Highlights

-

•

Piezoelectric scandium aluminium nitride (ScxAl1−xN) via sputter deposition.

-

•

Precise determination of piezoelectric constants (d33, d31) for thin films.

-

•

Laser Doppler Vibrometry compared to finite element simulations (FEM) using COMSOL.

-

•

Optimized circular electrode design (Bull's eye) with two-port excitation method.

-

•

Elastic constants of ScxAl1−xN via density functional theory.

Keywords: Aluminum nitride, AlN, ScAlN, Piezoelectric thin film, Vibrometry, Interferometry

Abstract

Piezoelectric scandium aluminium nitride (ScxAl1−xN) thin films offer a large potential for the application in micro electromechanical systems, as advantageous properties of pure AlN thin films are maintained, but combined with an increased piezoelectric actuation and sensing potential. ScxAl1−xN thin films with x = 27% have been prepared by DC reactive magnetron sputtering to find optimized deposition parameters to maximize the piezoelectric constants d33 and d31. For the accurate and simultaneous measurement of these constants Laser Doppler Vibrometry has been applied and compared to finite element (FEM) simulations. The electrode design has been optimized to rotational symmetric structures enabling a 180° phase shifted excitation, so that a straight-forward comparison of experimental displacement curves with those obtained from FEM is feasible.

1. Introduction

Micro electromechanical systems (MEMS) based on piezoelectric thin films is an emerging research area, as such devices and systems are strongly penetrating into new market applications [1]. Aluminium nitride (AlN) is increasingly used as piezoelectric material in MEMS sensors and actuators such as accelerometers [2] or to determine the viscosity and density of liquids [3,4], surface and bulk acoustic resonators [5], atomic force microscopy (AFM) cantilevers [6], or energy harvesting systems [7]. Complementary metal-oxide-semiconductor (CMOS) compatibility, high temperature and long term stability as well as low dielectric constants are beneficial properties of AlN. For the piezoelectric constants d33 and d31 values up to 6.5 pm/V and −2.9 pm/V are reported for pure AlN thin films prepared by reactive magnetron sputtering [8–10]. A significant enhancement was achieved via incorporation of scandium (Sc) into AlN, up to 27.6 pm/V for ScxAl1−xN thin films with x = 42.5% [11,12]. This increase was observed near a phase transition from a cubic to a wurtzite type crystal structure, starting at about 45%. In contrast, this work focuses on ScxAl1−xN thin films with a fixed scandium concentration of x = 27%. By choosing the latter value, the formation of the cubic type crystal structure is avoided, but a strong increase of piezoelectric constants is already expected. Measurements with bulk acoustic wave (BAW) resonators based on ScxAl1−xN with x = 35% showed a piezoelectric coefficient d33 = 16 pm/V, which is below the value predicted by ab initio calculations (d33 ∼ 23 pm/V) [13].

The precise knowledge of electro-mechanical constants of piezoelectric thin films is important for the design and simulation of MEMS. For example the use of finite element (FEM) software for device design requires the accurate implementation of elastic and dielectric as well as piezoelectric properties to predict precisely the performance of MEMS devices. Various measurement techniques exist for piezoelectric thin films probing either the direct piezoelectric effect, by measuring the resulting voltage upon application of mechanical stress or the inverse piezoelectric effect by measurement of the voltage induced expansion or compression. The principles of direct piezoelectric measurements were established by Lefki and Dormans for ideal cases regarding substrate clamping as well as substrate and electrode size [14]. The Berlincourt based direct measurement approach involving a reference sample with known piezoelectric properties is mentioned in this context. As this work deals with the measurement of piezoelectric constants via the indirect piezoelectric effect the discussion focuses in this direction.

Another approach, comprising the extraction of piezoelectric properties with MEMS devices, such as cantilevers, film bulk acoustic resonators (FBARs) or surface acoustic resonators (SAWs) is thoroughly covered in literature [15–18]. For an analytical evaluation of the piezoelectric properties some assumptions or important parameters need to be made or known, such as the quality factor, although the determination on device level is in principal beneficial, as it directly considers the intended application of the thin films. However, for studying new materials cantilever fabrication is a sophisticated and time consuming procedure and in general not feasible in an early stage of the work when process parameters are yet to be optimized. The evaluation of complete SAW devices or FBAR resonators via FEM simulation also requires input parameters such as the dielectric constant or sound velocity. They need to be included into the model and therefore induce further uncertainties.

As the typical intrinsic piezoelectric displacement of thin films is small (i.e. pm to nm range) measurement techniques are mostly based on optical interferometry, Laser Doppler Vibrometry (LDV) or piezoelectric force microscopy (PFM). Measurement of the piezoelectric displacement via single beam interferometry is not straight forward due to several reasons. First, the contribution of substrate bending is, compared to the change in film thickness not negligible, requesting an elaborated clamping. For a weakly clamped Si wafer covered with a piezoelectric layer Kholkin et al. showed that the measured piezoelectric displacement has a quadratic dependence on the electrode length. Hence, the known formula for the bending of a piezoelectric bimorph induced by the transverse piezoelectric effect is being proportional rather to d31 than to d33 [19]. Reduction of the electrode size and usage of a hard, conductive glue may be sufficient to suppress substrate bending. Moreover, a double beam interferometer for simultaneous measurement of thin film surface and substrate bottom-surface was used to minimize the impact of substrate bending [20]. However, the change in piezoelectric thin film thickness is not homogeneous below the electrode area, since the local deflection of the bottom surface of the piezoelectric thin film is also important to consider for an accurate evaluation of the displacement profile, as previously demonstrated by FEM simulations [21]. Furthermore, atomic force microscopy was used to apply the electric field via a conductive tip and measure the corresponding displacements for piezoelectric evaluation purposes [22]. However, when metallic electrodes deposited on the piezoelectric film are used the evaluation of the displacement curves is again not straight forward, but requires an in depth analysis taking the above mentioned issues into account.

The following sections discuss the deposition of highly c-axis oriented ScxAl1−xN with x = 27% via DC reactive magnetron sputtering together with a full evaluation of both piezoelectric coefficients d33 and d31. For the measurement of piezoelectric displacement profiles via LDV new circular electrodes were designed and evaluated in comparison to COMSOL based FEM simulations. In addition, elastic properties for various concentrations x of ScxAl1−xN were obtained from ab initio density functional theory (DFT) calculations.

2. Thin film preparation

In order to maximize the piezoelectric response of ScxAl1−xN thin films a deposition series has been prepared via DC reactive ion sputtering. Subsequently, circular shaped platinum electrodes have been sputter-deposited and lithographically structured on top of the piezoelectric material. The thin films were deposited in a production-type sputtering system (Von Ardenne LS730S). Prior to the ScxAl1−xN deposition, the Si(100) substrates have been cleaned by an in situ ion etching process (ISE), thus resulting in the complete removal of the native silicon surface oxide and an amorphization of the surface-near crystal structure [23]. Subsequently, thin films with a thickness of 500 nm were prepared by DC reactive magnetron sputtering from a 100 mm AlSc alloy target with a fixed ratio of 30 at.% Sc at nominally unheated substrate conditions. The base pressure prior to the deposition was kept below 4 × 10−7 mbar, while the other fixed process parameters are depicted in Table 1.

Table 1.

Process parameters for the ISE process and the ScxAl1−xN thin film synthetization (process pressure in the deposition chamber p, plasma power density P, process time t, argon gas flow vAr and electrode distance d).

| ISE | Deposition | |||||||

|---|---|---|---|---|---|---|---|---|

| p/Pa | P/W cm−2 | t/s | d/mm | vAr/sccm | p/Pa | P/W cm−2 | t/s | d/mm |

| 0.6 | 6.4 | 60 | 65 | 60 | 0.25 | 5.1 | 800–1300 | 65 |

During the deposition series the argon ratio in the process gas (Ar/N2 ratio: 0%, 25%, 50%) as well as the substrate bias conditions were varied. For the latter parameter, the sputter system allows three different configurations: grounded (DC: 0 V), floating (DC: 17 V) and biased (DC: 37 V), where the depicted value for each setting is corresponding to the effective substrate self-bias. Without the exception of grounded substrate, the measured self-biase was fluctuating throughout the deposition by approximately 1 V. The deposition time was set such that the expected thin film thickness remained approximately constant at 500 nm. The scandium concentration x was measured by a scanning electron microscopy based energy dispersive X-ray system (EDX, Oxford Instruments X-Max 50). The determined value was x = (27 ± 2)% and throughout the deposition series no significant variation of x was observed. For the purpose of an additional calibration standard pure AlN thin films with the same equipment and sputter parameters have been deposited as described by Schneider et al., including an ion etching process prior to the deposition [23]. The circularly shaped electrode design, as illustrated in Fig. 2(a) and (c), was achieved by image reversal lithography followed by a lift-off process of platinum thin films (t = 100 nm). For the determination of piezoelectric constants all samples were bonded to an aluminium plate using a conductive Ag epoxy glue (Polytec EC 101).

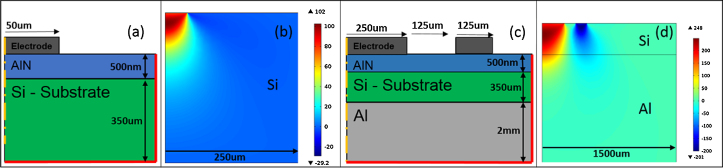

Fig. 2.

2D cross-sectional view of the rotationally symmetric electrode designs used as input for the FEM simulations (a and c). FEM results for the local displacement perpendicular to the wafer surface (b and d).

3. Elastic properties of ScxAl1−xN

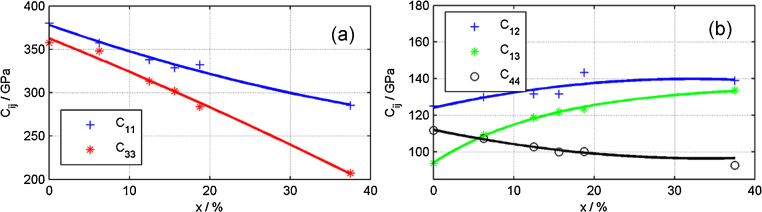

FEM based simulations of piezoelectric structures require the complete knowledge of the anisotropic compliance tensor of ScxAl1−xN. This work utilizes elastic constants obtained from ab initio DFT (density functional theory) calculations, as shown in Fig. 1.

Fig. 1.

All independent elastic stiffness tensor elements Cij (in GPa) of w-ScxAl1−xN from density functional theory.

The simulations were conducted using the Vienna Ab initio Simulation Package (VASP) [24], applying the projector augmented wave method and the generalized gradient approximation (PAW-GGA) [25]. To obtain representative structures, 4 × 4 × 2 supercells with altogether 128 atoms were constructed. ScxAl1−xN was assumed to be a solid solution, in which the Sc atoms are randomly distributed on the metal sublattice. The desired Sc content was then obtained by making use of the special quasi-random structure (SQS) approach [26]. Supercells with a Sc content of 6.25%, 12.5%, 15.625%, 18.75% and 37.5% were optimized by relaxing both, lattice constant and atomic positions, using a 2 × 2 × 3 Γ-centred k-point mesh and an energy cut-off of 600 eV. The structure optimization was only stopped when residual forces and stresses were less than 0.005 eV/Å and 0.05 GPa, respectively. Next, the ground state structures were strained, using the universal independent coupling strain approach [27]. The strained configurations were again relaxed, however, with fixed lattice constants, such that only an internal relaxation of the atomic positions was conducted. From the corresponding stress–strain relationship the elastic tensor is determined by a linear least square fit procedure using single value decomposition [27]. Finally, the hexagonal projection of the elastic tensor is determined to restore symmetry [28]. This is necessary since the introduction of Sc atoms distorts the crystal matrix and therefore the supercells slightly deviate from exact hexagonal symmetry. With increasing Sc concentration in AlN the elastic constants along the main crystallite axes C33 and C11 are strongly decreasing, as shown in Fig. 1(a). Hence, a pronounced softening of the material is observed, as these two elements are related to the out of plane and in-plane elastic moduli in the material. Published experimental data on the change of C33 with x agree reasonably well with our data, as for instance Matloub et al. evaluated MEMS resonators via a FEM model yielding C33 = 320 GPa at x = 12% as well as Moreira et al., who observed a decrease down to C33 = 270 GPa at x = 15% with FBAR structures [17,29]. Furthermore, off-diagonal elements of the stiffness tensor are also changing, as depicted in Fig. 1(b). For an accurate simulation of piezoelectric based MEMS devices these changes in elastic constant need to be considered.

4. Measurement setup & methodology

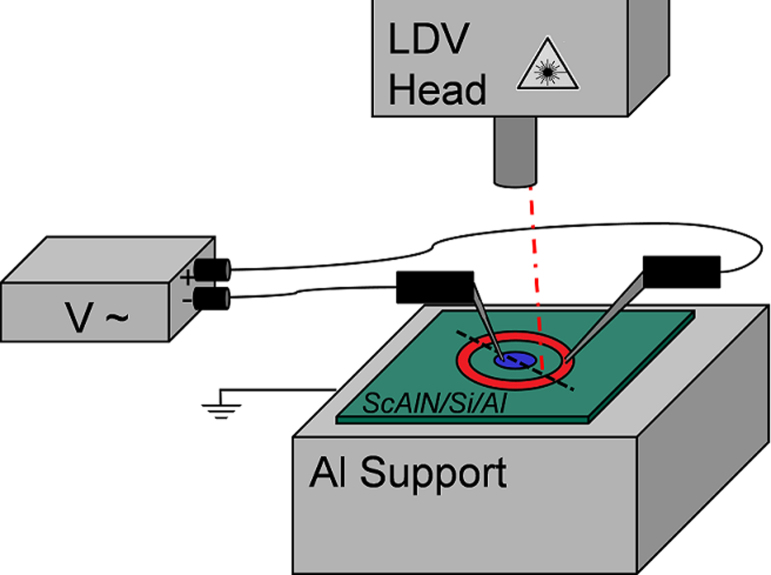

Recently, Hernando et al. introduced the FEM based evaluation of interferometrically determined deflection curves from quadratic electrodes on AlN thin films. This approach takes the inherent substrate bending and the movements of bottom and top surfaces into account by a complete simulation of a structure consisting of substrate/bottom-electrode/thin film/top-electrode configuration [21]. Following their approach piezoelectric constants were determined by a measurement of the voltage induced vertical deflection via a Laser Doppler Vibrometer (Polytec MSA 400) and subsequent comparison to COMSOL based FEM simulations. All samples are conductively bonded to an aluminium plate which is fixed to the setup via a vacuum chuck and connected to electrical ground. The AC electrical excitation is applied via tungsten tips to the electrodes at frequencies of 20 kHz and 65 kHz. Fig. 2(a) and (c) show the geometries of the two most important electrode designs used within this study. The design in Fig. 2(c) consists of two electrodes: An inner ring and an outer disc-shaped element, where a 180° phase shifted voltage (amplitude: U = 10 V) was applied by one tungsten needle placed on each electrode. Additionally, a version of the design in Fig. 2(c) was studied which was exactly scaled by a factor of 0.5. The vertical deflection along a line scan was measured via the vibrometer, as schematically depicted in Fig. 3.

Fig. 3.

Schematic drawing of the LDV based measurement setup. Indicated is the two port deflection measurement of a Bull's eye electrode design with 180° phase shifted excitation.

Prior to the measurements the original electrode design as introduced by Hernando et al. was optimized using the finite element software COMSOL. First, the original square shaped electrodes were changed to rotationally symmetric disc electrodes having a diameter of 100 μm resulting in a substantial reduction of computational effort thus, enabling a large accessible parameter range for the evaluation of the measurements. For each electrode geometry, the vertical piezoelectric constant was varied: d33 was increased from 1 pm/V to 18 pm/V, while the in-plane constant d31 was chosen in dependence of d33 such that d31 lies in between −d33/2 and −d33/2 + 2.2 pm/V (step sizes 0.1 pm/V). This selected range covers all meaningful d31 values, thus considering the established relationship d31 > −d33/2 for wurtzite-type crystals [30]. The FEM calculations were conducted electrostatically for a voltage of U = 10 V applied across the AlN layer.

Due to the rotational symmetry, the simulated structures consist of 2D boxes representing each layer as illustrated in Fig. 2. The piezoelectric thin film was meshed with at least four tetragonal elements across its thickness and with additional refinements at the electrode boundaries. This restricts the minimum film thickness, as with decreasing thickness more tetragonal elements are needed to keep an acceptable aspect ratio for the elements. Finally, the results of a complete sweep for the z-deflection along a centred line on the ScxAl1−xN surface are extracted into a dataset for measurement evaluation purposes.

5. Results

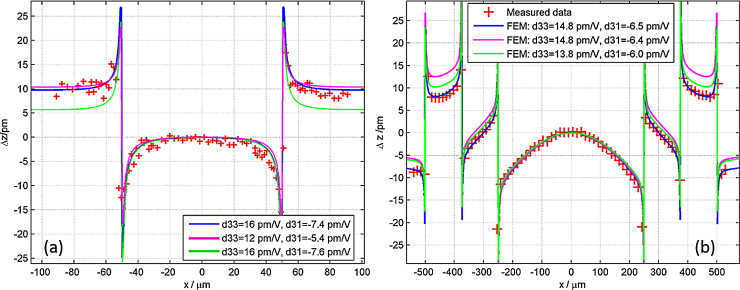

A comparison of deflection measurements and FEM curves corresponding to three pairs of piezoelectric constants is shown in Fig. 4. Qualitatively, the disc-shaped electrodes deflect similar to those having a square-shaped design where a tableau located below the top electrode is confined by an upward and downward peak at the edges. The characteristic feature for the d33 evaluation is the maximum tip-minimum tip distance, while the tableau height is depending on both the d31 and the d33 values, as previously shown [21]. As an example Fig. 4(a) shows a measurement with reasonable quality and three curves from FEM corresponding to three different values of d33 and d31. It is illustrated, that a rather large change of d33 from 16 to 12 pm/V results in nearly identical deflection (blue and magenta) curves apart from the maximum tip to minimum tip distance when keeping d33/2 + d31 constant, as this value is the critical parameter determining the tableau height. However, the accuracy in measuring the tip–tip distance is restricted to about 2 μm given by the lateral scanning resolution due to the finite laser diameter. Hence, a measurement of piezoelectric constants with small disc or square electrodes depends in principle on four points, all being affected by uncertainties resulting in a reduction of accuracy or the requirement of a large dataset.

Fig. 4.

Comparison of measured displacement characteristics with those gained from FEM simulations for three different values of d33 and d31. Experimental and simulation data are vertically shifted to align at x = 0. Single port excitation of the simple disc in (a) and phase shifted excitation on Bull's eye in (b).

To overcome the abovementioned problems, specifically designed Bull's eyes electrodes are introduced. The fundamental motivation is to accomplish a stronger curvature of the mentioned tableau, directly depending on d33, by an increase of the electrode area. Disadvantage of larger electrodes is the appearance of significant substrate bending together with the occurrence of eigenmodes. This is avoided via the introduction of Bull's eye type design where an outer ring is excited with the same voltage as the inner disc, but with a 180° phase shift. Thus, substrate bending can be reduced to a lower level. Therefore, FEM calculations for the Bull's eyes type electrodes include a part of the aluminium ground plate, as schematically shown in Fig. 2(c). This improves the accuracy in the determination of piezoelectric parameters, as the complete 350 μm thick silicon wafer still deflects. A FEM result for the z-deflection along a 2D cross section of the Bull's eyes structures is shown in Fig. 2(d) in order to illustrate the deflection close to the ground plate. In contrast, there is no deflection extending beyond the silicon wafer in the case of small simple disc electrodes, as depicted in Fig. 2(b). In these theoretical pre-investigations, the excitation voltage was set to 10 V and large piezoelectric constants were used (i.e. d33 = 15 pm/V and d31 = −7.5 pm/V) for both configurations representing a worst case scenario in mechanical deflection characteristics.

The Bull's eye type electrodes with phase shifted excitation enable a simultaneous evaluation of d33 and d31. Fig. 4(b) displays the LDV based scan along the centre of the electrode in comparison to data from FEM simulations for three d33 and d31 combinations. As illustrated, the electrode design results in significant differences between the height of inner and outer deflection plateaus even for slight variations in d33 of 1 pm/V. Thus, attributing measured data to simulations with piezoelectric constants is possible with high accuracy. Measurement and simulation data in Fig. 4(b) were shifted to the same absolute height at the electrode's centre (x = 0). Foremost, the plateau height itself is depending on the deviation of d31 from d31 = −d33/2. The lowest value for the piezoelectric coefficient d33, which can be determined with our Bull's eye type electrode design is limited mainly by the resolution and noise level in the Laser Doppler Vibrometer, as lower piezoelectric coefficients manifest in lower deflection amplitudes. A value for d33 of 1 pm/V results in approximately 3 pm vertical surface deflection, thus reaching the system resolution limit.

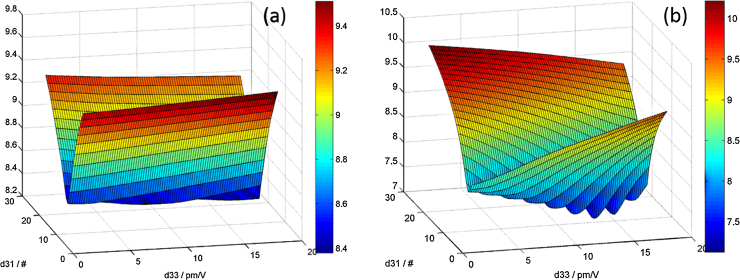

For a fast and precise evaluation of piezoelectric constants, a routine for automated comparison of measurements and simulations was written in MatLab. First, the absolute height of LDV data and deflection curves from FEM are aligned at a point along the scanning path, in general the centre. The best simulation is chosen on basis of a least square fitting procedure with respect to the measurement data. For a single Bull's eye electrode design Fig. 5(a) shows a graphic representation of the deviation data for each d31 and d33 combination. The discrimination along d31 is more pronounced because of the large differences in plateau height. The minimum along the d33 axis is less distinct but still present and suffices for an accurate evaluation.

Fig. 5.

Logarithmic view of the deviation of Bull's eye based measurements from a complete set of FEM simulations; (a) is for the original design while (b) is for a Bull's eye design with half of the diameter. Simulations differ with respect to d33 and d31 where d33 is in pm/V and d31 is an index in a vector of d31 values with minimum -−d33/2 and maximum −d33/2 + 2.2 pm/V.

Furthermore, smaller Bull's eye type electrode designs were used aiming to minimize any substrate bending effects. However, as the electrode area is reduced variations in d33 result in less pronounced changes of the curvature in the simulations. For illustration purposes, Fig. 5(b) shows the deviation values for a measurement of a specific Bull's eye type design that was scaled by factor of 0.5. A clear minimum along the d33 axis cannot be identified anymore, thus for the described evaluation procedure the smaller Bull's eye type design is not applicable and the originally introduced design, as shown in Fig. 2, performs best for the evaluation of piezoelectric constants.

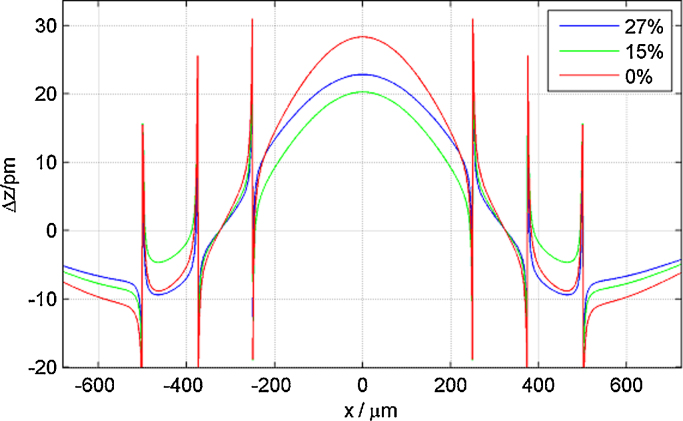

The influence of elastic properties on the vertical displacement of Bull's eye type electrodes was studied to estimate its impact on the proposed piezoelectric constant evaluation procedure. The deflection curves for the same Bull's eye type electrode and piezoelectric constants (d33 = 15 pm/V, d31 = −7 pm/V) is shown in Fig. 6 for elastic constants corresponding to three different Scandium concentrations x. The depicted curves for lower x values exhibit a stronger deflection compared to the synthesized thin film at x = 27%. This behaviour is attributed to the relationship d33 ∼ e33/C33. With higher x, e33 increases while the decrease of C33 is more pronounced, hence leading to the strong increase in d33. An evaluation of the measurement depicted in Fig. 4(a) with elastic constants corresponding to x = 27% ScxAl1−xN yields a d33 of about 14.8 pm/V which is roughly 1.6 times higher than an evaluation with elastic constants for pure AlN (d33 = 9 pm/V). This agrees reasonable well with the published ab initio based increase of e33 from 1.5 to 2.1 C/m2 [31].

Fig. 6.

Bull's eye electrode vertical displacement for ScxAl1−xN with elastic constants corresponding to x = 0%, x = 15% and x = 27% at the same piezoelectric constants.

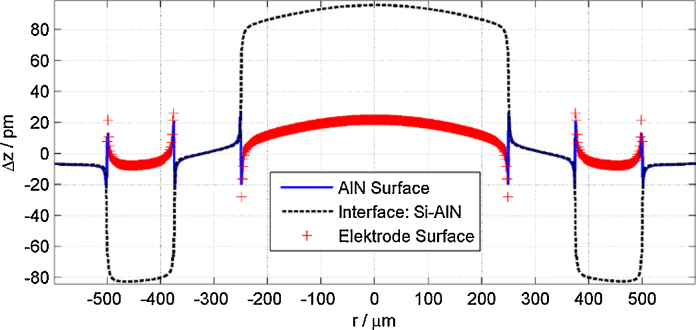

The deflection shape of Bull's eye is further studied via evaluations of FEM simulations to explain the origin of the individual features and to illustrate the nature of the thickness change across the AlN film. Vertical displacement values at points on the Pt electrodes and between Si substrate and AlN thin film are compared with the displacement at the AlN surface, shown in Fig. 7. The polarity is such that the voltage induces a compression of the AlN in the centre disc, thus resulting in a positive deflection force at the silicon substrate and a negative deflection at the AlN surface. In contrast, the AlN layer of the outer ring shows the inverse behaviour. In addition, Fig. 7 shows, that the tableau deflection at the interface between AlN and Si is at its maximum value and the shape of the deflection is in principle such as one would expect by straight-forward considerations as a response of the film surface to the piezoelectric exaction. In contrast, the experimentally determined surface deflection of the thin film is comparatively flat. This illustrates, that the thickness change of the piezoelectric thin film is primarily located at the substrate near interface region.

Fig. 7.

Origin of piezoelectric deflection shape from two-port Bull's Eye evaluation, pure AlN, d33 = 15 pm/V, d31 = −7.5 pm/V, U = 10 V – results obtained via FEM simulation.

It is beneficial to evaluate the deflection curves with analytical models of the piezoelectric thin film performance. An accurate analytical description may have advantages, especially when FEM simulation programs are not accessible or a large parameter range in terms of thin film composition and thickness needs to be considered. Lefki and Dormans showed that a measurement of voltage (V) induced deflection (ΔL) is not simply related to the out-of plane constant d33 via d33 = ΔL/V, but rather a combination of piezoelectric and elastic material properties, as described by an effective d33,f:

| (1.1) |

With the applied electric field E3 the vertical strain ɛ3 and elastic compliance tensor elements at constant electric field . Moreover, perfect clamping parallel to the interface i.e. no strains (ɛ1 = ɛ2 = 0) and a free thin film surface, hence no stress in z-direction (i.e. σ3 = 0), are assumed for Eq. (1.1).

Experimental application of these requirements is further compromised by effects such as substrate bending, finite electrode size and the nature of thin film deflection. The simulation shown in Fig. 7 are based on piezoelectric constants d33 = 15 pm/V and d31 = −7.5 pm/V (elastic properties of pure AlN) yielding a d33,f = 11 pm/V. Considering the applied voltage U = 10 V this would result in a deflection of Δz = d33,f · U = 110 pm, which strongly overestimates the surface deflection. The reason for this overestimation is on the one hand the implied condition of a perfectly clamped substrate and on the other hand the relatively small electrode size, inducing clamping throughout the whole electrode area. These results have also implication for other indirect-piezoelectric measurement techniques, such as piezoelectric deflection measurements via piezoresponse atomic force microscopy (AFM/PFM), as it illustrates that piezoelectric constants simple cannot be calculated from the deflection amplitude of electrodes.

6. Discussion

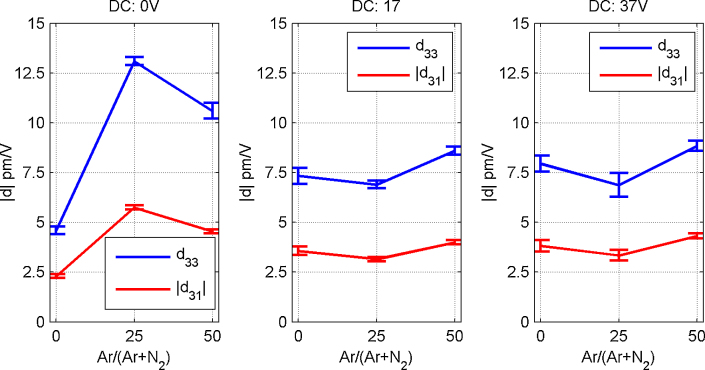

To verify the applicability of the novel test structure, pure AlN thin films with well investigated material properties have been measured first by employing the presented methodology. The resulting piezoelectric coefficients for these AlN samples were d33 = 4.2 pm/V and d31 = −1.9 pm/V, thus agreeing excellent with those reported by Hernando et al. [21]. Next, the piezoelectric constants of ScxAl1−xN thin films (x = 27%) with varying deposition parameters as described above have been evaluated with the Bull's eye type electrode design. Fig. 8 shows the resulting values for d33 and d31 with varying Ar ratio in the process gas and varying substrate bias conditions. Each depicted data point is the average of about four measurements taken at excitation frequencies of 25 kHz and 65 kHz. Error bars are based on the corresponding standard deviation, but minimum values of 0.25 pm/V for d33 and 0.1 pm/V for d31 were estimated originating from the uncertainty when comparing measurements and FEM simulations.

Fig. 8.

Piezoelectric constants of ScxAl1−xN with x = 27% with varying deposition parameters: substrate bias, depicted in the upper right of each graph and ratio of argon in the process gas on the axis.

A maximum in both piezoelectric constants is obtained for 25% Ar and grounded substrate configuration. Therefore, these deposition conditions can be regarded as the optimum to achieve highest actuation potential of ScxAl1−xN thin films within the investigated parameter range. They yield d33 = 13.2 pm/V and d31 = −5.8 pm/V. These results agree well with earlier measurements of d33 of ScxAl1−xN (d33 ∼ 15 pm/V) [11]. In addition, the values for d33 and d31 are in line with results from ab initio calculations that predict values for x = 27% of about d31 ∼ 7 pm/V and d33 ∼ 17 pm/V [13].

Optimized parameters for the DC reactive sputter deposition of AlN thin films are crucial in order to obtain highly c-axis oriented thin films with a maximized piezoelectric response [22]. For ScxAl1−xN thin films with a low concentration of x = 6% the sputtering power showed to have an impact on the degree of c-axis orientation and thus, on the piezoelectric response of the films [32]. On the other hand, for ScxAl1−xN thin films with x up to 15% we previously showed that the Ar ratio in the process gas has a particular influence on crystalline quality and c-axis orientation [33]. Ar addition leads to higher ad-atom mobility during the sputter process which in turn results in a lower amount of defects in crystallites and a highly pronounced c-axis oriented growth. Hence, the requirement of Ar admixture for maximized piezoelectric response is in-line with these results. Additionally, the substrate bias also proved to have an influence, as for pure AlN thin film deposition an enhancement of the c-axis orientation was shown for decreasingly negative substrate self-bias [34]. The observed behaviour for the deposition of ScxAl1−xN is similar though in this work, the substrate bias could not be further decreased due to system limitations.

7. Conclusion

This work studies the piezoelectric behaviour of DC sputter deposited ScxAl1−xN (x = 27%) thin films. Ar ratio in the process gas and substrate bias were varied and found to have a significant impact on the piezoelectric constants d33 and d31. For the advanced determination of piezoelectric constants test structures are reported requiring low fabrication effort, with optimized platinum electrode designs for FEM evaluation of LDV based vertical deflection measurements. The resulting Bull's Eye shaped electrodes with rotational symmetry enable a precise and simultaneous straight-forward evaluation of d33 and d31 by comparing experimental and theoretical results. For FEM based calculation of piezoelectric deflection curves elastic constants from ab initio calculation have been used. The piezoelectric response (d33 = 13.2 pm/V and d31 = −5.8 pm/V) was maximized for an argon concentration of 25% and for grounded substrate conditions. Thus, a further step towards ScxAl1−xN based piezoelectric MEMS devices with enhanced electromechanical properties is provided.

Acknowledgements

We gratefully acknowledge the financial support from the Austrian Science Fund (FWF), number P 25212-N30. Computational results from DFT presented have been achieved using the Vienna Scientific Cluster (VSC).

Biographies

Patrick Mayrhofer studied physics at University of Technology Graz, Austria and Uppsala Universitetet, Sweden. He completed his Master's degree in 2012. In Graz he conducted research at the Institute of Solid State Physics. From 2012 on, he is working towards a PhD degree in Electrical Engineering at University of Technology Vienna. There, he is part of the Institute of Sensor- and Actuator Systems. His current interests lie in the preparation of doped Aluminium Nitride thin films via sputter deposition, their electromechanical and crystallographic characterization and the integration into MEMS devices.

Holger Euchner studied physics at the University of Stuttgart and the University of Missouri, St. Louis, where he obtained his MSc at in 2007. In 2011 he finished his PhD at the Institute for Theoretical and Applied Physics (ITAP) at the University of Stuttgart. His PhD work focused on the study of the lattice dynamics of complex metallic alloys, using ab initio and molecular dynamics simulations. Currently he is a postdoctoral scientist at the Institute of Materials Science and Technology at the Vienna University of Technology, with his research focus on ab initio simulation of thin film materials.

Achim Bittner performed his diploma thesis 2005 at Robert Bosch GmbH in Bamberg where he worked on the improvement of thick film technology. Afterwards, he started as development engineer at MSE in Berg with focus on LTCC substrates. In 2006 he started his PhD Thesis at Saarland University, Chair of Microsystems Technologies with the topic local reduction of permittivity of LTCC substrates. Since 2010 he is a postdoctoral scientist at Vienna University of Technology, Institute of Sensor and Actuator Systems. His current research interests are piezoelectric thin films and functional ceramics for MEMS devices.

Ulrich Schmid started studying physics and mathematics at the University of Kassel in 1992. He performed his diploma work at the research laboratories of the Daimler-Benz AG on the electrical characterization of silicon carbide (6H-SiC) microelectronic devices. In 1999, he joined the research laboratories of DaimlerChrysler AG (now Airbus Group) in Ottobrunn/Munich, Germany. In 2003 he received his PhD degree from the Technische Universität München. From 2003 to 2008, he was post-doc at the Chair of Micromechanics, Microfluidics/Microactuators at Saarland University. Since October 2008, he is full professor for Microsystems Technology at the Vienna University of Technology.

Footnotes

Selected papers presented at EUROSENSORS 2014, the XXVIII edition of the conference series, Brescia, Italy, September 7–10, 2014.

References

- 1.Piazza G., Felmetsger V., Muralt P., Olsson R.H., Ruby R. Piezoelectric aluminum nitride thin films for microelectromechanical systems. MRS Bull. 2012;37:1051–1061. [Google Scholar]

- 2.Gerfers F., Kohlstadt M., Bar H., He M.-Y. 2007. Sub-μg Ultra-Low-Noise MEMS Accelerometers Based on CMOS-Compatible Piezoelectric AlN Thin Films Transducers, 2007, Lyon; pp. 1191–1194. [Google Scholar]

- 3.Kucera M., Wistrela E., Pfusterschmied G., Ruiz-Diez V., Manzaneque T., Sanchez-Rojas J.L. Characterization of a roof tile-shaped out-of-plane vibrational mode in aluminum-nitride-actuated self-sensing micro-resonators for liquid monitoring purposes. Appl. Phys. Lett. 2014;104:233501-1–233501-5. [Google Scholar]

- 4.Kucera M., Wistrela E., Pfusterschmied G., Ruiz-Diez V., Manzaneque T., Hernando-Garcia J. Design-dependent performance of self-actuated and self-sensing piezoelectric-AlN cantilevers in liquid media oscillating in the fundamental in-plane bending mode. Sens. Actuators B. 2014;200:235–244. [Google Scholar]

- 5.Dow A.B.A., Popov C., Schmid U., Kherani N.P. Super-high-frequency SAW transducer utilizing AlN/ultrananocrystalline diamond architectures. IEEE Trans. Ultrason. Ferr. 2013;60:1581–1586. doi: 10.1109/TUFFC.2013.2738. [DOI] [PubMed] [Google Scholar]

- 6.Quenzer H.J., Drechsler U., Sebastian A., Marauska S., Wagner B., Despont M. Fabrication of conducting AFM cantilevers with AlN-based piezoelectric actuators. Eurosensors XXV. 2011;25:665–668. [Google Scholar]

- 7.Elfrink R., Kamel T.M., Goedbloed M., Matova S., Hohlfeld D., van Andel Y. Vibration energy harvesting with aluminum nitride-based piezoelectric devices. J. Micromech. Microeng. 2009;19:094005-1–094005-8. [Google Scholar]

- 8.Zheng L., Ramalingam S., Shi T., Peterson R.L. Aluminum nitride thin-film sensor for force, acceleration, and acoustic-emission sensing. J. Vac. Sci. Technol. A: Vac. Surf. Films. 1993;11:2437–2446. [Google Scholar]

- 9.Khine L., Wong L.Y.L., Soon J.B.W., Tsai J.M. Evaluation of piezoelectric properties of AlN using MEMS resonators. Adv. Mater. Res. (Switzerland) 2011;254:74–77. [Google Scholar]

- 10.Doll J.C., Petzold B.C., Ninan B., Mullapudi R., Pruitt B.L. Aluminum nitride on titanium for CMOS compatible piezoelectric transducers. J. Micromech. Microeng. 2010;20:025008-1–025008-8. doi: 10.1088/0960-1317/20/2/025008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Akiyama M., Kamohara T., Kano K., Teshigahara A., Takeuchi Y., Kawahara N. Enhancement of piezoelectric response in scandium aluminum nitride alloy thin films prepared by dual reactive cosputtering. Adv. Mater. 2009;21:593–596. doi: 10.1002/adma.200802611. [DOI] [PubMed] [Google Scholar]

- 12.Akiyama M., Tabaru T., Nishikubo K., Teshigahara A., Kano K. Preparation of scandium aluminum nitride thin films by using scandium aluminum alloy sputtering target and design of experiments. J. Ceram. Soc. Jpn. 2010;118:1166–1169. [Google Scholar]

- 13.Umeda K., Kawai H., Honda A., Akiyama M., Kato T., Fukura T. Piezoelectric properties of scaln thin films for piezo-mems devices. Micro Electro Mech. Syst. 2013:733–736. [Google Scholar]

- 14.Lefki K., Dormans G.J.M. Measurement of piezoelectric coefficients of ferroelectric thin-films. J. Appl. Phys. 1994;76:1764–1767. [Google Scholar]

- 15.Chun D.M., Sato M., Kanno I. Precise measurement of the transverse piezoelectric coefficient for thin films on anisotropic substrate. J. Appl. Phys. 2013;113:044111-1–044111-9. [Google Scholar]

- 16.Leighton G.J.T., Kirby P.B., Fox C.H.J. In-plane excitation of thin silicon cantilevers using piezoelectric thin films. Appl. Phys. Lett. 2007;91:183510-1–183510-3. [Google Scholar]

- 17.Moreira M., Bjurstrom J., Katardjev I., Yantchev V. Aluminum scandium nitride thin-film bulk acoustic resonators for wide band applications. Vacuum. 2011;86:23–26. [Google Scholar]

- 18.Campanella H. Artech House Inc; 2010. Acoustic Wave and Electromechanical Resonators Concept to Key Applications (Integrated Microsystems) [Google Scholar]

- 19.Steel M.R., Harrison F., Harper P.G. Piezoelectric bimorph – experimental and theoretical-study of its quasistatic response. J. Phys. D: Appl. Phys. 1978;11:979–989. [Google Scholar]

- 20.Kholkin A.L., Wutchrich C., Taylor D.V., Setter N. Interferometric measurements of electric field-induced displacements in piezoelectric thin films. Rev. Sci. Instrum. 1996;67:1935–1941. [Google Scholar]

- 21.Hernando J., Sanchez-Rojas J.L., Gonzalez-Castilla S., Iborra E., Ababneh A., Schmid U. Simulation and laser vibrometry characterization of piezoelectric AIN thin films. J. Appl. Phys. 2008;104:053502-1–053502-9. [Google Scholar]

- 22.Tonisch K., Cimalla V., Foerster C., Romanus H., Ambacher O., Dontsov D. Piezoelectric properties of polycrystalline AlN thin films for MEMS application. Sens. Actuators A: Phys. 2006;132:658–663. [Google Scholar]

- 23.Schneider M., Bittner A., Patocka F., Stoger-Pollach M., Halwax E., Schmid U. Impact of the surface-near silicon substrate properties on the microstructure of sputter-deposited AlN thin films. Appl. Phys. Lett. 2012;101:221602-1–221602-4. [Google Scholar]

- 24.Kresse G., Furthmuller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B. 1996;54:11169–11186. doi: 10.1103/physrevb.54.11169. [DOI] [PubMed] [Google Scholar]

- 25.Kresse G., Joubert D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B. 1999;59:1758–1775. [Google Scholar]

- 26.van de Walle A., Tiwary P., de Jong M., Olmsted D.L., Asta M., Dick A. Efficient stochastic generation of special quasirandom structures. Calphad. 2013;42:13–18. [Google Scholar]

- 27.Yu R., Zhu J., Ye H.Q. Calculations of single-crystal elastic constants made simple. Comput. Phys. Commun. 2010;181:671–675. [Google Scholar]

- 28.Tasnadi F., Oden M., Abrikosov I.A. Ab initio elastic tensor of cubic Ti0.5Al0.5N alloys: dependence of elastic constants on size and shape of the supercell model and their convergence. Phys. Rev. B. 2012;85:144112-1–144112-9. [Google Scholar]

- 29.Matloub R., Artieda A., Sandu C., Milyutin E., Muralt P. Electromechanical properties of Al0.9Sc0.1N thin films evaluated at 2.5 GHz film bulk acoustic resonators. Appl. Phys. Lett. 2011;99:092903-1–092903-3. [Google Scholar]

- 30.Bernardini F., Fiorentini V. First-principles calculation of the piezoelectric tensor (d)over-left-right-arrow of III–V nitrides. Appl. Phys. Lett. 2002;80:4145–4147. [Google Scholar]

- 31.Tasnadi F., Alling B., Hoglund C., Wingqvist G., Birch J., Hultman L. Origin of the anomalous piezoelectric response in wurtzite ScxAl1−xN alloys. Phys. Rev. Lett. 2010;104:137601-1–137601-4. doi: 10.1103/PhysRevLett.104.137601. [DOI] [PubMed] [Google Scholar]

- 32.Yang J.C., Meng X.Q., Yang C.T., Zhang Y. Influence of sputtering power on crystal quality and electrical properties of Sc-doped AlN film prepared by DC magnetron sputtering. Appl. Surf. Sci. 2013;287:355–358. [Google Scholar]

- 33.Mayrhofer P.M., Eisenmenger-Sittner C., Stöger-Pollach M., Euchner H., Bittner A., Schmid U. The impact of argon admixture on the c-axis oriented growth of direct current magnetron sputtered ScxAl1−xN thin films. J. Appl. Phys. 2014;115:193505-1–193505-8. [Google Scholar]

- 34.Clement M., Iborra E., Sangrador J., Sanz-Hervas A., Vergara L., Aguilar M. Influence of sputtering mechanisms on the preferred orientation of aluminum nitride thin films. J. Appl. Phys. 2003;94:1495–1500. [Google Scholar]