Abstract

Present study was conducted to investigate effects of pregelatinized rice flour and extrusion process parameters such as feed moisture (16–19 %), die temperature (115–145 °C) and screw speed (150–250 rpm) on physicochemical properties of ready-to-eat expanded snacks by using co-rotating twin-screw extruder. Higher die temperature increased extrudate density and WSI but reduced die pressure, torque and expansion. Increased feed moisture content resulted in extrudates with increased density, WAI and hardness but reduced die pressure, expansion and WSI. Screw speed was found to have no significant effect on expansion and hardness of extrudates, while increase in screw speed resulted in increased WAI of extrudates and reduced torque of extrudates. Effect of pregelatinized rice flour on extrudate expansion and hardness was analysed at 16 % feed moisture, 135 °C die temperature and 150 rpm screw speed. Use of pregelatinized rice flour increased expansion while it reduced hardness of extrudates.

Keywords: Twin-screw extrusion, Optimization, Pregelatinized rice, System parameters, Extrudate characteristics

Introduction

Extrusion cooking technology plays a key role in food industry as a continuous cooking, mixing, shearing and forming process used especially for production of cereal-based snacks. Extrusion is very efficient technology in food processing having advantage of low cost, high temperature short time (HTST) process and a versatile nature (Harper 1981). Although there is increased use of extrusion processing, but still there is no fully developed theory to predict the effects of process variables on various raw materials and their mixtures. Any change in feed composition and process variables can influence extrusion performance as well as product quality (Desrumaux, Bouvier and Burri 1999). Therefore, it is crucial to study the effect of extrusion process parameters (feed moisture, die temperature and screw speed) on system parameters and extrudate characteristics.

The choice of rice as a raw material for extrusion processing is due to its bland taste, its low protein content that could limit the non-enzymatic browning reaction and its ability to expand well to produce excellent extruded snack (Saccheti et al. 2004). Among all cereal components, starch plays an important role. Extrusion of starchy foods results in gelatinization, partial or complete destruction of crystalline structure and molecular fragmentation of starch polymers (Gonzalez et al. 2006; Perez et al. 2008).

Many researchers focus on extrusion cooking of rice flour mixed with other ingredients for production of extrudate snacks but limited information is available on extrusion processing of pregelatinized rice flour. Several researchers have demonstrated that the expansion ratio of extruded cereals depends on the degree of starch gelatinization (Chinnaswamy and Hanna 1988). Heating of pregelatinized rice flour during extrusion cooking can considerably modify the texture of extrudate, depending on the degree of starch gelatinization. Thus, it is important to understand the changes that occur in the extrudate characteristics after addition of pregelatinized rice flour. This study was undertaken to investigate the relationship and interactions between extrusion processing and resulting extrudate properties of ungelatinized and pregelatinized rice flour.

Materials and methods

Sample preparation

A sample of low cost rice IET-1411 (ratna) variety was obtained as paddy from Rice Research Centre Karjat, India. Paddy samples were dehusked and milled in local rice mill at Karjat.

Milled rice grains weighing 500 g were washed three times with enough deionised water to immerse them and excess water was removed by means of straining. Rice grains were cooked for 15 min by taking rice:water ratio as 1:1.2 (w/v) in an automated autoclave (Equitron, SLE series, Medica Instrument mfg Co. India) at five different cooking temperatures as 80, 90, 100, 110 and 120 °C. For further analysis, autoclaved samples were taken from middle of cooking bowl after 1 cm layer of top and bottom were skimmed off and discarded. Samples were spread evenly on 40 × 30 cm meshed tray and then dried in programmable environmental test chamber (Remi Instruments Ltd. India) at 25 °C and 40 % relative humidity until around 11–12 % moisture content. Rice samples were then ground in hammer mill and passed through 80 mesh (British standard) sieve. Moisture content of all rice flour samples were estimated using oven method (AOAC method, 1984) and later calculated amounts of water being sprayed onto each sample. After that, samples were packed in polythene bags and stored at 4 °C overnight to reach homogeneous moisture distribution. Before extrusion the feed was allowed to come to ambient temperature (≈25 °C) and mixed again after checking the moisture content.

Analysis of rice flour

Thermal properties

Thermal properties of rice flour samples were evaluated with a differential scanning calorimeter (DSC-60, Shimadzu, India). The instrument was calibrated with indium and an empty pan was used as reference. Rice flour (approximately 4–6 mg) was weighed accurately into stainless steel sample pan and then the pan was hermetically sealed and allowed to stand for at least 1 h prior to analysis. Samples were heated from 30 to 130 °C at a rate of 5 °C/min. Gelatinization enthalpy, onset, peak, and conclusion temperatures were recorded. The percentage of gelatinized starch was calculated based on the change in enthalpy of the cooked rice flour sample (ΔHCooked) in comparison with the uncooked one (ΔHUncooked), by the following equation (Marshall et al. 1993): Gelatinized starch (%) = [1 − (ΔHCooked/ΔHCooked)] × 100.

X-ray diffraction measurements

One gram of rice flour was packed tightly in rectangular silicon cells. Sample was spread evenly to obtain a smooth surface. The sample cell was then placed in sample holder. X-ray diffraction patterns were obtained with diffractometer (Rigaku Miniflex) using monochromatic Cu-Kα radiation 1.5406 Å. Diffractometer was operated at 30 kV, 15 mA and the spectra scanned over a diffraction angle (2θ) range of 2–40 ° with scanning rate of 3 °/min. Percentage of crystallinity was calculated as the percentage of peak area to the total diffraction area using following equation (Cheetam and Tao 1998): .

Extrusion

Extrusion was performed in a laboratory-scale-co-rotating twin-screw extruder (KETSE 20/40 Brabender GmbH and Co. KG, Duisburg, Germany) with 20:1 barrel length to diameter ratio. Extruder barrel consisted of four heating/cooling zones. Extruder was fitted with a circular die having nozzle of 4 mm diameter. Feed rate was kept constant at 14 kg/h by using vertical dosing screw feeder (Brabender GmbH and Co. KG, Duisburg, Germany). Extrudates were cooled to room temperature (25 ± 3 °C), packed in sealed polyethylene bags and stored at room temperature till further analysis.

Effect of extrusion process parameters

Central Composite RSM design of three variables at five levels each with six central point combinations was used. Independent variables included feed moisture (X1), die temperature (X2) and screw speed (X3). Coded levels for independent variables are shown in Table 1. Actual levels were selected according to the preliminary (one factor at a time) studies and literature data surveyed (not reported here). Outline of experimental design with the coded and uncoded levels is presented in Table 2. Response variables were system parameters such as die pressure and torque and extrudate characteristics such as overall expansion, bulk density, WSI, WAI and hardness.

Table 1.

Coded levels for independent variables used in developing experimental data

| Code | Level | |||||

|---|---|---|---|---|---|---|

| Factor | -α (−1.68) | −1 | 0 | 1 | α (1.68) | |

| Feed Moisture (%) | X1 | 14.98 | 16 | 17.5 | 19 | 20.02 |

| Die Temperature (°C) | X2 | 104.77 | 115 | 130 | 145 | 155.23 |

| Screw Speed (rpm) | X3 | 11.91 | 150 | 200 | 250 | 284.09 |

Table 2.

Variables and their levels employed in Central Composite Design

| Feed moisture (X1) | Die temperature (X 2) | Screw speed (X3) | ||||

|---|---|---|---|---|---|---|

| Experiment | Coded value | Uncoded value | Coded value | Uncoded value | Coded value | Uncoded value |

| 1 | −1 | 16 | −1 | 115 | −1 | 150 |

| 2 | 1 | 19 | −1 | 115 | −1 | 150 |

| 3 | −1 | 16 | 1 | 145 | −1 | 150 |

| 4 | 1 | 19 | 1 | 145 | −1 | 150 |

| 5 | −1 | 16 | −1 | 115 | 1 | 250 |

| 6 | 1 | 19 | −1 | 115 | 1 | 250 |

| 7 | −1 | 16 | 1 | 145 | 1 | 250 |

| 8 | 1 | 19 | 1 | 145 | 1 | 250 |

| 9 | −1.68 | 14.98 | 0 | 130 | 0 | 200 |

| 10 | 1.68 | 20.02 | 0 | 130 | 0 | 200 |

| 11 | 0 | 17.5 | −1.68 | 104.77 | 0 | 200 |

| 12 | 0 | 17.5 | 1.68 | 155.23 | 0 | 200 |

| 13 | 0 | 17.5 | 0 | 130 | −1.68 | 115.91 |

| 14 | 0 | 17.5 | 0 | 130 | 1.68 | 284.09 |

| 15-20 | 0 | 17.5 | 0 | 130 | 0 | 200 |

Extrusion with pregelatinized rice flour

Extrusion processing of pregelatinized rice flour samples were done at 16 % feed moisture; 135 °C die temperature and 150 rpm screw speed to evaluate the effect on expansion and hardness of extrudate.

Statistical analysis

Analysis of variance (ANOVA) test was carried out using commercial statistical package, Design Expert 6.0 (State-Ease Inc., Minneapolis, USA) to determine the significance at different levels. Same software was used for the generation of response surface plots. A Pearson’s correlation coefficient matrix on system parameters and product responses was carried out using SPSS 7.5 (SPSS Inc., Chicago, USA) in order to determine correlation coefficient between parameters.

System parameter analysis

Die pressure was measured using a pressure transducer (Dynisco, USA). Readings were recorded every 6 s for at least 2 min and average values were expressed as kPa. Torque was recorded every 6 s for at least 2 min and average values were expressed as Nm.

Physicochemical analysis

Expansion

Sectional expansion i.e., ratio of diameter of extrudate and the diameter of the die was used to express expansion of extrudate (Ding et al. 2005). Ten random readings were taken for each sample and their average was taken as the mean diameter of the extrudate. Diameter of the die was 4 mm.

Density

Extrudate density was calculated as suggested by method of (Alvarez-Martinez et al. 1988): Density = 4m/πd2LWhere, m is the mass (g) of a length L (cm) of cooked extrudate with diameter d (cm).

Ten random readings were taken for each sample and their average was taken as the mean value.

Water solubility index (WSI) and water absorption index (WAI)

WSI and WAI were determined using the method of Ding et al. (2005). Extrudates were ground to pass through 30 mesh sieve. 2.5 g ground extrudate was suspended in 25 ml water at room temperature for 30 min, with intermediate stirring, and then centrifuged at 3,000 g for 15 min. Supernatant was decanted into an evaporating dish with a known weight. WSI is the weight of dry solids in the supernatant expressed as a percentage of the original weight of sample where as WAI is the weight of residue obtained after removal of the supernatant per unit weight of original dry solids, and is given as follows: WSI (%) = (Weight of dry solids in supernat/Dry weight of extrudate) × 100 WAI (g/g) = weight of sediment/sample dry weightWSI and WAI measurements were reported as an average of three to four replicates.

Texture

Hardness of the extrudate was determined using a Stable Micro System TAXT2i texture analyzer (Serial No.4650, TEE version 2.64, UK). 2 mm cylindrical probe was used for the measurement of hardness of the extrudates (Ding et al. 2005). Maximum force needed to break the sample was recorded and analysed by Texture Exponent software associated with the texture analyser. Ten measurements were performed for each sample and their average was taken as the mean value.

Results and Discussion

Rice flour analysis by DSC and XRD

DSC and XRD results were used to characterize the degree of gelatinization of starch in the uncooked rice (assumed to be fully un-gelatinized) and heat treated rice samples. Table 3 shows the thermal properties of rice as affected by heat treatments ranging from 80 to 120 °C. Onset, peak and endset gelatinization temperature of uncooked rice was 51, 109 and 79 °C respectively. Gelatinization temperature parameters (onset, peak and endset) generally shifted to higher values (from 56 to 90, 113 to 132 and 80 to 123 °C respectively) while gelatinization enthalpy values went on decreasing as a result of increase in heat treatment (80 to 120 °C) given to rice samples. These results are in agreement with previous studies that onset, peak and endset gelatinization temperature increased while gelatinization enthalpy decreased with the severity of parboiling treatment (Ong and Blanshard 1995; Islam et al. 2002; Lamberts et al. 2006; Manful et al. 2008). Amount of gelatinized starch in the heat treated rice samples based on DSC measurements of gelatinization enthalpy ranged from 13.79 to 84.02 % (Table 3). Amount of gelatinized starch is an indicator of the severity of heat process. Extent of gelatinization increased with increasing cooking temperature as expected.

Table 3.

Effect of gelatinization temperatures on DSC and XRD characteristics of rice flour

| Characteristics | Temperature of heat treatment given to rice (°C) | |||||

|---|---|---|---|---|---|---|

| Uncooked | 80 | 90 | 100 | 110 | 120 | |

| Onset GT (°C) | 51 ± 1.36 | 56 ± 1.61 | 60 ± 1.26 | 64 ± 0.65 | 72 ± 1.20 | 90 ± 1.34 |

| Endset GT (°C) | 109 ± 2.73 | 113 ± 0.66 | 124 ± 2.13 | 127 ± 0.16 | 129 ± 0.54 | 132 ± 2.01 |

| Peak GT (°C) | 79 ± 1.25 | 80 ± 0.13 | 90 ± 2.17 | 105 ± 0.84 | 112 ± 2.09 | 123 ± 1.38 |

| Enthalpy (J/g) | −205 ± 5.60 | −188 ± 4.82 | −176 ± 2.92 | −132 ± 2.15 | −66 ± 6.93 | −23 ± 3.43 |

| Gelatinized starch (%) | 0.00 | 13.79 | 15.19 | 50.44 | 59.63 | 84.02 |

| Crystallinity (%) | 3.2 ± 0.30 | 3.0 ± 0.52 | 2.6 ± 0.11 | 2.5 ± 0.94 | 2.0 ± 0.73 | 1.8 ± 0.69 |

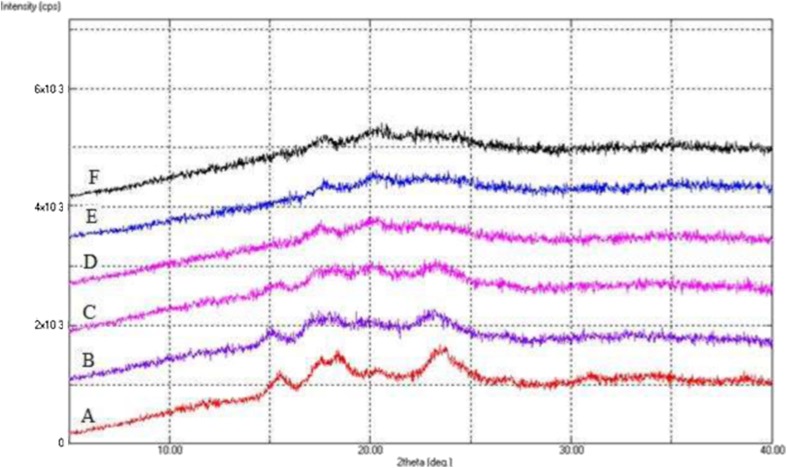

Crystalline features of native and heat-treated rice samples were assessed by XRD. All rice flour samples exhibited patterns which are characteristic of crystalline arrangements of polysaccharide chains in starch (Fig. 1). Un-gelatinized rice flour sample showed peaks positioned at 2θ = 15.2 °, 17.1 °, 18.1 °, 23 °, which are typical of the A type of starch crystalline structure (Chauhan et al. 2003; Kadan and Pepperman 2002). Gelatinized rice starch heated at 80–120 °C showed that the A-amylose pattern (i.e., peaks at 15.2 ° and 17.1 °) became weaker and the V-amylose (i.e., peak at 19.7 °) became more apparent. After heat treatment also the peak at 18.3 ° was still visible which is characteristic of A-amylose. Additionally, weak peak at 2θ = 22.3 ° may be indicative of trace of B-type starch structure acquired during the heat treatment. Granular structure of uncooked rice starch was less destroyed, while completely amorphous X-ray diffractograms of heat treated rice samples indicated a complete loss of the granular order (Fig. 1). Degree of crystallinity was 3.21 % for the un-gelatinized rice, while the value reduced after increase in heat treatment. Heat treatment at higher temperatures could destroy more crystalline structure, resulting in lower degrees of crystallinity as seen in Fig. 1 and Table 3. Degrees of crystallinity of heat treated rice were found to decrease from 3 to 2 % when the gelatinization temperatures increased from 80 to 120 °C. From this study it is observed that with increase in heat treatment given to rice samples, extent of gelatinization (as determined by DSC) increased while % crystallinity (as determined by XRD) decreased.

Fig 1.

XRD diagrams of ungelatinized (Control) and pregelatinized rice flour. (A: Ungelatinized rice flour; B-F: Gelatinized rice flour heat treated from 80–120 °C)

Effect of extrusion process parameters

System parameter analysis

| 1 |

The regression equation (Eq.1) accounts for 96.20 % (P < 0.001) of the total variation in die pressure. Whereas from Table 4 it is seen that lack-of-fit was not significant (P > 0.05). Statistical analysis revealed that pressure was positively correlated (R = 0.571, P < 0.01) with torque and negatively correlated (R = −0.658, P < 0.01) with density (Table 6). These results are indicating that high pressure naturally offers low density product. Increase in extruder pressure directly increases expansion while decreasing density of product.

Table 4.

Analysis of variance results for system parameters

| Response | Source | df | Sum of squares | Mean squares | F-value | P-value |

|---|---|---|---|---|---|---|

| Die pressure | Regression | 9 | 636.833 | 70.759 | 28.097 | < 0.0001 |

| Lack-of-fit | 5 | 20.616 | 4.123 | 4.513 | 0.0619 | |

| Pure error | 5 | 4.568 | 0.914 | |||

| Residual | 10 | 25.184 | 2.518 | |||

| Total | 19 | 662.016 | ||||

| R 2 (0.9620) | ||||||

| Torque | Regression | 9 | 248.417 | 27.602 | 37.681 | < 0.0001 |

| Lack-of-fit | 5 | 2.557 | 0.511 | 0.536 | 0.7447 | |

| Pure error | 5 | 4.768 | 0.954 | |||

| Residual | 10 | 7.325 | 0.733 | |||

| Total | 19 | 255.742 | ||||

| R 2 (0.9714) |

Table 6.

Correlation coefficient between system parameters and product responses

| Pressure | Torque | Expansion | Density | WSI | WAI | Hardness | |

|---|---|---|---|---|---|---|---|

| Pressure | 1 | 0.571* | 0.432ns | −0.658* | −0.235ns | 0.020ns | −0.350ns |

| Torque | 1 | −0.099ns | −0.365ns | −0.368ns | 0.391ns | 0.087ns | |

| Expansion | 1 | −0.717* | 0.658* | −0.710* | −0.908* | ||

| Density | 1 | −0.344ns | 0.348ns | 0.834* | |||

| WSI | 1 | −0.729* | −0.699* | ||||

| WAI | 1 | 0.721* | |||||

| Hardness | 1 |

*Significant at P < 0.01; ns Not significant

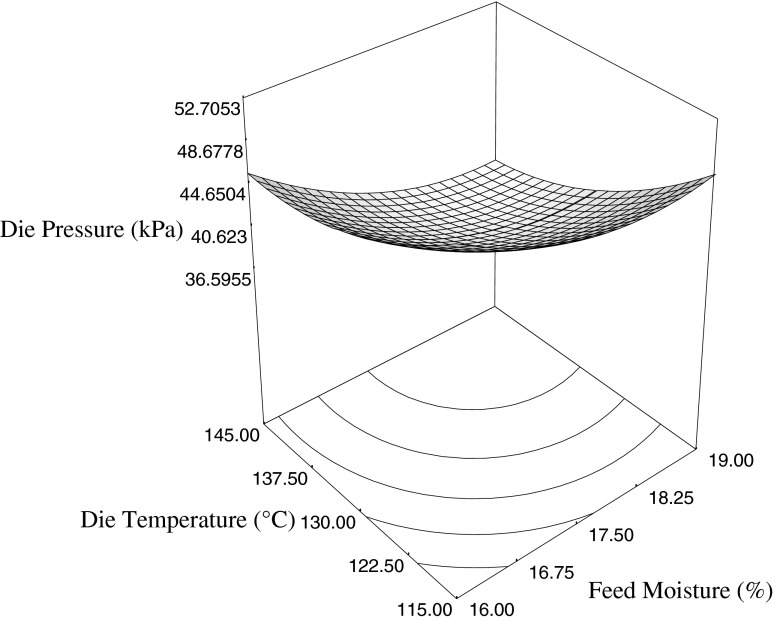

From Fig. 2 it is seen that die pressure of extrudates decreased with an increase in moisture content and die temperature. This phenomenon is attributed to decrease in viscosity of melt due to fragmentation of swollen and gelatinized starch granules (Akdogam, Towas and Oliveira 1997; Singh and Smith 1997). Increase in die temperature with increase in feed moisture affects the viscosity of mass through the extruder that leads to decrease in die pressure value. Influence of melt viscosity on die pressure was expressed as a decrease in die pressure with increasing hydration level of feed material (Fig. 2). Feed moisture had a lubricating effect on molten starch inside the extruder that may affect the heat generation simultaneously with decrease in die pressure. These observations are in agreement with the work reported by Govindasamy et al. (1997) and Singh et al. (2007).

Fig 2.

Die pressure of extrudate as a function of feed moisture and die temperature at a screw speed of 200 rpm

The regression equation relating response function torque and process variables is represented by (Eq.2):

| 2 |

ANOVA for quadratic model as fitted to experimental results of torque showed significance (P < 0.001). The coefficient of determination (R2) for torque was 0.971. However, model showed lack-of-fit was not significant (P > 0.05) (Table 4). Statistical analysis revealed that torque was not correlated with any response variables (pressure, expansion, density, WSI, WAI and hardness) (Table 6).

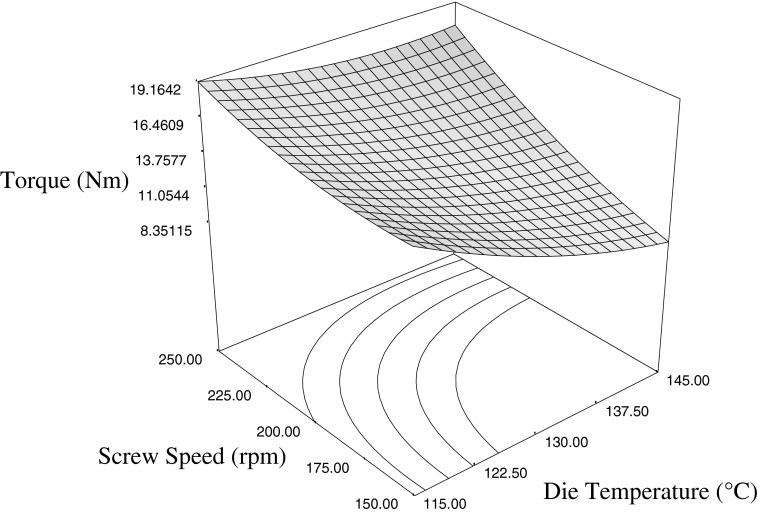

Torque is the measure of safety indicator for extruder operation, varied between 8.35 and 19.16 Nm. Torque of extrudates decreased with an increase in die temperature and screw speed. Temperature was found to have strong positive linear effect on the torque. The lowest torque value was obtained at lower temperature with a low level of screw speed, whereas the highest torque value was obtained at higher temperature and higher level of screw speed. Response surface graph (Fig. 3) shows that torque decreased with decreasing die temperature and screw speed. These observations are in agreement with the work reported by Bhattacharya (1997).

Fig 3.

Torque of extrudate as a function of die temperature and screw speed at feed moisture of 17.5 %

Expansion and density

The regression equation (Eq.3) relating expansion with feed moisture is:

| 3 |

Experimental data fit the response equation with a high degree of significance (P < 0.001) (Table 5). A high value of coefficient of determination (R2 = 0.974) with a low value of coefficient of variation (CV = 5.62 %) of the predicted model were observed. However, lack-of-fit was not significant (P > 0.05). Statistical analysis revealed that expansion was positively correlated (R = 0.658, P < 0.01) with WSI and negatively correlated (R = −0.717, P < 0.01), (R = −0.710, P < 0.01), with density, WAI and hardness respectively (Table 6). Results are indicating that well expanded product naturally offers low hardness evident by high correlation (R = −0.908, P < 0.01) between product expansion and hardness.

Table 5.

Analysis of variance results for extrudate characteristics

| Response | Source | df | Sum of squares | Mean squares | F-value | P-value |

|---|---|---|---|---|---|---|

| Expansion | Regression | 9 | 3.4 | 0.009 | 42.25 | < 0.0001 |

| Lack-of-fit | 5 | 0.067 | 0.013 | 2.991 | 0.1272 | |

| Pure error | 5 | 0.022 | 4.480 × 10−3 | |||

| Residual | 10 | 0.089 | 8.941 × 10−3 | |||

| Total | 19 | 3.489 | ||||

| R 2 (0.9744) | ||||||

| Density | Regression | 9 | 0.025607 | 0.002845 | 133.7002 | < 0.0001 |

| Lack-of-fit | 5 | 6.281 × 10−5 | 1.256 × 10−5 | 0.418718 | 0.8193 | |

| Pure error | 5 | 1.500 × 10−4 | 3.000 × 10−5 | |||

| Residual | 10 | 2.128 × 10−4 | 2.128 × 10−5 | |||

| Total | 19 | 0.025820 | ||||

| R 2 (0.9918) | ||||||

| WSI | Regression | 9 | 126.997 | 14.111 | 9.291 | 0.0009 |

| Lack-of-fit | 5 | 11.819 | 2.364 | 3.509 | 0.0973 | |

| Pure error | 5 | 3.368 | 0.674 | |||

| Residual | 10 | 15.188 | 1.519 | |||

| Total | 19 | 142.185 | ||||

| R 2 (0.8932) | ||||||

| WAI | Regression | 9 | 0.75347 | 0.08372 | 42.22915 | < 0.0001 |

| Lack-of-fit | 5 | 8.942 × 10−3 | 1.788 × 10−3 | 0.821584 | 0.5827 | |

| Pure error | 5 | 0.011 | 2.177 × 10−3 | |||

| Residual | 10 | 0.020 | 1.982 × 10−3 | |||

| Total | 19 | 0.773 | ||||

| R 2 (0.9744) | ||||||

| Hardness | Regression | 9 | 1.463 × 10+7 | 1.626 × 10+6 | 65.73326 | < 0.0001 |

| Lack-of-fit | 5 | 1.135 × 10+5 | 22703.55475 | 0.848578 | 0.5693 | |

| Pure error | 5 | 1.338 × 10+5 | 26754.83402 | |||

| Residual | 10 | 2.473 × 10+5 | 24729.19439 | |||

| Total | 19 | 1.488 × 10+7 | ||||

| R 2 (0.9834) |

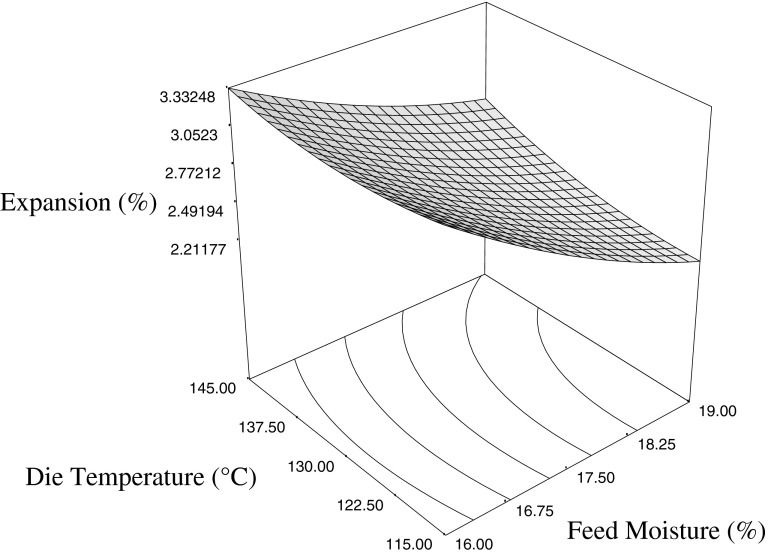

In starchy extrudates, such as expanded snacks and RTE cereals, one of the most important textural properties is the ability of material to expand at the die. From Fig. 4 it is seen that overall expansion of extrudates decreased with an increase in feed moisture content. Increase in die temperature lead to slight decrease in expansion value while screw speed had no significant effect on the extrudate expansion. Effect of screw speed on product expansion is usually complex and is temperature dependent. Decrease in expansion at higher extruder temperatures can be attributed to increase in dextrinization and weakening of structure (Altan et al. 2008). These observations are consistent with the work reported by (Singh et al. 2007; Ding et al. 2005 and Gujral et al. 2001).

Fig 4.

Expansion of extrudate as a function of feed moisture and die temperature at a screw speed of 200 rpm

Density is a major physical property of the extrudate products. Density and expansion are the indices of degree of puffing of extrudates. Low density (a desirable characteristic of expanded product) was achieved at low feed moisture (≤17.5 %) and moderate die temperature (140 °C). Increase in feed moisture as well as die temperature leads to decrease in density. Lower the bulk density and higher expansion ratio, leads to greater degree of puffing of the extrudates. Response surface figures for density are not given for the sake of simplicity.

The regression equation (Eq.4) accounts for a total of 97.44 % variation in extrudate density:

| 4 |

Analysis of variance for density of quadratic model is given in Table 5. It is seen that F-value for bulk density was significant (P < 0.001), whereas lack-of-fit was not significant (P > 0.05). A positive correlation was found between density and hardness (R = 0.834, P < 0.01) (Table 6). These results are indicating that density of product directly correlate with hardness values evident by high correlation between product density and hardness.

Water solubility index (WSI) and water absorption index (WAI)

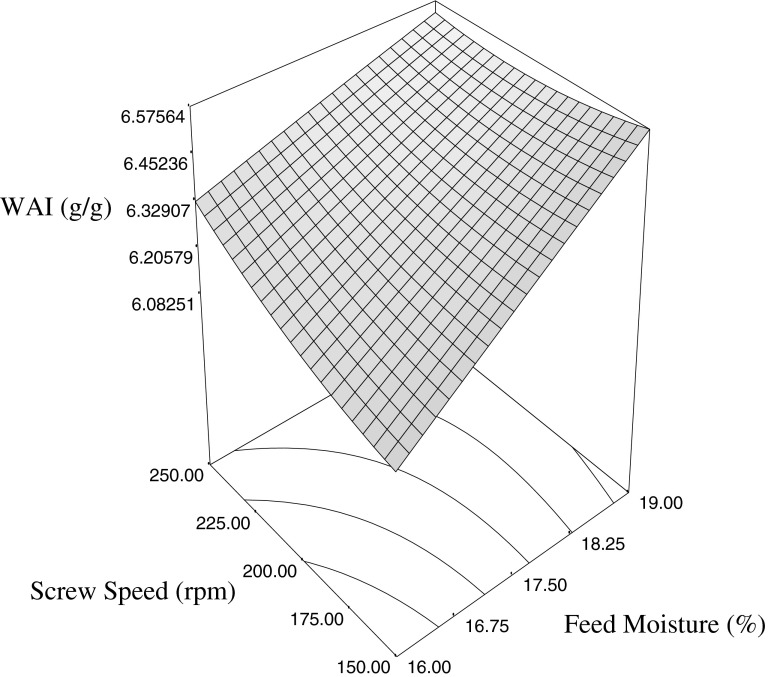

WSI is used as an indicator of degradation of molecular components. It measures the amount of soluble components released from the starch after extrusion. Feed moisture and die temperature was found to have significant effect on WSI of extrudate. Response surface figures for WSI are not given for the sake of simplicity. Increase in feed moisture was observed to result in significant decrease in WSI of extrudate. These observations are consistent with previous studies (Harper 1981). WAI measures the volume occupied by the granule or starch polymer after swelling in excess water. Effect of extrusion conditions on extrudate WAI can also be found in the 3-D surface plot (Fig. 5). Extrusion process parameters had significant effect on WAI, as increase in feed moisture and screw speed significantly increased the WAI of rice extrudate (Fig. 5). However, increase in die temperature was observed to cause a slight decrease in extrudate WAI. A decrease in WAI with increasing temperature was probably due to decomposition or degradation of starch (Altan et al. 2008). Ding et al. (2006) also stated that the WAI decreases with increasing temperature if dextrinization or starch melting prevails over the gelatinization phenomenon.

Fig 5.

WAI of extrudate as a function of feed moisture and screw speed at a die temperature of 130 °C

In actual level of variables, the regression equations (Eq.5 and 6) relating WSI and WAI with feed moisture (X1) and die temperature (X2) are represented as:

| 5 |

| 6 |

From Table 5 it is seen that regression model fitted to experimental results of WSI and WAI showed higher coefficient of determination. The coefficients of determination (R2) for water solubility and absorption indices were 0.893 and 0.974, respectively. The F-value for both was significant (P < 0.001), whereas lack-of-fit was not significant (P > 0.05). Statistical analysis revealed that WSI was negatively correlated (R = −0.729, P < 0.01), (R = −0.699, P < 0.01) with WAI and hardness respectively. A positive correlation was found between WAI and hardness (R = 0.721, P < 0.01) (Table 6). These correlation results are indicative of inverse relationship of WSI with WAI.

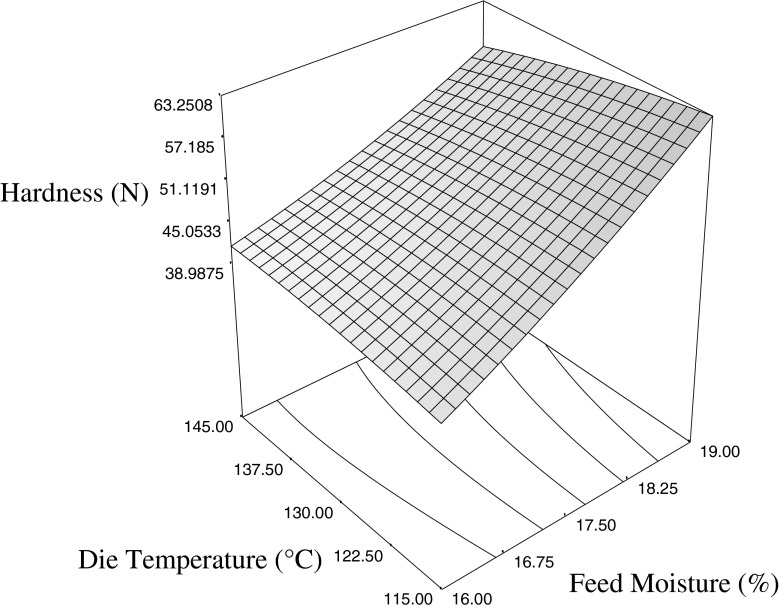

Texture

The regression equation (Eq.7) accounts for extrudate texture is given as:

| 7 |

Expanded volume of cereals and starches is generally governed by extrusion cooking parameters (Chinnaswamy and Hanna 1988). Effect of extrusion process parameters on hardness are shown in Fig. 6. ANOVA for quadratic model as fitted to experimental results of hardness showed significance (P < 0.001). The coefficient of determination (R2) for hardness was 0.983. However, model showed lack-of-fit was not significant (P > 0.05) (Table 5). Statistical analysis revealed that hardness was negatively correlated (R = −0.908, P < 0.01), (R = −0.699, P < 0.01) with expansion and WSI respectively, while it was positively correlated (R = 0.834, P < 0.01), (R = 0.721, P <0.01) with density and WAI respectively (Table 6). These results are indicating that high density product naturally offers high hardness evident by high correlation between product density and hardness. Feed moisture was found to have the most significant effect on hardness of extrudates. Increasing feed moisture content significantly increased hardness of the extrudate. Previous studies have also reported that hardness of extrudate increased as the feed moisture content increased (Badrie and Mellowes 1991; Liu et al. 2000). Extrusion process parameter such as screw speed was found to have no significant effect on extrudate hardness. Hardness of extrudates increased with increase in die temperature at low feed moisture while it decreased with increase in die temperature at higher feed moisture content (Fig. 6).

Fig 6.

Hardness of extrudate as a function of feed moisture and die temperature at a screw speed of 200 rpm

Effect of pregelatinized rice flour on expansion and hardness of extrudate

From Table 7 it is seen that use of pregelatinized rice flour prominently increased expansion of extrudates. Lowest expansion value obtained for ungelatinized rice flour sample was 3.42 %, while maximum expansion value 5.81 % was obtained for rice sample heat treated at 120 °C. That means, as the extent of gelatinization increases there is increase in expansion and near about 70 % increase in expansion was achieved due to use of pregelatinized rice flour. This may be because expansion in extrusion is governed by material (“elastic”) and moisture effects. Material effects are related to the release of pressure from the “dry” phase of the extrusion melt; moisture effects relate to the flashing of water into steam. Moisture effects are responsible for the production of evenly distributed bubbles; material effects cause a few, large and middle-sized bubbles. Our results clearly demonstrated that the expansion of extrudate increases as the extent of gelatinization increases.

Table 7.

Effect of gelatinization temperature on characteristics of rice flour extrudates

| Characteristics | Temperature of heat treatment given to rice (°C) | |||||

|---|---|---|---|---|---|---|

| Uncooked | 80 | 90 | 100 | 110 | 120 | |

| Pressure (kPa) | 38.1 | 43.8 | 44.2 | 46.5 | 48.9 | 51.2 |

| ± 1.31 | ± 0.44 | ± 0.32 | ± 0.52 | ± 0.27 | ± 0.35 | |

| Torque (Nm) | 9.33 | 10.66 | 11.99 | 13.33 | 14.66 | 15.99 |

| ±0.02 | ± 0.01 | ± 0.01 | ± 0.03 | ± 0.04 | ± 0.09 | |

| Expansion (%) | 3.42 | 4.12 | 4.67 | 4.99 | 5.22 | 5.81 |

| ± 0.02 | ± 0.03 | ± 0.03 | ± 0.07 | ± 0.08 | ± 0.02 | |

| Density (g/cm3) | 0.29 | 0.26 | 0.25 | 0.23 | 0.22 | 0.21 |

| ± 0.03 | ± 0.02 | ± 0.02 | ± 0.01 | ± 0.03 | ± 0.04 | |

| WSI (%) | 38.89 | 38.02 | 37.52 | 36.95 | 36.42 | 32.14 |

| ± 0.01 | ± 0.02 | ± 0.05 | ± 0.06 | ± 0.04 | ± 0.05 | |

| WAI (g/g) | 4.26 | 4.31 | 4.35 | 4.38 | 4.4 | 4.78 |

| ± 0.05 | ± 0.03 | ± 0.02 | ± 0.01 | ± 0.05 | ± 0.01 | |

| Hardness (N) | 41.37 | 39.82 | 39.24 | 39.01 | 38.45 | 37.90 |

| ± 0.09 | ± 0.10 | ± 0.07 | ± 0.04 | ± 0.02 | ± 0.05 | |

Expansion depends on gelatinization and dispersion of the starch in the extruder. Starch forms an even, continuous phase or “film”, that retains air cells as they expand. Several researchers have demonstrated that the expansion ratio of extruded cereals depends on the degree of starch gelatinization (Chinnaswamy and Hanna 1988). However, this is the first work reporting the extrusion of pregelatinized flour and it is observed that as the extent of gelatinization increases the expansion of the extrudates also increases (Table 7).

Texture is multidimensional, hardness and stickiness is critical, with hardness being the most important and most commonly measured parameter as a quality indicator of extruded finished product. Hardness is determined by the average force required for a probe to penetrate the extrudate. Hardness of cooked rice extrudate decreased as the extent of gelatinisation increased from 80 to 120 °C. From Table 7 it is seen that uncooked rice flour extrudate showed maximum hardness value (41.37 N). The intra-and/or intermolecular interactions of starch with other component in rice such as protein, lipid and non-starch polysaccharides results in alteration of texture (Ong and Blanshard 1995). The texture of cooked rice extrudate was usually firmer and less sticky than that of uncooked rice extrudate. The firmer texture of cooked rice extrudate was related to level of crystalline amylose-lipid complexes formed.

Conclusion

Gelatinization temperature parameters (onset, peak and endset) increased (from 55 to 90, 113 to 132 and 79 to 123 °C respectively) while degree of crystallinity decreased (from 3 to 2 %) as a result of increase in heat treatment given to rice samples ranging from 80 to 120 °C. System parameters and product responses of rice-based extrudate on twin-screw extrusion process were dependent on process variables. Feed moisture and barrel temperature had significant effect on various extrudate properties, with feed moisture having the greatest influence on the properties of the extrudate. Low density (a desirable characteristic of expanded product) was achieved at low feed moisture (≤17.5 %) and moderate die temperature (140 °C). Also, findings of this study demonstrate the feasibility of developing value added products from pregelatinized rice flour by extrusion processing. Due to use of pregelatinized rice flour the expansion of extrudate was increased and near about 70 % increase in expansion was achieved.

Acknowledgment

This work was supported by funding from University Grants Commission, India.

References

- Akdogam H, Towas RL, Oliveira JC. Rheological properties of rice starch at high moisture content during twin screw extrusion. LWT. 1997;30:488–496. doi: 10.1006/fstl.1996.0215. [DOI] [Google Scholar]

- Altan A, McCarthy KL, Maskan M. Evaluation of snack foods from barley-tomato pomace blends by extrusion processing. J Food Eng. 2008;84:231–242. doi: 10.1016/j.jfoodeng.2007.05.014. [DOI] [Google Scholar]

- Alvarez-Martinez L, Kondury KP, Karper JM. A general model for expansion of extruded products. J Food Sci. 1988;53:609–615. doi: 10.1111/j.1365-2621.1988.tb07768.x. [DOI] [Google Scholar]

- Badrie N, Mellowes WA. Texture and microstructure of cassava flour extrudate. J Food Sci. 1991;56:1319–1322. doi: 10.1111/j.1365-2621.1991.tb04762.x. [DOI] [Google Scholar]

- Bhattacharya S. Twin-screw extrusion of rice-green gram blend: extrusion and extrudate characteristics. J Food Eng. 1997;32:83–99. doi: 10.1016/S0260-8774(97)00004-6. [DOI] [Google Scholar]

- Chauhan GS, Sharma P, Bains GS. Effect of extrusion cooking on X-ray diffraction characteristics of rice and rice-legume blends. Int J Food Prop. 2003;6(1):127–133. doi: 10.1081/JFP-120016629. [DOI] [Google Scholar]

- Cheetam NWH, Tao L. Variation in crystalline type with amylose content in maize starch granules: an X-ray powder diffraction study. Carbohydr Polym. 1998;36(4):277–284. doi: 10.1016/S0144-8617(98)00007-1. [DOI] [Google Scholar]

- Chinnaswamy R, Hanna MA. Relationship between amylase content and extrusion-expansion properties of corn starches. Cereal Chemistry. 1988;65:138–143. [Google Scholar]

- Desrumaux A, Bouvier JM, Burri J. Effect of free fatty acids addition on corn grits extrusion cooking. Cereal Chemistry. 1999;76:699–704. doi: 10.1094/CCHEM.1999.76.5.699. [DOI] [Google Scholar]

- Ding QB, Ainsworth P, Tucker G, Marson H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-expanded snacks. J Food Eng. 2005;66:283–289. doi: 10.1016/j.jfoodeng.2004.03.019. [DOI] [Google Scholar]

- Ding QB, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;73:142–148. doi: 10.1016/j.jfoodeng.2005.01.013. [DOI] [Google Scholar]

- Gonzalez RJ, Torres RL, De Greef DM, Guadalupe BA. Effect of extrusion conditions and structural characteristics on melt viscosity of starchy materials. J Food Eng. 2006;74(1):96–107. doi: 10.1016/j.jfoodeng.2005.02.007. [DOI] [Google Scholar]

- Govindasamy S, Campanella OH, Oates CG. Enzymatic hydrolysis of sago starch in a twin-screw extruder. J Food Eng. 1997;32:403–426. doi: 10.1016/S0260-8774(97)00017-4. [DOI] [Google Scholar]

- Gujral H, Singh N, Singh B. Extrusion behaviour of grits from flint and sweet corn. Food Chem. 2001;74:303–308. doi: 10.1016/S0308-8146(01)00156-X. [DOI] [Google Scholar]

- Harper JM. Extrusion of starches and starches materials. In: Harper JM, editor. Extrusion of food. 2. Boca Raton: CRC Press; 1981. pp. 41–60. [Google Scholar]

- Islam MD, Shimizu N, Kimura T. Effect of processing conditions on thermal properties of parboiled rice. Food Sci and Technol Res. 2002;8(6):131. doi: 10.3136/fstr.8.131. [DOI] [Google Scholar]

- Kadan RS, Pepperman AB. Physicochemical properties of starch in extruded rice flours. Cereal Chem. 2002;79(4):476–480. doi: 10.1094/CCHEM.2002.79.4.476. [DOI] [Google Scholar]

- Lamberts L, De Bie E, Derycke V, Veraverbeke WS, DeMan W, Delcour JA. Effect of processing conditions on color change of brown and milled parboiled rice. Cereal Chem. 2006;83:80–85. doi: 10.1094/CC-83-0080. [DOI] [Google Scholar]

- Liu Y, Hsieh F, Heymann H, Huff HE. Effect of process conditions on the physical and sensory properties of extruded oat–corn puff. J Food Sci. 2000;65:1253–1259. doi: 10.1111/j.1365-2621.2000.tb10274.x. [DOI] [Google Scholar]

- Manful JT, Grimm CC, Gayin J, Coker RD. Effect of variable parboiling on crystallinity of rice samples. Cereal Chem. 2008;85(5):92. doi: 10.1094/CCHEM-85-1-0092. [DOI] [Google Scholar]

- Marshall WE, Wadsworth JI, Verma LR, Velupillai L. Determining the degree of gelatinization in parboiled rice: comparison of a subjective and objective method. Cereal Chem. 1993;70:226–300. [Google Scholar]

- Ong MH, Blanshard JMV. Texture determinants of cooked, parboiled rice. Physicochem prop and leaching behav of rice J of Cereal Sci. 1995;21(3):261–269. [Google Scholar]

- Perez AA, Drago SR, Carrara CR, De Greef DM, Torres RL, Gonzalez RJ. Extrusion cooking of maize/soybean mixture: factors affecting expanded product characteristics and flour dispersion viscosity. J Food Eng. 2008;87(3):333–340. doi: 10.1016/j.jfoodeng.2007.12.008. [DOI] [Google Scholar]

- Saccheti G, Pinnavaia GG, Guidolin E, DallaRosa M. Effects of extrusion temperature and feed composition on the functional, physical and sensory properties of chestnut and rice flour-based snack-like products. Food Res Int. 2004;37:527–534. doi: 10.1016/j.foodres.2003.11.009. [DOI] [Google Scholar]

- Singh N, Smith AC. A comparison of wheat starch, whole-wheat meal and oat flour in the extrusion process. J of Food Eng. 1997;34:15–32. doi: 10.1016/S0260-8774(97)00069-1. [DOI] [Google Scholar]

- Singh B, Sekhon KS, Singh N. Effect of moisture, temperature and level of pea grits on extrusion behaviour and product characteristics of rice. Food Chem. 2007;100:198–202. doi: 10.1016/j.foodchem.2005.09.042. [DOI] [Google Scholar]