Abstract

Peach (Prunus persica L. Batsch) fruits of cultivar ‘Shan-i-Punjab’ were harvested at colour break stage and packed in paper moulded trays followed by wrapping with different packaging films viz. cryovac heat shrinkable RD-106, cling and low density polyethylene (LDPE) film. After packaging, the fruits were stored under two different conditions i.e. super-market conditions (18–20 °C; 90–95 % RH) and ordinary market conditions (28–30 °C; 60–65 % RH). The fruits were evaluated for various quality attributes periodically. The shrink film helped in reducing the loss in weight, firmness, decay incidence and maintained the various qualities attributes like total soluble solids, sugars, acidity and ascorbic acid content of the fruits during shelf-life better than unwrapped control fruits. The pectin methyl esterase enzyme activity was also found to be lower in shrink film packed fruits over the unwrapped control fruits. The in-package gaseous composition (O2 and CO2) in shrink film packed fruits was found to be at desired level which resulted in maintenance of pleasant flavour of the fruits. On the other hand LDPE film accumulated very high level of CO2, which led to formation of fermenting odour and decay of fruits in the package. The data revealed that RD-106 film proved quite effective in prolonging the shelf-life and maintaining the quality of peach fruits for 9 and 4 days under super market conditions (SMC) and ordinary market conditions (OMC), respectively as against 6 and 2 days only in case of unpacked control fruits under both the marketing conditions. The results suggest that shrink film could be used in packaging of peach without negative effects on quality.

Keywords: Peach, Packaging films, Storage conditions, Quality

Introduction

The Peach (Prunus persica L. Batsch) is one of the most important fruits grown in the temperate zones of the world. In India, it is grown in the mid hill zone of the Himalayas in the states of Jammu & Kashmir, Himachal Pradesh, Uttarakhand and in North eastern region. The low chilling cultivars of peach are becoming popular in Punjab state as these come early in the market and growers get remunerative price for their produce. Peach is a delicious but highly perishable fruit and has a short shelf life under ambient conditions. Shan-i-Punjab is a low chilling cultivar of peach that grows well under subtropical conditions of Punjab and attains physiological maturity in the months of May–June, when the atmospheric temperature is high, which leads to fruit softening, shrinkage, decay and heavy post harvest losses (Pongener et al. 2011). Immediately after harvest, the nutritional and organoleptic quality of fresh produce start to declining as a result of altered plant metabolism. This quality deterioration is the result of produce transpiration, senescence, ripening associated processes and development of postharvest disorder (Gorris and Peppelenbos 2007). The postharvest technologies providing even a short extension of shelf-life could have a profound effect on marketing of peach fruits.

The concept of super market is fast gearing up in Indian markets and small quantity of selected Indian and exotic fruits are being displayed in the super markets for attracting upper end consumers. Packing of fruits in polymeric films creates modified atmospheric conditions around the produce inside the package allowing lower degree of control of gases and can interplay with physiological processes of commodity resulting in reduced rate of respiration, transpiration and other metabolic processes of fruits (Zagory and Kader 1988; Erkan and Wang 2006). Modified atmosphere packaging techniques are accepted now as the technology of the future. The present investigation was conducted to study the effect of different packaging films on storage life and quality of peach fruits cv. ‘Shan-i-Punjab’ under super-market conditions (SMC) and ordinary market conditions (OMC).

Materials and methods

The fruits of peach cv. ‘Shan-i-Punjab’ were harvested at colour break stage. The bruised and diseased fruits were sorted out and only healthy and uniform sized fruits were selected for the study. Three types of packaging films commercially available in the market viz shrink (15 μ), cling (15 μ) and low density polyethylene film (LDPE, 25 μ) films were used for packaging of peach fruits in paper moulded trays (22 cm × 13 cm). Peach fruits were packed in trays and tightly sealed with different packaging films. However, the shrink film wrapped packs were passed through a shrink wrapping machine (Model BS-450, Samrath Engineers, India) at 165 ºC for 10 s. Thereafter, the packed fruits as well as control (non-packed) fruits were stored at 18–20 °C and 90–95 % RH (SMC) and 28–30 °C and 60–65 % RH (OMC).

Evaluation of physico-chemical attributes

The physiological loss in weight (PLW) of stored fruit was calculated by subtracting final weight from the initial weight of the fruits and expressed in per cent. The fruit firmness was measured with the help of a penetrometer (Model FT- 327, USA) using 8 mm stainless steel probe and expressed in terms of pound force pressure (lb force). The overall organoleptic rating of the fruits was done by a panel of ten judges on the basis of external appearance of fruits, texture, taste, and flavor and overall quality rating was calculated making use of a nine-point Hedonic scale (Amerine et al. 1965). The total soluble solids (TSS) of the fruit juice were determined using a hand refractometer and expressed as percent TSS after making the temperature correction at 20 °C. The total sugars and titratable acidity were estimated as per standard procedure (AOAC 2005).

Pectin methyl esterase activity

For enzyme extraction, fruit samples were stored immediately after harvest in the cool chamber. Twenty grams of fruit pulp was blended in 60–100 ml 0.15 M NaCl solution, filtered through two layers of cheese-cloth, centrifuged at 2,000 rpm for 30 min at 4 °C. The pH of the titration was constantly maintained at 7.0 for 0.15 M of NaCl solution for maximum PME activity considering the results of Castaldo et al. (1989); Denes et al. (2000) and Contreras-Esquivel et al. (1999) as there is direct correlation between pH and salt concentration used. The supernatant was used as an enzyme source. The activity of PME was determined by measuring the increase in acidity after the hydrolysis of pectin by the enzyme (Mahadevan and Sridhar 1982). Pectin methyl esterase units were expressed by the symbols PME (units/ml juice) which represents the milli equivalents of esters hydrolyzed per min per ml of juice, which represents the milli equivalents of esters hydrolyzed per min per ml of juice. The units per milliliter were multiplied by 1,000 for easy interpretation as described by Balaban et al. (1991).

Gaseous composition (CO2 and O2 concentration)

The in-package gaseous composition (CO2 and O2 concentration) of sealed fruit package was monitored at periodic intervals with the help of portable Head Space Gas Analyzer (Model: GS 3/P, Make: Systech Instruments, U.K.). A sample of 0.5 ml was automatically withdrawn from the headspace atmosphere with a pin-needle connected to the injection system. Gases were analyzed with inbuilt sensors for CO2 and O2. The instrument was calibrated towards air.

Experimental design and statistical analysis

The experiment consisted of 4 treatments and 3 storage intervals for SMC experiment and 4 treatments and 2 storage intervals for OMC experiment. Both experiments were laid out in completely randomized design with three replications for each treatment and each storage interval. Data were analyzed for variance by using the SAS (V 9.3, SAS Institute Inc., and Cary, NC, USA) package.

Results and discussion

Physiological loss in weight (PLW)

The percent PLW, in general, increased with the advancement of storage period rather slowly in the beginning but at a faster pace as the storage period advanced (Table 1). It was noticed that shrink film packed fruits registered the lowest average PLW (0.63 %) and ranged between 0 and 1.10 from 3 to 9 days of storage as compared to control where PLW was found to be the highest and ranged between 3 and 8 % under SMC. Similarly under OMC, the lowest mean PLW (1.81 %) was observed in fruits packed in shrink film and the highest (16.25 %) was observed in control fruits. The increase in PLW under different storage conditions is obvious due to respiratory activity leading to moisture loss (Salisbury and Ross 1992). The reduction in weight loss in film-packed fruits is attributed to lower moisture loss due to restricted respiratory process of fruits inside the packaging films (Ben Yehoshua 1985). The apparent increase in in-pack relative humidity prevented the weight loss (Rai et al. 2011). The positive role of shrink film in reducing the PLW of papaya has been reported by Singh and Rao (2005).

Table 1.

Effect of different packing films on PLW, firmness, organoleptic quality and spoilage of peach fruit during super market conditions (SMC) and ordinary market conditions (OMC)

| Treatment | SMC | OMC | |||||

|---|---|---|---|---|---|---|---|

| 3 days | 6 days | 9 days | Mean | 2 days | 4 days | Mean | |

| PLW (%) | |||||||

| Shrink film | 0.00 | 0.80 | 1.10 | 0.63 D | 1.02 | 2.60 | 1.81 D |

| Cling film | 0.80 | 1.14 | 1.30 | 1.08 C | 1.97 | 3.78 | 2.87 C |

| LDPE film | 1.20 | 1.70 | 2.15 | 1.68 B | 2.15 | 4.20 | 3.17 B |

| Control (unpacked) | 3.00 | 6.40 | 8.00 | 5.80 A | 11.70 | 20.80 | 16.25 A |

| Mean | 1.25 C | 2.51 B | 3.14 A | 4.21 B | 7.84 A | ||

| Firmness (lb force) | |||||||

| Shrink film | 14.30 | 8.80 | 6.20 | 9.77 A | 11.40 | 8.00 | 9.70A |

| Cling film | 14.20 | 7.50 | 6.00 | 9.63 B | 11.20 | 7.30 | 9.25 B |

| LDPE film | 12.00 | 7.00 | 6.10 | 8.37 C | 10.50 | 6.89 | 8.69 C |

| Control (unpacked) | 12.30 | 6.10 | 2.30 | 6.90 D | 8.00 | 3.40 | 5.70 D |

| Mean | 13.20 A | 7.35 B | 5.15 C | 10.28 A | 6.39 B | ||

| Sensory quality | |||||||

| Shrink film | 7.50 | 7.00 | 6.70 | 7.07 A | 7.50 | 7.00 | 7.25 A |

| Cling film | 7.20 | 6.80 | 6.00 | 6.67 B | 7.26 | 6.77 | 7.02 B |

| LDPE film | 6.50 | 6.00 | 5.00 | 5.83 C | 6.00 | 5.50 | 5.75 C |

| Control (unpacked) | 6.70 | 6.00 | 5.00 | 5.90 C | 6.00 | 5.00 | 5.50 D |

| Mean | 6.97 A | 6.45 B | 5.67 C | 6.69 A | 6.07 B | ||

| Spoilage (%) | |||||||

| Shrink film | 0 | 3.00 | 5.00 | 2.67 D | 0.00 | 3.00 | 1.50 D |

| Cling film | 0 | 3.00 | 7.00 | 3.33 C | 0.00 | 5.00 | 2.50 C |

| LDPE film | 5 | 12.00 | 16.00 | 11.00 A | 8.00 | 14.00 | 11.00 A |

| Control (unpacked) | 0 | 10.00 | 18.00 | 9.33 B | 0.00 | 8.00 | 4.00 B |

| Mean | 1.25 C | 7.00 B | 11.50 A | 2.00 B | 7.50 A | ||

Means within the same column with same letter are not significantly different (P < 0.05)

Firmness

The fruit firmness, in general, followed a declining trend commensurate with advancement in storage period (Table 1). The fruits packed in shrink packaging film maintained the highest average firmness (9.77 lb force) and control fruits registered the lowest mean firmness (6.90 lb force) under SMC. The firmness of fruits in shrink film declined slower and steadily and ranged between 14.30 and 6.20 lb force from 3 to 9 days of storage interval, whereas in case of control fruits, the decline in firmness was found to be abrupt and sharp and ranged between 12.30 and 2.30 lb force, thereby leading to excessive softening and shriveling of fruits. Under OMC, the shrink film packed fruits recorded highest average firmness (9.70 lb force) and ranged between 11.40 and 8.00 lb force from 2 to 4 days of storage. Whereas, in control, the fruits experienced a faster loss of firmness during storage and ranged between 8 and 3.40 lb force with the average fruit firmness of 5.70 lb force. The progressive decrease in the fruit firmness with the advancement of storage may be due to the breakdown of insoluble protopectins into soluble pectin or by hydrolysis of starch (Mattoo et al. 1975). The lower rate of softening in packaging film packed fruits might be due to the effect of the films in lowering the rate of respiration, delaying the ripening process and reduction in moisture loss (Zagory and Kader 1988). The maintenance of higher firmness with polymeric film packaging has been reported in pear fruits (Mahajan et al. 2013).

Sensory quality

A gradual decline in sensory score was noticed in shrink film packed fruits as compared to control where decline was sharp under both the storage conditions (Table 1). The maximum average sensory score was shown by fruits packed in shrink film (7.09 and 7.25) under both the marketing conditions. The control fruits registered the minimum sensory score (5.90 and 5.50). The flavour of peach fruit depends on a delicate balance of sugars, acids, phenols and aromatic compounds with a number of additional factors such as pulp texture and visual appearance also influence the perceived quality and consumer acceptance and appreciation (Predieri et al. 2006). The recording of higher sensory score in shrink wrapped fruit might be due to the ability of heat shrinkable film to retain the desirable gaseous atmosphere inside the package which is responsible for maintaining the texture and flavour of the fruit (Nanda et al. 2001). The maintenance of freshness, crispness and aroma in shrink packaging has been reported in apple (Sharma et al. 2010) and Nagpur mandarin (Sonkar et al. 2009).

Spoilage

The spoilage of peach fruits under both storage conditions was found to be lower in shrink film packed fruits (Table 1). The LDPE film packed fruits recorded the highest spoilage of fruits even higher than unpacked control fruits. The occurrence of higher decay incidence in LDPE film might be due to accumulation of excessive water vapour inside the package, because of restricted movement of water through the film. The WVTR of LDPE is highest as compared to shrink and cling film (Robertson 1993). Singh et al. (2012) reported that packaging of pear fruits in LDPE polythene bags resulted in development of off- flavour and decay during storage. Dhall et al. (2012) mentioned that shrink film wrapped cucumber exhibited lower decay incidence and better retention of green colour and other physico-chemical attributes during storage as compared to unwrapped cucumber.

Total Soluble Solids (TSS) and total sugars

The fruits packed in shrink film registered maximum average TSS and total sugars content (9.97 % and 5.33 %) under SMC (Table 2). The control fruits recorded the lowest average TSS and total sugar content (8.36 % and 4.72 %). Similar trend was noticed under OMC, where shrink film packed fruits recorded higher TSS and total sugars content (9.32 % and 6.29 %) as compared to control package (8.03 % and 6.03 %). Under super market conditions, a gradual increase in TSS and total sugar upto 6 days was observed in film packed fruits and thereafter declined slowly and steadily, whereas control fruits recorded highest TSS and total sugars after 6 days of storage as compared to film packed fruits and thereafter declined at a faster rate resulted in development of flat taste. The increase in TSS during storage period could be attributed to the water loss and hydrolysis of starch and other polysaccharides to soluble form of sugars (Wills et al. 1980). The gradual increase and decrease in TSS and sugars in film wrapped peach fruits during storage may be possibly due to retarded ripening and senescence processes which simultaneously delayed the conversion of starch into sugars. The present results confirmed the findings of Sharma et al. (2012) who have reported a delayed and sustained increase in the total soluble solids and sugars in shrink film packed kiwi fruits.

Table 2.

Effect of different packing films on TSS, Total Sugars Acidity and Vitamin C of peach fruit during super market conditions (SMC) and ordinary market conditions (OMC)

| Treatment | SMC | OMC | |||||

|---|---|---|---|---|---|---|---|

| 3 days | 6 days | 9 days | Mean | 2 days | 4 days | Mean | |

| TSS (%) | |||||||

| Shrink film | 9.6 | 10.3 | 10.0 | 9.97 A | 9.60 | 9.03 | 9.32 A |

| Cling film | 9.4 | 10.0 | 9.8 | 9.73 B | 9.40 | 9.20 | 9.30 A |

| LDPE film | 8.9 | 9.6 | 9.2 | 9.23 C | 8.90 | 8.40 | 8.65 B |

| Control (unpacked) | 8.9 | 10.2 | 6.0 | 8.36 D | 8.90 | 7.17 | 8.03 C |

| Mean | 9.20 B | 10.02 A | 8.75 C | 9.20 A | 8.45 B | ||

| Total Sugars (%) | |||||||

| Shrink film | 5.20 | 5.70 | 5.10 | 5.33A | 6.80 | 5.78 | 6.29 A |

| Cling film | 5.08 | 5.61 | 5.00 | 5.23B | 6.65 | 5.70 | 6.18 B |

| LDPE film | 5.26 | 5.40 | 4.60 | 5.09C | 6.50 | 5.30 | 5.90 D |

| Control (unpacked) | 5.30 | 5.06 | 4.80 | 4.72D | 6.90 | 5.16 | 6.03 C |

| Mean | 5.21 B | 5.44 A | 4.87 | 6.71 A | 5.48 B | ||

| Acidity (%) | |||||||

| Shrink film | 0.62 | 0.52 | 0.41 | 0.52 A | 0.60 | 0.46 | 0.53 AB |

| Cling film | 0.60 | 0.48 | 0.36 | 0.48 B | 0.63 | 0.45 | 0.54 A |

| LDPE film | 0.57 | 0.42 | 0.31 | 0.43 C | 0.58 | 0.40 | 0.49 C |

| Control (unpacked) | 0.55 | 0.40 | 0.30 | 0.41 C | 0.60 | 0.42 | 0.51 BC |

| Mean | 0.59 A | 0.45 B | 0.34 C | 0.60 A | 0.43 B | ||

| Ascorbic acid (mg%) | |||||||

| Shrink film | 10.20 | 9.20 | 8.20 | 9.20 A | 8.50 | 7.60 | 8.05 A |

| Cling film | 10.10 | 8.90 | 7.80 | 8.93 B | 8.60 | 7.00 | 7.80 B |

| LDPE film | 9.50 | 9.00 | 7.00 | 8.50 C | 8.20 | 6.80 | 7.50 C |

| Control (unpacked) | 9.60 | 8.20 | 6.00 | 7.93 D | 8.00 | 6.20 | 7.10 D |

| Mean | 9.85 A | 8.82 B | 7.25 C | 8.32 A | 6.90 B | ||

Means within the same column with same letter are not significantly different (P < 0.05)

Acidity

The acidity of peach fruits experienced a linear decline as the storage period advanced (Table 2). It was noticed that shrink film packed fruits showed higher acidity over the other treatments throughout the storage period and recorded mean acidity (0.52 %) followed by cling film packed fruits (0.48 %). The control fruits showed the lowest mean acidity (0.41 %) under SMC. The acidity content in shrink and cling film packed fruits, ranged between 0.62 and 0.41, 0.60 to 0.36, percent, respectively from 3 to 9 days of storage as compared to control where acidity was found to be the lowest and ranged between 0.55 and 0.30 %. Under OMC, the highest mean acidity content (0.54 %) was observed in cling film packed fruits and it was closely followed by shrink film packed fruits (0.53 %). On the other hand, the lowest mean acidity (0.49 %) was observed in LDPE film packed fruits. The progressive reduction in the acidity with advancement of storage period might be due to the increased catabolism of organic acids present in fruit through the process of respiration. The decrease in titratable acids during storage may be attributed to utilization of organic acid in pyruvate decarboxylation reaction occurring during the ripening process of fruits (Echeverria and Valich 1989). The packaging films helped in better retention of acidity as compared to control. In wrapped fruits, the lowering of acidity was delayed, which might be due to the effect of packaging films in delaying the respiratory and ripening process. Nanda et al. (2001) and Sharma et al. (2012) observed higher acidity content in shrink wrapped pomegranate and kiwi fruits.

Ascorbic acid

The ascorbic acid content of the fruit showed linear decline during storage irrespective of different treatments (Table 2). However, the shrink film packed fruits maintained the highest ascorbic acid content as compared to control fruits under both the storage conditions. The decrease in ascorbic acid during storage may be due to the oxidation of L-ascorbic acid into dehydroascorbic acid (Mapson 1970). The influence of heat shrinkable films on maintaining higher ascorbic acid content in citrus fruits has also been reported (Ladaniya and Singh 2001; Ladaniya 2003).

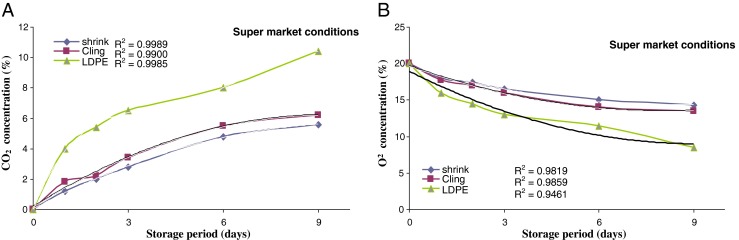

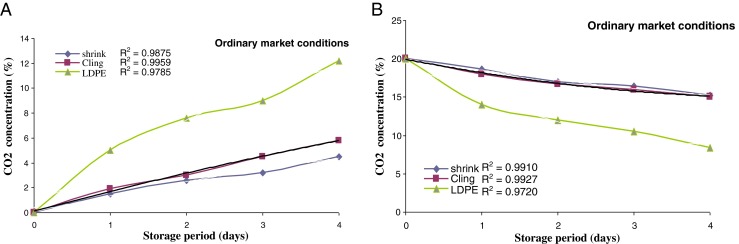

In-package gaseous composition

During storage a decrease in O2 and an increase in CO2 levels occurred for passive modified atmospheric packaging (MAP) in all the three films under SMC as well as under OMC (Figs. 1 and 2). However, gaseous composition in-side the package was significantly different depending on the type of film used. The heat shrinkable packaging film registered a gradual increase in CO2 and decrease in O2 concentration within the package where as LDPE film recorded a sharp increase in CO2 and decrease in O2 concentration inside the package. These findings are in accordance with Nanda et al. (2001) who observed reduced respiration rate in shrink packed pomegranate fruit due to impressive gas barrier properties of heat shrinkable film. The shrink film is known to have better gas exchange properties due to its structure which promote desirable permeability for better gaseous environment within the package which is indicator of controlled respiration of fruit. Zagory and Kader (1988) confirmed about modification of the atmosphere around the fresh produce in the package made of flexible plastic films.

Fig. 1.

Effect of different packaging films on in-package CO2 concentration (a) and O2 concentration (b) under super market conditions

Fig. 2.

Effect of different type of film on in-package CO2 concentration (a) and O2 concentration (b) under ordinary market conditions

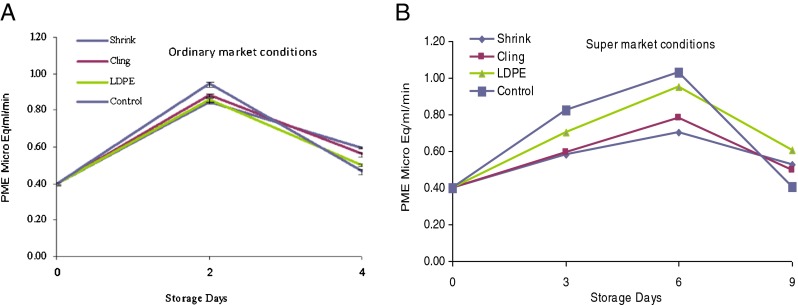

Pectin methyl esterase activity

The packaging films significantly influence the PME activity in peach fruit and this was due to the difference in gaseous conditions generated inside the packages (Fig. 3). Under SMC the PME activity increased upto 6 days of storage and the declined thereafter irrespective of different treatments. The increase in PME activity was quite low in shrink film packed fruits upto 6 days of storage and thereafter declined gradually. On the other hand control fruits recorded maximum activity upto 6 days of storage and thereafter a sharp decline was noticed. Under OMC the shrink film packed fruits recorded the lowest average enzyme activity closely followed by cling film, whereas the control fruits recorded the highest enzyme activity. Pectin methyl esterase removes the methyl groups of the galacturonic acid polymers. De-esterification of polygalacuronic acid chain by PME may make the chain more susceptible to polygalacturonade degradation (Carpita and Gibeaut 1993) facilitating rapid loss of cell wall structure. The increase in PME activity for all samples on 6th day (SMC) and 2nd day (OMC) may be due to increase in respiratory activity which led to ripening of fruits and thereafter decline in PME activity could be due to accelerated senescence leading to over softening of fruits. The lowering of PME activity in shrink film packed fruit may be due to slower respiratory activity occurring inside the package due to creation of modified atmospheric conditions (Sen et al. 2012; Giacalone and Chiabrando 2013). Kaur et al. (2012) reported lower PME activity during storage in pear fruits packed in polymeric film.

Fig. 3.

Effect of different packaging films on the PME activity peach fruit under ordinary and super market conditions

Conclusion

One of the major benefits of modified atmosphere packaging (MAP) is the prevention or retardation of fruit senescence (ripening) and associated biochemical and physiological changes. Packaging of peach fruits in paper moulded trays followed by wrapping with heat shrinkable film seems to hold promise in improving the shelf life and maintaining the quality under super market and ordinary market conditions by 9 and 4 days respectively as against 6 and 2 days only in case of unpacked control. This technology can be helpful in minimizing the postharvest losses of peach fruits during retail marketing.

References

- Amerine MA, Pangborn RM, Roessler EB. Principles of sensory evaluation of food. London: Academic; 1965. p. 5. [Google Scholar]

- AOAC (2005) Official method of analysis of AOAC International. 18th edn, Suite 500 481, North frederick avenue, Gaithersburg, Maryland, USA, pp 20877–2417

- Balaban MO, Arreola AG, Marshall M, Peplow A, Wei CI, Cornel J. Inactivation of pectinesterase in orange juice by supercritical carbon dioxide. J Food Sci. 1991;56:743–746. doi: 10.1111/j.1365-2621.1991.tb05372.x. [DOI] [Google Scholar]

- Ben Yehoshua S. Individual seal packaging of fruits and vegetables in plastic film-A new post-harvest technique. Hort Sci. 1985;20:32–37. [Google Scholar]

- Carpita NC, Gibeaut DM. Structural models of the primary cell walls in flowering plants: consistency of molecular structure with physical properties of walls during growth. Plant J. 1993;3:1–30. doi: 10.1111/j.1365-313X.1993.tb00007.x. [DOI] [PubMed] [Google Scholar]

- Castaldo D, Quagliuolo L, Servillo L, Balestrieri C, Giovanne A. Isolation and characterization of pectinmethylesterase from apple fruit. J Food Sci. 1989;54:653–655. doi: 10.1111/j.1365-2621.1989.tb04674.x. [DOI] [Google Scholar]

- Contreras-Esquivel JC, Correa-Robles C, Aguilar CN, Rodriguez J, Romero J, Hours RA. Pectinesterase extraction fromMexican lime (Citrus aurantifolia Swingle) and prickly pear (Opuntia ficus indica L.) peels. Food Chem. 1999;65:153–156. doi: 10.1016/S0308-8146(98)00012-0. [DOI] [Google Scholar]

- Denes JM, Baron A, Drilleau JF. Purification, properties and heat inactivation of pectinmethylesterase from apple (cv Golden Delicious) J Sci Food Agric. 2000;80:1503–1509. doi: 10.1002/1097-0010(200008)80:10<1503::AID-JSFA676>3.0.CO;2-U. [DOI] [Google Scholar]

- Dhall RK, Sharma SR, Mahajan BVC. Effect of shrink wrap packaging for maintaining quality of cucumber during storage. J Food Sci Technol. 2012;49:495–499. doi: 10.1007/s13197-011-0284-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Echeverria E, Valich J. Enzymes of sugar and acid metabolism in stored Valencia organges. J Am Soc Hort Sci. 1989;114:445–449. [Google Scholar]

- Erkan M, Wang CY. Modified and controlled atmosphere storage of subtropical crops. Stewart Postharvest Rev. 2006;5:1–8. doi: 10.2212/spr.2006.5.4. [DOI] [Google Scholar]

- Giacalone G, Chiabrando V. Modified atmosphere packaging of sweet cherries with biodegradable films. Int Food Res J. 2013;20:1263–1268. [Google Scholar]

- Gorris LGM and Peppelenbos HW (2007) Modified atmospheric packaging of produce. In: Rehman MS (ed) Handbook of food preservation. CRC Press, Taylor and Francis Group, LLC, New York, pp 316–329

- Kaur K, Dhillon WS, Mahajan BVC. Changes in pectin methyl esterase activity with different packaging materials and stages of fruit harvesting during cold storage of pear cv Punjab Beauty. J Food Sci Technol. 2012 doi: 10.1007/s13197-012-0773-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ladaniya MS. Shelf life of seal-packed ‘Mosambi’ sweet orange fruits in heat-shrinkable and stretchable films. Haryana J Hort Sci. 2003;32:50–53. [Google Scholar]

- Ladaniya MS, Singh S. Tray over-wrapping of Mosambi sweet orange. J Food Sci Technol. 2001;38:362–365. [Google Scholar]

- Mahadevan A, Sridhar R. Methods in physiological plant pathology. Madras: Sivagami Pub; 1982. [Google Scholar]

- Mahajan BVC, Kumar D, Dhillon WS. Effect of different polymeric films on the shelf life and quality of pear fruits under supermarket conditions. Indian J Hort. 2013;70:309–312. [Google Scholar]

- Mapson LW. Vitamins in fruits. In: Hulme AC, editor. The biochemistry of fruits and their products. London: Academic; 1970. pp. 369–383. [Google Scholar]

- Mattoo AK, Murata T, Pantastico EB, Chachiss K, Ogata K, Phan CT. Chemical changes during ripening and senescence. In: Pantastico EB, editor. Post-harvest physiology, handling and utilization of tropical and subtropical fruits and vegetables. Westport Connecticut: The AVI Pub. Co. Inc.; 1975. pp. 103–127. [Google Scholar]

- Nanda S, Rao DVS, Krishnamurthy S. Effect of shrink film wrapping and storage temperature on the shelf life and quality of pomegranate fruits cv Ganesh. Postharvest Biol Technol. 2001;22:61–69. doi: 10.1016/S0925-5214(00)00181-2. [DOI] [Google Scholar]

- Pongener A, Mahajan BVC, Singh H. Effect of different films on storage life and quality of peach fruits under cold storage conditions. Indian J Hort. 2011;68:240–245. [Google Scholar]

- Predieri S, Ragazzini P, Rondelli R. Sensory evaluation and peach fruit quality. Acta Hort. 2006;713:429–434. [Google Scholar]

- Rai DR, Chadha S, Kaur MP. Biochemical, microbiological and physiological changes in Jamun kept for long term storage under modified atmosphere packaging. J Food Sci Technol. 2011;48:357–365. doi: 10.1007/s13197-011-0254-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Robertson GL. Food packaging: principles and practice. New York: Marcel Dekker Inc; 1993. [Google Scholar]

- Salisbury FB, Ross CW. Plant physiology. Belmont: Wadsworth; 1992. [Google Scholar]

- Sen C, Mishra HN, Srivastav PP. Modified atmosphere packaging and active packaging of banana: a review on control of ripening and extension of shelf life. J Stored Prod Postharvest Res. 2012;3:122–132. [Google Scholar]

- Sharma RR, Pal RK, Singh D, Samuel DVK, Kar A, Asrey R. Storage life and fruit quality of individually shrink-wrapped apples (Malus domestica) in zero energy cool chamber. Indian J of Agric Sci. 2010;80:338–341. [Google Scholar]

- Sharma RR, Pal RK, Rana V. Effect of heat shrinkable films on storability of kiwifruits under ambient conditions. Indian J Hort. 2012;66:404–408. [Google Scholar]

- Singh SP, Rao DVS. Quality assurance of papaya by shrink film wrapping during storage and ripening. J Food Sci Technol. 2005;42:523–525. [Google Scholar]

- Singh J, Mahajan BVC, Dhillon WS. Effect of different packaging films on shelf life of individually wrapped pear fruits. J Res Punjab Agric Univ. 2012;49:35–39. [Google Scholar]

- Sonkar RK, Sarnaik DA, Dikhshit SN, Saxena RR. Individually stretch cling film wrapped kinnow mandarin under ambient storage. Indian J Hort. 2009;66:22–27. [Google Scholar]

- Wills RBH, Cambridge PA, Scott KJ. Use of flesh firmness and other objective tests to determine consumer acceptability of delicious apples. Aust J Exp Agric Anim Husb. 1980;20:252–256. doi: 10.1071/EA9800252. [DOI] [Google Scholar]

- Zagory D, Kader AA. Modified atmosphere packaging of fresh produce. Food Technol. 1988;42:70–77. [Google Scholar]