Abstract

Effect of substitution of brown flour (BF) with fiber rich ingredient mixture, FRIM (banana flour, psyllium husk, partially defatted coconut flour and oats) and protein rich ingredient mixture, PRIM (chickpea flour, sesame, soya protein isolate and whey protein concentrate) at the levels of 25, 50 and 75 % on the rheological, nutritional and quality characteristics of baked energy bars (BEB) were studied. Use of increasing amount of FRIM increased farinograph water absorption and amylograph peak viscosity while PRIM decreased the aforementioned parameters. Addition of FRIM or PRIM increased the bar dough hardness and decreased cohesiveness and springiness. The overall quality score of BEB increased only up to the substitution of 50 % of BF with FRIM or PRIM. The BEB with 50 % FRIM and PRIM remained chemically stable during storage up to 3 months and showed 9 times increase in dietary fiber content and about 2 times increase in protein content respectively.

Keywords: Baked energy bars, Rheology, Protein, Dietary fiber

Introduction

Cereal bars are highly nutritious as they are the good source of energy, rich in fiber, protein, vitamins, antioxidants, etc. They are prepared using multiple ingredients like cereals, fruits, nuts, raisins, sugar, etc. (Lobato et al. 2012). The bars are often fortified using a wide range of proteins such as soya or whey; fibres including cereal brans, oats, barley; vitamins, minerals, herbs and other nutrient or energy-rich ingredients (Gonzales and Draganchuk 2003). Commercially several types of bars are available, such as meal replacement bars, bars targeted to the nutritional needs of diabetics, women and children (Johnson 2001), high-protein, high fibre, high calorie, mineral and vitamin rich, bars with functional additives such as prebiotic, etc. They have also become popular because of the health benefits associated with them. Boustani and Mitchell (1990) examined consumer opinion and found many respondents associated the bars with health foods, and claimed ‘healthiness’ along with ‘taste’, as a reason for buying.

Several attempts have been made to utilise functional ingredients in cereal bars including isoflavones, soy protein in diets to control dyslipidemia (Lobato et al. 2012), fish oil for the benefits of omega-3-polyunsaturated fatty acids (Nielsen and Jacobsen 2009), three sources of fibres-inulin, oligofructose and gum acacia (Dutcosky et al. 2006), dairy proteins (Hogan et al. 2012) and wheat and soya products (Aramouni and Abu-Ghoush 2011).

Chemical and physical interaction among ingredients in baked bar can occur over time and begin to affect the taste and texture of the product. Water activity (aw) measurements help to predict food mechanical properties, stability and shelf life. Bars packed in polypropylene have a shelf life of 3 months and 6 months in paper aluminium foil polyethylene, metallised polyester plus vaccum packing under ambient and 37 °C temperature conditions (Padmashree et al. 2012).

In order to get multiple benefits in baked goods such as improved taste, aroma, enhanced appearance and nutritional quality (Indrani et al. 2010) incorporation of a mixture of grains, legumes, seeds and/or combination of protein concentrates from soya, whey with fibres from cereal brans, husk, oat and barley is a recent trend in the baking industry. With this background, work was undertaken to study the influence of substitution of brown flour with fiber rich ingredient mixture, FRIM (banana flour, psyllium husk, partially defatted coconut flour and oats) and protein rich ingredient mixture, PRIM (chickpea flour, sesame, soya protein isolate and whey protein concentrate) at the levels of 25, 50 and 75 % on the rheological, nutritional and quality characteristics of baked energy bars.

Materials and methods

Brown flour (BF) prepared by blending refined wheat flour and whole wheat flour in the ratio of 50:50 (w/w), having 7.4 % dry gluten, 20 ml Zeleny’s sedimentation value and 498 s Hagberg falling number was used for the study. Banana flour, Musa paradisiaca L (Safety foods, Kerala, India); Oats (Baggry’s India Limited, New Delhi), psyllium husk (The Sidhpur, Gujrat, India), soya protein isolate powder (The Solae Company, Gurgaon, Haryana) and whey protein concentrate (Mahan Proteins, New Delhi) were procured. Partially defatted coconut flour (25 % fat content), chickpea flour, sesame seeds, hydrogenated fat (Dalda), water, salt (common food grade sodium chloride), skim milk powder and sugar powder procured from the local market were used in the studies.

Preparation of blends

In order to produce two types of baked energy bars (BEB), with increased dietary fiber and protein contents, BF was partially replaced with Fiber rich ingredient mixture (FRIM) containing banana flour, oats, psyllium husk, partially defatted coconut flour and Protein rich ingredient mixture (PRIM) containing chickpea flour, sesame, soya protein isolate and whey protein concentrate respectively. The proportions of ingredients in the blends are given in Table 1.

Table 1.

Preparation of blends

| Ingredients (g) | BF: FRIM or BF: PRIM | ||||

|---|---|---|---|---|---|

| FRIM | PRIM | 100:0 | 75:25 | 50:50 | 25:75 |

| Brown flour | Brown flour | 100 | 75 | 50 | 25 |

| Banana flour | Sesame | 0 | 6.25 | 12.5 | 18.75 |

| Oats grits | Chickpea flour | 0 | 6.25 | 12.5 | 18.75 |

| Psyllium husk | Soya protein isolate | 0 | 6.25 | 12.5 | 18.75 |

| Partially defatted Coconut flour | Whey protein concentrate | 0 | 6.25 | 12.5 | 18.75 |

BF Brown flour (Mixture of 50 % whole wheat flour + 50 % refined wheat flour); FRIM Fibre Rich Ingredients Mixture; PRIM Protein Rich Ingredients Mixture

Chemical characteristics

The BF, FRIM and PRIM were analysed for different parameters: moisture (method 44–15), protein (method 46–10), total ash (method 08–01), and total fat (method 30–10) using standard AACC (2000) methods. The dietary fibre was analysed according to Asp et al. (1983).

Rheological characteristics of blends

The rheological characteristics of the blends, such as farinograph (method 54–21) and amylograph (method 22–10) were determined using AACC (2000) methods.

Preparation of BEB

The following formulation and method were used for the preparation of BEB (ingredients mentioned below are in grams)-brown flour (BF): FRIM/PRIM (100:0, 75:25, 50:50, 25:75); fat, 75; sugar, 25; invert syrup, 75; cashew nuts, 25; raisins, 25; skim milk powder, 15; salt,0.5; baking powder, 3; water (just to dissolve the salt). Fat, sugar and essence were creamed in a Hobart mixer (Model N-50, Hobart, GmbH, Offenburg, Germany) with a flat blade for 1 min at 58 rpm, 3 min at 112 rpm and 5 min at 173 rpm with scraping after every speed. Salt dissolved in water was added to the cream and mixed for 5 min at 58 rpm. BF, skim milk powder, baking powder were sifted thrice and added to the above cream and mixed at 58 rpm for ½ min and 112 rpm for 1 min with the intermittent scraping. Nuts and raisins were added and mixed at speed of 112 rpm for ½ min to form dough. The dough was divided into three equal portions, placed side by side horizontally in the baking pan (15 × 10 cm), gently pressed uniformly so that the thickness of dough was about 1.5 cm, baked at 180 ° C for 45 min oven (APV, Queensland, Australia). The baked bars were cooled for 2 h, cut into 7.5 × 3.3 cm pieces and packed in metallised polyester films (12 μ) and heat sealed. Each experiment was carried out in triplicate. The samples were stored under ambient conditions (30 0 C, 65 % RH).

Rheological characteristics of bar dough

Texture Profile Analysis (TPA) of bar dough was performed at room temperature by using an LR-5 K Texture Analyzer (Lloyd Instruments Ltd, Hampshire, England) with 5-kg load cell. The samples were compressed by using an aluminium 80 mm diameter circular disc probe. A segment of circular dough (40 × 15 mm) was evaluated. The texture parameters were determined with crosshead speed of 50 mm/min compression distance 50 % of dough’s height, 5-s delay between two bites. The data was analyzed by using Nexygen Version 4.0 Software (LR-5 K) to measure the hardness, cohesiveness, springiness, gumminess, chewiness and adhesiveness as described by Bourne (1978).

Physical and Sensory characteristics of BEB

The weight, length, width and thickness of BEB were recorded. Score card for evaluation of BEB was prepared by identifying desirable and undesirable characteristics of BEB based on 5 different parameters having maximum score of 10 each and overall quality score of 50. Sensory evaluation of BEB was carried out by the panellists consisting of 10 baking technologists who were trained in four sessions involving 2 h of training in each session. 4 samples of BEB in 4 replicates were evaluated by each panellist for crust colour (1 = pale dark brown and 10 = golden brown), crust surface (10 = smooth and 1 = uneven rough), crumb colour (10 = brownish and 1 = whitish), texture (10 = medium softness with slight gumminess, chewiness and 1 = hard, powdery), mouthfeel (10 = easy breakdown with no residue and 1 = dry, sticky with residue formation) and overall quality score (combined score of all 5 quality attributes).

Chemical characteristics of BEB

BEB Control with 50 % FRIM and PRIM were analyzed for moisture content, protein, total ash, fat, dietary fiber (Asp et al. 1983) and total sugars as described above. The water activity (aw) of the baked bars was measured at room temperature using Water activity meter (Thermoconstanter Novasina. TH200, Switzerland), the sample was kept and stabilized for 30 min at 27 ° C. In-vitro protein digestibility was measured by the method of Akeson and Stahmann (1964). The values reported are the average of four readings.

Storage characteristics of BEB

The stored BEB samples were evaluated for moisture, peroxide value (AOCS method, Cd 8–53, 1997) and free fatty acids (AOCS method, Ca 5a-40, 1997) every month during storage at ambient conditions (30 °C, 65 % RH) for three months.

Statistical analysis

The data pertaining to chemical and nutritional characteristics was expressed as mean ± standard error. Results of BEB making characteristics were analyzed using Duncan’s new multiple range test with different experiment groups appropriate to the completely randomized design with four replicates each, as described by Steel and Torrie (1980). The significant level was established at P < 0.05.

Results and discussion

Chemical characteristics of BF, FRIM and PRIM

The BF, FRIM and PRIM had 9.1, 6.1 and 2.6 % moisture, ash (1.2, 2.8 and 5.4 %), protein (12.6, 6.5 and 49.0 %), fat (2.2, 1.2, and 1.7 %) and dietary fibre (1.2, 35.8 and 7.9 %) respectively. These results expressed on dry basis excepting moisture show that when compared to BF, the FRIM is having lesser protein and fat; higher dietary fiber and mineral contents while PRIM is having higher protein, ash, dietary fibre and lesser fat.

Effect of FRIM and PRIM on rheological characteristics of BF

Farinograph characteristics

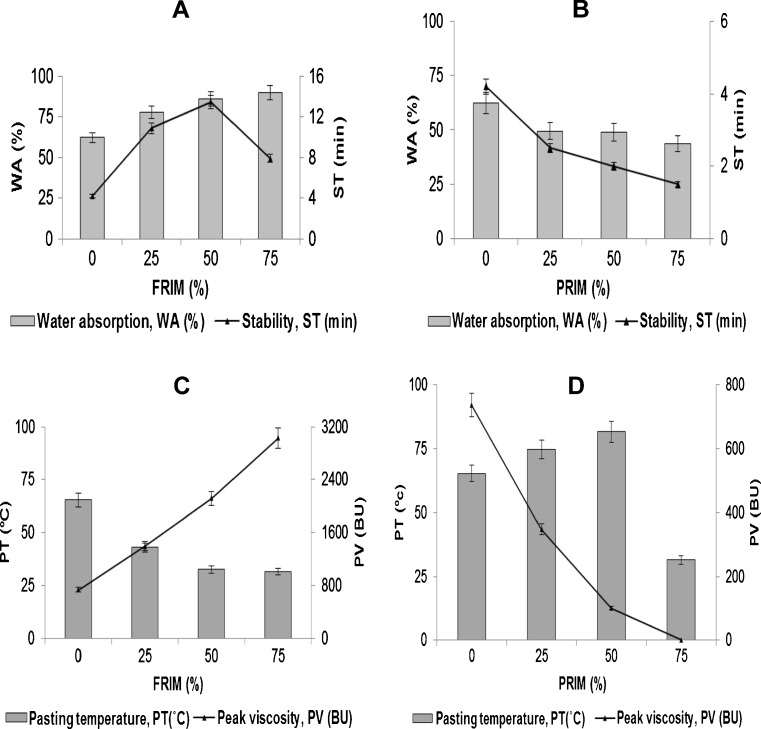

Increasing the amount of FRIM in the blend from 0 to 75 % increased farinograph water absorption from 62.3 to 90.1 % (Fig. 1A) indicating high water binding capacity of fibers. The dough development time and stability values increased from 2.5 to 5.0 and 5.5 min, dough stability (4.2 to 10.9 to 13.5 min) with substitution of 25 and 50 % FRIM. These results may be due to the delay in the hydration and development of gluten caused by the presence of fibers. However substitution of above 50 % FRIM decreased the dough stability indicating an adverse effect of FRIM on the mixing profile of the dough. Farheen et al. (2012) also reported a reduction in the farinograph stability value with the incorporation of blend of soy protein isolate, oat bran and chickpea flour due to the interaction between non-wheat protein, fiber and gluten leading to a delay in the hydration and development of gluten. Similar effects on dough properties with the use of fiber and protein rich materials have been reported (Krishnan et al. 1987; Serna-Saldivar et al. 1988).

Fig. 1.

A, B, C & D. Effect of different levels of substitution of BF with FRIM or PRIM on the farinograph and amylograph characteristics of brown flour; FRIM Fibre Rich Ingredients Mixture; PRIM Protein Rich Ingredients Mixture

Substitution of 0 to 75 % BF with PRIM decreased the water absorption from 62.3 to 43.7 % indicating lower water binding capacity of protein rich ingredients when compared to gluten proteins used for the study (Fig. 1B). The dough development time increased from 2.5 to 5.8 min only up to 50 % substitution of BF with PRIM. This indicates that there is a delay in the hydration and development of gluten in the presence of PRIM. The dough stability values indicating the strength of the dough decreased gradually with an increase in the substitution of BF with PRIM from 0 to 75 %. The decrease in the stability value could be due to dilution of gluten. Mixing tolerance index is inversely proportional to the strength of the dough, higher values indicate lower strength or tolerance to mixing. Use of FRIM or PRIM increased the mixing tolerance index from 43 to 120 and 103 BU indicating poor tolerance of the dough to mixing in the presence of FRIM or PRIM. These data indicates that the dough properties are adversely affected above 50 % substitution of BF with either FRIM or PRIM.

Amylograph characteristics

Use of increasing amount of FRIM decreased the pasting temperature, increased peak viscosity, hot paste viscosity, cold paste viscosity, breakdown and set back values (Fig. 1C). Lower pasting temperature indicates that the various starches present in the mixture swell more easily than the wheat starch alone. The increase in viscosity during heating from 30 to 90 ° C, cooking at 95 ° C, cooling from 95 to 50 ° C indicates more resistance of the paste to heating, cooking and cooling. Higher break down and set back values show that the fibers interacted with the starch make the swollen granules more fragile and the swollen starch granules gelled into a semi solid paste while cooling.

Substitution of BF with PRIM significantly (P ≤ 0.05) increased the pasting temperature only up to 50 %. The peak viscosity, hot paste viscosity, cold paste viscosity, set back and breakdown values decreased with increase in PRIM from 0–75 %. This shows that the starches of PRIM had a higher resistance to swelling. Also, the decrease in swelling capacity of starch and cooking stability of the paste with substitution of BF with PRIM may be due to dilution of starch. The decrease in the set back and breakdown values indicates less retrogradation capacity of starch and the paste is more resistant to heating and mechanical shearing due to the presence of more protein rich ingredients in the system. Substitution of BF with PRIM above 50 % level significantly altered the behavior of the BF paste to heating, cooking and cooling. It can be concluded that the changes in the pasting properties of BF on addition of FRIM and PRIM could be due to their lower starch content and different protein content. The influence of FRIM and PRIM on the pasting characteristics of the BF is significantly different and substitution of BF with PRIM or FRIM above 50 % level significantly altered the pasting characteristics of BF. Shipra et al. (2012) also reported that incorporation of blends of barley flour, banana flour and soya protein isolate increased amylograph pasting temperature, peak viscosity, hot paste viscosity and cold paste viscosity due to the presence of protein, fiber and resistant starch.

Effect of FRIM and PRIM on the Texture Profile Analysis of bar dough

The results presented in the Table 2 show that the substitution of 0, 25, 50 and 75 % BF with FRIM caused an increase in the bar dough hardness from 13.23 to 41.84 N, gumminess (2.73 to 5.93 N), and decrease in the cohesiveness (0.21 to 0.11) and springiness (4.54 to 1.72 mm). The chewiness and adhesiveness values increased only up to 50 % substitution of BF with FRIM. These results show that the bar dough containing mixture of fiber rich ingredients is harder than the control. The bar dough is less cohesive owing to dilution of gluten and shows less springiness and more gumminess when compared to control bar dough.

Table 2.

Effect of different levels of substitution of BF with FRIM or PRIM on rheological characteristics of bar dough

| Parameters | Control | BF: FRIM | BF: PRIM | ||||

|---|---|---|---|---|---|---|---|

| 100:0 | 75:25 | 50:50 | 25:75 | 75:25 | 50:50 | 25:75 | |

| Hardness | 13.23 | 18.52 | 31.28 | 41.84 | 21.6 | 34.72 | 53.51 |

| (N) | ±0.15a | ±0.20b | ±0.18c | ±0.10d | ±0.11b | ±0.14c | ±0.15e |

| Cohesiveness | 0.21 | 0.20 | 0.14 | 0.11 | 0.20 | 0.13 | 0.09 |

| (N) | ±0.01c | ±0.00c | ±0.01b | ±0.02a | ±0.01c | ±0.03b | ±0.00a |

| Springiness | 4.54 | 3. 98 | 2.39 | 1.72 | 3. 24 | 2.22 | 1.57 |

| (mm) | ±0.04d | ±0.05c | ±0.03b | ±0.06a | ±0.05c | ±0.02b | ±0.03a |

| Gumminess | 2.73 | 4.91 | 5.22 | 5.93 | 4.22 | 4.45 | 2.67 |

| (N) | ±0.01a | ±0.02c | ±0.01c | ±0.11d | ±0.05b | ±0.06b | ±0.11a |

| Chewiness (Nmm) | 12.88 ± 0.15c | 14.61 ± 0.18d | 16.94 ± 0.20e | 7.84 ± 0.22a | 11.21 ± 0.25c | 9.54 ± 0.15b | 7.33 ± 0.30a |

| Adhesiveness | 0.44 | 0.85 | 0.90 | 0.33 | 0.50 | 0.57 | 0.42 |

| (Nmm) | ±0.01b | ±0.02d | ±0.02d | ±0.03a | ±0.01c | ±0.02c | ±0.03b |

BF Brown flour; FRIM Fibre Rich Ingredients Mixture; PRIM Protein Rich Ingredients Mixture

Values in the row with the same letter in the superscript are not significantly different from each other at P ≤ 0.05. Values are means of three replicates ± standard deviation

Substitution of 0, 25, 50 and 75 % BF with PRIM increased the hardness of the bar dough due to the presence of more protein rich ingredients. The cohesiveness, springiness and chewiness values of the bar dough decreased; gumminess and adhesiveness values increased with the use of PRIM up to 50 % level. These results show that the bar dough containing mixture of protein rich ingredients is harder, less cohesive and shows less springiness, chewiness, more gumminess and adhesiveness than control bar dough.

Effect of FRIM and PRIM on the quality of BEB

Physical characteristics

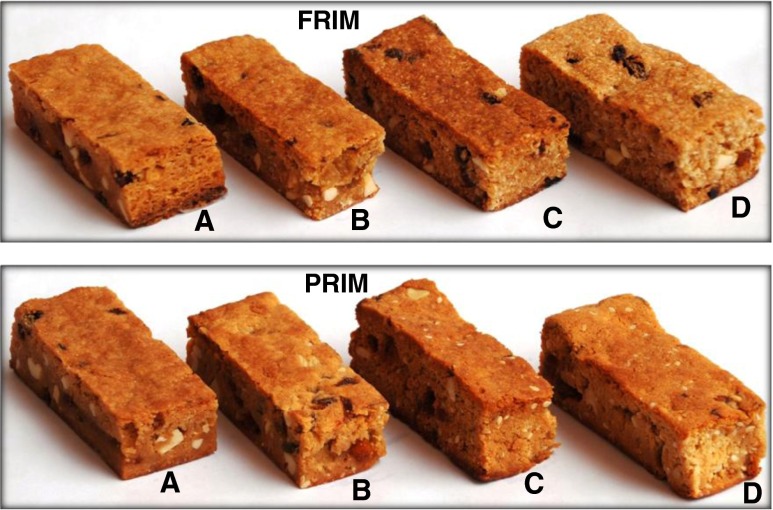

Effect of substitution of 0, 25, 50 and 75 % BF with FRIM on the physical quality of BEB is presented in Table 3 and Fig. 2. With increased substitution of FRIM from 0 to 75 % BF, the weight of the bars increased from 49.1 to 53.3 g, there was not much change in the length of the bar, though, small increase in the width and thickness of the BEB was observed. With increased substitution of BF with PRIM from 0 to 75 %, there was not much change in the weight, length and width, though, with respect to thickness; small increase in the BEB was noticed.

Table 3.

Effect of different levels of substitution of BF with FRIM or PRIM on physical and sensory quality of baked energy bars (BEB)

| Parameters | Control | BF: FRIM | BF: PRIM | ||||

|---|---|---|---|---|---|---|---|

| 100:0 | 75:25 | 50:50 | 25:75 | 75:25 | 50:50 | 25:75 | |

| Weight | 49.1 | 49.3 | 49.9 | 53.3 | 49.2 | 49.4 | 49.9 |

| (g) | ±0.05a | ±0.08a | ±0.10a | ±0.12b | ±0.15a | ±0.18a | ±0.15a |

| Length | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| (cm) | ±0.03a | ±0.02a | ±0.01a | ±0.02a | ±0.01a | ±0.02a | ±0.01a |

| Width | 2.9 | 3.0 | 3.0 | 3.1 | 3.0 | 3.0 | 3.1 |

| (cm) | ±0.00a | ±0.01a | ±0.00a | ±0.01ab | ±0.01a | ±0.02a | ±0.01ab |

| Thickness | 2.2 | 2.4 | 2.5 | 2.6 | 2.3 | 2.4 | 2.5 |

| (cm) | ±0.01a | ±0.02b | ±0.03b | ±0.02bc | ±0.01a | ±0.02b | ±0.01b |

| OQS (50) | 38 | 40 | 43.5 | 31.5 | 40 | 42 | 30.5 |

| ±0.11b | ±0.15c | ±0.18de | ±0.20ab | ±0.25c | ±0.22d | ±0.28a | |

BF Brown flour; FRIM Fibre Rich Ingredients Mixture; PRIM Protein Rich Ingredients Mixture

Values in the row with the same letter in the superscript are not significantly different from each other at P ≤ 0.05. OQS Overall quality score, Values are means of three replicates ± standard deviation

Fig. 2.

Photograph of baked energy bars with different levels of FRIM and PRIM. A: Control; B: 25 %; C: 50 %; D: 75 %; FRIM Fibre Rich Ingredients Mixture; PRIM Protein Rich Ingredients Mixture

Sensory characteristics

Substitution of FRIM changed the crust colour of the BEB from golden brown to pale brown and surface character from smooth to slightly rough (Fig. 2). The texture of the control BEB showed significant improvement in softness and chewiness with the substitution of BF with FRIM up to 50 %. The BEB was slightly firm, more gummy and chewy. The mouthfeel also improved with FRIM up to 50 %, as shown by wholesome fibrous taste due to the presence of partially defatted coconut flour. However substitution of BF with FRIM above 50 % resulted in residue formation in the mouth, more dry feeling and took more time to disintegrate indicating adverse effect of FRIM at 75 % level. This is indicated by an increase in the overall quality score from 38 to 43.5 up to 50 % level and decrease to 31.5 at 75 % level.

Substitution of increasing amount of PRIM changed the crust colour from golden brown to slightly dark brown. The surface character which was smooth for control BEB bar changed to slightly rough (Fig. 2). With the increase in PRIM in the blend from 0 to 50 %, the BEB showed gradual improvement in the gumminess and chewiness. There was no residue formation in the mouth up to 50 % level. At 75 % level, the BEB were very dark, firmer, showed very rough surface, residue formation and dominating foreign taste. The BEB with 50 % PRIM possessed mild sesame taste. The overall quality score for control BEB was 38 which improved at 25 % PRIM (40) and 50 % PRIM (42) but decreased at 75 % PRIM (30.5) for the maximum score of 50. These results show that the overall quality of BEB was acceptable only up to 50 % PRIM level.

Nutritional characteristics of baked energy bars

Nutritional evaluation of bars with 50 % FRIM and PRIM showed increased contents of moisture, fat; total, soluble and insoluble fibres; ash and decreased contents of carbohydrate and energy when compared to control BEB. It is clear from Table 4 that the fiber content increased by about 9 times whereas the protein content increased by about 2 times with the use of 50 % FRIM and 50 % PRIM respectively (Table 4). Digestibility of the protein as analysed by in-vitro enzymatic method of control baked energy bar was 80.24 %. In the BEB with 50 % PRIM, protein rich ingredients (chickpea flour, sesame, soya protein isolate and whey protein concentrate) cause an increase in protein content from 6.84 to 12.3 %. Out of 12.3 g protein, 90.5 % was found to be in the digestible form. The protein content in BEB with 50 % FRIM was 6.72 g of which 79 % was in the digestible form. The lower protein and digestible values in these bars are due to the presence of fibre rich ingredients in FRIM. It is reported that use of 20 % soya protein isolate (SPI) increases the protein content of cookies from 12.25 to 20.43 % (Mohsen et al. 2009) and defatted soya flour improves the amino acid profile of chapatti (Lindell and Walker 1984). Control BEB, BEB with 50 % FRIM, PRIM provide 520, 483 and 518 kcal of energy per 100 g as computed from proximate composition of the bar. Aigster et al. (2011) reported 15.1 % moisture, 5.87 % protein, 17.8 % lipid, 2.3 % ash, 58.9 % carbohydrate and 380 kcal in granola bars supplemented with 15 % resistant starch. Freitas and Moretti (2006) also developed a high protein bar using soy which contain 60.97 % carbohydrate, 15.31 % protein, 5.64 % lipid and 5.17 % dietary fiber. Lobato et al. (2012) developed a soy snack bar with 39.88 % dietary fiber, 34.25 % protein, 100.39 mg % isoflavones and 245.47 kcal per 100 g.

Table 4.

Nutritional characteristics of BEB

| Proximate composition | BEB | ||

|---|---|---|---|

| Control | 50 % FRIM | 50 % PRIM | |

| Moisture (%) | 4.26 ± 0.05a | 6.55 ± 0.02c | 5.85 ± 0.06b |

| Protein (%) | 6.84 ± 0.09a | 6.72 ± 0.10a | 12.3 ± 0.11b |

| Digestible protein (g) | 5.47 ± 0.02a | 5.31 ± 0.05a | 11.13 ± 0.071b |

| Percent digestible | 80.24 ± 0.15a | 79 .0 ± 0.11a | 90.5 ± 0.12b |

| Fat (%) | 28.59 ± 0.20a | 28.61 ± 0.25a | 30.85 ± 0.28b |

| Dietary fiber (%) | 0.48 ± 0.01a | 4.44 ± 0.02c | 1.55 ± 0.01b |

| Soluble fiber | 0.14 ± 0.00a | 1.23 ± 0.01c | 0.35 ± 0.00b |

| Insoluble fiber | 0.34 ± 0.01a | 3.21 ± 0.01c | 1.20 ± 0.00b |

| Ash (%) | 1.11 ± 0.01a | 3.94 ± 0.01c | 1.51 ± 0.01b |

| Carbohydrate (%) | 58.73 ± 0.25c | 49.74 ± 0.30b | 47.94 ± 0.22a |

| Energy (Kcal) | 520 ± 1.55b | 483 ± 1.24a | 518 ± 1.81b |

BF Brown flour; FRIM Fibre Rich Ingredients Mixture; PRIM Protein Rich Ingredients Mixture

Values in the row with the same letter in the superscript are not significantly different from each other at P ≤ 0.05. Values are means of three replicates ± standard deviation

Effect of storage on the chemical characteristics of baked bars

The aw of control BEB, BEB with 50 % FRIM, 50 % PRIM were 0.54, 0.48 and 0.48 respectively. These low aw indicate low risk of microbial proliferation, pathogenic spoilage and good shelf life (Beuchat 1981). Changes in lipid oxidation during storage of control BEB and BEB with 50 % FRIM and PRIM were monitored by estimating peroxide value and free fatty acid value up to 3 months at room temperature (30 °C, 65–75 % RH). It was observed that during storage of BEB the peroxide value and FFA of control BEB, BEB with 50 % FRIM, PRIM varied from 4.9 to 7.85 meq O2/kg fat and 4.82 to 8.6 % oleic acid respectively (Table 5). There was not much change in the moisture content of all three BEB’s during storage up to 3 months. Aramouni and Abu-Ghoush (2011) also observed that products having aw level below 0.7 have a shelf life of approximately 6 months. Sensory evaluation showed that during storage up to 3 months, there was not much change in the external characteristics such as crust colour, crust surface, crumb colour, texture and mouthfeel. This is reflected in the overall quality score of 38.0 and 37.0 for control BEB, 43.5 and 42.5 for BEB with 50 % FRIM and 42.0 and 40.5for BEB with 50 % PRIM at 0 and 3 months storage period respectively.

Table 5.

Effect of storage on the chemical and sensory characteristics of BEB

| Attributes | Storage period (months) | |||||

|---|---|---|---|---|---|---|

| 0 | 3 | |||||

| Control | 50 % FRIM | 50 % PRIM | Control | 50 % FRIM | 50 % PRIM | |

| Moisture (%) | 4.26 | 6.55 | 5.85 | 4.56 | 6.80 | 6.05 |

| ±0.05a | ±0.03b | ±0.01c | ±0.06 a | ±0.04b | ±0.05c | |

| Peroxide value | 6.13 | 6.14 | 4.9 | 7.45 | 7.85 | 6.88 |

| (meq O2/kg) | ±0.05b | ±0.04b | ±0.02a | ±0.05c | ±0.06c | ±0.05b |

| Free fatty acid | 5.26 | 5.02 | 4.82 | 8.60 | 7.83 | 7.23 |

| (% oleic acid) | ±0.04a | ±0.03a | ±0.04a | ±0.06bc | ±0.07c | ±0.05b |

| OQS | 38.0 | 43.5 | 42.0 | 37.0 | 42.5 | 40.5 |

| ±0.11b | ±0.18a | ±0.22a | ±0.20b | ±0.25a | ±0.28a | |

BF Brown flour; FRIM Fibre Rich Ingredients Mixture; PRIM Protein Rich Ingredients Mixture

Values in the row with the same letter in the superscript are not significantly different from each other at P ≤ 0.05. OQS Overall quality score. Values are means of three replicates ± standard deviation

These results confirm that the BEB with 50 % FRIM and PRIM remained chemically stable and showed good sensorial characteristics during storage up to 3 months.

Conclusions

Effect of substitution of BF with 0–75 % FRIM (banana flour, psyllium husk, partially defatted coconut flour and oats) increased farinograph water absorption, amylograph peak viscosity while PRIM (chickpea flour, sesame, soya protein isolate and whey protein concentrate) decreased the aforementioned parameters. The bar dough hardness increased; cohesiveness and springiness decreased with increase in FRIM or PRIM levels. The optimum level of incorporation of FRIM or PRIM in BEB was found to be 50 %. The BEB with 50 % FRIM and PRIM were chemically stable up to 3 months and showed increased dietary fiber and protein contents compared to control BEB respectively.

References

- AACC . American Association of Cereal Chemists. St. Paul, Minnesota: Approved methods of Analysis; 2000. [Google Scholar]

- Aigster A, Duncan SE, Conforti FD, Barbeau WE. Physicochemical properties and sensory attributes of resistant starch-supplemented granola bars and cereals. Food Sci Technol. 2011;4:2159–2165. [Google Scholar]

- Akeson WR, Stahmann MA. A pepsin pancreatin digest index of protein quality evaluation. J Nutri. 1964;83:257–261. doi: 10.1093/jn/83.3.257. [DOI] [PubMed] [Google Scholar]

- Aramouni FM, Abu-Ghoush MH. Physicochemical and sensory characteristics of no-bake wheat–soy snack bars. J Sci Food Agri. 2011;91:44–51. doi: 10.1002/jsfa.4134. [DOI] [PubMed] [Google Scholar]

- Asp NG, Johansson CG, Hallmer H, Siljeström M. Rapid enzymatic assay of insoluble and soluble dietary fiber. J Agri Food Chem. 1983;31:476–482. doi: 10.1021/jf00117a003. [DOI] [PubMed] [Google Scholar]

- Beuchat LR. Microbial stability as affected by water activity. Cereal Foods World. 1981;26:345–349. [Google Scholar]

- Bourne MC. Texture profile analysis. J Food Technol. 1978;32(62–66):72. [Google Scholar]

- Boustani P, Mitchell VW. Cereal bars: a perceptual, chemical and sensory analysis. Brit Food J. 1990;92:17–22. doi: 10.1108/00070709010003652. [DOI] [Google Scholar]

- Dutcosky SD, Grossmann MVE, Silva RSSF, Welsch AK. Combined sensory optimization of a prebiotic cereal product using multicomponent mixture experiments. Food Chem. 2006;98:630–638. doi: 10.1016/j.foodchem.2005.06.029. [DOI] [Google Scholar]

- Farheen D, Jyothi Lakshmi A, Prakash J, Indrani D. Effect of ingredients on rheological, nutritional and quality characteristics of high protein, high fibre and low carbohydrate bread. Food Biopro Technol. 2012;5:2998–3006. doi: 10.1007/s11947-011-0752-y. [DOI] [Google Scholar]

- Freitas DGC, Moretti R. Caracterrizacao e availacao sensorial de barra de cereais functional de alto teor proteico e vitaminico. Ciencia e Technologia de Alimentos. 2006;26:318–324. doi: 10.1590/S0101-20612006000200014. [DOI] [Google Scholar]

- Gonzales E, Draganchuk M. Flavouring nutrition bars. Cereal Foods World. 2003;48:250–251. [Google Scholar]

- Hogan SA, Chaurin V, Brendan TO’K, Kelly PM. Influence of dairy proteins on textural changes in high-protein bars. Int Dairy J. 2012;26:1–8. doi: 10.1016/j.idairyj.2012.02.006. [DOI] [Google Scholar]

- Indrani D, Soumya C, Rajiv J, Venkateswara RG. Multigrain bread-its rheology, microstructure, quality and nutritional characteristics. J Text Stud. 2010;41:302–319. doi: 10.1111/j.1745-4603.2010.00230.x. [DOI] [Google Scholar]

- Johnson S. Bar none. Baking Snack. 2001;23:38–50. [Google Scholar]

- Krishnan PG, Chang KC, Brown G. Effect of commercial oat bran on the characteristics and composition of bread. Cereal Chem. 1987;64:55–58. [Google Scholar]

- Lindell MJ, Walker CE. Soy enrichment of chapaties made from wheat and non-wheat flours. Cereal Chem. 1984;61:435–438. [Google Scholar]

- Lobato LP, Pereira AEC, Lazaretti MM, Barbosa DS, Carreira CM, Mandarino JMG, Grossmann MVE. Snack bars with high soy protein and isoflavone content for use in diets to control dyslipidemia. Int J Food Sci Nutri. 2012;63:1–10. doi: 10.3109/09637486.2011.596148. [DOI] [PubMed] [Google Scholar]

- Mohsen SM, Fadel HHM, Bekhit MA, Edris AE, Ahmed MYS. Effect of substitution of soy protein isolate on aroma volatiles, chemical composition and sensory quality of wheat cookies. Int J Food Sci Technol. 2009;44:1705–1712. doi: 10.1111/j.1365-2621.2009.01978.x. [DOI] [Google Scholar]

- Nielsen NS, Jacobsen C. Methods for reducing lipid oxidation in fish-oil-enriched energy bars. Int J Food Sci Technol. 2009;44:1536–1546. doi: 10.1111/j.1365-2621.2008.01786.x. [DOI] [Google Scholar]

- Padmashree A, Sharma GK, Srihari KA, Bawa AS. Development of shelf stable protein rich composite cereal bar. J Food Sci Technol. 2012;49:335–341. doi: 10.1007/s13197-011-0283-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Serna-Saldivar SO, Lopez-Ahumada G, Ortega-Ramireza R, Abril DR. Effect of sodium stearoyl–2-lactylate on the rheological and baking properties of wheat bread fortified with defatted soybean and sesame meal. J Food Sci. 1988;53(211–214):230. [Google Scholar]

- Shipra B, Jyothi Lakshmi A, Indrani D. Effect of barley, banana and soya protein isolate on rheological, microstructural and nutritional characteristics of North Indian Parotta. J Text Stud. 2012;43:246–256. doi: 10.1111/j.1745-4603.2011.00334.x. [DOI] [Google Scholar]

- Steel RGD, Torrie JH. Principles and procedures of statistics. New York: McGraw-Hill; 1980. [Google Scholar]