Abstract

Background

The aim of this study was to evaluate the effectiveness of individual-focused stress management training namely Deep Breathing Exercise (DBE) on self-perceived occupational stress among male automotive assembly-line workers.

Methods

A quasi-experimental study was conducted at 2 automotive assembly plants in Malaysia over 9 months, from January 2012 to September 2012. Assembly-line workers from Plant A received DBE training while Plant B acted as a control by receiving pamphlets on stress and its ill-effects. Intention-to-treat analysis was conducted among the self-voluntary respondents in Plant A (n=468) and Plant B (n=293). The level of stress was measured using Depression Anxiety Stress Scales-21 (DASS-21) stress subscale.

Results

Significant favorable intervention effects were found in Plant A (Effect size=0.6) as compared to Plant B (Effect size=0.2) at the end of the study in those receiving DBE. Time and group interaction effects were examined using the repeated measure ANOVA test in which there was a significant group *time interaction effect [F (1, 1) = 272.45, P<0.001].

Conclusion

The improvement in stress levels showed the potential of DBE training as part of Employee Assistance Program in the automotive assembly plant. Future studies should be carried out to assess the long term effects of an on-site relaxation training to provide stronger evidence for the introduction of DBE among assembly-line workers as a coping strategy to alleviate occupational stress.

Keywords: Occupational stress, Deep breathing, Automotive assembly line, Employee assistance

Introduction

Stress is a physiological reaction to undesired emotional or physical situations. A stressor is defined as any “demand made by the internal or external environment that upsets a person's balance and for which restoration is needed” (1). They affect organizational performance by reducing productivity and efficiency (2-4).

Although the development of stress management programs at workplaces is still rather limited (5), the number of studies on worksite stress intervention has been gradually increasing and evidence for its effectiveness has been accumulating (6). Stress management interventions under Employee Assistance Program (EAP) can be minimized through relaxation training programs like DBE.

DBE or diaphragmatic breathing is known to counteract the fight or flight response symptoms that are often associated with stress exposure (7). It is the act of breathing deeply into the lungs by flexing the diaphragm rather than the rib cage. DBE has been successfully used in the management of acute stressful tasks (8) showing significant improvement in the body's hemodynamic changes.

Over the last decade, automotive assembly line workers in specific are one of several occupational groups who report disproportionately high levels of occupational stress (9, 10). Studies have shown that the industry dictates a high job demand and low job control (9, 11-13). Heavy workload, infrequent rest breaks, long working hours and shift work; hectic and routine tasks that have little inherent meaning, do not utilize workers' skills, and provide little sense of control (14). The automotive sector is a key industry in the Malaysian economy. Establishment of PROTON in 1985 and PERODUA in 1993 acted as catalysts to the development of the automotive sector which heralded a new phase for the Malaysian automotive sector. Given the significant challenges facing the automotive industry, occupational stress becomes a pertinent psychosocial issue affecting the assembly line workers.

Hence in this study, we will show the effectiveness of a DBE for coping with stress in the automotive assembly line. This will be the first in-depth study on a single component, individual focused stress management training as part of an EAP in an automotive assembly plant.

Materials and Methods

Study design

A quasi-experimental study was conducted in two automotive assembly plants in a district in Malaysia over a period of 9 months, from January 2012 to September 2012. The study population was automotive assembly line workers directly attached to the Body shop, Paint shop and Assembly section of the plant. Plant A was selected as the DBE group and Plant B the pamphlet group.

Inclusion criteria were all male workers directly attached to the production line and who had been working at the site for more than 1 year. Respondents with psychiatric illnesses with or without medication, having prior training or current use of relaxation therapy, working less than 1 year and respondents without consent were excluded.

Sample size obtained for the study was calculated via Open-Epi software for data analysis, in which minimal sample size estimated was 115 participants in each group from a previous study (11). Attrition rate 10% was taken with confidence interval set at 95% and statistical significance declared at two-tailed P- value <0.05. Participation for the study was voluntary.

Study procedure

Recruitment process in both the plants was undertaken within the assembly line in which an “Anti-Stress Wellness Clinic” was set up next to the already existing in-house clinic in both plants. The clinic was opened daily from Monday to Saturday, according to the hours stipulated by the management. Recruitment was targeted during their breaks to avoid any disruption to the work process at the company.

The intervention in Plant A was DBE as part of an EAP. Respondents from Plant A were taught and given a training session on DBE by the primary investigator who had himself undergone training with a certified trainer in relaxation techniques in the Department of Psychiatry and Rehabilitation Medicine, University Malaya Medical Centre. The respondents were briefed on stress and its ill effects followed by a 10 minute DBE training session.

The respondents were seated in a quiet room and were instructed to follow the DBE demonstrated by the investigator. The respondents were advised to practice the exercise at home, atleast twice daily. They were encouraged to keep a record in a diary on their home DBE sessions. To supplement the training session, the respondents were given graphically presented pamphlets on DBE techniques in which they could use as a guide while practicing at home. The investigator initiated phone calls, assembly unit contacts and emails to encourage and monitor the respondent's compliance.

Baseline assessment was done using self–administered questionnaire to collect information on socio-demographic characteristics and level of stress. Depression, Anxiety Stress Scale-21 (DASS-21) questionnaire was used at baseline and end of 2nd, 4th, 6th, and 8th month from baseline to assess the stress levels. Four follow-up reinforcement sessions from baseline to 9th month were conducted to promote compliance and to clarify arising related problem.

The comparison group in Plant B was not given any intervention. They were only given pamphlets on stress and its ill-effects and only minimal general information on how to reduce stress in their daily life. Only two assessment of stress level was done at baseline and end of 9th month with DASS-21, as it did not require any formal training.

Research Assessment

Self-administered DASS-21 is the short-form of Lovibond and Lovibond's 42-item self-report which measures the negative emotional states of depression, anxiety and stress (15). The questionnaire consists of three scales: DASS-Depression Scale (Cronbach's alpha = 0.81), DASS-Anxiety Scale (Cronbach's alpha = 0.85) and DASS-Stress Scale (Cronbach's alpha =0.85) (16, 17). The DASS assessment has been translated into various languages (18, 19, 20, 21). The translated Malay version of DASS-21 demonstrated good concurrent and criterion-related validity (17). The DASS-21 stress subscale of Malay version has a Cronbach's alpha of 0.79 (21).

In this study the Malay version of DASS-21 was used. The DASS-21 stress subscale which has seven items assessed the difficulty in relaxing, nervous arousal and being easily upset or agitates, over-reactive or irritable and impatient (16). Respondents were informed to use a 4 point Likert scale (0 = Did not apply to me at all, 1 = Applied to me to some degree, or some of the time, 2 = Applied to me a considerable degree, or a good part of the time, and 3 = Applied to me very much, or most of the time) to rate the extent to which they have experienced over the past 9 months. Scores for DASS-21 stress subscale was calculated by summing the scores and multiplying by two to get the final score (15). The higher scores indicated greater stress levels.

Statistical analysis

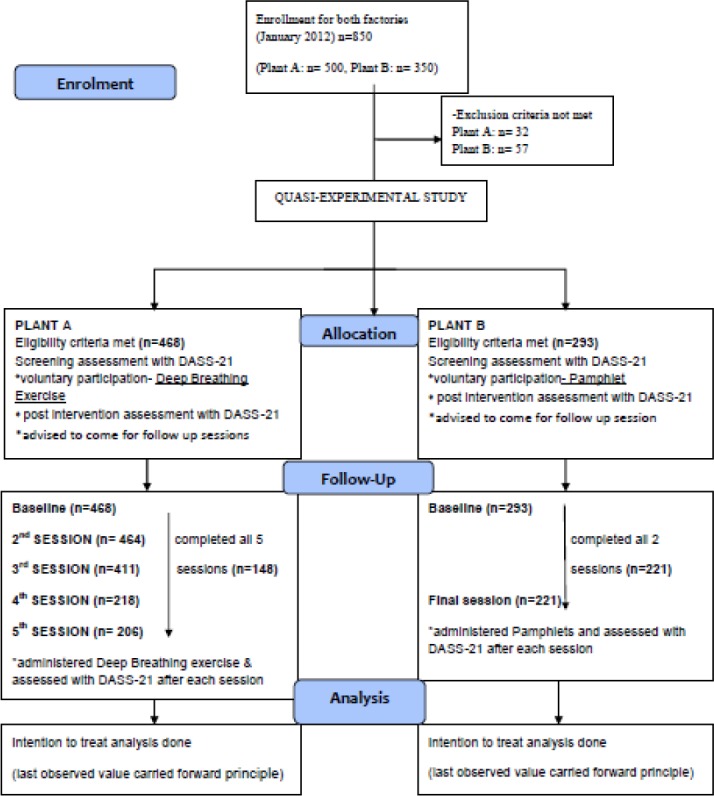

Data analysis was done using the SPSS version 20 (SPSS Inc, Chicago, IL, USA). Analysis was conducted based on intention-to-treat (ITT) whereby the last observation carried forward method was done. For descriptive analysis, the frequency distribution, measure of central tendencies and measure of distribution produced. The significant level pre-set at α<0.05. The normally distributed continuous data presented in the form of mean values with the corresponding standard deviations. A CONSORT checklist was used to improve the quality of the research (22) as in Fig. 1.

Fig. 1.

Flow Diagram of Study

Baseline characteristics of the respondents in both plants were analyzed with independent sample t test. The effect size (Cohen's d) was calculated as a standardized measure of change (23). Effectiveness of the DBE and pamphlet in the respective groups was examined using the repeated measure analysis of variance (RMANOVA). This procedure was used in the analysis to compare the mean response over time between intervention and comparison groups. The rationale for RMANOVA is to regard time and also as a factor addition to treatment. We examined both for main effect (changes for whole sample over time) and for differentiate between treatment conditions taking into consideration the time-group interaction effect.

Results

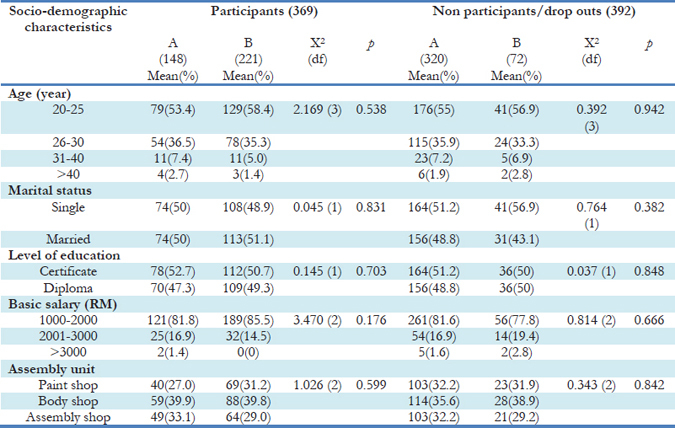

A total of 468 respondents in Plant A and 293 in Plant B met inclusion criteria and participated in the study. At the end of study, there were 148 respondents in Plant A and 221 respondents in Plant B. Intention-to-treat analysis was used to evaluate the details of the intervention effect. The demographic and social characteristics are shown in Table 1. Both groups were homogenous at baseline (P>0.05). Table 2 shows the homogeneity of the demographic characteristics of the participants who took part in the study as well as non-participants at end of the study in both groups. Table 3 shows the change in mean DASS-21 score for Group A and B from baseline to 9th month (within group). Significant changes occurred in Group A (large effect size) as compared to Group B (small effect size) across time. Table 3 also shows the difference in mean DASS-21 score between the groups at baseline and 9th month. At baseline there were no significant changes (small effect size) but there were significant changes in mean DASS-21 score at 9th month between Group A and B, enhancing the effectiveness of the DBE as compared to pamphlet distribution.

Table 1.

Socio-demographic characteristics of group a & group B at baseline

| Socio-demographic characteristics | Group A (n=468) Mean (%) | Group B (n=293) Mean (%) | X2 (df) | p |

|---|---|---|---|---|

| Age (year) | ||||

| 20-25 | 255(54.5) | 170(58.0) | 1.415(3) | 0.702 |

| 26-30 | 170(36.3) | 102(34.8) | ||

| 31-40 | 32(6.8) | 16(5.5) | ||

| >40 | 11(2.4) | 5(1.7) | ||

| Marital status | ||||

| Single | 243(51.9) | 149(50.9) | 0.083(1) | 0.774 |

| Married | 225(48.1) | 144(49.1) | ||

| Level of education Certificate | 249(53.2) | 148(50.5) | 0.524(1) | 0.469 |

| Diploma | 219(46.8) | 145(49.5) | ||

| Basic salary (RM) | ||||

| 1000-2000 | 380(81.2) | 245(83.6) | 1.786(2) | 0.409 |

| 2001-3000 | 80(17.1) | 46(15.7) | ||

| >3000 | 8(1.7) | 2(0.7) | ||

| Assembly unit | ||||

| Paint shop | 139(29.7) | 92(31.4) | 0.795(2) | 0.672 |

| Body shop | 179(38.2) | 116(39.6) | ||

| Assembly shop | 150(32.1) | 85(29.0) |

Table 2.

Socio-demographic characteristics of group a & group B at 9th month

Table 3.

Difference in mean scores (SD) across time and between groups

| Baseline mean (SD) | 9th month mean (SD) | P-value (within group) | Effect size | |

|---|---|---|---|---|

| Group A | 34.57 (3.74) |

26.10 (6.64) |

<0.001 | 0.6(large) |

| Group B | 34.83 (2.40) |

32.62 (4.83) |

<0.001 | 0.2(small) |

| P-value (between groups) | 0.29 | <0.001 | ||

| Effect size | 0.1(small) | 1.2(large) |

To investigate if DBE impacted stress levels in the automotive assembly line workers, RMANOVA was performed with the scores on stress subscale of DASS-21 as the dependent variable and group membership and time as the independent variables. After adjusting the data for the primary outcomes on the basis of intention to treat and last observation carried forward principle, there was a difference between the 2 groups at least at one time point [F (1, 1) =270.27, P<0.001]. Since there was no difference at baseline, the difference was only evident from 2nd, 4th, 6th and 8th month from baseline, with significant group *time interaction effect [F (1, 1) = 272.45, P<0.001] (Table 4).

Table 4.

Results of repeated measure ANOVA with DASS-21 stress scale as the dependent variable across time in group A (trial group)

| Source of variance | Sum of squares | df | Mean squares | F | P value |

|---|---|---|---|---|---|

| Group | 7139.87 | 1 | 7139.87 | 270.27 | <0.001 |

| Error (group) | 20054.89 | 759 | 26.42 | ||

| Time | 3687695.25 | 1 | 3687695.25 | 48335.71 | <0.001 |

| Group*time | 20786.04 | 1 | 20786.04 | 272.45 | <0.001 |

| Error (time) | 57906.68 | 759 | 76.30 |

Job types of the participants were matched in the trial and control group by RMANOVA between baseline and 9th month, with Group as fixed factors in Table 5 and Group and Job Units (Paint, Body and Assembly shop) as fixed factors in Table 6.

Table 5.

Repeated measure ANOVA with group as fixed factor from baseline to 9th month among participants

| Source of variance | Sum of squares | df | Mean squares | F | P-value |

|---|---|---|---|---|---|

| Group | 1730.68 | 1 | 1730.68 | 103.31 | <0.001 |

| Error (group) | 6148.03 | 367 | 16.75 | ||

| Time | 717428.45 | 1 | 717428.45 | 25375.54 | <0.001 |

| Group*time | 2180.40 | 1 | 2180.40 | 77.12 | <0.001 |

| Error (time) | 10375.99 | 367 | 28.27 |

Table 6.

Repeated measure anova with group & job units as fixed factor from baseline to 9th month among participants

| Source of variance | Sum of squares | df | Mean squares | F | P-value |

|---|---|---|---|---|---|

| Unit | 63.55 | 2 | 31.78 | 1.90 | 0.15 |

| Error (unit) | 6060.90 | 363 | 16.70 | ||

| Time | 702810.26 | 1 | 702810.26 | 24783.11 | 0.001 |

| Group*unit*time | 30.07 | 2 | 15.04 | 0.53 | 0.59 |

| Error (time) | 10294.11 | 363 | 28.36 |

Table 5 shows there was a statistically significant main effect for group assignment [F (1,367) = 103.31, P<0.001], indicating that the trial and control group differed in their average scores across time. There was also a statistically main effect for time [F (1,367) = 25375.54, P<0.001], indicating that when the two groups were combined, the average at baseline (Mean=34.70) was higher than the average at 9th month (Mean=29.36). Additionally, the interaction between group and time was statistically significant [F (1,367) = 77.12, P<0.001], indicating that the difference in means between the baseline and 9th month for the two groups were not the same. Table 6 shows the main effect for job units were not statistically significant [F (1,363) = 1.90, P>0.05], indicating that the trial and control group participants did not differ across job units. The main effect for time, however was statistically significant [F (1,363) = 24783.11, P<0.001], indicating that when the two groups were combined, the average baseline mean scores in the respective job units were higher than the 9th month mean scores. The interaction between group, unit and time was not statistically significant [F (1,363) = 0.53, P>0.05], indicating that there was no difference in mean scores across the job units for the two groups, from baseline and 9th month.

Discussion

A non-random sampling was done for the group allocation because only 1 of the assembly plants allowed an active interventional study to be done at their site whereas the other one was more accommodating for a passive study. However both the plants were highly comparable, producing similar and identical work processes. Cross contamination of respondents and treatment bias were minimized by conducting in assembly plants located far apart from each other.

Intention to treat analysis in this study gave a very conservative understanding of the independent variable's impact. Although the dropout rates were higher in the DBE group as compared to the pamphlet group, the effect size was large (0.6) which attributed to a significant improvement in the stress levels, thus attributing to a significant intervention effect.

The automotive assembly plant had a strong regional work ethic and culture which may have led to a high attrition rate in the trial group. Participants may have had difficulty in the process of leaving the work stations at their break time to participate in the employee assistance programme. While recruiting individuals for this intervention, the most common responses to an invitation to participate were, “I'm too stressed out to go to a stress management workshop,” , “I don't have time to learn about stress and its ill effects” or “My supervisor or head of unit did not permit me to leave my work station”. Many individuals in both groups who began the intervention stated that they were unable to complete it due to increased work-load, conflicting job demands or simply having too much to do in too little time.

Stress management training provides a psychological education program for individual employees to teach and empower themselves, hence becoming aware and develop effective skills to cope with stress (24). Evidence suggests that stress relaxation techniques are one of the most effective training programs to enhance psychological resources and reduce psychological distress (25). It is believed that the best relaxation techniques are those that are easy to teach and learn (26, 27). Majority of stress relaxation techniques are considered safe in healthy adults and there have been no severe adverse effects reported (28, 29).

A meta-analysis (30) suggested that at least 6 sessions were needed to achieve favourable effects on health outcomes, otherwise the favourable effects were limited to just knowledge and professional efficacy. This might attribute to plateauing effect on stress levels at the 5th session in the 9th month. Perhaps in future studies, the reinforcement sessions should be extended to an optimal session of 7 (30).

The use of DASS-21 in our study may be considered not adequately objective, but it should be noted that the use of such measures is both a reliable and standard approach to studying the effects of interventions for work stress. There is good evidence that these measures are clinically useful and reliable (31). Although more objective measures might be more desirable in studies like this, there is currently no agreement amongst work stress researchers about which objective measures are both reliable and feasible for use in field studies.

Only one study has tested the effects of a short duration stress management training to reduce stress in the automotive assembly industry but with a multi component entity (11). Our study is the first in-depth, single component study on effects of individual focused DBE on stress in the automotive industry. Studies that examine the effects of short duration individual-focused stress management training as part of EAP are deeply lacking. Poor organizational support that presume stress management training is time-consuming, expensive and inability of workers to practice coping skills are also attributing factors to high stress at the workplace (32).

Stress management is a lifelong process of learning that must be practiced regularly. It is applicable not only to people who manifest a disease or disorder, but also to healthy people, when added to daily routine practice. As the long-term use of functional coping strategies is necessary to enhance subjective well-being, it is vital to investigate how commitment to these strategies can be reinforced. The more the participants attempt to use these coping strategies in their daily lives, the greater the probability will be that they will use them successfully. Consequently, it is of utmost importance that the participants in the training be strongly encouraged to practice the competencies at home (in the form of homework during the training) and then to use the strategies as often as possible in their daily lives in order to become reinforced in their practice. These are evidence-based techniques, easy to learn and practice, with good results in individuals with good health or with a disease (33).

Limitations

The study design was neither blinded nor randomized which might have introduced bias to the outcomes reported by participants and a confounding bias due to unknown confounders.

The present study could not provide data on how long the effects remained after the intervention program. The post treatment measures were taken immediately after training. It would be useful to know how long these effects last. By increasing the retention of teaching outcomes, continuous application and integrated repetition is mandatory, which was not attainable merely by the short duration interventions in the current study.

The participants were all male workers from the assembly plant which may not be applicable to the general working population. The frequency and duration of practice of DBE before each reinforcement sessions were not available because the participants did not keep a detailed record despite being informed. The extent of practice at home and the workplace could have been analyzed further which may have had some influence on the intervention effects.

Conclusion

Reducing occupational stress in automotive assembly workers by stress intervention program is an important issue. The present study was conducted to examine the effects of stress relaxation training on self-perceived occupational stress in automotive workers using the validated short-form Malay version of the Depression Anxiety Stress Scales (DASS-21). Results indicated that DBE is effective in reducing some aspects of self-perceived occupational stress in these workers. Therefore, intervention programs to reduce occupational stress in the workplace may facilitate automotive workers to provide high-quality service in the automotive assembly plant setting.

Because this study focuses only on changes in stress levels, it would be interesting to compare these changes with improvements in daily life experience such as physical and psychological well-being, professional performance and life satisfaction. To answer these questions it will be crucial to ascertain the usefulness and effectiveness of stress prevention programs in the field of health care. Thus, it is our opinion that further studies on the impact of stress prevention programs are needed.

Ethical Consideration

Ethical issues (Including plagiarism, Informed Consent, misconduct, data fabrication and/or falsification, double publication and/or submission, redundancy, etc) have been completely observed by the authors.

Acknowledgements

We would like to acknowledge all respondents, plant supervisors, human resource manager and the assistant general managers of both automotive assembly plants who assisted in the study. The study protocol was reviewed and approved by the Research and Ethics Committee of University Malaya on 16th of January 2012 (MEC Reference Number: 895.11). The authors declare that this study was not supported by any financial source. We declare that there is no conflict of interest.

References

- Larson LL (2004). Internal auditors and job stress. Managerial Auditing Journal, 19(9): 1119–1130. [Google Scholar]

- Dua JK (1994). Job stressors and their effects on physical health, emotional health, and job satisfaction in a university. Journal of Educational Administration, 32(1): 59–78. [Google Scholar]

- Brown ZA, Uehara DL (2008). Coping with teacher stress: A research synthesis for Pacific education. URL (last checked 2 June 2008). http:www.prel.org

- Reskin A (2008). Podcast transcript for working with stress. URL (last checked 29 April 2008). http://online.sagepub.com/.

- Kawaharada M, Ueda I, Yoshioka E, Hirano M, Ikeno T, Shindou Y and Kishi, R (2009). Depression prevention program for workers in private companies: A randomized controlled trial. Open Journal of Nursing, 3: 114–121. [Google Scholar]

- Lamontagne AD, Keegel T, Louie AM, Ostry A, Landsbergis PA (2007). A Systematic Review of the Job Stress Intervention Evaluation Literature: 1990-2005, Int J Occup Med Environ Health, 13: 268–280. [DOI] [PubMed] [Google Scholar]

- Mourya M, Mahajan AS, Singh NP, Jain AK (2009). Effect of slow- and fast-breathing exercises on autonomic functions in patients with essential hypertension. J Alternative & Complement Med, 15(7): 711–717. [DOI] [PubMed] [Google Scholar]

- Nogawa M, Yamakoshi T, Ikarashi A, Tanaka S, Yamakoshi K (2007). Assessment of slow-breathing relaxation technique in acute stressful tasks using a multipurpose non-invasive beat-by-beat cardiovascular monitoring system. Conf Proc IEEE Eng Med Biol Soc, 5323–5325. [DOI] [PubMed] [Google Scholar]

- Oleske DM, Neelakantan J, Andersson GB, Hinrichs BG, Lavender SA, Morrissey MJ, Zold-Kilbourn P, Taylor E (2004). Factors affecting recovery from work-related, low back disorders in autoworkers. Arch Phys Med Rehabil, 85(8): 1362–1364. [DOI] [PubMed] [Google Scholar]

- Kvarnström S (1997): Stress prevention for blue-collar workers in assembly-line production. Geneva: International Labour Office (ILO), 1–32. [Google Scholar]

- Edimansyah B, Rusli B, Naing L (2008). Effects of short duration stress management training on self-perceived depression, anxiety and stress in male automotive assembly workers: a quasi-experimental study. J Occup Med Toxicol, 3(1): 28. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lottridge D (2004). Work at the Uddevalla Volvo Plant from the perspective of the demand control model. Bull Sci Tech Society, 24: 435–440. [Google Scholar]

- Karasek R, Baker D, Marxer F, Ahlbom A, Theorell T (1981). Job decision latitude, job demands, and cardiovascular disease: a prospective study of Swedish men. Am J Public Health, 71(7): 694–705. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fairbrother K, Warn J (2003). Workplace dimensions, stress & job satisfaction. Journal of Managerial Psychology, 18 (1): 8–21. [Google Scholar]

- Lovibond SH, Lovibond PF (2002). Manual for the Depression Anxiety Stress Scales 2nd edition Sydney: School of Psychology, University of New South Wales; 18. [Google Scholar]

- Lovibond SH, Lovibond PF (1995). Manual for the Depression Anxiety Stress Scales (2nd Ed) Sydney: Psychology Foundation. [Google Scholar]

- Edimansyah BA, Rusli BN, Naing L, Mazlan BA, Rampal KG, Shamsul Bahri BMT, Nik Khairol Reza BMY, Ahmad Syaarani BY, Azwan BA, Mazalisah BM, Kamarudin BH (2005). Reliability and concurrent validity of the Malay version of Depression Anxiety Stress Scale (DASS) in automotive assembly workers in Malaysia. Malaysian J Public Health Med, 5 (Suppl.1). [Google Scholar]

- Bados A, Solanas A, Andrés R (2005). Psychometric properties of the Spanish version of Depression, Anxiety and Stress Scales (DASS). Psicothema, 17: 679–83. [Google Scholar]

- Apóstolo JLA, Mendes AC, Azeredo ZA (2006). Adaptation to portuguese of The Depression, Anxiety and Stress Scales (DASS). Rev Latino-am Enfermagem, 14: 863–71. [DOI] [PubMed] [Google Scholar]

- Akin A, Çetin B (2007). The Depression Anxiety and Stress Scale (DASS). The study of validity and reliability. Educational Sciences: Theory and Practice, 7: 260–8. [Google Scholar]

- Musa R, Fadzil MA, Zain Z (2007). Translation, validation and psychometric properties of Bahasa Malaysia version of the Depression Anxiety and Stress Scales (DASS). Asean J Psychiatry, 8: 82–9. [Google Scholar]

- Schulz KF, Altman, DG and Moher D (2010), CONSORT 2010 statement update guideline for reporting parallel group randomized trials. British Medical Journal, 340, c332. doi:10.1136/bmj.c332. [DOI] [PubMed] [Google Scholar]

- Cohen J (1992). A power primer. Psychol Bull, 112: 155–9. [DOI] [PubMed] [Google Scholar]

- Jones D, Tanigawa T, Weiss SM (2003). Stress management and workplace in the US, Europe and Japan. J Occupational Health, 45: 1–7. [DOI] [PubMed] [Google Scholar]

- Umanodan R, Kobayashi Y, Nakamura M, Kitaoka K, Kawakami N, Shimazu A (2009). Effects of a worksite stress management training program with six short-hour sessions: A controlled trial among Japanese employees. J Occupational Health, 51: 294–304. [DOI] [PubMed] [Google Scholar]

- Benson H (1975). The relaxation response New York: Morrow. [DOI] [PubMed] [Google Scholar]

- Benson, H (1983). The relaxation response and norepinephrine: A new study illuminates mechanisms. Integrative Psychiatry, 1: 15–18. [Google Scholar]

- Barlow DH, Lehrer PM, Woolfolk, RL, Sime WE (2007). Principles and practice of stress management (3rd ed). New York: Guilford Press. [Google Scholar]

- Varvogli L, Darviri C (2011). Stress Management Techniques Evidence-based procedures that reduce stress and promote health. Health Science Journal, 5(2): 74–89. [Google Scholar]

- Klink JJ, Blonk RW, Schene AH, van Dijk FJ (2001). The benefits of interventions for work related stress. Am J Public Health, 91: 270–276. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gloster AT, Rhoades HM, Novy D (2008). Psychometric properties of the Depression Anxiety and Stress Scale-21 in older primary care patients. J Affective Disorders, 110, 248–59. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yung P, Fung M, Chan T, Lau B (2004). Relaxation training methods for nurse managers in Hong Kong: a controlled study. Int J Ment Health Nurs, 13: 255–261. [DOI] [PubMed] [Google Scholar]

- Richardson KM & Rothstein HR (2008). Effects of occupational stress management intervention programs: a meta-analysis. J Occup Health Psychol, 13(1), 69. [DOI] [PubMed] [Google Scholar]