Abstract

Pistachio (Pistacia vera L.) oil has important nutritional and therapeutic properties because of its high concentration of essential fatty acids. The extraction method used to obtain natural compounds from raw material is critical for product quality, in particular to protect nutritional value. This study compared the fatty acid composition of pistachio oil extracted by two conventional procedures, Soxhlet extraction and maceration, analyzed by a gas chromatography-flame ionization detector (GC-FID). Four solvents with different polarities were tested: n-hexane (Hx), dichloromethane (DCM), ethyl acetate (EtAc) and ethanol (EtOH). The highest unsaturated fatty acid content (88.493 %) was obtained by Soxhlet extraction with EtAc. The Soxhlet method extracted the most oleic and linolenic acids (51.99 % and 0.385 %, respectively) although a higher concentration (36.32 %) of linoleic acid was extracted by maceration.

Keywords: Fatty acid composition, Gas chromatography, Pistachio oil, Solvent extraction

Introduction

Pistachio nut (Pistacia vera L.) is one of the most popular tree nuts in the world (Nejad et al. 2003; Tsantili et al. 2010). Pistachio nuts have high nutritional value, the kernels being a good source of fat, especially high in unsaturated fatty acids (UFAs) (about 50–70 %) that are essential to the human diet (Maskan and Karatas 1999; Satil et al. 2003). Essential fatty acids include linolenic, linoleic and oleic acids that have cardioprotective effects, being able to reduce the level of cholesterol in the blood (Satil et al. 2003).

Iran is the largest importer and exporter of pistachio nuts. In 2011, Iran produced more than 220,000 t pistachio nuts (Sheibani and Ghaziaskar 2008). Even though a portion of the harvested pistachios has no or low marketable value due to poor appearance or quality, it still has nutritional value. Oil derived from unmarketable pistachio nuts adds market value since it can be sold as a derivative product, encouraging pistachio cultivation (Sheibani and Ghaziaskar 2008).

The extraction of pistachio kernel oil results in an oil rich in oleic and linolenic acids (Sheibani and Ghaziaskar 2008) that have important therapeutic properties (Azlan et al. 2010). Pistachio oil is thus nutritionally attractive due to its fatty acid composition. Oleic acid is a mono-unsaturated fatty acid (MUFA) essential to human nutrition and helps to reduce triglycerides, low-density cholesterol (LDL), total cholesterol and the glycemic index (Kocyigit et al. 2006). Moreover, oleic acid is responsible for the increased stability and subdued oxidation of vegetable oil (Kocyigit et al. 2006). Essential fatty acids are necessary in the human diet for the maintenance of growth and reproduction (Sari et al. 2010). Linoleic acid, an essential fatty acid of the omega-3 group, is very important for the development and maintenance of the nervous system and physiological functions in humans since it reduces total and LDL-cholesterol levels (Sari et al. 2010).

The extraction techniques used to obtain high aggregate value compounds from natural products are critical for product quality (Mezzomo et al. 2010). There are several well-established and conventional organic solvent extraction procedures, including the Folch, Bligh and Dyer, Soxhlet, maceration, Pont, pentane digestion, and supercritical fluid extraction (Ruiz-Rodriguez et al. 2010). Table 1 evaluates the extraction techniques for fatty acids in different food matrices.

Table 1.

Saturated fatty acid content of pistachio oil obtained by Soxhlet and maceration techniques

| Extraction method | Solvent | Saturated fatty acids (%) | ||||

|---|---|---|---|---|---|---|

| Myristic | Palmitic | Stearic | Arachidic | Total | ||

| Soxhlet | Hx | 0.1020 ± 0.02 c | 10.515 ± 0.1 a | 1.535 ± 0.04 b | 1.152 ± 0.04 c | 13.304 ± 0.3 a |

| Soxhlet | DCM | 0.0801 ± 0.01 bc | 10.428 ± 0.02 a | 1.0245 ± 0.02 ab | 0.548 ± 0.05 a | 12.080 ± 0.1 b |

| Soxhlet | EtAc | 0 a | 9.9970 ± 0.08 a | 0.9730 ± 0.05 ab | 0.5360 ± 0.1 a | 11.506 ± 0.5 b |

| Soxhlet | EtOH | 0.0751 ± 0.2 bc | 10.0477 ± 0.3 a | 0.9720 ± 0.01 ab | 0.5410 ± 0.01 a | 11.636 ± 0.3 b |

| Maceration | Hx | 0.0730 ± 0.6 bc | 10.0030 ± 0.2 a | 0.9720 ± 0.01 ab | 0.5250 ± 0.02 a | 11.57 ± 0.5 b |

| Maceration | DCM | 0.0804 ± 0.1 bc | 10.373 ± 0.02 a | 0.9730 ± 0.08 ab | 0.5460 ± 0.01 a | 12.00 ± 0.2 b |

| Maceration | EtAc | 0.0754 ± 0.1 bc | 9.989 ± 0.3 a | 0.9730 ± 0.04 ab | 0.5400 ± 0.07 a | 11.60 ± 02 b |

| Maceration | EtOH | 0 a | 11.811 ± 0.1 b | 0.9110 ± 0.1 a | 0.9110 ± 0.01 b | 13.70 ± 0.1 a |

Hx n-hexane; DCM dichloromethane; EtAc ethyl acetate; EtOH ethanol

The same letter (in a column) indicates no significant difference at P < 0.05 according to DMRT, n = 3

Since the accurate determination of fatty acid composition in oil extracted by different extraction techniques can be used to evaluate their efficiency, the aim of this work was to extract pistachio oil by two conventional extraction techniques, Soxhlet and maceration, using solvents with different polarity indices.

Materials and methods

Chemicals and samples

n-Hexane, dichloromethane, ethyl acetate, ethanol, methanol and potassium hydroxide (GC grade) were supplied by Merck Co. (Darmstadt, Germany). A domestic, commercial pistachio (cv. ‘Akbari’) was obtained from the Pistachio Research Institute, Damghan, Iran. All experiments were performed in the food quality control laboratory of Semnan University of Medical Sciences, Semnan, Iran during January to March, 2011.

Sample preparation for extraction

After peeling nuts manual, fruit samples were dried at 70 °C in an oven (Memert, Model UNE 400 PA, Scheabach, Germany). Dry pistachio kernels were milled (FW-100 Test Instrument Co., Ltd., Tianjin, China) with a fast rotating knife (15,000 rp; 1 min) and passed through a mesh size 16 sieve to obtain identically sized particles then dried once more at 70 °C to constant weight. Dry, milled pistachio was retained in a sealed bag in a refrigerator (1–2 °C) until use. Milled pistachio kernel particle size is important to facilitate analyses of mass transfer (i.e., fat) during the extraction process and to obtain reproducible extraction yield (Mezzomo et al. 2010).

Extraction techniques

Soxhlet extraction was performed according to Mezzomo et al. (2010). The extraction was performed at least in duplicate, with four solvents, n-hexane (Hx), dichloromethane (DCM), ethyl acetate (EtAc) and ethanol (EtOH), each with a polarity of 0, 3.1, 4.4 and 5.2, respectively. An automated Soxhlet set (Buchi extraction system B-811, Flawil, Switzerland) was used to extract pistachio oil. To achieve this, 5 g of sample (dry milled pistachio powder) was packed in a cartridge placed inside a 250-ml extractor device. The sample was extracted for 6 h at the solvent’s boiling point temperature. The proportion of solvent was 150 ml in a 250 ml Soxhlet flask. The maceration method consisted of macerating 50 g of the pistachio kernel particles in 200 ml of each solvent (Hx, DCM, EtAc and EtOH), as described by Mezzomo et al. (2010) with some modifications, and was carried out at least in duplicate.

Separation of the mixture oil/solvent

A rotary-evaporator (Buchi, R-210/215, Switzerland) was used to release the solvent from the extracts obtained by the two methods by evaporating the solvents under vacuum with a vacuum control and thermostatic bath (Buchi, V-700, Switzerland).

Fatty acid composition

The fatty acid composition of the pistachio oil was determined by a gas chromatography-flame ionization detector (GC-FID) according the Ce1f-96 Method of American Oil Chemists’ Society (AOCS 2002). Oil samples were converted to methyl esters by vigorous shaking of the oil solution in 7 ml Hx with 2 ml of methanolic potassium hydroxide. The tube holding the solution was placed in a water bath (55 °C) for 20 min and was shaken for 5 min. After decanting during the final 5 min, 1 μl of the upper layer was injected into the GC-FID (6890 N, Agilent, US) equipped with a BPX70 capillary column (120 m × 0.25 mm × 0.25 μm) under the following conditions: initial temperature = 16 °C, final temperature = 220 °C, heating rate = 18 °C/min, detector temperature = 250 °C, injector temperature = 230 °C, pressure of nitrogen (carrier gas) = 42.12 psi.

Statistical analysis

The results were statistically evaluated by one-way analysis of variance (ANOVA) in a completely randomized design using SPSS v. 11.5 (IBM SPSS, New York, USA) Significant differences between means were assessed at P < 0.05 using Duncan’s Multiple Range test.

Results and discussion

A chromatogram of a pistachio oil sample is shown in Fig. 1. The saturated fatty acid (SFA) and unsaturated fatty acid (UFA) profiles of pistachio oil extracted by Soxhlet and maceration methods, as detected by GC-FID analysis, were not different but their contents were statistically different (Tables 1 and 2, respectively). In pistachio oil, oleic acid, linoleic acid and palmitic acid were the predominant fatty acids. The relative concentration of SFAs in pistachio oil extracts ranged from 11.51 % in the Soxhlet-EtAc sample to 13.70 % in the maceration-EtOH sample.

Fig. 1.

Chromatogram of fatty acids profiles of the pistachio oil obtained by GC-FID: 16.164 min (miristic acid), 18.554 min (palmitic acid), 19.714 min (palmitoleic acid), 21.801 min (stearic acid), 22.968 min (oleic acid), 24.617 min (linoleic acid), 26.710 min (arachidic acid), 27.698 min (linolenic acid)

Table 2.

Unsaturated fatty acid content of pistachio oil obtained by Soxhlet and maceration techniques

| Extraction method | Solvent | Unsaturated fatty acids (%) | ||||

|---|---|---|---|---|---|---|

| Palmitoleic | Oleic | Linoleic | Linolenic | Total | ||

| Soxhlet | Hx | 0.914 ± 0.01 a | 49.850 ± 0.02 b | 35.478 ± 0.2 d | 0.379 ± 0.4 b | 86.621 ± 0.02 c |

| Soxhlet | DCM | 0.925 ± 0.3 a | 51.939 ± 0.03 c | 34.670 ± 0.3 c | 0.391 ± 0.2 b | 87.925 ± 0.06 b |

| Soxhlet | EtAc | 0.899 ± 0.02 a | 53.263 ± 0.2 f | 33.948 ± 0.5 a | 0.383 ± 0.09 b | 88.493 ± 0.08 a |

| Soxhlet | EtOH | 0.914 ± 0.04 a | 52.904 ± 0.06 e | 34.0788 ± 0.01 b | 0.392 ± 0.01 b | 88.289 ± 0.2 a |

| Maceration | Hx | 0.9125 ± 0.01 a | 52.875 ± 0.02 e | 34.168 ± 0.3 b | 0.398 ± 0.12 b | 88.353 ± 0.08 a |

| Maceration | DCM | 0.955 ± 0.07 a | 52.000 ± 0.06 d | 34.591 ± 0.8 c | 0.389 ± 0.45 b | 87.935 ± 0.1 b |

| Maceration | EtAc | 0.923 ± 0.03 a | 52.300 ± 0.15 d | 34.738 ± 0.14 c | 0.405 ± 0.3 b | 88.400 ± 0.05 a |

| Maceration | EtOH | 0.912 ± 0.05 a | 43.698 ± 0.1 a | 41.756 ± 0.1 f | 0.000 a | 86.366 ± 0.03 d |

Hx n-hexane; DCM dichloromethane; EtAc ethyl acetate; EtOH ethanol

The same letter (in a column) indicates no significant difference at P < 0.05 according to DMRT, n = 3

Palmitic and stearic acids are the most representative SFAs in pistachio oil while myristic and arachidic acids are present only in trace amounts, for all extracts studied, with a relative concentration lower than 0.9 % (except for arachidic acid content of Soxhlet-Hx) (Table 1).

Pistachio oil contains mainly UFAs ranging from 86.37 % in the maceration-EtOH sample to 88.49 % in the Soxhlet-EtAc sample (Table 2).

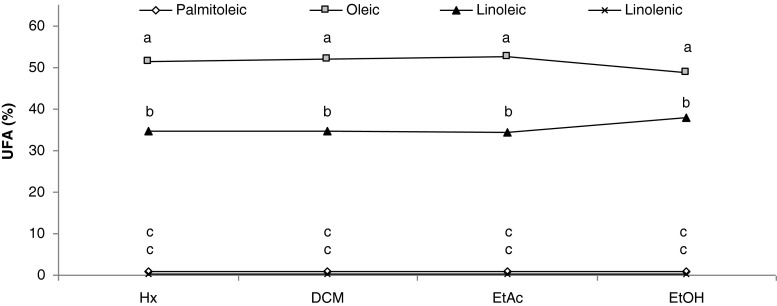

The UFA content indicate that oleic and linoleic acids are the major UFAS in all oil pistachio samples obtained by the two extraction methods. The oleic acid content following Soxhlet extraction in different solvents was significantly different (P < 0.05). The highest and lowest oleic acid content were obtained in Soxhlet-EtAc (53.26 %) and maceration-EtOH (43.70 %) samples, respectively (Table 2). Linoleic acid ranged from 33.95 % in the Soxhlet-EtAc sample to 41.76 % in the maceration-EtoH sample (Table 2). Palmitoleic and linolenic acids were presented in low quantities (less than 0.96 %) for all samples studied (Table 2). No significant correlation was found between PI and FAs in this study (data not shown).

Pistachio nut represents an important raw material to obtain edible oil with high content of unsaturated fatty acids. The resulting oil from two conventional extraction methods showed oleic and linoleic acids as the major compounds. The Soxhlet method provided the highest UFA, mainly due to the high operational temperature, solvent recycle and solvent/solute interactions. Maceration showed the lowest UFA values despite the highest concentrations of SFAs. The concentration of fatty acids due to use of different solvents in pistachio oil extraction was different. Thus, in order to obtain pistachio oil with high quality, attention must be paid to the technique to oil extraction.

Oil samples are not chemically esterified before fatty acid analysis (Mezzomo et al. 2010). Natural esterification may occur during sample handling, allowing solvent polarity to influence oil fractionation. This can be explained by the use of high temperature and reflux in Soxhlet extraction overcoming the polarity effect during the extraction of UFAs. The effect of solvent polarity index (PI) in conventional technique on fractionation of SFAs and UFAs was observed from the fatty acid concentration shown in Figs. 2 and 3, respectively. Figures 1 and 2 compare different extraction techniques on the fatty acid composition of pistachio oil.

Fig. 2.

Ability of four solvents to fractionate saturated fatty acids (myristic, palmitic, stearic, arachidic) derived from pistachio oil. Solvents tested: n-hexane (Hx), dichloromethane (DCM), ethyl acetate (EtAc) and ethanol (EtOH). Different letters indicate significant differences across saturated fatty acids and across solvents at P < 0.05 according to DMRT, n = 3

Fig. 3.

Ability of four solvents to fractionate unsaturated fatty acids (palmitoleic, oleic, linoleic, linolenic) derived from pistachio oil. Solvents tested: n-hexane (Hx), dichloromethane (DCM), ethyl acetate (EtAc) and ethanol (EtOH). Different letters indicate significant differences across unsaturated fatty acids and across solvents at P < 0.05 according to DMRT, n = 3

Our results relative to the differences between fatty acid concentration derived from different oil extraction techniques, especially with regard to method and solvent, are in agreement with other researches who assayed the effects of extraction techniques on fatty acids, including the extracts of: a red-green-brown macro alga (Kumari et al. 2011); oil extract of animals and plants (Schafer 1998); Microula sikkimensis seed oil (Cao and Suo 2010); palm oil (Tan et al. 2009); pistachio oil (Sheibani and Ghaziaskar 2008); peach almond oil (Mezzomo et al. 2010); oil extracted from different parts of Indian mackerel (Rastrelliger kanagurta) (Sahena et al. 2010). All these studies reported that the concentration of SFA and UFA were statistically different when different methods and solvents were used to extract oil.

To obtain high quality pistachio oil with high UFAs, especially oleic acid content, Soxhlet extraction is best. Sheibani and Ghaziaskar (2008) extracted pistachio oil using pressurized fluid extraction (PFE) method. They found that PFE yield (i.e. 52.6 g/100 g) and fatty acid composition of pistachio oil were similar to Soxhlet extraction and variations were not statistically significant. They used two different solvents (n-hexane and ethanol) for pistachio oil PFE. The extraction yield was about one-third (i.e. 18 g/100 g) when ethanol was used as the solvent.

Conclusion

In this study, two techniques for the extraction of oil from pistachio were investigated and compared. The saturated and unsaturated fatty acid profiles of pistachio oil extracted by Soxhlet and maceration method were not different but their content was statistically different. The highest UFA and SFA contents were obtained by Soxhlet with EtAc and maceration with EtOH. The Soxhlet method could extract the highest concentration of oleic acid and linolenic acid (51.99 % and 0.385 %, respectively) while maceration could extract the highest concentration of linoleic acid (36.22 %). Since UFAs are known to have positive effects on human health (Monge-Rojas et al. 2013), Soxhlet is an effective and feasible method for the extraction of oil pistachio. Thus, it could be used for the industrial-scale production of pistachio oil.

Acknowledgments

The authors wish to thank the Food and Drug Administration of Semnan University of Medical Sciences for financial support and the quality control laboratory of Semnan University of Medical Sciences for helping and providing laboratory facilities for conducting the experiment.

Conflict of interest

The authors declare no financial or other conflicts of interest.

References

- AOCS (2002) Official methods of analysis. 5th ed. American oil chemist’s society. Champaign, Illinois, Washington DC.

- Azlan A, Prasad KN, Khoo HE, Abdul-Aziz N, Mohamad A, Ismail A, Amom Z. Comparison of fatty acids, vitamin E and physicochemical properties of Canarium odontophyllum Miq. (dabai), olive and palm oils. J Food Compos Anal. 2010;23:772–776. doi: 10.1016/j.jfca.2010.03.026. [DOI] [Google Scholar]

- Cao Y, Suo Y. Extraction of Microula sikkimensis seed oil and simultaneous analysis of saturated and unsaturated fatty acids by fluorescence detection with reversed-phase HPLC. J Food Compos Anal. 2010;23:100–106. doi: 10.1016/j.jfca.2009.07.006. [DOI] [Google Scholar]

- Kocyigit A, Koylu AA, Keles H. Effects of pistachio nuts consumption on plasma lipid profile and oxidative status in healthy volunteers. Nutr Metab Cardiovasc Dis. 2006;16:202–209. doi: 10.1016/j.numecd.2005.08.004. [DOI] [PubMed] [Google Scholar]

- Kumari P, Reddy CRK, Jha B. Comparative evaluation and selection of a method for lipid and fatty acid extraction from macroalgae. Anal Biochem. 2011;415:134–144. doi: 10.1016/j.ab.2011.04.010. [DOI] [PubMed] [Google Scholar]

- Maskan M, Karatas S. Storage stability of whole-split pistachio nuts (Pistachia vera L.) at various conditions. Food Chem. 1999;66:227–233. doi: 10.1016/S0308-8146(99)00055-2. [DOI] [Google Scholar]

- Mezzomo N, Mileo BR, Friedrich MT, Martínez J, Ferreira SRS. Supercritical fluid extraction of peach (Prunus persica) almond oil: process yield and extract composition. Bioresour Technol. 2010;101:5622–5632. doi: 10.1016/j.biortech.2010.02.020. [DOI] [PubMed] [Google Scholar]

- Monge-Rojas R, Aragón MC, Chinnock A, Campos H, Colón-Ramos U. Changes in dietary in take and food sources of saturated and cis and trans unsaturated fatty acids in Costa Rican adolescents: 1996 versus 2006. Nutrition. 2013;29:641–645. doi: 10.1016/j.nut.2012.10.004. [DOI] [PubMed] [Google Scholar]

- Nejad MK, Tabil LG, Mortazavi AS, Kordi AS. Effect of drying methods on quality of pistachio nuts. Dry Technol. 2003;21:821–838. doi: 10.1081/DRT-120021688. [DOI] [Google Scholar]

- Ruiz-Rodriguez A, Reglero G, Ibanez E. Recent trends in the advanced analysis of bioactive fatty acids. J Pharm Biomed Anal. 2010;51:305–326. doi: 10.1016/j.jpba.2009.05.012. [DOI] [PubMed] [Google Scholar]

- Sahena F, Zaidul ISM, Jinap SA, Yazid AM, Khatib A, Norulaini NAN. Fatty acid compositions of fish oil extracted from different parts of Indian mackerel (Rastrelliger kanagurta) using various techniques of supercritical CO2 extraction. Food Chem. 2010;120:879–885. doi: 10.1016/j.foodchem.2009.10.055. [DOI] [Google Scholar]

- Sari I, Baltaci Y, Bagci C, Davutoglu V, Erel O, Celik H, Ozer O, Aksoy N, Aksoy M. Effect of pistachio diet on lipid parameters, endothelial function, inflammation, and oxidative status: a prospective study. Nutrition. 2010;26:399–404. doi: 10.1016/j.nut.2009.05.023. [DOI] [PubMed] [Google Scholar]

- Satil F, Azcon N, Baser KHC. Fatty acid composition of pistachio nuts in Turkey. Chem Nat Compd. 2003;39:322–324. doi: 10.1023/B:CONC.0000003408.63300.b5. [DOI] [Google Scholar]

- Schafer K. Accelerated solvent extraction of lipids for determining the fatty acid composition of biological material. Anal Chim Acta. 1998;358:69–77. doi: 10.1016/S0003-2670(97)00587-4. [DOI] [Google Scholar]

- Sheibani A, Ghaziaskar H. Pressurized fluid extraction of pistachio oil using a modified supercritical fluid extractor and factorial design for optimization. LWT Food Sci Technol. 2008;41:1472–1477. doi: 10.1016/j.lwt.2007.09.002. [DOI] [Google Scholar]

- Tan CH, Ghazali HM, Kuntom A, Tan CP, Ariffin AA. Extraction and physicochemical properties of low free fatty acid crude palm oil. Food Chem. 2009;113:645–650. doi: 10.1016/j.foodchem.2008.07.052. [DOI] [Google Scholar]

- Tsantili E, Takidelli C, Christopoulo MV, Lambrinea E, Rouskas D, Roussos PA. Physical, compositional and sensory differences in nuts among pistachio (Pistachia vera L.) varieties. Sci Hortic. 2010;125:562–568. doi: 10.1016/j.scienta.2010.04.039. [DOI] [Google Scholar]