Abstract

Aim:

This in vitro study was carried out to compare the effect of LED light curing system on polymerization and hardness of silorane-based and methacrylate-based posterior composite resin.

Materials and Methods:

A total of 40 samples, 20 of silorane-based composite Filtek P-90 and 20 of methacrylate-based composite Heliomolar HB measuring 2 mm thickness and 8 mm diameter were prepared using Teflon molds and cured using LED curing light. The samples were polished and tested in Knoop hardness tester using a 50-gram load and dwell time of 15 seconds on top and bottom surfaces. The percentage depth of cure was calculated, and statistical analysis was performed using two-way ANOVA test and Student t- test.

Results:

Higher statistically significant values were seen for both the top and bottom surface hardness in silorane-based resins than methacrylate-based resins on LED light curing.

Conclusion:

Greater depth of cure was achieved in silorane-based posterior composite than in methacrylate-based posterior composite resins with a statistically significant difference.

Keywords: Depth of cure, methacrylate-based posterior composites, posterior composites, Silorane-based posterior composites, surface hardness

INTRODUCTION

The search for an ideal restoration led to the introduction of composite resins by Bowen in 1962 and its continuous evolution since then to this present day. A variety of composites, including conventional, microfilled, hybrid, flowable, packable, nanofilled have been introduced till date. Though they have become the material of choice for anterior restorations, they were found lacking in strength to suit the requirements of a posterior restorative material. Various modifications in chemical structure and composition have been tried to overcome this issue.[1]

With the intention of extending the use of microfilled composite for posterior restoration along with anterior restorations, the proportional composition of the monomer mixture, i.e., the portion of comparatively large copolymers was lowered while the portion of microfillers was slightly raised by manufacturers. Also, a rheology modifier in the form of an organically modified compound silicate was added to the material.[1]

Currently, most composite resins have their common basis in the radical polymerization of methacrylates. Mozner and Salz (2001)[2] have reported that vinyl cyclopropane derivatives are also able to copolymerize with common methacrylate-based resins. The reaction involves the cationic ring opening of spiro ortho carbonates especially in combination with epoxy monomers. Silorane (3M ESPE), a low shrinkage tooth-colored restorative material, as claimed by the manufacturer, has been recently introduced in the market. Silorane was so named to indicate a hybrid compound of siloxane and oxirane functional moieties. Studies in the past have shown this material to be superior to conventional methacrylate-based composites.[3] Dye penetration tests have proved silorane-based composites to show significantly less microleakage at both the resin-enamel and resin-cementum interface.[4]

Solid state light emitting diodes (LED) have been used for curing composites since 1995. LEDs emit light at a specific wavelength of 470 nm required for activating camphoroquinone. These lamps offer high-energy performance, have a longer life span of more than 10,000 hours and undergo little degradation over time. Also, they consume little power and can be battery-operated.[5]

The degree of cure of resin composites influences its mechanical properties, solubility, dimensional stability, color change and biocompatibility.[6] Depth of cure and microhardness testing have been reliably and widely used to assess the relative degree of cure of resins, and thus the efficiency of light sources. The Knoop microhardness test has been shown to be one of the best indirect methods for testing the hardness of resin composite.[7]

The present in vitro study was carried out to compare the surface hardness and depth of cure achieved in methacrylate-based and silorane posterior composite resin on curing with LED curing unit.

MATERIALS AND METHODS

Table 1 shows all the equipment and materials tested in the study. A total of 40 samples were prepared. Teflon moulds with inner diameter of 8 mm and thickness of 2 mm were prepared. Moulds were placed on Mylar strips placed on a glass slab and were filled with composite using bulk insertion technique. In all, 20 samples were prepared using silorane-based Filtek P-90 posterior composite A3 shade (3M ESPE St. Paul, MN, USA) and 20 samples were prepared using methacrylate-based Heliomolar HB posterior composite, A3 shade (Ivoclar Vivadent AG, Schaan, Germany). A Mylar strip was placed on the upper surface and the material was flattened with a glass slide. After the removal of the excess material the glass slide was removed, leaving the Mylar strip. LED curing light (Rotex, India), with a light intensity of 1000 mw/cm2 and a tip diameter of 8 mm was used to cure the samples for a period of 40 seconds with the tip kept at a distance of 1 mm. The intensity of the light curing unit was checked by an external hand-held radiometer before curing each specimen.

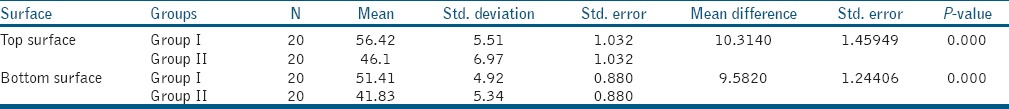

Table 1.

Descriptive statistics and comparative analysis of top and bottom surface hardness values by Bonferroni test

The specimens were then removed from the molds, and polished and measured using digital Vernier calipers. The top surface was marked with an indelible marker. All samples were stored dry at room temperature in light-proof containers for 24 hours.

Knoop hardness testing was performed using a 50-gram load and a dwell time of 15 seconds. For each sample, three indentations were made on both the top and the bottom surfaces. The mean hardness values for the top and bottom surfaces were noted and percentage depth of cure was calculated using the following formula:

The data was statistically analyzed using a two-way ANOVA test, Bonferroni test and Student t-test. All the data collected was tabulated and statistically analyzed using SPSS (Statistical Package for Social Science) 14.0 software.

OBSERVATIONS AND RESULT

Table 1 shows the mean top and bottom surface hardness values between the groups. Results showed greater surface hardness for the silorane-based group (Group I) than the methacrylate-based group (Group II) with a p value of 0.000 (highly statistically significant) on both the top and bottom surfaces.

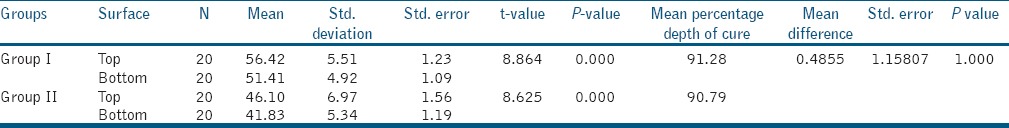

Table 2 shows the comparison of top and bottom values in each group and the comparison of depth of cure. The difference in top and bottom surface hardness was statistically significant in both the groups. However, the difference in mean depth of cure was not statistically significant between silorane- and methacrylate-based groups.

Table 2.

Descriptive statistics and comparative analysis of depth of cure by Bonferroni test

DISCUSSION

Siloranes, a new class of ring-opening monomers, were synthesized to overcome the problems related to polymerization shrinkage. Obtained from the reaction of oxirane and siloxane molecules, the volumetric shrinkage of a silorane-based composite was determined to be 0.99 vol. %. This resin is considered to have combined the two key advantages of the individual components: Low polymerization shrinkage due to oxirane monomers and increased hydrophobicity due to the presence of siloxane species in its composition.[3]

Apart from the predominant radical polymerization initiation in conventional methacrylate resin-based composites (RBCs), the silorane composite polymerizes by a cationic process, which is insensitive to oxygen. The silorane-based composite revealed decreased water sorption, solubility and associated diffusion coefficient compared with conventional methacrylate RBCs.[3] Nanjundasetty et al.,[4] have shown superior marginal integrity both below and above the CEJ with siloranes compared to methacrylate-based composites.

The present study showed that greater hardness and depth of cure values were achieved in silorane-based posterior composite samples than with methacrylate-based posterior composite samples when cured with LED light.

Customized Teflon moulds were used, as the material does not stick to the mold and can be easily demolded after polymerization. As bulk insertion technique was adopted in this study and a maximum of 2 mm is acceptable, the thickness of the samples was standardized to 2 mm.[8]

The International Organization for Standardization (ISO) has standardized the specifications for light curing units to have a minimum intensity of 300 mW/cm2 in 400-515 nm wavelength bandwidth at the curing light tip.[9] These criteria set by the ISO were fulfilled by the LED curing unit used in this study.

Light cured composites polymerize both during and after visible light activation, known as light and dark reactions, respectively. In all composites, maximum hardness is attained after 24 hours.[10] The samples were stored in dark light-proof boxes after curing in this study in order to prevent further curing due to exposure to light after the stipulated curing cycle.

The hardness of the composite is directly related to the degree of polymerization, and thus a good indicator of the degree of conversion of composite resins and a valuable parameter to estimate the mechanical properties. DeWald and Ferracane[11] have stated that Knoop hardness correlates well with the degree of conversion. Also, it minimizes the effect of elastic recovery, is a relatively simple technique and shows reliability of obtained result, hence it was the method chosen in this study.

The results of this study are in agreement with those of Guiraldo et al.[12] Composite hardness is influenced by several factors, such as organic matrix composition, type and amount of filler particles, and degree of conversion. The organic matrix of Filtek P-90 is composed mainly of silorane resin and inorganic particles, quartz and yttrium fluoride. In contrast, the organic matrix of Heliomolar is composed mainly of Bis-GMA, UDMA and 1,10- decandiol dimethacrylate, and a combination of inorganic particles silicon dioxide, ytterbium trifluoride and copolymers. Heliomolar HB is a microfilled composite. Several studies have suggested that microfilled composites are more difficult to cure because the small filler particles cause light to scatter, thus decreasing the effectiveness of the curing light. On the other hand, silorane-based composites have cationic polymerization reaction, which is characterized by continuous ring opening expansion initiated at the time of curing and promoted further cross-linking and hardening of the entire resin matrix.

CONCLUSION

Within limitations of the study, higher top and bottom hardness values were achieved in silorane-based posterior composites as compared to methacrylate-based posterior composites, though both attained similar percentage depth of cure.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

REFERENCES

- 1.Roberson TM, Heymann HO, Ritter AV. 5th ed. St. Louis: Mosby; 2006. Introduction to composite restorations. Sturdevant's Art and Science of Operative Dentistry; pp. 495–526. [Google Scholar]

- 2.Mozner N, Salz U. New developments of polymeric dental composites. Prog Polym Sci. 2001;26:535–76. [Google Scholar]

- 3.Al-Boni R, Raja OM. Microleakage evaluation of silorane based composite versus methacrylate based composite. J Conserv Dent. 2010;13:152–5. doi: 10.4103/0972-0707.71649. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Nanjundasetty JK, Nanda S, Panuganti V, Marigowda JC. Marginal sealing ability of silorane and methacrylate resin composites in class II cavities: A scanning electron microscopic study. J Conserv Dent. 2013;16:503–8. doi: 10.4103/0972-0707.120952. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 5.Malhotra N, Mala K. Light curing considerations for resin- based composite materials: A review Part I. Compend Contin Educ Dent. 2010;31:498–505. [PubMed] [Google Scholar]

- 6.Ceballos L, Fuentes MV, Tafalla H, Martinez A, Flores J, Rodriguez J. Curing effectiveness of resin composites at different exposure times using LED and halogen units. Med Oral Patol Oral Cir Bucal. 2009;14:51–6. [PubMed] [Google Scholar]

- 7.Price RB, Fahey J, Felix CM. Knoop microhardness mapping used to compare the efficiency of LED, QTH and PAC curing lights. Oper Dent. 2010;35:58–68. doi: 10.2341/09-055-L. [DOI] [PubMed] [Google Scholar]

- 8.Yap AU. Effectiveness of polymerization in composite restoratives claiming bulk placement: Impact of cavity depth and exposure time. Oper Dent. 2000;25:113–20. [PubMed] [Google Scholar]

- 9.Fan PL, Schumacher RM, Azzolin K, Geary R, Eichmiller FC. Curing light intensity and depth of cure of resin based composites tested according to international standards. J Am Dent Assoc. 2002;133:429–34. doi: 10.14219/jada.archive.2002.0200. [DOI] [PubMed] [Google Scholar]

- 10.Albers HF. 9th ed. London: BC Decker Inc; 2002. Resin polymerization. Tooth colored restoratives; pp. 81–111. [Google Scholar]

- 11.DeWald JP, Ferracane JL. A comparison of four modes of evaluating depth of cure of light activated composites. J Dent Res. 1987;66:727–30. doi: 10.1177/00220345870660030401. [DOI] [PubMed] [Google Scholar]

- 12.Guiraldo RD, Consani S, Consani RL, Berger SB, Mendes WB, Sinhoreti MA, et al. Comparison of silorane and methacrylate based composite resins on the curing light transmission. Braz Dent J. 2010;21:538–42. doi: 10.1590/s0103-64402010000600010. [DOI] [PubMed] [Google Scholar]