Abstract

Limitations of current treatment options for critical size bone defects create a significant clinical need for tissue engineered bone strategies. This review describes how control over the spatiotemporal delivery of growth factors, nucleic acids, and drugs and small molecules may aid in recapitulating signals present in bone development and healing, regenerating interfaces of bone with other connective tissues, and enhancing vascularization of tissue engineered bone. State-of-the-art technologies used to create spatially controlled patterns of bioactive factors on the surfaces of materials, to build up 3D materials with patterns of signal presentation within their bulk, and to pattern bioactive factor delivery after scaffold fabrication are presented, highlighting their applications in bone tissue engineering. As these techniques improve in areas such as spatial resolution and speed of patterning, they will continue to grow in value as model systems for understanding cell responses to spatially regulated bioactive factor signal presentation in vitro, and as strategies to investigate the capacity of the defined spatial arrangement of these signals to drive bone regeneration in vivo.

1. Need for bone tissue engineering

Over two million bone grafts are performed each year, at a cost of over $2.5 billion [1]. These procedures are used to heal acute injuries such as non-union fractures, critical size defects caused by injury or tumor resection, as well as chronic conditions such as congenital malformations. Treating these defects in the craniofacial region and extremities is important as bone serves as mechanical support, sites of muscle attachment, a barrier to protect vital organs, a framework for bone marrow, and a reservoir for ions [2]. Despite bone’s capacity for self-repair, existing treatments for large defects or non-union fractures all show limited success and/or are associated with complications [3]. For example, the utility of autografts, the gold standard for treatment, is limited by the supply of healthy tissue to graft as well as donor site morbidity, and alternatives such as allografts carry the risk of immune rejection or disease transmission [4]. Distraction osteogenesis comes with problems including prolonged treatment time, pain to the patient and potential infections at the pin sites [3]. Synthetic materials that simply act as void fillers may have limited integration with host tissue, and can exhibit minimal resorption, which inhibits replacement by new healthy bone tissue [4]. The limitations of these current treatments motivate bone regeneration using tissue engineering. Bone tissue engineering typically involves presenting physical and/or biochemical signals to transplanted or host cells which are capable of then responding to these signals, and forming new, functional bone tissue that can integrate with surrounding host tissue. Biochemical signals can be in the form of soluble bioactive factors, such as growth factors, genetic material, and drugs and small molecules, and they can be delivered to cells from a variety of biomaterials, with both temporal and spatial control.

Bone has been a tissue of much research and clinical interest since the early days of tissue engineering [5, 6]. Researchers worked to understand how to leverage bone’s capacity for self-repair of smaller defects when designing systems to heal larger ones. It quickly became apparent that it would be valuable to harness biochemical signaling molecules present during natural bone healing, either by delivering these molecules themselves or other factors that can drive bone regeneration. For example, bone morphogenetic proteins (BMPs) released from collagen sponges have been used for clinical treatment of femur and tibia fracture non-unions [7-9] and spinal fusions [10-12]. While these sponges have demonstrated success in their approved applications, the systems provide minimal control over the growth factor release in time and space, and the surrounding tissue is exposed to much higher BMP concentrations than present during natural healing [13, 14]. As a result, these systems have led to vertebral body bone resorption [15], and swelling that causes significant side effects when used in the anterior cervical spine [16]. These limitations inspired the development of systems to better control the delivery of bioactive factors in time and space. A number of excellent papers review progress in the controlled delivery of bioactive factors for bone regeneration, predominantly describing accomplishments in temporal control of their release profiles [17-19]. Recently, a great deal of exciting new research has been performed to develop systems that are not only capable of temporal control, but also able to spatially direct the presentation of desired bioactive factors. This review focuses on thoroughly exploring strategies for the controlled spatial presentation of therapeutic molecules for tissue engineering, with an emphasis on bone regeneration.

2. Motivation for spatial control of bioactive factor delivery

While most early bioactive factor delivery work was done from homogeneous, bulk materials [20], recent research has focused on tailoring the spatiotemporal presentation of these factors. Temporal control is advantageous to allow the bioactive factor to be released over the time course necessary to achieve the desired cellular responses without the need for repeated dosing. Some efforts have been made to recapitulate the timing of signal presentation to match that of bone development and healing [17, 21]. Similarly, during these processes cellular gene expression and extracellular matrix production are all tightly controlled in space [22], motivating the development of scaffolds with control over spatial presentation of bioactive factors that direct these behaviors.

2.1 Recapitulating bone development and healing

Microenvironmental signals presented during bone development and healing, including soluble factors, are highly regulated, motivating the control of bioactive factor presentation in biomimetic approaches for bone tissue engineering. Efforts to regenerate bone tissue often seek to recapitulate one of the two main pathways for bone development: intramembranous ossification or endochondral ossification [23]. In intramembranous ossification, mesenchymal stem cells (MSCs) respond to a growth-factor laden microenvironment and some differentiate directly into osteoblasts, or bone-building cells, laying down randomly oriented bone matrix that is later remodeled to form mature bone [24]. In contrast, during endochondral ossification, bone is laid down following development of a cartilage template [25]. Here, MSCs differentiate into chondrocytes that hypertrophy, calcify their extracellular matrix (ECM), and secrete specific matrix metalloproteases and growth factors triggering vascular invasion; this brings progenitor cells that can become osteoblasts, again to form immature bone tissue that will be remodeled over time [26]. Bone tissue engineering efforts have attempted to recapitulate both intramembranous and endochondral ossification, but the bioactive factors used and their spatiotemporal distribution will depend on which process is being pursued to drive bone formation.

Since bone maintains a unique capacity for self-repair of small defects throughout life [27], this healing process can also serve as a roadmap for bone regeneration by tissue engineering. Briefly, an acute inflammatory response occurs as a reaction to a bone fracture, with a hematoma, or localized collection of blood at the injury site, bringing immune cells that secrete highly regulated pro-inflammatory cytokines, fibroblasts that form granulation tissue, and growth factors and progenitor cells that will participate in the repair. This acute inflammation peaks at 24 hours after injury, and is complete within 7 days [28]. Growth factors produced by cells at the fracture site, including stromal-derived growth factor-1 (SDF-1) and vascular endothelial growth factor (VEGF), are key for recruiting MSCs and inducing vascular formation at the location of injury. These cells then differentiate into osteoblasts to form a bony collar around the fracture site, and into chondrocytes which deposit cartilaginous matrix in the interior, also under the influence of growth factors, especially the transforming growth factor-β (TGF-β) superfamily which includes the BMPs [29]. As the cartilaginous template is replaced by a mineralized bone matrix, vascular morphogenetic proteins, especially VEGF and angiopoietins, are responsible for regulating neoangiogenesis to provide a vascular supply to the newly formed bone [30]. After a structure of immature woven bone is formed to bridge the fracture gap, it is remodeled by the same process used to maintain all bones in the body to achieve the architecture and biomechanical properties of mature lamellar bone. Similar to bone development, this process is regulated by growth factors with very controlled spatiotemporal presentation [27], and some excellent reviews describe it in detail [27, 31-33]. These bioactive factors can be presented from tissue engineering scaffolds in biomimetic approaches to tissue regeneration aimed at recapitulating the native presentation of these signals to cells in both time and space [34].

2.2. Bone interfaces

Another biological motivation for creating bone tissue engineering scaffolds with spatially controlled presentation of bioactive factors is the presence of interfaces between bone and other tissues, including cartilage, ligament and tendon. Given the importance of bone’s connections to its associated musculoskeletal connective tissues for restoring movement, when these interfaces are damaged, their repair is essential to the success of tissue engineered bone. At bone transitions to the aforementioned other tissues, calcified cartilage or fibrocartilage interface directly with the bone [35]. In vivo, these interfaces are not discrete zones with sharp transitions in properties, but instead composed of physical and biochemical gradients. ECM molecule, growth factor and cell type, composition and organization, as well as mechanical properties, all shift gradually between the different tissues [36]. Notably, the presence of mechanical property gradients facilitates continuous load transfer between two different tissue types [36]. Recapitulating such gradients of bioactive factors in scaffolds for bone tissue engineering may influence cell phenotype, which can in turn affect their differentiation state and ECM production and organization. These changes may then lead to differences in resultant tissue mechanical properties, mimicking those seen in vivo. Biomimetic approaches aimed at recreating these transitions zones can utilize spatially restricted bioactive factor presentation from biomaterials, often in addition to spatial variation in scaffold physical parameters such as stiffness and porosity [37, 38].

2.3 Vascularization

Vascularization is not only important for bringing oxygen and nutrients and removing waste products from adult bone, but is also essential to regulation of bone development and remodeling bone development [22, 39]. In fact, bone formation is impaired in mice lacking VEGF, a key vasculogenic signaling molecule [40]. In regenerating bone, osteoblasts produce VEGF, among other factors, to induce local angiogenesis [41], but this growth factor also promotes differentiation of progenitor cells into osteoblasts [42]. Similarly, smooth muscle and endothelial cells produce growth factors during bone formation, including BMP-2 and platelet-derived growth factor (PDGF), to enhance osteogenic differentiation of osteoblast progenitors and mineralization by mature osteoblasts [43-45]. Because the location of cells that secrete these growth factors is tightly regulated in vivo [22], it may be desirable to develop biomaterial systems to control the delivery of bioactive factors in space, specifically providing local angiogenic signals to encourage vascular development alongside osteogenesis. Early work has shown that combined delivery of BMP-2 and VEGF led to improved osteogenesis by human MSCs (hMSCs) in an ectopic mouse model [46]. Other studies also support dual delivery of BMPs and VEGF for enhancing osteogenesis, but addition of VEGF did not lead to enhanced vascular networks compared to BMP-2 alone [47-49]. However, a combination of growth factors uniformly distributed throughout a scaffold may not be ideal for vascularized bone tissue engineering. Systems allowing spatiotemporally controlled delivery of multiple factors could segregate the osteogenic from the angiogenic signals, potentially resulting in improved vasculature in engineered bone.

3. Important Bioactive Factors for Bone Tissue Engineering

Bone tissue engineering is a broad field: in addition to a variety of cell types and biomaterial scaffolds explored, a large number of technologies have been developed to deliver bioactive factors including growth factors, genetic material, and drugs or small molecules. Understanding the structure and function of these factors is important in engineering the systems for their delivery.

3.1 Growth factors

Growth factors are soluble signaling proteins secreted by cells to induce specific biological responses such as cell survival, migration, differentiation and proliferation [50]. They act by binding to cell surface receptors, and the complex may or may not be internalized by the cell. The binding event can affect gene expression when, for example, the receptor is then phosphorylated which induces receptor conformational changes that sets off signaling cascades within the cell [51]. Alternatively, internalized growth factor-receptor complexes can go on to phosphorylate intracellular signal transduction proteins, including transcription factors that when activated can translocate to the nucleus and regulate gene activation [52] . Growth factor production follows a distinct time course throughout osteoprogenitor cell differentiation and maturation [53]. These growth factors tend to diffuse only short distances through the ECM, and act on cells near the site of their production. They are subject to proteolytic degradation, and the half-life for their biological activity is on the order of hours [54]. Additionally, they only act on cells expressing their receptors, which are highly regulated in vivo, allowing for additional specificity in their biological effects [55, 56]. As an example, one growth factor, fibroblast growth factor-2 (FGF-2), causes MSCs in various states of differentiation to upregulate other growth factors, but the magnitude of the effect and the relative increases in expression are dependent on the cell differentiation state [57].

While the BMPs have been most frequently used in bone tissue engineering, the range of growth factors used, alone and in various combinations, is extensive. These include BMP-2, BMP-4, BMP-7, FGF-2, TGF-β1, TGF-β2, TGF-β3, VEGF, insulin-like growth factor (IGF-1), PDGF and SDF-1 [58, 59]. While these growth factors are found at very low concentrations at fracture sites, on the order of pg/mL to single digit ng/mL [60], current clinical therapies often require much greater quantities of growth factor to positively impact bone formation: for example, Osigraft® contains 3.5 mg of BMP-7 per package, with some surgeons using more than one package to treat a bone defect [61]. To produce these large quantities of growth factor for laboratory research and clinical applications, recombinant DNA technology permits the synthesis of human growth factors in hosts including bacteria and mammalian cell lines. These recombinant human growth factors have been safely used in patients for decades [62]. However, synthesizing growth factors in quantities sufficient for clinical use comes at high cost: a 2008 study found that when the BMP-7 system described above was used to treat tibial fractures, the cost of the growth factor alone was £3000 (~$6000) [63]. New production techniques have the potential to reduce the cost of recombinant human growth factors, which could facilitate more clinical translation [64]. Another alternative is synthetic peptides that mimic growth factor activity. These shorter peptide sequences still activate the growth factor receptors, but are smaller molecules that can easily be modified with chemical groups to control their presentation. A number of BMP-2 mimicking peptide sequences have been used to stimulate osteogenic behavior in vitro [65, 66] and in vivo [65, 67, 68]. Peptide sequences that mimic other growth factors important for bone formation, such as analogues for FGF-2 [69] and VEGF [70], have also been identified and shown to have bioactivity.

Sustained presentation of BMP-2, the growth factor most often used for bone regeneration, is important: in vivo delivery of the growth factor over four weeks led to significantly improved ectopic bone formation compared to burst release of the same amount of BMP-2 [71]. This effect is likely because the BMP-2 presentation more closely mimics the signaling cascade after a bone fracture: osteoprogenitor cells upregulate BMP-2 expression for approximately 21 days at the site of injury [32]. More recently, work has been done studying the combinatorial effects of growth factors and the time course of their presentation. In one case, BMP-2 and IGF-1 delivered together did not lead to osteogenic differentiation of mouse pluripotent stem cells, but early delivery of BMP-2 alone followed by increased release of both growth factors led to matrix mineralization [72]. Research has also demonstrated that growth factor-induced blood vessel formation may also benefit from controlled release. For example, in one study early release of a vasculogenic growth factor combined with a more sustained presentation of an osteogenic growth factor improved in vivo ectopic bone formation [73]. In contrast, others reported that osteogenic growth factor release kinetics was critical to ectopic bone formation, and the timing of vasculogenic growth factor presentation was less important [74]. These discrepancies warrant further investigation, which can be undertaken with the many synthetic and natural polymers, as well as ceramics, that have been explored as carrier materials for growth factor delivery in bone engineering systems [18]. Past work on temporal control of the delivery of these growth factors for bone regeneration has been previously described in several thorough reviews [17, 18, 59, 75, 76].

3.2 Genetic material

Delivery of genetic material provides a potential alternative to delivery of growth factors; nucleic acids, including DNA and RNA, can induce changes in gene expression at the transcriptional or post-transcriptional levels. Since there is now a strong understanding of the processes of bone development and repair, there exist known candidate genes that can be used to stimulate bone regeneration or inhibit antagonistic pathways [77]. Genetic material affecting these processes has been studied extensively in 2D cell culture experiments and incorporated into 3D biomaterial scaffolds [78-80].

DNA can encode the same growth factors described in the preceding section. Targeted cells can take up the delivered DNA and then express proteins that may aid in healing a defect. Modifying gene expression eliminates some concerns associated with delivering high concentrations of recombinant human growth factors: the cost and risk of unwanted physiological reactions are decreased because large quantities of expensive proteins are not required, cells continue to produce the growth factor so there is no concern of loss of bioactivity over time, and post-translational modifications are performed by host cells reducing the risk of an immune response to the proteins [79].

DNA that is intended to encode for new protein production must first enter the cell and then reach the nucleus. This can be accomplished using viral or non-viral approaches [81]. As a whole, viral vectors are known for their high transduction efficiency but also potential antigenicity. Since they do not require carriers for their uptake, viral vectors encoding BMP-2 have been injected directly into bone defects [82] or adsorbed onto the surface of polymer scaffolds implanted into bone defects [83] and shown to improve bone healing. Viral vectors differ in their size, cytotoxicity, whether or not they require dividing cells and whether they lead to integration of their cargo into host cell DNA. A thorough review summarizes the advantages and disadvantages of viral vectors that have been used to carry genes for bone regeneration [84]. Once the bone regeneration process is complete, it is usually undesirable for the genes of interest to have permanently integrated into the host genome, as occurs with retroviral and lentiviral vectors [81, 85]. As a result, though they can result in an immune response, recombinant adenoviruses have been the most frequently used viral vectors in bone engineering, as they can be cleared from the body instead of integrating into the genome [79]. Non-viral delivery systems can address some of the drawbacks of viral delivery: they show decreased immunogenicity, and improved safety due to transient effects on gene expression [86]. However, the key challenge of non-viral delivery is that plasmid DNA (pDNA) is a large and negatively charged macromolecule with limited ability to penetrate the negatively charged cell membrane on its own [87]. To overcome this issue, pDNA is typically complexed with cationic lipids or polymers into nanoparticles. These carriers can protect the pDNA from enzymes such as DNAses, and facilitate endocytosis so the pDNA can enter the cell and achieve gene expression [88]. Though much early work utilized polyethyleneimene (PEI) [89] or cationic lipids [90] to complex with DNA to promote entry into the cell, researchers today are developing other synthetic polymers that can be used as non-viral gene carriers to avoid potential cytotoxicity, and are additionally functionalized to improve targeting to the cell population of interest [88]. An alternative to DNA sequences that must enter the nucleus and be transcribed, antisense oligonucleotides are short, single strands of DNA that can pair with complementary mRNA and inhibit its translation [91]. Target sequences have been identified to regulate diverse and clinically relevant functions such as multipotent hematopoietic progenitor cell proliferation [92] and osteoclast bone resorption [93, 94]. Several excellent reviews summarize work on DNA transfection for bone tissue engineering, elaborating upon target genes, transfection modes, in vivo applications, and safety concerns [79, 81, 86, 95]. Controlled release of DNA from many different biomaterial scaffolds has also been demonstrated [96, 97]. Importantly, these systems protect the DNA until it is released, permitting delivery of the DNA, with carrier if needed, to the cell for subsequent uptake, transport to the nucleus and resulting biological effects.

In addition to DNA delivery, genetic material in the form of RNA can also be delivered from biomaterials. While most DNA is introduced to cells to increase the expression of a target gene, new discoveries in the field of RNA interference (RNAi), non-coding RNA sequences which lead to targeted degradation or impaired translation of select mRNA sequences, hold great promise for silencing gene expression at the post-transcriptional level [98, 99]. RNAi involves short interfering RNA (siRNA), short double stranded RNA sequences of which one strand can perfectly base pair with a specific complementary mRNA sequence and induce its degradation, or microRNA (miRNA), similar single stranded sequences which have incomplete base pairing with their target mRNA sequences, allowing them to affect a number of similar mRNAs instead of only one specific sequence [100]. As the field of biology enhances our knowledge of pathways antagonistic to osteogenesis, this technology allows the blocking of relevant genes as a way to enhance osteogenesis. Here, the host genome is not changed, adding to the safety of RNAi. siRNA has been used to silence noggin, a BMP-2 antagonist, to induce ectopic bone formation in mice [101], to knock down chordin, another BMP-2 antagonist, to enhance osteogenic differentiation of hMSCs [102], and to knock down the receptor activator of nuclear factor κB (RANK) to inhibit bone resorption [103]. A number of miRNAs have also been shown to play a role in bone development [104], osteogenic differentiation [105] and vascularization [106]. A variety of systems have been developed for localized presentation of interfering RNA molecules [80, 107], including sequences that stimulate osteogenesis [108]. As more siRNA and miRNA targets for osteogenesis are identified, spatiotemporal control of interfering RNA delivery may be a useful tool to help recapitulate the process of bone development.

3.3 Drugs and small molecules

There are many drugs and small molecules that may be valuable for bone regeneration by serving antibiotic, anti-inflammatory or osteotrophic roles. Antibiotics are used to control infections at a surgical site – in the case of medical devices, bacterial infections pose a significant risk of increased pain, medical costs, and likelihood of device failure [109]. As a result, there is much interest in controlling antibiotic presentation from medical devices [109, 110]. Similarly, controlled antibiotic release from biomaterials may also be used to avoid infections in bone tissue engineering strategies. A number of systems, mostly comprised of ceramic composites, have been designed to present antibiotic agents, including gentamicin, tetracycline, vancomycin and silver, from materials often used for bone tissue engineering [111]. Antibiotic delivery is also used clinically in bone repair: the Masquelet technique releases antibiotics to prevent infection at the surgical site while a vascularized membrane, a pseudo-periosteum, grows around it; 4-12 weeks later, the synthetic spacer is removed and replaced with autografted bone tissue, which is supported biologically by the induced vascularized membrane [112, 113]. Implanting a biomaterial system in the body causes local inflammation, motivating the use of anti-inflammatory drugs to minimize the immune response around the implanted scaffold [114]. These drugs can be glucocorticoids, most typically dexamethasone [115], or non-steroids, including ibuprofen [116]. Localizing both antibiotics and anti-inflammatories to the implant site avoids side effects associated with systemic delivery (e.g., oral or intravenous administration). This review will not focus on delivery of these agents because control over their spatial presentation may be less likely to affect osteogenesis.

Osteogenic drugs have also been delivered from tissue engineering scaffolds with favorable outcomes. Bisphosphonates, which are widely used in the treatment of osteoporosis because they prevent bone resorption, have been released with a degree of control from biomaterial scaffolds, showing concentration-dependent inhibition of osteoclast activity [117, 118]. While these results are limited to in vitro studies, this approach may hold promise especially for repairing bone in patients with a bone disease causing increased bone resorption. Fluvastatin and simvastatin, members of the statin family, have been found to induce bone formation [119-121]. Their release from biomaterial scaffolds was shown to promote osteogenic differentiation of hMSCs [122] and MC3T3 mouse preosteoblast cells [123], and regeneration of nasal bone defects in rabbits [124]. Lastly, parathyroid hormone (PTH) has also been shown to enhance bone formation [125]. With PTH, delivery control is especially important, as continuous exposure can result in bone resorption, but pulsatile, intermittent administration can lead to enhanced bone formation [126, 127]. For this reason, temporal control may enhance the effectiveness of PTH as an osteoinductive agent in bone tissue engineering.

4. Strategies for temporal control over bioactive factor delivery

A wide variety of biomaterial delivery systems have been developed for temporal control of bioactive factor presentation, and many of these systems can be exploited for spatial control as well [128]. For this reason, this review will first summarize techniques for varying the release kinetics of bioactive factors. Most strategies for presentation of bioactive factors from scaffolds include physical entrapment of the factor in the biomaterial; if the factor is free to move through the material then diffusion governs release, otherwise scaffold degradation is the rate limiting step. If a free biomolecule has affinity for the biomaterial, its diffusion out of the scaffold is slowed, leading to more sustained presentation. Alternately, the factor can be covalently tethered to the material, which localizes it to the scaffold until the material degrades or the bond is broken. Lastly, a system can be designed such that an external stimulus triggers the release of the biomolecule. In all cases, the biomolecule carrier system must protect the bioactivity of the bioactive factor while also delivering it at appropriate concentrations over a desired time frame. These factors are functions of the bioactive factor of interest.

Diffusion-based release of a bioactive factor physically entrapped in a biomaterial is the simplest approach, but typically achieves the least control over the timing and location of delivery. The bioactive factor is loaded into the bulk of a biomaterial scaffold, usually by mixing it into a solution before it solidifies or gels or by rehydrating a lyophilized scaffold with solution containing the bioactive factor. These biomaterial scaffolds can then protect the loaded bioactive factor from enzymes in the body; in this way its bioactivity is preserved until it is released to cells [128]. The release kinetics are a function of the ability of the molecule to diffuse out of the scaffold, which is affected by interactions between the scaffold and the biomolecule, as well as the scaffold pore size, architecture and degradation, which changes the pore structure and swelling over time. In purely diffusion-based systems, release profiles are often characterized by an initial burst: free molecules of interest are quickly driven outside of the scaffold by a steep concentration gradient [129]. While this may be desirable in the case of certain molecules, some tissue engineering strategies may require more sustained presentation of the bioactive factors [20]. Additionally, a burst may necessitate higher initial loading because a potentially large fraction of the available biomolecules will be released during the burst [129]; high initial local concentrations may also have adverse effects. When degradation governs delivery, usually by hydrolysis or activity of cell-secreted enzymes, release profiles depend on the scaffold degradation kinetics. These kinetics can be a function of a number of factors, including the molecular weight, concentration and hydrophobicity of the base polymer, the degree of crosslinking and swelling, pH changes due to degradation products, applied mechanical stress/strain and the mode of degradation [130]. While hydrolytic degradation occurs at similar rates in different areas of the body, enzymatic degradation depends on the local concentrations of enzymes, which are often a function of local cellular activity, and release profiles will vary depending on the tissue microenvironment [131].

Many material systems slow diffusion by various intermolecular interactions, permitting more sustained release over days, weeks, or even months compared to diffusion alone. These methods rely on affinity interactions, noncovalent binding that can result from associations between molecules of opposite charge, hydrogen bonding, van der Waals forces or hydrophobic interactions between bioactive factors and the biomaterial to similarly slow their diffusion out of the scaffold [128]. An example of how affinity interactions are used to delay diffusion takes advantage of the net electrostatic charge on some growth factors. BMP-2, TGF-β1, FGF-2 and VEGF, which all have been explored for bone tissue regeneration, carry a net positive charge at physiological pH [132]. These growth factors will thus form polyionic complexes with negatively charged biomaterial matrices such as some gelatins. These electrostatic interactions will slow diffusion, and can serve as the basis of controlled delivery systems [133]. Similarly, DNA itself has a negative charge at physiological pH, but as mentioned previously, it is often complexed with cationic polymers to yield particles of net positive charge [134], which may be exploited to slow the release of DNA from a charged biomaterial matrix . RNA molecules also exhibit negative charge, and electrostatic interactions have been harnessed to achieve localized and controlled release from a biomaterial for sustained gene knockdown for two weeks [135]. Another commonly exploited affinity interaction is growth factor delivery binding to heparin or its derivatives [136]. BMP-2, TGF-β1, FGF-2 and VEGF all exhibit heparin affinity [137-139], and exploiting these interactions can yield more delayed release systems for bone tissue engineering.

Covalent immobilization of a bioactive factor to a biomaterial allows for long-term presentation by delaying diffusion until the scaffold degrades or the covalent bond is broken; a number of these systems have been developed for tissue regeneration [140]. BMP-2 has been covalently coupled to materials such as glass coverslips or slides for in vitro studies, or biomaterial scaffolds including poly(lactic-co-glycolic acid) (PLGA), chitosan, type I collagen, and polycaprolactone (PCL), all with the goal of bone repair [140]. Such presentation may be relevant to tissue engineering because some growth factors in the in vivo environment are sequestered in the ECM by affinity interactions and act without being taken up by cells [141]. For example, tethered BMP-2 has been shown to have increased bioactivity compared to the same amount of free BMP-2: it is not internalized and instead can continue to activate its receptor [142, 143]. Especially relevant for spatial patterning, these coupling reactions can be photo-initiated: the growth factor is first functionalized with a photoreactive group, such as a phenyl azide or acrylate group, and then bound to a biomaterial in the presence of ultraviolet (UV) light, which can be spatially restricted [140].

Finally, stimuli-responsive growth factor delivery systems allow for the creation of dynamic microenvironments with on-demand release. Here, the bioactive factor is released in response to a cell-mediated or externally applied physical or biochemical trigger [144]. For example, matrix metalloproteinase (MMP)-degradable linkages in the backbone of hydrogels can be broken down by cell-secreted MMPs to release BMP-2 [145]. Additional work has been pursued using stimuli ranging from magnetic fields [146], mechanical loading [147] and ultrasound waves [148] to release various bioactive factors. These stimuli-responsive tools are amenable to spatial patterning of growth factor release when the stimuli can be applied to specific regions of a biomaterial.

5. Spatially controlled delivery technologies

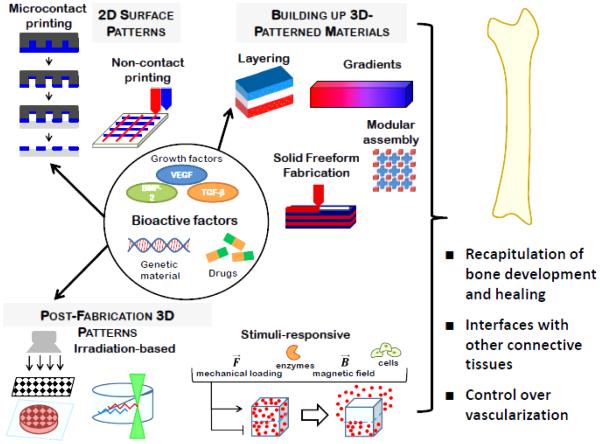

Given the role local presentation of signals may have on the formation of complex tissues, a wide variety of technologies have been engineered to regulate the spatial organization of bioactive factors, and many of these have been applied for bone regeneration. These technologies, illustrated in Figure 1, vary in their complexity and degree of control they allow. This section describes the scientific basis behind each approach, highlighting their use in bone tissue engineering. A summary of the approaches that have been used to drive local osteogenesis by spatially controlling the presentation of bioactive factors is presented in Table 1. Many additional patterning techniques that have not yet been applied to bone regeneration, but have this potential, are also described throughout this section, and summarized in Table 2.

Figure 1.

Schematic illustrating technologies to spatially control bioactive factor presentation.

Table 1.

Examples of spatially controlled patterning of biomolecules for osteogenic applications

| Pattern Creation Technique |

Scaffold Material |

Patterned Molecule(s) |

Cells | Model | Outcome(s) | Ref. |

|---|---|---|---|---|---|---|

| Noncontact printing: Inkjet |

Fibrin | FGF-2 | Human MG- 63 cells |

In vitro | Proliferation dependent on FGF-2 concentration |

[174] |

| Fibrin | BMP-2, BMP-2/ FGF-2 |

Mouse C2C12 cells |

In vitro | Localized osteogenic and tenogenic differentiation |

[176, 177] | |

| Decellularized skin allograft |

BMP-2 | Mouse C2C12 cells |

In vitro | Localized osteogenic and myogenic differentiation |

[179] | |

| BMP-2/ SDF-1/ TGF-β1 |

None | Mouse calvarial defect |

Localized in vivo bone formation |

[179, 180] | ||

| Osteochondral layered scaffolds |

OPF/gelatin microparticles |

TGF-β1 or TGF-β3 |

Rabbit MSCs |

In vitro | Localized osteogenic and chondrogenic differentiation of rabbit MSCs |

[194, 195] |

| PLGA microspheres in segmented polyurethane |

TGF-β1 or BMP-2 |

None | Rabbit knee osteochondral defect |

Formation of new hyaline- like cartilage tissue |

[196] | |

| Gelatin sponges |

Platelet rich plasma, BMP-2, β-TCP |

Horse MSCs | Horse talus osteochondral defect |

Visible defect repair | [198] | |

| Chitosan/ gelatin/ hydroxyapatite |

Plasmid DNA for TGF-β1 and BMP-2 |

Rabbit MSCs |

Rabbit knee osteochondral defect |

Support of both cartilage and subchondral bone formation |

[199] | |

| Cell aggregates with gelatin/ hydroxyapatite microparticles |

TGF-β1 and BMP-2 |

Human MSCs |

In vitro | Localized osteogenic and chondrogenic differentiation |

[200] | |

| Gradient formation |

PLGA and silk microspheres in alginate |

BMP-2 and IGF-1 |

Human MSCs |

In vitro | Gradient of osteogenic and chondrogenic differentiation |

[213] |

| Sintered PLGA microspheres |

BMP-2 and TGF-β1 |

Human MSCs | In vitro | Localized osteogenic and chondrogenic differentiation |

[214] | |

| BMP-2 and TGF-β1 |

None | Rabbit knee osteochondral defect |

Defect filled with bony ingrowth and overlying cartilage layer |

[215] | ||

| Alginate | BMP-2 and TGF-β1 |

Human MSCs |

In vitro | Gradient of osteogenic and chondrogenic differentiation |

[206] | |

| PCL nanofiber mesh |

Insulin and β- glycerophosp hate |

Human ASCs |

In vitro | Localized osteogenic and chondrogenic differentiation |

[216] | |

| Collagen and PLL |

DNA encoding Runx2 |

Rat fibroblasts |

In vitro | Mineralization dependent on DNA gradient |

[217] |

Table 2.

Biomaterial scaffolds with spatially patterned presentation of biomolecules for applications not specifically focused on osteogenesis

| Patterned Molecule(s) |

Surface or 3D Pattern |

Pattern Creation Technique |

Scaffold Material | Ref. | |

|---|---|---|---|---|---|

| Inert markers |

Fluorescent dye | 3D | Multiphoton excitation |

Agarose | [285, 286] |

| Vacuum molding | Collagen/ chitosan |

[245] | |||

| Lock-and-key assembly |

PEGDA | [248] | |||

| Subunit micromanipulation |

[235, 244] | ||||

| 3D printing | [268] | ||||

| Polyvinyl alcohol | Surface | Microcontact printing |

Human lens capsule |

[156] | |

| Cell adhesion molecules |

RGD-containing peptides |

Surface | UV laser light | PEGDA | [186] |

| PEG on silicon wafers |

[190] | ||||

| 3D | UV light projection through a photomask |

PEGDA | [277-279] | ||

| Agarose | [280] | ||||

| Alginate | [282] | ||||

| Multiphoton excitation |

PEGDA | [289-291] | |||

| Proteins | VEGF | Surface | UV light projection through a photomask |

PEGDA | [188] |

| PDGF and FGF- 2 |

[187] | ||||

| VEGF and FGF- 2 |

Surface | Electron beam | PEG on silicon wafers |

[189] | |

| VEGF/anti-VEGF antibody |

3D | Layering | Porous PLGA | [203] | |

| VEGF | 3D | 3D printing channels |

Hydroxyapatite | [257] | |

| FGF-2 | 3D | Stereolithography | PEGDA / heparan | [268] | |

| Gradient | PEGDA | [212] | |||

| Multiphoton excitation |

Agarose | [287] | |||

| Sonic hedgehog and CNTF |

3D | Multiphoton excitation |

Agarose | [288] | |

| Genetic material |

Biotinylated DNA | Surface | Electron beam | PEG-coated glass | [191] |

| Plasmid DNA for GFP |

Surface | Noncontact printing |

Collagen | [181] | |

| Cells in monolayer on tissue culture plastic |

[184] | ||||

| siRNA | 3D | UV light projection through photomask |

Dextran | Alsberg lab unpublished data |

|

| Activation of heat-sensitive luciferase gene switch |

3D | Localized ultrasound application |

Fibrin | [304] | |

5.1 Generating patterns of bioactive factors on scaffold surfaces

There is a great deal of interest in biomaterial surfaces, both as cell culture tools that allow the investigation of basic science questions, and to regulate seeded cell behavior or that of host cells that come in contact with the surface shortly upon implantation for enhancing tissue regeneration. Spatial patterning of bioactive factors on these surfaces has been extensively explored using a variety of innovative technologies, many of which have exciting potential for bone tissue engineering.

5.1.1 Microcontact printing

Lithographic techniques developed by the microelectronics industry for manufacturing integrated circuits and printed circuit boards have been adapted by bioengineers to create micro- and nano-patterned biomaterials. Biocompatible soft lithography can be used to engineer elastomeric stamps and molds with a minimum feature size on the order of tens of nanometers [149]. One technique that has been especially useful for controlling bioactive factor presentation for tissue engineering is microcontact printing. Developed by the Whitesides group, the procedure employs a polydimethylsiloxane (PDMS) stamp made using standard photolithography techniques [150].The stamp is coated by immersion in “ink,” a solution containing the biomolecule of interest, and then direct contact transfers the biomolecule from raised features of the stamp onto a substrate [151]. Some of the first work implementing microcontact printing to study spatial control of cell behavior used printed islands of fibronectin, a cell-adhesive ECM molecule, onto a non-adhesive hard substrate; these studies showed that cell spreading could be limited by controlling the size of the adhesive islands, and were integral to understanding how cell shape controls cell behavior [152, 153]. Microcontact printing was also used to print fibronectin onto substrates coated with poly(N-isopropylacrylamide) [154, 155], a thermoresponsive material that cells can grow on at 37°C, but that undergoes a lower critical solution temperature phase transition when cooled. Decreasing the temperature caused the cells that grew on areas coated in fibronectin to be released as sheets with controlled geometry. In a particularly clinically relevant example, polyvinyl alcohol, a biocompatible polymer that inhibits cell growth and attachment, was printed onto human lens capsule tissue for retinal transplantation in a hexagonal grid micropattern. The organization of retinal or iris pigment epithelial cells was controlled when seeded on the patterned lenses: the cells maintained a globular, epithelioid shape on patterned substrates, as compared to spindle-shaped cells on unpatterned substrates, better mimicking the orientation and shape lost in age-related macular degeneration [156].

While the controlled presentation of ECM signals is valuable, these tools can be applied for printing materials that present other bioactive factors specifically relevant to bone tissue engineering in a spatially regulated way. For example, microcontact printing can stamp solutions containing growth factors, genetic material and/or small molecule therapeutics, or a biomaterial macromer solution containing one or more of these factors, either free or covalently bound, for immediate release or more sustained presentation. In addition, several different stamps can be used to pattern more than one factor onto a single substrate, and backfilling (i.e. modifying the unstamped regions with a polymer like polyethylene glycol (PEG), which does not have intrinsic bioactivity) to create a neutral base [157]. Microcontact printing has been applied to create DNA microarrays [158, 159], to stamp specific proteins or gradients of proteins like bovine serum albumin [160, 161], to stamp controlled patterns of antibodies, which may then bind growth factors of interest [162], to stamp avidin patterns which can then bind biotinylated proteins [163] and to use antibodies on a stamp to select for specific proteins of interest in a solution before stamping them onto a substrate [164-166]. These systems permit examination of the role of these 2D biomolecule patterns in inducing local cell behaviors, including those relevant to osteogenesis.

5.1.2 Non-contact printing

Commercial printer technology has also been embraced by the biomaterials community to achieve high resolution spatial control over substrate surface properties to guide cell behavior. The most common of these, inkjet printing, is a non-contact technique which uses thermal, piezoelectric or magnetic triggers to release ink droplets of volumes ranging from 10 to 150 pL from a nozzle whose position can be carefully controlled in space [167]. If ink is replaced with a solution of biological molecules, the same method can be used to control their spatial presentation. Early work in this field focused on printing proteins onto solid substrates such as glass or tissue culture plastic to control cell adhesion and morphology. For example, researchers modified a commercially available Canon inkjet printer, loading the ethanol-sterilized cartridges with collagen solutions, and printing defined shapes from a document created in Microsoft Office onto glass slides. Such a straightforward approach using off-the-shelf components achieved collagen patterns with 350 μm resolution that localized where smooth muscle cells attached to the substrate [168]. Similar results were seen using laminin patterns generated by inkjet printing to control neuronal adhesion [169]. Inkjet printing was also used for multiple materials: first a uniform non-adhesive PEG background layer was printed onto a slide, and then a second layer of islands of a cell adhesive collagen/poly-D-lysine mixture was printed on top of the PEG. Neurons grown on these substrates adhered only to the collagen/poly-D-lysine, maintaining the patterns after weeks in culture [170]. Multiple printed layers could also be patterned to provide a more complex signaling environment. Growth factors have also been printed using this young technology. IGF-1 and FGF-2 modified with photoreactive phenyl azido groups were loaded into the different cartridges of a Canon printer and deposited onto polystyrene or silicone substrates; the resolution of the printer allowed for creation of 16 different growth factor combinations and concentrations on individual substrates that fit in a standard 24-well culture plate. After printing, the substrates were irradiated with UV light, covalently immobilizing the growth factors on the surfaces, and creating growth factor arrays that were used to study myogenic differentiation of C2C12 cells [171].

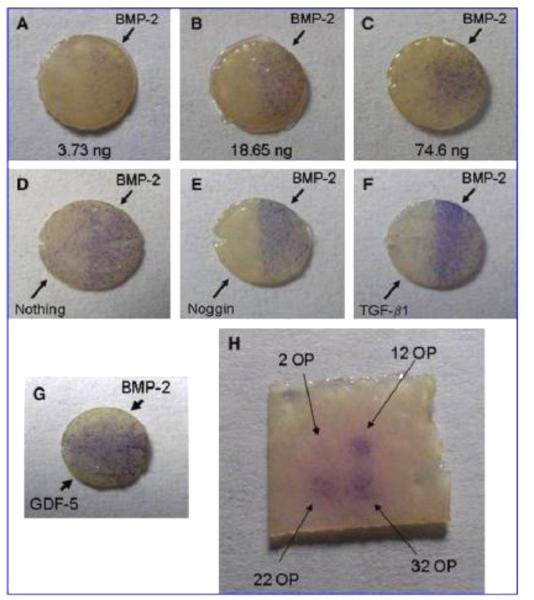

Researchers have since applied inkjet printing for spatial control over the delivery of a variety of growth factors to progenitor and stem cells. By 2005, spatial resolution under 100 nm was possible [172], and inkjet printing was used to pattern FGF-2 onto fibrin hydrogels, relying on affinity between the fibrin and FGF-2 to immobilize the growth factor [173]. When a gradient of FGF-2 concentration and discrete islands of the growth factor were printed, higher amounts of FGF-2 promoted proliferation of human MG-63 "preosteoblastic" osteosarcoma cells seeded on the hydrogel surface [174], locally increasing the number of cells present capable of forming new bone tissue. Printed growth factors can also be used to induce localized stem cell differentiation. For example, on polyacrylamide gel areas with printed FGF-2, neural stem cells were maintained in an undifferentiated state, but on areas printed with fetal bovine serum they differentiated down the smooth muscle cell lineage [175]. In another system relevant to bone repair, mouse muscle-derived stem cells seeded onto fibrin substrates with printed BMP-2 and cultured in myogenic medium underwent osteogenic differentiation in the BMP-2 containing regions, and myogenic differentiation elsewhere [176]. The approach was extended by patterning multiple growth factors (i.e., BMP-2 and FGF-2) with the goal of locally guiding cell differentiation down 3 separate lineages. Muscle-derived stem cells responded as described above, undergoing osteogenic differentiation in response to BMP-2 and myogenic differentiation in the absence of growth factor. In addition, tenocyte markers were upregulated in response to areas patterned with FGF-2 [177]. Such instructive biomaterials may be useful for engineering tendon interfaces to bone and muscle. This growth factor printing technique does not require a substrate with smooth topography: recently, growth factor printing has been performed on a matrix of aligned sub-micron scale polystyrene fibers [178], allowing control of cell alignment in response to the organization of the fibers in addition to growth factor presentation. Additionally, BMP-2 maintained its activity when printed onto microporous scaffolds made from acellular dermis, and led to improved bone healing in mouse calvarial defects in regions of printed BMP-2 compared to regions without growth factor (Figure 2) [179]. Further, co-printing SDF-1 with the BMP-2 augmented bone formation both in vitro and in vivo [180].

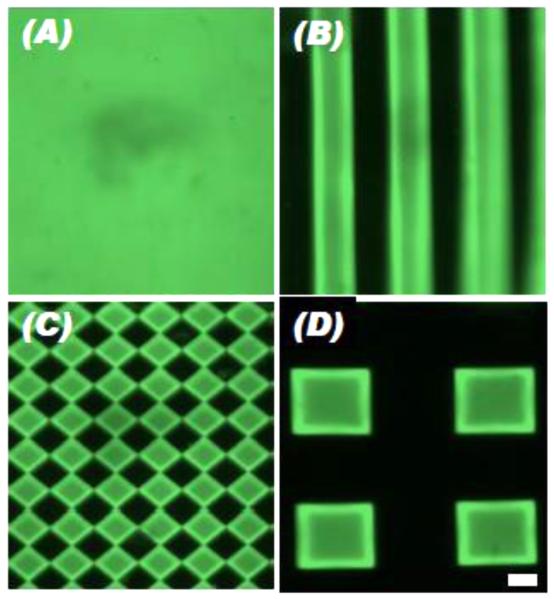

Figure 2.

ALP staining (blue) of C2C12 cells on 5 mm decellularized skin discs printed with bioactive factors resulting from (A-C) varying amounts of BMP-2 printed on the right halves of the scaffolds, (D-F) BMP-2 printed uniformly on the scaffolds with inhibitors printed on the left halves, (G) GDF-5 printed on the left halves, BMP-2 on the right halves, as well as (H) on a square piece with increasing number of BMP-2 overprints (OP). Adapted, with permission, from Cooper, et al. [179]. Copyright Mary Ann Liebert, Inc. 2010.

Another promising application of inkjet printing on 2D substrates is the delivery of genetic material. As a proof of concept, endothelial cells were mixed with naked plasmid DNA encoding green fluorescent protein (GFP), and this solution was printed onto collagen hydrogels. After printing, cells exhibited >90% viability, and >10% transfection efficiency, which was similar to the transfection efficiency obtained when cells on tissue culture plastic were treated with the commercially available Lipofectamine reagent [181]. While transfection efficiency may need to be increased to make this approach clinically applicable, the idea might be translated to deliver any genetic material that would influence cell behaviors such as differentiation or vascular network formation.

Other methods of non-contact printing have been developed, including those that allow for printing not only on dry surfaces but also on surfaces that are submerged in aqueous solutions, which is especially beneficial because they allow printing onto cell-laden materials which must typically be immersed in media during culture. Printing on wet surfaces is accomplished using a polymeric aqueous two-phase system: the surface to be printed on is covered with a PEG solution, and the molecules to be printed are loaded in a dextran solution, which has higher density than the PEG; because the two are immiscible and have low interfacial energy, dispensing the dextran solution near the substrate surface with a pipet or microarray pins can generate micron-scale patterns that are stable over time. With this system, researchers were able to deliver droplets containing GFP plasmid DNA with Lipofectamine in a spatially controlled manner onto cells cultured in monolayer leading to localized GFP expression [182]. The PEG/dextran system was also used to print mouse embryonic stem cells (ESCs) onto a layer of supporting stromal cells to create stem cell colonies of varying sizes [183]. Notably, the addition of media required for cell culture does not wash away the transfection patterns or cell colonies in either of these systems. A dextran/collagen solution could be similarly patterned and gelled in an aqueous PEG environment on top of a layer of living cells, indicating that this biphasic approach could be used to print and pattern polymer solutions [184]. The capacity to pattern gene transfection, cells and biomaterials demonstrates the versatility of this technology. The aforementioned 2D printing tools are promising for monolayer in vitro studies to better understand cellular responses to osteogenic signals, both as tools for high throughput screening and for examining the effects of their spatial presentation. In addition, a patterned coating of bioactive signals on biomaterial constructs can provide localized cues to cells seeded on the scaffold surface or to adjacent host cells to drive bone regenerative processes.

5.1.3. Two-dimensional irradiation-based patterning

Bioactive factors can also be immobilized on the surface of a biomaterial scaffold in controlled regions using UV light and photomasks. This can be very simply applied to create localized regions of photocrosslinked hydrogels, and if a bioactive factor is included in the prepolymer solution, it is effectively patterned with the biomaterial. An interesting application of this approach used a base layer of crosslinked PCL/gelatin nanofibers created using electrospinning, and applied a very thin layer of a solution of PEGDA containing BMP-2 onto this layer. The PEGDA was crosslinked through a photomask, uncrosslinked mononmer was removed, and a solution of FGF-2 was applied and allowed to adsorb to the nanofibers in areas not covered by the PEGDA. As a result, the FGF-2 diffused off of the nanofibers within several days, and in the photocrosslinked regions the BMP-2 entrapped in the hydrogel was released over three weeks. When hMSCs were seeded on the nanofibers, those cultured on scaffolds that released both FGF-2 and BMP-2 showed greater osteogenic differentiation than those cultured on scaffolds releasing either growth factor alone [185].

Chemistries that have been developed to crosslink biomolecules with UV light-reactive moieties to biomaterials are another attractive method for spatial control. For example, peptide attachment to PEG-diacrylate (PEGDA) hydrogels was achieved when the amine groups of RGDS adhesion ligands were covalently coupled to PEG-acrylate, and a solution of the modified peptide covering the surface of PEGDA hydrogels was then irradiated with UV light that was restricted in space by a photomask. In regions exposed to UV light, the acrylate-PEG-RGDS was covalently attached to the hydrogel surface. These RGDS patterns with ~10 μm resolution were shown to affect capillary morphogenesis by endothelial cells [186]. These chemistries are often tested with peptides containing the RGD adhesion peptide sequence, but can be used to control the presentation of other biomolecules. A similar approach was used to couple PDGF and FGF-2 to the surface of PEGDA hydrogels. Acryloyl-PEG-PDGF and acryloyl- PEG-FGF-2 were synthesized using acryloyl-PEG-succinimidyl carbonate, and solutions of these functionalized growth factors were applied to crosslinked PEGDA hydrogels before exposure to UV light through a photomask. Immobilization of these growth factors along with RGDS, led to increased endothelial cell tubule length compared to cells cultured on hydrogels modified with RGDS alone [187]. For patterned VEGF coupling, the growth factor was again PEGylated for crosslinking into PEGDA, but the immobilization was done with laser scanning lithography, using a confocal microscope to focus the laser onto regions of the hydrogel, leading to spatially controlled VEGF presentation [188]. In such a system, the laser parameters, including the power, scan time, and number of scanning iterations, are easily controlled to vary pattern density, and because photomasks are not used, a large number of patterns can easily be created without the need to fabricate new masks.

Electron beam irradiation has been used to attach biomolecules to surfaces with nanoscale resolution. The high energy of an electron beam can form free radicals that initiate crosslinking reactions. For example, an electron beam crosslinked a pattern of styrene-sulfonate-containing PEG-based macromers onto silicon wafers with 100 nm resolution; the resulting substrate could then be incubated with the growth factors VEGF and FGF-2, which adhered to the patterned regions due to the heparin-mimicking properties of the styrene-sulfonate [189]. When PEG-aminooxy was crosslinked in a pattern on the wafers with an electron beam, ketone-functionalized GRGDSPG peptides in solution adhered to the patterned regions via oxime bond formation, causing the material to be cell adhesive and support the growth of human umbilical vein endothelial cells (hUVECs) [190]. Interestingly, electron beam irradiation of a PEG-coated glass substrate created surface patterns of carbon nanodeposits by the phenomenon of electron beam induced deposition: the high energy of the electron beam caused decomposition of organic residues in the atmosphere, which accumulated on the surface as carbon nanodeposits, and to which proteins in solution adhered in concentrations that correlated to the electron beam intensity. Its precision led the technique to be called “painting with biomolecules” [191]. Protein adhesion to the deposits was confirmed with IgG, ferritin, avidin and streptavidin, and biotinylated DNA was shown to have affinity for regions of bound avidin [191]. While nanoscale patterning allows for fine spatial resolution over growth factor presentation, the high energy associated with electron beams may degrade polymeric biomaterials. Despite this limitation, the approach may find strong utility modifying biomaterials such as ceramics and metals with coatings of bioactive factors at high resolution.

5.2. Building up patterned 3D scaffolds

While 2D biomaterial surface modifications are useful, native in vivo signal presentation to cells during development and healing is often tightly regulated and occurs at defined locations in 3D space. For this reason, when advancing beyond material coatings and in vitro monolayer culture tools, it is important to engineer systems where cells can be exposed to 3D microenvironments of patterned bioactive factors. These systems can be used for in vitro studies of cell behavior in an environment more representative of in vivo conditions because it enables cell interactions with the surrounding matrix in all directions. They can also be used as tissue engineering scaffolds: being three dimensional, they can serve the initial space filling and mechanical functions required of scaffolds for tissue regeneration while providing non-uniform instructive signals to cells. Creation of controlled patterns of bioactive factor presentation in scaffolds can be achieved via building up layer-by-layer, mixing prepolymer solutions to create gradients, or assembling from individual subunits. The approaches described in this section are the tools that have been exploited most directly for spatial control of osteogenic molecules and applied for bone tissue engineering.

5.2.1. Layered Scaffolds

The most straightforward method to producing a spatially patterned material is to connect two materials to one another, each delivering a different signal. This method is often used in efforts to generate interface tissues, such as the cartilage-bone transition zone. Such an approach to regenerating osteochondral interfaces was reported as early as 1997, when bilayer scaffolds made of a dense type I collagen layer for the bony side and a porous layer seeded with chondrocytes for the cartilage side were developed and tested showing promising results [192]. The osteochondral interface is an especially appealing target for spatially controlled growth factor delivery, as much work has been done characterizing both the potential of growth factors in the TGF-β superfamily to drive chondrogenesis [193], and that of the BMP subfamily of growth factors to drive osteogenesis [34].

Several groups have leveraged the inductive behavior of these growth factors to create scaffolds with a chondrogenic layer attached to an osteogenic layer. For example, Mikos and colleagues have developed a system based on oligo(polyethylene glycol) fumarate (OPF) with gelatin microparticles to release several different growth factors. Here, the charged nature of gelatin leads to electrostatic interactions with the growth factors, which are charged at physiological pH, delaying their release [132]. The inclusion of rabbit MSCs in OPF hydrogel constructs, with a pro-chondrogenic layer containing either TGF-β1 or TGF-β3 loaded gelatin microspheres, showed that the system could be used for spatial control over cell differentiation in vitro; cells in the growth factor-containing layer expressed chondrogenic markers, while cells in the layer with no growth factor expressed alkaline phosphatase, an osteogenic marker [194, 195]. Similar experiments examined bilayer scaffolds of porous polylactic-co-glycolic acid (PLGA) and segmented polyurethane, with either BMP-2 or TGF-β1 loaded in PLGA microspheres included in the polyurethane layer [196]. PLGA microspheres are a common growth factor delivery vehicle for which release is a function of the microsphere hydrolytic degradation rate and growth factor diffusion [197]. When implanted into a rabbit osteochondral defect with the PLGA-only side of the scaffold in the subchondral bone, and the growth factor-laden polyurethane side lining up with the cartilage, these scaffolds showed promising repair of both the cartilage and underlying bone [196].

As an extension of this idea, recent work has used both osteogenic and chondrogenic growth factors layered in two different scaffold regions to enhance osteogenesis in one layer and chondrogenesis in the other. For example, a bilayer scaffold system used BMP-2 and platelet rich plasma, a growth factor source containing both TGF-β1 and PDGF, for osteochondral defect repair. The system consisted of horse MSCs, both undifferentiated and pre-cultured in chondrogenic media, in bilayer scaffolds in which both layers were made up of gelatin sponges. The chondrogenic layer was loaded with platelet rich plasma, undifferentiated equine bone marrow-derived MSCs, and the MSCs that had been chondrogenically differentiated in vitro. The osteogenic layer contained β-tricalcium phosphate (TCP), as well as BMP-2 and undifferentiated MSCs [198]. These constructs were shown to repair osteochondral defects in the talus of horses [198]. Bilayer osteochondral scaffolds have also been explored for targeted gene delivery. In one study, composite scaffolds comprised of a chitosan-gelatin layer loaded with plasmid DNA for TGF-β1, and a chitosan-gelatin-hydroxyapatite layer mixed with plasmid DNA for BMP-2 were seeded with rabbit MSCs. The tissue constructs led to upregulation of the growth factors that the plasmids encoded, indicating that the gene delivery led to the desired protein expression. More importantly, regional MSC differentiation was observed, and the constructs supported both cartilage and subchondral bone formation in a rabbit knee osteochondral defect [199]. Lastly, it was demonstrated that biphasic high-density hMSC constructs made with incorporated gelatin microspheres releasing TGF-β1 in one layer and mineral-coated hydroxyapatite microspheres releasing BMP-2 in the other layer could drive regional specific hMSC osteogenic or chondrogenic differentiation [200].

Layering techniques are also used in driving vascularization in defined areas, which is of critical importance for bone repair. For instance, the Mooney group has used bilayer made from PLGA microspheres loaded with PDGF and pressed together, sometimes with free VEGF, into discs using gas foaming/particulate leaching, and then stacked. The result was scaffolds with layers of the different growth factors. Growth factors remained confined in the regions they were loaded, and maintained bioactivity: the layers delivering first VEGF and then PDGF led to development of more mature vasculature in a mouse ischemic hindlimb model [201]. Multilayer materials can also allow for improved biomimicry in recapitulating in vivo development, where stimulatory and inhibitory biomolecules are present in spatially restricted areas [202]. This principle was applied in a system of porous PLGA discs either left empty, loaded with VEGF as a proangiogenic molecule, or loaded with anti-VEGF antibody, which is antiangiogenic. The scaffolds consisted of three layers in different combinations, including blank/VEGF/blank or anti-VEGF/VEGF/anti-VEGF. Only the latter composition led to angiogenesis that was spatially restricted to the region where the VEGF was delivered, and formation of stable vasculature in a mouse hindlimb ischemia model [203]. These layering approaches, which allow for discrete regions of bioactive factor presentation, can be a simple tool for evaluating the benefits of separating biochemical signals as opposed to uniformly mixing various bioactive factors throughout a scaffold.

5.2.2. Gradient formation

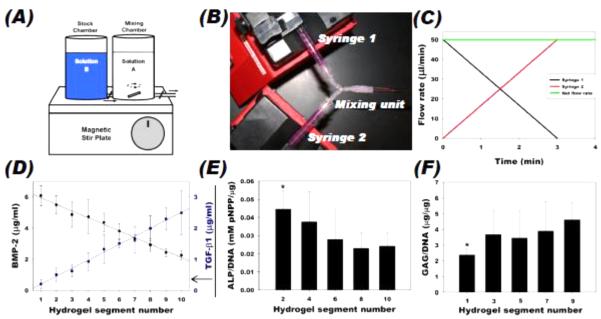

While work with bilayer scaffolds has made some progress in recreating osteochondral interfaces, in vivo, biointerfaces are not discrete layers but instead are established by gradients of mechanical and biochemical cues, driving the formation of tissues with graded properties and composition as described in section 2.2. A number of tools have been developed for creating gradients of bioactive factors, and these are often used for regeneration of the graded osteochondral interface. Gradient making equipment is commercially available; the device most often sold as a “gradient maker” consists of two vertical chambers into which prepolymer solution is poured; one side contains the molecule to be patterned in the desired gradient, and the other does not (or contains a different factor) [204]. A valve connects the two chambers, and when open, allows the material in the first chamber to flow into the second, where they are mixed, usually using a magnetic stir plate (Figure 3A, [205]). The second chamber has an outlet, where the mixture is collected and polymerized. Another system involves two syringe pumps that pump at different rates into a common outlet, which also allows for control of the biomolecule concentration profile [206]. Microfluidic mixing devices have also been used to create gradients of soluble factors. Two inlet ports are each loaded with a different prepolymer solution with or without desired bioactive factors. These ports connect to microchannels that join and split repeatedly, mixing the solutions at each juncture, and ultimately lead to an increased number of output ports that then each contain varying amounts of the two input solutions. Each successive output microchannel contains increasing or decreasing concentrations of the bioactive factors of interest, which can then be combined to form a continuous gradient. Depending on the prepolymer used, the gradient can be crosslinked into place by a variety of mechanisms such as UV light [207]. The same approach can be used for the perfusion of media to cells in culture, constantly presenting the gradient of soluble factors [208].

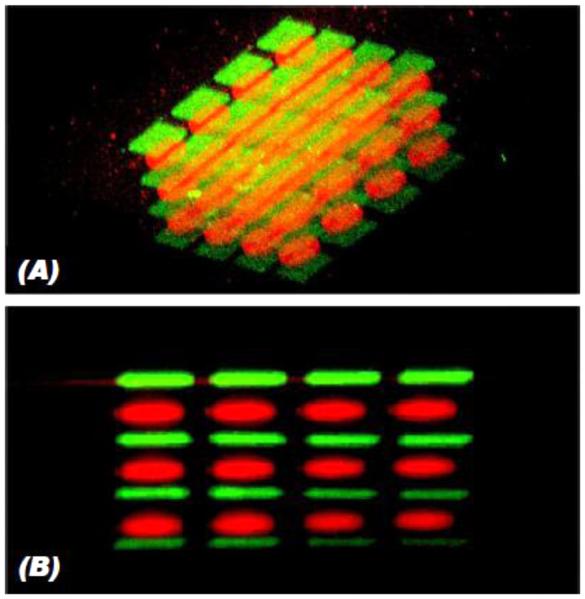

Figure 3.

Examples of bioactive factor gradient formation. (A) Schematic of a commercially available gradient maker design. (B) Dual syringe pump system used for gradient fabrication in alginate/heparin hydrogels, where (C) the flow rate from each syringe is controlled over time to create (D) measurable BMP-2 and TGF-β1 linear gradients in opposite directions. Encapsulated hMSCs expressed increased (E) osteogenic and (F) chondrogenic differentiation markers on the side of the gradient with increased BMP-2 and TGF-β1, respectively. (A) Adapted, with permission, from Chatterjee, et al. [205]. Copyright Bentham Science Publishers 2011. (B-F) Adapted, with permission, from Jeon, et al. [206]. Copyright John Wiley and Sons 2013.

Growth factor gradients are commonly explored [209], as these are present in vivo during healing and development and have been shown in vitro to direct a wide range of cell behaviors along the gradient ranging from neurite outgrowth [210] to branching morphogenesis [211] to stem cell differentiation [208]. For example, a gradient of covalently attached FGF-2 was formed in photocrosslinkable PEGDA hydrogels using a commercially available gradient maker; the FGF-2 was conjugated to a PEG derivative to allow for its photocrosslinking into the bulk hydrogel. The resulting hydrogels increased proliferation and directed migration of smooth muscle cells in the direction of increasing FGF-2 [212]. For osteochondral applications, several systems rely on two opposing gradients: in one direction an increasing gradient of an osteogenic growth factor (usually BMP-2), and a decreasing gradient of a chondrogenic growth factor (usually TGF-β1 or IGF-1) in the other direction, to drive the formation of a transition between bone and cartilage. For example, a commercially available gradient maker was used to make alginate scaffolds with gradients of BMP-2-loaded silk microspheres and IGF-1-loaded silk or PLGA microspheres. The growth factors showed localization and controlled release over time, and led to a gradient of osteogenic and chondrogenic differentiation of encapsulated hMSCs [213]. Alternatively, a syringe pump system was used to create opposing linear gradients using PLGA microspheres loaded with BMP-2 or TGF-β1 that were sintered together after gradient formation to form a solid scaffold. Enhanced hMSC osteogenic and chondrogenic differentiation were observed on the sides of the gradient with increased BMP-2 and TGF-β1, respectively [214]. When the BMP-2-loaded microspheres also contained hydroxyapatite, and a similar process was used for gradient formation, these constructs improved repair of osteochondral defects in rabbit knees with bone ingrowth into the scaffold and an overlying cartilage-like layer [215]. In another hydrogel-based approach, opposing BMP-2 and TGF-β1 gradients were formed using syringe pumps in an alginate/heparin system with encapsulated hMSCs (Figure 3 B-F) [206]. The heparin modification slowed growth factor diffusion due to affinity interactions, inducing regional osteogenesis and chondrogenesis. Other molecules have been used in osteochondral gradients as well: a PCL nanofibrous mesh with gradients of insulin, which stimulates chondrogenic differentiation, and β-glycerophosphate, for promoting mineralization, was shown to result in localized chondrogenesis and formation of mineralized tissue by human adipose-derived stem cells (hASCs) [216].

Local presentation of genetic material can also be controlled via gradients. One of the first such examples reported was collagen scaffolds soaked in a solution containing a positively charged polymer, poly(L-lysine) (PLL). The scaffolds were dipped into the PLL solution at a controlled rate; more PLL was adsorbed onto the end that was in solution for longer, creating a gradient of positive charge on the collagen surfaces. The slopes of these gradients were a function of the dipping speed. Then, the constructs were soaked in a solution containing retroviral DNA encoding Runt-related transcription factor 2 (Runx2), an osteogenic transcription factor, which was noncovalently immobilized in amounts dependent on the local amount of adsorbed PLL. When primary rat fibroblasts were seeded into the matrices and cultured in osteogenic growth medium, a gradient of cellular Runx2 expression was evident, along with a gradient of mineral deposition and construct stiffness, indicating that the cells were expressing an osteogenic phenotype that spatially correlated with the amount of retroviral DNA presented [217]. Further, gradients of siRNA were engineered into photocrosslinkable dextran hydrogels. Using the dual syringe pump mixing system described earlier, a gradient of siRNA against GFP was created, UV-crosslinked into place, and drove differential gene silencing in encapsulated cells along the hydrogel gradient that persisted over time [218]. These approaches may be extended to study gradients of different DNA or RNA sequences to enhance osteogenesis.

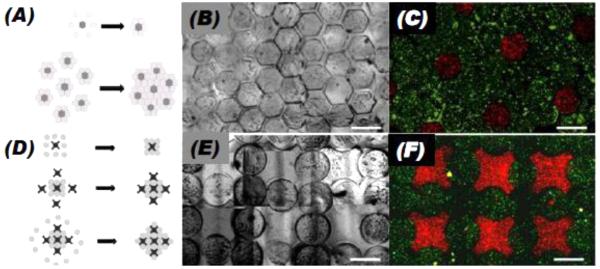

5.2.3. Modular assembly

A number of research groups are exploring an approach using modular tissue engineering, where base units, often high cell density aggregates or hydrogel particles with either seeded or encapsulated cells, are formed and assembled into more complex tissues [219]. A key benefit of this approach is the ability to make subunits with different biomaterial compositions, cell types and/or bioactive factors, and arranging them to form a heterogeneous engineered composite that can mimic the spatial variation in native tissue. The different properties of the individual modules allow them to serve different functional roles in the assembled construct. Because one subunit type can be vasculogenic, the approach is frequently used to improve vascularization in engineered constructs [220, 221] including for vascularized bone [222].

Techniques ranging from simple mixing to more complex photopatterning have been developed to make modules in various defined shapes and sizes. Spherical particles can be made relatively easily using a water-in-oil emulsion for water-soluble polymers such as gelatin, and oil-in-water emulsions for water-insoluble polymers such as PLGA, where microsphere size is controlled by variables such as temperature, the amount of solvent used and the speed at which the emulsions are stirred [223]. In ionically crosslinkable polymers, the macromer solution can be dropped into a bath containing dissolved ions, for example divalent cations for an alginate solution, causing it to crosslink in the form of spheres [224]. This method allows for size control by, for example, varying the size of the nozzle or the rate at which the droplets of macromer solution are ejected, and cell encapsulation, as the ionic crosslinking is often gentle enough to maintain cell viability [225]. Microspheres made by both emulsions or ionic crosslinking can be loaded with bioactive factors, either by directly mixing in an aqueous solution of the bioactive factors during synthesis or rehydrating lyophilized hydrogel microspheres with the solution [223, 226]. For the case of high cell density aggregates, cell-cell adhesion interactions are the mechanism that forms the individual modules. Small spherical aggregates can easily be made by hanging drop culture [227], or larger aggregates can be made by culturing cells in a non-adhesive container such as wells of a V-bottom plate, where cell-cell interactions lead to formation of cell clusters, which can be enhanced by centrifuging the plates to force cell aggregation [228]. Biomaterial microparticles of varying size and composition can also be included in the aggregates [229, 230].

Molding techniques allow for flexibility in the shape and size of the individual modules. Molds containing many replicates of micron-scale patterns can easily be made from polymers such as PDMS using approaches including soft lithography. These molds can be rendered nonadhesive by plasma cleaning, and can be used to control the geometry of cell aggregates [231-233]. Thermo-gelling hydrogels, including collagen, Matrigel, and agarose are easily crosslinked in these molds: the molds are loaded with a solution of hydrogel precursor containing the desired cells, and then incubated at 37°C to allow for crosslinking. The hydrogels are then removed by shaking the gels free from the mold and have been shown to maintain high cell viability [234]. Molds can also be used with photopolymerizable hydrogels using the same process but crosslinking with UV light, again with high cell viability [235]. Photomasks that restrict the location of UV light can be used with photopolymerizable hydrogels to eliminate the need for molds. If the light is applied through a photomask to a layer of uncrosslinked polymer solution, potentially containing cells, it can isolate regions of crosslinking creating geometrically defined shapes [236]. Simply rinsing off the uncrosslinked solution leads to a solution of microgels with controlled 3D shapes [237]. While these reports delivered only cells from the individual hydrogels, other signals, including bioactive molecules such as DNA or growth factors, could be localized to specific modules using these techniques. Techniques exist for controlling placement of different cell types within microgels, such as one cell type encapsulated inside of the microgels and another cell type (usually endothelial cells) seeded on their surface [238]. Combined with existing techniques to layer different growth factors on microparticle surfaces [239], such pursuits could be extended to spatially regulate placement of different bioactive factors in or on microparticles.