Abstract

Background

The objective of this study was to determine the distribution of an economically–important class of mycotoxins, the aflatoxins (AFs) in Pakistani Brown Rice.

Methods

A total of 262 of brown rice samples were collected from different vendors during July 2006 to June 2011. Samples were analyzed for the occurrence of aflatoxin B1 (AFB1), B2 (AFB2), G1 (AFG1) and G2 (AFG2) by thin layer chromatography (TLC) technique.

Results

AFB1 was detected in 250 (95.4%) samples, whereas AFB2 was detected in 20 (7.6%) samples. Furthermore, AFG1 and AFG2 were not found in any sample. The contamination range of AFB1 and AFB2 was found 1.07–24.65 μg/kg and 0.52–2.62 μg/kg, respectively. Total AFs were quantified in 250 (95.4%) samples with an average of 3.89 μg/kg and contamination range was noted to be between 1.07–27.27 μg/kg. The overall results indicated that in 12 (4.6%) samples, AFs were not found within detectable limits. Furthermore, in 188 (71.7%) samples, AFs level was found below than maximum tolerated levels (MTL) as recommended by the European Union (4 μg/kg). Moreover, in 61 (23.3%) samples, AFs range was found between 4–20 μg/kg, which were fit for human consumption as per MTL (20 μg/kg) assigned by USA (FDA and FAO) and Pakistan (PSQCA). While only one sample (27.27 μg/kg) exceeded the above mention regulation limits.

Conclusion

Low level of AFs occurs frequently in brown rice, and can be improved using proper harvesting practices, storage and transportation conditions. The small quantities of AFs warrant performing further investigation, monitoring and routine analysis on regular basis.

Keywords: Brown rice, Aflatoxins, TLC, Pakistan

Introduction

Rice (Oryza sative L.) is one of the most important staple diets in the world. In Pakistan, rice is the third largest crop after wheat and cotton. Rice is cultivated on an area of more than 2.5 million hectares and accounts for 16% of the total cereals produced annually. In 2011–2012, the production of milled rice was about 6.16 million tones. This accounts for 5% of the total agriculture sector with 1.0% contribution in GDP (1). Brown rice often termed as hulled rice is a partly milled or un–milled form of whole natural grain. Brown rice is comparatively more nutritious than traditional white rice. The underlying reason is the preservation of essential nutrients and vitamins (usually 5–80%) which are destroyed during the milling and polishing process of white rice (2).

Rice is highly vulnerable to fungal contamination owing to cultivation in wet–season. The pathogenic fungi such as Aspergillus sp., Fusarium sp. and/or Penicillium sp. might attack on the rice kernel (i) during the cultivation of crop and/or (pre–harvest) (ii) during the storage of matured crops (post–harvest). Pre–harvest fungal contamination generally occurs in the field and associated with drought and high temperature during the grain–fall. Post–harvest contamination usually developed when grain is improperly managed during the drying and storage process (3).

In general, warm and moist conditions along with hygroscopic nature of rice kernel are believed to be very favorable for the growth of toxigenic fungi, associated with mycotoxins production.

Mycotoxins are low molecular weight secondary fugal metabolites. Fungal proliferation and mycotoxins biosynthesis are highly susceptible to temperature, moisture, water activity, pH and oxygen concentration (4, 5).

Aflatoxins (AFs) are the best known and most widely studied mycotoxins. AFs are injurious to the human health, livestock and poultry. Adverse effects of AFs include growth impairment, decreased resistance to pathogens, hepato- and nephrotoxicity (6). Aspergillus species particularly A. flavus and A. parasiticus are ubiquitous and cosmopolitan AFs producing fungi in various agricultural commodities (7).

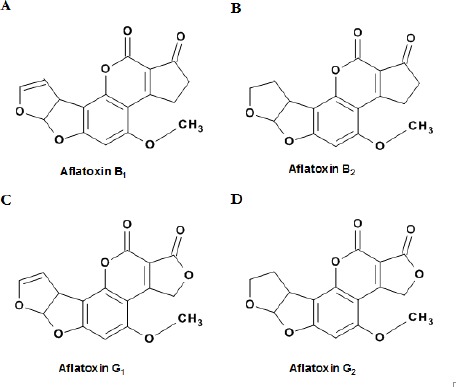

The most important AFs are aflatoxin B1 (AFB1), B2 (AFB2), G1 (AFG1) and G2 (AFG2) (Fig. 1).

Fig. 1.

Chemical structures of aflatoxins. (A) aflatoxin B1, (B) aflatoxin B2, (C) aflatoxin G1 and (D) aflatoxin G2

Considering aflatoxins, AFB1 is the most toxic than other AFs such as AFB2, AFG1 and AFG2 and has been widely reported in rice (8-10).

Several countries including Pakistan have established strict guidelines and acceptance limits for AFs (11). In Pakistan, the climatic conditions are usually very hot and humid. Thus, provide an excellent environment for fungal propagation and AFs production. For instance, Sorenson et al. examined the effect of temperature on AFs production in rice. It was observed that the suitable temperature for AFs production was 28 °C (12). Together with AFs production, fungal invasion cause organoleptic changes such as grain discoloration, shape, size and mustiness. Furthermore, reduced germ–inability crop due to embryo destruction during the storage phase (13).

Due to the toxicity of AFs, their effect in public health and lack of available surveys on AFs content particularly in Pakistani brown rice. This study was conducted to investigate AFs level in brown rice that is sold in local supermarkets, traditional bazaars and export to several countries.

Materials and Methods

Reagents and apparatus

Aflatoxin B1, B2, G1 and G2 standards (crystalline powder) were purchased from Sigma–Aldrich (St. Louis–MO, USA). Pre–coated TLC plates of silica gel 60 (layer thickness 0.25 mm, 20 x 20 cm) on glass or aluminum, without fluorescent indicator were purchased from E. Merck (Darmstadt, Germany). Analytical grade acetone, acetonitrile, benzene, chloroform, cupric carbonate, ferric chloride, potassium chloride, potassium hydroxide, sodium hydroxide, sodium sulfate, sulfuric acid, xylene and other solvents procured from BDH (Poole, England).

Sampling

A total of 262 samples of brown rice were collected from various vendors across the Pakistan during July 2006 to June 2011. It is well documented that AFs are heterogeneously distributed throughout most food and feed commodities. For this reason, sampling procedures was based on the method as described in AOAC official method no. 977.16 for the accurate estimation of AFs (14). Briefly, a minimum sample size of 500–1000 g was taken and thoroughly mixed for 10 min. Samples were pulverized into particles ≤ 1 mm by passing through sieve no. 20 in a sample grinder (Cyclotec 1093 mill, Sweden) to obtain a homogeneous and representative sample. Finally, pulverized samples were kept in air tight polyethylene bags and stored at -20°Ctill further analysis.

Preparation of aflatoxins standards

The standard stock solutions (10 μg/ml) of each AFB1, AFB2, AFG1 and AFG2 were prepared by dissolving 1 mg crystalline powder in 100 ml benzene : acetonitrile (98 : 2; v/v). Final concentration of each AFs stock solution was thereafter determined by measuring the absorbance at 350 nm using Jenway Genova MK3 spectrophotometer (Dunmow–Essex, England).

Working standard solution of each AFB1 and AFG1 (1 μg/ml) was individually prepared by combining 100 μl of each stock solution (10 μg/ml) and 900 μl of benzene : acetonitrile (98 : 2; v/v). Whereas, working standard solutions of each AFB2 and AFG2 (0.5 μg/ml) were separately prepared by adding 50 μl of each stock solution (10 μg/ml) in 950 μl of benzene : acetonitrile (98 : 2; v/v).

Aflatoxins analysis

A modified Romer method based on bi–directional thin layer chromatography (TLC) was used for the detection of AFs as described in the AOAC official method no. 975.36/968.22 (14). The whole analytical procedure could be sub–divided into two major steps as mentioned below:

1. Sample purification and aflatoxins extraction

2. Thin layer chromatography

Sample purification and aflatoxins extraction

Fifty grams of each grinded brown rice sample was weighed accurately and dispersed in 250ml of acetone: water (85: 15; v/v). Sample suspension was blended for 3 min at 5000 rpm using Eberbach 8017 explosion–proof blender (Haverhill–Massachusetts, USA). The blended extract was filtered through Whatman no. 4 filter paper. An aliquot of 150 ml of sample extract was taken and mixed with 3 g of cupric carbonate for 20 s. The sample mixture was then added into a conical flask already contained 170 ml sodium hydroxide (0.2 M) and 30ml ferric chloride (0.41 M), mixed well and filtered through Whatman no. 4 filter paper. An aliquot of 250 ml filtrate was taken into a separating funnel, vigorously shake in the presence of 150 ml sulfuric acid (0.03%; v/v) and 10 ml chloroform and allowed to settle–down for 2min. The lower layer of chloroform was transferred into another separating funnel already contained 1g potassium chloride and 100 ml potassium hydroxide (0.02 M) solution. After a gentle swirling of 30 s, the lower chloroform layer was separated and re–collected into a graduated cylinder after passing through a bed of anhydrous Sodium sulfate (1 g). Finally 8mlof chloroform extract was evaporated to dryness at 45°C under gentle stream of nitrogen and stored at -20 °C till the further quantification by TLC.

Thin layer chromatography

Dried extracts were solublized in 100 μl benzene : acetonitrile (98 : 2; v/v) and vortexed. Finally, spots of 2, 5 and 10 μl of samples and standards were individually applied on the TLC plate. Chromatographic plates were developed in unlined tank containing 20 ml chloroform : xylene: acetone (6: 3: 1; v/v). TLC Plates were dried and observed under long wavelength UV light (λ = 254 and 366 nm) in an enclosed Camag 2930 UV visulizer (Germany). The retention factor (Rf) of each AFs (B1, B2, G1 and G2) was calculated in accordance with the equation (i).

Rf = distance moved by compound/distance moved by solvent (i)

Furthermore, the concentration of individual AFB1, AFB2, AFG1 or AFG2 was calculated according to the following equation (ii).

Concentration of AFB1, AFB2, AFG1 or AFG2 in μg/kg = S × Y × V / X × W (ii)

Where:

S = Volume (μl) of AFB1, AFB2, AFG1 or AFG2 standard equal to unknown

Y = Concentration (μg/ml) of AFB1, AFB2, AFG1 or AFG2 standard

V = Volume (μl) of final dilution of sample extract

X = Volume (μl) of sample extract spotted to give fluorescent intensity equal to S

W = Weight (g) of sample contained in final extract.

The concentration of Total AFs (B1, B2, G1 and G2) was calculated as mentioned in equation (iii).

Total AFs = Concentration of AFB1 + AFB2 +AFG1 + AFG2 (iii)

All positive findings of AFs, naturally present in rice samples were confirmed by spraying the TLC plates with H2SO4 (50%; v/v) and making the derivative with trifluoroacetic acid.

Method validation and analytical quality assurance

The accuracy of the analytical procedure was verified by performing the analysis in triplicate. Furthermore, method validation was done through the analysis of control samples. Briefly, homogenized control rice samples (n = 20) were analysed five times per day for four successive days. Results were incorporated in a control chart with an upper and lower warning (±2σ; 95% confidence limit) and control limits (±3σ; 90% confidence limit). Additionally, at least two control samples were tested with each series of routine samples (n = 25) and results were compared with the previous control measurements. Results of control samples were found within ±2σ range. The accuracy of procedure was determined by the recoveries of AFB1, AFB2, AFG1 and AFG2 from spiked samples. Furthermore, the recovery studies were performed by the analysis of uncontaminated (blank) rice samples before and after the addition of 2, 5 and 10 μg/kg of each AFs standard. The average recoveries rate for the four AFs was from 83.3% to 91.8%. Results from the recovery studies are presented in Table 1. The limit of detection (LOD) for AFB1 and AFG1 was 1 μg/kg and for AFB2 and AFG2 was 0.50 μg/kg, respectively. General laboratory performance (GLP) was verified by participation in the FAPAS® proficiency testing program via test no. 0488/2006, 0490/2006, 0493/2006, 04109/2007, 04113/2007, 04132/2008 and 04169/2011. Results were found within the range (±2 Z score) and showed in Table 2. Food and feed safety laboratory has an ISO–17025 accreditation status with Pakistan National Accreditation Council (PNAC).

Table 1.

Summary of FAPAS® Proficiency Testing Program during 2006–2011

| S. No. | Test No. | Z–Score | Total Aflatoxins (μg/kg) |

|

|---|---|---|---|---|

| Assigned Value | Lab. Value | |||

| 1. | 0488/2006 | -0.1 | 5.59 | 5.44 |

| 2. | 0490/2006 | -0.9 | 7.92 | 6.33 |

| 3. | 0493/2006 | 0.9 | 7.53 | 8.96 |

| 4. | 04109/2007 | -1.4 | 7.01 | 7.18 |

| 5. | 04113/2007 | 0.4 | 13.70 | 14.82 |

| 7. | 04115/208 | 1.2 | 7.83 | 9.82 |

| 8. | 04132/2008 | 0.2 | 16.70 | 17.29 |

| 9. | 04169/2011 | -0.1 | 13.70 | 13.59 |

Table 2.

Recovery of AFB1, AFB2, AFG1 and AFG2 from spiked samples of brown rice. All measurements were done in triplicate

| Concentration added | AFB1 | AFB2 | AFG1 | AFG2 | ||||

|---|---|---|---|---|---|---|---|---|

| (μg/kg) | Recovery concentration (μg/kg) | Mean recovery (%) | Recovery concentration (μg/kg) | Mean recovery (%) | Recovery concentration (μg/kg) | Mean recovery (%) | Recovery concentration (μg/kg) | Mean recovery (%) |

| 2 | 1.83 ± 0.11 | 91.8 | 1.70 ± 0.11 | 85.2 | 1.70 ± 0.11 | 85.2 | 1.77 ± 0.20 | 88.5 |

| 5 | 4.39 ± 0.45 | 87.8 | 4.16 ± 0.49 | 83.3 | 4.16 ± 0.25 | 83.3 | 4.52 ± 0.34 | 90.5 |

| 10 | 8.85 ± 0.59 | 88.5 | 8.65 ± 0.34 | 86.5 | 8.85± 0.59 | 88.5 | 8.46 ± 0.34 | 84.6 |

Results

Relevant data regarding AFs contamination is summarized in Table 3. AFB1 was detected in 250 (95.4%) samples. The average concentration of AFB1 was 3.80 μg/kg with a range of 1.07–24.65 μg/kg. In contrast, AFB2 was found only in 20 (7.6%) samples with an average of 0.09μg/kg. The range of AFB2 was found between 0.52–2.62 μg/kg. AFG1 and AFG2 contaminations were not detected in any rice sample. Altogether, 250 (95.4%) rice samples were found contaminated with AFs (B1+B2) with an average of 3.89 μg/kg. The range of AFs (B1+B2) contamination was found between 1.07–27.27 μg/kg. The overall results showed that AFs were not found within detectable limits (> 1 μg/kg) in 12 (4.6%) samples. Furthermore, 188 (71.7%) samples contained AFs level below than maximum tolerated level (MTL) of 4μg/kg as assigned by the European Union. Moreover, 61 (23.3%) samples retained AFs levels ranged between 4–20 μg/kg. These rice samples were fit for human consumption as per MTL (20 μg/kg) assigned by USA (FDA and FAO) and Pakistan (PSQCA). Only one sample was found un–fit for human consumption owing to AFs contamination of 27.27 μg/kg.

Table 3.

Distribution of AFB1, AFB2 and Total AFs in brown rice during 2006–2011. All measurements were done in triplicate

| Toxins | Tested samples | Number of samples in concentration range, μg/kg |

Mean (μg/kg) | Range (μg/kg) | ||||

|---|---|---|---|---|---|---|---|---|

| Positive samples | NFa | < 4b | 4 to 20c | > 20 | ||||

| AFB1 | 262 | 250 (95.4%) | 12 (4.6%) | 188 (71.7%) | 61 (23.3%) | 1 (0.38%) | 3.80 | 1.07–24.65 |

| AFB2 | 262 | 20 (7.6%) | 242 (92.4%) | 20 (7.6%) | 0 | 0 | 0.09 | 0.52–2.62 |

| Total AFs | 262 | 250 (95.4%) | 12 (4.6%) | 188 (71.7%) | 61 (23.3%) | 1 (0.38%) | 3.89 | 1.07–27.27 |

a Not found within detectable limit (≥ 1 μg/kg )

b Below than EU MTL (≤ 4 μg/kg )

cBelow than FDA, FAO and PSQCA MTL (≤ 20 μg/kg )

Discussion

AFB1 and AFB2 were observed as the most common contaminant in the tested rice samples. However, none of the tested rice sample showed AFG1 and AFG2 contamination. The underlying reason is that the optimal temperature for AFs production ranged between 20–35 °C. Elevation of temperature up to 40 °C or decline up to 10 °C could result in reduced AFs production. The high temperature within the optimal range favors the production of aflatoxin B (B1 and B2). In contrast, low temperature favors the production of aflatoxin G (G1 and G2) (15).

Pakistan is situated in a region which has a tropical climate, with high temperatures averaging 23.9 °C and a double maxima rainfall pattern (489 mm) (16). These hot and humid climatic conditions are supposed to be very favorable for the production of AFs (17). The findings of the current study support the above mentioned facts and figures.

In early 2006, the export of Pakistani brown rice to the European Union was reduced abruptly. The reason was the high moisture (≥ 30%) in paddy rice. As a result, AFs contamination was significantly enhanced and consignments were rejected (18). The current study found that the average AFs contamination in brown rice was 5.63 μg/kg in the year 2006.

In this circumstance, rice exporters urged the government to establish strict regulations for the permitted AFs levels in various food commodities. Furthermore, it was demanded to provide peer to peer testing facilities for AFs in Pakistan as currently practiced in the EU counterparts. Consequently, government of Pakistan took the immediate action and storage facilities with dryer were established in the first step. Furthermore, farmers were bounded to examine their consignments prior to export. The collective efforts rise by rice exporters and the government of Pakistan have resulted in a gradual decrease in AFs contamination in brown rice. Thus, a safe level of average AFs contamination equivalent to 2.51 μg/kg was achieved in the year 2011.

The yearly progress regarding AFs contamination is presented in Table 4. The results illustrated that brown rice were found contaminated with AFs. However, contamination level lies within tolerated limits (≤ 4 μg/kg). The underlying reason that AFs contamination still persists even in traces is associated with the unique physical structure of the rice hull that plays a vital role in protecting seed kernels from being infected by the aflatoxigenic moulds (19). The same rice hull being rich in nutrients enables brown rice an ideal substrate for fungi by providing adequate energy required for moulds growth and toxin production (20).

Table 4.

Annual distribution of AFB1, AFB2 and total AFs content in brown rice

| Years | Toxins | Concentration in μg/kg | ||

|---|---|---|---|---|

| Positive samples (%) | Mean | Range | ||

| Jun–Dec 2006 (n = 13) | ||||

| AFB1 | 12 (92.3) | 5.19 | 3.15–14.16 | |

| AFB2 | 2 (15.4) | 0.18 | 0.94–1.42 | |

| Total AFs | 12 (92.3) | 5.37 | 3.15–15.58 | |

| 2007 (n = 78) | ||||

| AFB1 | 67 (85.9) | 5.45 | 1.12–24.65 | |

| AFB2 | 8 (10.2) | 0.17 | 1.42–2.62 | |

| Total AFs | 67 (85.9) | 5.63 | 1.12–27.27 | |

| 2008 (n = 36) | ||||

| AFB1 | 36 (100) | 3.91 | 1.99–11.34 | |

| AFB2 | 2 (5.6) | 0.07 | 1.12–1.32 | |

| Total AFs | 36 (100) | 3.98 | 1.99–12.66 | |

| 2009 (n = 44) | ||||

| AFB1 | 44 (100) | 2.72 | 1.29–11.59 | |

| AFB2 | 3 (6.8) | 0.054 | 0.52–1.30 | |

| Total AFs | 44 (100) | 2.78 | 1.29–12.89 | |

| 2010 (n = 49) | ||||

| AFB1 | 49 (100) | 2.80 | 1.38–13.77 | |

| AFB2 | 3 (6.1) | 0.06 | 0.56–1.42 | |

| Total AFs | 49 (100) | 2.86 | 1.38–15.19 | |

| Jan–Jun 2011 (n = 42) | ||||

| AFB1 | 42 (100) | 2.47 | 1.07–7.89 | |

| AFB2 | 3 (7.1) | 0.04 | 0.52–0.74 | |

| Total AFs | 42 (100) | 2.51 | 1.07–7.89 | |

In Pakistan, AFs contamination in rice varies with their place of origin. This is due to the variable temperature, humidity, microbial flora, soil type and diverse agricultural practices.

Unfortunately, to–date no systematic survey is available on the occurrence of AFs particularly in brown rice. However, few comparative studies are reported. For instance, Asghar et al. investigated AFs contamination in 2047 samples comprising basmati rice. About 73.3% samples were contaminated with AFB1 ranging from 1.17–6.91 μg/kg and a mean of 1.15μg/kg. In 70.6% samples, AFB1 level was found lower than MTL as recommended by European Union. Moreover, all the samples were found below than MTL of as assigned by the authorities in United State (FDA and FAO) and Pakistan (PSQCA) (11). Shamma Firdous analyzed of 599 samples comprising white, brown and sella rice. About 49% samples were found positive with AFs. Mean concentrations of AFB1/AFB2 were 0.56/0.03 μg/kg for brown rice, 0.49/0.03 μg/kg for white rice and 0.73/0.02 μg/kg for sella rice, respectively. The highest concentration of AFB1 and AFB2 was 16.65 and 2.64 μg/kg, respectively (21). In another study, Iqbal and colleagues pointed that about 65, 38, 33, 42 and 50% samples comprising paddy, parboiled, brown, white and broken rice were found contaminated with AFs with an average of 16.35, 14.20, 9.85, 7.10 and 8.50 μg/kg, respectively (22).

The results of present study revealed that the quality of Pakistani brown rice is far better than rice produced in other countries of the same region such as Sri Lanka and India. For instance, In Sri Lanka, the AFB1 and AFG1 contents were found significantly higher in parboiled rice than in raw milled rice. The highest AFB1 and AFG1 content were 185 and 963μg/kg, respectively (23). In India, the incidence of AFB1 was found at level of 5 μg/kg in 38.5% samples. Whereas, about 17% samples exceeded the Indian regulatory limit of 30μg/kg. The average concentration of AFB1 in rice samples collected Assam, Bihar and Tripura states was 15 μg/kg (24). Another study from India indicated that out of 1200 rice samples, about 67.8% samples were found contaminated with AFB1 ranging between 0.1–308 μg/kg (10).

Several studies from other countries reported detectable levels of AFs in rice as well. For instance, Sales and Yoshizawa from Philippines investigated that out of 78 samples, about 94 and 100% of polished and brown rice samples were found contaminated with AFs, respectively. The contamination range in polished and brown rice was found 0.025–2.7 and 0.03–8.7 μg/kg, respectively (25). Similarly, J. Feizy et al. from Iran reported that out of 261 rice samples, about 68.9% samples were found contaminated with AFB1 ranged between 0.20–4.3 μg/kg (26). Another study from Iran reported that out of 71 rice samples, 59 (83%) samples were found contaminated with AFs. The mean concentration of AFs was 2.09 μg/kg. Furthermore, about 12.7% samples exceeded the EU MTL (27). Furthermore, Reiter et al. from Iran reported that 24 out of 81 samples were found positive with AFs. AFB1 was quantified in 15 samples and AFB2 was detected only in one sample. However, AFG1 and AFG2 were not found in any of the tested rice samples. The range of AFB1 and AFB2 was found 0.45–9.86 and 1.5 μg/kg, respectively. The maximum concentration of AFB1 was found 9.86μg/kg (28).

All the above mentioned surveys indicated that AFs contamination in rice is quiet frequent. In order to achieve low level of AFs, it is essential to conduct regular training programs to create awareness about the toxicity potential of AFs. Furthermore, good manufacturing and storage practices should be adapted along with implementation on Hazard Analysis and Critical Control Points (HACCP) based safety program. It is also pre–requisite to carry on further investigations, regular monitoring and performing routine AFs analysis as per food quality control measures. Numerous techniques are currently in practice nowadays to control AFs contamination. For instance, Nkama et al. introduced the use of light intensity for reduction in AFs contamination. It was observed that rate of destruction of AFs was found directly proportional to the light intensity. About 63 to 93% reduction in AFs level was achieved in the presence of different light intensities (29). Moreover, Hussain reduced AFB1 contamination by utilizing different cooking methodologies. AFB1 level was significantly reduced up to 87.5 % when rice samples were cooked in excess water (30).

Indeed, AFs contamination could be reduced by adapting good processing and storage practices. Therefore, it is needed to take proper actions such as the use of better harvesting practices, handling, packaging, storage and as well as transportation. AFs have a high impact in human health. Thus, storage conditions should be controlled and widespread. The industry and government should continue to take steps and bound the farmers, growers and other stake holders to keep AFs levels in food and animal feed as low as possible. Growers and processors, for instance, follow voluntary “Good Manufacturing Practices” that include monitoring of mold growth and testing of the samples for AFs.

A comprehensive plan is required to deliver the food and feed safely that engaged to full fill the requirement regarding the issues of not only rice, but also all other foods, feed and their ingredients. On the other hand, substantial work has been put forth on methodologies for the detection and quantification of aflatoxins, however, sampling is of prime importance as to have a representative sample of the total lot under assessment, secondarily sample handling and finally the analysis. It is very unfortunate that sampling, sample handling and analysis is not standardized on part of growers, farmers, producers and ultimately the consumers whom are at great risk. Care must be taken in the elucidation and evaluation of results.

Conclusion

The present status of the aflatoxins (AFs) level in Pakistani brown rice does not concurrently present a potential risk to the human health. Nevertheless, the detection of small quantities of AFs warrants further investigation, regular monitoring and performing routine analysis, as per food quality control measure. The initial approach to control AFs is to take precaution and proper action such as better harvesting practices, handling, packaging, storage and as well as transportation.

Ethical Consideration

All Ethical issues (such as informed consent, conflict of interest, plagiarism, misconduct, co–authorship, double submission, etc.) have been considered carefully.

Acknowledgements

The authors declare that there is no conflict of interests.

References

- Ministry of Finance, Government of Pakistan, Pakistan Economic Survey, 2011-12. Available: http://www.finance.gov.pk/survey_1112.html

- The world Healthiest Food, Brown Rice. Available: http://www.whfoods.com/genpage.php?tname=foodspice&dbid=128

- Reddy CS (2009). Mycotoxin Contamination of Rice. Rice Knowledge Management Portal (RKMP) Directorate of Rice Research, Rajendranagar, Hyderabad 500030. [Google Scholar]

- Paterson RRM, Lima N (2010). How will climate change affect mycotoxins in food?. Food Res Int, 43: 1902–14. [Google Scholar]

- Bryden WL (2007). Mycotoxins in the food chain: human health implications. Asia Pac J of Clin Nutr, 16: 95–101. [PubMed] [Google Scholar]

- Joint FAO/WHO Expert Committee on Food Additives (JECFA) (1998). Safety evaluation of certain food additives and contaminants. World Health Organization, Geneva, Available from: whqlibdoc.who.int/publications/2011/9789241660648_eng.pdf [PubMed]

- Rustom IYS (1997). Aflatoxin in food and feed: Occurrence, legislation and inactivation by physical methods. Food Chem, 59: 57–67. [Google Scholar]

- Bansal J, Pantazopoulos P, Tam J, Cavlovic P, Kwong K, Turcotte A-M, Lau BP-Y, Scott PM (2011). Surveys of rice sold in Canada for aflatoxins, ochratoxin A and fumonisins. Food Addit Contam A, 28: 767–74. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fredlund E, Thim AM, Gidlund A, Brostedt S, Nyberg M, Olsen M (2009). Moulds and mycotoxins in rice from the Swedish retail market. Food Addit Contam, 26, 527–33. [DOI] [PubMed] [Google Scholar]

- Reddy KRN, Reddy CS, Muralidharan K (2009). Detection of Aspergillus spp. and aflatoxin B1 in rice in India. Food Microbiol, 26: 27–31. [DOI] [PubMed] [Google Scholar]

- Asghar MA, Iqbal J, Ahmed A, Shamsuddin ZA, Khan MA (2013). Incidence of aflatoxins in export quality basmati rice collected from different areas of Pakistan. Sci Tech Dev, 32: 110–119. [Google Scholar]

- Sorenson WG, Hesseltine CW, Shotwell OL (1967). Effect of temperature on production of aflatoxin on rice by Aspergillus flavus. Mycopathol, 33(1): 49–55. [Google Scholar]

- Taligoola HK, Ismail MA, Chebon SK (2004). Mycobiota Associated with Rice Grains Marketed in Uganda. J Biol Sci, 4: 271–8. [Google Scholar]

- Truckess MW (2005). Natural Toxins In: Official Methods of Analysis of AOAC International. Ed, Hortiz W, Latimer GW. Association of Official Analytical Chemists Publishers, 18th ed Washington DC, pp. 1–85. [Google Scholar]

- Schroeder HW, Hein HJR (1967). Aflatoxins: production of the toxins in vitro in relation to temperature. Appl Microbiol, 15(2): 441–5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Climatemps.com, Available from: http://www.pakistan.climatemps.com.

- Cotty PJ, Jaime-Garcia R (2007). Influences of climate on aflatoxin producing fungi and aflatoxin contamination. Int J Food Microbiol, 119: 109–15. [DOI] [PubMed] [Google Scholar]

- Saeed M (2006). The world Trade Review. Brown rice export from Pakistan to EU declines Available: http://www.worldtradereview.com/news.asp?pType=N&iType=A&iID=144&siD=20&nID=30453 [Google Scholar]

- Stössel P (1986). Aflatoxin contamination in soybeans: role of proteinase inhibitors, zinc availability, and seed coat integrity. Appl Environ Microbiol, 52: 68–72. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Food and Agriculture Organization (1983). Post harvest losses in quality of food grains. (FAO Food and Nutrition Paper, 29). [PubMed] [Google Scholar]

- Firdous S, Ejaz N, Aman T, Khan N (2012). Occurrence of aflatoxins in export-quality Pakistani rice. Food Addit Contam B, 5(2): 121–5. [DOI] [PubMed] [Google Scholar]

- Iqbal SZ, Asi MR, Ariño A, Akram N, Zuber M (2012). Aflatoxin contamination in different fractions of rice from Pakistan and estimation of dietary intakes. Mycotoxin Res, 28(3): 175–180. [DOI] [PubMed] [Google Scholar]

- Bandara JM, Vithanege AK, Bean GA (1991). Occurrence of aflatoxins in parboiled rice in Sri Lanka. Mycopathol, 116(2): 65–70. [DOI] [PubMed] [Google Scholar]

- Toteja GS, Mukherjee A, Diwakar S, Singh P, Saxena BN, Sinha KK, Sinha AK, Kumar N, Nagaraja KV, Bai G, Krishna Prasad CA, Vanchinathan S, Roy R, Sarkar S (2006). Aflatoxin B(1) contamination of parboiled rice samples collected from different states of India: A multi-centre study. Food Addit Contam, 23(4): 411–4. [DOI] [PubMed] [Google Scholar]

- Sales AC, Yoshizawa T (2005). Updated profile of aflatoxin and Aspergillus section Flavi contamination in rice and its byproducts from the Philippines. Food Addit Contam, 22(5): 429–36. [DOI] [PubMed] [Google Scholar]

- Feizy J, Beheshti HR, Fahim NK, Janati SSF, Davari G (2010). Survey of aflatoxins in rice from Iran using immunoaffinity column clean-up and HPLC with fluorescence detection. Food Addit Contam B, 3(4): 263–7. [DOI] [PubMed] [Google Scholar]

- Mazaheri M (2009). Determination of aflatoxins in imported rice to Iran. Food Chem Toxicol. 47(8): 2064–6. [DOI] [PubMed] [Google Scholar]

- Reiter EV, Vouk F, Böhm J, Razzazi-Fazeli E (2010). Aflatoxins in rice – A limited survey of products marketed in Austria. Food Cont, 21(7): 988–91. [Google Scholar]

- Nkama I, Nobbs JH, Muller HG (1987). Destruction of aflatoxinB1 in rice exposed to light. J Cereal Sci, 5(2): 167–73. [Google Scholar]

- Hussain A (2009). Reduction of Aflatoxin-B1 and Ochratoxin-A levels in Polished Basmati Rice (Oryza sativa Linn.) by Different Cooking Methods. J Chem Soc Pak, 31(6): 911–5. [Google Scholar]