Abstract

This article summarises the results of the investigation of application of microwave exposure on the dehulling characteristics of the black gram and the properties of the dehulled grains. Black gram was exposed to 3 microwave power levels, viz., 450, 630 and 810 W for 7 different exposure, ranging from 60 to 150 s at an interval of 15 s with a view to determine the suitable combination of dosage in order to get the maximum yield with little change in colour. Related changes in properties were also studied. It was observed that the surface temperature of the grain increased with the increase in microwave power level from 450 to 810 W as well as exposure time from 60 to 150 s in the range from 58 to 123 °C while the dehulling time reduced from 445 to 170 s. The dehulling yield increased with increasing microwave dosage in the beginning and reached to the maximum value followed by decreasing trend. The colour of the dehulled grain changed slowly up to a microwave dosage of 972 J/g after that it changed vividly darker than the control. The dehulling and dhal yields and colour change were polynomial functions of microwave dosage. The highest yield of 73.7 % was achieved at about 972 J/g with a little change in colour (CIELAB ΔE* value of 2.58). The corresponding dehulling time, cooking time and losses during dehulling were respectively 185 s, 10 min and 15.1 % as compared to 492 s, 20 min and 31.5 % for control respectively. It is concluded that a dosage of about 972 J/g was the best for the black gram dehulling at a rate of 630 W or higher power level.

Keyword: Black gram, Microwave exposure, Dehulling time, Dehulling yield, Dhal yield, Dehulling loss

Introduction

Black gram (Vigna mungo L) or urid is reported to be originated in India and being cultivated in Burma, Bangladesh, Sri Lanka and to a lesser extent in Thailand, Australia and other Asian and South Pacific countries (Poehlman 1991). Black gram is a rich protein food containing around 24 % protein, 59.6 % carbohydrate and 1.4 % fat (Gopalan et al. 1989). Black gram is extensively used in South Asian subcontinent for direct consumption as dehulled grain and as flour in various fermented foods, in Japan to make “moyashi” and its flour for making fresh skinless beef sausages in some European nations as protein substitute.

The pulses are reported to contain antinutrients in seed coat. Also, the seed coat is hard and imparts a bitter taste, reducing the palatability of the pulses. In order to remove the antinutrients and improve the palatability, it is common practice to dehull the pulses before using. Dehulling is a process of removal of hull from the cotyledon of pulses. It reduces the fibre content and improves appearance, texture, cooking quality, palatability and digestibility of grain legumes (Tiwari et al. 2007). Dehulling of black gram has been a difficult operation due to the presence of vitreous layer of gums and mucilages, which makes bond between hull and cotyledon stronger. Pulse dehulling constitutes two major steps, viz., loosening of the hull followed by its removal in suitable milling machine (Narasimha et al. 2003).

Loosening the hulls during dehulling is traditionally achieved either by wet or dry methods (Kurien 1977). Dry method involves application of oil and water. In this method, cleaned and graded grains are subjected to pitting to increase soaking. Then these pitted grains are mixed thoroughly with 1 % edible oil and spread for sun drying in thin layer for 2–3 days. At the end of drying, 2.5 % water is sprayed and mixed thoroughly. For tempering, grains are heaped overnight. Then the grains are dehulled with roller machine. The wet method is now a day obsolete and rarely used.

It has been reported by several researchers that heat treatment significantly improves the protein quality in pulses by destruction or inactivation of the heat labile anti-nutritional factors (Jenkins et al. 1982; Deosthale 1982; Khokhar and Chauhan 1986; Wang et al. 1997; Vijayakumari et al. 1998). Therefore, it may be useful to apply treatments for loosening the hulls by thermal means. The traditional thermal processing takes longer and exhibit all associated risk. Based on preliminary studies it was found that microwave can be used as an effective pre-treatment for dehulling pulses, which is hygienic and easy to apply, with the benefit of heat treatment. Also, the thermal treatment is expected to increase the pore sizes in the pulses which in turn reduce the water penetration time as well as reduce the cooking time (processing time for use as component in food product development) of the pulses. Microwave can also provide disinfestations of the grains and improve the shelf life of the dehulled grains (Vadivambal et al. 2007).

Heating by microwave would disrupt the bondage between the hull and cotyledon of pulses by denaturing the protein and gums present between them. The information on the rate of microwave power application, dosage required to get the desired effect are essential in order to assess the suitability of the process. So far, there is no study explaining the effect of microwave treatment on the dehulling of black gram and its effect on quality parameters of the dehulled pulses.

Keeping this in view, the present work has been undertaken with an overall objective to study the effect of microwave application, viz., energy input (power level), exposure and dosage, on the dehulling of black gram as well as its effect on the quality, viz., colour and cooking time of dehulled pulses.

Materials & methods

Materials

Samples

Black gram ADT5 variety was purchased from the local market and was first cleaned well to remove the extraneous matter before conducting the experiments. The moisture content of the sample was 12.7 % (w.b.). Normally, in the commercial market about 12–13 % moisture content is common which comes to dehulling to the pulse processor and hence only single initial moisture content was considered in this study.

Microwave oven

A domestic microwave oven (Model: IFB 30SC2) having the operation frequency of 2,450 MHz and maximum input power of 1,400 W was used to conduct the experiment. The rated power output from the microwave oven is 900 W corresponding to 100 % power level. The oven has facility to be used at 10 to 100 % power level at an interval of 10 %.

Methodology

Microwave treatment

A total weight of 100 g of cleaned seeds were taken in a glass dish of 155 mm diameter and placed on the turn table in the microwave oven. Three levels of microwave energy input, viz., 450, 630 and 810 W, were applied each at 7 different exposure times ranging from 60 to 150 s at an interval of 15 s. The depth of grain layer was approximately 5 mm. The maximum exposure time was set through preliminary study corresponding to the beginning of the emergence of roasted smell. The microwave dosage supplied to the black gram is calculated by Eq. 1.

| 1 |

Average surface temperature of microwave treated samples

The surface temperature of the microwave treated grains was monitored immediately after the samples were taken out from the microwave oven, using an Infrared thermometer (Model: Center 350, Center Technology Corporation, Shu-Lin, Taiwan). The temperature was measured by holding the IR thermometer at a horizontal distance of 15 cm above the grain surface. Five temperature measurements at surface of the grains were taken, one at the centre and four around the perimeter of the petridish and the average value was calculated.

Dehulling procedure

Dehulling of black gram was performed in laboratory model emery roll polisher (Model: TM05, Satake Corporation, Japan). Dehulling was continued till complete removal of husk was achieved in all grains and corresponding dehulling time was noted. After dehulling, the different fractions were collected and graded as dehulled whole and split, broken, powder and fine brokens. They were weighed separately and noted for further analysis. All samples were studied in triplicates.

Analysis of dehulling properties of black gram

The dehulling properties of black gram were assessed in terms of dehulling time, dehulling yield, dhal yield and losses.

Dehulling time

Dehulling time was defined as the duration of dehulling of black gram for complete removal of husk from the cotyledons, i.e., 100 % dehulling of the grains.

Dehulling yield

Dehulling yield was defined as the quantity of total whole dehulled kernels and broken kernels (except fine brokens, powder and husk) that are produced in the dehulling of pulses. Head kernels are defined as the kernels retained over the sieve no. 10 (BSS mesh). Broken is defined as cotyledon retained on sieve no. 30 and pass through sieve no. 10 (BSS mesh). Fine broken is defined as the broken that passed through sieve no. 30 (BSS mesh). The dehulling yield is calculated using the formula given in Eq. 2.

| 2 |

Dhal yield

Dhal yield (from APQ Method 104.1, Burridge et al. 2001) was defined as the yield of dehulled whole and split kernels (dhal) as a percentage of original seed weight. It is calculated by the relationship given in Eq. 3.

| 3 |

Dehulling loss

Dehulling loss is calculated as the weight fraction of the powder and fine broken relative to the total weight of the grain used for dehulling. It is calculated using the relationship given by Eq. (4) (Goyal et al. 2007).

| 4 |

Analysis of the quality of dehulled dhal

Colour

Colour of seeds was determined by Hunter colour lab colorimeter (Model: Colour Quest XE, USA). Calibration of this machine was done using black and white standardizing templates. The sample was placed over the eye and the CIELAB L*, a*, and b* values were monitored for each sample as the average of six readings. The colour difference between the control sample (grains without any treatment) and the dhal samples subjected to microwave treatment was calculated using Eq. 5 in terms of ΔE*(Francis and Clydesdale 1975).

| 5 |

Where L0*, a0*, and b0* are the colour parameters of the control sample.

It has been reported that if the value of ΔE <1.0then the difference between two colours would be sensorial imperceptible (Zamfir 2009). A trained eye could differentiate two colours if the value of ΔE* <2 and a casual viewer can notice a difference between two colours only when ΔE* >2–3.5(Krapfenbauer et al. 2006).

Cooking time

A boiling water bath was used to maintain uniform and constant temperature during cooking time determination. Approximately 200 ml of deionized water was brought to boiling in 250 ml beakers kept inside the water bath and 20 g each of microwave treated, and control grains (dhal) of black gram were added in separate beakers in the water bath. Boiling was continued and few kernels were withdrawn every 30s with spatula and were placed between two glass slides. Then the slides were pressed against each other with no lateral movement. Cooking was considered complete when the kernels no longer had opaque or uncooked centres and the time required for this was taken as the optimum cooking time (Ranghino 1966). Slides were cleaned and dipped in water for each time they were used.

Statistical analysis

All the experiments were carried out in triplicates and the data with respect to microwave dosages were represented as mean ± SD (Table 1). MS Excel was used to fit regression equations. SPSS18.0 (SPSS Inc. Released 2009) was used to conduct analysis of variance (ANOVA) followed by Duncan’s multiple range test to investigate the significant difference among treatments.

Table 1.

Effect of different microwave (MW) power and exposure times and corresponding microwave dosages on the quality parameters of black gram

| MW power (W) | MW exposure time (s) | MW dosage (J/g) | Quality parameters | |||||

|---|---|---|---|---|---|---|---|---|

| Dehulling time (s) | Dehulling yield (%) | Dhal yield (%) | Dehulling loss (%) | Colour difference | Cooking time (min) | |||

| 450 | 60 | 270.0 | 445 ± 5.0o | 53.8 ± 0.48a | 51.3 ± 0.60a | 29.8 ± 0.48k | 0.70 ± 0.001a | 16.0 ± 0.50k |

| 75 | 337.5 | 420 ± 5.0n | 56.6 ± 0.17b | 53.6 ± 0.48c | 29.0 ± 0.55j,k | 0.90 ± 0.002b,c | 15.3 ± 0.28j,k | |

| 90 | 405.0 | 405 ± 5.0l | 58.2 ± 0.56c | 55.1 ± 0.43d | 28.5 ± 0.63h,i,j | 0.97 ± 0.002b,c,d | 14.8 ± 0.28i | |

| 105 | 472.5 | 398 ± 2.9k | 58.2 ± 0.57c | 55.2 ± 0.94d | 28.3 ± 0.16h,i,j | 1.03 ± 0.042c,d,e,f | 14.5 ± 0.00i | |

| 120 | 540.0 | 387 ± 2.9j | 59.7 ± 0.35d | 56.6 ± 0.31e | 27.2 ± 0.39g,h,i | 1.12 ± 0.017d,e,f,g | 13.8 ± 0.50h | |

| 135 | 607.5 | 385 ± 5.0j | 60.1 ± 0.39d | 56.8 ± 0.45e,f | 27.3 ± 0.26g,h,i | 1.17 ± 0.002e,f,g | 13.5 ± 0.28h | |

| 150 | 675.0 | 383 ± 5.8j | 61.1 ± 0.69e | 57.7 ± 0.52f | 27.5 ± 1.04g,h,i | 1.21 ± 0.002f,g | 12.5 ± 0.50f,g | |

| 630 | 60 | 378.0 | 413 ± 2.9m | 55.9 ± 0.65b | 52.3 ± 1.03b | 28.8 ± 0.63i,j,k | 0.83 ± 0.003a,b | 14.8 ± 0.76i,j |

| 75 | 472.5 | 393 ± 2.9k | 58.7 ± 0.44c | 55.3 ± 0.25d | 27.6 ± 0.59h,i | 0.99 ± 0.008b,c,d,e | 14.7 ± 0.28i,j | |

| 90 | 567.0 | 322 ± 2.9h | 62.1 ± 0.40f | 58.9 ± 0.25g | 26.3 ± 0.57g | 1.18 ± 0.003e,f,g | 14.2 ± 0.28h,i | |

| 105 | 661.5 | 297 ± 2.9f | 63.3 ± 0.25g | 60.7 ± 0.42h | 23.6 ± 0.38e,f | 1.20 ± 0.003f,g | 13.7 ± 0.28h | |

| 120 | 756.0 | 267 ± 2.9e | 67.2 ± 0.69h | 64.4 ± 0.53i | 20.6 ± 0.42d | 1.28 ± 0.003g | 12.8 ± 0.57g | |

| 135 | 850.5 | 262 ± 2.9e | 69.2 ± 0.20i | 65.3 ± 1.30i | 20.4 ± 0.38d | 1.65 ± 0.008h | 9.5 ± 0.50c | |

| 150 | 945.0 | 200 ± 0.0c | 73.0 ± 0.64k,l | 70.8 ± 0.24l | 16.2 ± 0.09b | 2.15 ± 0.050k | 8.0 ± 0.50a,b | |

| 810 | 60 | 486.0 | 367 ± 2.9i | 59.9 ± 0.16d | 57.4 ± 0.43e,f | 27.9 ± 1.54h,i,j | 1.82 ± 0.009h,i | 12.5 ± 0.50f,g |

| 75 | 607.5 | 307 ± 2.9g | 63.0 ± 0.14g | 60.8 ± 0.22h | 24.5 ± 0.38f | 1.94 ± 0.087i,j | 12.0 ± 0.50f | |

| 90 | 729.0 | 263 ± 2.9e | 69.1 ± 0.40i | 66.9 ± 0.16j | 22.6 ± 0.26e | 2.02 ± 0.005j,k | 10.8 ± 0.57e | |

| 105 | 850.5 | 242 ± 2.9d | 70.1 ± 0.10j | 68.7 ± 0.51k | 19.2 ± 0.88c | 2.13 ± 0.010k | 10.3 ± 0.57d,e | |

| 120 | 972.0 | 185 ± 0.0b | 73.7 ± 0.44l | 72.7 ± 0.40m | 15.1 ± 0.94a,b | 2.59 ± 0.008l | 9.7 ± 0.28c,d | |

| 135 | 1093.5 | 180 ± 5.0b | 72.5 ± 0.75k | 71.1 ± 0.40l | 14.4 ± 1.07a | 4.28 ± 0.190m | 8.7 ± 0.29b | |

| 150 | 1215.0 | 170 ± 5.0a | 70.3 ± 0.17j | 69.3 ± 0.15k | 14.2 ± 1.22a | 9.54 ± 0.390n | 7.8 ± 0.29a | |

Values are expressed as mean ± standard deviation

The values of each quality parameter in a column bearing same letter in superscript doesn’t differ significantly at 95 % confidence interval

Results and discussions

Average surface temperature of the microwave treated grains

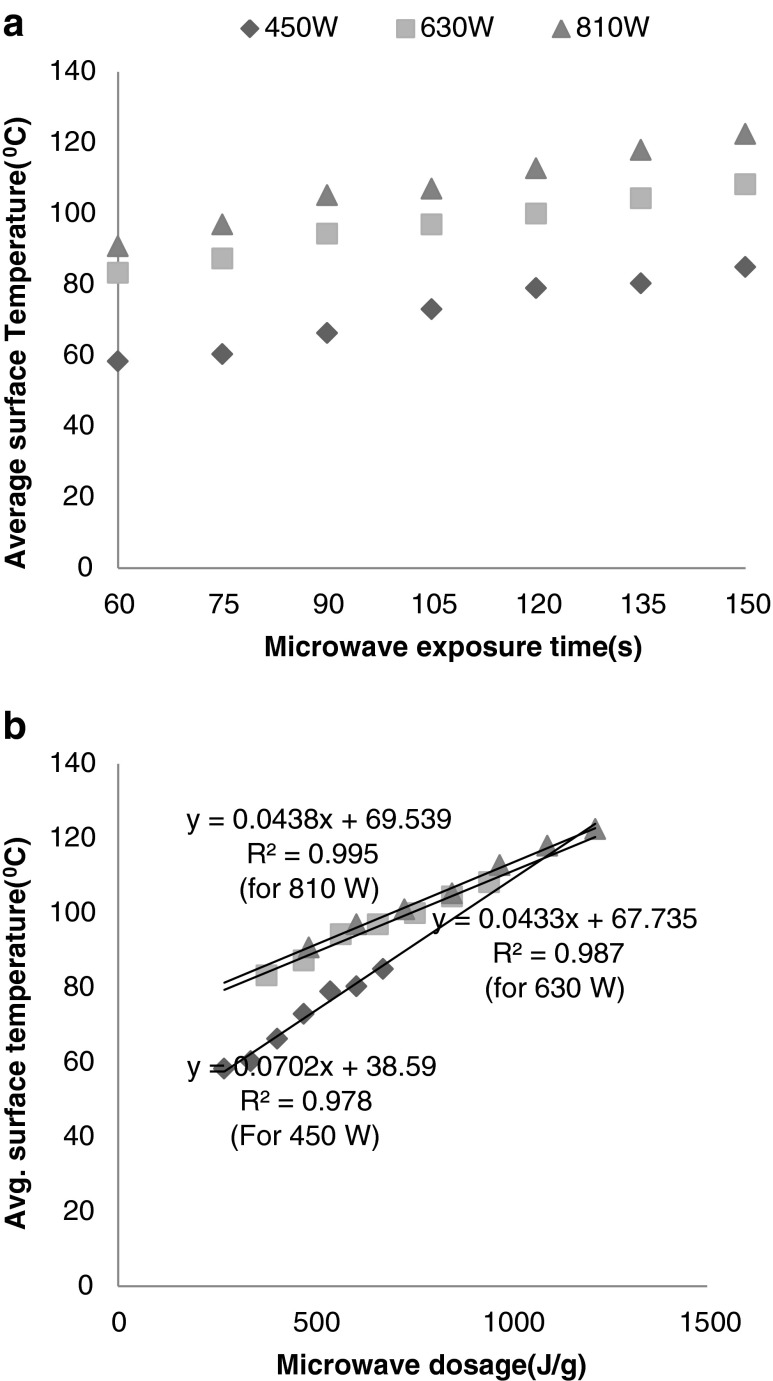

The average surface temperature of the black gram grains subjected to microwave treatments is shown in Fig. 1a. It was noticed that with the increase in the microwave power and exposure time, the average surface temperature of the grains increased. At 450 W, as the exposure time was increased from 60 to 150 s the average surface temperature of the grains increased from 58 to 85 °C. Corresponding increase in temperature at 630 and 810 W were respectively, 83 to 108 °C and 91 to 123 °C. The average surface temperature varied approximately linearly with the exposure time at different microwave powers. But the rate of temperature increase per unit dosage was different at different power level. The effect of microwave dosage on the average surface temperature is shown in Fig. 1b.

Fig. 1.

Variation of average surface temperature (°C) with different microwave (a) exposure times and (b) microwave dosage at different microwave power levels

It was found that for same microwave dosage, the grain surface temperature attained at 450 W is lower than that of 630 and 810 W (Fig. 1a, b). This might be due to insufficient microwave power available at 450 W to be absorbed by the sample. On the other hand, at 630 and 810 W, the temperature rise i.e. the temperature build up for a particular microwave dosage is almost equal, i.e., 0.04 °C per unit dosage (J/g) as compared to 0.07 °C per unit dosage (J/g) for 450 W.

Effect of microwave treatment on the dehulling of black gram

Dehulling time

The dehulling times of black gram subjected to different microwave dosage are given in Table 1. It was observed that the dehulling time was varying from 445 to 170 s depending upon the microwave dosage (product of power level and exposure time) as compared to the 492 s for control. Specifically, the reduction in dehulling time for the dosage applied using power level of 450, 630 and 810 W were respectively from 445 to 383 s, 413 to 200 s and 367 to 170 s for exposure time of 60 to 150 s. It was observed that with the increasing dosage due to increase in exposure time at any microwave power, the dehulling time reduced. Also, the dehulling time decreased with the increase in dosage due to increase in microwave power level. It was noticed that the change in dehulling time due to increase in dosage was insignificant from 120 s onward at 450 W. This might be due to insufficient power availability for the sample used in the study (Table 1). As explained in “Average surface temperature of the microwave treated grains” section, at higher power level and exposure times, the grains are exposed to higher temperatures. This factor enabled the microwave treatment to denature the gums and mucilages present between husk and cotyledon so as to break the bond between them by thermal means. Also, at the higher temperatures, the moisture content of the grains reduced, which helped in dehulling and reduced the dehulling time (Ramakrishnaiah and Kurien 1983; Goyal et al. 2007).

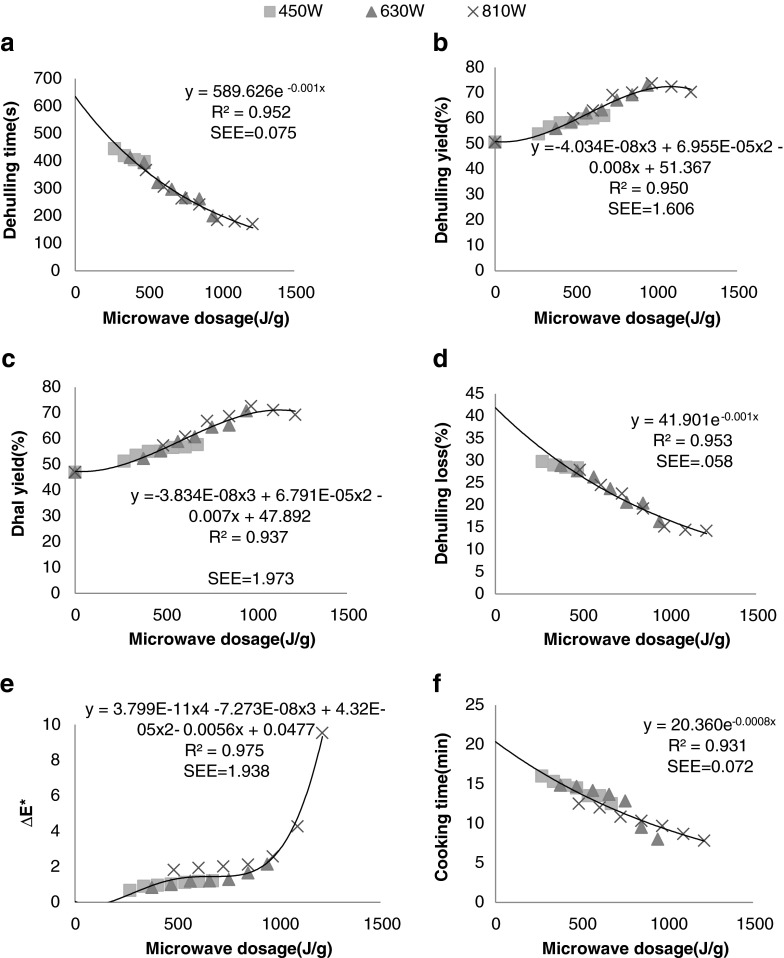

The variation of the dehulling time against the dosage is shown in Fig. 2a. The trend suggests that the dehulling time was reducing with the increased dosage. The reduction in the beginning was higher as compared to that at higher dosage, which was evident by flattening tendency of the curve at the higher dosage. Out of several model used to represent the process, it was found that the exponential relationship represented the process satisfactorily. The relationship could be expressed by the Eq. (6).

| 6 |

Fig. 2.

Variation of (a) dehulling time, (b) dehulling yield, (c) dhal yield, (d) dehulling loss, (e) color difference, ΔE* and (f) cooking time with microwave dosage at different power levels

Where td is the dehulling time (s) and Md is the microwave dosage (J/g).

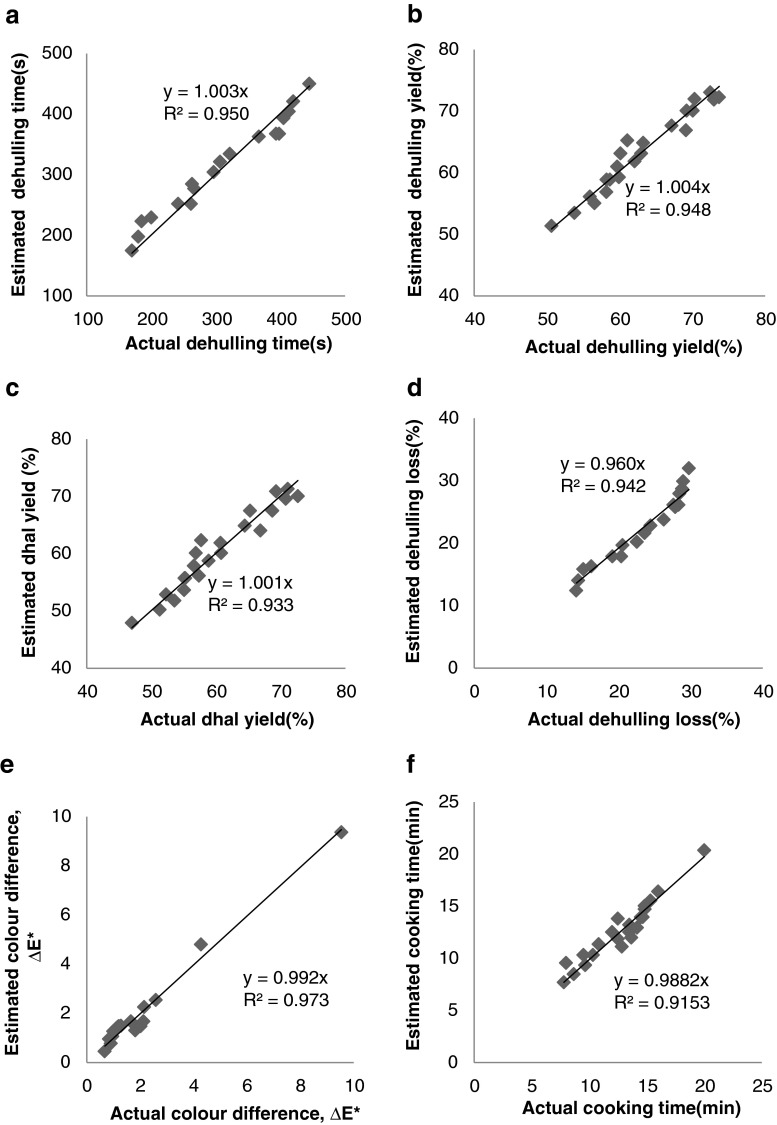

The actual and estimated values of dehulling time for various microwave dosages was presented in the Fig. 3a. It was found that the most of the estimated values were close to the actual values which was evident from the close to unity slope (1.003) and high R2 values of 0.95 for the straight line fit between them.

Fig. 3.

Actual and estimated values of (a) dehulling time, (b) dehulling yield, (c) dhal yield, (d) dehulling loss, (e) color difference, ΔE* and (f) cooking time using developed models

Dehulling yield

The dehulling yield of black gram for various microwave treatment is shown in Table 1. It is obvious from Table 1 that the dehulling yield increased with increase in microwave power level and exposure time. At 450 W, the dehulling yield varied from 53.8 to 61.1 %. Similarly, at 630 and 810 W, the dehulling yield varied from 55.9 to 73.0 % and 59.9 to 73.7 %, respectively depending upon the exposure time as compared to that of control sample of 50.6 %. The maximum dehulling yield (73.7 %) was obtained at 120 s exposures with 810 W power level. The higher yield might be due to lowering of moisture level due to microwave treatment. It is in line with the findings of earlier researchers who reported that dehulling yield increased with reduction in moisture level (Kurien 1981; Ramakrishnaiah and Kurien 1983). And also, heat treatment of grains breaks the bond between hull and cotyledon which in turn makes it easier to dehull and fetch higher yield (Sokhansanj and Patil 2003; Daniella 2010).

The chemical nature of the mucilage and gums, which are networks of cellulosic microfibrils embedded in a matrix of non starch polysaccharides (NSP) and proteins (Cosgrove 1997), present in the interface between the husk and cotyledons play an important role in the dehulling of legume grains. A temperature of about 70 to 80 °C is essential for disruption of cell integrity including protein denaturation and starch granule disruption (Blaszczak et al. 2002). At 630 and 810 W, the grains were subjected to temperatures above 85 °C, which resulted in better dehulling. Therefore, microwave treatment should be applied with a power level of 630 W or more for better result.

As said earlier, the pulses are conventionally dehulled by oil pretreatment. In the published literature a maximum of 74.1 % yield of dehulled kernels has been reported (Sreerama et al. 2009). The dehulling yield achieved in the current study is close to the reported value.

The result of analysis of variance showed that the yield was significantly varying with the increased exposure time for almost each power level except at 810 W where the dehulling yield started decreasing after 120 s exposure time. This suggested that the maximum dosage for the sample should be about 810 W for 120 s combination or equivalent for better result.

At 810 W, the dehulling yield decreased when exposed to microwave for more than 120 s. This might be because of generation of an erratic high temperature at higher dosage leading to sudden moisture loss in the grain, which ultimately resulted in partial roasting and weight loss of the grain.

The plot of dehulling yield with the dosage achieved by different combination of microwave power level and exposure time is shown in Fig. 2b. The dehulling yield was modelled as a function of microwave dosage using SPSS18.0. It was found that dehulling yield of black gram exposed to a microwave dosage could be estimated by the Eq. 7.

| 7 |

Where My is the dehulling yield (%) and Md is the microwave dosage (J/g).

The actual and estimated values of the dehulling yield using Eq. 7 were compared as shown in Fig. 3b. It is evident that both the values are in close agreement as evident by the close to unity slope (1.004) and high R2 values (0.948) of the straight line fit between actual and estimated values.

Dhal yield

Effect of microwave treatments at various power levels for different exposure time on dhal yield is shown in Table 1. The dhal yield ranged from 51.3 to 57.7 % (6.42 % increase) for 450 W power level when exposure times were increased from 60 to 150 s whereas corresponding values of dhal yield for 630 & 810 W were respectively, 52.3 to 70.8 % (18.5 % increase) and 57.4 to 72.7 % (15.3 % increase) as compared to dhal yield of 47.0 % for the control sample. The dhal yield followed similar trends as dehulling yield with slight lower values due to separation of brokens due to similar reasons. It was noted that the maximum dhal yield of 72.7 % was obtained at the power level of 810 W and 120 s exposure.

Figure 2c shows the plot of dhal yield of black gram with microwave dosages achieved by different microwave power levels and exposures. The trend is almost similar to the dehulling yield and could be expressed as a function of dosage by third degree polynomial as expressed by Eq. 8.

| 8 |

Where, Dy is the dhal yield (%) and Md is the microwave dosage (J/g).

The comparison of actual and estimated values using Eq. 8 of the dhal yield is shown in Fig. 3c. The actual values are close to the estimated values as evident from the close to unity slope (1.001) and high R2 value (0.933) of the straight line fitted between the actual and estimated values.

Dehulling loss

The effect of microwave treatment on the dehulling loss of black gram is shown in Table 1. The dehulling losses reduced with increased exposure time at each microwave power level. It varied from 29.8 to 27.5 %, 28.8 to 16.2 % and 27.9 to 14.2 % respectively for 450, 630 and 810 W as compared to the loss of 31.5 % for control sample. The reduction in dehulling losses is facilitated by less breakage and powder formation due to reduction in dehulling time. The results are in agreement with Deshpande et al. (2007) who reported that in conventional dehulling of pigeon pea, percent loss decreased with decreased dehulling time from 45 to 25 s. The minimum loss was accorded to 14.2 % corresponding to power level of 810 W and exposure time of 150 s.

The variation of dehulling loss of black gram with varying microwave dosages attained using various power levels and exposures are given in Fig. 2d. It was found that the dehulling loss decreased with increased dosage non-linearly. The relationship was satisfactorily expressed by an exponential relationship given by Eq. 9.

| 9 |

Where Dl is the dehulling loss (%) and Md is the microwave dosage (J/g).

The comparison of actual and estimated values of dehulling loss using Eq. 9 is shown in Fig. 3d. The actual values are close to the estimated values as evident from the close to unity slope (0.960) and high R2 value (0.942) of the straight line fitted between actual and estimated values.

Effect of microwave power level and exposure time on the properties of dehulled dhal

Colour

The change in colour of dehulled dhal in terms of ΔE* for samples treated at varying microwave power levels and exposures as compared to control sample is given in Table 1. It was found that the ΔE* values increased with increasing power level and exposure for all samples. The ΔE* values of the grains exposed to power level of 450 W ranged from 0.7 to 1.2, while the corresponding range for 630 and 810 W were respectively, 0.8 to 2.2 and 1.8 to 9.5. The colour change might be due to the effect of heat on the grains. It was noted that colour change started at temperatures above 105 °C which deepened with the extended exposure. Though there is slight discolouration, the black gram dhal may be used for cooking purposes as it has an added advantage of having less cooking time, i.e., saving of lots of cooking energy.

It was noticed that up to the ∆E* of 2.0 the change in colour is almost not noticeable by naked eye. A similar observation has also been reported earlier who recommended that till ∆E* <2.0 the change in colour is not noticeable by normal observer, if ∆E* is in between 2 and 3.5 then there is slight colour change noticeable by normal observer but still close to the original colour and beyond 3.5, colour change become quite noticeable as expressed by Krapfenbauer et al. 2006.

The colour difference (∆E*) was plotted as a function of microwave dosage (Fig. 2e). The total colour difference was modelled as a function of microwave dosage using SPSS18.0. It was found that ∆E*of black gram exposed to a microwave dosage could be estimated by the Eq. 10.

| 10 |

Where ∆E* is the total colour difference and Md is the microwave dosage (J/g).

It is evident from Fig. 2e that initially degree of colour change was small which increased rapidly once the microwave dosage became higher than 972 J/g, which was evident from the near vertical trend after that. This might be due to higher surface temperature beyond that dosage, i.e., more than 112 °C. Since the colour change in term of ∆E* more than 3.5 is not at all desirable, it is essential to apply the microwave dosage up to 972 J/g in order to limit the colour change within acceptable limit.

The comparison of actual and estimated values of ∆E* using Eq. 10 is shown in Fig. 3e. The actual values are close to the estimated values as evident from the close to unity slope (0.992) and high R2 value (0.973) of the straight line fitted between actual and estimated values.

Cooking time

Cooking time of dehulled dhal is an important property as it decides the energy required to cook the dhal for consumption or further usage during product formulation. It was found that the cooking time of microwave treated dhal is significantly reduced with the increased levels of power as well as exposure time (Table 1). It reduced from 20.0 min (for the control sample) to 12.5, 8.0 and 8.0 min respectively for the power level of 450, 630 and 810 W. The reduction of cooking time might be attributed to the increased intermolecular spaces due to denaturation of the intermolecular bonds due to thermal effect. The increased intermolecular space allowed more water penetration during cooking with ease, which in turn helped the dhal in getting cooked fast.

The cooking time was plotted as a function of microwave dosage and relationship was determined using SPSS18.0 (Fig. 2f). It was found that cooking time was exponentially related to the microwave dosage as expressed by the Eq. 11.

| 11 |

Where tc is the cooking time (min) and Md is the microwave dosage (J/g).

The comparison of actual and estimated values of the cooking time showed that the data were in close agreement, which was evident from an almost unity slope (0.988) and high R2 value (0.915) of the straight line fitted between the actual and estimated values using Eq. 11(Fig. 3f).

Conclusion

Microwave treatment of black gram plays an important role in improving the dehulling qualities of black gram. The dehulling time for black gram was reduced by 62.3 % when compared to that of the control sample. Using the microwave treatment a maximum dehulling yield of 73.7 % and dhal yield of 72.7 % was achieved as compared to 50.6 % and 47 % respectively for control sample. Even by the oil treatment method, maximum yield has been reported to be about 74.1 % which needed about 4 days in processing such as pitting, oil mixing, drying, water mixing and tempering before dehulling as well as use of a fair amount of edible oil (Sreerama et al. 2009). Also, the process poses risk for contamination. Microwave pre-treatment eliminates these unit operations and thus reduces the total processing time, which ultimately results in energy saving. Microwave treatment also eliminates the usage of oil which adds to the processing cost of the conventional oil pre-treatment method. In addition to that, the microwave treatment also helps in reducing the cooking time for dehulled dhal by approximately 50 % which would be helpful in saving cooking energy.

In the present study, a minimum dosage of about 972 J/g was found to be the best for getting higher yield with almost a little change in colour of dhal and also having lesser cooking time. The relationships were developed for dehulling yield, dhal yield, total colour difference, cooking time for the black gram dhal during microwave treatment. These results are useful for pulse processors as well as in designing a microwave assisted continuous type pulse dehulling system. Thus it could be concluded that the microwave treatment is beneficial for black gram dehulling and also presents an alternative to be commercially adopted.

References

- Blaszczak WJ, Gralik E, Klockiewicz-Kaminska E, Warchalewski J. Effect of g-radiation and microwave heating on endosperm microstructure in relation to some technological properties of wheat grain. Nahrung/Food. 2002;46:122–129. doi: 10.1002/1521-3803(20020301)46:2<122::AID-FOOD122>3.0.CO;2-J. [DOI] [PubMed] [Google Scholar]

- Burridge P, Hensing A, Petterson D. Australian pulse quality laboratory manual. Urrabrae: SARDI Grain Laboratory for GRDC; 2001. [Google Scholar]

- Cosgrove DJ. Assembly and enlargement of the primary cell wall in plants. Annu Rev Cell Dev Biol. 1997;13:171–201. doi: 10.1146/annurev.cellbio.13.1.171. [DOI] [PubMed] [Google Scholar]

- Daniella AL (2010) Effect of storage pre-treatments and conditions on the dehulling efficiency and cooking quality of red lentils. PhD thesis, Winnipeg, MB, Canada: University of Manitoba. Available from: http://hdl.handle.net/1993/3986, (2010/5/7)

- Deosthale YG. Food processing and nutritive value of legumes. In: Srivastava HC, editor. Pulse production, constraints and opportunities. New Delhi: Oxford/IBH Publishing Co; 1982. pp. 377–388. [Google Scholar]

- Deshpande SD, Balasubramanya RH, Khan S, Bhatt DK. Influence of preliminary treatments on dal recovery and cooking characteristics of Pigeon pea. J Agric Eng. 2007;44(1):53–56. [Google Scholar]

- Francis FJ, Clydesdale FH. Food colorimetry theory and applications. Westport: Avi Publishing; 1975. pp. 131–224. [Google Scholar]

- Gopalan C, Sastri BVR, Balasubramanian SC. Nutritive value of Indian foods. India: National Institute of Nutrition, Indian Council of Medical Research; 1989. p. 156. [Google Scholar]

- Goyal RK, Vishwakarma RK, Wanjari OD. Optimisation of the pigeon pea dehulling process. Biosyst Eng. 2007;99(1):51–56. [Google Scholar]

- Jenkins DJ, Thorne MJ, Camelon K, Jenkins A, Rao AV, Taylor RH, Thompson LU, Kalmusky J, Reichert R, Francis T. Effect of processing on digestibility and the blood glucose response: a study of lentils. Am J Clin Nutr. 1982;36(6):1093–1101. doi: 10.1093/ajcn/36.6.1093. [DOI] [PubMed] [Google Scholar]

- Khokhar S, Chauhan BM. Antinutritional factors in mothbean (Vignaaconitifolia): varietal difference and effect of methods of domestic processing and cooking. J Food Sci. 1986;51(3):591–594. doi: 10.1111/j.1365-2621.1986.tb13887.x. [DOI] [Google Scholar]

- Krapfenbauer G, Kinner M, Gossinger M, Schonlechner R, Berghofer E. Effect of thermal treatment on the quality of cloudy apple juice. J Agric Food Chem. 2006;54:5453–5460. doi: 10.1021/jf0606858. [DOI] [PubMed] [Google Scholar]

- Kurien PP (1977) Grain milling technology. Paper presented at FAO experts meeting on grain legume processing. Central Food Technological Research Institute (CFTRI), Mysore

- Kurien PP (1981) Advances in milling technology of pigeonpea. In: Proceedings of the International Workshop on Pigeonpea, International Crops Research Institute for Semi-Arid Tropics (ICRISAT). Patancheru, India, pp. 321–328

- Narasimha HV, Ramakrishnaiah N, Pratape VM. Milling of pulses. In: Chakraverty A, Mujumdar AS, Raghavan GSV, Ramaswamy HS, editors. Handbook of postharvest technology: cereals fruits, vegetables, tea, and spices. New York: Marcel Dekker; 2003. pp. 427–454. [Google Scholar]

- Poehlman JM. History, description, classification and origin. In: Poehlman JM, editor. The mungbean. Boulder: West View; 1991. pp. 6–21. [Google Scholar]

- Ramakrishnaiah N, Kurien PP. Variability in the dehulling characteristics of pigeon pea (Cajanuscajan) cultivars. J Food Sci Technol. 1983;20:287–291. [Google Scholar]

- Ranghino F (1966) Evaluation of rice resistance to cooking based on the gelatinization time of kernels. II Riso, XV, pp. 117–127

- Sokhansanj S, Patil RT. Dehulling and splitting pulses. In: Chakraverty A, Mujumdar AS, Raghvan GSV, Ramaswamy HS, editors. Handbook of post harvest technology. Marcel Dekker: New York; 2003. pp. 397–426. [Google Scholar]

- SPSS Inc. Released . PASW statistics for windows, version 18.0. Chicago: SPSS Inc.; 2009. [Google Scholar]

- Sreerama YN, Sasikala VB, Pratape VM. Effect of enzyme pre-dehulling treatments on dehulling and cooking properties of legumes. J Food Eng. 2009;92:389–395. doi: 10.1016/j.jfoodeng.2008.12.008. [DOI] [Google Scholar]

- Tiwari BK, Jagan Mohan R, Vasan BS. Effect of heat processing on milling of black gram and its end product quality. J Food Eng. 2007;78:356–360. doi: 10.1016/j.jfoodeng.2005.10.003. [DOI] [Google Scholar]

- Vadivambal R, Jayas DS, White NDG. Wheat disinfestation using microwave energy. J Stored Prod Res. 2007;43:508–514. doi: 10.1016/j.jspr.2007.01.007. [DOI] [Google Scholar]

- Vijayakumari K, Sidduraju P, Pugalenthi M, Janardhanan K. Effect of soaking and heat processing on the levels of antinutrients and digestible proteins in seeds of Vignaaconitifolia and Vignasinensis. Food Chem. 1998;63:259–264. doi: 10.1016/S0308-8146(97)00207-0. [DOI] [Google Scholar]

- Wang N, Lewis MJ, Brennan JG, Westby A. Effect of processing methods on nutrients and anti-nutritional factors in cowpea. Food Chem. 1997;58:59–68. doi: 10.1016/S0308-8146(96)00212-9. [DOI] [Google Scholar]

- Zamfir CI (2009) Study on the authenticity and typicity of red wines obtained from local grape varieties (in Romanian). U.S.A.M.V. Ion Ionescu de la Brad, Iaşi, PhD Thesis