Abstract

Response surface methodology (RSM) is a mathematical and statistical technique for testing multiple process variables and their interactive, linear and quadratic effects, and useful in solving multivariable equations obtained from experiments simultaneously. In present study optimum meat level and processing conditions for development of shelf stable chicken meat noodles was determined using central composite design of response surface methodology (RSM). Effects of meat level (110–130 g); processing conditions such as steaming time (12–18 min) and drying time (7–9 h) on the water activity, yield, water absorption index, water solubility index, hardness, overall acceptability and total colour change of chicken noodles were investigated. The aim of present study was to optimize meat level and processing conditions for development of chicken noodles. The coefficients of determination, R2 of all the response variables were higher than 0.8. Based on the response surface and superimposed plots, the optimum conditions such as 60 % meat level, 12 min steaming time and 9 h drying time for development of chicken noodles with desired sensory quality was obtained.

Keywords: Response surface methodology, Chicken noodles, Central composite design, WAI, WSI, Hardness of noodles

Introduction

Snacks contribute an important part of many consumers’ daily nutrient and caloric intake and they are prepared from natural ingredients or components to yield products with specified functional properties (Garriguet 2006; Kerver et al. 2006; Ovaskainen et al. 2006). Snacks are associated with high intakes of sucrose, refined starch and carbohydrate, and low intakes of fibre, vitamins or minerals (Bellisle et al. 2003; Howarth et al. 2007; Kerver et al. 2006; Ovaskainen et al. 2006) In contrast, consumers with dietary restrictions may regard snacking as a healthy dietary solution (Berteus Forslund et al. 2005; Goulet et al. 2008). Extruded products such as snacks can be produced in combination with meat and other non-meat ingredients (Chung et al. 1989). Extrusion cooking is basic principle behind processing of various starch based foods, pre-gelatinized starches, precooked cereal based blends and pasta products like noodles (Li and Vasanthan 2003). It is a continuous cooking, mixing and forming process, involves chemical and structural transformations of raw material such as starch gelatinization, protein denaturation, complex formation between amylose and lipids, and degradation reactions of vitamins, pigments, etc. and end product will show distinct textural property such as a high expansion ratio, low density, crispiness, crunchiness and hardness (Brennan et al. 2013; Meng et al. 2010; Ilo and Berghofer 1999). Noodles are one of main staple food throughout Asian countries (constitutes 20–50% of total wheat flour consumption) because of variety, versatility and satisfying flavour and these features make it suitable for persons of all ages (Hou 2010). Noodles are low in calories, sodium and fat and high in complex carbohydrates which are source of food energy and also provide protein, calcium, iron, magnesium and vitamins. But this cereal flour based product lacks essential amino acid so needs to be improved with animal proteins that have high biological value. Addition of meat into flour based products made it more susceptible to lipid oxidation because of high ambient temperature and lack of cold chains in developing countries. Therefore development of shelf-stable meat product is required which can be stored at room temperature without refrigeration facilities. Hurdle technologies provide a framework for combining a number of milder preservation techniques to achieve an enhanced level of product safety and stability (Gupta et al. 2012). In present study modified atmospheric packaging and processing conditions like steaming and drying were hurdles applied during preparation and storage of noodles.

Response surface methodology (RSM) is a mathematical and statistical technique for testing multiple process variables and their interactive, linear and quadratic effects, and useful in solving multivariable equations obtained from experiments simultaneously. It is significant technique to determine interaction between responses (dependent variable) and factors (independent variable) and also to reduce number of experimental trials as compared to complete experimental design (Murphy et al. 2004; Tiwari et al. 2008 and Ghodke et al. 2009). It has been used for the simultaneous analysis of the effects of process parameters in fresh meat processing (Jakobsen and Bertelsen 2000) and also in some meat products (Desmond et al. 1998; Hsu and Yu 1999 and Hsu and Chung 2000). In present study meat level (110–130 g) and processing conditions; drying time (7–9 h) and steaming time (12–18 min) were independent variables while physicochemical properties such as yield, water activity, WAI, WSI, hardness, overall acceptability and total colour change were dependent variable and these independent variables were optimized using central composite design of response surface methodology.

Materials and methods

Chemicals and other materials

All chemicals used were procured from standard firms like SRL, Fisher Scientific, CDH, HiMedia, Sigma-Aldrich etc. Meat samples required in the experiment was obtained from spent layer fowls slaughtered as per standard procedure in the experimental slaughterhouse of Department of Livestock Products Technology, College of Veterinary Science, GADVASU, Ludhiana, Punjab, India. The refined saffola oil (Manufactured and Packed by Marico Ltd., Mumbai, India), Refined wheat flour (Maida) spices, Table salt (Tata Chemicals Ltd., Mumbai, India), tetra sodium pyrophosphate (HiMedia Laboratories Pvt., Ltd., Mumbai, India), Low density polyethylene (LDPE) were procured from local market of Ludhiana and reputed firms.

Tenderization of meat

Frozen meat samples were taken out as per requirement and cut into smaller cubes after partial thawing in a refrigerator (4 ± 1 °C). The meat chunks were then tenderized using marinade containing calcium chloride (0.15 M) and papain (0.25 %) and kept under refrigeration temperature for 40 h (Biswas et al. 2009). Tenderized meat was washed repeatedly in distilled water, packed in LDPE bags and then frozen at −18 ± 1 °C for subsequent use.

Chicken noodles preparation

The tenderized frozen meat samples were cut into small chunks after partial thawing in a refrigerator and double minced through a meat mincer (Kalsi motors, Ludhiana, India) using 6 mm plate. The minced meat sample was blended with salt, tetra-sodium pyrophosphate (TSPP), refined vegetable oil, spice mix and refined wheat flour. Three coded level (Table 1) were incorporated in design and total of 20 combinations with six central points were obtained based on three-factor three levels central composite experimental design of Response Surface Methodology (Table 1 and 2). Products from these 20 different combinations were prepared. The level of refined wheat flour (Maida) remained constant (100 g) for all samples, while levels of meat were determined based on preliminary trials as mentioned under the Table 2. All other ingredients namely salt, STPP, refined vegetable oil, spice mix were added at 3, 0.3, 4 and 1.5% level, respectively, and these were weighed and added on the basis of meat + flour weight. Salt and TSPP were added first and refined vegetable oil were slowly added at the time of mixing manually. Final mixing was done in Inalsa food mixer for 1 min. Dough prepared by this way was free from connective tissues and fibers. The dough prepared in the previous section was cold extruded (pore size 3 mm for each noodle) through a hand extruder. The raw noodles were placed on multipored aluminium foil, gelatinized by steaming (as mentioned in Table 2), and finally hardened by quick chilling. Moisture content of noodles were reduced by drying in a cabinet industrial tray dryer at a constant temperature of 60 °C for varying period mentioned in Table 2. The dried samples were cooled to room temperature, packed in LDPE bags, sealed and kept in controlled humidity cabinet (Sonar Plus BOD 1 062 M, F-0.0031900610, Associated Scientific Technologies, New Delhi, India) at ambient temperature (35 ± 2 °C, 70 % R.H.) before quality evaluation. The products were evaluated for cooking yield, water activity (aw), water absorption index (WAI), water solubility index (WSI), hardness, delta E and OAA etc.

Table 1.

Experimental range levels of three independent variables in terms of actual values

| Variables | Symbols | Coded variable levels | ||||

|---|---|---|---|---|---|---|

| -α | -1 | 0 | +1 | + α | ||

| Meat level (%) | X1 | 103.182 | 110 | 120 | 130 | 136.818 |

| Steaming time (min) | X2 | 9.95 | 12 | 15 | 18 | 20.045 |

| Drying time (hr) | X3 | 6.32 | 7 | 8 | 9 | 9.68 |

-α- minimum value and + α- maximum value

Table 2.

Mean values of yield, water activity, water absorption index, water solubility index, hardness, delta E and overall acceptability

| S.No. | Meat level | S.T. | D.T. | Yield | Water activity | WAI | WSI | Hardness | Delta-E | OAA |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 110 | 12 | 7 | 59.14 | 0.60 | 3.24 | 0.100 | 132.30 | 7.6 | 6.1 |

| 2 | 130 | 12 | 7 | 66.70 | 0.69 | 3.18 | 0.104 | 150.40 | 9.8 | 6.6 |

| 3 | 110 | 18 | 7 | 57.76 | 0.56 | 3.52 | 0.091 | 139.00 | 8.5 | 6.6 |

| 4 | 130 | 18 | 7 | 63.70 | 0.60 | 3.24 | 0.098 | 155.00 | 9.7 | 6.9 |

| 5 | 110 | 12 | 9 | 56.41 | 0.54 | 3.68 | 0.084 | 145.20 | 9.1 | 6.6 |

| 6 | 130 | 12 | 9 | 62.11 | 0.59 | 3.32 | 0.098 | 158.80 | 9.4 | 6.9 |

| 7 | 110 | 18 | 9 | 57.13 | 0.52 | 3.72 | 0.084 | 160.10 | 8.8 | 6.8 |

| 8 | 130 | 18 | 9 | 61.07 | 0.62 | 3.56 | 0.095 | 162.70 | 9.8 | 71 |

| 9 | 103.18 | 15 | 8 | 52.62 | 0.50 | 3.76 | 0.082 | 128.00 | 6.9 | 6.2 |

| 10 | 136.81 | 15 | 8 | 64.80 | 0.62 | 2.95 | 0.108 | 160.20 | 9.6 | 6.9 |

| 11 | 120 | 15 | 8 | 63.52 | 0.62 | 3.16 | 0.099 | 130.60 | 8.2 | 6.5 |

| 12 | 120 | 9.95 | 8 | 57.50 | 0.56 | 3.28 | 0.089 | 156.60 | 9.8 | 6.9 |

| 13 | 129 | 20.04 | 8 | 63.00 | 0.60 | 3.20 | 0.097 | 130.03 | 7.6 | 6.5 |

| 14 | 120 | 15 | 6.32 | 57.50 | 0.59 | 3.26 | 0.098 | 155.03 | 7.8 | 6.8 |

| 15 | 120 | 15 | 9.68 | 59.00 | 0.57 | 3.35 | 0.098 | 144.40 | 8.7 | 6.6 |

| 16 | 120 | 15 | 8 | 59.30 | 0.58 | 3.31 | 0.097 | 145.40 | 8.6 | 6.5 |

| 17 | 120 | 15 | 8 | 59.90 | 0.57 | 3,28 | 0.098 | 144.00 | 8.6 | 6.6 |

| 18 | 120 | 15 | 8 | 58.50 | 0.57 | 3.24 | 0.098 | 145.00 | 8.6 | 6.7 |

| 19 | 120 | 15 | 8 | 59.30 | 0.57 | 3.26 | 0.99 | 144.30 | 8.6 | 6.6 |

| 20 | 120 | 15 | 8 | 59.30 | 0.58 | 3.34 | 0.098 | 144.00 | 8.5 | 6.6 |

S.T = Steaming time, D.T = Drying time, WAI = Water absorption index, WSI = Water solubility index, OAA = Overall acceptability

Data analysis and modelling

A three factor three level central composite design with five replicates at centre point and total twenty number of combinations (meat level: 110–130 g, steaming time: 12–18 min, drying time: 7–9 h) (Table 2) were used to develop predictive models for physicochemical parameters. The following second order polynomial equation of function Xi was fitted for each factor assessed:

| 1 |

From the equation presented, Y may be defined as the response for the variables assessed, βo, βi, βii and βij are the equation parameter estimates (βo a constant, i a parameter estimate for linear terms, βii an estimate for quadratic terms and βij an estimate for interactive terms). i and j are the levels of the factors with k being the number of factors assessed. In the centre point of model where medium levels of three independent variables were represented, experimental combination were performed five times (15th-20th runs) to estimate experimental variance.

The majority of generated models adequately explain variation of responses with satisfactory R2 values (R2 > 0.90) and Modal F-value, which indicated that most variations could be well explained by the quadratic models and can be considered adequate, because the probability level of F was P < 0.01.

The computational work, including the surface and contour graphical presentations of response surface models, analysis of variance (ANOVA) and other statistical analysis was performed with 0.05 significance level using STAT-EASE software design expert 8.0.4 trial version.

Selection of pertinent variables and experimental ranges

The first step was selecting the appropriate factors in development of chicken meat noodles and experimental ranges for independent variables. The selection of meat level was critical because it affects quality of final product. Steaming time and drying time was selected due to reason that gelatinization of starch and drying of product was required. Pronyk et al. (2008) already explored importance of steaming time in noodle preparation. Noodle is starch based products, therefore steaming and drying played important role in gelatinization of product. Because of scarcity of literature on chicken noodles, preliminary trials were conducted to determine range of variables. On the basis of preliminary trials 55–65 % meat level, 12–18 min steaming time and 7–9 h drying time were selected as range of independent variables.

Product yield

Yield of chicken noodles is calculated as percentage of weight of product after drying to weight of doughbefore extrusion.

Water activity (aw)

Water activity (n = 6) is determined using hand held potable digital water activity meter (Rotonix HYGRO Palm AW1 Set/40 Serial No. 60146499). Briefly, finely ground chicken meat noodle is filled up (80 %) in a moisture free sample cup provided along with aw meter. The sample cup is placed into the sample holder, and then sensor is placed on it for five min for aw value. Duplicate reading was performed for each sample.

Water absorption index (WAI)

Water absorption index is determined in accordance with method described by Anderson et al. (1969). Accurately 2.5 g of finely ground noodle sample was taken in a centrifuge tube, added 30 ml of distilled water, allowed to settle for 30 min, and finally centrifuged at 5 000 rpm (1 957 × g) for 10 min. Gel obtained after centrifugation is weighed and water absorption index is determined using following formula:

Water absorption index is determined in accordance with method described by Anderson et al. (1969). For this, finely ground noodle sample (2.5 g) was taken in a centrifuge tube, added 30 ml of distilled water, allowed to settle for 30 min, and finally centrifuged at 5 000 rpm (1 957 × g) for 10 min. Supernatant obtained after centrifugation allowed to completely dry in hot air oven. Weight of sample left after drying is taken and water solubility index determined using following formula:

Texture profile analysis (TPA)

Texture profile analysis (TPA) was conducted using Texture Analyzer (TMS-PRO, Food Technology Corporation, USA). A set of five chicken noodles each of 6.5 cm (L) × 0.2 cm (r) was subjected to pretest speed (30 mm/s), post test speed (100 mm/s) and test speed (100 mm/s) to a five sets of Allo Kramer Shear blade with a load cell of 2 500 N. The texture TPA was performed as per the procedure outlined by Bourne (1978). Hardness [peak force (N) required to cut the sample (V1)] were calculated automatically by the preloaded Texture Pro software in the equipment from the force-time plot.

Colour profile analysis

Colour profile was measured using Lovibond Tintometer (Lovibond Tintometer RT-300) set at 2° of cool white light (D65) and known as ‘L’, a, and b values. ‘L’ value denotes (brightness 100) or lightness (0), a (+redness/- greenness), b (+yellowness/-blueness) values were recorded on/in a hundreds of chicken noodles kept in a plate. The instrument was calibrated using light trap (black hole) and white tile provided with the instrument. Then the above colour parameters were selected. The instrument was directly put on the surface of chicken meat noodles at three different points. Mean and standard error for each parameter were calculated. Delta E (Total colour difference) was calculated by using following formula:-

where, ΔL = L - Lbase, Δa = a - abase and Δb = b - bbase, and L, a, and b are the color coordinates of the sample and Lbase, abase, and bbase are the color coordinates of the control sample.

Sensory evaluation

A six member experienced panel of judges (equal numbers of male and female) with average age of 25–60 years consisting of teachers and postgraduate students of College of Veterinary Science, Guru Angad Dev Veterinary and Animal Sciences University evaluated the samples for the attributes of appearance and colour, texture, flavour, juiciness and overall acceptability (OAA) using an 8 point descriptive scale (Keeton 1983), where 8 = extremely desirable and 1 = extremely undesirable. Three sittings (n = 18) were conducted for each replicate and at each storage time on samples warmed in a microwave oven for 20 s. During optimization through CCD of RSM only OAA were taken as dependent variable from various sensory attributes.

Results and discussion

Product characteristics

Raw noodles after extrusion were white in colour, sticky in nature with 3 mm diameter and 10–15 cm in length approximately. This white colour and adhesiveness attributed to addition of refined wheat flour and meat respectively, but after steaming colour changes to brown and adhesiveness decreases, might be due to gelatinization of starch. On drying at 60 °C for 7–9 h noodles becomes hard due to complete dehydration. Dried noodles then water cooked for 5 min, water cooked noodles exhibits white colour and other highly acceptable sensory qualities and are ready to serve.

Model fitting from RSM

The effects of meat level and processing conditions on cooking yield, water activity (aw), water absorption index (WAI), water solubility index (WSI), hardness, OAA and delta E etc. of chicken noodles are shown in Table 2. The independent and dependent variables were fitted to the second-order model equation and examined for the goodness of fit. Second order polynomial equation can be used to determine response for any combination by substituting values of independent variables and regression coefficients and their interaction (Table 4). The analyses of variance were performed to determine the lack of fit and the significance of the linear, quadratic and interaction effects of the independent variables on the dependent variables (Table 3). The lack of fit test is a measure of the failure of a model to represent data in the experimental domain at which points were not included in the regression (Varnalis et al. 2004). Coefficient of determination or R2 is the proportion of variation in the response attributed to the model rather than to random error and was suggested that for good fit model, R2 should be at least 80 %. The results showed that the models for all the response variables were highly adequate because they have satisfactory levels of R2 of more than 80 % and that there is no significant lack of fit in all the response variables. The regression coefficients are shown in Table 4 and the equations for each of the response variables could be derived from the predicted values of each response variable. The R2 values of all of the responses exceeded 80 % indicating a high proportion of variability as explained by the data. Therefore, the response surface models developed were adequate.

Table 4.

Regression coefficients of second order polynomial equations showing relationships among response variables and independent variables

| Coefficient | Yield | Water activity | WAI | WSI | Hardness | Delta-E | OAA |

|---|---|---|---|---|---|---|---|

| Intercept | |||||||

| β0 | +1.01 | +9.63 | −0.06 | +2.28 | +0.27 | +0.19 | +0.06 |

| β2 | -1.58 | -0.09 | +0.24 | −3.20 | +2.13 | -0.55 | +0.11 |

| β3 | -8.03 | -0.23 | +0.08 | −5.74 | +17.10 | +6.15 | +0.17 |

| Interaction | |||||||

| β12 | -0.02 | +8.33 | −9.17 | −1.06 | -0.05 | -1.25 | -8.33 |

| β13 | -0.04 | -5.84 | −4.75 | +1.75 | -0.22 | -0.15 | -2.51 |

| β23 | +0.17 | +5.83 | −0.01 | +5.00 | +0.31 | -0.03 | -0.02 |

| Quadratic | |||||||

| β11 | -4.36 | -3.06 | +3.92 | −1.29 | +0.01 | +4.25 | -4.04 |

| β22 | +0.06 | +1.04 | −9.52 | −4.54 | +0.12 | +0.03 | +5.44 |

| β33 | +0.59 | +7.54 | +0.05 | −1.65 | +0.74 | -0.03 | +0.03 |

WAI = Water absorption index, WSI = Water solubility index, H = Hardness of noodles, OAA = Overall acceptability, ΔE (delta E) = Total colour change

Table 3.

F-values and effect of independent variables on responses

| SV | df | Yeild (%) | (ag) | WAI | WSI | Hardness | Delta E | OAA |

|---|---|---|---|---|---|---|---|---|

| Linear | ||||||||

| X1 | 1 | 150.80 | 59.20 | 53.47 | 85.36 | 30.15 | 20.78 | 84.68 |

| X 2 | 1 | 31.16 | 9.88 | 3.52 | 7.13 | 15.06 | 3.14 | 44.71 |

| X3 | 1 | 17.14 | 12.40 | 20.65 | 32.00 | 23.46 | 149.47 | 37.04 |

| Interaction | ||||||||

| X12 | 1 | 2.02 | 0.17 | 0.07 | 0.00 | 0.81 | 0.037 | 0.87 |

| X13 | 1 | 1.55 | 0.00 | 2.25 | 4.49 | 1.51 | 1.83 | 0.87 |

| X19 | 1 | 2.23 | 8.53 | 1.05 | 3.30 | 0.27 | 0.20 | 3.48 |

| Quadratic | ||||||||

| X11 | 1 | 0.03 | 0.47 | 2.75 | 4.41 | 0.91 | 0.987 | 0.041 |

| X22 | 1 | 5.48 | 2.86 | 0.13 | 0.44 | 0.68 | 4.53 | 6.02 |

| X33 | 1 | 3.98 | 4.83 | 4.13 | 7.16 | 0.30 | 1.11 | 2.46 |

| Residual | 10 | |||||||

| Lack of Fit | 5 | 7.82 | 20.50 | 7.20 | 26.26 | 187.16 | 0.82 | 1.87 |

| Pure Error | ||||||||

| Cor Total | 19 | |||||||

| R2 | 0.95 | 0.90 | 0.89 | 0.90 | 0.87 | 0.82 | 0.84 | |

| Modal F-value | 23.78 | 10.90 | 9.83 | 15.88 | 8.09 | 3.67 | 19.98 | |

df = Degree of freedom; aw = water activity; WAI = Water Absorption Index; WSI = Water Solubility Index; OAA = Overall acceptability

Effect of meat level, steaming and drying time

Product yield

Yield of chicken meat noodles varied from 59.10 % to 66.70 %. Regression analysis showed that product yield significantly (P < 0.05) dependent on meat level and processing variables. Second order polynomial equation using actual factors which indicates relationship between response and linear, interactive and quadratic terms of independent variables is mentioned below:

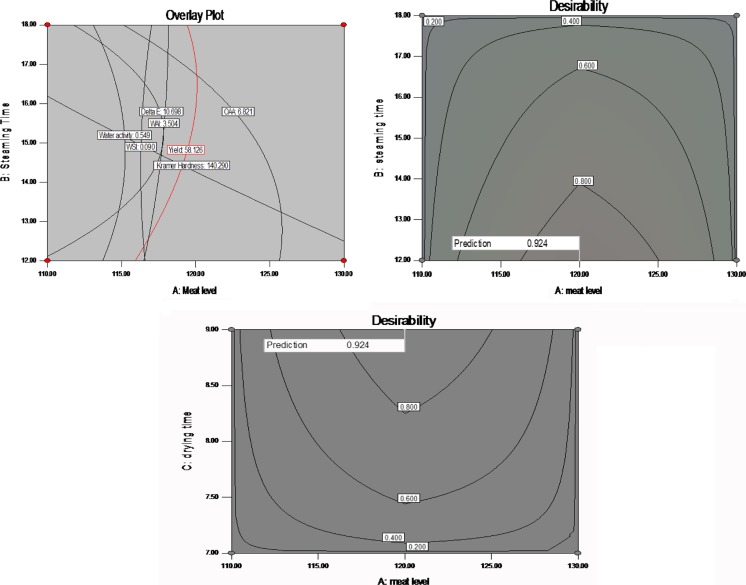

According to final equation meat level had positive linear and quadratic effect (P < 0.05) on yield of chicken noodles. Increasing level of meat (110–130 g) increased products yield from 59–66 % which could be due to increase of moisture content in the formulation as meat level constitutes 75% water. Processing conditions has negative linear and positive quadratic effect (Fig. 1) on product yield which is attributed to loss of moisture due to drying. Danowska-Oziewicz et al. (2007) in chicken and Konieczny et al. (2007)) in beef jerky also reported that steaming time has inverse relationship with product yield. The interactions between meat level and steaming time and meat level and drying time shown to have negative impact on yield due to moisture loss by drying and steaming processes, as moisture dominantly responsible for weight of product decrease in weight consequently decreases product yield.

Fig. 1.

Effect of meat level and processing conditions on yield and various quality characteristics of chicken meat noodles

Water activity

Water activity of chicken noodles varies from 0.5 to 0.69. Regression analysis showed that water activity significantly dependent on meat level and processing variables. The maximum (0.69) and minimum (0.50) water activity values were observed at 130 g meat level, 12 min. steaming time and 7 h drying time and 103.18 g, 15 min and 8 h respectively. Second order polynomial equation for water activity is mentioned below

According to final equation meat level had positive linear effect on water activity of chicken noodles (P < 0.05) which could be due to water content present in meat. Drying and steaming time had a negative effect on water activity; it might be due to loss of moisture through dehydration reaction during processing of noodles. When Pronyk et al. (2008) studied on the effect of superheated steam in noodle quality, they reported that with the increase in temperature, time and steam velocity moisture level decreases and therefore water activity also decreases. Akkose and Aktas (2014); Petit et al. (2014); Konieczny et al. (2007) also reported that salted and dried meat products, such as pastrima, biltong and beef jerky has lower water activity than fresh meat. The interaction of meat level and steaming time had a positive effect on this response could be attributed to dominating effect of moisture level inherently present in meat and water gains during tenderization process. However interactions between meat level and drying time, and steaming time and drying time (Fig. 1) had a negative and positive quadratic effect, respectively.

Water absorption index (WAI)

Water absorption has been generally attributed to the dispersion of starch in excess water, and the dispersion is increased by the degree of starch damage due to gelatinization and extrusion-induced fragmentation, that is, molecular weight reduction of amylose and amylopectin molecules (Rayas-Duarte et al. 1998). Changes in WAI of chicken noodles were affected significantly by meat level, steaming time and drying time. Second order polynomial equation for WAI is mentioned below:

Water absorption index (Y) = 5.300 - 0.060X1 + 0.240X2 + 0.074X3 - 9.166X1X2 - 4.750X1X3 - 0.011X2X3 + 3.916X12 - 9.518X22 + 0.048X32 (df =9, R2 = 0.89)

According to final equation for WAI meat level had significant negative effect on water absorption index which could be due to interaction between meat and gluten protein of refined wheat flour as with the increase of interaction of these two proteins reduced the binding sites for water molecules. Again WAI is mostly relevant with the functional property of flour which is constant in noodles and when meat were added, it become more concentrated and decreased moisture content thereby WAI. At high moisture content, the viscosity of the starch would be low, allowing for extensive internal mixing and uniform heating which would account for enhanced starch gelatinization (Lawton and Handerson 1972) which may lead to increased water absorption. Similar effects of increasing moisture content on WAI have been reported earlier for rice based extrudates (Ding et al. 2005). Oikonomou and Krokida (2012) also reported that with increase in extrusion variables such as moisture content WAI increases in extruded food products. Drying and steaming time, however, had positive linear effect (P < 0.05) which could be due to ability of drier product to absorb more water, as steaming and drying time increased product dryness increased as well. WAI is measure of ability of flour in product to absorb water. Peplinski and Pfeifer (1970) and Kothakota et al. (2013) reported similar results in extruded products and they reported that WAI increased with the increase in steaming time and barrel temperature. The interactions in between meat level × steaming time and meat level × drying time had negative effect on WAI (Fig. 1)

Water solubility index (WSI)

Changes in WAI of chicken noodles were affected significantly by meat level, steaming time and drying time. Second order polynomial equation for WSI is mentioned below:

Water solubility index (Y) = − 8.652 + 2.285X1 − 3.200X2 − 5.738X3 − 1.063X1X2 + 1.750X1X3 + 5.000X2X3 − 1. 292X12 − 4. 535X22 − 1. 645X32 (df = 9, R2 = 0.93) According to final equation (Table 4) meat level had significant (P < 0.05) positive linear effect on WSI that might be due to decrease in overall moisture level of product because on addition of meat to the formulation it becomes more concentrated hence increased WSI (Anderson et al. 1969). The steaming and drying time had negative linear and quadratic effect on WSI due to starch gelatinization during steam cooking (Singh et al. 2007). Nathakaranakule et al. (2007) reported that superheated steaming of chicken meat products lowers WSI due to protein denaturation. The interactions of meat level × drying time and meat level × steaming time respectively had positive and negative effect on WSI (Fig. 1) due to addition of meat and reduction of moisture during drying. However Peplinski and Pfeifer (1970) reported that slight increase (from 1.5 to 2 %) in WSI during stream treatment of corn grits.

Hardness (N) of Raw Noodles

The second order polynomial equation generated in relation to Warner-Bratzler shear hardness values of raw noodles and three independent variables (meat level, steaming time and drying time) is shown as under.

Hardness (Y) = − 42.551 + 0.270X1 + 2.131X2 + 17.102X3 − 0.054X1X2 − 0.223X1X3 + 0.312X2X3 + 0.012X12 + 0. 124X22 + 0. 737X32(df = 9, R2 = 0.87) As seen in Table 3 all independent variables meat level, steaming time and drying time were significantly affecting hardness of raw noodles. Response surface models and contour plots depicted in Fig. 1 show meat level had positive linear and quadratic effect (P < 0.05) due to mechanical resistance of the myofibrillar structure which is responsible for primary tougness in meats, and secondary toughness, by the virtue of amount of connective tissues and their orientation in them. Steaming and drying time also had significantly positive effect on hardness. It is assumed that on continuous heat processing lead to loss of water (90–92%) from the noodles, and as water content is responsible for softness of product, increase of steaming and drying time obviously results in harder product. These results are supported by study of Pronyk et al. (2008) who reported that with the increase in processing time firmness or hardness of noodles increases. Sofos et al. (1995) studied cohesion and hardness of extrusion-cooked mechanically and hand deboned poultry meat with soy protein isolate and kappa-carrageenan and concluded that with the increase of meat level hardness of extruded product increases. However interactions between meat level × steaming time and meat level × drying time indicate decrease in hardness (Fig. 1). This might be due to gelation of collagenous and myofibrillar protein of meat on steam cooking. Steaming × drying time interaction was responsible for complete removal of moisture from product, hence exhibited higher hardness values which correlates positively with this interaction. Thiagarajan 2008 also reported that drying rate and time had positive impact on hardness of beef jerky (North American beef based snacks).

Total colour change delta-E (ΔE) of cooked noodles

Second order polynomial equation generated for Δ-E is shown as under

Interactions between meat level × steaming time and meat level × drying time had positive effect on ΔE value due to increase in both redness (a-value) and yellowness (b-value) with the increase in processing time. The ΔE value was increased in chicken noodles with the increase in meat level because of myoglobin content in meat which resulted in increase of a-value (redness) thereby ΔE value. Pronyk et al. (2008) reported that with the increase in steaming time all the colour coordinates (L, a- and b-values) decreased significantly. Similar results observed by Wang et al. (2013) in thermally treated fish and starch gel where all color coordinates decreases due to starch gelatinization in the starch and mixed gel chips. Interaction between drying and steaming time showed negative effect on ΔE value (Fig. 1). But contradictory result was reported by Oztop et al. (2007). According to them osmotic dehydration of potatoes significantly affected ΔE values and these values were increased with the increase in drying time and temperature. Thiagarajan 2008 reported that hybrid microwave-convection drying with highest drying rate produced beef jerky with lighter and reddish color (Highest ΔE values). In dry-cured hams from white pigs, L* showed higher values for Biceps femoris (BF) than for semimembranosus (Garcia-Esteban et al. 2003; Perez-Alvarez et al. 1999; Sanabria et al. 2004) due to the higher water content of BF. Costa-Corredor et al. (2009) also reported similar results in dry cured hams where increase in drying temperature decreases instrumental color (L*). They attributed the overall drop in L* to dehydration of the dry-cured ham during the process, as a loss of water content raises the concentration of pigments.

Overall acceptability (OAA)

The second order polynomial equation of overall acceptability is shown as under-

Overall acceptability (Y) = − 0.602 + 0.061X1 + 0.115X2 + 0.173X3 − 8.333X1X2 − 2.500X1X3 − 0.016X2X3 − 4.036X12 + 5. 444X22 + 0.031X32(df = 9, R2 = 0.94) Overall acceptability was evaluated on basis of colour and appearance, flavour, texture, meat flavour intensity and after taste. Multiple regression analyses indicated that all independent variables along with their interactions significantly affecting overall acceptability. Textural properties were more favourable for steam cooked noodles, steaming increases hardness of raw noodles so ability to absorb water increases after cooking while adhesiveness or stickiness decreases, hence both the conditions makes noodles more palatable (Pronyk et al. 2008). Interaction between meat level × steaming time and meat level × drying time had negative effect on overall acceptability; it may be due to excessive denaturation of soluble meat protein during heat processing which ultimately leads to slight loss of flavour (Fig. 1). Drying and steaming time interaction also exhibited negative effect on OAA scores.

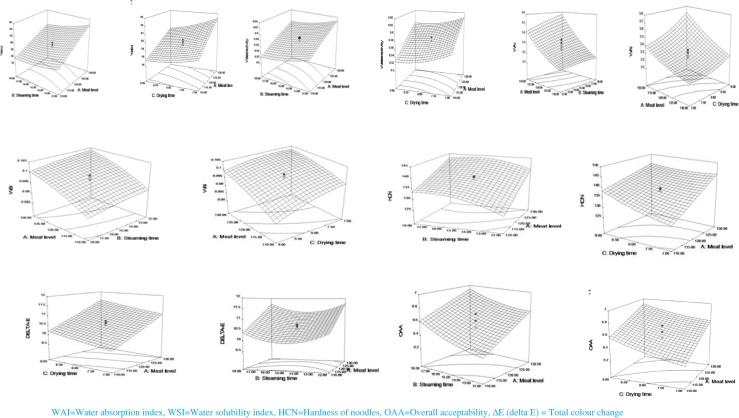

Optimization

A series of contour plots was generated (Fig. 2) and compared visually. The contour plots were superimposed (Capanzana and Buckle 1997) (Fig. 2) and an area of optimum performance was located for all the response variables in which limits of each response have been established. The region that satisfied all the limits was selected as the optimum point. Optimal meat level and processing conditions were determined by superimposing the plots for all response variables (Capanzana and Buckle 1997; Vatsala et al. 2001. The optimum formulations were selected and used for calculating the predicted values of response variables using the prediction equations derived by RSM. Finally desirability table (Table 5) and graphs (Fig. 2) obtained and more than 92% desirability were selected which gives optimized meat level and processing conditions. Based on these superimposed plots, it is suggested that the optimum formulation of chicken meat noodles was meat level 120 g (60 %), steaming time 12 min and drying time 9 h. Once the optimum formulation was determined, they were used to produce chicken meat noodles and all the response variables of the final products were analysed. The experimental and predicted values were within the range and found to be not statistically different at 5 % level. Thus, the model can be used to optimize the basic formulation of chicken meat noodles.

Fig. 2.

Overlay and desirability plots indicating optimized processing conditions and meat level

Table 5.

Desirability of products based on response surface methodology (RSM)

| No | Meat level | S.T. | D.T. | Yield | aw | WAI | WSI | H | OAA | ΔE | Desirability |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 120.00 | 12.00 | 9.00 | 59.40 | 0.570 | 3.43 | 0.090 | 134.30 | 6.70 | 11.30 | 0.924 |

| 2 | 120.00 | 12.00 | 8.98 | 59.43 | 0.570 | 3.42 | 0.090 | 134.29 | 6.71 | 11.30 | 0.921 |

| 3 | 120.20 | 12.00 | 9.00 | 59.40 | 0.570 | 3.42 | 0.092 | 133.62 | 6.72 | 11.39 | 0.920 |

| 4 | 120.00 | 12.07 | 9.00 | 59.38 | 0.574 | 3.43 | 0.092 | 134.57 | 6.71 | 11.35 | 0.919 |

| 5 | 118.33 | 12.00 | 9.00 | 58.89 | 0.568 | 3.46 | 0.091 | 134.43 | 6.68 | 11.26 | 0.872 |

aw = water activity, WAI = Water Absorption Index, WSI = Water Solubility Index, H = Hardness of noodles, OAA = Overall acceptability, ΔE (delta E) = Total colour change

Conclusions

RSM is a useful tool in optimization of the basic formulation of chicken meat noodles. Meat level and processing conditions significantly affects all responses. The model equation developed can be used for predicting the quality of chicken meat noodles. Based on the contour and superimposed plots, the basic formulation with desired quality could be obtained by incorporating 60 % of meat and 12 min and 9 h steaming and drying time respectively.

Acknowledgment

This work was supported by the department of livestock products technology GADVASU Ludhiana Punjab India and special thanks to Dr. S. Balasubramanium for their valuable support related to response surface methodology (RSM) study.

References

- Akkose A, Aktas N. Curing and diffusion coefficient study in pastırma, a Turkish traditional meatproduct. Meat Sci. 2014;96:311–314. doi: 10.1016/j.meatsci.2013.07.026. [DOI] [PubMed] [Google Scholar]

- Anderson RA, Conway HF, Pfeifer VF, Griffin EL. Gelatinization of corn grits by roll and extrusion cooking. Cer. Sci Today. 1969;14(1):4–12. [Google Scholar]

- Bellisle F, Dalix AM, Mennen L, Galan P, Hercberg S, De-Castro JM. Contribution of snacks and mealsin the diet of French adults: a diet-diary study. Physiol & Behav. 2003;79(2):183–189. doi: 10.1016/S0031-9384(03)00088-X. [DOI] [PubMed] [Google Scholar]

- Berteus Forslund H, Torgerson JS, Sjostrom L, Lindroos AK (2005) Snacking frequency in relation to energyintake and food choices in obese men and women compared to a reference population. Inter J Obesity29 (6):711–719 [DOI] [PubMed]

- Biswas AK, Sahoo J, Chatli MK, Sharma DK. Effect of lactic acid, calcium chloride and papain on thephysico-chemical and sensory qualities of turkey meat chunks. Indian J Poultry Sci. 2009;44(1):131–133. [Google Scholar]

- Bourne MC. Texture profile analysis. Food Tech. 1978;32(7)):62–66. [Google Scholar]

- Brennan M, Derbyshire E, Tiwari BK, Brennan C. Ready-to-eat snack products: the role ofextrusion technology in developing consumer acceptable and nutritious snacks. Inter J Food Sci Technology. 2013;48:893–902. doi: 10.1111/ijfs.12055. [DOI] [Google Scholar]

- Capanzana MV, Buckle KA. Optimization of germination conditions by response surface methodologyof a high amylose rice (Oryza sativa) cultivar. Lebensmittel-Wissenschaftund-Technologie. 1997;30:155–163. doi: 10.1006/fstl.1996.0142. [DOI] [Google Scholar]

- Chung S, Betchel P, Villota R (1989) Production of meat based intermediate moisture snack foods by twin screw extrusion. Paper presented in 49th Annual Meeting of Institute of Food Technologist Chicago, IL June 25–29

- Costa-Corredor AX, Serra J, Arnau PG. Reduction of NaCl content in restructured dry-cured hams: Post-resting temperature and drying level effects on physicochemical and sensory parameters. Meat Sci. 2009;83:390–397. doi: 10.1016/j.meatsci.2009.06.011. [DOI] [PubMed] [Google Scholar]

- Danowska-Oziewicz M, Karpinska-Tymoszczyk M, Borowski J. The effect of cooking in a steam-convectionoven on the quality of selected dishes. J Food service. 2007;18(5):187–197. [Google Scholar]

- Desmond EM, Troy DJ, Buckley DJ. The effects of tapioca starch, oat fibre and whey protein on the physicaland sensory properties of low-fat beef burgers. Lebensmittel-Wissenschaft and Technologie. 1998;31(7–8):653–657. doi: 10.1006/fstl.1998.0415. [DOI] [Google Scholar]

- Ding QB, Ainsworth P, Tucker G. The effect of extrusion conditions on the physicochemical propertiesand sensory characteristics of rice-expanded snacks. J Food Eng. 2005;66:283–289. doi: 10.1016/j.jfoodeng.2004.03.019. [DOI] [Google Scholar]

- Garcia-Esteban M, Ansorena D, Gimeno O, Astiasaran I. Optimization of instrumental colouranalysis in dry-cured ham. Meat Sci. 2003;63(3):287–292. doi: 10.1016/S0309-1740(02)00084-0. [DOI] [PubMed] [Google Scholar]

- Garriguet D. Overview of Canadians’ eating habits 2004. Statistics Canada. 2006;82–620(2):1–15. [Google Scholar]

- Ghodke SK, Ananthanarayan L, Rodrigues L. Use of response surface methodology to investigate the effectsof milling conditions on damaged starch, dough stickiness and chapatti quality. Food Chem. 2009;112(4):1010–1015. doi: 10.1016/j.foodchem.2008.05.036. [DOI] [Google Scholar]

- Goulet J, Provencher V, Piche ME, Lapointe A, John Weisnagel S, Nadeau A, Bergeron J, Lemieux S. Relationship between eating behaviours and food and drink consumption in healthypostmenopausal women in a real-life context. Brit J Nutr . 2008;100(4):910–917. doi: 10.1017/S0007114508925459. [DOI] [PubMed] [Google Scholar]

- Gupta S, Chatterjee S, Vaishnav J, Kumar V, Variyar PS, Sharma A (2012) Hurdle technology for shelf-stableminimally processed French beans (Phaseolus vulgaris): a response surface methodology approach. LWT Food Sci Tech 48:182–189

- Hou GG (2010) Preface. In G. G. Hou (Ed.) Asian noodles: Science, technology, and processing (pp. Ix-xii). Hoboken: John Wiley & Sons, Inc

- Howarth NC, Huang TT, Roberts SB, Lin BH, McCrory MA. Eating patterns and dietary composition in relation to BMI in younger and older adults. Inter J Obesity. 2007;31(4):675–684. doi: 10.1038/sj.ijo.0803456. [DOI] [PubMed] [Google Scholar]

- Hsu SY, Chung HY. Interactions of konjac, agar, curdlan gum, j-carrageenan and reheating treatment inemulsified meatballs. J Food Eng. 2000;44(4):199–204. doi: 10.1016/S0260-8774(00)00026-1. [DOI] [Google Scholar]

- Hsu SY, Yu SH. Effects of phosphate, water, fat and salt on qualities of low-fat emulsified meatball. J Food Eng. 1999;39(2):123–130. doi: 10.1016/S0260-8774(98)00134-4. [DOI] [Google Scholar]

- Ilo S, Berghofer E. Kinetics of colour changes during extrusion cooking of maize grits. J Food Eng. 1999;39(1):73–80. doi: 10.1016/S0260-8774(98)00148-4. [DOI] [Google Scholar]

- Jakobsen M, Bertelsen G. Colour stability and lipid oxidation of fresh beef. Development of aresponse surface model for predicting the effects of temperature, storage time, and modified atmosphere composition. Meat Sci. 2000;54:49–57. doi: 10.1016/S0309-1740(99)00069-8. [DOI] [PubMed] [Google Scholar]

- Keeton JT. Effect of fat and sodium chloride and phosphate levels on the chemical and sensory properties of pork patties. J Food Sci. 1983;48(3):878–881. doi: 10.1111/j.1365-2621.1983.tb14921.x. [DOI] [Google Scholar]

- Kerver J, Yang E, Obayashi S, Bianchi L, Song W. Meal and snack patterns are associated withdietary intake of energy and nutrients in US adults. J Am Dietetic Assoc. 2006;106:46–53. doi: 10.1016/j.jada.2005.09.045. [DOI] [PubMed] [Google Scholar]

- Konieczny P, Stangierski J, Kijowski J. Physical and chemical characteristics and acceptability of home style beef jerky. Meat Sci. 2007;76:253–257. doi: 10.1016/j.meatsci.2006.11.006. [DOI] [PubMed] [Google Scholar]

- Kothakota A, Jindal N, Thimmaiah B. A study on evaluation and characterization of extruded product byusing various by-products. Afr J Food Sci. 2013;7(12):485–497. doi: 10.5897/AJFS2013.1065. [DOI] [Google Scholar]

- Lawton BT, Handerson BA. The effects of extruder variables on the gelatinization of corn starch. The Can J Chem Eng. 1972;50:168–172. doi: 10.1002/cjce.5450500205. [DOI] [Google Scholar]

- Li JH, Vasanthan T. Hypochlorite oxidation of field pea starch and its suitability for noodle making using an extrusion cooker. Food Res Intern. 2003;36(4):381–386. doi: 10.1016/S0963-9969(02)00230-2. [DOI] [Google Scholar]

- Meng X, Threinen D, Hansen M, Driedger D. Effects of extrusion conditions on system parameters and physical properties of a chickpea flour based snack. Food Res Int. 2010;43:650–658. doi: 10.1016/j.foodres.2009.07.016. [DOI] [Google Scholar]

- Murphy SC, Gilroy D, Kerry JF, Buckley DJ, Kerry JP. Evaluation of surimi, fat and water content in a low/no added pork sausage formulation using response surface methodology. Meat Sci. 2004;66(3):689–701. doi: 10.1016/j.meatsci.2003.07.001. [DOI] [PubMed] [Google Scholar]

- Nathakaranakule A, Kraiwanichkul W, Soponronnarit S. Comparative study of different combined superheated-steam drying techniques for chicken meat. J Food Eng. 2007;80(4):1023–1030. doi: 10.1016/j.jfoodeng.2006.04.067. [DOI] [Google Scholar]

- Oikonomou NA, Krokida MK. Water Absorption Index and Water Solubility Index Prediction forExtruded Food Products. Int J Food Properties. 2012;15:157–168. doi: 10.1080/10942911003754718. [DOI] [Google Scholar]

- Ovaskainen ML, Reinivuo H, Tapanainen H, Hannila ML, Korhonen T, Pakkala H. Snacks as anelement of energy intake and food consumption. Eur J Clin Nutr. 2006;60(4):494–501. doi: 10.1038/sj.ejcn.1602343. [DOI] [PubMed] [Google Scholar]

- Oztop MH, Sahin S, Sumnu G. Optimization of microwave frying of osmotically dehydrated potato slices by using response surface methodology. Eur Food Res Tech. 2007;224(6):707–713. doi: 10.1007/s00217-006-0362-5. [DOI] [Google Scholar]

- Peplinski AJ, Pfeifer VF. Gelatinization of corn and sorghum grits by steam cooking. Cereal Sci Today. 1970;15(5):144–151. [Google Scholar]

- Perez-Alvarez JA, Sayas-Barbera ME, Fernandez-Lopez J, Gago-Gago MA, Pagan Moreno MJ, Aranda-Catala V. Chemical and color characteristics of spanish dry-cured ham at the end of the aging process. J Muscle Foods. 1999;10(2):195–201. doi: 10.1111/j.1745-4573.1999.tb00395.x. [DOI] [Google Scholar]

- Petit T, Petit Y, Santchurn SJ, Collignan A. Physicochemical and microbiological characteristics of biltong, a traditional salted dried meat of South Africa. Meat Sci. 2014;96:1313–1317. doi: 10.1016/j.meatsci.2013.11.003. [DOI] [PubMed] [Google Scholar]

- Pronyk C, Cenkowski S, Muir WE, Lukow OM. Effects of superheated steam processing on the textural and physical properties of Asian noodle. Drying Tech. 2008;26(2):192–203. doi: 10.1080/07373930701831382. [DOI] [Google Scholar]

- Rayas-Duarte P, Majewska K, Doetkott C. Effect of extrusion process parameters on the quality of buckwheat flour mixes. Cereal Chem. 1998;75:338–345. doi: 10.1094/CCHEM.1998.75.3.338. [DOI] [Google Scholar]

- Sanabria C, Martin-Alvarez PJ, Carrascosa AV. Colour and moisture changes during the manufacture of Iberian dry-cured ham caused by some biotic and abiotic factors. Food Sci and Tech Inter. 2004;10(4):269–275. doi: 10.1177/1082013204046094. [DOI] [Google Scholar]

- Singh B, Sekhon KS, Singh N. Effects of moisture, temperature and level of pea grits on extrusion behaviour and product characteristics of rice. Food Chem. 2007;100:198–202. doi: 10.1016/j.foodchem.2005.09.042. [DOI] [Google Scholar]

- Sofos JN, Ba-Jaber AS, Schmidt GR, Maga JA. Quality of extrusion-cooked poultry meat products. Develop in Food Sci. 1995;37:1265–1280. [Google Scholar]

- Thiagarajan IV. Combined microwave - convection drying and textural characteristics of beef Jerky. SK: A Thesis of Degree of Master of Science in the Department of Agricultural and Bioresource Engineering University of Saskatchewan Saskatoon; 2008. [Google Scholar]

- Tiwari BK, Muthukumarappan K, O’Donnell CP, Cullen PJ. Colour degradation and quality parameters of sonicated orange juice using response surface methodology. LWT – Food Sci and Tech. 2008;41(10):1876–1883. doi: 10.1016/j.lwt.2007.11.016. [DOI] [Google Scholar]

- Varnalis AI, Brennan JG, Macdougall DB, Gilmour SG. Optimization of high temperature puffing of potato cubes using response surface methodology. J Food Eng. 2004;61:153–163. doi: 10.1016/S0260-8774(03)00082-7. [DOI] [Google Scholar]

- Vatsala CN, Saxena DC, Rao HP. Optimization of ingredients and process conditions for the preparation of puri using response surface methodology. Int J Food Sci and Tech. 2001;36:407–414. doi: 10.1046/j.1365-2621.2001.00474.x. [DOI] [Google Scholar]

- Wang Y, Zhang M, Mujumdar AS. Effect of cassava starch gel, fish gel and mixed gels and thermal treatment on structure development and various quality parameters in microwave vacuum-dried gel slices. Food Hydrocoll. 2013;33:26–37. doi: 10.1016/j.foodhyd.2013.02.005. [DOI] [Google Scholar]