Abstract

Wellbore cement, a procedural component of wellbore completion operations, primarily provides zonal isolation and mechanical support of the metal pipe (casing), and protects metal components from corrosive fluids. These are essential for uncompromised wellbore integrity. Cements can undergo multiple forms of failure, such as debonding at the cement/rock and cement/metal interfaces, fracturing, and defects within the cement matrix. Failures and defects within the cement will ultimately lead to fluid migration, resulting in inter-zonal fluid migration and premature well abandonment. Currently, there are over 1.8 million operating wells worldwide and over one third of these wells have leak related problems defined as Sustained Casing Pressure (SCP)1.

The focus of this research was to develop an experimental setup at bench-scale to explore the effect of mechanical manipulation of wellbore casing-cement composite samples as a potential technology for the remediation of gas leaks.

The experimental methodology utilized in this study enabled formation of an impermeable seal at the pipe/cement interface in a simulated wellbore system. Successful nitrogen gas flow-through measurements demonstrated that an existing microannulus was sealed at laboratory experimental conditions and fluid flow prevented by mechanical manipulation of the metal/cement composite sample. Furthermore, this methodology can be applied not only for the remediation of leaky wellbores, but also in plugging and abandonment procedures as well as wellbore completions technology, and potentially preventing negative impacts of wellbores on subsurface and surface environments.

Keywords: Physics, Issue 93, Leaky wellbores, Wellbore cement, Microannular gas flow, Sustained casing pressure, Expandable casing technology.

Introduction

The reported experimental procedure has two main components that are critical: composite cylinders that simulate wellbores and the expansion fixture that is used to carry out mechanical manipulation of the cement.

Wellbores are the main gateway for production of subsurface fluids (water, oil, gas, or steam) as well as injection of various fluids. Regardless of its function, the wellbore is required to provide a controlled flow of produced/injected fluids. Wellbore construction has two distinct operations: drilling and completion. Wellbore cement, part of the completions procedure, primarily provides zonal isolation, mechanical support of the metal pipe (casing), and protection of metal components from corrosive fluids. These are essential elements of uncompromised, fully functioning wellbores. The integrity of the wellbore cement sheath is a function of the chemical and physical properties of the hydrated cement, the geometry of the cased well, and the properties of the surrounding formation/formation fluids2,3. Incomplete removal of drilling fluid will result in poor zonal isolation since it prevents formation of strong bonds at interfaces with rock and/or metal. Cement sheaths can be subjected to many types of failure during the life of a well. Pressure and temperature oscillations caused by completion and production operations contribute to the development of fractures within the cement matrix; debonding is caused by pressure and/or temperature changes and cement hydration shrinkage4,5,6. The result is almost always presence of microannular fluid flow, although its occurrence can be detected early or after years of service life.

Heathman and Beck (2006) created a model of cemented casing subjected to over 100 pressure and temperature cyclic loads, which showed visible debonding, initiation of cement cracks which can pose preferential pathways for migrating fluid7. In the field, the expansion and contraction of metal components of a wellbore will not coincide with those of cement and rock, causing interfacial debonding and formation of a microannulus, leading to an increase in permeability of the cement sheath. An additional casing loading can cause the propagation of radial cracks in the cement matrix once the tensile stresses exceed the tensile strength of the material8. All of the aforementioned cement failures can result in micro-channeling, which leads to gas migration, the occurrence of SCP, and long-term environmental risks.

A considerable number of producing and abandoned wells with SCP constitute a potentially new source of continuous natural gas emission9. The analysis conducted by Watson and Bachu (2009) of 315,000 oil, gas, and injection wells in Alberta, Canada also showed that wellbore deviation, well type, abandonment method, and the quality of cement are key factors contributing to potential well leakage in the shallower part of the well10. The existing remedial operations are costly and unsuccessful; the squeeze cementing, one of the most commonly used remedial techniques, has a success rate of just 50%11.

In this paper we report on the evaluation of the Expandable Casing Technology (ECT) as a new remediation technique for leaky wellbores12,13. ECT can be applied in new or existing wells14. The first commercial installation of this technology was performed by Chevron on a well in shallow waters of the Gulf of Mexico in November 1999 15. The current operating envelope for expandable tubulars encapsulates an inclination of 100° from vertical, temperature up to 205 °C, mud weight to 2.37 g/cm3, a depth of 8,763 m, hydrostatic pressure of 160.6 GPa and a tubular length 2,092 m 16. A typical expansion rate for solid expandable tubulars is approximately 2.4 m/min 17.

This study offers a unique approach to the adaptation of ECT technology as a new remediation operation for SCP. The expansion of the steel pipe compresses the cement which would result in closure of the gas flow at the interface and seal the gas leak. It is important to mention that the focus of this study is the sealing of an existing microannular gas flow, therefore we only focused on that as a possible cause of leaky wellbores. In order to test the effectiveness of newly adapted technology for this purpose, we designed a wellbore model with an existing microannular flow. This is obtained by rotating the inner pipe during cement hydration. This is not to simulate any field operations, but simply to fast-forward what would happen after decades of thermal and pressure loading in a wellbore.

Protocol

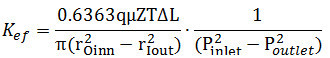

1. Composite Sample (Figure 1)

NOTE: Most cement jobs in the Gulf of Mexico (USA) are done using Class H cement18, therefore, the same type of cement was used to perform the lab experiments to simulate field-like conditions, the potential applicability of this technology for SCP remediation in the Gulf of Mexico.

- Sample preparation NOTE: The 61-cm long sample consists of two grade B electrically resisted welded (ERW) carbon steel pipes (Figure 1). The inner pipe is 61 cm long and has a 6 cm outside diameter (OD) with 2.8 mm wall thickness. The outer pipe is 59.7 cm long, has 10 cm OD and a wall thickness of 5.7 mm. Yield strength and tensile strength of the pipes are 241 MPa and 414 MPa, respectively.

- Drill 12 holes of 2.4 mm on the outer pipe to provide the relief of pressure during expansion and mimic porosity of rocks in field conditions. Drill eight 8.6 mm holes next on the outer pipe, 90° apart with four holes 13 cm from the top and four holes 53 cm from the top.

- Thread these holes with 3.2 mm NPT (National Pipe Thread) threading tip to allow connection with pipe fittings and nylon tubing manifold assembly on the bottom (inlet) and top (outlet) side of the sample. Ensure that the inlet and outlet ports are 40.64 cm apart and are used for running of pre- and post-expansion multi-rate gas flow-through experiments.

- Coat outer pipe with anti-corrosion spray to prevent corrosion during the curing period which could interfere with the experiments due to formation of iron hydroxide and corrosion products could cause microfracturing of cement. NOTE: This scenario will be tested in the future experiments as corrosion of metal is often present in wellbore systems.

- Machine out the welding bead on the inside wall of the inner pipe.

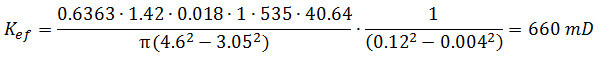

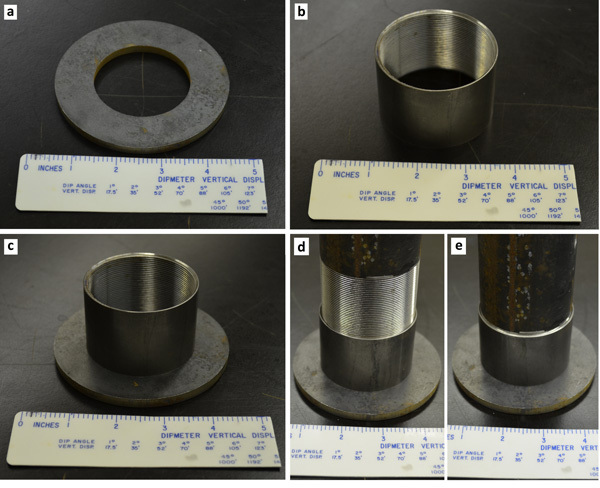

- Cut custom-made steel coupling to a length of 4.5 cm, from 6.35 cm OD pipe. Thread the piece on the inside wall and weld it to the 0.63 cm thick steel plate ring (Figure 2). Thread the bottom part of the inner pipe on the outside wall in length of 4.5 cm to allow connection with the welded coupling, as shown in Figure 2.

- Weld the outer pipe to the steel plate ring.

- Lubricate the inner pipe’s outside wall with petroleum jelly and baking spray along its entire length. Screw the inner pipe into the coupling to finish the composite sample assembly.

- Cement the volume between inner and outer pipes with 1.57 g/cm3 cement slurry, 0.87 w/c ratio.

- Cure samples in a water bath at ambient conditions for a minimum period of 28 days. Keep the pH of the water bath between 12 and 13 by adding Ca(OH)2 to the water to maintain high pH environment.

- Preparation of 13.1 lb/gal cement slurry (for volume of 2.2 L)

- Pour 1,350 g of water into the 4 L, 3.75 horsepower laboratory blender and pre-hydrate 30 g (2% by weight of cement) of bentonite for 5 min on low speed (30,000 x g).

- After 5 min, pour 5 ml of defoaming agent and 1,500 g of cement powder into the blender and shear for 40 sec on high speed of 51,755 x g. Pour the cement slurry into the annulus of the pipe assembly and cover with a wet cloth and plastic wrap to avoid exposure to air and prevent carbonation of cement.

- Six hours after the cement slurry is poured between the pipes, rotate the inner pipe a quarter-turn back and forth every 15 min for the next 20 hr of cement hydration to prevent cement bonding with the inner pipe and create a microchannel (required for microannular gas flow).

- Place the cemented composite sample horizontally in the water bath for a minimum period of 28 days. Ensure that the water bath has a pH value of around 13 which is achieved by adding 100 g of Ca(OH)2 into 20 L of water.

2. Pre-expansion Flow-through Experiments

Screw 3.2 mm fittings into four inlet and outlet ports on the outer pipe of the sample. Connect inlet and outlet manifolds with pressure transducers to the fittings (Figure 5).

Pressurize gas cylinder to initial inlet pressure of 50 kPa. Turn on computer software to record pressures.

Open the flow meter and begin the flow-through test. Monitor inlet and outlet pressures on the screen for 1 min, as shown in Figure 6.

Pressurize gas cylinder to inlet pressure of 172 kPa and monitor the pressure for another 2 min.

End flow-through experiment and pressure recording. Close the gas cylinder and vent the remaining gas into the atmosphere. Dismantle the manifolds and cover top of the sample with wet cloth while powering the expansion unit, to prevent carbonation and drying of cement.

Coat the inside wall of the inner pipe with lubricant for smooth running of the expansion cone and the sample is ready for expansion.

3. Expansion Setup and Expansion Procedure

Fully retain the expansion mandrel from the lower housing by the hydraulic cylinder, as shown in Figure 4a. Place the composite sample with hydrated cement in the lower sample housing of the fixture through the opening at the top (Figure 4b).

Fully elongate the expansion mandrel through the sample after which the expansion cone with desired expansion ratio (Figure 3) is slipped onto it, as shown in Figure 4c. Screw the retaining mandrel onto expansion mandrel, then screw the retaining mandrel guide onto the lower connector of the lower housing. The sample is ready for expansion.

Power the hydraulic unit to an optimum pressure of 10.3 MPa, and turn on the computer software for axial force recording.

Activate the control switch to retract the expansion mandrel and pull the expansion through the inner pipe of the sample, thus expanding the pipe and compressing the cement sheath. Expand samples to the length of 40.64 cm (Figure 4d) and then elongate the expansion mandrel into original position. Stop recording of axial forces.

Unscrew the retaining mandrel guide and remove the retaining mandrel. Take off the expansion cone from the expansion mandrel and fully retract the mandrel in order to remove the sample form the lower housing.

After the sample is removed, prepare it for post-expansion multi-rate gas flow-through experiments.

4. Post-expansion Multi-rate Flow-through Experiments

Clean inlet and outlet ports from any excess of squeezed cement paste.

Screw pipe fittings into four inlet and outlet ports on the outer pipe of the sample. Connect inlet and outlet manifolds to the fittings, as shown in Figure 5.

Pressure the gas cylinder to initial inlet pressure of 172 kPa. Turn on computer software to record pressures.

Open the flow meter and begin the flow-through test. Monitor inlet and outlet pressures on the screen (Figure 6).

After 5 min, pressurize the gas cylinder to inlet pressure of 345 kPa and monitor the pressures for another 5 min.

After 5 min increase the inlet pressure to 517 kPa.

After 5 min increase the inlet pressure to final inlet pressure of 690 kPa for another 5 min.

End the flow-through experiment and pressure recording. Close the gas cylinder and vent the remaining gas into the atmosphere. Dismantle manifolds from the sample.

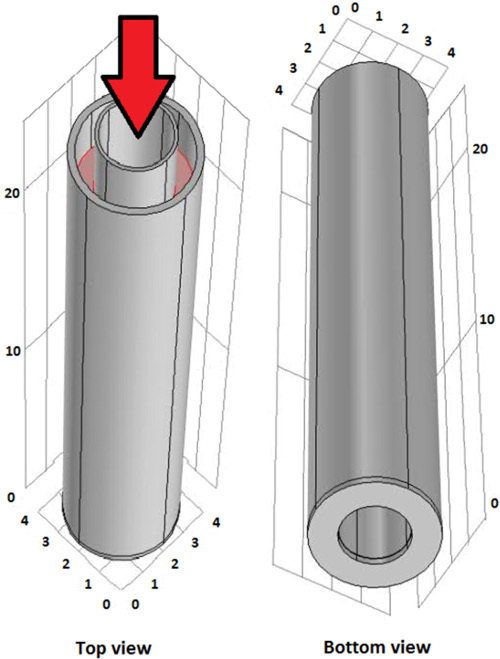

5. Calculations of the Effective Permeability of the Microannulus

NOTE: The main purpose of this study was to provide qualitative information regarding existence of gas flow before and after expansion. The experimental design does not possess sophisticated components to be able to measure the width of the channel and flow rate accuracy. During these preliminary experiments sealing of gas flow was the main focus. Therefore, any of permeability calculations shown here are more semi-quantitative and not main goal of the study.

For calculation of the effective permeability, use the constant nitrogen flow rate of approximately q=1.42 cm3/sec upon pressure stabilization. The gas deviation factor for nitrogen at ambient conditions is Z=1 and viscosity μ=0.018 cP. Conduct all the flow-through tests at ambient conditions of T=535 ºR.

Calculate the area of the cemented annular space by taking inner radius of the outer pipe, rOinn=4.6 cm, and outer radius of the inner pipe, rIout=3.05 cm. The distance between inlet and outlet ports (ΔL) is 40.64 cm. Pressure differential (Pinlet-Poutlet), recorded by inlet and outlet pressure transducers, is the only variable used in calculations of effective permeability of the pre-manufactured microannulus (Kef)19:

Eq. 1 q – nitrogen flow rate [cm3/sec] Kef – effective perm. of microannulus [mD] rIout – ID of outer pipe [cm] rOinn

– OD of inner pipe [cm] µ – gas viscosity [cP] Z– gas deviation factor T – temperature [ºR] ΔL – distance between pressure transducers [cm] Pinlet – inlet pressure [atm] Poutlet – outlet pressure [atm]

Eq. 1 q – nitrogen flow rate [cm3/sec] Kef – effective perm. of microannulus [mD] rIout – ID of outer pipe [cm] rOinn

– OD of inner pipe [cm] µ – gas viscosity [cP] Z– gas deviation factor T – temperature [ºR] ΔL – distance between pressure transducers [cm] Pinlet – inlet pressure [atm] Poutlet – outlet pressure [atm]Substitute all of the above values into the Equation 1 and calculate the effective permeability as shown below in Example 1. The inlet pressure recorded during pre-expansion flow-through experiment was Pinlet=12 kPa (0.12 atm) while the outlet pressure transducer was Poutlet=0.4 kPa (0.004 atm). Example 1:

Representative Results

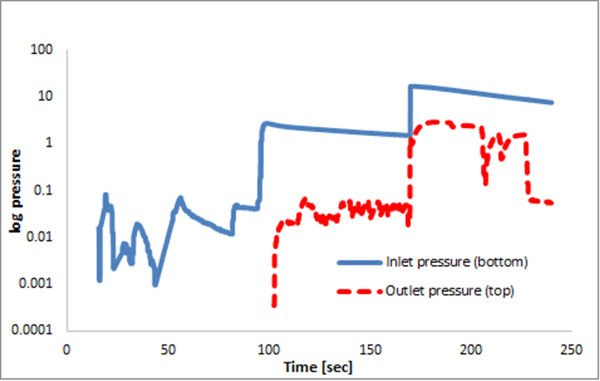

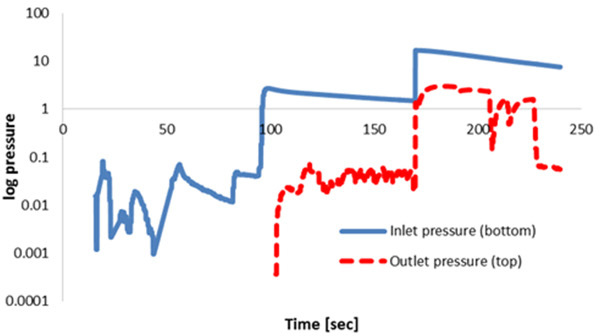

Pre-expansion gas flow-through tests on the composite sample showed pressure recording on the outlet pressure transducer, confirming gas flow through the pre-manufactured microannulus (Figures 7 and 8). Initial conditions were kept the same where initial inlet pressure was 103 kPa and the gas flow rate was kept at 85 ml/min for that period. The time lag in pressure recording between the inlet and outlet pressure transducers was 7.5 seconds, while the highest pressures recorded after increasing the inlet pressure to 172 kPa were 117 kPa (inlet) and 20.7 kPa (outlet). Due to preferential flow of gas through the microannulus, the entire permeability is taken as the effective permeability of the microannulus (Kef). Stabilized pressures used in Kef calculations were Pinlet=12 kPa and Poutlet=0.4 kPa, giving a microannulus effective permeability of Kef=0.66 D. Any residual stress within the cement matrix due to pipe expansion and its effect on permeability is negligible.

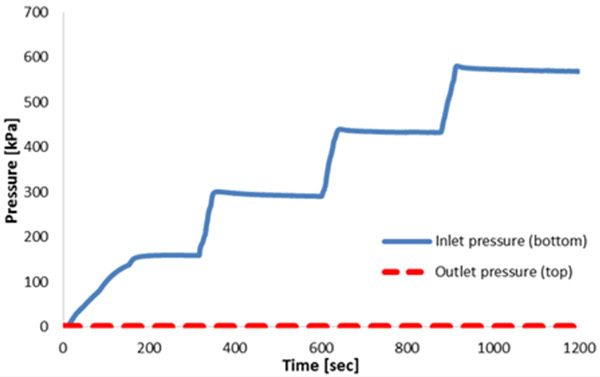

The second gas flow-through test was run immediately after imposing an 8% expansion ratio, with a gradual increase in inlet pressure by 172 kPa every five minutes from an initial pressure of 172 kPa to a final pressure of 690 kPa. The test showed no pressure recording on the outlet pressure transducer, as shown in Figure 9.

The same procedure was repeated after 24 hours and then after 60 days. Both tests showed no pressure readings on the outlet pressure transducer, which confirmed that the 8% expansion rate was successful in closing the microannular gas flow in the wellbore model. Four additional samples were expanded with different expansion ratios (2% and 4%) and tested for flow in the same way as the aforementioned sample. The same results were obtained and confirmed the successful sealing of the microannular gas flow (Table 1). It is important to mention that each sample preparation requires labor intensive preparation and time, which is why it cannot be compared with simple studies of cement cores that can be molded effortlessly in large numbers.

| Sample | Kef [D] | Expansion ratio [%] | Kef [D] | Kef [D] | Kef [D] |

| 0 hr | 24 hr | 60 days | |||

| 1 | 0.14 | 4 | 0 | 0 | 0 |

| 2 | 0.66 | 8 | 0 | 0 | 0 |

| 3 | 2.11 | 2 | 0 | 0 | 0 |

| 4 | 2.31 | 2 | 0 | 0 | 0 |

| 5 | 7.04 | 8 | 3 x 10-7 | 0 | 0 |

Table 1. List of samples with calculated microannulus effective permeabilities (Kef) and post-expansion results of flow-through tests conducted immediately, 24 hr and 60 days after expansion.

Figure 1. Wellbore model schematic. Top view shows the cement (red color) between inner and outer pipe. The arrow points the direction of expansion. Bottom view shows the steel plate ring welded to outer pipe and pipe coupling. Inner pipe is screwed into the coupling (the scale is in inches).

Figure 1. Wellbore model schematic. Top view shows the cement (red color) between inner and outer pipe. The arrow points the direction of expansion. Bottom view shows the steel plate ring welded to outer pipe and pipe coupling. Inner pipe is screwed into the coupling (the scale is in inches).

Figure 2. Metal components of the bottom part of the wellbore model: a. Steel plate ring (0.63 cm in thickness); b. 6.35 cm OD steel pipe coupling; c. Pipe coupling welded onto steel plate ring; d. Threaded part of the inner pipe being screwed into the pipe coupling; e. Finished assembly. Final part of the wellbore model is the outer pipe which is placed at the end and welded for the steel plate ring on the outer region.

Figure 2. Metal components of the bottom part of the wellbore model: a. Steel plate ring (0.63 cm in thickness); b. 6.35 cm OD steel pipe coupling; c. Pipe coupling welded onto steel plate ring; d. Threaded part of the inner pipe being screwed into the pipe coupling; e. Finished assembly. Final part of the wellbore model is the outer pipe which is placed at the end and welded for the steel plate ring on the outer region.

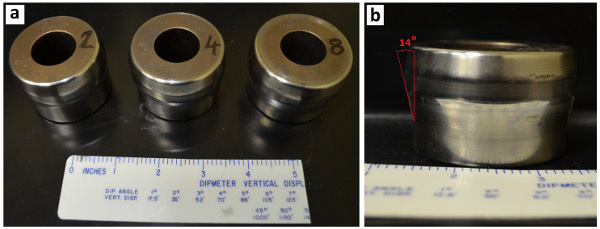

Figure 3. a. Expansion cones with 2%, 4% and 8% expansion ratio; b. Side view of 2% expansion ratio cone. All cones have 14° cone angle and are custom-made from alloy steel which was heat treated to the hardness of 60 RC.

Figure 3. a. Expansion cones with 2%, 4% and 8% expansion ratio; b. Side view of 2% expansion ratio cone. All cones have 14° cone angle and are custom-made from alloy steel which was heat treated to the hardness of 60 RC.

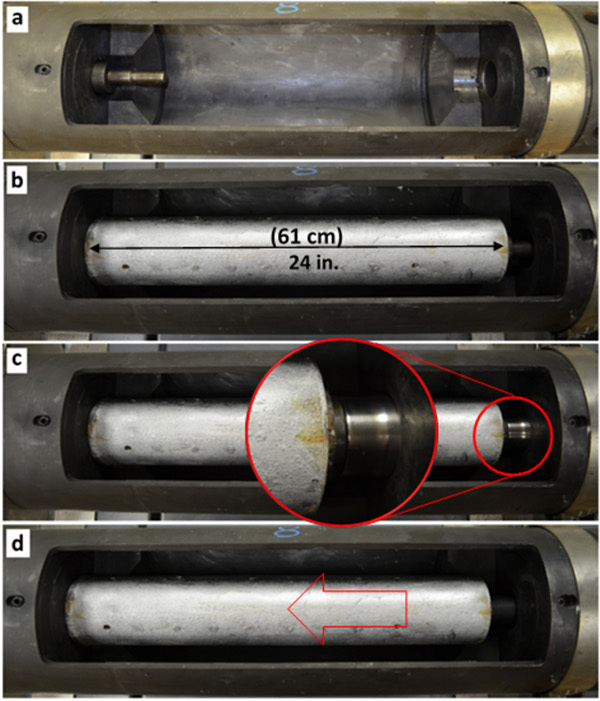

Figure 4. Setup and expansion process (top view): a. the expansion mandrel is retained in order to clear the lower housing for placement of the composite sample; b. the composite sample is placed in the lower housing and the expansion mandrel is fully elongated through the inner pipe; c. the expansion cone is slipped onto the expansion mandrel. Magnified view shows the expansion cone being held in place with the retaining mandrel; d. the expansion mandrel is retained and the expansion cone is pulled through the inner pipe (red arrow shows the direction of expansion).

Figure 4. Setup and expansion process (top view): a. the expansion mandrel is retained in order to clear the lower housing for placement of the composite sample; b. the composite sample is placed in the lower housing and the expansion mandrel is fully elongated through the inner pipe; c. the expansion cone is slipped onto the expansion mandrel. Magnified view shows the expansion cone being held in place with the retaining mandrel; d. the expansion mandrel is retained and the expansion cone is pulled through the inner pipe (red arrow shows the direction of expansion).

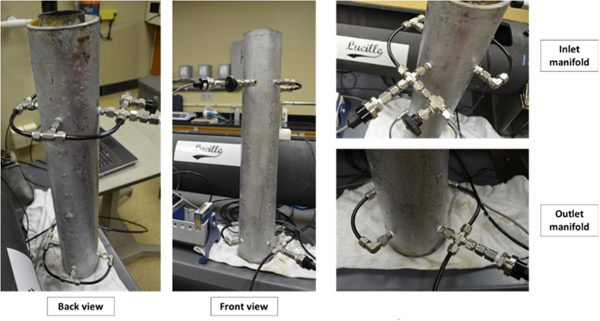

Figure 5. Back and front view of the sample showing the gas manifold assembly with pipe fittings and nylon tubing. Closer view of inlet and outlet manifolds showing positioning of pressure transducers.

Figure 5. Back and front view of the sample showing the gas manifold assembly with pipe fittings and nylon tubing. Closer view of inlet and outlet manifolds showing positioning of pressure transducers.

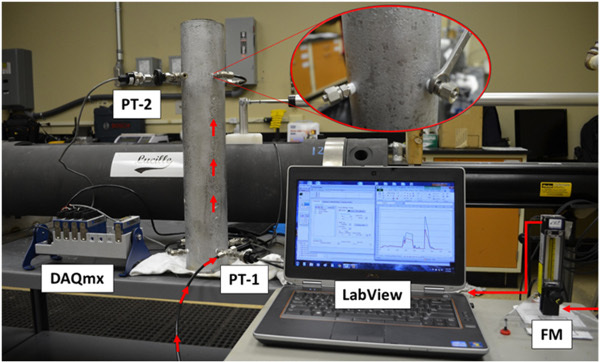

Figure 6. Flow-through experimental setup. The flow meter (FM) controls nitrogen gas flow (red arrows) throughout the experiment. Gas flows and enters the composite sample on the inlet manifold where the inlet pressure transducer (PT-1) records the inlet pressure. Gas flows through the sample’s pre-manufactured microannulus and the pressure recording on the outlet manifold’s pressure transducer (PT-2) provides the information of whether there is a connectivity and microannular gas migration through the composite sample. Pressure transducers are connected to the data acquisition system and pressures are monitored and recorded in real time on the computer and available to view on the screen. Magnified view shows installation of the pipe fittings.

Figure 6. Flow-through experimental setup. The flow meter (FM) controls nitrogen gas flow (red arrows) throughout the experiment. Gas flows and enters the composite sample on the inlet manifold where the inlet pressure transducer (PT-1) records the inlet pressure. Gas flows through the sample’s pre-manufactured microannulus and the pressure recording on the outlet manifold’s pressure transducer (PT-2) provides the information of whether there is a connectivity and microannular gas migration through the composite sample. Pressure transducers are connected to the data acquisition system and pressures are monitored and recorded in real time on the computer and available to view on the screen. Magnified view shows installation of the pipe fittings.

Figure 7. Pre-expansion gas flow-through test data plot showing registered pressures on both the inlet and outlet pressure transducers, confirming the microannular gas flow through the wellbore model. The starting inlet pressure on the gas cylinder was 50 kPa, and it was increased to 172 kPa, which resulted in a spike of both pressures on inlet and outlet ports.

Figure 7. Pre-expansion gas flow-through test data plot showing registered pressures on both the inlet and outlet pressure transducers, confirming the microannular gas flow through the wellbore model. The starting inlet pressure on the gas cylinder was 50 kPa, and it was increased to 172 kPa, which resulted in a spike of both pressures on inlet and outlet ports.

Figure 8. Pre-expansion gas flow-through test data semi-log plot clearly showing a pressure differential (ΔP) between pressures registered on the inlet and outlet pressure transducers. Based on the measured ΔP, calculations of effective permeability of the microannulus resulted in a value of 660 mD.

Figure 8. Pre-expansion gas flow-through test data semi-log plot clearly showing a pressure differential (ΔP) between pressures registered on the inlet and outlet pressure transducers. Based on the measured ΔP, calculations of effective permeability of the microannulus resulted in a value of 660 mD.

Figure 9. Multi-rate gas flow-through test data plot recorded immediately after expansion with the 8% expansion ratio cone. After a gradual increase of 172 kPa in inlet pressure on the gas cylinder every five minutes from 172 kPa to 690 kPa, there was no recorded pressure on the outlet pressure transducer, indicating successful remediation of the microannular gas flow.

Figure 9. Multi-rate gas flow-through test data plot recorded immediately after expansion with the 8% expansion ratio cone. After a gradual increase of 172 kPa in inlet pressure on the gas cylinder every five minutes from 172 kPa to 690 kPa, there was no recorded pressure on the outlet pressure transducer, indicating successful remediation of the microannular gas flow.

Discussion

The reported experimental procedure has two main components that are critical: composite cylinders that simulate wellbores and the expansion fixture that is used to carry out mechanical manipulation of cement. When designing wellbore models (cement/pipe composite cylinders), it is critical to choose adequate cement density, store samples under total humidity conditions (100% RH) and establish pipe-cement debonding before cement slurry completely sets. Failing to achieve this would make the entire gas flow experiment impossible.

Regarding the expansion fixture, only qualified and certified manufacturers capable of providing quality assurance can be used. The high pressures and significant forces can pose a serious safety hazard to the operator if the equipment is not properly designed, manufactured from the adequate materials, assembled, calibrated and tested prior to any data acquisition.

The reported experimental protocol in terms of major steps is applicable to sample design of different cement densities, however the fixture used in this study would not be able to expand samples with lower water to cement ratios (stronger cement) and would require more powerful hydraulic unit. A more powerful hydraulic unit of 34.5 MPa maximum pressure will be used for future research, which will include experiments on samples cemented with different water to cement ratio slurries and also different types of pipe/cement interface contamination, such as drilling fluid. In addition, the ongoing research is investigating behavior of foamed cements using this procedure. Separate set of experiments will be carried out on samples where temperature cycling will be applied within the inner pipe as a method for interfacial debonding, rather than inner pipe rotation.

In order to be able to directly measure changes within cement during the experiment, various sensors, such as strain gauges and piezoelectric sensors, will be embedded within cement and be connected to a data acquisition portal in the future sample design, which will enable us to gather direct measurements of stresses and potential water buildup in cement during metal expansion. Furthermore, microhardness testing is being incorporated in order to investigate the effect of pipe expansion on mechanical properties of cement. All of this is being investigated in ongoing research and will be reported in future publications.

The main limitation of this procedure is that we used metal to simulate rock wall, which is not ideal and can be approximated only for low permeability rocks such as clay-rich formations, or for simulation of cement sheath between two pipes. The second major improvement we are working on is an alternative design of wellbore model specimens that will be able to withstand higher gas pressures (from current 0.69 MPa to 3.45 MPa or even 6.9 MPa) in order to make this experiment more applicable to the field conditions.

The ongoing research is being carried out on sample design that will allow post-expansion direct coring of cement sheath. These cores will be used to measure permeability of cement using pulse-decay permeameter. This non-invasive technique will allow us to obtain direct measurements of changes in permeability, as the main parameter indicative of an effective zonal isolation and successful hydraulic barrier.

Although we suggest, and are currently working on several improvements of existing setup, this is a unique set up at lab/bench-scale and, to our knowledge, the first of its kind.

Disclosures

The authors have nothing to disclose.

Acknowledgments

The authors would like to thank the following people and institutions for their help and support: William Portas and James Heathman (Industry Advisors, Shell E&P), Richard Littlefield and Rodney Pennington (Shell Westhollow Technology Center), Daniele di Crescenzo (Shell Research Well Engineer), Bill Carruthers (LaFarge), Tim Quirk (now with Chevron), Gerry Masterman and Wayne Manuel (LSU PERTT Lab), Rick Young (LSU Rock Mechanics Lab), and members of the SEER Lab (Arome Oyibo, Tao Tao, and Iordan Bossev).

References

- King GE. Well Integrity: Hydraulic Fracturing and Well Construction – What are the Factual Risks. SPE Wellbore Integrity Webinar. 2013;5 [Google Scholar]

- Taylor HF. Cement Chemistry. London, United Kingdom: Telford Thomas; 1997. [Google Scholar]

- Thiercelin MJ, Dargaud B, Baret JF, Rodriguez WJ. Cement design based on cement mechanical response. SPE Drill & Compl. 1998;13(4):266–273. [Google Scholar]

- Nelson EB, Guillot D. Well Cementing. Second edition. Sugar Land, Texas: Schlumberger; 2006. [Google Scholar]

- Carter L, Evans G. Paper SPE 164 presented at the California Regional Meeting. Santa Barbara, California: 1964. A Study of Cement-Pipe Bonding; pp. 24–25. [Google Scholar]

- Goodwin K, Crook R. Cement Sheath Stress Failure. SPE Drill Eng. 1992;7(4):291–296. [Google Scholar]

- Heathman J, Beck FE. Finite Element Analysis Couples Casing and Cement Designs for HP/HT Wells in East Texas; Paper SPE 98869 presented at the IADC/SPE Conference; 2006 Feb 21-23; Miami, Florida. Halliburton; 2006. [Google Scholar]

- Boukhelifa L, et al. Evaluation of Cement Systems for Oil and Gas Well Zonal Isolation in a Full-Scale Annular Geometry; Paper SPE 87195 presented at the IADC/SPE Drilling Conference; 2004 Mar 2-4; Dallas, Texas. 2004. [Google Scholar]

- Duan S, Wojtanowicz A. A Method for Evaluation of Risk of Continuous Air Emissions from Sustained Casinghead Pressure; Paper SPE 94455 presented at SPE/EPA/DOE Exploration and Production Environmental Conference; 2005 Mar 7-9; Galveston, Texas. 2005. [Google Scholar]

- Watson TL, Bachu S. Evaluation of the potential for gas and CO2 leakage along wellbores. SPE Drill & Compl. 2009;24(1):115–126. [Google Scholar]

- Wojtanowicz AK, Nishikawa S, Xu R. Diagnosis and remediation of SCP in wells; Final report submitted to US Department of Interior MMS; 2001; Virginia. 2001. [Google Scholar]

- Kupresan D, Heathman J, Radonjic M. Experimental Assessment of Casing Expansion as a Solution to Microannular Gas Migration; Paper SPE 168056 presented at IADC/SPE Drilling Conference and Exhibition; 2014 Marc 4-6; Fort Worth, Texas. 2014. [Google Scholar]

- Kupresan D, Heathman J, Radonjic M. Application of a New Physical Model of Expandable Casing Technology in Mitigation of Wellbore Leaks. CETI Journal. 2013;1(5):21–24. [Google Scholar]

- Demong K, Rivenbark M. Breakthroughs using Solid Expandable Tubulars to Construct Extended Reach Wells; Paper SPE 87209 presented at the IADC/SPE Drilling Conference; 2004 Mar 2-4; Dallas, Texas. 2004. [Google Scholar]

- Grant T, Bullock M. The evolution of Solid Expandable Tubular Technology: Lessons Learned Over Five Years. Offshore Technology Conference; 2005.2005. [Google Scholar]

- Jennings I. Dynamic formations rendered less problematic with solid expandable technology. IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition; 2008.2008. [Google Scholar]

- Fanguy C, Mueller D, Doherty D. Improved method of cementing solid expandable tubulars. SPE Annual Technical Conference and Exhibition; 2004.2004. [Google Scholar]

- American Petroleum Institute. Recommended Practice for Testing Oilwell Cements and Cement Additives. American Petroleum Institute; 1971. Appendix C (tentative), Fluid Density Balance. [Google Scholar]

- Nelson EB. Well cementing. Amsterdam, Denmark: Elsevier Science; 1990. [Google Scholar]