of carp meat were rated as the best and to have higher nutritive values. During the storage period there was significant decrease in moisture (P < 0.05), protein content (P < 0.01). A significant increase (P < 0.01) was observed in the crude fat, ash, chemical analysis and between the sensory attributes. Despite a decline in various sensory qualities with the increase in storage period, the fish burgers were acceptable up to 15 days. It was established that all quality criteria mentioned above including the microbiological analysis were not reached to the maximum limits for the acceptability of fish burgers.

References

- Annual report of Animal Husbandry (2012) Department of Animal Husbandry, Dairying and Fisheries, Ministry of Agriculture, Government of India, New Delhi, 51–68

- AOAC (2000) Official Methods of Analysis of Association of Analytical Chemists INTERNATIONAL, 17th Edition, Suite 500, 481 North Frederick Avenue, Gaithersburg, Maryland 20877–2417 USA

- APHA . In: Compendium of methods for the microbiological examination of foods. Speck ML, editor. Washington: APHA Publication; 1992. [Google Scholar]

- Arekere G. Effect of freezing and frozen storage on the properties of proteins from common carp (Cyprinus carpio) M.F.Sc thesis. Bangalore: University of Agricultural Sciences; 1993. [Google Scholar]

- Baygar T, Erkan N, Mol S, Ozden O, Ucok D, Yildirim Y. Determination of the shelf-life of trout (Oncorhynchus mykiss) raw meat ball that packed under modified atmosphere. Pak J Nutr. 2008;7(3):412–417. doi: 10.3923/pjn.2008.412.417. [DOI] [Google Scholar]

- Conway EJ. Microdiffusion analysis of volumetric error. 5. London: Crospy Lockwood and Son Ltd.; 1962. [Google Scholar]

- EEC Decision 95/149/EC. Total volatile basic nitrogen TVBN limit values for certain categories of fishery products and specifying the analysis method to be used. Off J. 1995;97:84–87. [Google Scholar]

- Elyasi A, Zakipour Rahim Abadi E, Sahari MA, Zare P. Chemical and microbial changes of fish fingers made from mince and surimi of common carp (Cyprinus carpio L., 1758) Int Food Res J. 2010;17:915–920. [Google Scholar]

- Hwang KT, Regenstein JM. Characteristics of mackerel mince lipid hydrolysis. J Food Sci. 1993;58:79–83. doi: 10.1111/j.1365-2621.1993.tb03216.x. [DOI] [Google Scholar]

- International Commission in Microbial Specification for Foods (ICMSF). (1978) Sampling plans for fish and fishery products. In: Micro-organisms in Foods, Sampling for Microbiological Analysis, Principles and Specific Applications Vol 2 International Commission on Micro-biological Specification for Foods (Ed.) pp. 92–104, Toronta, Canada

- IS: 6273 [II] Indian standard guide for sensory evaluation of foods (part II, methods and evaluation cards) New Delhi: Indian Standard Institute; 1971. [Google Scholar]

- Jacobs MB. The chemical analysis of foods and food products. New York: Krieger Publication Co; 1958. pp. 393–394. [Google Scholar]

- Joseph J, Perigreen PA, Thampuran N. Preparation and storage of cutlet from low priced fish. J Fish Technol. 1984;21:70–74. [Google Scholar]

- Kilinc B. Microbiological, sensory and color changes of anchovy (Engraulis encrasicholus) patties during refrigerated storage. J Muscle Foods. 2007;20:129–137. doi: 10.1111/j.1745-4573.2009.00139.x. [DOI] [Google Scholar]

- Kose S, Balaban MO, Boran M, Boran G. The effect of mincing on the quality of refrigerated whiting burgers. J Food Sci Technol. 2009;44:1649–1660. doi: 10.1111/j.1365-2621.2009.01984.x. [DOI] [Google Scholar]

- Metin S, Erkan N, Varlik C. The application of hypoxanthine activity as a quality indicator of cold stored fish burgers. Turk J Vet Anim Sci. 2002;26:363–367. [Google Scholar]

- Olley J, Lovern JA. Phospholipids hydrolysis of cod flesh stored at various temperatures. J Sci Food Agric. 1960;11:644–652. doi: 10.1002/jsfa.2740111109. [DOI] [Google Scholar]

- Sayar S. A study on production of croquet from whiting fillets (Merlangius merlangius euxinus L., 1758). Under graduate thesis. Izmir: Ege University, Faculty of Fisheries; 2001. p. 25. [Google Scholar]

- Sehgal GK, Seghal HS. Development of fish salad from two carp species. J Food Sci Technol. 2003;40:436–438. [Google Scholar]

- Sehgal HS, Sehgal GK, Thind SS, Kaur A, Rehal J. Development of “fish mince pakora” from a cultured carp species, Labeo rohita (Ham.) J Food Process Preserv. 2010;34:15–23. doi: 10.1111/j.1745-4549.2008.00263.x. [DOI] [Google Scholar]

- Siddaiah D, Reddy GVS, Raju CV, Chandrasekhar TC. Changes in lipids, proteins and kamaboko forming ability of silver carp (Hypophthalmichthys molitrix) mince during frozen storage. J Food Res Int. 2001;34:47–53. doi: 10.1016/S0963-9969(00)00127-7. [DOI] [Google Scholar]

- SPSS . SPSS for windows. Release 10. Chicago: 1:SPSS Inc; 2010. [Google Scholar]

- Tarladgis BG, Watts M, Younathan M. A distillation method for the quantitative determination of malonaldehyde in rancid foods. J Am Oil Chem Soc. 1960;37:44–48. doi: 10.1007/BF02630824. [DOI] [Google Scholar]

- Taskaya L, Cakli S, Kisla D, Kilinc B. Quality changes of fish burger from rainbow trout during refrigerated storage. J Fish Aquat Sci. 2003;20:147–154. [Google Scholar]

- Tokur B, Ozkutuk S, Atici E, Ozyurt G, Ozyurt CE. Chemical and sensory quality changes of fish fingers, made from mirror carp (Cyprinus carpio), during frozen storage (−18°C) Food Chem. 2006;99:335–341. doi: 10.1016/j.foodchem.2005.07.044. [DOI] [Google Scholar]

- Turhan S, Evren M, Yazici F. Shelflife of refrigerated raw anchovy (Engraulis encrasicholus) patties. Ege Univ J Fish Aquat Sci. 2001;18:391–398. [Google Scholar]

- Ucak I, Ozogul Y, Durmus M. The effects of rosemary extract combination with vacuum packing on the quality changes of Atlantic mackerel fish burgers. J Food Technol. 2011;46:1157–1163. doi: 10.1111/j.1365-2621.2011.02610.x. [DOI] [Google Scholar]

- Vijayan PK. Report on training programme on retort pouch processing of fish and fish analysis at Tropical Development and Research Institute and Metal Box (R & D), UK. Cochin: Central Institute of Fisheries Technology; 1984. [Google Scholar]

- Yerlikaya P, Gokoglu N, Uran H. Quality changes of fish patties produced from anchovy during refrigerated storage. Eur Food Res Technol. 2005;220:287–291. doi: 10.1007/s00217-004-1035-x. [DOI] [Google Scholar]