Abstract

Rice milling plays a key factor in determining rice quality and value. Therefore accurate quality assessments are critical to the rice industry. This study was undertaken to assess the effect of exposing rice to elevated temperatures during milling, on cooked rice texture and rice flour pasting properties. Two long (Cybonnett and Francis) and one medium (Jupiter) rice (oryzae sativa L.) cultivars were milled using McGill laboratory mill for 30 and 40 s after warmed up the mill before milling. Four different milling temperatures per milling duration were achieved. Cooked rice texture properties were assessed using a uniaxial compression test and rice flour pasting properties measured using a TA-2000 rheometer. Results of this study showed that exposure of rice to high temperatures during milling significantly decreased cooked rice firmness. An increase in milled rice temperature after milling from 10.0 to 13.3 °C resulted in a 5.4 and 8.1 N decrease in cooked rice firmness. Although not always significant, the increase in milled rice temperature during milling resulted in an increase in cooked rice stickiness. The increase in milling temperature also showed significant increase in rice flour pasting properties. Changes in rice functional characteristics were attributed to the changes occurring to rice chemical constituents due to temperature exposure as indicated by the increase in rice protein hydrophobicity. Proteins are known to affect rice starch water holding capacity and other starch gelatinization properties.

Keywords: Cooked rice, Texture, Pasting properties, Milling temperature

Introduction

Milling of rice is usually measured quantitatively by head rice yield (HRY) and qualitatively by the degree of milled (DOM). Therefore, factors affecting such measures are of great importance and thus studied extensively. These factors include planting and pre-harvest treatments, harvest moisture content, drying, storage and milling (Afzalinia et al. 2004; Champagne et al. 2004; Daniels et al. 1998; Daniels et al. 1996; Meullenet et al. 1999; Pearce et al. 2001; Ranalli et al. 2003; Saleh and Meullenet 2007; Wang et al. 2004).

DOM of rice still considers the primary factor that determines rice value (Reid et al. 1998). Milling of rice involves the removal of the most outer layers, namely the hull and bran of the rough rice grain. The efficiency of removing these layers, therefore, would determine the degree to which rice is actually milled. Archer and Siebenmorgen (1995) for instance, indicated that the properties of rice bran are affected by many factors including ambient temperature surrounding the mill and the mill temperature. The authors indicated that the oil in the bran is more viscous at low temperatures, thus difficult to be removed from the kernel than when it is at a warmer temperature; a less viscous state. Siebenmorgen et al. (1998) also studied the effect of air temperature and relative humidity on rice breakage during milling. The authors reported an increase in breakage with the increase in air temperature during milling. However, less breakage of milled rice was reported when milled samples were exposed to the environmental conditions right after milling. This was attributed to the state of rice kernels; a rubbery state that permitted moisture desorption without causing cracks.

Archer and Siebenmorgen (1995) studied the effect of lowering brown rice temperature before milling on rice quality. The authors reported an improvement in HRY. The improvement, however, was not significant when adjusting for degrees of milling. Pan and Thompson (2002), on the same manner, reported significant reduction in HRY when the high cutter bar and milled rice temperature reached 74 °C and 84 °C respectively. Mohapatra and Bal (2004) also reported a similar trend with no indications of rice degree of milling. Recently Pan et al. (2005) investigated the effect of cooling methods, internal and external heat exchanger for McGill No. 3 Mill, on milled rice quality. The authors reported a 1.7 percentage point increase in HRY for every 10 °C reduction in milled rice temperature. However, a decrease in milled rice whiteness was reported.

Changes in the functional properties of rice were long attributed to the changes occurring in rice chemical composition due to various processing of rice. Drying temperature of rice, for instance, was reported to significantly affect rice functionality. Meullenet et al. (1999) reported that drying rice at high temperature (54.3 °C) produced less firm cooked rice kernels, but with higher cohesiveness of mass. During milling, however, the temperature of milled rice usually rises in a high order of magnitude but is of short duration, known as flash temperature (Guha and Chowdhury 1996). Limited information was found in literature on the effect of this rise in temperature during milling on rice functional properties. Therefore, this study was initiated to investigate the effect of milling temperature of rice in determining cooked rice instrumental texture and rice flour pasting properties.

Material and methods

Rice sampling

Two long (Cybonnett and Francis) and one medium (Jupiter) grain rice cultivars, harvested from Keiser and Stuttgart AR at moisture contents (MC) of 19.2, 17.1 and 17.3 % (wet bases (wb)) respectively. Rice samples were brought to the University of Arkansas Rice Processing Program laboratories in Fayetteville, AR, where the rice was cleaned (Carter-Day Dockage Tester, Carter-Day Co., Minneapolis, MN). Rough rice samples were stored in storage containers at a refrigerated temperature (~7 °C) for 4 months before drying and milling. Rough rice samples were then dried in a controlled atmosphere chamber (22 °C/65RH) to a MC of approximately 12.5 % w.b. before milling.

Rough rice from each cultivar was kept at 22 °C in plastic bags for at least 24 h before milling. Duplicate 150 g lots of each rough rice sample were de-hulled using a de-husker (THU-35, Satake, Hiroshima, Japan). A laboratory mill (McGill No. 2, RAPSCO, Brookshire, TX) was warmed up for various durations, to achieve a wide range of final milled rice temperatures, using dummy rice before milling. Rice was milled for 30 and 40 s for four different final milled rice temperatures. Milled rice temperature was measured using a thermocouple. A double-tray sizing device (GrainMan Machinery Mfg. Corp., Miami, FL) was used to separate whole kernels from broken kernels. Only full rice kernels were used throughout this study.

Chemical composition

Milled rice surface lipid content (SLC) of each rice sample was determined in duplicate using a Soxtec system (Avanti 2055, Foss North America, Eden Prairie, MN) according to AACC method 30–25.01 (AACC International 2000a) with modifications to the petroleum ether washing duration (from 30 to 20 min) as described by Matsler and Siebenmorgen (2005).

A cyclone sample mill (Udy, Fort Collins, CO) fitted with a 100-mesh sieve was used for grinding milled rice samples to obtain rice flour from each rice treatment. Protein content of milled rice flour was then determined on duplicate of each treatment using the Kjeldahl procedure, AACC method 46–13.01A (AACC International 2000b). The protein content of rice flour was calculated by multiplying the nitrogen content by 5.95.

Pasting properties measurements

A TA-2000 Rheometer (TA Instruments, Waters LLC New Castle, DE) fitted with a starch-pasting cell was used for measuring the pasting properties of rice flour. Slurries of milled rice treatment (approximately 3 g + 25 ml Distilled water) were stirred at 50 °C for 10 s at 960 RPM before being heated from 50 °C to 95 °C at a heating rate of 12 °C/min and at a constant speed of 160 RPM. The hot paste was held at 95 °C for 2.5 min before being cooled down to 50 °C at a cooling rate of 12 °C/min. The TA software (Rheology Advantage Data Analysis, Version 5.0.38, TA Instruments Ltd. 1994–2003) was used to determine pasting parameters commonly calculated from rheological pasting curves. Duplicate measurements were performed for each treatment.

Protein extraction and surface hydrophobicity

Rice flour (10 g) was homogenized with 150 ml of de-ionized water for 5 min. The slurry was adjusted to pH 11.0 by 1 M NaOH and the suspensions were stirred for 2 h at room temperature. The solubilized protein in the solution was then separated by centrifugation at 3,840 × g for 30 min. This procedure was repeated to extract additional protein from the residue. Proteins in combined supernatants of first and second extractions were isoelectrically precipitated at pH 4.5 and kept at 4 °C for 1 h. The precipitate was recovered by centrifugation at 5,000 × g for 30 min, washed with de-ionized water, adjusted to pH 7.0, freeze dried and stored at 5 °C (Paraman et al. 2008). Isolated proteins were used for surface hydrophobicity determination.

Surface hydrophobicity of the isolated rice protein was determined using hydrophobic fluorescence probes of 1-anilino-8-naphthalene sulfonate (ANS) by the method of Hayakawa and Nakai (1985). Protein solutions (4 ml) were made in concentrations of 0.00125, 0.0025, 0.005, 0.01, and 0.02 % w/v with 0.01 M phosphate buffer (pH 7.0). Then 10 μL of 8 mM ANS in 10 mM phosphate buffer was added into each protein solution and fluorescence intensities of these solutions were measured immediately at 390 nm of excitation and 470 nm of emission with a spectrofluorophotometer (model RF-1501, Shimadzu, Kyoto, Japan). Surface hydrophobicity, expressed as the slope of fluorescence intensity vs. protein concentration, was calculated by linear regression and used as an index of the protein hydrophobicity (S0).

Rice cooking

Rice was cooked using a miniature rice cooker, consisting of a glass-cooking vessel (200 ml in volume and semi-spherical) with a glass top and a heating mantle (TM 102, Glas-Col, Terre Haute, IN), the temperature of which was regulated by a temperature controller (89000–10, Eutech Instruments, Pte Ltd, Singapore). 100 ml water was preheated to boiling before the addition of 20 g of milled rice. Rice was cooked for 20 min to a maximum cooking temperature of 98.5 ± 1 °C, after which the excess water was drained. Cooked rice treatments were fluffed using a plastic fork and kept warm (50 °C) using a temperature-controlled mantle for 5 min before texture measurements. The cooking conditions were identical for all rice treatments to eliminate differences in cooked rice textural properties due to the cooking method.

Instrumental texture measurements

Cooked rice textural properties were determined by a uniaxial single compression method using a Texture Analyzer (TA-XT2 plus, Texture Technologies Corp., Scarsdale, NY/Stable Micro Systems, Godalming, Surrey, UK). 10 whole cooked rice kernels were compressed using a 50-Kg load cell to leave a 0.3 mm gap between two compression plates at the bottom of the compression cycle. The maximum compression force was used as an indicator of cooked rice hardness while the adhesion energy measured during the upward travel of the compression plate was used as an indicator of cooked rice stickiness. Rice treatments were cooked in replicate (i.e., four cooks for each milled rice temperature) and five measurements were taken for each cook. Cooked rice textural properties were obtained using the Texture Exponent software (Stable Microsystems, version 1, 0, 0, 92, Surrey, UK).

Cooked rice moisture content

MC of rice treatment was measured during cooking. Rice treatments were cooked in excess water for 20 min after which approximately 10 g of cooked rice was weighed, in triplicate, and dried at 130 °C for 24 h using a drying oven (Precision, Winchester, VA). Cooked rice MC was calculated as the percentage of moisture weight of cooked rice sample (wb).

Total solids leached during cooking

The total amount of solids leached out during cooking was measured for each treatment. Rice samples were cooked for 20 min in an excess amount of water. Cooked rice was drained and the cooking liquid was weighed and dried at 130 °C for 24 h using a drying oven (Precision, Winchester, VA). The percentage of solids in the cooking gruels was then calculated for each cook (Gujral and Kumar 2003).

Statistical analysis

Cooked rice texture and pasting measurements, MC and total solids leached out during cooking were averaged for each cook and regarded as a replicate. Analysis of variance (ANOVA) was performed using JMP (release 10.0 (SAS institute, Cary, NC). Least significant differences (LSD), at a 5 % level of probability, were determined.

Results and discussion

Milled rice quality characteristics

Milled rice temperatures ranged from 48.8 to 61.6 °C for Cybonnett, 48.6 to 61.9 °C for Francis and from 48.5 to 61.4 °C for Jupiter rice milled for 30 s. Milling for 40 s resulted in an average increase of 6 °C in milled rice temperature (Table 1). Significant variability (P < 0.05) in milled rice temperature was achieved by warming up a McGill # 2 mill for various durations before milling. Our goal was to examine the effect of the change in milled rice temperature, when milling rice for similar durations, on rice functional characteristics.

Table 1.

Milled rice temperature, head rice yield and surface lipid content of rice milled from 30 and 40 s

| Cultivar | Milling durations (Seconds) | Milled rice temperature (°C) | HRY (%) | SLC (%) |

|---|---|---|---|---|

| Cybonnett | 30 | 48.8d | 58.1a | 0.53a |

| 52.6c | 58.2a | 0.54a | ||

| 58.7b | 57.1a | 0.51b | ||

| 61.6a | 57.1a | 0.51b | ||

| 40 | 55.5c | 57.2a | 0.47a | |

| 57.5c | 56.9ab | 0.47a | ||

| 62.1b | 56.7ab | 0.46a | ||

| 68.8a | 55.3b | 0.46a | ||

| Francis | 30 | 48.6d | 56.3a | 0.54a |

| 52.8c | 56.4a | 0.53a | ||

| 58.5b | 57.9a | 0.52a | ||

| 61.9a | 54.4a | 0.52a | ||

| 40 | 55.1d | 55.5a | 0.50a | |

| 58.7c | 54.2ab | 0.49a | ||

| 62.9b | 52.8b | 0.49a | ||

| 67.4a | 51.7b | 0.49a | ||

| Jupiter | 30 | 48.5d | 66.7a | 0.58a |

| 53.1c | 66.6a | 0.57a | ||

| 55.7b | 66.8a | 0.57a | ||

| 61.4a | 66.2a | 0.57a | ||

| 40 | 57.2d | 64.4a | 0.52a | |

| 59.2c | 65.9a | 0.52a | ||

| 62.6b | 63.2a | 0.51a | ||

| 67.2a | 64.8a | 0.53a |

1HRY and SLC represent head rice yield and surface lipid content respectively

2Means of milled rice temperature, HRY and SLC of same cultivar milled for same duration with different letters are significantly (P < 0.05) different according to the LSD

Milled rice SLC ranged from 0.51 to 0.57 %, when milled for 30 s, and from 0.47 to 0.53 %, when milled for 40 s, respectively. As expected, milling of rice for longer durations resulted in decreasing milled rice SLC. This was attributed to the removal of a greater amount of the rice kernel’s caryopsis coat, aleurone, and sub-aleurone layers that are known to be rich in lipid. Results also showed variability in cultivar milling requirements. For instance, a medium grain cultivar, Jupiter, milled for 30 and 40 s had a greater amount of SLC than long grain cultivars, Cybonnett and Francis. This was probably due to intrinsic variations between different rice cultivars including their physical dimension. However, samples milled for the same duration to various milled rice temperatures were not significantly different (P > 0.05) (Table 1). This was critical in our case since degree of milling is known to significantly affect rice functional properties (Saleh and Meullenet 2007; Perdon et al. 2001).

Table 1 also shows the effect of rice milling to various temperatures on HRY. HRY ranged from 55.1 to 58.1 %, 54.4 to 56.3 % and from 66.2 to 66.7 % for Cybonnett, Francis and Jupiter rice samples, respectively, after milling for 30 s. Milling of rice for 40 s decreased HRY. This was attributed to the removal of a greater amount of bran layers as well as greater breakage of rice kernels due to the milling process (Reid et al. 1998; Siebenmorgen and Sun 1994)

Results also showed a decrease, although not significant (P > 0.05), in HRY with the increase in milled rice temperature. Archer and Siebenmorgen (1995) related the decrease in HRY of rice milled at high temperatures to the differences in rice degree of milling. The authors indicated that rice, in fact, needs to reach a sufficiently high temperature in order to remove its bran during milling. This explains the lower SLC of rice cultivars milled to high temperatures as compared with those milled to low temperatures. However, SLC did not vary significantly in this study, indicating that other factors were responsible for the decrease in HRY associated with the milling of rice at high temperatures. Pan and Thompson (2002) for example, suggested that the increase in HRY associated with milling at low temperatures could be due to a reduction in moisture loss and to low breakage of rice during milling.

Cooked rice texture properties

Cooked rice moisture content ranged from 72.8 to 76.7 % for long grain cultivars and from 74.1 to 75.4 % for medium grain (Table 2). Milling of rice to a high milled rice temperature resulted in an increase, although not always significant (P > 0.05), in cooked rice water uptake.

Table 2.

Cooked rice texture properties, moisture uptake and solids leached of rice during cooking of rice exposed to various temperatures during milling

| Cultivar | Milling duration (Seconds) | Temperature (°C) | Firmness (N) | Stickiness (N.s) | MC (%) | Solids leached (%) |

|---|---|---|---|---|---|---|

| Cybonnett | 30 | 48.8 | 79.30a | 7.82a | 74.1ab | 2.32ab |

| 52.6 | 77.04ab | 8.50a | 72.8b | 1.87b | ||

| 58.7 | 76.24b | 7.60a | 74.0ab | 2.26ab | ||

| 61.6 | 73.09c | 8.06a | 75.0a | 2.45a | ||

| 40 | 55.5 | 74.74a | 8.19a | 73.6a | 2.33a | |

| 57.5 | 71.72ab | 9.22a | 75.2a | 2.21a | ||

| 62.1 | 70.92b | 7.78a | 74.8a | 2.37a | ||

| 68.8 | 68.57b | 8.63a | 75.4a | 2.38a | ||

| Francis | 30 | 48.6 | 68.58a | 5.62a | 76.1a | 2.36a |

| 52.8 | 66.30a | 5.84a | 75.7a | 2.23a | ||

| 58.5 | 66.11a | 5.97a | 76.6a | 2.54a | ||

| 61.9 | 60.51b | 6.08a | 76.7a | 2.17a | ||

| 40 | 55.1 | 64.87a | 6.73a | 74.2b | 2.03c | |

| 58.7 | 62.13ab | 6.24a | 75.7ab | 2.16bc | ||

| 62.9 | 62.25ab | 7.24a | 76.2a | 2.28ab | ||

| 67.4 | 59.44b | 7.88a | 75.6ab | 2.35a | ||

| Jupiter | 30 | 48.5 | 55.92a | 8.34a | 74.1a | 2.18a |

| 53.1 | 54.12ab | 8.53a | 74.4a | 2.09a | ||

| 55.7 | 53.81b | 8.92a | 74.2a | 2.08a | ||

| 61.4 | 48.41c | 9.10a | 74.4a | 2.16a | ||

| 40 | 57.2 | 54.65a | 7.62a | 74.4b | 2.24a | |

| 59.2 | 53.22a | 8.06a | 74.7b | 2.19a | ||

| 62.6 | 50.72ab | 8.22a | 75.4a | 2.26a | ||

| 67.2 | 47.29b | 8.36a | 74.6b | 2.15a |

1MC represents moisture content of cooked rice

2Means cooked rice firmness, stickiness, MC and solids leached of same rice cultivar milled for same duration to various milled rice temperatures with different letters are significantly (P < 0.05) different according to the LSD

Table 2 represents the cooked rice texture properties of rice milled for the same durations to various milled rice temperatures. Cooked rice firmness values ranged from 73.1 to 79.3 N and from 68.6 to 74.7 N for Cybonnett, from 60.5 to 68.6 N and from 59.4 to 64.9 N for Francis rice milled for 30 and 40 s respectively. Cooked rice firmness of medium grain, Jupiter, ranged from 48.4 to 55.9 N and from 47.7 to 54.2 N for samples milled for 30 and 40 s respectively. Results showed a significant (P < 0.05) decrease in cooked rice firmness across cultivars and milling degree with the increase in milled rice temperature. Changes in the functional properties of rice chemical composition, due to the exposure to high temperatures during milling, is believed to result in a greater migration of water during cooking. This results in faster hydrate kernels’ core. Accordingly this resulted in greater cooked rice moisture uptake thus producing softer rice.

This is in line with Hamaker and Griffin (1990) that the structural characteristics of proteins influence rice cooking and eating qualities. The formation of protein matrix, when associated with the starch granule, was also reported to have a significant role in cooked rice texture. Protein tends to form a complex with starch that impairs starch granule swelling (Suwannaporn et al. 2007).

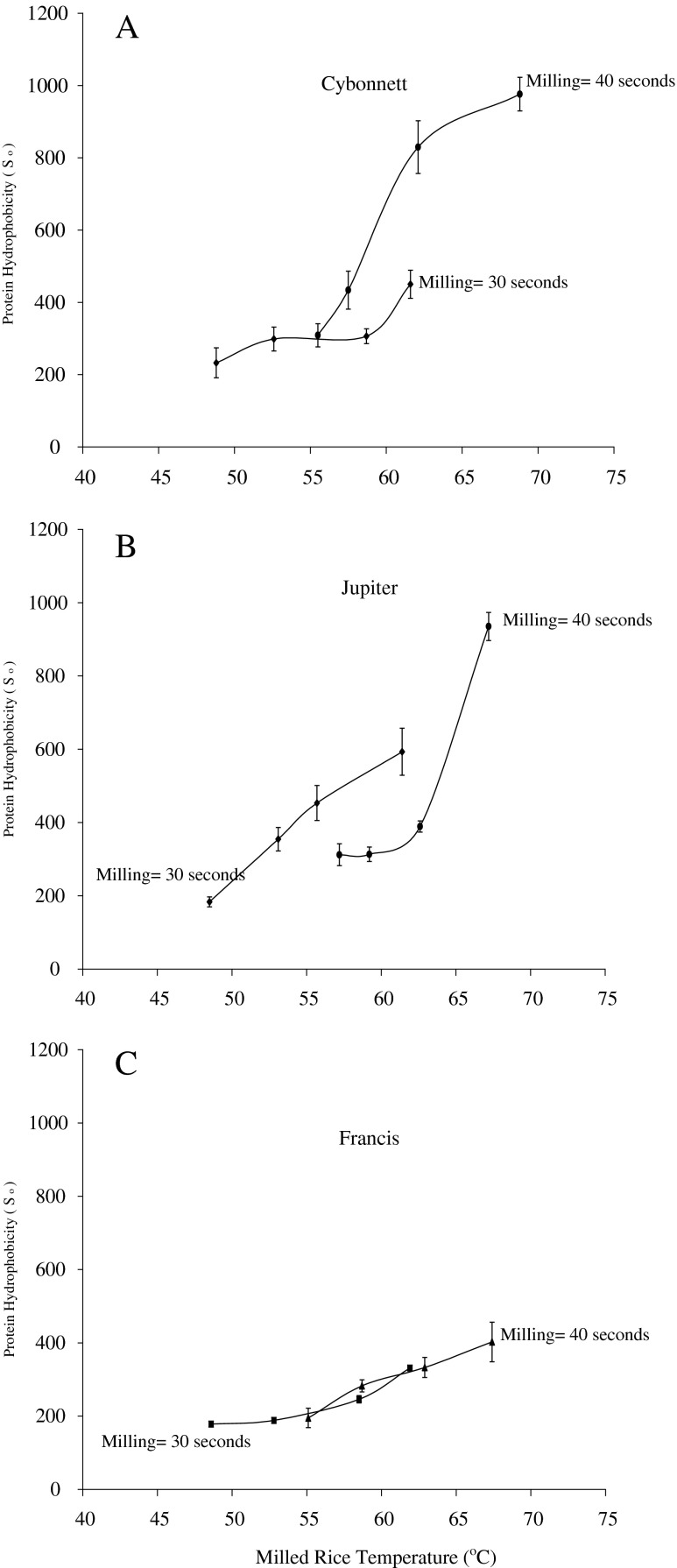

Protein surface hydrophobicity, an indication of protein denaturation, was measured to further investigate factors affecting cooked rice functional properties. Protein surface hydrophobicity is known as any non-covalent change in the secondary, tertiary or quaternary structure of a protein. In general, protein denaturation results in increasing protein surface hydrophobicity due to the exposure of hydrophobic groups that are folded inside the intact protein molecule. This exposure usually results in an increase in the binding ability of proteins with water, hence greater moisture absorption. Results in this study (Fig. 1) showed a significant (P < 0.05) increase in protein surface hydrophobicity with the exposure of rice to high temperatures during milling. Surface hydrophobicity (So) ranged from 177.9 to 976.0 in samples milled to various temperatures. Milling for 40 s resulted in greater surface hydrophobicity (So) compared with samples milled for 30 s across cultivars, an indication of greater protein denaturation when milling for longer durations. The increase in surface protein hydrophobicity provides evidence that milling of rice induced unfolding/denaturation of rice proteins, thus affecting various rice functional properties.

Fig. 1.

Isolated protein surface hydrophobicity of milled rice a Cybonnett, b Jupiter, and c Francis exposed to various temperatures during milled for 30 and 40 s

The effect of milling rice temperature on cooked rice stickiness is presented in Table 2. Cooked rice stickiness increased, although not significantly (P > 0.05), with the increase in milled rice temperature. Milling for longer durations produced stickier rice. Stickiness values ranged from 7.83 to 8.50, 5.62 to 6.08 and from 8.34 to 9.10 N.s for Cybonnett, Francis and Jupiter, respectively, when milled for 30 s; and from 7.78 to 9.22, 6.24 to 7.88 and from 7.62 to 8.36 N.s when milled for 40 s.

The total amount of solids leached during cooking seems to play a major role in determining cooked rice stickiness. Cooked rice stickiness and total solids leached was negatively correlated during cooking (r = −0.19 to −0.76, except for Francis samples milled for 40 s where r = 0.77). The removal of cooked rice gruel during draining probably limited the formation of a gel matrix surrounding rice kernels producing lower stickiness values. The increase in cooked rice stickiness with the exposure to high temperature during milling provided more evidence that changes occurring to rice chemical composition resulted in formation of a greater degree of gel matrix surrounding rice kernels and thus contributed to the increased cooked rice stickiness.

Stickiness of cooked rice is usually manifested by a sequence of events, based on the extent of occupation of spaces by water occurring during cooking and the interaction of rice chemical components (Adhikari et al. 2001). Initially, where liquid occupied only part of the total space between rice kernels, strong liquid bridges along the wetting surface are believed to develop. In the case of rice during cooking, negative capillary pressure is usually developed in the entire liquid space resulting in an increased tensile strength of the wet particles (Papadakis and Bahu 1992). Adhikari et al. (2001) reported a formation of bridges that would eventually transform into solid bridges, thus creating strong binding forces. These bridges are believed to be of starch and protein molecular bonds that was reported by Chrastil (1990), Hamaker and Griffin (1990 and 1993) causing the increase in cooked rice stickiness.

Rice flour pasting properties

Rice flour pasting properties, as impacted by the exposure of rice to high temperatures during milling, are presented in Table 3. Peak viscosity of rice flour ranged from 188.4 to 210.6 and from 196.1 to 218.2 RVU for Cybonnett and Frances rice milled for 30 and 40 s respectively. Medium grain Jupiter flour peak viscosity ranged from 212.6 to 222.1 and from 223.2 to 229.4 RVU when milled for 30 and 40 s. Moreover, results indicated that an increase in milled rice temperature of 12.3 or 13.3 °C resulted in a 5.4 and 5.6 RVU increase in peak viscosity of long grain rice. An increase of 10.0 and12.9 °C of milled rice temperature resulted in 7.5 and 9.5 RVU increase in peak viscosity for medium grain Jupiter. This result confirms that the exposure of rice to high temperatures during milling significantly impacted rice chemical constituents. The formation of starch protein networks is believed to provide mechanical support for starch granules and protect them against rupture. This in turns inhibits the thixotropic (shear thinning) nature of rice pastes, resulting in greater forces required to shear the paste slurry and consequently greater peak viscosity. Hamaker and Griffin (1990) also reported a potential effect of proteins on starch gelatinization. The endosperm matrix protein and protein associated with starch granules, respectively, were indicated to influence rice flour starch gelatinization properties.

Table 3.

Milled rice flour pasting properties of rice exposed to various temperatures during milling for 30 and 40 s

| Cultivar | Milling duration (Sec.) | Milled rice temp. (°C) | Peak Visc. (RVU) | Final Visc. (RVU) | Breakdown (RVU) | Setback (RVU) |

|---|---|---|---|---|---|---|

| Cybonnett | 30 | 48.8 | 188.4d | 161.3b | 106.7a | 79.6b |

| 52.6 | 192.1c | 169.3ab | 107.3a | 84.5a | ||

| 58.7 | 195.5a | 176.7a | 106.3a | 87.4a | ||

| 61.6 | 194.0b | 173.6a | 107.5a | 87.2a | ||

| 40 | 55.5 | 194.6c | 167.2c | 108.7c | 81.3bc | |

| 57.5 | 198.3b | 167.8c | 111.2a | 80.7c | ||

| 62.1 | 198.6b | 172.1b | 110.1ab | 83.6b | ||

| 68.8 | 200.1a | 178.1a | 109.6bc | 87.6a | ||

| Francis | 30 | 48.6 | 206.7c | 164.4c | 118.0b | 75.8c |

| 52.8 | 207.4c | 169.6b | 117.8b | 79.9b | ||

| 58.5 | 209.9b | 171.1b | 122.7a | 83.8a | ||

| 61.9 | 212.1a | 173.0a | 123.0a | 83.8a | ||

| 40 | 55.1 | 207.9c | 171.7b | 117.5a | 81.3b | |

| 58.7 | 209.7b | 175.4ab | 117.6a | 83.4ab | ||

| 62.9 | 212.5a | 178.3a | 119.0a | 84.8a | ||

| 67.4 | 213.4a | 179.1a | 119.1a | 84.8a | ||

| Jupiter | 30 | 48.5 | 212.6c | 132.7c | 126.4c | 46.4a |

| 53.1 | 214.4bc | 135.0b | 127.1bc | 47.7a | ||

| 55.7 | 216.4b | 135.5b | 128.0b | 47.2a | ||

| 61.4 | 220.1a | 136.6a | 130.7a | 47.2a | ||

| 40 | 57.2 | 220.0c | 132.1c | 133.0c | 45.1b | |

| 59.2 | 220.4c | 134.7b | 131.3d | 45.5b | ||

| 62.6 | 226.0b | 135.6a | 136.5b | 46.1a | ||

| 67.2 | 229.5a | 136.2a | 138.9a | 45.6ab |

1Means rice flour peak, final, breakdown and setback viscosities of rice milled for same duration to various milled rice temperatures with different letters are significantly (P < 0.05) different according to the LSD

Table 3 also shows rice flour breakdown viscosity for milled rice exposed to various temperatures during milling. Breakdown is usually associated with the tendency of gelatinized starch granules to break during holding at high temperature, accompanied with continuous shearing (Han and Hamaker 2001). Breakdown is usually calculated from a resulting viscogram by subtracting trough from peak viscosity. The increase in rice flour breakdown viscosity, although not always significant (P < 0.05), suggests a greater protection of the starch granule integrity. This probably is due to the increased affinity of proteins to interact with starch, as a result of protein denaturation. The resulting formation of protein–starch complexes tends to increase rice flour peak viscosity.

Final viscosity and setback followed similar trends as those of peak viscosity (Table 3). Results showed a significant (P < 0.05) increase in paste viscosities with the exposure of milled rice to high temperatures during milling. Leached starch and denatured protein molecules are believed to re-associate during the cooling step of the flour paste formation process. This indicates a greater impact of starch protein interactions during retro-gradation on rice flour paste.

Conclusion

Changes occurring to rice chemical composition during processing play important role in determining rice functional properties. This study demonstrated that changes in rice protein (i.e. due to the exposure of rice to temperature during milling) impacted cooked rice texture and rice flour pasting properties. Our results showed that exposing rice to higher temperature during milling resulted in exposing greater amount of protein hydrophobic groups, which in turn, increased the susceptibility of rice starch for swelling and leaching, hence, greater amount of water available for starch. This ultimately decreased cooked rice firmness. Although increased stickiness of cooked rice were credited mostly to the increase of leached soluble starch molecules, protein–starch interactions could also be the major factor responsible for the changes in cooked rice properties as a consequence of changes in the structure and properties of proteins due to the exposure to temperature during milling.

Results from this study indicated that the milling protocol of rice should be controlled when reporting rice quality/functional properties with the temperature of McGill # 2 milling chamber reported when assessing rice quality.

References

- AACC International . Approved methods of analysis, 11th Ed. Method 30–25.01. Crude fat in wheat, corn, and soy flour, feeds, and mixed feeds. St. Paul: AACC International; 2000. [Google Scholar]

- AACC International . Approved methods of analysis, 11th Ed. Method 46–13.01. Crude protein—Micro-Kjeldahl method. St. Paul: AACC International; 2000. [Google Scholar]

- Adhikari B, Howes T, Bhandari BR, Truong V. Stickiness in foods: A review of mechanisms and test methods. Int. J. Food Prop. 2001;4:1–33. doi: 10.1081/JFP-100002186. [DOI] [Google Scholar]

- Afzalinia S, Shaker M, Zare E. Comparison of different rice milling methods. Canadian Bio-systems Eng. 2004;3:3.63–3.66. [Google Scholar]

- Archer TR, Siebenmorgen TJ. Milling quality as affected by brown rice temperature. Cereal Chem. 1995;72:304–307. [Google Scholar]

- Champagne ET, Bett-Garber KL, McClung AM, Bergman C. Sensory characteristics of diverse rice cultivars as influenced by genetic and environmental factors. Cereal Chem. 2004;81:237–243. doi: 10.1094/CCHEM.2004.81.2.237. [DOI] [Google Scholar]

- Chrastil J. Protein–starch interactions in rice grains. Influence of storage on oryzenin and starch. J. Agr Food Chem. 1990;38:1804–1809. doi: 10.1021/jf00099a005. [DOI] [Google Scholar]

- Daniels MJ, Marks BP, Meullenet JF, Siebenmorgen TJ (1996) Effects of rice storage history on the end-use quality of long-grain rice. B.R. Wells Arkansas Rice Research Studies. 160–165

- Daniels MJ, Marks BP, Siebenmorgen TJ, McKnew RW, Meullenet JF. Effects of long-grain rough rice storage history on end-use quality. J Food Sci. 1998;63:832–835. doi: 10.1111/j.1365-2621.1998.tb17910.x. [DOI] [Google Scholar]

- Guha DR, Chowdhury SK. The effect of surface roughness on the temperature at the contact between sliding bodies. Wear. Ind. Lubricat. Tribology. 1996;197:63–73. [Google Scholar]

- Gujral HS, Kumar V. Effect of accelerated aging on the physicochemical and textural properties of brown and milled rice. J Food Eng. 2003;59:117–122. doi: 10.1016/S0260-8774(02)00438-7. [DOI] [Google Scholar]

- Hayakawa S, Nakai S (1985) Relationships of hydrophobicity and net charge to the solubility of milk and soy proteins. J Food Sci 50: 486–490

- Hamaker B, Griffin VK. Changing the visco-elastic properties of cooked rice through protein disruption. Cereal Chem. 1990;67:261–264. [Google Scholar]

- Hamaker BR, Griffin VK. Effect of disulfide bond-containing protein on rice starch gelatinization and pasting. Cereal Chem. 1993;70:377–380. [Google Scholar]

- Han XZ, Hamaker BR. Amylopectin fine structure and rice starch paste breakdown. J Cereal Sci. 2001;34:279–284. doi: 10.1006/jcrs.2001.0374. [DOI] [Google Scholar]

- Matsler A, Siebenmorgen TJ. Evaluation of operating conditions for surface lipid extraction from rice using a Soxtec system. Cereal Chem. 2005;82:282–186. doi: 10.1094/CC-82-0282. [DOI] [Google Scholar]

- Meullenet JF, Marks B, Griffin K, Daniels MJ. Effect of rough rice drying and storage conditions on sensory profiles of cooked rice. Cereal Chem. 1999;76:483–486. doi: 10.1094/CCHEM.1999.76.4.483. [DOI] [Google Scholar]

- Mohapatra D, Bal S. Wear of rice in an abrasive milling operation, part II: Prediction of bulk temperature rise. Biosystems Eng. 2004;89:101–108. doi: 10.1016/j.biosystemseng.2004.05.012. [DOI] [Google Scholar]

- Pan Z, Thompson JF (2002) Improvement of accuracy and consistency of rice sample milling. Research Progress Report of California Rice Research Board

- Pan Z, Thompson JF, Amaratunga KSP, Anderson T, Zheng X. Effect of cooling methods and milling procedures on the appraisal of rice milling quality. Transactions of the ASAE. 2005;48:1865–1871. doi: 10.13031/2013.19984. [DOI] [Google Scholar]

- Papadakis SE, Bahu RE. The sticky issue of drying. Drying Tech. 1992;10:817–837. doi: 10.1080/07373939208916484. [DOI] [Google Scholar]

- Paraman I, Hettiarachchy NS, Schaefer C, Beck MI. Physicochemical properties of rice endosperm proteins extracted by chemical and enzymatic methods. Cereal Chem. 2008;83:663–667. doi: 10.1094/CC-83-0663. [DOI] [Google Scholar]

- Pearce MD, Marks BP, Meullenet JF. Effect of postharvest parameters on functional changes during rough rice storage. Cereal Chem. 2001;78:354–357. doi: 10.1094/CCHEM.2001.78.3.354. [DOI] [Google Scholar]

- Perdon AA, Siebenmorgen TJ, Mauromoustakos A, Griffin VK, Johnson ER. Degree of milling effects on rice pasting properties. Cereal Chem. 2001;78:205–209. doi: 10.1094/CCHEM.2001.78.2.205. [DOI] [Google Scholar]

- Ranalli RP, Howell TA, Jr, Siebenmorgen TJ. Effects of controlled ambient aeration on rice quality during on-farm storage. Cereal Chem. 2003;80:9–12. doi: 10.1094/CCHEM.2003.80.1.9. [DOI] [Google Scholar]

- Reid JD, Siebenmorgen TJ, Mauromoustakos A. Factors affecting the slope of head rice yield vs. degree of milling. Cereal Chem. 1998;75:738–741. doi: 10.1094/CCHEM.1998.75.5.738. [DOI] [Google Scholar]

- Saleh M, Meullenet JF. The effect of moisture content at harvest and degree of milling (based on surface lipid content) on the texture properties of cooked long-grain rice. Cereal Chem. 2007;84:119–124. doi: 10.1094/CCHEM-84-2-0119. [DOI] [Google Scholar]

- Siebenmorgen TJ, Sun H. Relationship between milled rice surface fat concentration and degree of milling as measured with a commercial milling meter. Cereal Chem. 1994;71:327–329. [Google Scholar]

- Siebenmorgen TJ, Nehus ZT, Archer TR. Milled rice breakage due to environmental conditions. Cereal Chem. 1998;75:149–152. doi: 10.1094/CCHEM.1998.75.1.149. [DOI] [Google Scholar]

- Suwannaporn P, Pitiphunpong S, Champangern S. Classification of rice amylose content by discriminant analysis of physicochemical properties. Starch-Starke. 2007;59:171–177. doi: 10.1002/star.200600565. [DOI] [Google Scholar]

- Wang L, Siebenmorgen TJ, Master AD, Bautista RC. Effect of rough rice moisture content at harvest on peak viscosity. Cereal Chem. 2004;81:389–391. doi: 10.1094/CCHEM.2004.81.3.389. [DOI] [Google Scholar]