Abstract

Effect of spinach powder on the physico-chemical, rheological, nutritional and sensory characteristics on chapati premixes was studied by incorporating spinach powder at different concentrations from 1 % to 10 % based on wheat flour. Addition of 5 % of spinach powder to wheat flour was found to be optimum for chapati preparation. Effect of incorporation of spinach powder on the alveo-consistographic, mixographic and pasting characteristics were studied. It was observed that peak viscosity, breakdown viscosity significantly decreases whereas, peak time, tenacity increases with the increase in the concentration of spinach powder from 1 % to 10 % in chapati premixes. Addition of spinach powder also significantly affects the textural qualities of the chapaties. Premixes and prepared chapaties were also studied for chlorophyll content, total carotenoids,vitamins and minerals.

Keywords: Alveograph, Colour, Minerals, Texture, Vitamins

Introduction

The average diet in most of the Asian countries including India is predominantly cereal based. These diets have poor bioavailability of micronutrients leading to wide prevalence of iron-deficiency, anaemia and vitamin ‘A’. Certain green leafy vegetables are a rich source of β-carotene, a precursor of vitamin ‘A’ and grown abundantly in India. Though there are more than 25 varieties of green leafy vegetables are available in India, but still considered as local garden vegetables and the preference is based on the region (Premavalli et al. 2001). The most commonly used leafy vegetables are spinach, fenugreek, drumstick leaves, shepu, coriander, mint, chakota and curry leaves etc. Since these have short life, suitable processing and preservation can prevent wastage and increase availability in the diet during off season. In developing countries multiple micronutrient deficiency are more common than single deficiency and the cause for their high prevalence is due to poor consumption and poor bioavailability of micronutrients (Gupta and Prakash 2011). There are food based strategies by which micronutrient status of population can be increased. Food fortification is one of such approach along with food production and dietary diversification by which status of micronutrient in food can be increased (Allen et al. 2006).

In India, 90 % of wheat produced is consumed in the form of chapati and only 10 % is utilised for making biscuits, breads, cakes and such other products (Bedekar 2001). Chapati, a flat unleavened, hot-plate baked product prepared from whole wheat flour by converting into dough with water by adding other ingredients like salt and sugar according to the taste to make chapati. Though, wheat flour is a staple food for half of the world population, still it is not a complete diet which lacks micronutrients. Balanced diets are not accessible to a large population of the world, particularly those in developing countries. Among the plant foods green leafy vegetables are the cheapest and locally available food rich in micronutrients. Traditional preparations like chapati when prepared by incorporating with green leafy vegetables could serve a means of enhancing nutritive value of food.

Today due to urbanisation and lack of time to prepare food, there is a demand to have nutritious premixes which are ready to reconstitute and ready to prepare. There are various types of premixes like idli, dosa, jamoon premixes etc. are available in market, chapati premix fortified with nutrient rich green leafy vegetables are not available. Though green leafy vegetables have been tried as value additives for different products. Singh and Kawatra (2006), developed different Indian traditional snacks like pakora, vada etc. by incorporating fresh and dried powder of amaranthus leaves. Reddy et al. (2000) developed biscuits by using extracts of amla, drumstick and raisins. Dachana et al. (2010) evaluated the effect of dried moringa leaves on the rheological, microstructural, nutritional, textural and organoleptic characteristics of cookies. Therefore, attempts were made to develop chapati premixes by fortifying wheat flour with dehydrated spinach powder and to evaluate their effect on physico-chemical, rheological, nutritional and sensory characteristics.

Materials and methods

Commercially available sugar powder, skimmed milk powder, wheat, table salt, hydrogenated fat and fresh spinach leaves were procured from local market.

Blanching

Blanching of spinach leaves was carried out according to the method prescribed by Premavalli et al. (2001).

Physical tests and preparation of wheat flour

Test weight and thousand kernel weight, kernel length and width of wheat were determined by using a Vernier Calliper (ESAL, Scientific Industries, New Delhi, India) according to AACC approved methods (2000). Wheat was ground to 400 μm particle size and used for the development of chapati premixes.

Chemical analysis

Moisture, protein, total ash and crude fibre were determined by standard AOAC methods (1980). Chlorophyll and carotenoid were estimated using hexane–acetone solvent mixture by titrometry (Ranganna 1986).

Preparation of spinach fortified chapati premixes (SFCP)

Premixes were prepared by fortifying wheat flour with dehydrated spinach powder in the concentration of 1–10 % on wheat flour basis. Other ingredients like sugar powder (3.0 %), salt (2.2 %) and milk powder (2.0 %) were kept constant for all the formulations based on whole wheat flour: spinach powder weight basis.

Rheological characteristics of SFCP

Alveo-consistograph tests of SFCP like water absorption, dough development time (Tpr), tenacity (P), dough extensibility (L) and the deformation energy (W) were conducted using Alveograph (Alveolink NG Consistograph: Villeneuve La Garenne, Chopin, France) following the approved AACC method (2000). The mixing characteristics of chapati premixes were measured by using the 10 g moving mixograph (National Mfg, Division, TMCO, Lincoln, USA). Rapid Visco Analyser 4D (Newport Scientific Pvt Ltd, Warie Wood, Australia) was used to measure pasting properties of flours as described by AACC method (2000).

Preparation of spinach chapaties

Chapaties were prepared by using required amount of SFCP, water and hydrogenated fat as per the method prescribed by Arya et al. (1977). Control chapaties were prepared from 100 % whole wheat flour without using spinach powder. Other ingredients which were used in the preparation of spinach chapaties remained the same.

Sensory analysis

Organoleptic characteristics of chapaties were determined by evaluating different attributes like colour, aroma, taste, texture and overall acceptability (OAA) by a 25 semi trained panel of the laboratory on a 9 point hedonic scale having a score of 9 for extreme liking and 1 for extreme disliking (Larmond 1977).

Colour values

The colour values in terms of L ,a and b for chapaties prepared by using SFCP were measured using a Hunter Colour Meter (Data Lab; Silvasa, Gujarat, India) with illuminant D65 and 100 observer. A higher L value indicated a brighter or whiter sample. Values of a and b indicated the red-green and yellow-blue chromaticity respectively.

Texture profile analysis

Texture profile analysis of chapaties prepared by using SFCP was performed using a Texture Analyser Plus (Model No.01/TALS/LXE/UK; LLOYD Instruments, Hampshire.UK). The bite test on chapati was carried out using the volvodke bite set (part no.01/2663). Ten measurements per replication were taken for all the textural analysis.

Statistical analysis

Experiments were performed using a 2-way factorial design. All the experiments were performed in triplicate and Analysis of Variance were calculated using Statistica Software Version 7.0 of Stat Soft Incorporation, Tulsa OK, USA as per the methods of Snedecor and Cochran (1968).

Results and discussion

Wheat purchased from the local market had a test weight (75.0 ± 0.5 Kg hL−1) which is an important predictor milling yield for flour extraction rate, thousand kernel weight (41.4 ± 02 g) which describes wheat kernel composition and potential wheat extraction. Wheat with a higher thousand kernel rate should have a greater potential for flour extraction. Average kernel length and grain width which determine the quality and soundness of the kernel were found to be 6.4 ± 0.01 mm, 3.1 ± 0.02 mm respectively. The wheat flour contained 1.55 % ash, 12.25 % protein and 1.16 % crude fibre with a falling number of 436 s. The dried spinach powder had moisture of 4.82 %, ash 10.35 %, protein 21.25 %, crude fibre 11.32 %, iron 68.92, calcium 1,019, zinc 5.06, sodium 3,279 and potassium 1,094 mg /100 g. The total carotenoids, total chlorophyll and vitamin ‘C’ contents in dehydrated spinach powder were found to be 740 μg/100 g, 733 and 148 mg/100 g.

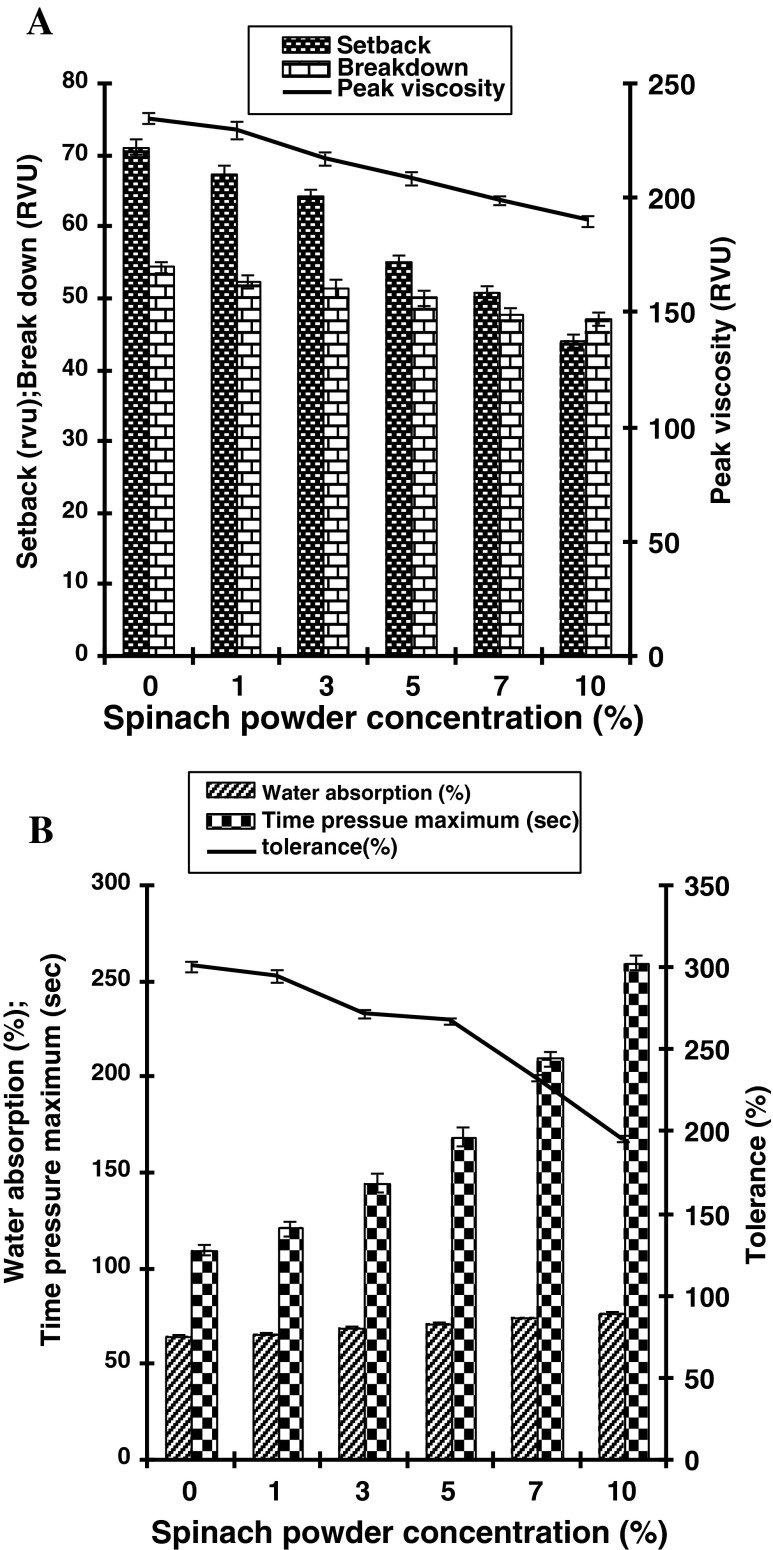

Effect of spinach powder on the alveo-consistographic characteristics of chapati premixes

Effect of spinach on the consistograph characteristics of chapati premixes are shown in Fig. 1. It is observed that water absorption was increased with the increase in spinach from 65.0 to 77.1 %. The increase in water absorption may be attributed to the fact that hydroxyl groups present in the fibre structure allow more water interaction through hydrogen bonding. Earlier, Dachana et al. (2010) and Gomez et al. (2003) also reported addition of fiber increase water absorption in cookies and bread due to the hydroxyl groups present in the fiber. The time required for dough development or to reach a dough consistency equivalent to 2,200 mb pressure (Tpr) was increased from 110 to 260 s, whereas the tolerance (To1) which measures the stability of the dough, decreased with the increase in the concentration of spinach powder from 301 to 165 s. The increase in time for dough development and decrease in stability may be attributed to the decrease in the strength of dough due to increase in fiber content owning to dilution and disruption of continuity of gluten. Earlier Gomez et al. (2003) reported that time required for dough development increases as a consequent of fiber addition to wheat flour. Dachana et al. (2010) also reported increase in time for dough development with the addition of increasing amount of dehydrated moringa leaves in wheat flour for the preparation of cookies.

Fig. 1.

Effect of spinach powder on a consistographic characteristics and b pasting properties of chapati premixes (n = 3)

The alveograph parameters also got affected significantly (p ≤ 0.05) with the increase in spinach concentration (more than 3 %). The tenacity (P) which gives information about the handling characteristics of the dough capacity increases with the increase in spinach powder from 152 to 190 mm, while extensibility of the dough (L), a predictor of the processing characteristics of the dough decreases from 28 to 18 mm. The increase in P value may be attributed to the interactions between the fiber structure and the wheat proteins due to partial disturption of gluten resulting in the increase of tenacity of the dough. Earlier also, Ghufran et al. (2009) and Gomez et al. (2003) reported addition of fiber in the dough resulted in increase in tenacity. The change in the balance of extensibility properties of the dough is attributed to the partial disruption of the gluten network due to the addition of spinach powder (Shirpa et al. 2012). The baking strength (W) which is represented by the area under the curve formed during the calculation of tenacity and extensibility decreases from 150 to 101 J with the increase in spinach powder concentration. The decrease in baking strength may be attributed to the fact that with the addition of spinach powder, the baking strength of the dough becomes weaker due to the disturption of gluten net work. Earlier also, Ghufran et al. (2009) reported that with the increase in rice bran (fiber), the baking strength of the wheat flour got decreased.

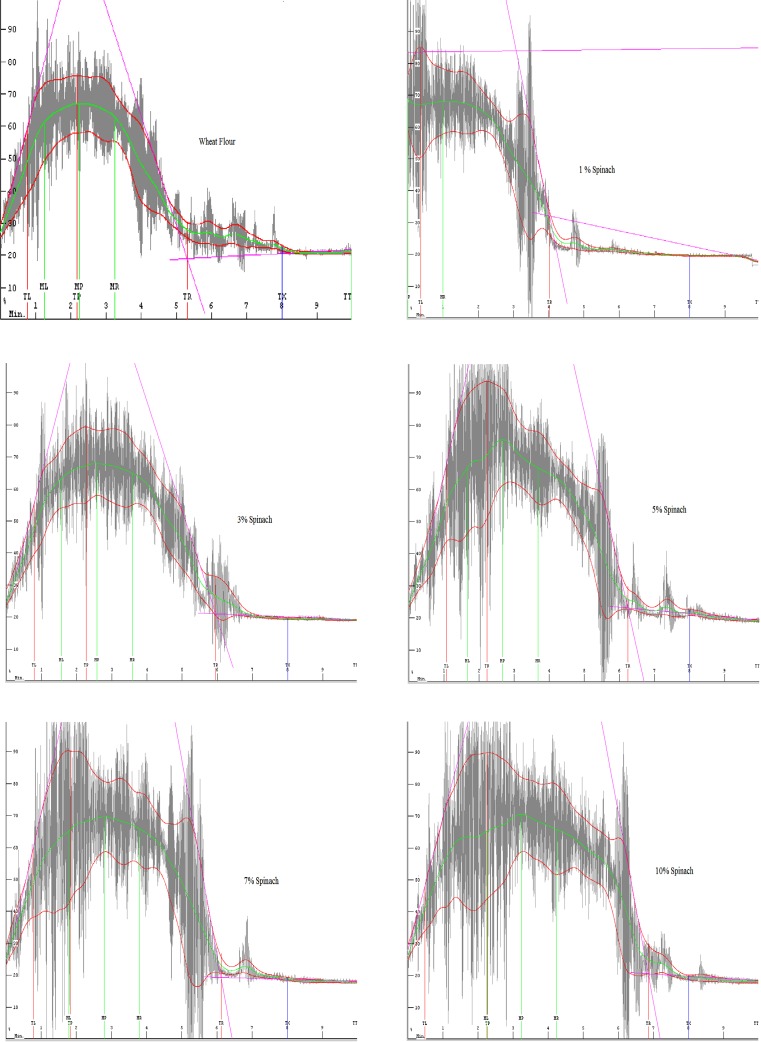

Effect of spinach powder on the mixographic characteristics of chapati premixes

Effect of spinach powder on the mixographic characteristics is shown in the Fig. 2. It is observed that with the increase in the concentration of spinach powder, there was an increase in peak time which is the measure of time taken for the dough development. Control wheat flour had a peak time 2.25 min and differ significantly (p ≤ 0.05) from the value 3.24 min obtained for the wheat flour fortified with 10 % spinach powder. The increase in mixing time may be attributed to the toughening effect of gluten due to the presence of fibre content and also due to the delay in the hydration and development of gluten (Shirpa et al. 2012). The ascending and descending slopes (% min) also get affected with the addition of spinach powder. Fortification of wheat flour with spinach powder results in the dilution and disruption of continuity of gluten which results in poor dough quality as indicated by ascending and descending slopes. The work function represented by Integral of percent*torque time, min tend to increase significantly (p ≤ 0.05) from 56.45 to 117.80 indicating decrease in strength of the gluten (Ghufran et al. 2009).

Fig. 2.

Effect of spinach powder on the mixographic characteristics of chapati premixes

Effect of spinach powder on the pasting properties of chapati premixes

Effect of spinach powder on the pasting properties of chapati premixes is shown in Fig. 1. It is observed that increase in the amount of spinach powder results in the decrease in peak viscosity, which relates to the ability of starch granule to swell freely before their physical break down decreases from 235.01 to 190.42 RVU. The decrease in peak viscosity may be due to the partial gelatinisation of starch and denaturation of proteins and less water available for initial swelling of starch granule (Yadav et al. 2008; Symons and Brennan 2004). Earlier also Dachana et al. (2010) reported decrease in peak viscosity with the increase in dried moringa leaves. The break down which is highly influenced by the amylose content and a measure of susceptibility of cooked starch granules to disintegration decreased significantly (p ≤ 0.05) from 54.50 to 47.10 RVU. The set back viscosity which is a measure of the recrystallisation of gelatinised starch during cooking and also represents the effect of cooking and tendency to retrograde (Lee et al. 1995; Yadav et al. 2008) decreases significantly (p ≤ 0.05) from 71.25 to 44.11 RVU. The decrease in the set back may be due to aggregation of amylase fractions, which leads to the reinforcement of swollen granules and fragments by the formation of bonds between and within them (Dengate and Meredith 1984). The pasting temperature which provides an indication of the minimum temperature required cooking a given sample, and also it is the temperature at the onset of rise in viscosity decreases from 85.50 to 80.05 °C.

Effect of spinach powder on the colour values of chapaties

Chapaties prepared using wheat flour fortified with different concentrations of spinach powder and the changes in colour values were recorded using Hunter Colour Meter and the results are given in Table 1. It was found that with the increase in spinach powder, there was a significant decrease (p ≤ 0.05) in brightness (L) value from 87.86 to 68.15 and also there was a decrease in redness in chapaties from 1.95 to 1.58. Yellowness (b) in chapaties significantly (p ≤ 0.05) increases from 11.85 to 27.12. The increase in ‘b’ values may be attributed to the maillard reaction between sugar and amino acid (Yadav et al. 2009).

Table 1.

Effect of spinach powder on hunter colour values, instrumental texture and sensory quality of chapaties prepared using chapati premixes

| Parameters | Dried Spinach powder (%) | |||||

|---|---|---|---|---|---|---|

| 0 | 1 | 3 | 5 | 7 | 10 | |

| Hunter colour values* | ||||||

| Lightness (L) | 87.86a ± 1.21 | 84.12b ± 1.02 | 80.87c ± 1.01 | 76.12d ± 0.90 | 72.30e ± 0.85 | 68.15f ± 0.83 |

| Redness (a) | 1.95a ± 0.02 | 1.92a ± 0.02 | 1.85b ± 0.01 | 1.72c ± 0.02 | 1.65d ± 0.03 | 1.58e ± 0.01 |

| Yellowness(b) | 11.85a ± 0.41 | 13.26b ± 0.32 | 16.40c ± 0.43 | 19.52d ± 0.42 | 21.82e ± 0.62 | 27.12f ± 0.72 |

| Instrumental texture* | ||||||

| Hardness (N) | 6.51a ± 0.11 | 6.53a ± 0.12 | 7.79b ± 0.11 | 9.47c ± 0.14 | 12.99d ± 0.16 | 16.52f ± 0.21 |

| Springiness (mm) | 1.18a ± 0.02 | 1.16a ± 0.01 | 1.12c ± 0.01 | 1.05d ± 0.02 | 0.94e ± 0.01 | 0.85f ± 0.02 |

| Gumminess (N, mm) | 2.62a ± 0.02 | 2.58a ± 0.03 | 2.30c ± 0.01 | 2.01d ± 0.01d | 1.82d ± 0.01e | 1.64f ± 0.02 |

| Sensory quality** | ||||||

| Colour | 8.3a ± 0.12 | 8.4b ± 0.13 | 8.3c ± 0.12 | 8.6d ± 0.16 | 8.0e ± 0.11 | 7.5f ± 0.12 |

| Aroma | 8.3a ± 0.11 | 8.4b ± 0.13 | 8.5c ± 0.14 | 8.6d ± 0.13 | 8.0e ± 0.12 | 7.4e ± 0.10 |

| Taste | 8.3a ± 0.11 | 8.4b ± 0.12 | 8.3c ± 0.13 | 8.6d ± 0.15 | 8.0e ± 0.11 | 7.3f ± 0.10 |

| Texture | 8.3a ± 0.10 | 8.4b ± 0.10 | 8.4c ± 0.12 | 8.5d ± 0.15 | 7.9e ± 0.11 | 7.2f ± 0.10 |

| Overall Acceptability (OAA) | 8.3a ± 0.12 | 8.4b ± 0.13 | 8.4c ± 0.14 | 8.6d ± 0.15 | 8.0e ± 0.13 | 7.2f ± 0.10 |

*Mean ± SD (n = 3)

**Mean ± SD (n = 15)

a–fValues within the same row followed by different superscripts differ significantly (p ≤ 0.05)

Effect of spinach powder on the texture profile analyis of chapaties

Effect of spinach powder on the textural properties of chapaties is shown in Table 1. From the Table 1, it is evident that with the increase in spinach powder, the hardness of chapaties was increased (p ≤ 0.05) from 6.51 to 16.52 N. Similarly chewiness increases significantly (p ≤ 0.05) from 2.45 to 4.88 whereas, springiness and gumminess decreases with the increase of spinach powder. Earlier, studies have also reported that with the addition of bran, high protein, dietary fibre, calcium and iron dilute the gluten which results in the development of hard dough having less gumminess and springiness with hard nature (Dachana et al. 2010). Lee et al. (2004) also reported that addition of oat bran, increased the hardness of cake and lowered the springiness.

Effect of spinach powder on the sensory quality of chapaties

Sensory analysis was performed to find out the suitability and level of incorporation of spinach powder in wheat flour. The changes in sensory scores of chapaties prepared by using spinach powder are given in Table 1. It is clear from the data that addition of spinach powder up to 5 % improved the acceptability of chapaties and further increase in the concentration adversely affected the texture, colour and overall acceptability. It is therefore concluded that, highly acceptable quality chapaties can be prepared using 5 % dehydrated spinach powder and addition of beyond 5 % levels of dehydrated spinach powder significantly reduced the overall acceptance of the chapaties.

Nutritional characteristics of premixes and chapaties

Nutritional characteristics of premixes and chapaties containing dehydrated spinach powder are reported in Table 2. Addition of spinach powder (1–10 %) significantly (p ≤ 0.05) increases total carotenoids, total chlorophyll, vitamin ‘C’, iron and calcium contents in premixes and chapaties prepared from these premixes. Total chlorophyll increased from 20.13 to 50.32 mg/100 g; total carotenoids from 62.32 to 118.32 μg/g and vitamin ‘C’ from 4.32 to 8.5 mg/100 g in chapati premixes. Similarly, same trend was also observed in prepared chapaties. The calcium content of control chapaties was 6.01 mg /100 g and chapaties with 10 % spinach powder were 16.32 mg/100 g. The significant increase in the calcium content is due to the presence of higher calcium content in dehydrated spinach powder. There was also a significant increase in magnesium content of chapaties with incorporation of spinach powder. However, during preparation of chapaties from premixes, there was significant decrease (p ≤ 0.05) in total carotenoids, total chlorophyll as well as vitamin ‘C’ contents. The degradation in total carotenoids and vitamin ‘C’ during baking of chapati was found to be approximately 20 and 30 % respectively. Earlier, Yuan et al. (2009) studied the effect of different cooking methods on vitamin ‘C’ and carotenoids of broccoli and reported similar losses during cooking, microwave, boiling and frying of broccoli. However, mineral contents remain almost constant both in premixes and in chapaties (Table 2).

Table 2.

Effect of spinach powder on the retention of chlorophyll (mg/100 g), carotenoids (μg /g), vitamin C (mg/100 g) and minerals (mg/100 g) of chapati premixes and chapaties prepared using premixes

| Parameters | Dried Spinach powder (%)* | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 1 | 3 | 5 | 7 | 10 | ||

| Total chlorophyll | Premix | – | 20.13a ± 0.24 | 28.12b ± 0.31 | 35.41c ± 0.28 | 41.26d ± 0.33 | 50.32e ± 0.35 |

| Chapati | – | 16.21f ± 0.35 | 22.62g ± 0.42 | 26.42h ± 0.30 | 32.92i ± 0.32 | 39.70j ± 0.29 | |

| Total carotenoids | Premix | – | 62.32a ± 0.41 | 73.51b ± 0.43 | 90.45c ± 0.56 | 103.40d ± 0.63 | 118.32e ± 0.61 |

| Chapati | – | 50.12f ± 0.36 | 58.41g ± 0.40 | 68.12h ± 0.51 | 81.41i ± 0.55 | 95.10j ± 0.59 | |

| Vitamin C | Premix | – | 4.3a ± 0.05 | 5.2b ± 0.03 | 6.4c ± 0.05 | 7.2d ± 0.06 | 8.5e ± 0.05 |

| Chapati | – | 3.1f ± 0.02 | 4.4g ± 0.02 | 5.6h ± 0.04 | 6.1i ± 0.04 | 6.3j ± 0.06 | |

| Minerals (mg/100 g)* | |||||||

| Calcium | Premix | 6.24 ± 0.05 | 7.59 ± 0.04 | 10.11 ± 0.05 | 12.39 ± 0.02 | 14.52 ± 0.06 | 16.46 ± 0.08 |

| Chapati | 6.01 ± 0.04 | 7.31 ± 0.03 | 9.89 ± 0.04 | 12.24 ± 0.01 | 14.35 ± 0.07 | 16.32 ± 0.07 | |

| Iron | Premix | 3.92 ± 0.01 | 4.87 ± 0.02 | 6.20 ± 0.03 | 6.92 ± 0.02 | 7.51 ± 0.01 | 8.21 ± 0.04 |

| Chapati | 3.91 ± 0.02 | 4.67 ± 0.02 | 6.11 ± 0.04 | 6.86 ± 0.03 | 7.48 ± 0.02 | 8.08 ± 0.03 | |

| Zinc | Premix | 2.62 ± 0.01 | 2.69 ± 0.01 | 2.90 ± 0.02 | 2.88 ± 0.01 | 3.02 ± 0.02 | 3.14 ± 0.02 |

| Chapati | 2.04 ± 0.01 | 2.50 ± 0.02 | 2.70 ± 0.03 | 2.84 ± 0.02 | 2.86 ± 0.01 | 2.94 ± 0.01 | |

| Magnesium | Premix | 55.26 ± 1.12 | 60.26 ± 1.14 | 66.38 ± 1.15 | 72.73 ± 1.67 | 75.25 ± 1.31 | 78.61 ± 1.57 |

| Chapati | 54.95 ± 1.15 | 59.01 ± 1.13 | 65.07 ± 1.37 | 72.13 ± 1.58 | 74.16 ± 1.54 | 77.26 ± 1.68 | |

| Sodium | Premix | 208 ± 4.5 | 310 ± 5.2 | 405 ± 5.8 | 510 ± 5.7 | 528 ± 6.1 | 570 ± 6.2 |

| Chapati | 204 ± 4.7 | 302 ± 5.7 | 392 ± 5.0 | 487 ± 5.1 | 512 ± 5.9 | 543 ± 6.0 | |

| Potassium | Premix | 415 ± 7.1 | 430 ± 7.7 | 460 ± 7.5 | 501 ± 8.2 | 517 ± 8.6 | 547 ± 8.6 |

| Chapati | 410 ± 7.4 | 422 ± 7.5 | 452 ± 8.0 | 489 ± 8.1 | 507 ± 8.3 | 530 ± 8.4 | |

*Mean ± SD (n = 3)

a–eValues within the same row and column followed by different superscripts differ significantly (p ≤ 0.05)

Conclusions

From the discussion it is evident that it is possible to utilise small amount of dehydrated spinach powder in chapati premixes to enhance the daily intake of green leafy vegetables. Chapaties prepared with 5 % dehydrated spinach powder were highly nutritious and acceptable to sensory panellists. Above the 5 % level adversely affected the quality of chapaties. Although the level of dehydrated spinach powder incorporation is small, the increase in the nutrient content is remarkable. Thus, dehydrated spinach powder chapaties have the potential to serve the valuable source of calcium, iron, fibre, vitamin ‘C’ and carotenoids in the diet of the population in India and other developing countries.

References

- AACC (2000) Approved methods of the AACC, 10th edn. The Association, St Paul MN

- Allen LDE, Benoist B, Dart O, Hurrel RF (2006) In: Guidelines on food fortification with micronutrients. Geneva, World Health Organisation and Food and Agricultural Organisation of the United Nations

- AOAC . Official methods of analysis of the Association of Official Analytical Chemists. 13. Washington, DC: The Association; 1980. [Google Scholar]

- Arya SS, Vidyasagar K, Parihar DB. Preservation of chapaties. Lebensm-Wiss-u-Technol. 1977;10:2008–2010. [Google Scholar]

- Bedekar BR. Chapati-Indian bakery product of the 21st century. Indian Food Ind. 2001;20:21–24. [Google Scholar]

- Dachana KB, Jyotsna R, Indrani D, Jamuna P. Effect of dried moringa (Moringa Oleifera Lam) leaves on rheological, microbiological, nutritional, textural and organoleptic characteristics of cookies. J Food Qual. 2010;33:660–667. doi: 10.1111/j.1745-4557.2010.00346.x. [DOI] [Google Scholar]

- Dengate HN, Meredith P. The pasting characteristics of various sizes of starch granules from wheat. Starch / Strake. 1984;36:305–309. doi: 10.1002/star.19840360905. [DOI] [Google Scholar]

- Ghufran Saeed SM, Saqib A, Mubarak A, Rashida A, Fred S (2009) Influence of rice bran on rheological properties of dough and in the new product development. J Food Sci Technol 46:62–65

- Gomez M, Ronda F, Carlos A, Pedro B, Cballero A, Apesteguia A. Effect of dietary fibre on dough rheology and bread quality. Eur Food Res Technol. 2003;216:51–56. [Google Scholar]

- Gupta S, Prakash J. Nutritional and sensory quality of micronutrient-rich traditional products incorporated with green leafy vegetables. Int Food Res J. 2011;18:667–675. [Google Scholar]

- Larmond E. Laboratory methods for sensory evaluation of food. Ottawa: Canada Department of Agriculture Publication; 1977. pp. 234–257. [Google Scholar]

- Lee MH, Hettiarachchy NS, Mcnew RW, Gnanasanbandam R (1995) Physico-chemical properties of calcium fortified rice. Cereal Chem 72:352–355

- Lee S, Inglett GE, Carriere CJ. Effect of nutrim oat bran and flaxseed on rheological properties of cakes. Cereal Chem. 2004;81:637–643. doi: 10.1094/CCHEM.2004.81.5.637. [DOI] [Google Scholar]

- Premavalli KS, Majumdar TK, Madhura CV. Processing effect on colour and vitamins of green leafy vegetables. J Food Sci Technol. 2001;38:79–81. [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. 2. New Delhi: Tata McGraw-Hill; 1986. [Google Scholar]

- Reddy V, Urooj A, Kumar A. Evaluation of antioxidant activity of some plant extracts and their application in biscuits. Food Chem. 2000;90:317–321. doi: 10.1016/j.foodchem.2004.05.038. [DOI] [Google Scholar]

- Shirpa B, Jyothi Lakshmi A, Indrani D. Effect of barley, banana and soy protein isolate on rheological, microstructural and nutritional characteristics of North Indian Parotta. J Texure Stud. 2012;43:246–256. doi: 10.1111/j.1745-4603.2011.00334.x. [DOI] [Google Scholar]

- Singh G, Kawatra A. Development and nutritional evaluation of recipes prepared using fresh and dried amaranthus leaves. J Food Sci Technol. 2006;33:509–511. [Google Scholar]

- Snedecor GW, Cochran WG. Statistical methods. 6. New Delhi: Oxford and IBH Pub Co; 1968. [Google Scholar]

- Symons LJ, Brennan CS. The effect of barley β-glucan fiber fractions on starch gelatinization and pasting characteristics. J Food Sci. 2004;69:257–261. [Google Scholar]

- Yadav DN, Patki PE, Sharma GK, Bawa AS. Effect of microwave heating of wheat grains on the browning of dough and quality of chapaties. Int J Food Sci Technol. 2008;43:1217–1225. doi: 10.1111/j.1365-2621.2007.01593.x. [DOI] [Google Scholar]

- Yadav DN, Patki PE, Sharma GK, Harila PT, Bawa AS. Studies on the prevention of dough discolouration by chemical additives. J Food Sci Technol. 2009;46:149–152. [Google Scholar]

- Yuan G, Bo S, Yuan J, Wang Q. Effects of different cooking methods on health-promoting compounds of broccoli. J Zhejiang Univ Sci B. 2009;10:580–588. doi: 10.1631/jzus.B0920051. [DOI] [PMC free article] [PubMed] [Google Scholar]