Abstract

Purpose:

The aim of this study was to compare frictional forces between monocrystalline alumina (MA), polycrystalline alumina (PA), and stainless steel (SS) brackets with two SS wires: Rectangular and round.

Materials and Methods:

In this in vitro study, 60 0.022 brackets [20 PA (0° torque, Forestadent, Germany) and 20 MA (0° torque, Ormco, California, USA)] brackets plus 20 SS brackets (0° torque, Foretadent, Germany) and 60 SS archwires (30 rectangular 0.019 ×0.025 archwires and 30 round 0.018 archwires, Ortho Technology, USA) were used in subgroups of 10 from the combination of all brackets and all archwires. A universal testing machine (Instron, Model STM 250, Germany) was used to investigate the static frictional resistance. The angulation between the bracket and wire was 0°, and the wires were pulled through the slots at a crosshead speed of 10 mm/min. Two-way and one-way analyses of variance (ANOVA) and Tukey tests were used to analyze the data.

Results:

Mean (SD) static frictional force for each group was as follows: MA + round: 3.47 (0.38); MA + rectangular: 4.05 (0.47); PA + round: 4.14 (0.37); PA + rectangular: 4.45 (0.65); SS + round: 3.28 (0.22); and SS + rectangular: 4.22 (0.61). Significant effects of bracket types (P = 0.001) and archwire types (P = 0.000) on the friction force were detected using ANOVA. Tukey test indicated significant differences between PA brackets with both SS and MA brackets (P < 0.05), but not between SS and MA brackets. The two archwires as well had significantly different effects (Tukey P = 0.000).

Conclusions:

Based on the present in-vitro study, the PA brackets might create higher frictional forces compared to both SS and MA brackets. The rectangular 0.019 ×0.025 archwire might create greater forces than round 0.018 archwire.

Keywords: Artificial saliva, ceramic bracket, rectangular arch wire, round arch wire, stainless steel bracket, static friction

INTRODUCTION

Orthodontic tooth movement relies on sliding mechanics usually achieved by sliding the wire through the brackets.[1,2,3] Sliding causes friction, which is a force resisting the relative motion of two contacting objects.[2,4,5] Static frictional resistance exhausts up to 60% of the exerted force for the tooth movement.[2,3,4,5,6] Frictional resistance is undesirable in orthodontic tooth movement, as it might lock the bracket position and disallow tooth movement; in addition, it might bow the archwire and tilt the tooth, or lead to unwanted tooth movements or space losses through anchorage interference.[3,7,8,9,10] Therefore, variables that might increase the friction are of interest.

Stainless steel (SS) brackets are still the most useful brackets in orthodontic practice because of their superior working qualities. The only drawback of these brackets is their appearance.[11] Because of the growing number of adult patients, the esthetic aspect of orthodontic therapy is becoming increasingly important.[12] In an effort to overcome the esthetic problem of orthodontic appliances, ceramic brackets were manufactured in two forms: Polycrystalline alumina (PA) and monocrystalline alumina (MA). These are made of aluminum oxides, which have many advantages such as biocompatibility, good aesthetics, and resistance to temperature and chemical changes.[12] The most apparent difference between polycrystalline and monocrystalline brackets is in their optical clarity. Single crystal brackets are obviously clearer than polycrystalline brackets, which might be translucent and more esthetic.[12,13] Although these brackets have solved the problem of esthetic, they can cause enamel abrasion, fracture more easily and have a higher coefficient of friction, increasing resistance to sliding mechanics. Ceramic brackets have been found to produce significantly more friction than SS ones. Moreover, the efficacy of tooth movement using ceramic brackets is significantly lower than that of metal brackets.[3,7,14,15,16,17] Besides, despite their superior esthetics, monocrystalline brackets are suggested to create higher frictional forces than polycrystalline brackets do.[18,19]

A decrease in frictional resistance results in a better response of hard and soft tissues. Studies have shown that approximately 50% of force required for movement of the teeth is used to overcome the frictional force.[20] Factors that affect frictional resistance include type of the bracket, physical properties, size, and alloy of arch wires, saliva, angulation of the wire to the bracket, method of ligation, contact angles, size and design of bracket slot, and the method of wire-bracket ligation.[3,7,17,21,22,23,27,25,26,27] Many studies have compared the frictional resistance of different brackets but studies on friction of newly introduced ceramic brackets are controversial.[12,28,29,30] Moreover, archwires as well should have a low friction,[31] which necessitates the need to assess the frictional force of different archwires.

The aim of this in vitro study was to evaluate frictional forces produced by three types of brackets combined with two common SS wires. The null hypotheses were that there would be no difference between the frictional forces of the brackets as well as between the frictional resistances of the two archwires.

MATERIALS AND METHODS

This in vitro experimental study was performed on 60 Roth 22 prescription 0.022” slot lower incisor brackets and 60 archwires. The brackets were divided into three groups of n = 20, each: Two ceramic brackets: MA (0° torque, Ormco, California, USA) and PA (0° torque, Forestadent, Germany) and one SS metal bracket (0° torque, Foretadent, Germany). The archwires were two groups of n = 30 each: both SS wires, rectangular (0.019” ×0.025”) and round (0.018”) (Ortho Technology, USA).

All the brackets were immersed in artificial saliva (Bioxtra, Belgium) for 5 min to simulate oral conditions.[30]

In order to stabilize each bracket in a standard vertical position during frictional tests, the bonding surface of each saliva-soaked bracket was glued to a metal surface, which would act as a base for the bracket-wire setup in the next steps. After fixing the brackets on metal bases, the wires were secured into the bracket slots by elastomeric O-rings (Ortho Technology, USA).

Bracket-wire combinations were divided into six subgroups (n = 10) of three bracket types and two wire types:

MA + round wire

MA + rectangular wire

PA + round wire

PA + rectangular wire

SS + round wire

SS + rectangular wire.

Measurement of Frictional Forces

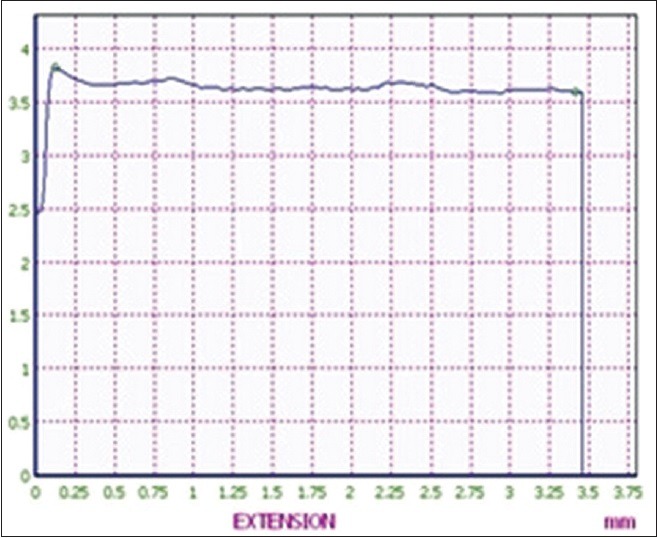

A universal testing machine (Instron, Model STM 250, Germany) with a maximum load of 50 kg was used to measure frictional forces. The metal base was adapted to the testing machine, and the wires were pulled through the slots at a speed of 10 mm/min while the angulation between the bracket and wire was 0°. The test was repeated 10 times for the 10 specimens in each subgroup. Based on the diagram obtained from the movement of the wire into the bracket, the average of the highest recorded force was considered as the static friction [Figure 1].

Figure 1.

The diagram obtained from the movement of the wire into the bracket

Statistical Analysis

Descriptive statistics were calculated for the groups. According to the Kolmogorov-Smirnov test, all groups were normally distributed. One-way and two-way analyses of variance (ANOVA) and Tukey post hoc test of SPSS (version 20, IBM, USA) were used to evaluate the results. The significance level was predetermined as 0.05.

RESULTS

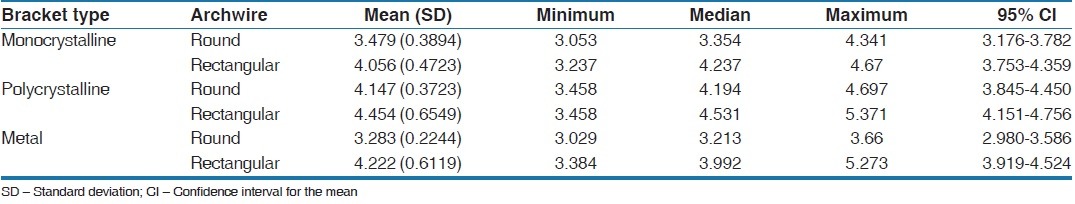

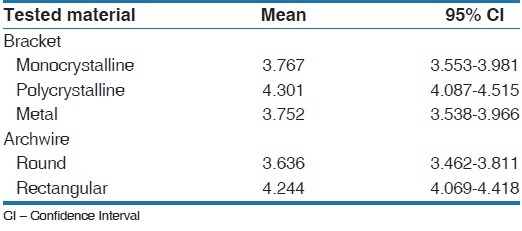

The lowest mean frictional forces with round wire belonged to the SS bracket, and then polycrystalline and monocrystalline bracket. The highest mean frictional forces recorded with rectangular wire belonged to the polycrystalline, and then SS and monocrystalline brackets [Table 1].

Table 1.

Descriptive statistics for groups

The null hypotheses were rejected. Two-way ANOVA indicated significant effects of bracket types (P = 0.001) and archwire types (P = 0.000) on the friction force. The interaction was nonsignificant [P = 0.120, Table 1].

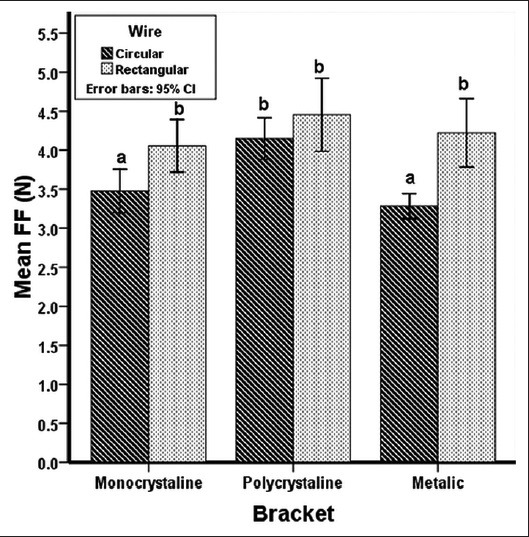

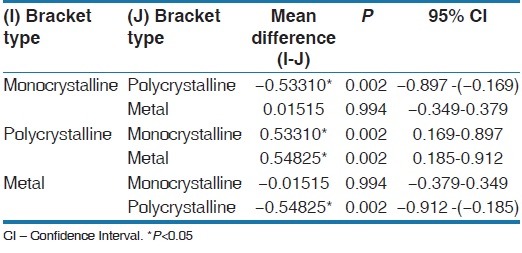

The Tukey post-hoc test indicated significant differences between polycrystalline brackets with both metal and monocrystalline brackets, but not between metal and monocrystalline brackets [Figure 2, Tables 2 and 3]. The two archwires as well had significantly different effects [Tukey P = 0.000, Table 3].

Figure 2.

Comparison of frictional forces between the brackets and wires. Different letters indicate statistically significant differences (P < 0.05) between the groups

Table 2.

Results of Tukey post hoc test, comparing friction in bracket types

Table 3.

Descriptive statistics for friction caused by archwires and brackets

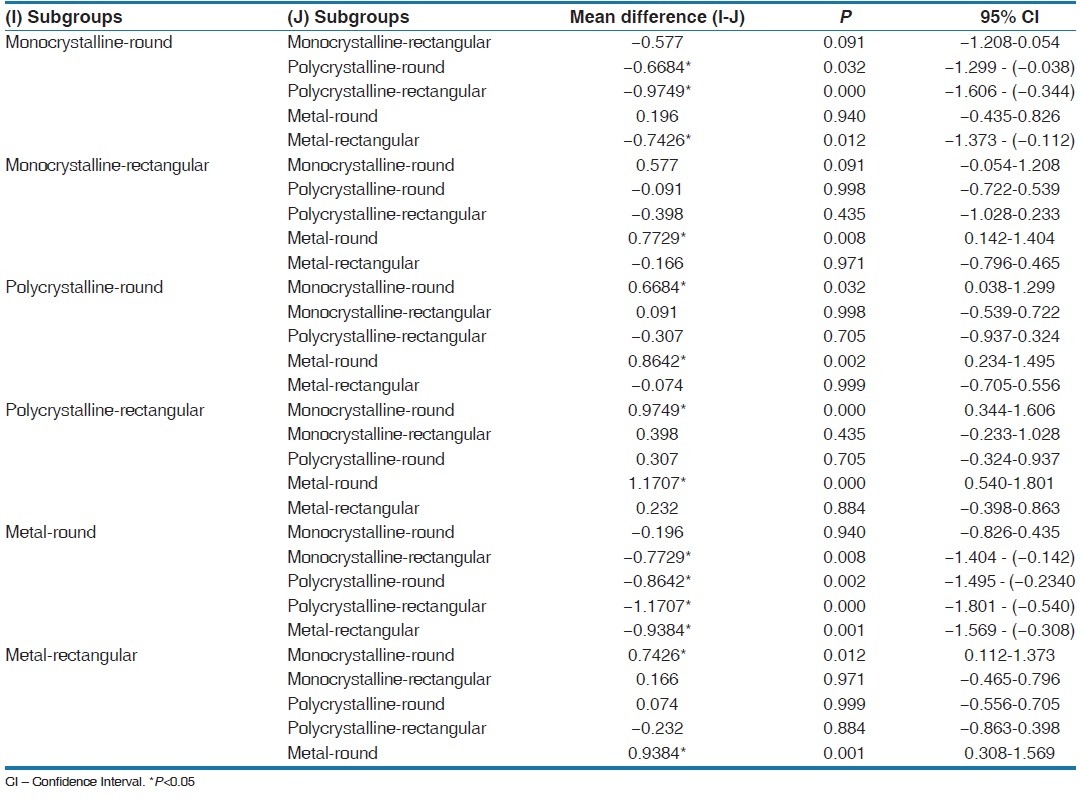

One-way ANOVA indicated an overall statistically significant difference between subgroups (P = 0.000). The Tukey test showed the fewest significant differences between monocrystalline-rectangular and all other subgroups while the metal-round subgroup showed the greatest number of significant differences with other subgroups [Table 4].

Table 4.

Pairwise comparisons between subgroups, using Tukey test

DISCUSSION

The present study compared frictional forces between two ceramic brackets and one SS bracket with two different sizes and shapes of SS wires. In this study, friction produced by polycrystalline bracket was higher than that produced by monocrystalline which had a frictional resistance similar to SS bracket, supporting some previous studies[32] and contrasting some others stating that monocrystalline might generate greater frictional.[18,19] The results of this study regarding the higher frictional forces produced by PA compared to MA and SS brackets were in contrast to those of Cha et al.,[33] in which the difference between PA and MA was not significant and friction in polycrystalline brackets was lower than SS brackets.[33] Similarly, De Franco et al.[28] reported that the frictional force between mono- and polycrystalline brackets were the same, which contrasted our results. As well, Saunders and Kusy[29] did not show any differences in frictional force between mono- and polycrystalline brackets. Guerrero et al.[30] showed that the highest frictional force was produced by monocrystalline bracket (Inspire) with 0.019" ×0.025" SS wire, and the lowest one was produced with SS bracket and SS wire (0.019" ×0.025"). Several factors such as different bracket and wire brands, different methods of manufacturing the brackets, different intersections of the base and walls of the slot, and the kind of artificial saliva used in the experiment might explain the differences. The metal slot has a smoother surface than ceramic and therefore it will create less frictional resistance to sliding. This agrees with many previous investigations that have shown frictional resistance was reduced by lining the slots of conventional ceramic brackets with SS inserts.[3,34,35,36,37]

In general, increasing the size of the bracket and using rectangular wire instead of round wire can increase friction. In addition, in some cases when there is bracket-wire angulation and binding, the friction in round wire may be greater than that in rectangular wire. The reason can be the bite into the round wire at one point, including an indentation in the wire. However, with a rectangular wire, the force is distributed over a larger area, resulting in less pressure and, therefore, less resistance to movement.[38] Friction in rectangular wire used in this study was more than that in round wire. The difference was significant except in polycrystalline bracket, resembling previous studies.[32] However, it should be noted that the wires were different not only in shape but also in the size of their cross-section, which disallows making strong conclusions regarding the wire type.[3]

In interpreting the findings of the study the limitations of the in-vitro studies should be considered. In the present study, artificial saliva was used to simulate the oral condition. Lubricants depending on the alloy type have different effects.[29] In SS alloys, lubricants react with the chromium oxide layer, which provides the wire with a lower coefficient of friction, changing their surface tension and producing an adhesive effect.[28] The important point in simulating is to choose a material with the same viscosity as that of natural saliva. Human saliva might lead to higher frictional forces than forces produced in artificial saliva but close to frictional forces measured in dry condition.[39] Artificial saliva might have a lower viscosity and a higher wettability than natural saliva.[39] However, salivary lubrication might have an inconsistent and controversial effect such as being invalid (if artificial saliva is used), increasing the friction, or playing an insignificant role.[3,14,21,40,41,42]

CONCLUSIONS

Within the limitations of this in vitro study, it was concluded that polycrystalline brackets might create higher frictional forces compared to both SS and monocrystalline brackets.

The rectangular (0.019" × 0.025") archwire can create greater frictional forces compared to the round (0.018") wire.

The rectangular wire combined with polycrystalline bracket had the highest frictional force. SS bracket combined with round wire produced the lowest frictional resistance.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

REFERENCES

- 1.Hosseinzadeh Nik T, Hooshmand T, Farazdaghi H, Mehrabi A, Razavi ES. Effect of chlorhexidine-containing prophylactic agent on the surface characterization and frictional resistance between orthodontic brackets and archwires: An in vitro study. Prog Orthod. 2013;14:48. doi: 10.1186/2196-1042-14-48. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Nanda R. Biomechanics in Clinical Orthodontics. Philadelphia: WB Saunders; 1997. pp. 50–1. [Google Scholar]

- 3.Williams CL, Khalaf K. Frictional resistance of three types of ceramic brackets. J Oral Maxillofac Res. 2013;4:e3. doi: 10.5037/jomr.2013.4403. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Hain M, Dhopatkar A, Rock P. The effect of ligation method on friction in sliding mechanics. Am J Orthod Dentofacial Orthop. 2003;123:416–22. doi: 10.1067/mod.2003.14. [DOI] [PubMed] [Google Scholar]

- 5.Tecco S, Festa F, Caputi S, Traini T, Di Iorio D, D’Attilio M. Friction of conventional and self-ligating brackets using a 10 bracket model. Angle Orthod. 2005;75:1041–5. doi: 10.1043/0003-3219(2005)75[1041:FOCASB]2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 6.Drescher D, Bourauel C, Schumacher HA. Frictional forces between bracket and arch wire. Am J Orthod Dentofacial Orthop. 1989;96:397–404. doi: 10.1016/0889-5406(89)90324-7. [DOI] [PubMed] [Google Scholar]

- 7.Omana HM, Moore RN, Bagby MD. Frictional properties of metal and ceramic brackets. J Clin Orthod. 1992;26:425–32. [PubMed] [Google Scholar]

- 8.Nicolls J. Frictional forces in fixed orthodontic appliances. Dent Pract Dent Rec. 1968;18:362–6. [PubMed] [Google Scholar]

- 9.Kapila S, Angolkar PV, Duncanson MG, Jr, Nanda RS. Evaluation of friction between edgewise stainless steel brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop. 1990;98:117–26. doi: 10.1016/0889-5406(90)70005-W. [DOI] [PubMed] [Google Scholar]

- 10.Huffman DJ, Way DC. A clinical evaluation of tooth movement along arch wires of two different sizes. Am J Orthod. 1983;83:453–9. [PubMed] [Google Scholar]

- 11.Nishio C, da Motta AF, Elias CN, Mucha JN. In vitro evaluation of frictional forces between archwires and ceramic brackets. Am J Orthod Dentofacial Orthop. 2004;125:56–64. doi: 10.1016/j.ajodo.2003.01.005. [DOI] [PubMed] [Google Scholar]

- 12.Eslamian L, Borzabadi-Farahani A, Mousavi N, Ghasemi A. A comparative study of shear bond strength between metal and ceramic brackets and artificially aged composite restorations using different surface treatments. Eur J Orthod. 2012;34:610–7. doi: 10.1093/ejo/cjr044. [DOI] [PubMed] [Google Scholar]

- 13.Swartz ML. Ceramic brackets. J Clin Orthod. 1988;22:82–8. [PubMed] [Google Scholar]

- 14.Kusy RP, Whitley JQ. Coefficients of friction for arch wires in stainless steel and polycrystalline alumina bracket slots. I. The dry state. Am J Orthod Dentofacial Orthop. 1990;98:300–12. doi: 10.1016/S0889-5406(05)81487-8. [DOI] [PubMed] [Google Scholar]

- 15.Tanne K, Matsubara S, Shibaguchi T, Sakuda M. Wire friction from ceramic brackets during simulated canine retraction. Angle Orthod. 1991;61:285–90. doi: 10.1043/0003-3219(1991)061<0285:WFFCBD>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 16.Ghafari J. Problems associated with ceramic brackets suggest limiting use to selected teeth. Angle Orthod. 1992;62:145–52. doi: 10.1043/0003-3219(1992)062<0145:PAWCBS>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 17.Keith O, Jones SP, Davies EH. The influence of bracket material, ligation force and wear on frictional resistance of orthodontic brackets. Br J Orthod. 1993;20:109–15. doi: 10.1179/bjo.20.2.109. [DOI] [PubMed] [Google Scholar]

- 18.Karamouzos A, Athanasiou AE, Papadopoulos MA. Clinical characteristics and properties of ceramic brackets: A comprehensive review. Am J Orthod Dentofacial Orthop. 1997;112:34–40. doi: 10.1016/s0889-5406(97)70271-3. [DOI] [PubMed] [Google Scholar]

- 19.Kusy RP, Whitley JQ. Friction between different wire-bracket configurations and materials. Semin Orthod. 1997;3:166–77. doi: 10.1016/s1073-8746(97)80067-9. [DOI] [PubMed] [Google Scholar]

- 20.Ehsani S, Mandich MA, El-Bialy TH, Flores-Mir C. Frictional resistance in self-ligating orthodontic brackets and conventionally ligated brackets. A systematic review. Angle Orthod. 2009;79:592–601. doi: 10.2319/060208-288.1. [DOI] [PubMed] [Google Scholar]

- 21.Read-Ward GE, Jones SP, Davies EH. A comparison of self-ligating and conventional orthodontic bracket systems. Br J Orthod. 1997;24:309–17. doi: 10.1093/ortho/24.4.309. [DOI] [PubMed] [Google Scholar]

- 22.Pizzoni L, Ravnholt G, Melsen B. Frictional forces related to self-ligating brackets. Eur J Orthod. 1998;20:283–91. doi: 10.1093/ejo/20.3.283. [DOI] [PubMed] [Google Scholar]

- 23.Schumacher HA, Bourauel C, Drescher D. The effect of the ligature on the friction between bracket and arch. Fortschr Kieferorthop. 1990;51:106–16. doi: 10.1007/BF02164848. [DOI] [PubMed] [Google Scholar]

- 24.Henao SP, Kusy RP. Frictional evaluations of dental typodont models using four self-ligating designs and a conventional design. Angle Orthod. 2005;75:75–85. doi: 10.1043/0003-3219(2005)075<0075:FEODTM>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 25.Thomas S, Sherriff M, Birnie D. A comparative in vitro study of the frictional characteristics of two types of self-ligating brackets and two types of pre-adjusted edgewise brackets tied with elastomeric ligatures. Eur J Orthod. 1998;20:589–96. doi: 10.1093/ejo/20.5.589. [DOI] [PubMed] [Google Scholar]

- 26.Lombardo L, Wierusz W, Toscano D, Lapenta R, Kaplan A, Siciliani G. Frictional resistance exerted by different lingual and labial brackets: an in vitro study. Prog Orthod. 2013;14:37. doi: 10.1186/2196-1042-14-37. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Nucera R, Lo Giudice A, Matarese G, Artemisia A, Bramanti E, Crupi P, et al. Analysis of the characteristics of slot design affecting resistance to sliding during active archwire configurations. Prog Orthod. 2013;14:35. doi: 10.1186/2196-1042-14-35. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.De Franco DJ, Spiller RE, Jr, von Fraunhofer JA. Frictional resistances using Teflon-coated ligatures with various bracket-archwire combinations. Angle Orthod. 1995;65:63–72. doi: 10.1043/0003-3219(1995)065<0063:FRUTLW>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 29.Saunders CR, Kusy RP. Surface topography and frictional characteristics of ceramic brackets. Am J Orthod Dentofacial Orthop. 1994;106:76–87. doi: 10.1016/S0889-5406(94)70024-9. [DOI] [PubMed] [Google Scholar]

- 30.Guerrero AP, Guariza Filho O, Tanaka O, Camargo ES, Vieira S. Evaluation of frictional forces between ceramic brackets and archwires of different alloys compared with metal brackets. Braz Oral Res. 2010;24:40–5. doi: 10.1590/s1806-83242010000100007. [DOI] [PubMed] [Google Scholar]

- 31.Chng CK, Foong K, Gandedkar NH, Chan YH, Chew CL. A new esthetic fiber-reinforced polymer composite resin archwire: A comparative atomic force microscope (AFM) and field-emission scanning electron microscope (FESEM) study. Prog Orthod. 2014;15:39. doi: 10.1186/s40510-014-0039-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Bazakidov E. [Thesis]: University of Oklahoma. 1995. Evaluation of frictional resistance of esthetic brackets. [Google Scholar]

- 33.Cha JY, Kim KS, Hwang CJ. Friction of conventional and silica-insert ceramic brackets in various bracket-wire combinations. Angle Orthod. 2007;77:100–7. doi: 10.2319/092705-333R.1. [DOI] [PubMed] [Google Scholar]

- 34.Cacciafesta V, Sfondrini MF, Scribante A, Klersy C, Auricchio F. Evaluation of friction of conventional and metal-insert ceramic brackets in various bracket-archwire combinations. Am J Orthod Dentofacial Orthop. 2003;124:403–9. doi: 10.1016/s0889-5406(03)00501-8. [DOI] [PubMed] [Google Scholar]

- 35.Kapur Wadhwa R, Kwon HK, Close JM. Frictional resistances of different bracket-wire combinations. Aust Orthod J. 2004;20:25–30. [PubMed] [Google Scholar]

- 36.Jones SP, Amoah KG. Static frictional resistances of polycrystalline ceramic brackets with conventional slots, glazed slots and metal slot inserts. Aust Orthod J. 2007;23:36–40. [PubMed] [Google Scholar]

- 37.Rajakulendran J, Jones S. Static frictional resistances of polycrystalline ceramic brackets with metal slot inserts. Aust Orthod J. 2006;22:147–52. [PubMed] [Google Scholar]

- 38.Kusy RP, Whitley JQ, Prewitt MJ. Comparison of the frictional coefficients for selected archwire-bracket slot combinations in the dry and wet states. Angle Orthod. 1991;61:293–302. doi: 10.1043/0003-3219(1991)061<0293:COTFCF>2.0.CO;2. [DOI] [PubMed] [Google Scholar]

- 39.Al-Mansouri N, Palmer G, Moles DR, Jones SP. The effects of lubrication on the static frictional resistance of orthodontic brackets. Aust Orthod J. 2011;27:132–8. [PubMed] [Google Scholar]

- 40.Kusy R, Saunders C. Surface textures and frictional characteristics of ceramic brackets. J Dent Res. 1991;70:483. doi: 10.1016/S0889-5406(94)70024-9. [DOI] [PubMed] [Google Scholar]

- 41.Downing A, McCabe JF, Gordon PH. The effect of artificial saliva on the frictional forces between orthodontic brackets and archwires. Br J Orthod. 1995;22:41–6. doi: 10.1179/bjo.22.1.41. [DOI] [PubMed] [Google Scholar]

- 42.Andreasen GF, Quevedo FR. Evaluation of friction forces in the 0.022×0.028 edgewise bracket in vitro. J Biomech. 1970;3:151–60. doi: 10.1016/0021-9290(70)90002-3. [DOI] [PubMed] [Google Scholar]