Abstract

Aims:

To observe and study the effect of multiple autoclave sterilization cycles, on the surface of nickel-titanium (NiTi) files.

Materials and Methods:

The file used for this study was the Mtwo file (VDW) and ProTaper (Dentsply). The apical 5 mm of the files were attached to a silicon wafer and subjected to autoclave cycles under standardized conditions. They were scanned with an AFM after 1, 5, and 10 cycles. The unsterilized files were used as control, before start of the study. Three vertical topographic parameters namely maximum height (MH), root mean square (RMS) of surface roughness, and arithmetic mean roughness (AMR)were measured with the atomic force microscope (AFM). Analysis of variance along with Tukey's test was used to test the differences.

Results:

The vertical topographic parameters were higher for both the files, right after the first cycle, when compared with the control (P < 0.01). The surface roughness increased sharply for Mtwo when compared to ProTaper, though ProTaper had a rougher surface initially.

Conclusions:

The study confirmed that the irregularities present on the surface of the file became more prominent with multiple autoclave cycles, a fact that should be kept in mind during their reuse.

Keywords: Atomic force microscope, autoclave sterilization, NiTi files, surface roughness

INTRODUCTION

The advent of nickel-titanium (NiTi) has really revolutionized every aspect, sphere, and branch of dentistry. It has undergone a plethora of changes since its inception, both in formulation and application, to suit the varying needs of the profession. Nitinol is the name given to a family of intermetallic alloys consisting of nickel and titanium, which have been ascribed to have properties of shape, memory, and super elasticity.[1]

Though they have superior clinical performance and mechanical properties, they are considered expensive and their high costs have prompted the clinicians to consider reusing these files, especially in the developing countries. Thus, inadvertently, they are at times, employed beyond their recommended usefulness.[2]

Infection control is of great significance in today's clinical practice. Apart from bacteria, there is a constant threat of cross infection involving viruses and prions. It has been shown in various studies conducted that normal chemical and mechanical cleaning procedures, fail to eliminate these threats. Steam sterilization, after a stringent cleansing protocol, with the use of chemicals is the best defense against such spread of infection.[3] However no consensus exists, even today, regarding the effect of such sterilization procedures, on the surface of rotary NiTi files.[2]

The topography of the surface affects the bulk properties and influences the behavior of a given material.[4] The atomic force microscope (AFM) is part of a larger family of scanning probe microscopes. It works by probing the surface of the sample with a small tip attached to a cantilever. This process provides valuable data regarding the topography of the surface of the sample.[5] The AFM is simple to use and can give detailed surface information even at the molecular level. The most commonly used parameters to describe the topographic characteristics of a surface using the AFM are the arithmetic mean roughness (AMR), the maximum height (MH), and the root mean square (RMS). These parameters describe the vertical amplitude of the surface topography.[2] Thus, the AFM can be readily applied to study the surface of NiTi endodontic files.

The objective of this study was to evaluate the surface alterations on the Mtwo NiTi rotary file, after being exposed to a specific number of sterilization cycles in an autoclave, using an AFM. This would help to shed some light on the delicate balance between the action of steam sterilization and its reaction, in terms of topographical changes on the surface of the instrument, which could have implications, in its clinical use.

MATERIALS AND METHODS

The study was performed on the following files: Mtwo rotary NiTi file (VDW) and ProTaper F1 file (Dentsply).

The new files were removed from the manufacturer's packaging and examined under ambient lighting conditions with the naked eye for any gross impurities or defects. After this the files were uniformly cut 5 mm from the tip of the file, and then mounted onto silicon wafers using cyanoacrylate glue.

At this stage, the samples were scanned for the first time using the AFM. The images from the AFM were recorded in contact operation mode, on a Picoscan AFM under ambient conditions. Typical AFM probes (curvature radius, <20 nm) mounted on cantilevers (200 μm) with spring constant of 0.032 N/m were used for this purpose. Scanned areas (1 Hz) were perfect squares (20 μm × 20 μm) in which a weak force (<1nN) was applied. AFM images were processed with WSXM 5.0 (Nanotec Electronica SL, Madrid, Spain). The vertical topographic parameters of AMR, MH, and RMS were recorded at five different points of each file, on the first 5 mm from its tip. The data obtained from the scan for each file was recorded and labeled as Cycle 0, which would correspond to the morphology of the surface of the files prior to any autoclave sterilization.

The sterilization was performed following a fixed standardized protocol, at a temperature of 121°C, and a pressure of 15 psi, for 15 min after which they were allowed to cool and dry at room temperature. The files were then again scanned by the AFM, exactly as the first time and the data that was recorded were labeled as Cycle 1 for each of the files. Similarly, the files were subjected to a total of 10 sterilization cycles. They were scanned by the AFM twice more, after the fifth cycle (data recorded as Cycle 5) and after the tenth cycle (data recorded as Cycle 10).

Once the data from the AFM scans were obtained, the AMR, MH, and RMS of each reading in all the groups (Cycle 0, Cycle 1, Cycle 5, Cycle 10) were recorded and tabulated. All statistical analyses were performed using Statav 10.0. The differences among the groups were tested by analysis of variance with Tukey's test for multiple comparisons.

RESULTS

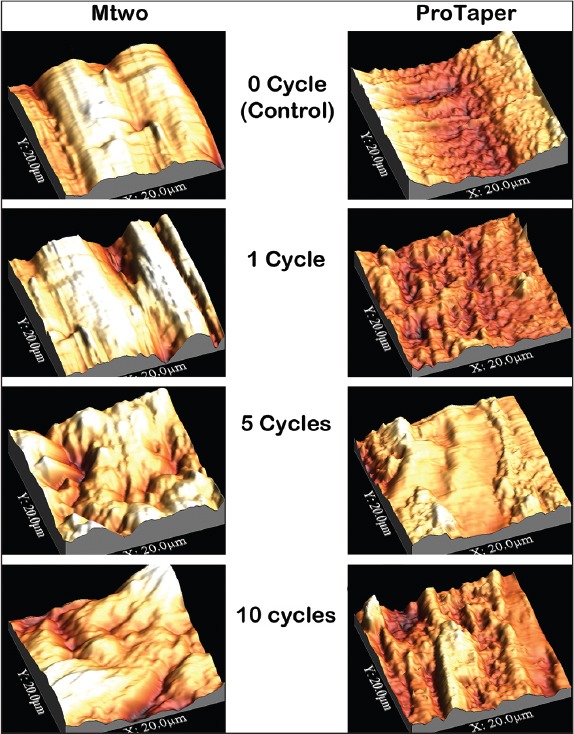

Figure 1 shows contact mode scans of both the files, before and after their respective sterilization cycles. The scans showed that the surface of both the brands of files had an initially rough surface to begin with. These scans revealed a significant increase in the surface roughness of the files between Cycle 0 and10.

Figure 1.

Shows contact mode scans of both the files, before and after their respective sterilization cycles

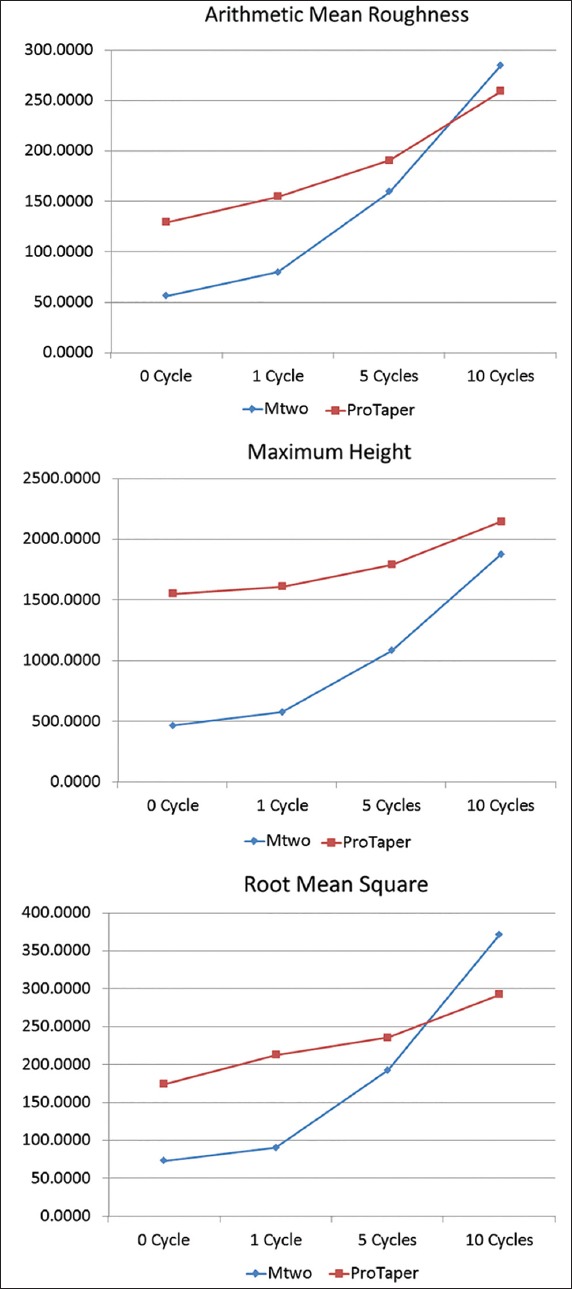

To confirm any statistically significant difference in the surface topography of the files because of the autoclave sterilization; the AMR, MH, and RMS parameters were evaluated. Figure 2 shows the mean of the AMR, MH, and RMS parameters of both Mtwo and ProTaper files. For the ProTaper file, the AMR significantly increased (P < 0.01) after one cycle of sterilization. The MH increased significantly (P < 0.01) between Cycle 1 and 5 of sterilization, and the RMS increased significantly (P < 0.01) after Cycle 1 of sterilization. For the Mtwo file, the AMR significantly increased (P < 0.01) after Cycle 1 of sterilization. The MH increased significantly (P < 0.01) after Cycle 1 of sterilization, and the RMS increased significantly (P < 0.01) between Cycle 1 and 5 of sterilization.

Figure 2.

Shows the mean of the AMR, MH, and RMS parameters of both Mtwo and ProTaper files. AMR = Arithmetic mean roughness, MH = Maximum height, and RMS = Root mean square

Thus, most of the vertical topographical parameters increased for both the files after just one autoclave sterilization cycle. ProTaper file surface showed greater roughness than Mtwo to begin with; however, the Mtwo file surface showed a greater degree of increase in roughness compared to ProTaper. This increase in surface roughness was much more drastic for both the files after the fifth and tenth sterilization cycle, and the roughest surface was observed after the tenth cycle for both the files.

DISCUSSION

One of the most important factors that govern modern dentistry is the infection control protocol, which needs to be universally applied and has thus influenced all aspects of dentistry. The Robert Koch Institute categorized endodontic instruments to the class of highest concern (Critical instruments class B) in 2006, because of its close contact with tissue and blood.[3]

Studies have shown that the currently employed methods in decontaminating endodontic instruments are ineffective in completely removing all biological debris. This is especially true if only chemicals like alcohol and commercially available disinfectants are being used for this purpose.[6] The use of the steam autoclave is thus imperative in conjunction with effective cleaning protocols to achieve the goal of completely sterilizing the file, thus making them safe for reuse in patients.

A lot of controversy exists regarding the effect of autoclave sterilization on the torsional strength of NiTi files. Some studies state an increase in the torsional strength by autoclaving (Silvaggio and Higgs, 1997). Other studies indicate a decrease in strength (Rapisarde et al., 1999; Alapati et al., 2005; and Valois et al., 2008).[7] It was well-acknowledged that NiTi alloys exhibit higher corrosion rates at higher temperatures (Pun and Berzins 2008). Furthermore, it was also found that nickel surface concentrations reduced with exposure to autoclave sterilization, and titanium oxides increased conveying that oxidation may be taking place on the surface, which was confirmed byAuger spectroscopy analysis (Rapisarda et al., 1999).[7]

It was thought that the temperatures reached during autoclave sterilization might not have been high enough to induce the precipitation of Ti3Ni4, which is responsible for increasing the hardness of the files. That being said, it was also observed that autoclave sterilization produced no deleterious effect on the files that could reduce their mechanical resistance.[8] Canalda-Sahli et al., (1998) showed that flexibility of NiTi files greatly decreased after autoclave sterilization, though this was not clinically significant.[9]

NiTi files have to be machined rather than twisted. This leads to surface irregularities (milling marks) and metal flash on the cutting edges that may potentially precipitate crack nucleation (Serene et al., 1995; Thompson 2000; and Martins et al., 2002). Cracks were found to start at surface irregularities, scratches, and inclusions, which act as stress raisers during cyclic loading (Eggeler et al., 2004). As noticed by Kuhn et al., (2001), when the material is subjected to deformation or stress by machining, a high density of lattice defects, such as dislocations, are produced.[8] Thus, the machined surfaces of the rotary files are a potential cause of increased fatigue failure of NiTi files.

Scanning electron microscopic observations of new rotary NiTi instruments showed that there were irregularities and structural defects present on the surface.[10] Files that were subjected to repeated sterilization cycles, showed an increased surface roughness when compared to those that were not sterilized. This was explained by a possible alteration in thickness of the passive, oxide layer that covers NiTi surfaces.[10]

To assess the quality of a file, it is the surface character that must be evaluated, because it is only this property that would define the resistance to corrosion of such files, in a broad range of conditions.[2] It is also widely acknowledged that an increase in the surface irregularities is associated not only with an increase in the tendency of the file to fracture, especially in a in a curved canal,[11] but also with a decrease in its cutting efficiency and an increased difficulty in its ability to be cleaned.[2]

In the present study, an atomic force microscope (AFM) was used for surface characterization of the files, since it is both sensitive and reliable in acquiring data regarding the surface topography of the NiTi rotary files which are both qualitative and quantitative in nature.[2] The results of the current study showed, that the all three vertical parameters that were measured in the scans increased significantly by autoclave sterilization from the baseline values. This increase in the surface roughness is consistent with the findings of Valois et al., (2008) who reported an increase in the vertical topographic parameters obtained by AFM scans of ProFile and GreaterTaper instruments that were subjected to sterilization cycles using a steam autoclave.

The rougher initial surface was seen for ProTaper. This could be because of the finishing treatment given to Mtwo in the form of electropolishing, which renders the surface smoother, when compared to ProTaper which is not electropolished. As stated by Kim et al., (2010) and confirmed in this study, even the electropolished surface of the files showed a lot of pitting and scratch marks making the surface rough. The surface roughness increased significantly after autoclave sterilization, consistent with the deposition of oxides of titanium and a decrease in the nickel content on the surface as reported in previous studies.[7,10]

Though the roughness profile of ProTaper had much higher values than Mtwo, it showed a lesser increase in roughness values when compared to Mtwo. The AMR and RMS values of Mtwo file surpassed even those of Pro Taper file after 10 autoclave sterilization cycles. The reason for the differences in the increase in roughness of the files could not be determined in this study, though this could be attributed to a difference in the manufacturing process and composition of the files, as observed in previous literature.

Even a single autoclave sterilization cycle showed a significant increase in surface roughness when compared to the control. This increase in the roughness, however, was much lesser than the increase in the roughness of the files after five cycles. This suggests that a single cycle of autoclave sterilization is less harmful to the NiTi files. Moreover, although autoclave sterilization has been shown to cause potentially damaging structural changes on the files, the clinical effects of these procedures have been felt only after a number of sterilization cycles.[12,13] This could be because it has a cumulative effect on the files, which leads to a lot of surface corrosion with increasing cycles. It is also important to note that the clinical conditions under which the file is used[14] and the type of disinfecting solution used,[15] also cause tremendous changes on the surface of the files.

All these factors when considered together, contribute to the accelerated surface deterioration of the NiTi files. Keeping this in mind, it would be prudent to limit the use of NiTi files to a single use, so that there is only a minimal effect of the reprocessing procedures, allowing the clinician to be more confident and an increased margin for error, during the use of these files.

CONCLUSION

From the present study it can be concluded that:

Both the files in the study (Protaper and Mtwo) showed many surface irregularities before being subjected to autoclave sterilization.

Autoclave sterilization causes an increase in the surface roughness of NiTi files.

The increase in roughness corresponds to the number of autoclave cycles that the instruments were exposed to.

Even single autoclave sterilization caused a significant increase in the surface roughness of both the files.

The degree of increase in roughness was different for both the files after varying number of autoclave cycles.

The results of the study confirmed the effect of autoclave sterilization on the surface of NiTi files, which manifested as an increase in the surface roughness of the files. However, this, along with the cumulative effects of other factors like manner of use, duration of use, and presence of other corrosive agents during instrumentation; all need to be studied in collaboration with the effect of sterilization, to completely understand its clinical implications.

Footnotes

Source of Support: Nil

Conflict of Interest: None declared.

REFERENCES

- 1.Thompson SA. An overview of nickel-titanium alloys used in dentistry. Int Endod J. 2000;33:297–310. doi: 10.1046/j.1365-2591.2000.00339.x. [DOI] [PubMed] [Google Scholar]

- 2.Valois CA, Silva LP, Azevado RB. Multiple autoclave cycles affect the surface of rotary nickel-titanium files: An atomic force microscopy study. J Endod. 2008;34:859–62. doi: 10.1016/j.joen.2008.02.028. [DOI] [PubMed] [Google Scholar]

- 3.Sonntag D, Peters O. Effect of prion decontamination protocols on nickel-titanium rotary surfaces. J Endod. 2007;33:442–6. doi: 10.1016/j.joen.2006.12.012. [DOI] [PubMed] [Google Scholar]

- 4.Assender H, Bliznyuk V, Porfyrakis K. How surface topography relates to materials’ properties. Mater Sci. 2002;297:973–6. doi: 10.1126/science.1074955. [DOI] [PubMed] [Google Scholar]

- 5.Valois CA, Silva LP, Azevado RB. Atomic force microscopy study of stainless steel and nickel-titanium files. J Endod. 2005;31:882–5. doi: 10.1097/01.don.0000164132.27285.2c. [DOI] [PubMed] [Google Scholar]

- 6.Popovic J, Gasic J, Zivkovic S, Petrovic A, Radicevic G. Evaluation of biological debris on endodontic instruments after cleaning and sterilization procedures. Int Endod J. 2010;43:336–41. doi: 10.1111/j.1365-2591.2010.01686.x. [DOI] [PubMed] [Google Scholar]

- 7.King JB, Roberts HW, Bergeron BE, Mayerchak MJ. The effect of autoclaving on torsional moment of two nickel-titanium endodontic files. Int Endod J. 2012;45:156–61. doi: 10.1111/j.1365-2591.2011.01958.x. [DOI] [PubMed] [Google Scholar]

- 8.Viana AC, Gonzalez BM, Buono VT, Bahia MG. Influence of sterilization on mechanical properties and fatigue resistance of nickel-titanium rotary endodontic instruments. Int Endod J. 2006;39:709–15. doi: 10.1111/j.1365-2591.2006.01138.x. [DOI] [PubMed] [Google Scholar]

- 9.Canalda-Sahli C, Brau-Aguade E, Sentis-Vilalta J. The effect of sterilization on bending and torsional properties of K-files manufactured with different metallic alloys. Int Endod J. 1998;31:48–52. [PubMed] [Google Scholar]

- 10.Alexandrou G, Chrissafis K, Vasiliadis L, Pavlidou E, Polychroniadis EK. Effect of heat sterilization on surface characteristics and microstructure of Mani NRT rotary nickel-titanium instruments. Int Endod J. 2006;39:770–8. doi: 10.1111/j.1365-2591.2006.01147.x. [DOI] [PubMed] [Google Scholar]

- 11.Alapati SB, Brantley WA, Svec TA, Powers JM, Nusstein JM, Daehn GS. SEM observations of Nickel Titanium Rotary endodontic instruments that fractured during clinical use. J Endod. 2005;31:40–3. doi: 10.1097/01.don.0000132301.87637.4a. [DOI] [PubMed] [Google Scholar]

- 12.Schafer E. Effect of sterilization on the cutting efficiency of PVD-coated nickel-titanium endodontic instruments. Int Endod J. 2002;35:867–72. doi: 10.1046/j.1365-2591.2002.00586.x. [DOI] [PubMed] [Google Scholar]

- 13.Rapisarda E, Bonaccorso A, Tripi TR, Condorelli GG. Effect of sterilization on the cutting efficiency of rotary nickel-titanium endodontic files. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 1999;88:343–7. doi: 10.1016/s1079-2104(99)70040-5. [DOI] [PubMed] [Google Scholar]

- 14.Inan U, Aydin C, Uzun O, Topuz O, Alacam T. Evaluation of the surface characteristics of used and new ProTaper instruments: An atomic force microscopy study. J Endod. 2007;33:1334–7. doi: 10.1016/j.joen.2007.07.014. [DOI] [PubMed] [Google Scholar]

- 15.O’hoy PY, Messer HH, Palamera JE. The effect of cleaning procedures on fracture properties and corrosion of nickel-titanium files. Int Endod J. 2003;36:724–32. doi: 10.1046/j.1365-2591.2003.00709.x. [DOI] [PubMed] [Google Scholar]