Abstract

Potato is one of the staple crops cultivated in upland farming in Japan and is propagated vegetatively by means of tubers. However once infected with diseases, potato yield decreases significantly. And one seed potato can produce approximately only 10 potato tubers. To improve the production system of seed potatoes in Japan, Japanese government established a three-stage propagation system for the production and distribution of healthy and disease-free seed potatoes. The National Center for Seeds and Seedlings (NCSS) has a role for the production of foundation seed potatoes and strictly manages the production in isolated fields that are treated thoroughly to control pests and diseases. Recently though the distribution of foundation seed potatoes is decreasing, the number of varieties of foundation seed potatoes has increased steadily. And new varieties of potato adapted various requirements, including resistance of the golden potato cyst nematode, have been increasing. Therefore, NCSS is introducing a new method of producing minitubers (MnTs) by using hydroponic cultivation greenhouse to increase the efficiency of propagation and to rapidly disseminate these new potato varieties. In this review, we describe a seed potato production system in Japan and the production of foundation seed potatoes as an important role of NCSS.

Keywords: seed potato, foundation seed potatoes, in vitro microplant, minituber (MnT), golden potato cyst nematode, hydroponic cultivation greenhouse, NCSS

Introduction

Potato (Solanum tuberosum L.) is one of the staple crops cultivated in upland farming in Japan. Because the plants can harvest tubers as product of the crop in a short time, potato is cultivated throughout the country and is an important upland crop. Japanese potato production, on a weight basis, is third after rice and sugar beet. In 2012, 81 200 ha and 2.5 Mt of potatoes were cultivated in Japan. Potato cultivation is especially popular on Hokkaido, which has a cold climate and accounts for nearly 80% of potato production in Japan.

Potato is propagated vegetatively by means of tubers. The planting material is called a “seed potato”, even though it is a tuber rather than a botanical seed. Tubers can be infected by many different diseases and pests, which can remain in tubers. The American Phytopathological Society Compendium of Potato Diseases (Stevenson et al. 2001) notes that potato can be damaged by many species of bacteria and viruses, and other fungus and nematodes (Diseases of Potato (Solanum tuberosum L.), The American Phytopathological Society: https://www.apsnet.org/publications/commonnames/Pages/Potato.aspx). Once infected with these diseases, potato yield decreases significantly. Recently, the golden potato cyst nematode (Globodera rostochiensis) has begun to spread nationwide, causing substantial damage to both quality and yield of potato (Agricultural Policy Planning Department, Hokkaido Government 2012). The nematode is currently one of the major constraints on commercial production, and is a particular concern for seed potato production in Japan.

Repeated cultivation by propagating tubers infested by pests or infected by diseases leads to transmission of these pathogens to healthy plants. This also causes the spread of pathogens to neighboring production areas, leading to heavy damage to the crops and thereby greatly affecting processors and consumers of potato (Loebenstein et al. 2001).

For these reasons, potato is currently the only target plant that is subject to domestic quarantine regulations under Japan’s Plant Protection Law (http://www.japaneselawtranslation.go.jp/law/detail_main?vm=&id=25), and in principle, the import of raw potatoes from any country in which potato disease is endemic is forbidden under the law. Exceptions exist for research institutions that meet rigorous screening criteria to ensure that they will not inadvertently release a foreign disease.

Because it is crucial to use healthy and disease-free seed potatoes every year for the sustainable production of potato, a seed potato production system has been implemented in Japan since the late 1940s. In this paper, we describe this system and the production of foundation seed potatoes as an important role of the National Center for Seeds and Seedlings (NCSS; http://www.ncss.go.jp/index_e.html).

1. Seed potato production in Japan

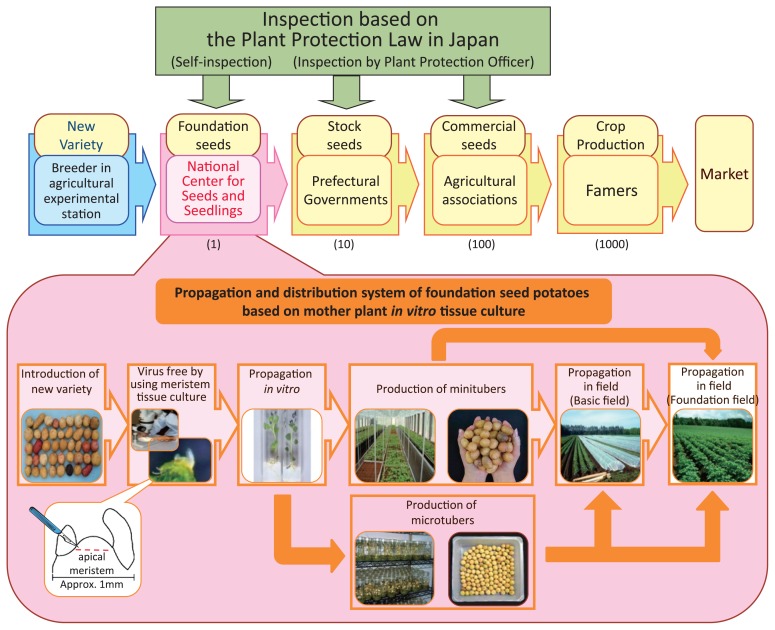

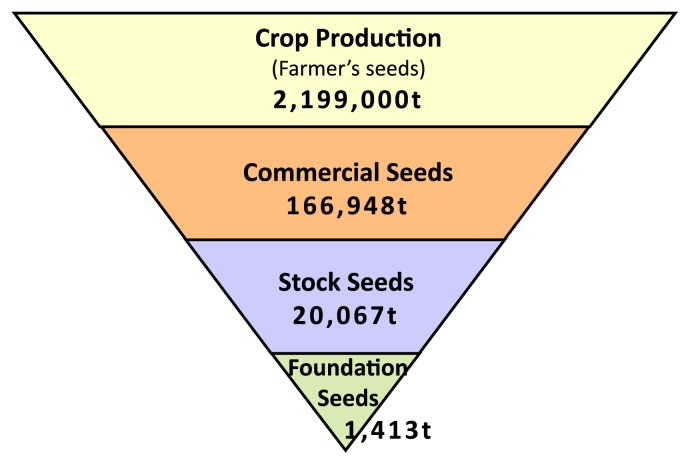

Potato is easily vegetatively propagated. One seed potato can produce approximately only 10 potato tubers. The propagation system was based on two-stage propagation by Japan’s prefectural governments (i.e., foundation stock seed potatoes → commercial seed potatoes). However, because the system did not decrease the incidence of important viral diseases and bacterial diseases such as ring rot (Clavibacter michiganensis subsp. sepedonicus), the Ministry of Agriculture and Forestry established seven potato foundation stock seed farms nationwide in 1947, which became the predecessors of NCSS and began the production of foundation seed potatoes. The primary purpose was to promote stable production of potato by supplying quality seed potatoes that were healthy and disease-free. Because of these efforts, a three-stage propagation system (i.e., foundation seed potatoes → stock seed potatoes → commercial seed potatoes) composed of breeders at agricultural experimental stations, NCSS, prefectural governments, and agricultural associations was established (Figs. 1 and 2).

Fig. 1.

Production and distribution system of seed potato from foundation seed potatoes.

Fig. 2.

Production of foundation seed potatoes (2013).

NCSS strictly manages the production of the foundation seed potatoes, which become the origin of subsequent propagation, in isolated fields that are treated thoroughly to control pests and diseases and that are continuously inspected to detect and solve any potential problems. NCSS is a centralized agency that provides the foundation seed potatoes to prefectural governments in a stable and equitable manner. As a result of these rigorous control efforts, damage by pests and diseases has decreased and the quality and yield of potato has increased; the potato yield per unit area in Japan is currently one of the highest in the world.

And these techniques on seed potato propagation of Japan contributed to the projects of Japan International Cooperation Agency (JICA) for technical cooperation in Indonesia and Syria as Japan’s ODA (Kano and Nakamura 2004).

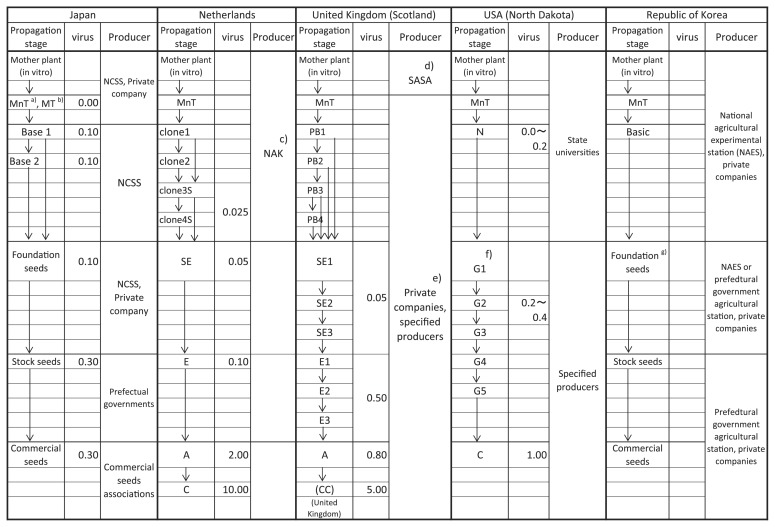

2. Seed potato production system in other countries

A mother plant that will be used to propagate potato is prepared and maintained by means of in vitro microplant production both in Japan and around the world. These plants are used to produce microtubers or minitubers (MnTs). In European countries, such as the Netherlands and Scotland, national research institutes or inspection institutes use a plant quarantine system similar to the Japanese system, and take on the role of propagating microplants in vitro. In the United States, state universities play this role. When the propagules are transferred to producers for field cultivation, specified producers (including some private companies) appointed by the abovementioned inspection institutes or state universities propagate seed potatoes in the field.

The propagation systems differ among countries in terms of the number of stages and other details; the number of steps typically ranges from five to eight, but usually includes a step to classify the materials as “super-elite,” “elite,” or lower grades. One large difference from the practice in Japan is that any seed potato from any propagation stage is available for purchase. Because seed potatoes from early stages have the lowest risk of contamination by a pest or disease, their price is predictably high. Therefore, choosing an appropriate (i.e., more affordable) grade is important for ordinary farmers. The Republic of Korea has a propagation system that is similar to that in Japan (Fig. 3).

Fig. 3.

Seed potato production system in other countries. (a) Minitubers. (b) Microtubers. (c) The Netherlands General Inspection Service for Agricultural Seeds and Seed Potatoes (NAK) inspects agricultural seeds and seed potatoes by order of the Dutch Ministry of Agriculture, Nature and Food Quality division. These inspections are required by law. NAK is an independent organization, and is managed by representatives of growers, breeders, and traders. (d) The Science and Advice for Scottish Agriculture (SASA) Division of the Scottish Government’s Agriculture, Food and Rural Communities Directorate has a primary role of providing scientific services and advice to support agriculture in Scotland and the wider environment. (e) Specified producers are appointed by SASA. (f) In the United States, the grade of the potatoes decreases as they move through the production and distribution chain. After they have reached the G1 grade, they are the equivalent of stock seed potatoes. The G grade is generally divided into five subgrades, but may include eight subgrades in some states. (g) In the Republic of Korea, the foundation seed potatoes pass through the same three stages of propagation as in Japan. Private companies may participate in the propagation system during any of these stages.

3. Distribution of foundation seed potatoes

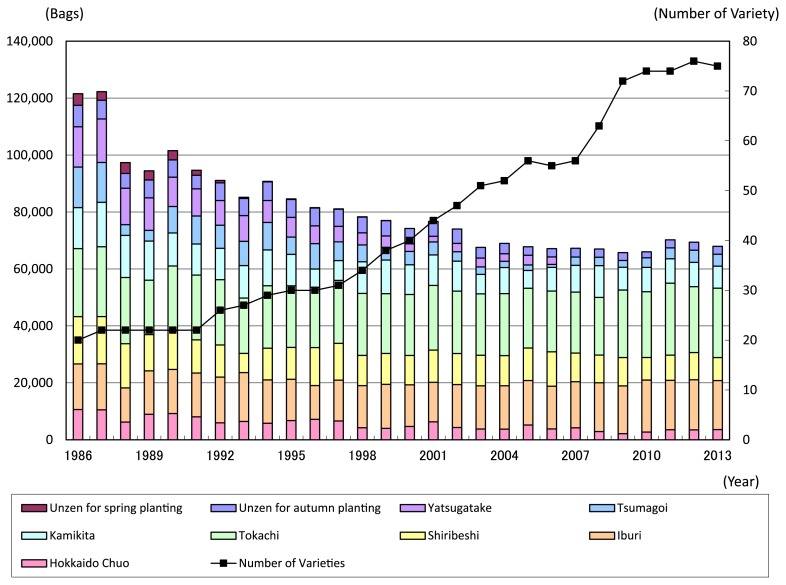

In 2013, NCSS delivered 1350 t of foundation seed potatoes from 75 varieties to 15 prefectural governments, amounting to approximately 68 000 bags (at 20 kg/bag). The recipients of the seed potatoes were widely distributed, from Hokkaido to Okinawa. To combat the growing number of pathogens, pest- and disease-resistant varieties have been developed, particularly to resist the golden potato cyst nematode and the potato late blight (Phytophthora infestans). In addition, varieties that are more suitable for processing have been developed, and foreign varieties with useful characteristics also have been introduced. As a result, the number of varieties of foundation seed potatoes has increased steadily since 1992, and these numbers will likely continue to increase (Fig. 4).

Fig. 4.

Number of distribution of foundation seed potatoes in each NCSS’s station.

Two varieties that were bred for table use, ‘Dansyaku-imo (Irish Cobbler)’ and ‘May Queen’, and that were introduced in the early 20th century, account for about 30% of the delivered foundation seed potatoes. This reflects their high popularity, but shipments of both varieties are decreasing. Recently, demand for ‘Kitaakari’ and ‘Touya’, which are new varieties that resist the golden potato cyst nematode, has been increasing.

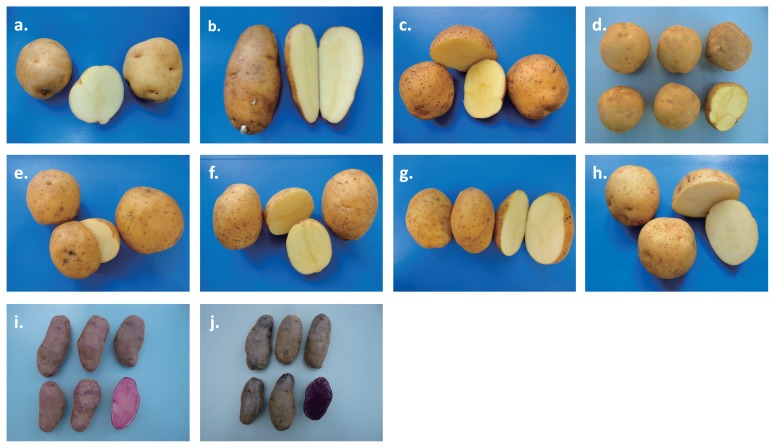

For other uses, ‘Dejima’ and ‘Nishiyutaka’ are varieties suitable for warm regions of Japan, and ‘Toyoshiro’ is suitable for processing, especially for potato chips, so its demand is expanding. ‘Konafubuki’ is a popular variety for the starch industry. Recently, new varieties for processing and starch also that resist the golden potato cyst nematode, have been increasing. In addition, the production and distribution of colorful potatoes such as ‘Northern Ruby’, which has red skin and flesh, and ‘Shadow Queen’, which has purple skin and flesh, are increasing in response to growing demand (Fig. 5).

Fig. 5.

Main varieties of potato in Japan. a. ‘Dansyaku-imo (Irish Cobbler)’, b. ‘May Queen’, c. ‘Kitaakari’, d. ‘Touya’, e. ‘Dejima’, f. ‘Nishiyutaka’, g. ‘Toyoshiro’, h. ‘Konafubuki’, i. ‘Northern Ruby’, j. ‘Shadow Queen’.

4. Production of foundation seed potatoes in strictly isolated fields

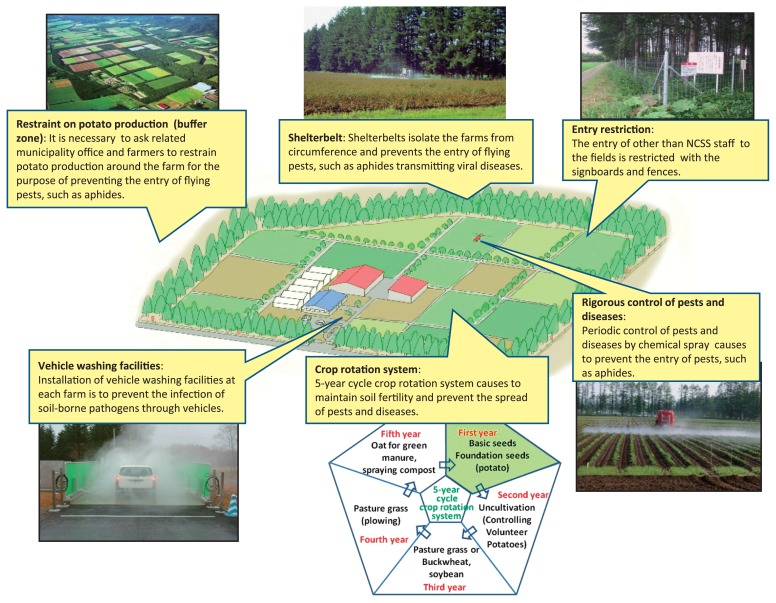

NCSS produces its foundation seed potatoes under the strictest possible management, in isolated fields that are thoroughly designed and treated to prevent the entry of pests and diseases (Fig. 6). Each NCSS station follows the same strict procedures.

Fig. 6.

Rigorous control of pests and diseases for production of foundation seed potatoes in NCSS.

These procedures are designed to prevent the entry of flying pests, such as aphids, that are capable of transmitting viral diseases, by planting shelterbelts that isolate the farm from the surrounding landscape. To prevent infection by soil-borne pathogens, such as the golden potato cyst nematode, fences are installed to restrict entry by wild animals and by anyone other than NCSS staff, and vehicle washing facilities are installed at the gate to each field. In addition, crop rotation has been implemented on a 5-year cycle, including plowing followed by cultivation of pasture grass and oats as green manure, to prevent soil-borne diseases from accumulating, which is a risk during continuous cultivation of a single crop.

In addition to this, NCSS has implemented an integrated soil-conditioning system (Fig. 7) that extends from plowing to planting, and has installed grading machines equipped with camera sensors (Fig. 8) to increase the accuracy of grading tubers, thereby leading to improved quality of foundation seed potatoes.

Fig. 7.

Soil-conditioning system.

Fig. 8.

Grading machine.

5. Inspection for pests and diseases, and maintenance of the varietal purity of foundation seed potaotes by NCSS

During the production of foundation seed potatoes by NCSS, staff thoroughly inspect potatoes to check disease-free condition of potatoes (Fig. 9). In addition, the genetic purity of the varieties is protected during all production stages.

Fig. 9.

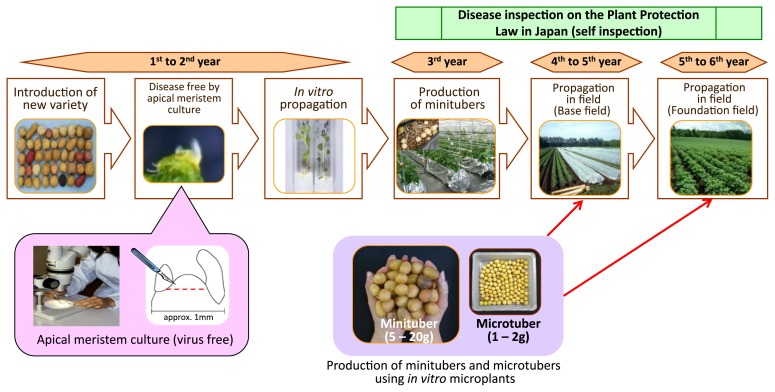

Propagation system of foundation seed potatoes based on in vitro mother plant.

The following operational details are an important part of these protective measures:

The apical meristem is dissected and incubated to produce in vitro microplants on culture media, under controlled temperature and light conditions. Before multiplication of the microplants, NCSS carries out inspections to detect viral diseases using various detection methods, such as enzyme-linked immunosorbent assays (ELISA) (Fig. 10), the polymerase chain reaction (PCR) based assays (Fig. 11) and inspection using an electron microscope (Fig. 12), for the purpose of determining if potatoes are disease-free. After ensuring freedom from viruses, the microplants then become mother plants used for the production of foundation seed potatoes.

The virus-free microplants are repeatedly propagated in large numbers using in vitro multiplication methods (Fig. 9).

After multiplication, the microplants are transferred to an isolated facility for the production of seed potato tubers by means of hydroponic cultivation systems. The hydroponic cultivation systems produce MnTs, which weigh approximately 10 g and range from 2 to 3 cm in diameter. In some cases, NCSS also propagates the microplants using microtubers in order to spread rapidly new potato varieties.

MnTs are then planted in isolated “base” fields at an NCSS station that have been carefully inspected to exclude the golden potato cyst nematode by soil sampling and testing for the presence of it, and used to produce the foundation seed potatoes (Fig. 9). They are cultivated in tunnels using non-woven fabric that prevents the entry of aphids that could transmit viral diseases to potato plants.

Seed potatoes produced in the base field are also planted in isolated “foundation” fields (Fig. 9) that have also been inspected to confirm the absence of the golden potato cyst nematode. Plants in the foundation field are protected by spraying appropriate chemicals based on the status of pest and disease outbreaks during the growing season, and visual inspections (i.e., rouging) are carried out five to ten times during the growing season to allow removal of diseased plants, physiological disordered plants and off-type plants.

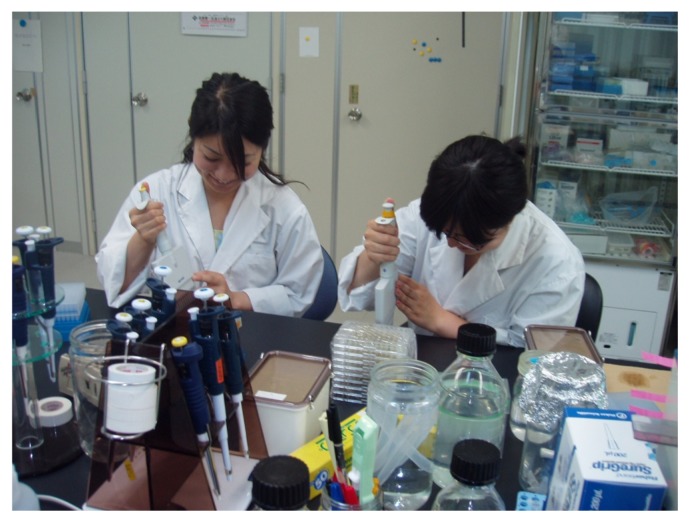

Fig. 10.

Enzyme-linked immunosorbent assays (ELISA).

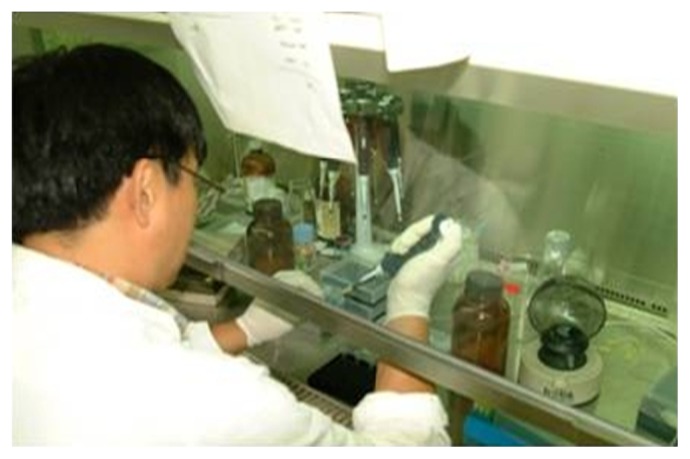

Fig. 11.

Polymerase chain reaction (PCR) based assay.

Fig. 12.

Inspection using electron microscope.

NCSS has been approved for self-inspection under the domestic quarantine guidelines in Japan’s Plant Protection Law. NCSS maintains this approval by rigorously checking for pests and diseases during each of the abovementioned propagation stages.

6. Hydroponic cultivation in isolated facilities

NCSS is introducing a new method of producing MnTs to increase the efficiency of propagation using in vitro microplants. This has become necessary due to the increasing number of potato varieties and the need for rapid dissemination of new potato varieties.

MnT production in isolated facilities is expected to produce more disease-free potatoes by avoiding the risk of soil-born disease outbreaks. To accomplish this goal, NCSS is using a soil-free greenhouse-based hydroponic cultivation system (Fig. 13), and is reconsidering the traditional propagation system that is based on cyclical cultivation in isolated screenhouses using potato mother plants. NCSS is continuing its research on the practical use of MnTs to establish a more productive propagation system. NCSS has obtained similar results using MnTs and normal tubers in terms of the sprouting of tubers and the yield of tubers, reaching up to 30 tubers per plant for MnTs that weigh approximately 10 g.

Fig. 13.

Hydroponic cultivation greenhouse.

Based on the results of these researches on using MnTs, NCSS decided to develop a facility for increasing the production of MnTs. First, a facility for mass in vitro propagation of potato microplants was developed (Fig. 14) and a new hydroponic cultivation greenhouse was built (Fig. 13). As a result, it was possible to shorten the period from acceptance of a new variety to distribution of foundation seed potatoes and to improve the efficiency of producing foundation seed potatoes.

Fig. 14.

In vitro microplants.

The main feature of the hydroponic cultivation greenhouse is its structure, which resists wind pressure and has good thermal insulation properties. This results from using multi-layered covering materials and blowing air into the space between the covering materials. In addition, greenhouse temperatures are automatically controlled by shade curtains and ventilation fans that counteract summer heat increases, and by controlling temperature variation, particularly during the day, using circulation fans and fog-cooling fans.

After preparing these facilities, NCSS shifted the production of seed potatoes for the base field from the production of seed tubers in screen houses to the production of MnTs using hydroponic cultivation greenhouses in 2009 (Fig. 15). Simultaneously, NCSS has begun to check the varietal purity of the potato varieties by observing carefully the physiological characteristics of the potato varieties in the field, to prevent varietal contamination and the occurrence of off-types, and continues its thorough quality control measures for seed potatoes.

Fig. 15.

Hydroponic cultivation system.

Conclusions

NCSS controls the overall process from production to distribution of potato foundation seed potatoes. In addition, it has taken on the production and distribution of sugarcane (Saccharum spp.) foundation seeds, DUS (Distinctness, Uniformity and Stability) growing tests under the Plant Variety Protection system, inspection of seed and seedlings based on the Plant Variety Protection and Seed Act, and conservation of plant genetic resources. NCSS is eager to continue further efforts to achieve its mission, To support agricultural development, the life of the people, and socio-economic stability by managing seeds and seedlings, which are fundamental and important components of agricultural production.

Acknowledgments

We thank Dr. Kazuo Watanabe, a professor at Tsukuba University, for providing suggestion and advice to complete this document.

Literature Cited

- Agricultural Policy Planning Department, Hokkaido government (2012) A significant to promote dissemination of resistant variety of golden potato cyst nematode, pp. 3–4. [Google Scholar]

- Kano, Y. and Nakamura, T. (2004) High quality seed potato multiplication project in Indonesia. Jpn. J. Trop. Agr. 48 (extra1): 11–12. [Google Scholar]

- Loebenstein, G., Berger, P.H., Brunt, A.A. and Lawson, R.H. (eds.) (2001) Virus and virus-like diseases of potatoes and production of seed-potatoes. Kluwer Academic Publishers, Netherlands, p. 28. [Google Scholar]

- Stevenson, W.R., Loria, R., Franc, G.D. and Weingartner, D.P. (eds.) (2001) Compendium of potato diseases, second edition.The American Phytopathological Society, USA, pp. 7–8. [Google Scholar]