Abstract

Background:

The luting cements must withstand masticatory and parafunctional stresses in the warm and wet oral environment. Mouth temperature and the temperature of the ingested foods may induce thermal variation and plastic deformation within the cements and might affect the strength properties. The objectives of this study were to evaluate the effect of temperature on the compressive and diametral tensile strengths of two polycarboxylate, a conventional glass ionomer and a resin modified glass ionomer luting cements and, to compare the compressive strength and the diametral tensile strength of the selected luting cements at varying temperatures.

Materials and Methods:

In this study, standardized specimens were prepared. The temperature of the specimens was regulated prior to testing them using a universal testing machine at a crosshead speed of 1 mm/min. Six specimens each were tested at 23°C, 37°C and 50°C for both the compressive and diametral tensile strengths, for all the luting cements.

Results:

All the luting cements showed a marginal reduction in their compressive and diametral tensile strengths at raised temperatures. Fuji Plus was strongest in compression, followed by Fuji I > Poly F > Liv Carbo. Fuji Plus had the highest diametral tensile strength values, followed by Poly F = Fuji I = Liv Carbo, at all temperatures.

Conclusion:

An increase in the temperature caused no significant reduction in the compressive and diametral tensile strengths of the cements evaluated. The compressive strength of the luting cements differed significantly from one another at all temperatures. The diametral tensile strength of resin modified glass ionomers differed considerably from the other cements, whereas there was no significant difference between the other cements, at all the temperatures.

Keywords: Compressive strength, diametral tensile strength, luting cement

Introduction

Dental luting agents provide the link between a fixed prosthesis and the supporting prepared tooth structure.1 Decementation was found to be the second leading cause of failure of the traditional crown and fixed partial dentures, preceded by secondary dental caries.2,3 Dental luting cements should provide a durable bond between dissimilar materials.4 They must maintain their integrity while transferring stresses, from crowns and fixed partial dentures to the tooth structure. Act as a barrier against microbial leakage, sealing the interface between the tooth and the restoration and holding them together through some form of surface attachment.5 This attachment may be mechanical, chemical or a combination of both methods. Polycarboxylate and glass ionomer cements have become immensely popular because of their good wettability and bonding to enamel and dentin.6 Strength is an important mechanical property to be considered for selecting a luting agent. The luting cements are subjected to compressive and tensile stresses by masticatory forces.7 Hence, it is necessary for the luting cements to possess good compressive and tensile strength for the success and longevity of the fixed prosthesis. Most of the data available on the strength of the luting cements are derived from studies performed with the cements that were not prepared for use as luting agents, but as bases, liners or restorative materials. Hence, more studies that evaluate the cements that are manufactured specifically to be used as luting agents are required. Mouth temperature and temperature of ingested foods may induce thermal changes within cements in the oral cavity. Laboratory testing for compressive and tensile strengths is generally conducted at room temperature. As the properties of luting cements may be affected by changes in temperature, the measurement of cement strength at increased temperatures may be more clinically significant.8

Materials and Methods

Materials used in the study

Poly F polycarboxylate luting cement (Dentsply, DeTrey Germany), Liv Carbo-polycarboxylate luting cement (GC Corp., Japan), Fuji I capsule - glass ionomer luting cement (GC Corp., Japan), Fuji Plus capsule - Resin modified glass ionomer luting cement (GC Corp., Japan), [Figure 1].

Figure 1.

Materials used in the study.

Armamentarium used in the study

Teflon molds, glass plates, clamps, capsule mixing amalgamator (Solilamat, Technojet), Fuji capsule applier (GC Asia, Singapore), incubator, water bath (Biotech and Scientific Industries, Agra), thermo statistically controlled oven, universal testing machine (Hounsfield), [Figure 2].

Figure 2.

Armamentarium used in the study.

Cylindrical Teflon molds of the dimensions, 6 mm in height and 4 mm in diameter, were fabricated for making the specimens for compressive strength testing, Cylindrical Teflon molds of the dimensions, 2 mm in height and 4 mm in diameter, were fabricated for making the specimens for diametral tensile strength testing.

The Teflon molds were placed on a glass plate the powder/liquid cements were proportioned and mixed according to manufacturers recommendations and mixed on a mixing pad with a plastic spatula. The freshly mixed cement was filled into the mold, as for the encapsulated cements, the cement capsules were activated, placed in a capsule mixing amalgamator and triturated according to the manufacturers recommendation, and loaded into the capsule applicator. The mixed cement was then extruded through the nozzle of the capsule directly into the mold. Another glass plate was pressed over the open end of the slightly overfilled mold, and the plates were held firmly against the molds with the help of a clamp.

The assembly was then placed in an incubator for 1 h in 100% humidity at 37°C. The specimens were removed from the mold [Figure 3] and stored in distilled water in a water bath at 37°C for the next 23 h. A total of 144 samples were prepared.

Figure 3.

Molds and specimens.

Testing of the specimen

The temperature of the specimens tested was regulated in a thermostatically controlled oven [Figure 4] prior to testing them in a Hounsfield universal testing machine.

Figure 4.

Thermostatically controlled oven.

For the testing of the compressive strength, the cylindrical specimens were mounted vertically along their long axis between the horizontal, parallely placed flat surface of the metal plates of the jig attached to the universal testing machine [Figure 5]. The specimens were loaded at cross head speed of 1 mm/min until they fractured. The load at which the specimen fractured appeared on the monitor and was recorded.

Figure 5.

Specimen being tested for compressive strength.

For the testing of the diametral tensile strength, the disk specimens were mounted diametrically between the metal plates [Figure 6] and they were tested and the reading was recorded in the manner similar.

Figure 6.

Specimen being tested for diametral tensile strength.

Statistical analysis

Descriptive data are expressed as mean ± standard deviation. One-way ANOVA was used for multiple group comparisons (between agents and between temperatures) followed by Newman–Keul’s range test to assess, which group differs significantly from other. A P = 0.05 or less was considered for statistical significance.

Results

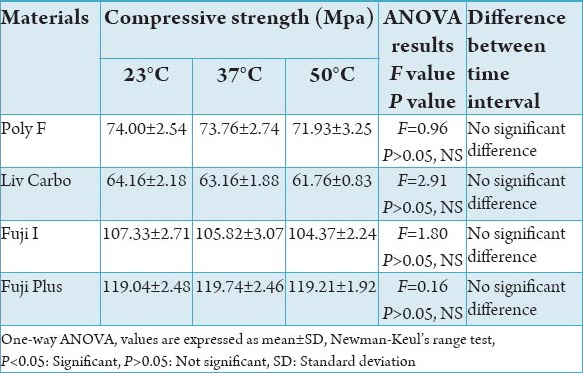

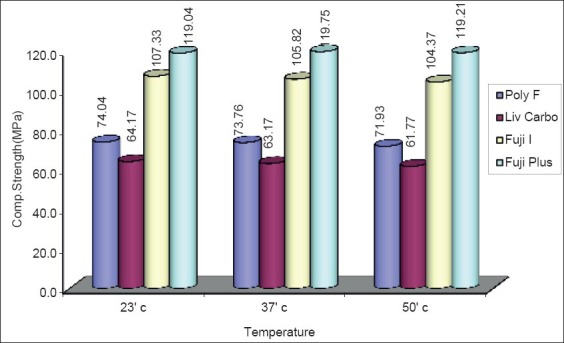

Table 1 shows the comparison of compressive strength at different temperatures for each luting cement (Graph 1).

Table 1.

The comparison of compressive strength values at different temperatures for each luting cement.

Graph 1.

Comparison of the compressive strength of each luting cement measured at different temperatures.

For Poly F, the mean compressive strengths were 74.00 ± 2.54 Mpa at 23°C, 73.74 ± 2.74 Mpa at 37°C and 71.93 ± 3.25 Mpa at 50°C. No statistically significant difference between the values at different temperature was noticed.

For Liv Carbo, the mean compressive strengths were 64.16 ± 2.18 Mpa at 23°C, 63.16 ± 1.88 Mpa at 37°C and 61.76 ± 0.83 Mpa at 50°C. There was no statistically significant difference between the values at different temperature.

For Fuji I, the mean compressive strength were 107.33 ± 2.71 Mpa at 23°C, 105.82 ± 3.07 Mpa at 37°C and 104.37 ± 2.24 Mpa at 50°C. No statistically significant difference was seen between the values at different temperature.

For Fuji Plus, the mean compressive strength were 119.04 ± 2.48 Mpa at 23°C, 119.74 ± 2.46 Mpa at 37°C and 119.21 ± 1.92 Mpa at 50°C. There was no statistically significant difference noticed between the values at different temperatures.

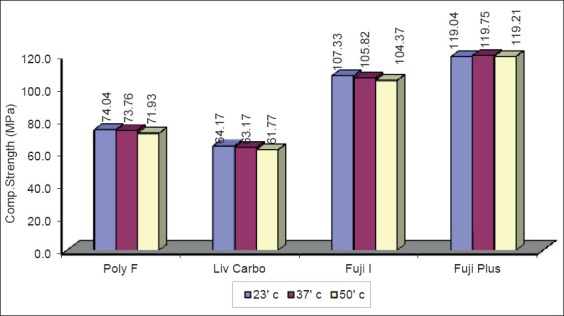

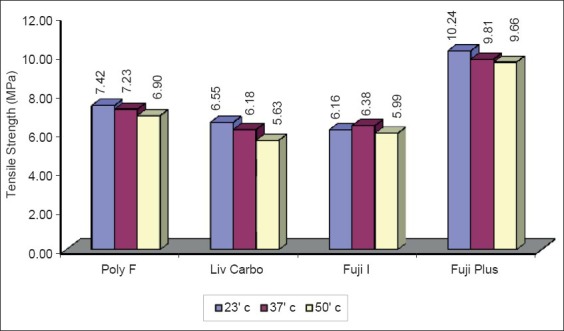

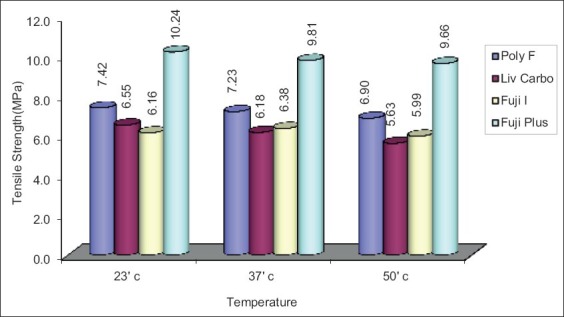

Table 2 shows the comparison of diametral tensile strength values at different temperatures for each luting cement (Graph 2).

Table 2.

The comparison of diametral tensile strength values at different temperatures for each luting cement.

Graph 2.

Comparison of the diametral tensile strength of each luting cement measured at different temperatures.

For Poly F, the mean diametral tensile strengths values were 7.42 ± 0.73 Mpa at 23°C, 7.23 ± 0.98 Mpa at 37°C and 6.89 ± 0.97 Mpa at 50°C. No statistically significant difference between the values at different temperature was noticed.

For Liv Carbo, the mean diametral tensile strength were, 6.55 ± 0.57 MPa at 23°C, 6.18 ± 0.59 Mpa at 37°C and 5.63 ± 0.65 Mpa at 50°C. No statistically significant difference was noticed between the values.

For Fuji I, the mean diametral tensile strength values were 6.16 ± 0.31 Mpa at 23°C, 6.38 ± 0.71 Mpa at 37°C and 5.99 ± 0.25 Mpa at 50°C. There was no statistically significant difference between the values.

For Fuji Plus, the mean diametral tensile strength values were, 10.23 ± 1.12 Mpa at 23°C, 9.81 ± 0.73 Mpa at 37°C and 9.66 ± 0.95 Mpa at 50°C. The difference between the values at different temperatures was not statistically significant.

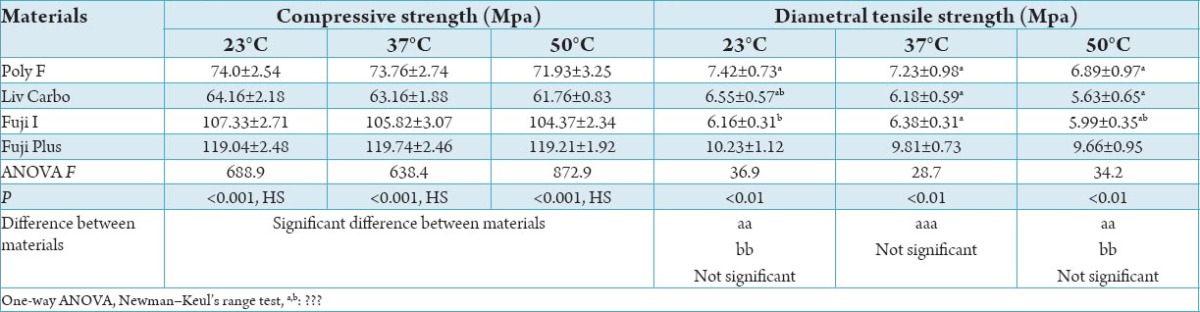

Table 3 shows the comparison of compressive strength and diametral tensile strength at different temperatures, between the luting cement.

Table 3.

The comparison of compressive strength and diametral tensile strength values between luting cements at different temperatures.

For the compressive strength, Fuji Plus exhibited the highest strength values at all temperatures, followed by Fuji I > Poly F > Liv Carbo (Graph 3).

Graph 3.

Comparison of compressive strength between the luting cements at different temperatures.

The values at 23°C were as follows: Fuji plus - 119.04 ± 2.48 Mpa, Fuji I - 107.33 ± 2.71 Mpa, Poly F - 74.0 ± 2.54 Mpa and Liv Carbo - 64.16 ± 1.18 Mpa. The difference in the values was found to be statistically highly significant.

At 37°C - Fuji Plus - 119.74 ± 2.46 Mpa; Fuji I - 105.82 ± 3.07 Mpa; Poly F - 73.76 ± 2.74 Mpa and Liv Carbo - 63.16 ± 1.88 Mpa. The difference in the values was found to be statistically highly significant.

At 50°C - Fuji Plus - 119.21 ± 1.92 Mpa; Fuji I - 104.37 ± 2.34 Mpa; Poly F - 71.93 ± 3.25 Mpa and Liv Carbo - 61.76 ± 0.23 Mpa. The difference in the values were found to be statistically highly significant.

For the diametral tensile strength, Fuji Plus showed the highest strength values followed by, Poly F > Fuji I = Liv Carbo at all the temperatures (Graph 4).

Graph 4.

Comparison of diametral tensile strength between the luting cements at different temperatures.

The values at 23°C were - Fuji Plus - 10.23 ± 1.12 Mpa; Poly F - 7.42 ± 0.73 Mpa; Liv Carbo - 6.55 ± 0.57 Mpa and Fuji I - 6.16 ± 0.31 Mpa. There was statistically significant difference between values of Fuji Plus and all the other cements whereas the difference between - Poly F and Liv Carbo; Liv Carbo and Fuji I were not statistically significant.

At 37°C the values were - Fuji Plus - 9.81 ± 0.73 Mpa; Poly F - 7.23 ± 0.98 Mpa Fuji I - 6.38 ± 0.31 Mpa and Liv Carbo - 6.18 ± 0.59 Mpa. The difference between values of Fuji plus and all the other cements was statistically significant. There was no statistically significant difference between the values of Poly F, Liv Carbo and Fuji I.

At 50°C the values were - Fuji Plus - 9.66 ± 0.95 Mpa; Poly F - 6.89 ± 0.97 Mpa; Fuji I - 5.99 ± 0.35 Mpa and Liv Carbo - 5.63 ± 0.65 Mpa. Fuji Plus differed significantly compared with the other cements. The difference in the values of Poly F and Fuji I; Liv Carbo and Fuji I were not statistically significant.

Discussion

The luting cements are one of the most important materials in clinical dentistry because of their application. For acceptable performance in luting application, the cement must have adequate resistance to dissolution in the oral environment. It must also develop an adequately strong bond through mechanical interlocking and adhesion. High strength in compression, shear and tension is required.6 The demonstration of marginal leakage involving penetration of bacteria to the dentin interface and a reduction in retention of restorations, led to the realization that luting cements possessing good wetting and bonding to enamel and dentin and low toxicity were needed.6 These concepts led to the development of adhesive cements based on polyacrylic acid. The luting cements are subjected to compressive and tensile stresses during mastication, which mandates the evaluation of these materials for compressive and tensile strength. The plastic deformation differs with varying temperatures and also with the loading rate. The lower loading rate leads to greater plastic deformation.9 In the present study, a loading rate of 1 mm/min has been used according to specifications. The earlier studies have found to have used a loading rate of 0.1 mm/min and 0.5 mm/min.8,10

However, irrespective of the loading rate in all the studies, a reduction in compressive strength at raised temperature up to 50°C has been noticed. The plastic deformation at fracture is limited for glass ionomer cements at higher temperature i.e., below 0.5%. The increase in temperature may not affect the strength of the glass ionomer cements.9 The same reason may also hold good for the newer resin modified glass ionomer cements.

At the tested temperatures, Fuji Plus was found to be the strongest in compression followed by Fuji I > Poly F > Liv Carbo. A trend towards the reduction of the diametral tensile strength with the increase in temperature was observed for both the cements, but the differences in the values were not statistically significant.

In the study conducted by Mesu,8 the diametral tensile strength values for the polycarboxylate cements at 23°C, 37°C and 50°C were 7.99 Mpa, 6.78 Mpa and 5.94 Mpa respectively. The reduction in the values at raised temperatures was of a lesser degree compared to the reduction in the compressive strength values observed at the same temperatures.

In the present study, the average diametral tensile strength values for both the polycarboxylate cements were 6.98 Mpa at 23°C, 6.70 Mpa and 6.26 Mpa at 37°C and 50°C respectively. The reduction in diametral tensile strength values at raised temperatures was less than that of the values found in the earlier study.

The mean diametral tensile strength values of the glass ionomer cements - Fuji I were 6.16 Mpa at 23°C 6.38 Mpa at 37°C and 5.99 Mpa at 50°C. For the Fuji Plus the mean diametral strength values of 10.23 Mpa, 9.81 Mpa and 9.61 Mpa were recorded at 23°C, 37°C and 50°C, respectively. Fuji I demonstrated a marginal increase in the strength at 37°C and at 50°C a decrease in strength values was noted, compared with the values at 23°C.

An insignificant decrease in the diametral tensile strength was noticed at raised temperatures for both the cements.

For the polycarboxylate cements, the difference in the load rates used may have been the cause for the difference in the results noted in the earlier study and the present study.9,10 The values of the glass ionomer cements might not have been affected, as the plastic deformation at fracture is less for glass ionomer cements with an increase in temperature.9

The diametral tensile strength values for all the cements were lower than that of their compressive strengths. The likely explanation being, although the cohesion within the material is identical in both compressive and diametral tensile strength tests, the direction of the forces, however, is reversed.11

The comparative evaluation of the luting cements for diametral tensile strength showed that, Fuji Plus had the highest strength values followed by Poly F = Fuji I = Liv Carbo at all temperatures. There was a significant difference (P > 0.01) found in the strength of Fuji Plus and the other cements, whereas there was no much difference in the values of Poly F, Fuji I and Liv Carbo.

The resin modified glass ionomer cement was stronger than the conventional glass ionomer cement when subjected to diametral tensile strength testing. This is in accordance with previous reports.4,5,12-15

The glass ionomer cements usually display higher diametral tensile strength values than the polycarboxylate cements.4,5,12,15 In the present study, the glass ionomer cement evaluated had values similar to that of polycarboxylate cements.

The exact composition of the encapsulated glass ionomer cement was not known. However, minor variations in P:L ratios and additional component might have influenced the varied strength properties. The mean compressive and diametral tensile strength of the polycarboxylate cements (Poly F and Liv Carbo) were in the range of values reported in earlier studies.1,4-8,15-17

The mean values of glass ionomer and resin modified glass ionomer luting cements (Fuji I and Fuji Plus) for compressive and diametral tensile strength fall within the range of values documented in previous reports.1,4-7,12,15,18-22

Throughout the study, Fuji Plus showed higher strength properties than the other cements tested.

Based on the results of this study, it can be inferred that, an increase in the temperature caused no significant reduction in the compressive and diametral tensile strength of the luting cements evaluated.

In the clinical situations, the luting cements might exhibit strength properties, different than that they demonstrate in laboratory investigations.

More in vivo studies that investigate the strength properties of the luting cements, when subjected to thermal variations are required.

Conclusion

Increase in the temperature caused a marginal reduction in the compressive strength of the polycarboxylate and the glass ionomer cements. However, the difference in the values at 23°C and at higher temperatures was not statistically significant

A marginal reduction was seen in the diametral tensile strength of polycarboxylate and glass ionomer cements, with an increase in the temperature. However, the difference in the values at 23°C and at higher temperatures was not statistically significant

At the tested temperatures, the resin modified glass ionomer cement showed higher compressive strength and diametral tensile strength than the other cements. The compressive strength of conventional glass ionomer was higher than that of polycarboxylate cements. The diametral tensile strength of conventional glass ionomer cement and polycarboxylate cements was similar.

Footnotes

Conflicts of Interest: None

Source of Support: Nil

References

- 1.Rosenstiel SF, Land MF, Crispin BJ. Dental luting agents: A review of the current literature. J Prosthet Dent. 1998;80(3):280–301. doi: 10.1016/s0022-3913(98)70128-3. [DOI] [PubMed] [Google Scholar]

- 2.Diaz-Arnold AM, Vargas MA, Haselton DR. Current status of luting agents for fixed prosthodontics. J Prosthet Dent. 1999;81(2):135–41. doi: 10.1016/s0022-3913(99)70240-4. [DOI] [PubMed] [Google Scholar]

- 3.Walton JN, Gardner FM, Agar JR. A survey of crown and fixed partial denture failures: length of service and reasons for replacement. J Prosthet Dent. 1986;56(4):416–21. doi: 10.1016/0022-3913(86)90379-3. [DOI] [PubMed] [Google Scholar]

- 4.White SN, Yu Z. Compressive and diametral tensile strengths of current adhesive luting agents. J Prosthet Dent. 1993;69(6):568–72. doi: 10.1016/0022-3913(93)90283-t. [DOI] [PubMed] [Google Scholar]

- 5.Li ZC, White SN. Mechanical properties of dental luting cements. J Prosthet Dent. 1999;81(5):597–609. doi: 10.1016/s0022-3913(99)70216-7. [DOI] [PubMed] [Google Scholar]

- 6.O’Brien WJ. 2nd ed. Chicago: Quintessence; 1997. Dental Materials: Properties and Selection. [Google Scholar]

- 7.Anusavice KJ. 10th ed. Philadelphia: W.B. Saunders Company; 1999. Philips’ Science of Dental Materials. [Google Scholar]

- 8.Mesu FP. The effect of temperature on the compressive and tensile strengths of cements. J Prosthet Dent. 1983;49(1):59–62. doi: 10.1016/0022-3913(83)90239-1. [DOI] [PubMed] [Google Scholar]

- 9.Oilo G. Luting cements: a review and comparison. Int Dent J. 1991;41(2):81–8. [PubMed] [Google Scholar]

- 10.Oilo G, Espevik S. Stress/strain behavior of some dental luting cements. Acta Odontol Scand. 1978;36(1):45–9. doi: 10.3109/00016357809026366. [DOI] [PubMed] [Google Scholar]

- 11.Yap AU, Pek YS, Cheang P. Physico-mechanical properties of a fast-set highly viscous GIC restorative. J Oral Rehabil. 2003;30(1):1–8. doi: 10.1046/j.1365-2842.2003.01006.x. [DOI] [PubMed] [Google Scholar]

- 12.Mitra SB, Kedrowski BL. Long-term mechanical properties of glass ionomers. Dent Mater. 1994;10(2):78–82. doi: 10.1016/0109-5641(94)90044-2. [DOI] [PubMed] [Google Scholar]

- 13.Li J, von Beetzen M, Sundström F. Strength and setting behavior of resin-modified glass ionomer cements. Acta Odontol Scand. 1995;53(5):311–7. doi: 10.3109/00016359509005993. [DOI] [PubMed] [Google Scholar]

- 14.Uno S, Finger WJ, Fritz U. Long-term mechanical characteristics of resin-modified glass ionomer restorative materials. Dent Mater. 1996;12(1):64–9. doi: 10.1016/S0109-5641(96)80066-2. [DOI] [PubMed] [Google Scholar]

- 15.Craig RG, Powers JM. 11th ed. St. Louis: Mosby; 2002. Restorative Dental Materials. [Google Scholar]

- 16.Powers JM, Johnson ZG, Craig RG. Physical and mechanical properties of zinc polyacrylate dental cements. J Am Dent Assoc. 1974;88(2):380–3. doi: 10.14219/jada.archive.1974.0060. [DOI] [PubMed] [Google Scholar]

- 17.Galun EA, Saleh N, Lewinstein I. Diametral tensile strength and bonding to dentin of type I glass ionomer cements. J Prosthet Dent. 1994;72(4):424–9. doi: 10.1016/0022-3913(94)90564-9. [DOI] [PubMed] [Google Scholar]

- 18.Johnson GH, Herbert AH, Powers JM. Changes in properties of glass-ionomer luting cements with time. Oper Dent. 1988;13(4):191–6. [PubMed] [Google Scholar]

- 19.Cattani-Lorente MA, Godin C, Meyer JM. Early strength of glass ionomer cements. Dent Mater. 1993;9(1):57–62. doi: 10.1016/0109-5641(93)90107-2. [DOI] [PubMed] [Google Scholar]

- 20.Cattani-Lorente MA, Godin C, Meyer JM. Mechanical behavior of glass ionomer cements affected by long-term storage in water. Dent Mater. 1994;10(1):37–44. doi: 10.1016/0109-5641(94)90020-5. [DOI] [PubMed] [Google Scholar]

- 21.Cattani-Lorente MA, Dupuis V, Moya F, Payan J, Meyer JM. Comparative study of the physical properties of a polyacid-modified composite resin and a resin-modified glass ionomer cement. Dent Mater. 1999;15(1):21–32. doi: 10.1016/s0109-5641(99)00010-x. [DOI] [PubMed] [Google Scholar]

- 22.Piwowarczyk A, Lauer HC. Mechanical properties of luting cements after water storage. Oper Dent. 2003;28(5):535–42. [PubMed] [Google Scholar]