Abstract

Designed experiments were conducted to study the rheological properties of baking dough prepared from different refined wheat flour (RWF) – barnyard millet blends with varying amount of water (WA), salt and sugar. Dough was subjected to thermo-mechanical stress in Mixolab, in which rheological properties were recorded in terms of five different torques. Second order polynomial models were developed using response surface methodology (RSM) to understand the effect of input variables (WA, barnyard millet, salt and sugar; all expressed as per cent of base flour) on torques recorded by Mixolab. Optimum values of input variables were obtained with constraints based on torque values which represented the qualities of acceptable bread dough. The models predicted that a dough with 57, 26, 1.8 and 3.3% of water, barnyard millet, salt and sugar, respectively, can be used for bread baking purposes.

Keywords: Millet, Baking, Rheology, Optimization

Introduction

Refined wheat flour (RWF) has a peculiar property of forming into extensible viscous dough upon kneading with water. This property is because of the wheat protein called gluten. The gas produced during the fermentation process is arrested by a network of gluten, giving structure to bread (Brites et al. 2010). Rapid urbanization has been indexed with a rise in consumption of leavened bread in India. A seismic shift from popular unleavened bread (chapatti or roti) to leavened bread is taking place in the Indian subcontinent. The RWF which is used to make this popular leavend bread has carbohydrates with high glycemic index and is also very less in essential nutrients. The style of life coupled with increased consumption of RWF based products has ordained India as the diabetic and cardiovascular diseases (CVD) capital of the world (Deedwania 2013). Contemporary researchers are attempting a plethora of ingredients to bolster the nutritional value of bread flour (Sanchez et al. 2002; Gallagher et al. 2004; Lopez et al. 2004; Moore et al. 2006).

In India millets are cultivated in about 1.3 million hectares (0.7 % of the total cropped area) of vast stretches of dry land and hilly area by small and marginal farmers (IASRI 2006). Nutritionally, millets are not only comparable but are superior to cereals in many aspects and are commonly referred as nutricereals. Apart from being source of nutraceuticals, micronutrients, phytochemicals; millets are very good source of dietary fibre. Clinical studies conducted on humans (Anderson and Tietyen-Clark 1986) and on animals (Ranhotra et al. 1987) have exhibited that consumption of total dietary fibre (TDF) and soluble dietary fibre (SDF) has led to a decrease in the blood cholesterol levels of the subjects.

Incorporation of dietary fibres in food systems has been often been associated with a negative effect upon the functional properties of the food (Brennan and Samyue 2004). It is therefore pertinent that a thorough prior study of the role of the ingredients of the food system, their synergistic and antagonistic properties upon the incidence of processing conditions has to be studied for ending up with an acceptable finished product. Apart from base flour, in the present research work a blend of RWF and millet, the ingredients like, − salt and sugar also have a substantial role in deciding characteristics of the finished product. Neutral salts like, sodium chloride are added to dough system for its positive effect on the dough development process (Preston 1989). Dietary salt intake has been identified as the main cause of elevated blood pressure leading to CVDs (World Health Organisation 2003; He and MacGregor 2007). Sugar, apart from acting as feed for the yeast, flavour and colour; sugar increases the glycemic index of the bread. Nutritional experts all over the world are advocating restrained use of sugar in diets to prevent diabetes and its associated disorders. Therefore, minimizing amount of salt and sugar without affecting the characteristics of bread is worth some exercise.

Mixolab is a rheological instrument that can be used to mimic the mechanical work as well as the heat conditions that expectantly occur during baking process, to understand physicochemical behaviour of dough (Rosell et al. 2007). Dough is prepared in this instrument by a rotating kneading arm; the torque generated during different stages of dough formations is recorded. These five real time torques (C1 - C5 Nm) are helpful in characterizing the dough on the basis of its suitability for various bakery products. Water absorption (WA) during mixing is a critical factor for generating the right torque during the Mixolab operation; it varies from flour to flour. WA should be such that maximum torque during mixing of dough ingredients should be 1.1 Nm.

The multiple regression approach of response-surface methodology (RSM) can be effectively used to demonstrate relationship between input variables and responses. This has been exhibited while playing with the ingredients of composite flours for bakery products by several researchers (McCarthy et al. 2005; Mezaize et al. 2009; Sabanis et al. 2009; Chakraborty et al. 2010; Demirkesen et al. 2011).

The present research work was conceived with the idea of obtaining fibre based dough, with optimal baking qualities based on Mixolab results, prepared from an optimized combination of input variables in terms of amount of water (WA) required to form dough, fibre in the form of millets, salt and sugar. The synergistic and antagonistic effects of input variables were understood by mathematical modeling using a proven multivariable analytical tool, RSM.

Materials and method

Materials

RWF of 60 % extraction and dehusked barnyard millet (Echinochloa frumantacea L.) was purchased from local market of Jhansi city of India. Dehusked millet was cleaned of all the foreign material before being ground in an attrition mill to millet flour in under flow of 140 mesh I.S. sieve. Moisture content (MC) of RWF-millet flour blends were determined by AACC 44–51 (AACC 2000) method. Determination of MC was important for it helped in deciding the amount of water that is to be added during dough formation in the Mixolab. A key input variable, WA was dependent on MC of base flour. The salt (NaCl) and sugar (sucrose) were locally available.

Experimental plan

Central composite rotatable design (CCRD) of RSM was used to design the experiments for the present research work. Dough formation is dependent on many factors, the scope of the present study was restricted to understand the effects of five levels of water absorption (%), barnyard millet fraction (%, of base flour), salt (%, of base flour) and sugar (%, of base flour). The levels of the processing parameters are reported in Table 1. Negation of effects of units and range of parameters in the experimental domain is neutralised in RSM by coding the variables (Bas and Boyaci 2007). The codes for the processing parameters,- water absorption (X1), barnyard millet (X2), salt (X3) and sugar (X4) were obtained by using the following equations:

| 1 |

| 2 |

| 3 |

| 4 |

Table 1.

Levels of input variables and experimental plan

| Uncoded values processing parameters | Coded values | |||

|---|---|---|---|---|

| WA, % | Millet, % | Salt, % | Sugar, % | |

| 55 | 10 | 1.6 | 2.8 | −1.68 |

| 56 | 14 | 1.8 | 3 | −1 |

| 57 | 20 | 2 | 3.2 | 0 |

| 58 | 26 | 2.2 | 3.4 | +1 |

| 59 | 30 | 2.4 | 3.6 | +1.68 |

| Coded processing parameters | ||||

| X 1 | X 2 | X 3 | X 4 | Number of experiments |

| 0 | 0 | 0 | 0 | 5 |

| ± 1.68 | 0 | 0 | 0 | 2 |

| 0 | ± 1.68 | 0 | 0 | 2 |

| 0 | 0 | ± 1.68 | 0 | 2 |

| 0 | 0 | 0 | ± 1.68 | 2 |

| −1 | −1 | ± 1 | −1 | 2 |

| +1 | +1 | ± 1 | −1 | 2 |

| +1 | −1 | ± 1 | +1 | 2 |

| −1 | +1 | ± 1 | +1 | 2 |

| Total number of experiments | 21 | |||

WA, Water absorption, −1 and +1 are factorial points, 0 is centre point, ± 1.68 are augmented points in the design area. X 1: Water absorption, %; X 2: Millet, %; X 3: Salt, %; X 4: Sugar, %

There were five levels of the processing parameters, two primary or factorial levels (−1 and + 1), one centre point (0), and two augmented points (−am and + am).

| 5 |

Dough characteristics

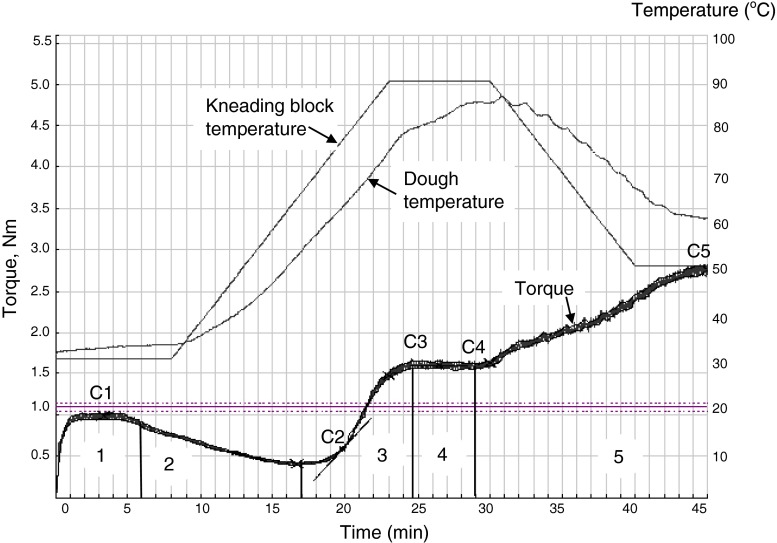

The dough in the present research work comprised five different blends of RWF and millet with varying amount of salt and sugar as per the experimental plan (Table 1). Pasting and mixing behaviour of dough was interpreted with the help of an instrument called, Mixolab (Chopin, Tripette et Renaud, Paris, France). The physico-chemical behaviour of dough was recorded by Mixolab in terms of real time torques (Nm) experienced by the kneading arms moving through dough. The dough was formed under controlled block temperature ranging up to 90 °C. Hydration of flour components during dough formation in Mixolab is a very critical step. The weight of the flour in every run was 50 g. Water absorption (WA, %) or amount of water added to flour should be such that C1 torque is 1.1 Nm. C1 is the maximum torque recorded during mixing, and C1 = 1.1 Nm reflects complete hydration of flour components, generally, leading to formation of an acceptable dough. The weight of this dough will be 75 g. A typical Mixolab curve can be seen in Fig. 1. In mixing section (1); the temperature is almost constant while mixing takes place. Section - 2 represents dough kneading process, dough is subjected to a great deal of thermo – mechanical stress resulting in thermal weakening of the protein, measured as C2 torque. Hydration and elevated temperature conditions in kneading chamber results in gelatinization of starch, extent of which is measured as C3 torque. The gelatinization process of the starch present in dough is represented by section - 3. Temperature of kneading block at this instant is at 90 °C, and it stays at this until C4 is recorded. Temperature remains constant through Section 4; it exhibits appreciable decrease in apparent viscosity due to enzymatic activity. The stability of starch gel is represented by torque C4. This gel now starts to cool, till temperature of kneading block reaches to about 50 °C. Starch retrogradation follows cooling and is marked by an increase in apparent viscosity; extent of retrogradation is gauged by C5 torque. There were some adopted fixed settings in the Mixolab, which were maintained as-it-is throughout experimentation (Table 2).

Figure 1.

A typical Mixolab curve

Table 2.

Fixed settings of mixolab

| Parameter | Value |

|---|---|

| Mixing rate (rpm) | 80 |

| Dough weight (g) | 75 |

| Tank temperature (°C) | 30 |

| Temperature of the first plateau (°C) | 30 |

| Duration of the first plateau (min) | 8 |

| Temperature of the second plateau (°C) | 90 |

| First temperature gradient (°C/min) | 4 |

| Duration of the second plateau (min) | 7 |

| Second temperature gradient (°C/min) | 4 |

| Temperature of the third plateau (°C) | 50 |

| Duration of the third plateau (min) | 5 |

| Total analysis time (min) | 45 |

Data analysis

The experimental data comprised responses in terms of five different torques of Mixolab from CCRD based twenty one experiments (Table 1). Five of the experiments were at centre point values of the processing parameters. The responses, viz. C1, C2, C3, C4 and C5 were fit into a second order polynomial equation (6).

| 6 |

Where, k is response, n is number of variables, X’s are the variables, βo, βi, βii and βij are the regression coefficients.

The statistical fitness of models was judged by lack-of-fit (by F-value), coefficient of determination (R2) and coefficient of variation (c.v.), while coefficients of the model terms were indicative of linear and interactive effect of input variables on responses. A model is said to be adequate in describing the response if the lack-of-fit is insignificant and R2 value for a model is more than 80 %. Coefficient of variation (c.v.) is a measure of estimating reproducibility of experiments and it indicates relative dispersion of experimental points from model predicted values. It is desirable for a model to have a c.v. of less than 10 %.

The optimum values of processing parameters were obtained by numerical optimization using RSM of Design Expert and version 8.0.7.1, (2013) software.

Results and discussion

The experimental data obtained was fitted into second order polynomial model (Eq. 6). Statistical veracity of models was understood by regression analysis and ANOVA (Table 3). All models are significant as revealed by F-values, and were found to have a R2 > 0.95, c. v. <10 % and insignificant lack-of-fit. Thus, further model analysis was carried out to understand effect of input variables on responses.

Table 3.

ANOVA for the second order polynomial models for the various responses

| Predictor | Regression coefficients for models of the responses | ||||

|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C5 | |

| Intercept | 1.2238*** | 0.4899*** | 0.9809*** | 1.9939*** | 3.3240*** |

| X 1 | −0.1368*** | −0.0386*** | 0.0357 | −0.0565 | −0.2259** |

| X 2 | −0.0654*** | 0.0059 | −0.0357 | −0.5738*** | −0.2497** |

| X 3 | −0.0505*** | −0.0147** | −0.0224 | −0.0972* | 0.0522 |

| X 4 | −0.2170*** | −0.1041*** | 0.1278*** | −0.2943*** | −0.4846*** |

| X 1 X 2 | −0.3108*** | −0.1341*** | 0.0853** | −0.5306*** | −0.4896*** |

| X 1 X 3 | −0.0863*** | −0.0225** | 0.0100 | −0.2013** | 0.0250 |

| X 1 X 4 | 0.0733** | 0.0609*** | −0.0407 | −0.3100** | −0.1172 |

| X 2 X 3 | −0.1088*** | −0.0350*** | 0.0850*** | −0.2313*** | 0.0325 |

| X 2 X 4 | 0.0445* | 0.0439*** | −0.0393 | 0.2273** | −0.1309 |

| X 3 X 4 | 0.0888*** | 0.0300*** | −0.1475*** | 0.2188** | −0.0200 |

| X 1 2 | 0.0226* | −0.0012 | −0.0006 | 0.1530** | 0.1212** |

| X 2 2 | 0.0367** | 0.0430*** | −0.0076 | −0.1900*** | 0.1071** |

| X 3 2 | −0.0428*** | −0.0171** | −0.0200 | 0.1070** | 0.1212** |

| X 4 2 | −0.1277*** | −0.0613*** | 0.0861*** | −0.0415 | −0.1104** |

| ANOVA | |||||

| Model F-value | 68.5*** | 50.1*** | 13.8*** | 16.4*** | 8.4*** |

| Coefficient of determination (R2), % | 99.4 | 99.2 | 97.0 | 97.4 | 95.2 |

| Coefficient of variation (c.v.), % | 3.37 | 4.23 | 5.12 | 8.33 | 4.60 |

| Lack of fit | n.s. | n.s. | n.s. | n.s. | n.s. |

* significant at p < 0.1, ** significant at p < 0.05, *** significant at p < 0.01, n.s. - not significant X 1: Water absorption, %; X 2: Millet, %; X 3: Salt, %; X 4: Sugar, %

Individual effect of variables

WA had significant negative relation at p < 0.01 with C1 and C2 and at p < 0.05 with C5. If WA is increased, availability of water to the dough ingredients also increases, resulting in decrease in torque (C1) and increase in dough development time. Increase in millet per cent in base flour led to a significant decrease in C1, C4 and C5 at p < 0.01 and at p < 0.05, respectively. Low gluten content of millet results in poor dough forming capabilities; this was reflected by a decrease of C1 with an increase in millet in base flour. Inverse relation of millet per cent in base flour and C4 represents weakness of dough, which shall result in a decreased gas retention power during fermentation. Salt, was observed to have significant negative effect on C1, C2, and C4 at p < 0.01, p < 0.05 and p < 0.1, respectively. Similar observations are also reported in Mixolab Application Handbook (2006). Thermal weakening of the proteins (decrease in C2) and amylase activity (decrease in C4) is slowed down with an increase in salt content in dough, leading to slowing of gelatinization process.

All five torques were highly sensitive to changes in sugar content of dough. Significant (p < 0.01) negative correlation of sugar content was observed with C1, C2, C4 and C5, positive with C3. The reduction in C1 can be accounted to increased hydration because of increased amount of sugar. Negative relation with C5 indicates that retrogradation is decreased with an increase in sugar content, an indication that shelf life of the product made from this dough will be better.

Interactive effect of variables

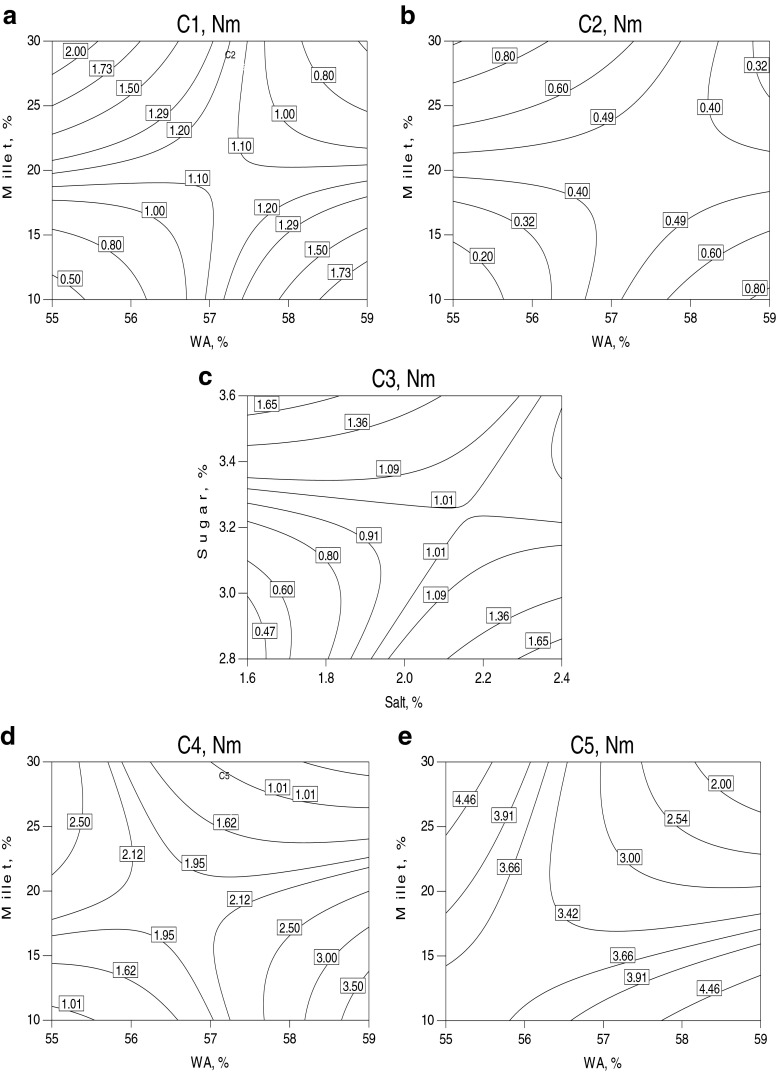

It can be evinced from Table 3 that responses were affected quite significantly by interactive effects of input variables. Discussed in the following literature are those cases where absolute value of regression coefficient is significantly high for a particular response. The interactive effects of WA and millet content of base flour were most prominent in significantly (p < 0.01) affecting the torques (C1, C2, C4 and C5), effect of salt-sugar combination was most pronounced for C4. It is desirable to have C1 = 1.1 Nm for dough to have acceptable quality in later stages of operation. This value of C1 can be achieved at centre point values of WA and millet (Fig. 2a). There is an increase in C2 values at high millet content – low WA (Fig. 2b). Protein content of millet is less than RWF. Base flour with more barnyard millet will have overall low protein content, therefore less protein weakening, more torque (C2). Non gluten flours have been reported to increase C2 (Moreira et al. 2011). High value of either salt or sugar results in an increased C3 (Fig. 2c). Salt delays gelatinization and it strengths gluten network (Lynch et al. 2009) resulting in an increased C3.

Figure 2.

Contour plots of the responses representing the interactive effect of input variables

As the amount of millet in base flour increases the amylatic activity is decreased, hence viscosity of the dough increases, so C4 is high at high millet content (Fig. 2d). However, even at high millet content, an increase in WA decreases viscosity of dough to the extent that C4 is reduced. Moreover, high amount of millet lower overall protein and lipid content of dough, thus increasing peak viscosity (Debet and Gidley 2006; Nelles et al. 2000.

The torque C5 indicates about the starch retrogradation (Haros et al. 2006; Collar et al. 2007; Rosell et al. 2007; Kahraman et al. 2008). Starch retrogradation is minimum at high millet and WA levels (Fig. 2e). This is possibly because of the lesser number of dextrin that could form after hydrolysis of starch because of lesser amount of RWF in dough.

Optimization and validation

The various torques that were measured during dough formation in Mixolab has direct correlation with quality of bread to be ultimately made from it. The input variables varied over a range in combination, resulting in varying torques. While it was desirable for some torques to increase, it was otherwise for some. Numerical optimization of models was generated by Design Expert 8.0.7.1 software to obtain right mix of input variables for desirable torques. During optimization suitable constraints were applied to responses (Table 4) for obtaining optimum values of input variables. Experiments were again conducted under optimum conditions. The efficacy of model was verified by comparing the results of model predicted responses and responses obtained after experimentation. A two-tailed t-test carried out to ascertain the difference in predicted values and experimental values (Table 5) showed that there was non-significant (p < 0.01) difference between the two.

Table 4.

Range and optimum conditions of input variables and responses (uncoded)

| Variables | Constraint | Range | Optimum values | |

|---|---|---|---|---|

| Lower | Upper | |||

| Input variables (%) | ||||

| WA | in range | 55 | 59 | 57 |

| Millet | maximize | 10 | 30 | 26 |

| Salt | in range | 1.6 | 2.4 | 1.8 |

| Sugar | in range | 2.8 | 3.6 | 3.3 |

| Responses (Nm) | ||||

| C1 | target = 1.10 | 0.36 | 1.53 | 1.10 |

| C2 | in range | 0.15 | 0.63 | 0.49 |

| C3 | in range | 0.82 | 1.42 | 0.98 |

| C4 | in range | 0.44 | 2.47 | 1.41 |

| C5 | minimize | 2.12 | 3.97 | 2.76 |

Table 5.

Verification of model predicted and actual responses at optimum conditions

| Torques (Nm) | Predicted values (μo) | Actual valuea (μ1) ± SD | Standard error | % Variation | Mean difference | tcal (2 -tailed) |

|---|---|---|---|---|---|---|

| C1 | 1.10 | 1.16 ± 0.192 | 0.0859 | 5.172 | 0.06 | 0.6969 |

| C2 | 0.49 | 0.534 ± 0.079 | 0.0353 | 8.240 | 0.044 | 1.2420 |

| C3 | 0.98 | 1.02 ± 0.135 | 0.0604 | 3.922 | 0.04 | 0.6607 |

| C4 | 1.41 | 1.368 ± 0.108 | 0.0483 | 3.070 | 0.042 | 0.8672 |

| C5 | 2.76 | 2.828 ± 0.155 | 0.0693 | 2.405 | 0.068 | 0.9783 |

Ho: μo = μ1, H1: μo ≠ μ1, tcal < ttable at p < 0.01, ‘Ho’ is not rejected, a mean of five replications

Conclusions

Rheological properties of dough for bakery products made from blend of RWF and millet can be studied by using Mixolab. The behaviour of the dough during the Mixolab operation can be modelled using RSM. The various torques representative of the dough behaviour reflected that an optimum mix of RWF-millet can be obtained for baking purposes. A WA value for RWF-millet blend could be obtained to produce a mixing torque, C1 = 1.1 N. Mixolab torques (C2, C4 and C5) produced during experiments were well within the range acceptable for bread manufacture. The behaviour of dough has reflected characteristics similar to durum-wheat-containing-damaged-starch, signifying the departure of starch quality of millet with respect to the starch of RWF. Furthermore, key ingredients of baking, − sugar and salt, exhibited significant relationship with dough characteristics. Optimization of the input variables revealed that acceptable dough for bread will have water, millet, salt and sugar in the ratio of 57, 26, 1.8, and 3.3 as per cent of the base flour.

References

- AACC (2000) Approved Methods of Analyses, Method 44–40.01. Moisture-Modified vacuum oven method. In: Approved methods of the American Association of Cereal Chemists, 10th edn. Minneapolis, MN

- Anderson JW, Tietyen-Clark J. Dietary fibre: hyperlipidemia, hypertension, and coronary heart disease. Am J of Gastroenterol. 1986;81:907–19. [PubMed] [Google Scholar]

- Bas D, Boyaci IH. Modeling and optimization i: usability of response surface methodology. J Food Eng. 2007;78:836–845. doi: 10.1016/j.jfoodeng.2005.11.024. [DOI] [Google Scholar]

- Brennan CS, Samyue E. Evaluation of starch degradation and textural characteristics of dietary fiber enriched biscuits. Int J of Food Prop. 2004;7:647–657. doi: 10.1081/JFP-200033070. [DOI] [Google Scholar]

- Brites C, Trigo MJ, Santos C, Collar C, Rosell CM. Maize-based gluten-free bread: influence of processing parameters on sensory and instrumental quality. J Food Bioprocess Technol. 2010;3:707–715. doi: 10.1007/s11947-008-0108-4. [DOI] [Google Scholar]

- Chakraborty SK, Singh DS, Kumbhar BK, Chakraborty S. Influence of processing parameters on textural characteristics and overall acceptability of millet enriched biscuits using response surface methodology (RSM) J Food Sci Technol. 2010;48:167–174. doi: 10.1007/s13197-010-0164-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Debet MR, Gidley MJ. Three classes of starch granule swelling: influence of surface proteins and lipids. Carbohydr Polym. 2006;64:452–465. doi: 10.1016/j.carbpol.2005.12.011. [DOI] [Google Scholar]

- Deedwania P. Diabetes, cardiovascular disease and ethnicity. J Am Coll Cardiol. 2013;61:1787–1789. doi: 10.1016/j.jacc.2013.01.059. [DOI] [PubMed] [Google Scholar]

- Demirkesen I, Sumnu G, Sahin S, Uysal N. Optimization of formulations and infra red- microwave combination baking conditions of chestnut-rice breads. Int J Food Sci Technol. 2011;46:1809–1815. doi: 10.1111/j.1365-2621.2011.02682.x. [DOI] [Google Scholar]

- Design Expert version 8.0.7.1 (2013) Stat-Ease, Inc., MN, USA

- Gallagher E, Gormley TR, Arendt EK. Recent advances in the formulation of gluten-free cereal-based products. Trends Food Sci Technol. 2004;15:143–152. doi: 10.1016/j.tifs.2003.09.012. [DOI] [Google Scholar]

- Haros M, Ferrer A, Rosell CM (2006) Rheological behaviour of whole wheat flour. In: Proceedings of Thirteenth IUFoST World Congress of Food Science & Technology. Nantes, pp 1139–1148

- He FJ, Macgregor GA. Dietary salt, high blood pressure and other harmful effects on health. In: Kilcast D, Angus F, editors. Reducing salt in foods. Cambridge: Woodhead Publishing; 2007. pp. 18–46. [Google Scholar]

- IASRI . Cropping pattern according to land utilization. In: Ali N, Sharma SD, editors. Agriculture research data book. New Delhi: Indian Agriculture Statistical Research Institute; 2006. [Google Scholar]

- Kahraman K, Sakyyan O, Ozturk S, Koksel H, Sumnu G, Dubat A. Utilization of mixolab to predict the suitability of flours in terms of cake quality. Eur Food Res Technol. 2008;227:565–570. doi: 10.1007/s00217-007-0757-y. [DOI] [Google Scholar]

- Lopez ACB, Pereira AJG, Junqueira RG. Flour mixture of rice flour, corn and cassava starch in the production of gluten-free white bread. Braz Arch Biol Techn. 2004;47:63–70. doi: 10.1590/S1516-89132004000100009. [DOI] [Google Scholar]

- Lynch EJ, Dal Bello F, Sheehan EM, Cashman KD, Arendt EK. Fundamental studies on the reduction of salt on dough and bread characteristics. Food Res Int. 2009;42:885–891. doi: 10.1016/j.foodres.2009.03.014. [DOI] [Google Scholar]

- McCarthy DF, Gallagher E, Gormle TR, Schober TJ, Arendt EK. Application of response surface methodology in the development of gluten-free bread. Cereal Chem. 2005;82:609–615. doi: 10.1094/CC-82-0609. [DOI] [Google Scholar]

- Mezaize S, Chevallier S, Le Bail A, De Lamballerie M. Optimization of gluten-free formulations for french-style breads. J Food Sci. 2009;74:140–146. doi: 10.1111/j.1750-3841.2009.01096.x. [DOI] [PubMed] [Google Scholar]

- Mixolab Applications Handbook . Rheological and Enzymatic Analysis. France: Villeneuve La Garenne; 2006. [Google Scholar]

- Moore MM, Heinbockel M, Dockery P, Ulmer HM, Arendt EK. Network formation in gluten-free bread with application of transglutaminase. Cereal Chem. 2006;83:28–36. doi: 10.1094/CC-83-0028. [DOI] [Google Scholar]

- Moreira R, Chenlo F, Torres MD. Rheological properties of commercial chestnut flour doughs with different gums. Int J Food Sci Technol. 2011;46:2085–2095. doi: 10.1111/j.1365-2621.2011.02720.x. [DOI] [Google Scholar]

- Nelles EM, Dewar J, Bason ML, Taylor JRN. Maize starch biphasic pasting curves. J Cereal Sci. 2000;31:287–294. doi: 10.1006/jcrs.2000.0311. [DOI] [Google Scholar]

- Preston KR. Effects of neutral salts of the lyotropic series on the physical dough properties of a Canadian red spring wheat flour. Cereal Chem. 1989;66:144–148. [Google Scholar]

- Ranhotra G, Gelroth J, Bright P. Effect of source of fibre in bread-based diets on blood and liver lipids in rats. J Food Sci. 1987;52:1420–1422. doi: 10.1111/j.1365-2621.1987.tb14097.x. [DOI] [Google Scholar]

- Rosell CM, Collar C, Haros M. Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the mixolab. Food Hydrocoll. 2007;21:452–462. doi: 10.1016/j.foodhyd.2006.05.004. [DOI] [Google Scholar]

- Sabanis D, Lebesi D, Tzia C. Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT-Food Sci Technol. 2009;42:1380–1389. doi: 10.1016/j.lwt.2009.03.010. [DOI] [Google Scholar]

- Sanchez HD, Osella CA, De La Torre MA. Optimization of gluten-free bread prepared from cornstarch, rice flour, and cassava starch. J Food Sci. 2002;67:416–419. doi: 10.1111/j.1365-2621.2002.tb11420.x. [DOI] [Google Scholar]

- World Health Organisation (2003) WHO technical report series. Diet, nutrition and the prevention of chronic disease. Report of a joint WHO-FAO expert consultation. pp 916 [PubMed]