Abstract

The effect of oil concentration (57.50, 58.75, 60.00 and 61.25 %) and temperature (5, 10 and 15 ºC) on steady shear rheological properties of O/W model system meat emulsions were investigated. The effect of temperature and oil concentration was modeled using power law and exponential type functions. The meat emulsions showed non-Newtonian flow behavior because flow behavior index was lower than unity. Consistency coefficient and flow behavior index values of O/W model system meat emulsions were calculated using Oswald de Waele model with higher coefficients of determination. Apparent viscosities of emulsions at a specified shear rate (50 s−1) were in the range of 0.652–0.941 Pa s. Increasing oil concentration provided an increase in apparent viscosity and increase in temperature levels resulted a decrease in consistency coefficient values. The exponential function performed better than the power-law function (R2 > 0.922) in terms of describing the effect of oil concentration on the steady shear rheological properties of the model system meat emulsions. Higher coefficients of determination (R2 = 0.979–0.999) were observed in exponential-type function compared to a power law function (R2 = 0.880–0.946).

Keywords: Meat emulsion, Rheology, Apparent viscosity, Temperature, Concentration

Introduction

Meat emulsions, mixtures of water, protein and fat are oil-in-water emulsions with a fluid character (Foegeding 1988). Rezler et al. (2007) indicated that meat products, particularly comminuted ones are complex food systems in which proteins as well as other constituents of the product affect the quality of the finished product. Among those constituents, fat plays very important functions since it helps to stabilize meat emulsions, reduces cooking loss, improves water-holding capacity, and provides juiciness and proper texture (Carballo et al. 1995; Pietrasik and Duda 2000; Yoo et al. 2007). It has also been reported that the binding, structural and stability properties, and mechano-rheological characteristics of meat products are affected by fat (Hughes et al. 1997; Rezler et al. 2003). Therefore, it is important to investigate the effect of different fat levels on those characteristics.

Model system studies have been effectively utilized to get information about the effect of various factors on meat emulsions such as pH, temperature, salt level (ionic strength), different ions, chopping capacity, fat and protein type, meat quality and type, meat condition (frozen or fresh, pre-or post-rigor state), fat temperature and level, particle size, and effects of vegetable and animal proteins other than meat. Model system emulsion studies are frequently preferred because they are convenient, economic, reproducible, and require less time (Karakaya 1990; Gökalp et al. 1990; Karakaya and Gökalp 1991).

Apparent viscosity measured by steady shear rheological analysis is generally considered to be one of the most important physical characteristics related to the quality of food products. Apparent viscosity is considerably influenced by changes both in the ingredient level in food formulations and in temperature levels. In steady shear rheological analysis, some parameters, such as apparent viscosity, shear stress, shear rate and consistency, are measured in order to determine changes in flow behavior of fluid foods depending on some factors like ingredient level and temperature. This is very important because knowledge of flow behavior is beneficial not only in quality control of the product, but also for energy input calculations, process design, and equipment selection, particularly for heat exchangers and pumps (Ibanoglu and Ibanoglu 1998). Additionally, the rheological characteristics of fluid foods are very important to understand the macroscopic behavior of emulsion systems with respect to the micro-structural organization (Barnes 1994; Quintana et al. 2007; Lorenzo et al. 2008). Sensory quality and consequently consumer preference are influenced by the rheological properties of fluid foods.

Several recent studies have been reported on properties of the model system emulsions such as emulsion viscosity (Zorba 2006; Saricoban et al. 2008; Saricoban et al. 2010), apparent yield stress, density (Zorba et al. 2005; Tuncturk and Zorba 2006; Zorba and Kurt 2006), dynamic shear properties (Karaman et al. 2011), and creep-recovery properties (Yilmaz et al. 2012). However, none of these studies reported on the effect of oil concentration on the steady shear rheological properties of the O/W model system meat emulsions. In addition to studied aforementioned properties of model system meat emulsions, studying the steady shear properties of a food system is also important with respect to the engineering design of continuous processes, development of new products, and quality control during processing of emulsion-type foods. Therefore, the present study was undertaken: (a) to determine the effect of temperature and oil concentration on the steady shear rheological properties of O/W model system meat emulsions; and (b) to model experimental data in order to interpret the effect of temperature and concentration on the steady shear rheological properties of the emulsion systems studied.

Materials and methods

Materials

Beef (M. semimembranosus muscle, 20.5 % protein, 3.5 % fat, 0.92 % ash, and 72 % moisture) was purchased from a local market in Kayseri, Turkey. Corn oil (11.01 % palmitic acid, 1.99 % stearic acid, 29.81 % oleic acid and 55.13 % linoleic acid) was provided from Ulker Bizim Co. (İstanbul, Turkey).

Methods

Preparation of O/W model system emulsions

Analytical grade NaCl and K2HPO4 (Merck, Darmstadt, Germany) were used. A combination of NaCl (2.5 %) and K2HPO4 (0.5 %) was prepared and dissolved in water. Four different emulsion samples including different concentrations of 57.50, 58.75, 60.00 and 61.25 % of commercial corn oil were used. For each emulsion sample, 25 g of beef meat plus 100 ml of cold (0–4 ºC) salt-phosphate solution (SPS) were placed into a blender jar and comminuted for 2 min at 13,000 rpm to obtain a slurry. A 25-g aliquot of the resulting slurry and 75 ml of additional SPS were transferred to another blender jar and homogenized for 10 s at high speed (20,000 rpm) and 50 ml of refined corn oil was added at first into each emulsion sample. Oil was added at 1.0 ml/s until the total amount of oil (dispensed plus original) reached to 135.3, 142.4, 150 and 158.1 ml each, which corresponded to the 57.50, 58.75, 60.00 and 61.25 % corn oil, respectively. The emulsions were prepared by mixing the oil into the dispersions and then, emulsifying with a Waring Blender (Waring Commercial Blendor®, Torrington, Connecticut USA) at 20,000 rpm during oil addition. The temperature was monitored to ensure that the emulsions never exceeded 15 ºC. All emulsions were prepared in triplicate samples with two replications.

Steady shear analysis

Rheological characteristics of model system meat emulsions were determined by using a controlled stress rheometer (THERMO-HAAKE, RheoStress 1, Karlsruhe Germany) equipped with a temperature control unit (Haake, Karlsruhe, Germany) and a cone-plate configuration (cone diameter 35 mm, angle 4°, gap size 0.140 mm). Measurements were carried out in the shear rate range of 1–100 s−1 at selected temperature (5, 10 and 15 ºC). Precisely, 1.0-ml sample was placed between the cone and plate and the measurement was started immediately. Twenty-five data points were recorded at 10 s intervals during shearing. Each measurement was replicated four times on four different samples (each 1 ml) from the same meat emulsion sample with two repetitions. The apparent viscosity was determined as a function of shear rate. The data were fitted to Oswald de Waele model using RheoWin Data Manager (RheoWin Pro V. 4.0, HAAKE, Karlsruhe, Germany) and consistency coefficient and flow behavior index values were calculated according to the following model used to describe shear-induced behavior of the model system meat emulsions:

| 1 |

The steady shear data were processed to determine the effect of temperature and corn oil concentration on apparent viscosity on the model system meat emulsion, as described below.

Effect of temperature and concentration

Effect of temperature

Temperature (T) dependency of the apparent viscosity η at a specified shear rate (50 s−1, shear rate in mouth) of the O/W model system meat emulsions was described by the Arrhenius model (Saravacos 1970; Rao et al. 1984):

| 2 |

Effect of oil concentration on steady shear parameters

The variation of apparent viscosity with concentration (C) can be described by several models (Rao et al. 1984; Ibarz et al. 1987). In our study, the variations of the other parameters with concentration were also described by these models. In this respect, the most common used models are generally power-law (Togrul and Arslan 2004) and exponential-type (Exp) models as follows:

| 3 |

| 4 |

Effect of oil concentration on activation energy

For a constant temperature, activation energy for flow depends on corn oil concentration. The variation of activation energy depending on the concentration was modeled by using power law (Eq. 5) and exponential functions (Eq. 6) as following:

| 5 |

| 6 |

Combined effect of temperature and corn oil concentration

Combined effect of temperature and concentration is very useful to obtain a single equation describing the combined effect of temperature and concentration on key parameters of O/W model system meat emulsions. For this purpose, the Eqs. (2) – (4) were combined to obtain the following model functions, which describe the combined effect of temperature and corn oil concentration:

| 7 |

| 8 |

Performance of the models

Different statistical parameters, such as mean percentage error (MPE), mean bias error (MEB), root mean square error (RMSE), modeling efficiency (EF), and chi-square (χ2), in addition to R2 were used to evaluate the performance of derived models (Eqs. 7 and 8). These statistics allow for the detection of differences between experimental data and the model estimates. These parameters can be estimated as following:

| 9 |

| 10 |

| 11 |

| 12 |

| 13 |

Statistical analysis

Statistical analysis was carried out using Statistical Analysis Software package of MINITAB for Windows Release 13. One-way Analysis of Variance (ANOVA) was applied to determine the effect of temperature and concentration and Duncan Multiple Range Test was applied to observe the differences between the mean combination values using MstatC software (α = 0.05). The analyses were conducted in triplicates with two repetitions.

Results and discussion

Steady shear properties

Before explaining the effect of the studied factors; namely, temperature and oil level on the steady shear properties of the O/W model system meat emulsion samples, we needed to show the simultaneous changes caused by these factors on the physicochemical properties of the emulsion samples. In our previous study (Yilmaz et al. 2012), protein, ash contents, and pH values of the O/W model system meat emulsion samples were determined to range from 0.424 to 0.381 %, 1.23 to 1.13 % and 6.89 to 6.98, respectively, reflecting logical increasing and decreasing trends depending on the increase in oil contents of the emulsion samples. Lightness (L*), redness (a*) and yellowness (b*) values were found to change from 69.11 to 72.00, 1.25 to 1.44 and 6.48 to 7.44. These values also reflected the expected trends depending on the oil contents added.

Figure 1 illustrates the shear stress (σ) versus shear rate () plots for the O/W model system meat emulsions prepared with different levels (57.50 and 61.25 %) of corn oil at temperatures within the 5–15 ºC range. Non-Newtonian shear-thinning behavior was observed for all model system meat emulsion samples because the values of flow behavior index (n) ranged from 0.135 to 0.261 (Table 1). Accordingly, Rao and Tattiyakul (1999) reported the same flow behavior for model fresh or frozen beef meat emulsions exhibiting non-Newtonian flow in which apparent viscosity decreased with increasing shear rate. On the other hand, n decreased and increased with increasing oil concentration and temperature level, respectively (Table 1). The Oswald de Waele model was adequate for describing the flow behavior of the model system meat emulsions because determination coefficients (R2) were higher than 0.920. Table 1 also indicates that increased oil concentration and decreased temperature increased consistency coefficients (K), as can be expected. Lower K values indicated less viscous nature because of increased fluidity in model system meat emulsions, and a consistent trend was observed in K and n values depending on corn oil concentration and temperature level. These results which are found for model system meat emulsion were consistent with the previous reports. Constenla et al. (1989) indicated that as the oil was emulsified, apparent viscosity increased because the protein matrix extended in the emulsions. Hassan and Hobani (1998) concluded that increment in apparent viscosity was desired in the high fat emulsion type products because elasticity increased with increasing apparent viscosity in emulsion type meat products.

Fig. 1.

Shear stress-shear rate plots for the O/W model system meat emulsions containing (a) 57.50 % and (b) 61.25 % oil over the entire temperature range and (c) different oil concentrations at 10 ºC

Table 1.

Steady shear parameters and temperature dependency of O/W model system meat emulsions at different oil concentrations

| Oil content % | Oswald de Waele parameters | Temperature dependency parametersa | ||||||

|---|---|---|---|---|---|---|---|---|

| Temperature [ºC] | K d | n | R 2b | η 50 e | η 0 | E a c | R 2 | |

| 57.50 | 5 | 14.06 | 0.218 | 0.997 | 0.652 | 0.146 | 3.46 ± 0.24 | 0.976 |

| 10 | 12.66 | 0.222 | 0.997 | 0.637 | ||||

| 15 | 10.86 | 0.261 | 0.997 | 0.619 | ||||

| 58.75 | 5 | 18.25 | 0.170 | 0.962 | 0.740 | 0.094 | 4.77 ± 0.31 | 0.971 |

| 10 | 17.68 | 0.170 | 0.969 | 0.702 | ||||

| 15 | 12.74 | 0.178 | 0.979 | 0.689 | ||||

| 60.00 | 5 | 23.79 | 0.155 | 0.961 | 0.828 | 0.011 | 10.03 ± 0.19 | 0.977 |

| 10 | 21.67 | 0.161 | 0.948 | 0.798 | ||||

| 15 | 18.58 | 0.175 | 0.970 | 0.712 | ||||

| 61.25 | 5 | 27.20 | 0.135 | 0.922 | 0.941 | 0.008 | 11.12 ± 0.14 | 0.897 |

| 10 | 26.59 | 0.141 | 0.940 | 0.919 | ||||

| 15 | 20.30 | 0.173 | 0.968 | 0.806 | ||||

a Temperature dependency on apparent viscosity values at 50 s−1

b R 2 is determination coefficient for the Oswald de Waele model

c E a is the activation energy pooled by the determination coefficient for the Arrhenius Equation (Eq.2)

d K is the consistency coefficient

e η 50 is the apparent viscosity at 50 s−1

Effect of temperature on apparent viscosity (η50)

The Arrhenius relationship (Eq. 2, Arslan et al. 2005) in which apparent viscosity (η50) decreases as an exponential function with temperature was used to describe the effect of temperature on η50 values of fluids at a specified shear rate (50 s−1). In order to determine the parameters of relation (Table 1), linear regression analysis was applied to the logarithmic form of Eq. 2. η50 values decreased with increasing temperature from 5 to 15 ºC within all corn oil concentration range studied (Table 1). The effect of temperature on decrease η50 values was ascribed to increased intermolecular distances due to thermal expansion (Saricoban et al. 2008, 2010). Thermal energy of the molecules increases with increasing temperature, which results in the development of molecular distances owing to reduction in intermolecular forces; therefore, viscosity of the fluid decreases (Togrul and Arslan 2004; Partal et al. 1997).

Effect of oil concentration on apparent viscosity (η50)

The effect of oil concentration on η50 values are also shown in Table 1. A linear increment in the η50 values was observed as oil concentration increased. This was expected because it is well known that increasing solid content normally increases the consistency (Saricoban et al. 2008, 2010).

Power-law and exponential type models were used to describe the variation of η50 values with concentration. Linearized forms of Eqs. (3) and (4) were plotted and corresponding model parameters are presented in Table 2, which represents the values of the parameters of power-law and exponential relationships. From the values of determination coefficients obtained from two models, the exponential model (R2 = 0.979–0.999) describes better the experimental than does the power-law model (R2 = 0.880–0.946) in relating the effect of oil concentration on η50 values in model system meat emulsions.

Table 2.

Effect of oil concentration on apparent viscosity of O/W model system meat emulsions at different temperatures

| Temperature [ºC] | Power-law function η 50 b = η 1 [C a1] | Exponential function η 50 = η 2exp [a 2 C] | ||||

|---|---|---|---|---|---|---|

| η 1 [Pa s] | a 1 | R 2a | η 2 [Pa s] | a 2 [(%)−1] | R 2 | |

| 5 | 3 × 10−6 | 3.049 | 0.880 | 2.45 × 10−3 | 0.097 | 0.999 |

| 10 | 1 × 10−6 | 3.428 | 0.900 | 2.01 × 10−3 | 0.099 | 0.997 |

| 15 | 4 × 10−6 | 2.960 | 0.946 | 13.5 × 10−3 | 0.067 | 0.979 |

a R 2 is determination coefficient for the Power law or Exponential function

b η 50 is the apparent viscosity at 50 s−1

Effect of oil concentration on activation energy

Table 1 indicates that the activation energy values and η0 of the emulsion samples increased from 3.46 to 11.12 kJmol−1 and decreased from 0.146 to 0.008 Pa s as the oil concentration increased, respectively, with high determination coefficients (R2 = 0.897–0.977) as oil concentration increased. Increasing oil concentration levels considerably changed the observed Ea values, revealing that there was a remarkable effect of concentration on Ea. The high Ea values of emulsion samples within the concentration range studied indicated that the rheological properties of O/W meat emulsions were highly temperature dependent. Similarly, Partal et al. (1997). reported that an increase in Ea with the increasing oil concentration in the structure of emulsion. They calculated Ea value of O/W emulsions added with 70 % sunflower oil and stabilized with 1 % sucrose palmitate to be 15.7 kJ mol−1.

The Eqs. (5) and (6) were used for fitting the values of Ea and their respective concentrations by least-squares methods to obtain estimates of the parameters of model. Table 3 illustrated the calculated parameters for these models. The dependency of Ea on the oil concentration was better described by the exponential function (R2 = 0.934) than by the power-law function (R2 = 0.516).

Table 3.

Effect of oil concentration on activation energy of steady shear flow

| Power-law function E a a = A 1 [C B1] | Exponential function E a = A 2exp [B 2 C] | |||||

|---|---|---|---|---|---|---|

| A 1 [(%)−1] | B 1 | R 2b | A 2 [kJ mol−1] | B 2 [(%)−1] | R 2 | |

| Coefficients | 6.6 × 10−5 | 2.847 | 0.516 | 2 × 10−6 | 0.255 | 0.934 |

a E a is the activation energy pooled by the determination coefficient for the Arrhenius Equation (Eq.2)

b R 2 is determination coefficient for the Power law or Exponential function

Combined effect of temperature and corn oil concentration on apparent viscosity (η50)

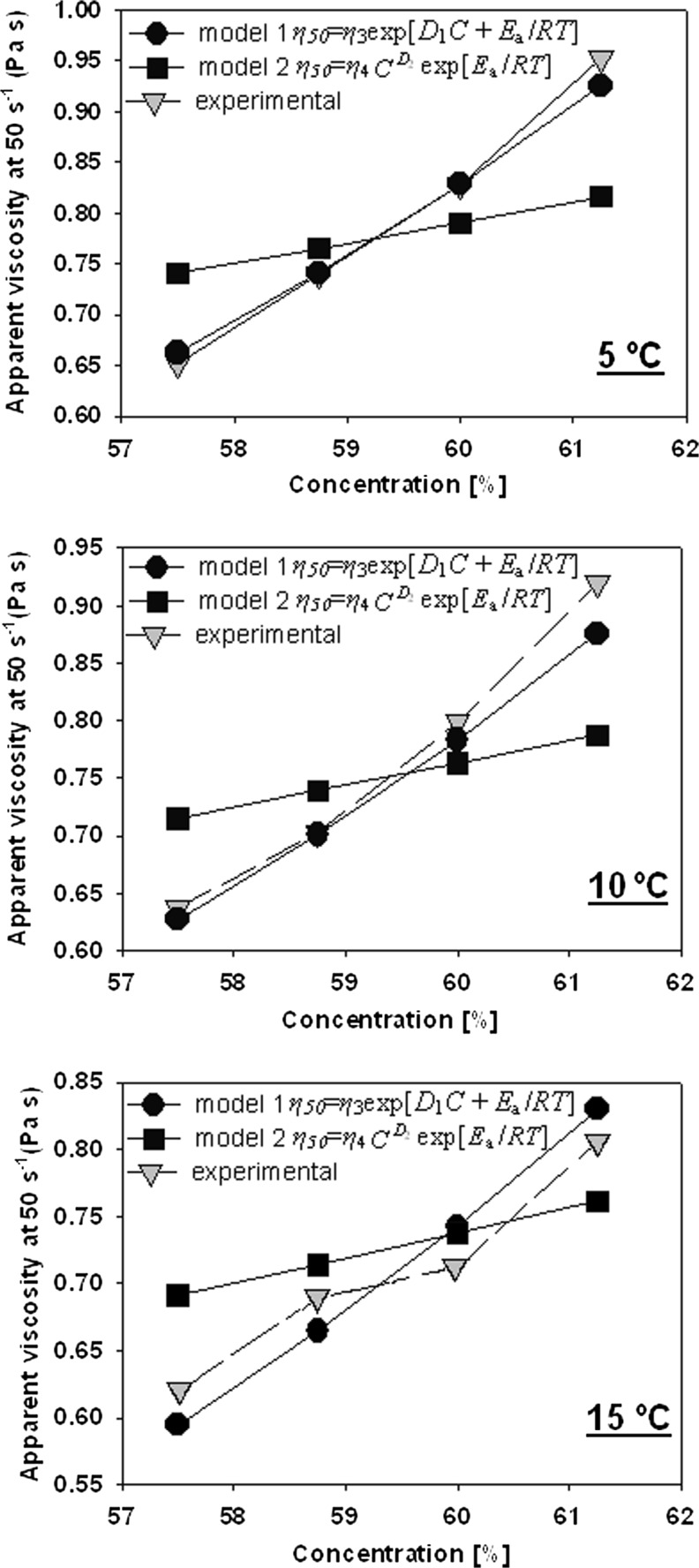

Multiple linear regression analyses were performed on the linearized forms of the Eqs. (7) and (8) to calculate their coefficients. Table 4 illustrates the values of these constants and abilities of Eqs. (7) and (8) to describe the combined effect of both temperature and oil concentration. It is clear from the table (Table 4) that the first model, Eqs. (7) better described the relationship (R2 = 0.979) than did the second model, Eqs. (8) (R2 = 0.713). The higher the values of EF and the lower the values of MPE, MBE, RMSE and χ2 mean the goodness of fit (Rao and Tattiyakul 1999). In this respect, the higher values of EF and the lower absolute values of RMSE, MPE and χ2 excluding MBE were obtained with the statistically fitted model of Eq. (7).

Table 4.

Combined effect of temperature and oil concentration on the apparent viscosity at 50 s−1

| Equations for combined effect | Statistical test parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| iη i | j | D j | E a a [kJ mol−1] | R 2b | MPE | MBE | RMSE | EF | χ 2 | |

| η 50 = η 3exp [D 1 C + E a/R (T + 273.2)] | η 3 [Pa s] | D 1 [%]−1 | ||||||||

| 1.81 × 10−4 | 1 | 0.089 | 7.140 ± 0.41 | 0.979 | 0.690 | −0.006 | 0.021 | 0.999 | 0.001 | |

| η 50 = η 4 exp [E a/R (T + 273.2)] | η 4 [Pa s] | D 2 | ||||||||

| 2.17 × 10−4 | 2 | 1.518 | 4.591 ± 0.24 | 0.713 | −0.980 | −0.002 | 0.071 | 0.987 | 0.007 | |

a E a is the activation energy

b R 2 is determination coefficient for the equations

MPE, mean percentage error; MBE, mean bias error; RMSE, root mean square error; EF, modeling efficiency and χ 2, chi-square

Multiple regression analysis on apparent viscosity (η50) -temperature-concentration data showed that the statistically fitted model of Eq. (7) could analyze the apparent viscosity of the O/W model system meat emulsions and be used as a single model as following:

| 14 |

The plots generated according to models 1 and 2 [Eqs. (7) and (8), respectively] and according to the experimental results demonstrate the effect of concentration and temperature on the apparent viscosity (Fig. 2). When the plots derived from models 1 and 2 were examined and compared with the those derived from the experimental results, there was a good agreement between the model 1 plots and the experimental plots (Fig. 2).

Fig. 2.

The efficiencies of the predicted models for the estimation of apparent viscosity at 50 s−1 of the O/W model system meat emulsions at different temperature levels. T (K) = absolute temperature (273.2+ T (ºC)

Conclusions

Increasing oil concentration resulted in an increment in apparent viscosity and consistency coefficient values. Increment in temperature levels caused a decrease in these parameters. Different mathematical models with high coefficient of determination were successfully constructed to estimate the steady shear properties such as apparent viscosity of the emulsion systems as a function of corn oil concentration and temperature. The effect of temperature on the apparent viscosity was clearly described by the Arrhenius relationship with high coefficient of determination (R2). The exponential model performed better than the power-law model. On the other hand, the multiple regression analysis indicated that the statistically fitted model (Eq.14) could be proposed to analyze the combined effect of temperature and concentration on the parameters of the emulsion systems.

Nomenclature

- a1

constant [dimensionless] for concentration effect

- a2

constant [(%)−1] for concentration effect

- A1

constant for a fixed temperature [(%)−1]

- A2

constant for a fixed temperature [kJ mol−1]

- B1

constant for a fixed temperature [dimensionless]

- B2

constant for a fixed temperature [(%)−1]

- C

concentration [(%)−1]

- D1

constant for combined effect [(%)−1]

- D2

constant for combined effect [dimensionless]

- Ea

activation energy [kJ mol−1]

- EF

modeling efficiency

- K

consistency coefficient [Pa sn]

- n

flow behavior index [dimensionless]

- η50

apparent viscosity at 50 s−1 [Pa s]

- N

number of data points

- nu

number of model parameters

- η0

constant for Arrhenius equation [Pa s]

- η1

constant for concentration effect [Pa s]

- η2

constant for concentration effect [Pa s]

- η3

constant for combined effect [Pa s]

- η4

constant for combined effect [Pa s]

- MBE

mean bias error

- MPE

mean percentage error

- R

universal gas constant [kJ mol−1 K−1]

- R2

coefficient of determination

- RMSE

root mean square error

- T

temperature (ºC)

experimental values

average of experimental values

predicted values

- χ2

chi-square

Greek symbols

shear rate [s−1]

- η

apparent viscosity [Pa s]

- σ

shear stress [Pa]

References

- Arslan E, Yener M, Esin A. Rheological characterization of tahin/pekmez (sesame paste/concentrated grape juice) blends. J Food Eng. 2005;69:167–172. doi: 10.1016/j.jfoodeng.2004.08.010. [DOI] [Google Scholar]

- Barnes HA. Rheology of emulsions - A review. Colloids and Surfaces A. Physicochem Eng Asp. 1994;91:89–95. doi: 10.1016/0927-7757(93)02719-U. [DOI] [Google Scholar]

- Carballo J, Barreto G, Colmenero FJ. Starch and egg white lnfluence on properties of bologna sausage as related to fat content. J Food Sci. 1995;60:673–677. doi: 10.1111/j.1365-2621.1995.tb06204.x. [DOI] [Google Scholar]

- Constenla D, Lozano J, Crapiste G. Thermophysical properties of clarified apple juice as a function of concentration and temperature. J Food Sci. 1989;54:663–668. doi: 10.1111/j.1365-2621.1989.tb04677.x. [DOI] [Google Scholar]

- Foegeding EA (1988) Gelation in meat batters. In: Reciprocal Meat Conference Proceedings, vol. 41. American Meat Science Association, 44–47

- Gökalp HY, Yetim H, Selçuk N, Zorba Ö. Et emülsiyonları ve bu emülsiyonların model sistemde çalıştırılması. Gida. 1990;15:21–27. [Google Scholar]

- Hassan B, Hobani A. Flow properties of Roselle (Hibiscus sabdariffa L.) extract. J Food Eng. 1998;35:459–470. doi: 10.1016/S0260-8774(98)00044-2. [DOI] [Google Scholar]

- Hughes E, Cofrades S, Troy D. Effects of fat level, oat fibre and carrageenan on frankfurters formulated with 5, 12 and 30 % fat. Meat Sci. 1997;45:273–281. doi: 10.1016/S0309-1740(96)00109-X. [DOI] [PubMed] [Google Scholar]

- Ibanoglu S. Ibanoglu E (1998) Rheological characterization of some traditional Turkish soups. J Food Eng. 1998;35:251–256. doi: 10.1016/S0260-8774(98)00016-8. [DOI] [Google Scholar]

- Ibarz A, Vicente M, Graell J. Rheological behaviour of apple juice and pear juice and their concentrates. J Food Eng. 1987;6:257–267. doi: 10.1016/0260-8774(87)90013-6. [DOI] [Google Scholar]

- Karakaya M. Farkli Tur Organ Etlerinin Bitkisel ve Degisik Hayvansal Yaglar ile Olusturdukları Emulsiyonlarin Cesitli Ozelliklerinin Model Sistemde Arastirilmasi. Erzurum: In Graduate School of Natural and Applied Sciences. Ataturk Univeristy; 1990. p. 60. [Google Scholar]

- Karakaya M, Gökalp HY. Farklı tür etlerin bitkisel ve değişik hayvansal yağlar ile oluşturdukları emülsiyonların çeşitli özelliklerinin model sistemde araştırılması. Bursa: II. International Food Symposium; 1991. pp. 383–397. [Google Scholar]

- Karaman S, Yilmaz MT, Dogan M, Yetim H, Kayacier A. Dynamic oscillatory shear properties of O/W model system meat emulsions: Linear viscoelastic analysis for effect of temperature and oil concentration on protein network formation. J Food Eng. 2011;107:241–252. doi: 10.1016/j.jfoodeng.2011.06.016. [DOI] [Google Scholar]

- Lorenzo G, Zaritzky N, Califano A. Modeling rheological properties of low-in-fat O/W emulsions stabilized with xanthan/guar mixtures. Food Res Int. 2008;41:487–494. doi: 10.1016/j.foodres.2008.02.005. [DOI] [Google Scholar]

- Partal P, Guerrero A, Berjano M, Gallegos C. Influence of concentration and temperature on the flow behavior of oil-in-water emulsions stabilized by sucrose palmitate. J Am Oil Chem Soc. 1997;74:1203–1212. doi: 10.1007/s11746-997-0046-8. [DOI] [Google Scholar]

- Pietrasik Z, Duda Z. Effect of fat content and soy protein/carrageenan mix on the quality characteristics of comminuted, scalded sausages. Meat Sci. 2000;56:181–188. doi: 10.1016/S0309-1740(00)00038-3. [DOI] [PubMed] [Google Scholar]

- Quintana J, Lorenzo G, Zaritzky N, Califano A, Lupano C (2007) Hydrocolloids as O/W emulsion stabilizers: effect of the structural features during storage. In: Lupano CE (ed) Functional Properties of Food Components. Research Signpost, Kerala, pp 1–22

- Rao M, Cooley H, Vitali A. Flow properties of concentrated juices at low temperatures. Food Technol. 1984;38:113–119. [Google Scholar]

- Rao M, Tattiyakul J. Granule size and rheological behavior of heated tapioca starch dispersions. Carbohyd Polym. 1999;38:123–132. doi: 10.1016/S0144-8617(98)00112-X. [DOI] [Google Scholar]

- Rezler R, Poliszko S, Dolata W, Piotrowska E. Dynamic-mechanical and thermal analysis of the hydro-colloidal phase in model meat emulsions with the addition of pea cellulose. Acta Agrophisic. 2003;2:417–424. [Google Scholar]

- Rezler R, Piotrowska E, Dolata W, Wojciechowski M. Effect of the substitution of meat by a protein preparation on the rheological properties of finely-comminuted sausage force meats. Acta Agrophisic. 2007;9:221–231. [Google Scholar]

- Saravacos G. Effect of temperature on viscosity of fruit juices and purees. J Food Sci. 1970;3:122–125. doi: 10.1111/j.1365-2621.1970.tb12119.x. [DOI] [Google Scholar]

- Saricoban C, Özalp B, Yilmaz MT, Özen G, Karakaya M, Akbulut M. Characteristics of meat emulsion systems as influenced by different levels of lemon albedo. Meat Sci. 2008;80:599–606. doi: 10.1016/j.meatsci.2008.02.008. [DOI] [PubMed] [Google Scholar]

- Saricoban C, Yilmaz MT, Karakaya M, Tiske SS. The effect of different levels of sunflower head pith addition on the properties of model system emulsions prepared from fresh and frozen beef. Meat Sci. 2010;84:186–195. doi: 10.1016/j.meatsci.2009.08.046. [DOI] [PubMed] [Google Scholar]

- Smith D. Meat proteins: Functional properties in comminuted meat products. Food Technol. 1988;42:116–121. [Google Scholar]

- Togrul H, Arslan N. Mathematical model for prediction of apparent viscosity of molasses. J Food Eng. 2004;62:281–289. doi: 10.1016/S0260-8774(03)00241-3. [DOI] [Google Scholar]

- Tuncturk Y, Zorba O. The effects of enzymatic hydrolysis of casein on apparent yield stress and some emulsion properties. Food Hydrocolloid. 2006;20:475–482. doi: 10.1016/j.foodhyd.2005.04.003. [DOI] [Google Scholar]

- Yilmaz MT, Karaman S, Dogan M, Yetim H, Kayacier A. Characterization of O/W model system meat emulsions using shear creep and creep recovery tests based on mechanical simulation models and their correlation with texture profile analysis (TPA) parameters. J Food Eng. 2012;108:327–336. doi: 10.1016/j.jfoodeng.2011.08.005. [DOI] [Google Scholar]

- Yoo SS, Kook SH, Park SY, Shim JH, Chin KB. Physicochemical characteristics, textural properties and volatile compounds in comminuted sausages as affected by various fat levels and fat replacers. Int J Food Sci Technol. 2007;42:1114–1122. doi: 10.1111/j.1365-2621.2006.01402.x. [DOI] [Google Scholar]

- Zorba O. The effects of the amount of emulsified oil on the emulsion stability and viscosity of myofibrillar proteins. Food Hydrocolloid. 2006;20:698–702. doi: 10.1016/j.foodhyd.2005.06.010. [DOI] [Google Scholar]

- Zorba O, Kurt S, Genccelep H. The effects of different levels of skim milk powder and whey powder on apparent yield stress and density of different meat emulsions. Food Hydrocolloid. 2005;19:149–155. doi: 10.1016/j.foodhyd.2004.05.001. [DOI] [Google Scholar]

- Zorba O, Kurt S. Optimization of emulsion characteristics of beef, chicken and turkey meat mixtures in model system using mixture design. Meat Sci. 2006;73:611–618. doi: 10.1016/j.meatsci.2006.02.017. [DOI] [PubMed] [Google Scholar]