Significance

New techniques of high-volume hydraulic fracturing (HVHF) are now used to unlock oil and gas from rocks with very low permeability. Some members of the public protest against HVHF due to fears that associated compounds could migrate into aquifers. We report a case where natural gas and other contaminants migrated laterally through kilometers of rock at shallow to intermediate depths, impacting an aquifer used as a potable water source. The incident was attributed to Marcellus Shale gas development. The organic contaminants—likely derived from drilling or HVHF fluids—were detected using instrumentation not available in most commercial laboratories. More such incidents must be analyzed and data released publicly so that similar problems can be avoided through use of better management practices.

Keywords: high-volume hydraulic fracturing, shale gas, natural gas, water quality, Marcellus Shale

Abstract

High-volume hydraulic fracturing (HVHF) has revolutionized the oil and gas industry worldwide but has been accompanied by highly controversial incidents of reported water contamination. For example, groundwater contamination by stray natural gas and spillage of brine and other gas drilling-related fluids is known to occur. However, contamination of shallow potable aquifers by HVHF at depth has never been fully documented. We investigated a case where Marcellus Shale gas wells in Pennsylvania caused inundation of natural gas and foam in initially potable groundwater used by several households. With comprehensive 2D gas chromatography coupled to time-of-flight mass spectrometry (GCxGC-TOFMS), an unresolved complex mixture of organic compounds was identified in the aquifer. Similar signatures were also observed in flowback from Marcellus Shale gas wells. A compound identified in flowback, 2-n-Butoxyethanol, was also positively identified in one of the foaming drinking water wells at nanogram-per-liter concentrations. The most likely explanation of the incident is that stray natural gas and drilling or HF compounds were driven ∼1–3 km along shallow to intermediate depth fractures to the aquifer used as a potable water source. Part of the problem may have been wastewaters from a pit leak reported at the nearest gas well pad—the only nearby pad where wells were hydraulically fractured before the contamination incident. If samples of drilling, pit, and HVHF fluids had been available, GCxGC-TOFMS might have fingerprinted the contamination source. Such evaluations would contribute significantly to better management practices as the shale gas industry expands worldwide.

Horizontal drilling and high-volume hydraulic fracturing (HVHF) are used in combination to extract natural gas, condensate, and oil from shale reservoirs in the United States at rates affecting the world economy (1–4). In the shale gas-rich Marcellus Formation, such slick water HVHF began in 2004, leading to >8,000 Marcellus wells drilled in Pennsylvania (PA) alone as of October 2014. Nearly 70% of these have been hydraulically fractured using large volumes of water and sand with relatively small volumes of gels, acids, biocide, and other compounds (5, 6). The fast rate of such shale development in the northeastern United States has led to several cases of water resource impacts, including surface discharges of contaminants as well as subsurface gas migration (6–12). Although media reports of incidents are common, published reports are few (10).

The most useful evidence for incidents links contaminants directly to the source with a high degree of certainty. To evaluate impacts, a “multiple lines of evidence” approach (13–16) is generally necessary, including (i) time series analyses of natural gas and organic and inorganic compound concentrations, (ii) comparisons of natural gas isotopic compositions between gas well annular gas and groundwater, (iii) assessments of gas well construction, (iv), chronology of events, (v) hydrogeologic characterization, and (vi) geospatial relationships.

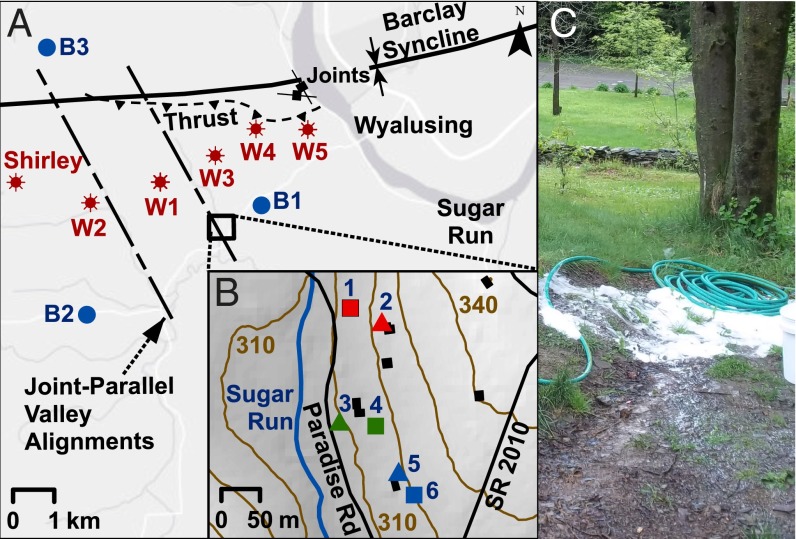

Here we provide data for a contamination incident from PA where the regulator (PA Department of Environmental Protection, PADEP) concluded that stray natural gas derived from nearby Marcellus Shale gas wells contaminated the aquifer used by at least three households in southeastern Bradford County, PA (Fig. 1). In addition to gas, the well waters were also observed to foam (Fig. 1C), but no cause was determined. To investigate this and other contaminants present, we demonstrate an investigative approach to identify unique organic unresolved complex mixtures (UCMs) and a target compound linked to shale gas-related contamination (2-n-Butoxyethanol, 2-BE).

Fig. 1.

(A) Study area showing the communities of Wyalusing and Sugar Run located on Susquehanna river (dark grey), gas wells (Shirley, Welles 1–5 well pads labeled as W1 through W5), domestic water wells not impacted by gas drilling activities (B1–B3), and notable geologic features (thrust fault surface expression, regional joint orientation, axis of syncline). (B) Expanded view of tributary of Sugar Run creek (blue line) showing domestic water Wells 1–6 impacted by gas drilling activities. Wells 2, 3, and 5 (triangles) are original impacted wells. Wells 1, 4, and 6 (squares) are replacement wells provided by gas company that also showed contamination. Brown lines are elevation contours (m-msl). Black squares are structures and lines are roads. (C) Foam emitted during purging of domestic water Well 2 in Spring, 2012.

History

Between 2009 and 2010, five gas well pads, known as Welles 1 through 5, were constructed about 1–2.25 km north of a small valley along the north branch tributary of Sugar Run where several private homes used groundwater for drinking (Fig. 1 A and B and Table S1). On each well pad, two wells with horizontal sections at depth were drilled and surface casing was emplaced to about 300 meters below ground surface (m-bgs) on the vertical section. The vertical casing consists of steel pipe surrounded by cement. At intermediate depths, no casing was installed. Production casing was used through the zone of gas production in the Marcellus Shale at depths between 2,100 m-bgs and 2,300 m-bgs (horizontal section).

By the end of September 2009 after both gas wells on the Welles 1 well pad were drilled, no construction problems associated with gas migration (6) were noted; however, a drilling fluid leak from a pit was documented by the PADEP on 7 August 2009 (Table S1). HVHF was completed for Welles 1-3H and Welles 1-5H in February 2010. Gas well naming convention includes the propery owner (e.g., “Welles”), followed by the pad number (e.g., “1”) and then the individual well designation (e.g., “3H” and “5H”).

Gas wells on Welles 2–5 pads were drilled between September 2009 and May 2010. In May 2010, annular pressures measured in Welles 3-2H (∼64 atm), Welles 3-5H (∼48 atm), Welles 4-2H (∼33 atm), and Welles 4-5H (∼34 atm) exceeded the maximum allowable pressure of 24 atm (17). In July 2010, natural gas and sediment were reported in well water by at least three households along the north branch of Sugar Run (Fig. 1 and Table S1). White foam was also observed in the water from impacted wells (Fig. 1C). Further, vapor intrusion of natural gas was reported in one basement, requiring household evacuation as a safety precaution.

On 11 May 2011, the PADEP cited the gas company for violations of the PA Oil and Gas Act and Clean Streams Law for allowing natural gas to enter aquifers (Table S1). Although they did not admit culpability, the gas company complied with the PADEP consent order and agreement (COA). The company remediated gas wells present at the Welles 3–5 pads with cement squeezes and plugs (SI Text and Table S1) to reduce gas well annular pressures.

The impacted water wells (Fig. 1) were sampled by environmental consultants and the PADEP and analyzed by commercial laboratories between July 2010 and May 2012 (Fig. 2 and Table S2). The gas company installed replacement groundwater wells (e.g., Wells 1, 4, and 6 illustrated in Fig. 1B); however, these wells also exhibited impacts, and treatment systems were installed for each household in late summer of 2010.

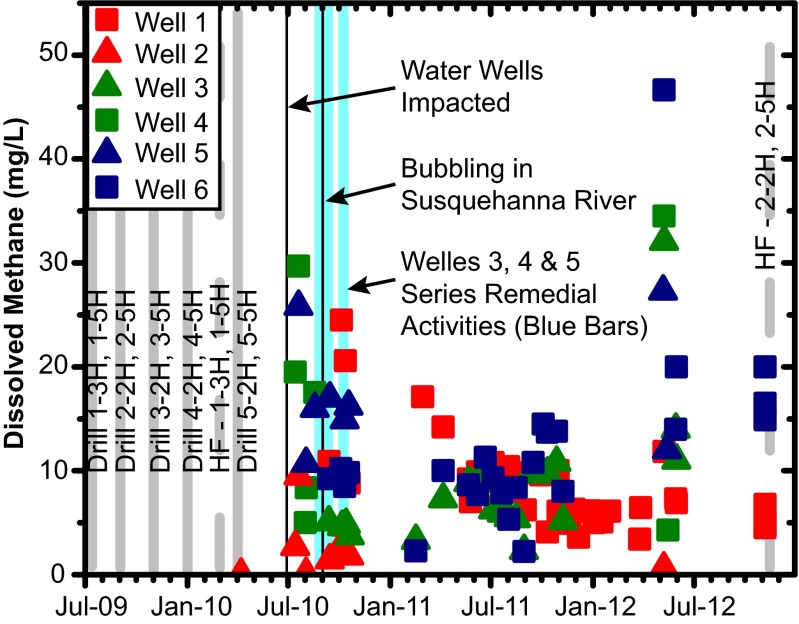

Fig. 2.

Time series plot of dissolved methane concentrations with notable events, such as gas drilling, high-volume hydraulic fracturing (dashed grey lines labeled HF), gas well remedial activities, and onset of impacts to water Wells 1–6.

A civil lawsuit initiated by the homeowners was settled in June 2012, and the gas company acquired the properties as part of a monetary settlement. No nondisclosure agreements were signed except for a subset of proprietary files. The Welles gas wells were identified by consultants working on the behalf of the homeowners as the most probable source of stray gas due to (i) nondetectable concentrations of dissolved methane in a predrill analysis of Well 2 (Figs. 1B and 2), (ii) groundwater quality time series data, (iii) comparison of isotopic signatures of natural gas from gas well annular spaces and in the potable wells, (iv) timing of the issues after gas drilling (Fig. 2 and Table S1), (v) excessive gas well annular pressures, and (vi) documentation of hydrogeologic conditions conducive to gas migration.

PADEP correspondence with the gas company in August 2010 requested documentation on the gas company's implementation of a 3-string casing design to include intermediate casing that would provide greater shallow aquifer protection. Following the case settlement and compliance with the PADEP's COA, the PADEP allowed the company to hydraulically fracture the gas wells on Welles 2–5 pads between November 2012 and September 2013 (www.FracFocus.org).

Here, we report new analyses on additional samples from the household wells before ownership passed to the gas company (e.g., data plotted for November 2012 in Fig. 2 and Tables S3−S6). Also, to investigate the cause of foam (Fig. 1C) and impacts previously unidentified, we used an analytical technique, comprehensive 2D gas chromatography coupled to time-of-flight mass spectrometry (GCxGC-TOFMS), that has not been previously used in similar cases. Although many attributes of the technique provide advantages for environmental forensics, few laboratories have GCxGC-TOFMS capabilities (14). We explored broad nontargeted organic compound classes at detection levels of nanograms per liter (e.g., detection limits lower than those achieved in most commercial laboratories). The method is amenable for forensic use in that it explores for broad classes of organic compounds and signatures rather than focusing on a specific list of target analytes that may or may not be present when impacts occur. No samples of HVHF fluid or flowback/production waters were available to us from the Welles series wells, but we investigated flowback and production waters from other similar unconventional gas wells in PA.

Methods

Samples were collected and analyzed from (i) ∼30 Marcellus Shale flowback/production waters sampled throughout PA and provided to us by commercial entities, (ii) one of the original household wells, (iii) two of the wells that were drilled as replacements for the homeowners that were still contaminated, (iv) one natural brine spring (Salt Springs) located about 50 km away in Susquehanna County, and (v) several potable water wells near the pollution incident that represent natural background. These background wells include a well from one of the relocated households, three nonimpacted households located within 5 km of the impacted homes, and a private house near Salt Springs. We also obtained and analyzed one common drilling additive (Airfoam HD). Sampling methodologies are described in SI Text.

Subsets of these samples were analyzed via gas chromatographic separation, specifically using GCxGC-TOFMS, isotope ratio mass spectrometry, and inductively coupled plasma atomic emission spectrometry (ICP-AES) (see SI Text and Table S3). GCxGC-TOFMS has previously been successful in identifying hydrocarbons in crude oil forensics (13). Here, TOFMS was used to detect analytes as they eluted from the second column. Concentrations were quantified, when possible, by running samples with known compounds injected in tandem with the sample. Additionally, surrogate standards were added to all samples before extraction to account for sample extraction efficiency.

Available natural gas analyses completed during investigations before settlement (Table S2 and Figs. S1 and S2) and completed on a subset of the samples we collected in November 2012 (Table S5) are reported in SI Text.

Aquifer testing was also conducted using household Well 4 as a pumping well and the other original and replacement wells as monitoring wells to investigate shallow aquifer characteristics (Fig. S3).

Results

Dissolved Organic Analysis.

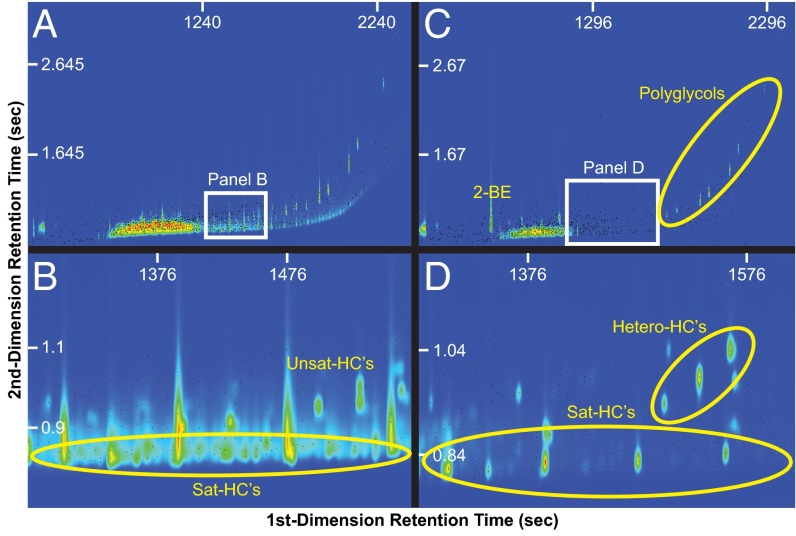

Every flowback/produced water sample we analyzed had a similar UCM of hydrocarbons when evaluated with GCxGC-TOFMS (Fig. 3). All groundwater samples from impacted sites (Wells 1, 3, and 6; see Fig. 1) that were analyzed with GCxGC-TOFMS showed UCMs similar to those detected in the flowback/production waters (e.g., Fig. 4A and Figs. S4−S6). Well 1 was analyzed both before and after purging (at which time the water no longer foamed). Peak intensities for the UCM were generally greater after purging (compare Fig. 4A and Fig. S6).

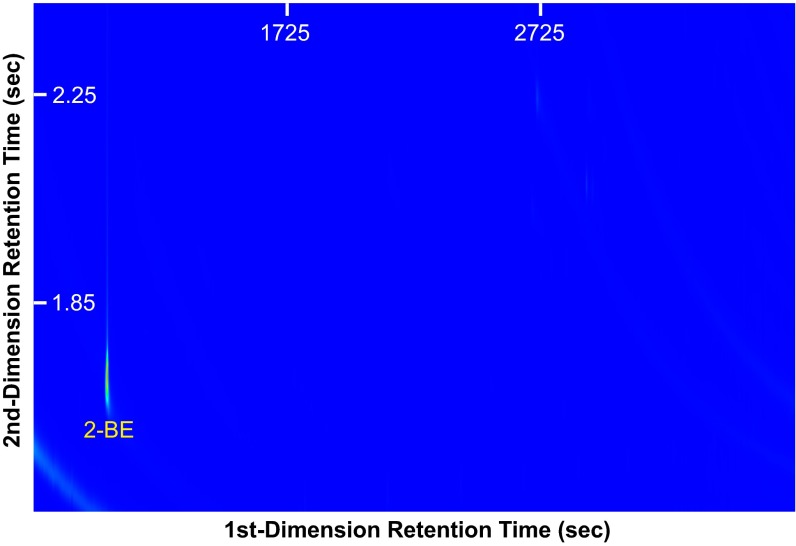

Fig. 3.

GCxGC-TOFMS chromatograms of flowback water. (A) Example from a gas well in Connelsville, PA. (B) Magnified portion of A as indicated by white rectangle. (C) Example from a gas well in Kittanning, PA. (D) Magnified portion of C as indicated by white rectangle. General compound classes are illustrated in panels. Unresolved complex mixture (UCM) concentrations are relative to each panel, but increase in concentration from cool (e.g., blue) to bright (e.g., red) color.

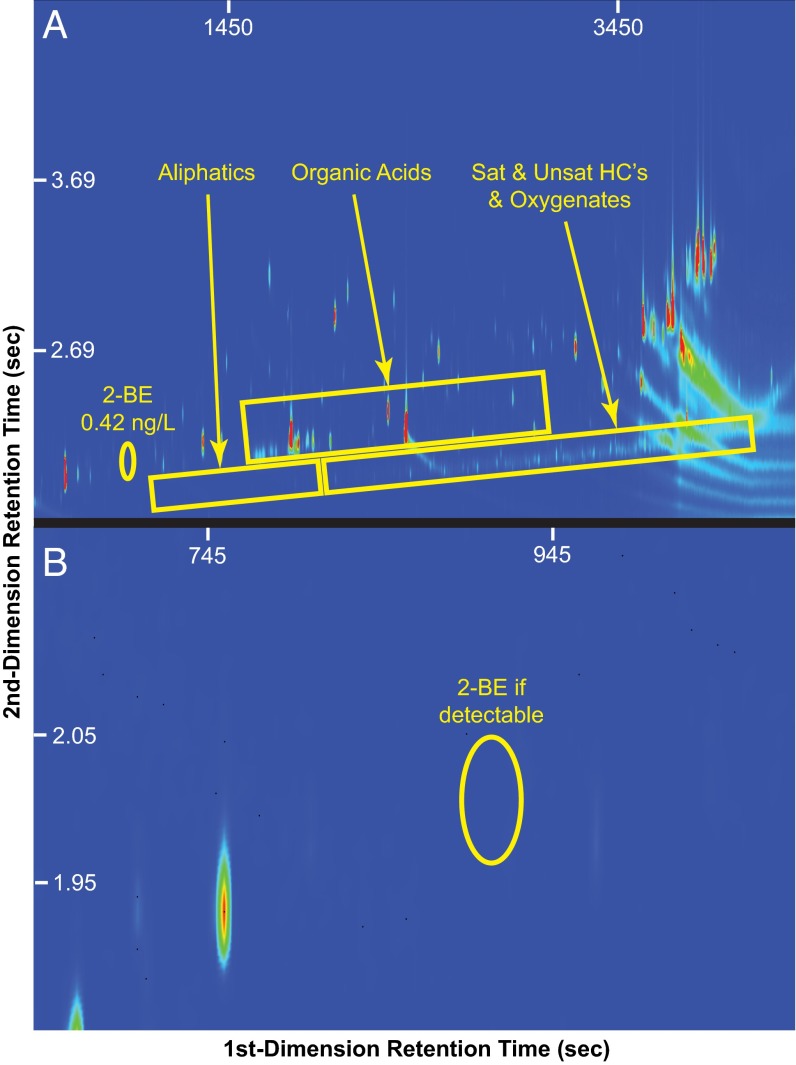

Fig. 4.

GCxGC-TOFMS chromatograms for (A) Well 1 (PLG-12-67A) before purging and (B) background Well B1 (PLG-13-7A) that was not impacted by gas drilling activities. The hydrocarbon UCM observed in Well 1 is similar to that observed in flowback samples (e.g., Fig. 3). The 2-BE was positively identified in Well 1 (impacted by gas drilling activities), but not as part of background water quality. B is magnified to illustrate the absence of 2-BE.

Classes of analytes in GCxGC-TOFMS, such as aliphatic hydrocarbons or organic acids, align along a diagonal of the 2D cross-plot chromatograms. For the specific conditions used here, aliphatic hydrocarbons cluster near the origin, while compounds with increasing heteratomic substitution or unsaturation lie further along the y axis. With the exception of the surrogate compounds (Table S7), only general classifications were determined from mass spectra. The detected molecules elute showing molecular weights <1,000 atomic mass units, and mass-to-charge ratios (m/z) of 50–550. Each flowback/production water sample had a similar but distinct pattern of saturated versus branched chain alkanes (compare Fig. 3 A and C).

A few of the ∼30 flowback/production water samples were positively identified as containing 2-BE (Chemical Abstracts Service (CAS) number 111-76-2) and glycols—compounds commonly used during drilling and HVHF (Fig. 3C). For example, 2-BE was the only compound identified using GCxGC-TOFMS in the drilling additive and surfactant Airfoam HD (Fig. 5). The groundwater well analyzed before and after purging (Well 1) also contained detectable 2-BE. In contrast to the UCM, which increased in peak intensity with purging, concentrations of 2-BE decreased after purging: Sample PLG-12-67A before purge (Fig. 4A) contained ∼0.42 ng/L 2-BE versus sample PLG-12-68A (after purging, Fig. S6) contained ∼0.086 ng/L 2-BE (concentrations on as-received basis). No 2-BE was detected in the other two groundwater wells, although they contained the UCM [no 2-BE was detected in Well 3 (Fig. S4) or Well 6 (Fig. S5)].

Fig. 5.

GCxGC-TOFMS chromatogram for Airfoam illustrating 2-BE as the sole detectable component.

To confirm the presence of 2-BE, sample extracts were reanalyzed using GCxGC with a high-resolution TOFMS (GCxGC-HR-TOFMS) at Leco Corporation. For example, the presence of 2-BE was confirmed in the accurate mass spectra for prepurge sample PLG-12-67A from Well 1 (e.g., one of the replacement wells) by comparison with the 2-BE standard (Fig. S7). Only 2-BE matched the molecular ion determined by the GCxGC-HR-TOFMS within 5 ppm. None of the field blanks or preparatory blanks contained 2-BE above detection (∼0.01 ng/L). Likewise, neither UCM nor 2-BE were detected from groundwater (e.g., Fig. 4B and Fig. S8) sampled from three household wells (e.g., B1, B2, and B3 illustrated in Fig. 1) located outside of the impacted area and used to evaluate background conditions.

Inorganic Analysis.

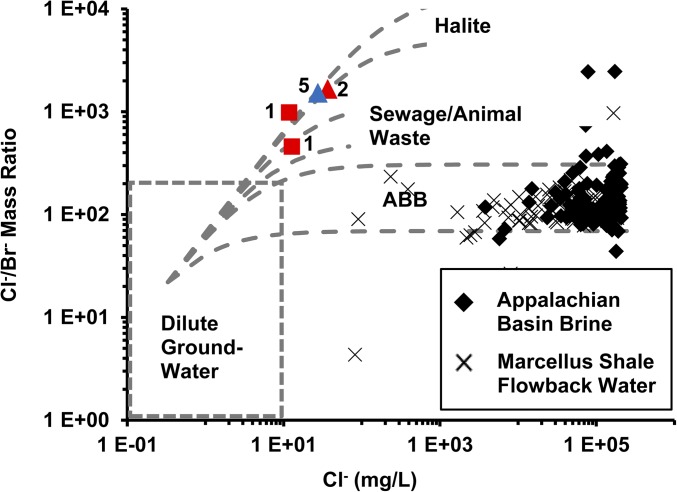

Conservative inorganic constituents (e.g., Cl and Br) can be used to determine if flowback or production waters have contaminated groundwater because these wastewaters can contain total dissolved solids in concentrations greater than 300,000 mg/L (6, 18). Further, if upward migration of HVHF fluids occurred after mixing with formation waters, dissolved Cl/Br mass ratios are more likely to be useful as effective fingerprints than the HVHF fluid components themselves, due to their more conservative behavior in groundwater (6, 10). Crossplots of Cl/Br (mass ratio) versus Cl concentration (Fig. 6) can help elucidate the source of Cl. For example, the natural water quality data for Salt Spring in Susquehanna County, PA, documents that Appalachian Basin brine (ABB) up-wells naturally into groundwater and surface water in Susquehanna County in that location as well as others (18). Although diluted, this spring water has a similar composition to flowback/production waters throughout PA and a few other brine springs and deep formation waters in the state (18–26) (Fig. 6 and Table S6). Conversely, Fig. 6 illustrates that the Cl concentrations and Cl:Br ratios of the impacted household waters from Bradford County are more likely gaining dissolved salts from sources with higher Cl:Br mass ratios than ABB.

Fig. 6.

Crossplot of Cl/Br mass ratio vs. Cl concentrations for samples collected from Wells 1, 2, and 5 (labeled) with bounding upper and lower conservative mixing curves for various endmembers (e.g., Appalachian Basin brine, sewage and animal waste, and halite sources). Appalachian Basin brine samples (20–22, 24) and Marcellus Shale flowback samples (23, 25, 26) are also plotted for comparison.

Dissolved Gas and Isotopic Analyses.

The dissolved methane concentrations measured in the impacted wells reached as high as 46.6 mg/L between 2010 and 2012 (Fig. 2 and Table S2). Such a high value is similar to methane concentrations we measured in three samples from Salt Springs State Park, where ABB is emitting naturally (Susquehanna County, 35.2 ± 1.53 mg/L, Table S5). In contrast, the predrill concentration in Well 2 was reported as <0.02 mg/L (e.g., plotting at the origin in Fig. 2). Likewise, the 1,701 drinking water wells collected by gas companies before drilling in adjacent Susquehanna County between 2008 and 2011 and analyzed in commercial laboratories (27) varied from a high (90th percentile) of 1.8 mg/L for valleys to a low of 0.017 mg/L for uplands. A steady decrease in dissolved methane was observed for at least one impacted household well (Well 1) with ample time series data, subsequent to the remediation of the Welles 3, 4, and 5 series gas wells (Fig. 2). An anomalous concentration spike was observed for all sampled wells in May 2012; however, differences in well purging and sampling protocols from that event complicate comparison with those that preceded it.

A plot of δD versus δ13C data for methane is illustrated in Fig. S1 for the (i) impacted household wells, (ii) annular space of Welles 2, 3, 4, and 5 gas wells, and (iii) predrill private household wells from the region (16). Notably, methane isotopic characteristics are consistent between gas sampled from the annular spaces of Welles 2, 3, 4, and 5 gas wells and groundwater sampled from the impacted homeowner wells. In contrast, methane characterized from predrill water wells in the region (16) illustrate generally different isotopic characteristics (Fig. S1). In addition, Fig. S2 illustrates that δ13C for methane and ethane are also consistent among gas samples from Welles 3, 4, and 5 wells’ annuli and the impacted groundwater wells.

Hydrogeologic Considerations.

The impacted homeowner wells lie along the north branch of Sugar Run valley between the axes of two east−west aligned structural folds (Fig. 1 and Fig. S9). The concave Barclay fold (syncline), is located 1–3 km to the north of Welles 1–5 pads; the convex Wilmot fold (anticline) lies to the south at a distance of 5–7 km (Fig. S9). Under the impacted valley (between the folds), bedrock strata dip ∼5–10 degrees downward to the northwest toward the Welles series gas wells.

In September 2010, significant gas bubbling commenced in the Susquehanna River near the community of Sugar Run southeast of the impacted homeowner wells (Fig. 1 and Fig. S9). When projected back to the Welles gas wells, bedding planes that outcrop near the river (and that presumably facilitate methane migration) intersect the boreholes at ∼400–600 m-bgs (Fig. S9). In comparison, the gas wells were cased to ∼300 m-bgs (Fig. S10).

Well-developed vertical to near-vertical fractures (joints) are observed in outcrop to trend NNW−SSE in the study area. A second, lesser-developed set is aligned E−W. Many stream valleys, such as the impacted north branch of Sugar Run, lie parallel to the NNW−SSE joints, consistent with joint-controlled valley development (Fig. 1). In addition to jointing, Fig. 1 and Fig. S9 also illustrate the surficial trace of a thrust fault identified from seismic reflection data. The fault plane dips ∼16 degrees downward to the south: This dip intersects the Welles 1–5 series gas wells at depths between ∼180 m-bgs and 580 m-bgs (Figs. S9 and S10). Thus, the thrust fault structural plane likely intersects some uncased portions of boreholes at the Welles 1, 2, and 3 pads. Of these three series, the Welles 1 and 2 wells did not reveal excessive, sustained annular gas pressures; however, elevated annular pressures of ∼64 atm and ∼48 atm were detected for Welles 3-2H and 3-5H, respectively. In response to the PADEP’s COA with the gas company, cement was squeezed into boreholes for the Welles 3, 4, and 5 series (Table S1 and Fig. S10), with subsequent decreases in gas well annular pressure.

To evaluate the local bedrock aquifer used by the three impacted households, aquifer testing was conducted for 7 h in November 2012, using Well 4 as a pumping well (25.8 L/min). Static groundwater elevations near the three impacted households ranged from 303.5 m above mean sea level (m-msl) to 308.9 m-msl, with flow converging toward the north branch of Sugar Run (Fig. S3). The aquifer test results indicated preferential drawdown parallel to the valley alignment, suggesting aquifer anisotropy and/or heterogeneity. Additional aquifer characterization is provided in SI Text.

Discussion

Even though drinking water consistently foamed in three households in Bradford County (e.g., Fig. 1C), commercial laboratories reported no compounds other than natural gas present at concentrations above regulatory recommended action levels, and no constituents were detected above regulatory drinking water standards. However, commercial laboratory analyses did sporadically detect ethylene and propylene glycol and surfactants near microgram-per-liter detection limits (SI Text). When we analyzed a subset of the household waters with GCxGC-TOFMS in 2012, we detected very low concentrations of 2-BE. This compound is of special interest because the US Environmental Protection Agency (USEPA) has suggested that 2-BE could be an indicator of contamination from HVHF activities (29). Additional information on 2-BE is provided in SI Text. GCxGC-TOFMS also documented a UCM of organic contaminants in all three water wells analyzed. Background groundwater outside of the affected area had no such contamination (Fig. 4B and Fig. S8). It is not possible to prove unambiguously that the UCM and 2-BE were derived from shale gas-related activities. However, the timing (Fig. 2 and Table S1) and the presence of UCMs and 2-BE in flowback/production waters in PA (Fig. 3) are consistent with shale gas activity as the most probable source.

We also conclude that the foam identified from the homeowner wells was likely derived from either the UCM hydrocarbons (28) or 2-BE (a known surfactant). Methane degassing is exacerbated during the onset of household well pumping due to rapid water level drawdown and drop in hydrostatic pressure. The resulting effervescence and groundwater agitation then aids as a foaming facilitator. Given that 2-BE was only found in Well 1, despite foaming observed in all water wells, it might be reasonable to conclude that the UCM aided by gas effervescence was the most probable cause. Further, foaming and concentrations of 2-BE decreased with increasing well purging, unlike the UCM. On the other hand, 2-BE is a known surfactant, making it a more probable cause of foaming at low concentrations. Detection of 2-BE is difficult at these low concentrations in the presence of other organic compounds. Therefore, the compound may have been present in the foaming drinking waters even though we could not detect it in all wells.

There are no reports of 2-BE as a natural constituent in waters from shale (30). However, the common drilling additive Airfoam HD contains 2-BE as the only detectable organic component from our analyses (Fig. 5). Although we have no evidence that Airfoam HD was used in the Welles series gas wells in drilling fluids, this substance has been commonly used in northern and central PA. Indeed, it was cited by the PADEP as the cause of foam from a spring discharging to the canyon wall above Pine Creek in Lycoming County (PA) that began 15 March 2010. Further, a more recent PADEP contamination determination letter, dated 14 May 2014, identified at least one private water well in Springville Township, Susquehanna County, PA, that was impacted by drilling fluids using Airfoam HD as a surfactant. Here, 2-BE in addition to volatile organic compounds and ethyl glycol were detected at microgram-per-liter concentrations in that household well and were deemed responsible for the foaming groundwater in the household well. This contamination was attributed to drilling fluid additives and not HVHF by the PADEP.

Notably, the Welles 1 gas well pad was the location of a drilling fluid pit leak in August 2009 (Table S1). Further, well construction issues required remedial efforts in the Welles 3–5 series gas wells. Therefore, drilling fluids used in their installation could reasonably account for the observed foam impacts to household Wells 1–6 (Fig. 1C). Since 2-BE and the UCM were identified together, drilling fluids might be the source of both.

Alternately, since the UCMs are similar in the well waters and flowback/production waters and 2-BE was only observed with the UCM, another scenario is that the UCM and 2-BE are derived from HVHF fluids. In fact, HVHF was initiated in February 2010 at the Welles 1 pad—5 mo before the turbidity and natural gas problems in the homeowner wells (Table S1 and Fig. 2). This well pad was also one of the two closest pads to the aquifer contamination incident. Notably, gas wells situated on the Welles 2–5 pads were hydraulically fractured in 2012 using fluids containing 2-BE (www.fracfocus.org; see Table S8). Although no data were reported online (www.fracfocus.org) regarding the compounds used during HVHF of Welles 1 pad wells, it is reasonable that the same nonemulsifier agent (which contained 2-BE) was likely used. Therefore, we conclude that it is possible that HVHF fluids used at the Welles 1 pad contaminated the drinking water aquifer.

If HVHF fluids did contaminate the water wells, it would be surprising if such contamination were due to fluids returning upward from deep strata, given that (i) this has never been reported (6), (ii) the time required to travel 2 km up from the Marcellus along natural fractures is likely to be thousands to millions of years (31), and (iii) Fig. 6 shows that the Cl:Br ratios in the drinking waters indicate the absence of salts that would be diagnostic of fluids from the Marcellus Shale (e.g., flowback/production waters). The most likely way for HVHF fluids to contaminate the shallow aquifers would therefore be through surface spillage of HVHF fluids before injection or by shallow subsurface leakage during injection.

It is possible that the provenance of the UCM and 2-BE was different from that of the stray gas. Indeed, the most reasonable explanation for the natural gas impacts to water wells is that gas migrated from Welles 3-2H or possibly from multiple gas wells drilled on the Welles 3–5 pads due to excessive annular pressures and lack of competent annular cement that allowed gas to move vertically upward along the wellbore and into shallow uncased portions of bedrock fractures, including an identified fault zone (Table S1, Fig. 1, and Figs. S9 and S10). Induced fracture propagation below the surface casing of Welles 3-2H is also possible given the recorded gas well annular pressures (see SI Text). In addition to potentially opening fracture pathways, excessive annular pressures and natural gas buoyancy likely drove gas up-dip along bedding-plane partings to the southeast, intermittently stair-stepping upward along near-vertical joints to Sugar Run (Fig. 1 and Figs. S3, S9, and S11). Well water turbidity was likely due to the entrainment of fine-grained sediment as a result of off-gassing and groundwater effervescence (32). The lower hydrostatic pressure of the shallow aquifer beneath the impacted valley, exacerbated by household pumping, likely drew in the contaminating fluids (Figs. S3 and S11).

Conclusions

We used comprehensive GCxGC-TOFMS to document that organic compounds derived from one or more shale gas wells in PA were the likely cause of foaming and a complex suite of UCMs in three homeowner wells. In one well, 2-BE was positively identified and is a common constituent of both HVHF and drilling fluids. These impacts were likely caused by drilling or HVHF fluids used in the gas wells. Two of the closest shale gas wells were hydraulically fractured by the time of the impact, and the well pad was cited by the PADEP for a pit leak. Despite noticeable white foaming of groundwater, reported concentrations for dissolved organics were below applicable regulatory standards when investigated by both environmental consultants and the PADEP. Only natural gas was previously reported as a confirmed contaminant. If contaminants entered groundwater during HVHF or drilling, then they persisted 2.5 y in the subsurface, i.e., until the November 2012 sampling.

Importantly, the techniques we needed to identify the impacts, GCxGC-TOFMS and GCxGC-HR-TOFMS, are not readily available in most commercial laboratories. Investigating gas drilling impacts with these analytical methods may be more effective than using target compound lists that may or may not include appropriate analytes and appropriate laboratory detection limits.

Although much of the concern shown by the public focuses on the possibility that some of the 1,000 compounds (29, 33) used in HVHF could migrate upward from the target shale, such upward leakage has never been documented. This is probably because HVHF fluids remain trapped in deep rock strata. However, the public cannot ascertain the cause of most shale gas-related problems (10) because the full datasets are often not released publicly and explained.

The data released here do not implicate upward flowing fluids along fractures from the target shale as the source of contaminants but rather implicate fluids flowing vertically along gas well boreholes and through intersecting shallow to intermediate flow paths via bedrock fractures. Flow along such pathways is likely when fluids are driven by high annular gas pressure or possibly by high pressures during HVHF injection. Such shallow- to intermediate-depth contaminant flow paths are not limited to HVHF but rather have been previously observed with conventional oil and gas wells. As shale gas development expands worldwide, problems such as those that occurred in northeastern PA will only be avoided by using conservative well construction practices, such as intermediate casing strings, proper cementation, and mitigating overpressured gas well annuli.

Supplementary Material

Acknowledgments

The homeowners whose wells were affected are acknowledged for their willingness to allow our data collection and data release to the general public. David Oakley and Don Fisher are acknowledged for assistance with Fig. S9. Leco Corporation is acknowledged for funding for the Pegasus GCxGC-TOFMS and data collection on the GCxGC-HR-TOFMS. Some reference materials and chromatographic consumables were donated by Restek Corporation. Funding for P.G. was derived from National Science Foundation (NSF) Grant OCE-11-40159 (to S.L.B.) and the Penn State Earth and Environmental Systems Institute. T.S. acknowledges funding from NSF ANT 1043500 for mass spectrometric instrument support.

Footnotes

Conflict of interest statement: G.T.L. and Appalachia Consulting provided litigation support and environmental consulting services to the impacted households.

This article is a PNAS Direct Submission.

This article contains supporting information online at www.pnas.org/lookup/suppl/doi:10.1073/pnas.1420279112/-/DCSupplemental.

References

- 1.MIT . The Future of Natural Gas. MIT; Cambridge, MA: 2011. [Google Scholar]

- 2.Engelder T. Should fracking stop? No, it's too valuable. Nature. 2011;477:272–275. doi: 10.1038/477271a. [DOI] [PubMed] [Google Scholar]

- 3.Arthur MA, Cole DR. Unconventional hydrocarbon resources: Prospects and problems. Elements. 2014;10(4):257–264. [Google Scholar]

- 4.Blumsack S. Dash for gas, 21st-century style! Elements. 2014;10(4):265–270. [Google Scholar]

- 5.King GE. 2012. Hydraulic Fracturing 101: What Every Representative, Environmentalist, Regulator, Reporter, Investor, University Researcher, Neighbor and Engineer Should Know About Estimating Frac Risk and Improving Frac Performance in Unconventional Gas and Oil Wells (Soc Petrol Eng, Richardson, TX), Pap 152596.

- 6.Vidic RD, Brantley SL, Vandenbossche JM, Yoxtheimer D, Abad JD. Impact of shale gas development on regional water quality. Science. 2013;340(6134):1235009. doi: 10.1126/science.1235009. [DOI] [PubMed] [Google Scholar]

- 7.Entrekin S, Evans-White M, Johnson B, Hagenbuch E. Rapid expansion of natural gas development poses a threat to surface waters. Front Ecol Environ. 2011;9(9):503–511. [Google Scholar]

- 8.Wilson JM, VanBriesen JM. Oil and gas produced water management and surface drinking water sources in Pennsylvania. Environ Pract. 2012;14(4):288–300. [Google Scholar]

- 9.Osborn SG, Vengosh A, Warner NR, Jackson RB. Methane contamination of drinking water accompanying gas-well drilling and hydraulic fracturing. Proc Natl Acad Sci USA. 2011;108(20):8172–8176. doi: 10.1073/pnas.1100682108. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Brantley SL, et al. Water resource impacts during unconventional shale gas development: The Pennsylvania experience. Int J Coal Geol. 2014;126:140–156. [Google Scholar]

- 11.Darrah TH, Vengosh A, Jackson RB, Warner NR, Poreda RJ. Noble gases identify the mechanisms of fugitive gas contamination in drinking-water wells overlying the Marcellus and Barnett Shales. Proc Natl Acad Sci USA. 2014;111(39):14076–14081. doi: 10.1073/pnas.1322107111. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Jackson RB, et al. The environmental costs and benefits of fracking. Annu Rev Environ Resour. 2014;12(18):327–362. [Google Scholar]

- 13.Breen KJ, Revesz K, Baldassare FJ, McAuley SD. 2007. Natural Gases in Ground Water near Tioga Junction, Tioga County, North-Central Pennsylvania–Occurrence and Use of Isotopes to Determine Origins, 2005 (US Geol Surv, Reston, VA) Sci Invest Rep 2007-5085.

- 14.Revesz KM, Breen KJ, Baldassare FJ, Burruss RC. Carbon and hydrogen isotopic evidence for the origin of combustible gases in water-supply wells in north-central Pennsylvania. Appl Geochem. 2010;25:1845–1859. [Google Scholar]

- 15.Molofsky LJ, Connor JA, Farhat SK, Wylie AS, Jr, Wagner T. 2011. Methane in Pennsylvania water wells unrelated to Marcellus shale fracturing Oil Gas Dev 109(19):54-67. [DOI] [PMC free article] [PubMed]

- 16.Baldassare FJ, McCaffrey MA, Harper JA. A geochemical context for stray gas investigations in the northern Appalachian Basin: Implications of analyses of natural gases from Neogene- through Devonian-age strata. AAPG Bull. 2014;98(2):341–372. [Google Scholar]

- 17. General provision for well construction and operation, The Pennsylvania Code, Chapter 25, Sect. 78.73(c) (1989)

- 18.Llewellyn G. Evidence and mechanisms for Appalachian Basin brine migration into shallow aquifers in NE Pennsylvania, U.S.A. Hydrogeol J. 2014;22(5):1055–1066. [Google Scholar]

- 19.Warner NR, et al. Geochemical evidence for possible natural migration of Marcellus Formation brine to shallow aquifers in Pennsylvania. Proc Natl Acad Sci USA. 2012;109(30):11961–11966. doi: 10.1073/pnas.1121181109. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Poth CW. The occurrence of brine in western Pennsylvania. Pa Geol Surv Bull. 1962;M47:1–53. [Google Scholar]

- 21.Dresel E. 1985. The geochemistry of oilfield brines from western Pennsylvania, MSc thesis (Pennsylvania State University, University Park, PA)

- 22.Osborn SG, McIntosh JC. Chemical and isotopic tracers of the contributions of microbial gas in Devonian organic-rich shales and reservoir sandstones, northern Appalachian Basin. Appl Geochem. 2010;25(20):456–471. [Google Scholar]

- 23.Hayes TD. Sampling and Analysis of Water Streams Associated with the Development of Marcellus Shale Gas. Final Report Prepared for the Marcellus Shale Coaliton. Gas Technol Inst; Des Plaines, IL: 2009. [Google Scholar]

- 24.Kelley D, DeBor D, Malanchak J, Anderson D. Subsurface brine analyses of Pennsylvania from deep formations, OFR 73-02. Pa Bur Topogr Geol Surv; Harrisburg, PA: 1973. [Google Scholar]

- 25.Haluszcak LO, Rose AW, Kump LR. Geochemical evaluation of flowback brine from Marcellus gas wells in Pennsylvania, USA. Applied Geochemistry. 2013;28(2013):55–61. [Google Scholar]

- 26.Pennsylvania Department of Environmental Protection . Frac and flowback water analyses. Pa Dep Environ Prot; Harrisburg, PA: 2010. Available at www.shalenetwork.org. [Google Scholar]

- 27.Molofsky LJ, Connor JA, Wylie AS, Wagner T, Farhat SK. Evaluation of methane sources in groundwater in northeastern Pennsylvania. Ground Water. 2013;51(3):333–349. doi: 10.1111/gwat.12056. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Lea JF, Nickens HV, Wells M. Gas Well Deliquification. Elsevier; New York: 2008. [Google Scholar]

- 29.US Environmental Protection Agency 2012. Study of the Potential Impacts of Hydraulic Fracturing on Drinking Water Resources: Progress Report (US Environ Prot Agency, Washington, DC), EPA 601/R-12/011. [PubMed]

- 30.Leenheer JA, Noyes TI, Stuber HA. Determination of polar organic solutes in oil-shale retort water. Environ Sci Technol. 1982;16(10):714–723. [Google Scholar]

- 31.Engelder T. Capillary tension and imbibition sequester frack fluid in Marcellus gas shale. Proc Natl Acad Sci USA. 2012;109(52):E3625, and author reply (2012) 109(52):E3626. doi: 10.1073/pnas.1216133110. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 32.Gorody AW. Factors affecting the variability of stray gas concentration and composition in groundwater. Environ Geosci. 2012;19(1):17–31. [Google Scholar]

- 33.U.S. House of Representatives Committee of Energy and Commerce Minority Staff . Chemicals Used in Hydraulic Fracturing. US House Rep; Washington, DC: 2011. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.