Abstract

The oil and gas extraction industry is rapidly growing due to horizontal drilling and high volume hydraulic fracturing (HVHF). This growth has provided new jobs and economic stimulus. The industry occupational fatality rate is 2.5 times higher than the construction industry and 7 times higher than general industry; however injury rates are lower than the construction industry, suggesting injuries are not being reported. Some workers are exposed to crystalline silica at hazardous levels, above occupational health standards. Other hazards (particulate, benzene, noise, radiation) exist. In this article, we review occupational fatality and injury rate data; discuss research looking at root causes of fatal injuries and hazardous exposures; review interventions aimed at improving occupational health and safety; and discuss information gaps and areas of needed research. We also describe Wyoming efforts to improve occupational safety in this industry, as a case example.

Keywords: occupational health, occupational safety, hydraulic fracturing, oil and gas industry, silica exposure

INTRODUCTION

Proved oil and natural gas reserves are rapidly increasing in the U.S. Oil reserves have risen 63% and natural gas reserves 17% from 2009 to 2010, due in large part to new accessibility to tight shale formations using horizontal drilling and high volume hydraulic fracturing (HVHF) technologies [United States Energy Information Administration, 2010, 2011, 2012, 2014a,b]. Because of the high occupational fatality rate in the oil and gas extraction industry there are concerns that the rapid growth and new technologies may increase or change the nature of hazards for oil and gas industry workers [Mode and Conway, 2008]. Therefore, a need to characterize risks, identify solutions, and discover research gaps exists so that occupational health and safety in this growing industry sector may be addressed.

In total, energy-related industries make up 5.9% of business sector GDP and 1.2% of the total share of business sector employment [World Economic Forum, 2012]. A workforce assessment conducted by the Marcellus Shale Education and Training Center found that development of a single using HVHF technologies in the Marcellus Shale region requires 420 individuals in 150 occupations. Calculating 260 eight-hour days annually, the first well drilled on a well pad requires 13.1 full-time equivalent (FTE) workers and subsequent wells drilled on the same pad require 9.7 FTE. Once wells are in production many fewer workers are needed: only 0.17 FTE annually, per well [Marcellus Shale Education and Training Center, 2011]. Oil and gas extraction companies can broadly be divided into operators (contracting lease owners) drilling sub-contractors, and well servicing (i.e., hydraulic fracturing) sub-contractors. These companies can also be divided by number of employees (<20), medium (20–99), and large (100+) [Bureau of Labor Statistics, 2009].

While much of the future growth of natural gas production is predicted to come from the Marcellus shale in the northeastern United States, HVHF development of gas and oil fields in the western United States (Colorado, Wyoming, New Mexico, Utah and North Dakota) has been occurring over the last 15 years [United States Energy Information Administration, 2010, 2012]. Understanding the oil and gas workforce issues in the western states, can inform future initiatives, policies and regulations that promote the health and safety of oil and gas workers throughout the US. We review what is known and unknown about the major health and safety risks specific to workers in the natural gas and oil extraction industries in this paper and discuss research needs. A brief summary is listed in Table I.

TABLE I.

Major Conclusions and Research Needs

| Conclusions | Research Needs |

|---|---|

| Safety | Safety |

| High fatality rate: motor vehicle accidents are number one cause | Root cause analysis for occupational fatalities and injuries to inform industry interventions |

| Low injury rate: possibly due to underreporting | Examination of the low injury rates |

| Small companies have higher risk for fatality | Analysis of safety interventions for effectiveness |

| New employment is higher risk for fatality | Exploration safety culture successes in the industry |

| Training and safety culture are key to improving worksite safety | |

| Health | Health |

| Silica levels on worksites are often above safety and regulatory standards | Exposure assessment for a chemical hazard exposures |

| Exposure to other chemicals, including benzene, may exist | Exposure assessment for physical hazard exposures that lead to occupational illness (noise, radioactivity) |

| Exposure to noise is likely to exist | Screening and surveillance systems to assess incidence and prevalence of occupational illness |

| Expertise for high quality exposure assessment exists | Innovative industry/academic collaboration needed to conduct occupational epidemiologic studies |

| Most significant barrier to exposure assessment research is access to worksites | Effectiveness assessment of industry interventions to reduce exposures |

| Lack of occupational illness recognition, reporting and surveillance limits existing data sources for understanding impacts to occupational health |

|

| Access to the workforce,workforce characteristics,and illness latency make traditional epidemiologic studies challenging |

Occupational Fatalities and Injuries

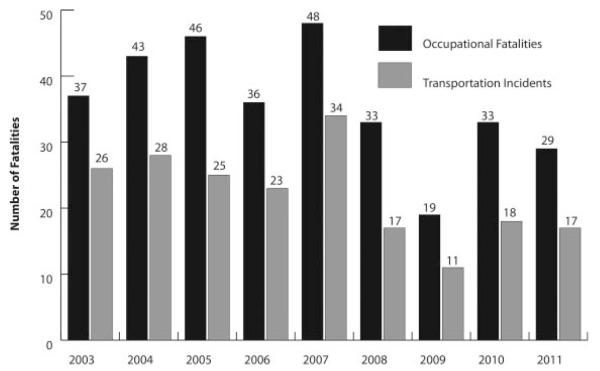

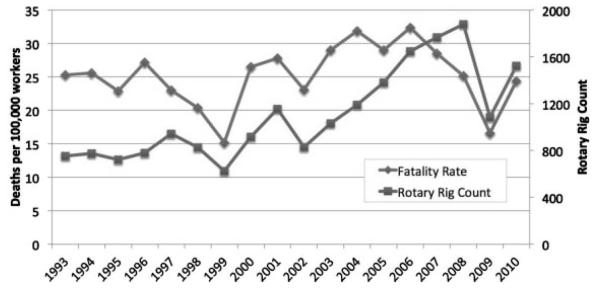

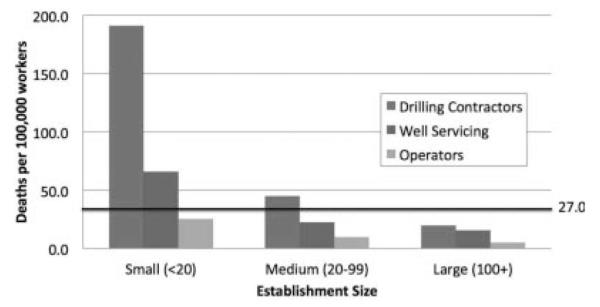

In the years 2005–2009, the occupational fatality rate of the oil and gas extraction industry was 2.5 times higher than the construction industry and 7 times higher than general industry [Bureau of Labor Statistics, 2008, 2009]. The industry’s fatal injury rate is correlated with fluctuations of industry activity, as measured by the number of active drilling rigs [Baker Hughes Incorporated, 2010; Bureau of Labor Statistics, 2009; Mode and Conway, 2008; National Institute for Occupational Safety and Health, 2014a] (Fig. 1). The most common fatal events were due to highway crashes (29.3%) and being struck by an object (20.1%). When a fatal traffic accident occurred, light duty trucks were most often involved; single vehicle rollover events were most common; most fatalities were associated with lack of seat belt use [Retzer et al., 2013]. Well servicing workers were at highest risk for fatal traffic accidents. Among companies involved in oil and gas extraction, small companies had higher rates of fatal injuries than did medium and large-sized companies [National Institute for Occupational Safety and Health; Retzer et al., 2013]. Drilling contractors had higher fatality rates than well servicing companies and operators [National Institute for Occupational Safety and Health; Retzer et al., 2013] (Fig. 2). New company employees were at highest risk of a fatal injury, regardless of the length of time working in the industry: over half (53.4%), of fatal injuries occurred within 1 year of service with employer, and over one quarter (28.2%) of fatal injuries occurred within 1–5 years of service with employer [Bureau of Labor Statistics, 2009; Retzer et al., 2013] (Fig. 3). Additional hazards are associated with newer extraction methods. For instance, a 2006 fatality occurred when a worker was engulfed in sand after entering an operating sand bin [Occupational Safety and Health Administration, 2011c].

FIGURE 1.

Occupational fatality rate and oil and gas extraction activity, 1993–2010.

FIGURE 2.

Occupational fatality rate by company type and establishment size, oil, and gas, 2003–2009.

FIGURE 3.

Fatalities to oil and gas workers by length of service, 2003–2009.

Although the oil and gas industry has had a high rate for fatalities, reported injuries are below that for construction and injury underreporting is likely [National Institute for Occupational Safety and Health, 2014a]. In the years 2005–2009, when compared to the construction industry, the oil and gas industry injuries were three-fold lower with respect to recordable, nonfatal injuries (1.2 vs. 4.0), days away from work (0.7 vs. 2.1), and injuries with job transfer or restriction (0.2 vs. 0.6) [United States Department of Commerce and United States Census Bureau, 2011]. Days away from work were due to being struck by/against object (35.8%); caught in an object, equipment, material (21.2%); falls on same/lower level (14.6%); overexertion (11.5%); exposure to harmful substance (3.3%); slips, trips (1.3%); or other (10.6%). Of note, transportation accidents were responsible for only 2.0% of the injuries with days away from work [United States Department of Labor and Bureau of Labor Statistics, 2010]. While these data provide some insight into the causes of injury in this industry, systematic underreporting to the Bureau of Labor Statistics (BLS) is well documented and likely due to many causes [Committee on Education and Labor, 2008; Azaroff et al., 2002; Fan et al., 2006]. Further investigation into the injuries occurring in this industry is warranted.

During the period from October 2010 to September 2011, Federal OSHA conducted 141 inspections of oil and gas drilling sites (SIC 1381), resulting in 581 citations and $1,576,646 in penalties assessed. In the same period, there were 122 inspections of oil and gas field services (SIC 1389), resulting in 447 citations and $1,089,568 in penalties [Occupational Safety and Health Administration, 2011c]. For the oil and gas industry, the OSHA top 5 violations nationwide included failure to guard floor openings (1910.23); safety violations related to confined spaces (1910.146); citations under the general duty clause (5(a) (1)); electrical wiring (1910.305); and personal protective equipment (1910.132). The top health-related violations included work in confined spaces (1910.146); violations in hazard communication (1910.1200); medical services & first aid (1910.151); respiratory protection (1910.134); and injury/illness recordkeeping (1904.7) [Occupational Safety and Health Administration, 2011b]. Regarding violations of hazard communication, fifteen OSHA inspections in the drilling sector resulted in 26 citations for hazard communication standard violations and $102,719 in penalties and fourteen field services sector inspections resulted in 23 citations and $27,225 in penalties [Occupational Safety and Health Administration, 2011b].

For the same time period, OSHA Region 8 offices (covering Colorado, Wyoming, North Dakota, South Dakota, Montana, and Utah) conducted 23 inspections of the oil and gas drilling sector, issued 49 citations and assessed fines of $16,661 [Occupational Safety and Health Administration, 2011c]. The Region 8 office conducted 46 inspections of the well servicing sector, issued 49 citations, and assessed $91,971 in fines [Occupational Safety and Health Administration, 2011c]. During FY2010, the five most frequently cited paragraphs in Colorado were violations of the general duty clause (5(a)(1)); personal protective equipment (1910.132(a)); signage for confined spaces (1910.146(c)(2)); guardrails for platforms (1919.23)(c)(1); and guarding of vertical belts (1910.219(e)(3)(i)). The signage for confined spaces and hazard communication were the most frequently health related standards [Occupational Safety and Health Administration, 2011b].

Occupational Illness

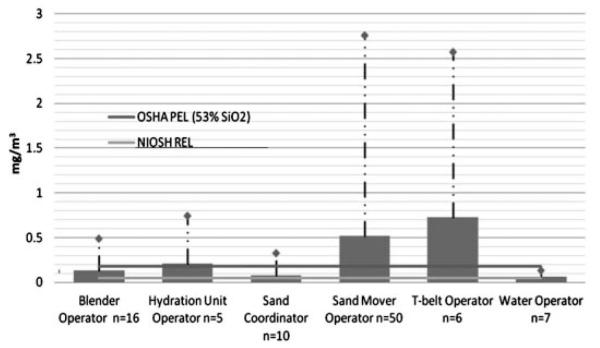

In 2010, NIOSH partnered with natural gas companies to measure worker exposure to respirable crystalline silica [National Institute for Occupational Safety and Health, 2010; Occupational Safety and Health Administration, 2012b; Esswein Eric et al., 2013]. One hundred sixteen samples were collected at 11 sites throughout the US; 47% showed silica exposures greater than the calculated OSHA PEL {10/[%Quartz + %cristobalite × 2) + % tridymite × 2) + 2]}(2008) 79% had levels greater than the NIOSH REL (0.05 mg/m3); 9% were 10 or more times the OSHA PEL; and 31% were 10 or more times over the NIOSH REL [Occupational Safety and Health Administration, 2002, 2011b, 2012b, 2014b]. The NIOSH researchers identified seven primary sources of silica dust exposure during hydraulic fracturing operations, including: ejected from thief hatches on the top of sand movers; ejected from side fill ports on the sides of sand movers; generated by onsite vehicle traffic; released from transfer belt under sand movers; created when sand is moved into or agitated in blender hopper; released from transfer belts between sand mover and blender; and released from top of sand transfer belt. Several job tasks were identified as having silica exposures exceeding OSHA and NIOSH exposure limits, in particular those working near sand operations (Fig. 4). To date, however, there have not been reports of silica related disease in this workforce.

FIGURE 4.

Arithmetic means, maximum values, comparisons to an OSHAL PEL, NIOSH REL.

Additional research documenting occupational chemical exposures and health hazards in oil and gas workers is scarce. Two published research studies looked at radon exposure. In Algeria, radon concentrations were higher in natural gas liquids and natural gas when compared to produced water and crude oil [Hamlat et al., 2003]. Radon levels below were occupational standards in a Canadian gas processing plant [van Netten et al., 1998]. Another Canadian study found evidence of occupational exposure to benzene in a small fraction of oil and gas workers associated with certain operations such as glycol dehydrators and recommended additional task based monitoring be conducted [Verma et al., 2000]. A study found workers were exposed to lead based drilling compounds brought lead home on their work clothes to expose family members [Khan, 2011]. The only study of health outcomes identified in PubMed found workers with hydrogen sulfide exposure had an increased risk of respiratory symptoms [Hessel et al., 1997]. These reports reflect the variability of the potential contaminants associated with natural gas.

It is difficult to track the extent of occupational illness in any industry. Occupational illness is often unrecognized as work related or not reported to OSHA or the employer and is rarely claimed in the worker’s compensation system. A national medical surveillance system for occupational illness fatalities comparable to the Census of Fatal Occupational Injuries (CFOI) does not exist.

The oil and gas drilling and servicing industries are generally covered by OSHA general industry standards and in some situations by the OSHA construction standards. However, these industries are exempt from four standards or parts of standards: Noise-Hearing conservation 1910.95(o); Lockout 1910.147(a)(1)(ii)(E); Process safety management 1910.119(a) (2)(ii); Benzene 1910.1028(a)(2)(iv). Health exposure data resulting from OSHA inspections, and in particular hearing conservation and benzene exposures, are limited by these exemptions [Occupational Safety and Health Administration, 2014a]. An OSHA database from the years 1984 to 2009 has limited industrial hygiene air monitoring data [Occupational Safety and Health Administration, 2011a]. For oil and gas well drilling sector there are 284 samples of a wide range of air contaminants, including hydrocarbons and silica. These data indicate that there have been some hydrocarbon overexposures and examples of silica overexposures documented in Colorado. For oil and gas field services sector there have been 786 sample analyses, documenting some overexposures to hydrocarbons as well. Exposures can occur when drilling operations are in producing formations and during servicing operations (swabbing, fracturing, open hole work, flow testing, plugging, cementing, wireline and other operations when the wellhead is under pressure) [Occupational Safety and Health Administration, 2014c].

Hydrogen sulfide can be found in natural gas (referred to as “sour gas”) or can occur as a result of anaerobic bacterial digestion of organic matter during the extraction process. Hydrogen sulfide exposures can occur during well servicing, tank gauging and swabbing operations. Many companies in the industry routinely require use of personal LEL/H2S monitors and ANSI/ASSE Z390.1-2006 (R2010) hydrogen sulfide training programs. Additional OSHA recommendations to reduce H2S exposures in the natural gas industry include installing ground level tank gauges and continuous monitoring during servicing operations [Occupational Safety and Health Administration, 2006]. Data regarding the frequency of exposure to hydrogen sulfide in the oil and gas extraction worksite are not available.

There are many sources of noise exposure on the oil and gas extraction site, including diesel engines, generators, heavy equipment, mechanical brakes, draw works, radiator fans, pipe handling, and drilling. During the period of October 2010–September 2011, OSHA inspections of the oil and gas industry resulted in two citations and fines of $2,400. Inspections and citations are limited because companies involved in oil and gas well drilling and servicing are exempt from several sections of the OSHA noise standard [Occupational Safety and Health Administration, 2011c].

Industries supporting oil and gas extraction have grown in tandem with the oil and gas industry. For example, mining in the quartz-rich sandstone of the upper Mississippi River basin in Wisconsin will grow 33% over the next several years to provide sand for hydraulic fracturing operations throughout the United States [Wisconsin Department of Natural Resources, 2012] and Minnesota and Iowa have experienced similar increases in silica sand mining [Minnesota Department of Natural Resources, 2014; National Public Radio, 2011]. Sand mining occurs both on the surface and underground; occupational health hazards include silica dust, diesel exhaust and noise. Silica sand mining is regulated by Mining Safety and Health Administration (MSHA) [Mine Safety and Health Administration, 2014]. MSHA keeps detailed records of occupational injury and injury related fatalities, however, like OSHA, data related to health hazards and occupational illness are not systematically collected.

Another industry supporting oil and gas extraction is that of hauling, treatment, disposal extraction and production (E&P) waste and wastewater recycling. This waste is commonly associated with flammable, explosive and/or poisonous vapors and gases. Systematically aggregated data for this industry is difficult to obtain since the BLS data is captured in the broader North American Industry Classification System (NAICS) codes 211111 (Crude Petroleum and Natural Gas Extraction), 213112 (Support Activities for Oil and Gas Operations), and 213111 (Drilling Oil and Gas Wells). The Chemical Safety Board (CBS) has investigated numerous fatalities and injuries involving the oil and gas waste disposal industry. Important common factors in the incidents investigated by CSB were inadequate identification of hazardous nature of the materials being handled, inadequate hazard communication to workers and poor safety training for workers. [Chemical Safety Board 1998, 2003a,b, 2006]. Because this industry is inevitably growing alongside the oil and gas industry, further investigation of injury and health hazards and development of effective mitigations are important to protect these workers.

Federal Agency and Industry Interventions

To address transportation fatalities associated with all industries, the US Department of Labor, through OSHA, has partnered with the Department of Transportation to develop a Distracted Driving Initiative, with an initial focus is on texting and driving. [Occupational Safety and Health Administration and Department of Transportation, 2010] This initiative states that employers should prohibit any policy or practice that requires or encourages workers to text while driving and if employers fail to do so they are in violation of the OSHA act. In this context, OSHA is educating all industries, including oil and gas, about the enforcement of safe driving practices and the dangers of texting and driving. In addition, NIOSH is evaluating the effectiveness of In-Vehicle Monitoring Systems (IVMS) that record information such as speed, harsh braking and acceleration, and seat-belt use and, in some systems, provide the driver with immediate feedback and the driver’s supervisor with email alerts about any unsafe driving behaviors. When properly planned and implemented, companies have seen a 50–93% reduction in motor vehicle crash rates. NIOSH is developing a guide specific to the industry: “Implementing In-Vehicle Monitoring System Program: A guide for improving driver performance in the oil and gas extraction industry” to disseminate their findings and assist companies interested in using IVMS [National Institute for Occupational Safety and Health, 2012].

The NIOSH exposure studies revealing silica as a health hazard on oil and gas extraction sites have prompted OSHA and NIOSH to issue a joint Hazard Alert to the industry. This Hazard Alert includes several recommendations to monitor and reduce silica exposures [Occupational Safety and Health Administration, 2012b]. Short-term changes that can decrease exposures include capping ports, reducing transfer heights, limiting time in high exposure areas, and wetting work areas. Equipment changes aimed at decreasing dust release, enclosing operations or workers, and replacing/retrofitting transfer belts with screw augers can also decrease exposures. Under OSHA regulation, companies must provide proper respiratory protection and have a Respiratory Protection Program if silica exposures are above OSHA standards and companies must have a Hazard Communication Program for all potential exposures [Occupational Safety and Health Administration].

OSHA Regional Emphasis Programs (REP) for the Oil and Gas Industry are in effect in Region 3 (District of Columbia, Delaware, Maryland, Pennsylvania, Virginia, West Virginia), Region 6 (Arkansas, Louisiana, Oklahoma, and Texas), and Region 8. Under this program OSHA conducts targeted enforcement inspections of randomly selected oil and gas field exploration services and oil and gas field services employers as well as conducting inspections resulting from complaints, referrals, and accidents [Occupational Safety and Health Administration, 2010, 2011d].

A revised Hazard Communication standard, aligning chemical labeling and safety data sheets with the United Nations’ Globally Harmonized System (GHS) of Classification and Labeling of Chemicals, became effective 5/12/2012, with employee training to be completed by 12/1/2013 and manufacturer compliance by 6/1/2015 [Occupational Safety and Health Administration, 2012a].

New drilling and well servicing equipment can have advanced features designed to enhance safety. Despite such improvements, safety concerns persist. For example, fatalities are most often associated with workers new to a company (not just new to an industry). Thus, even workers with previous industry experience are at an increased risk on new jobsites. Accordingly, all companies need a strong safety culture and thorough training for all new employees, regardless of previous experience [National Institute for Occupational Safety and Health].

Occupational Injury and Illness Research Needs

The large discrepancy between occupational fatality and injury rates when compared to the construction industry suggests underreporting of injuries in the oil and gas extraction industry. Investigation of occupational injuries should focus on identification of specific causes of injuries and fatalities, as well as the causes of underreporting. Such research will guide safety interventions, provide insight into aspects of the safety culture and barriers to reporting in the industry. It will also be important to monitor the impacts of new technologies, effectiveness of safety interventions and efforts to improve safety culture. Poor safety culture was recognized as a key factor leading to the Deepwater Horizon explosion [Committee on the Analysis of Causes of the Deepwater Horizon Explosion, 2012].

In order to understand and address occupational health hazards in the oil and gas extraction industry, federal and state agencies, academic institutions and industry must collaborate to produce high quality research. Potential studies fall into two main categories: (1) exposure assessment, such as the one conducted by NIOSH looking at silica and (2) health outcomes studies. Potential health hazards may include exposures to hydrocarbons (e.g., benzene, toluene, ethylbenzene, xylene (BTEX)), diesel exhaust, fracturing chemicals (e.g., glutaraldehyde, hydrochloric acid, acetic acid, potassium hydroxide and ammonium chloride and petroleum distillates), hydrogen sulfide, natural occurring radioactive materials (NORM) including radon, heat and cold stress, and noise [National Institute for Occupational Safety and Health]. Expertise for robust exposure assessment of these health hazards exists; however, in order to obtain high quality data, access to worksites is needed. Post-intervention exposure assessment studies, evaluating industry health and safety mitigations are also needed to ensure that industry efforts to reduce hazards are effective.

Measuring occupational illness in the oil and gas extraction workforce will require long term coordinated effort from industry, government, health care providers and research institutions. Many occupational health outcomes, such as silica-related lung disorders, benzene-related hematopoietic disease and noise-induced hearing loss, involve long latency periods; workers must be followed for years before outcomes are measurable in epidemiologic studies. Researchers must develop creative study designs to follow workers and enlist the cooperation of the industry to develop new datasets. Federal agencies should develop surveillance systems for specific occupational illnesses.

Industry and NIOSH have articulated areas of health and safety concerns and have developed consensus around research needs. NIOSH and industry leaders have collaborated to create the National Occupational Research Agenda (NORA), which outlines priority safety and health issues in the oil and gas extraction industry. The NORA 5 strategic research goals include occupational fatalities, motor vehicle fatalities, contact injuries, non-fatal injuries, and chemical exposures. Industry practices and environmental hazards are likely to vary by region. For instance, hazardous weather conditions in Wyoming (ice, snow, and freezing temperatures) differ from hazardous conditions in the southeast (high temperatures and humidity); and wastewater recycling may expose workers to dangerous chemicals while disposal using deep injection wells may not involve such exposures. The longer history with directional drilling and high volume hydraulic fracturing in the Western region provides insight into the occupational hazards of this industry. However, while many of the research needs identified for the western region will be applicable to the eastern part of the United States, there may be additional research needed to identify risks and protect workers in other regions of the United States.

CASE STUDY: THE WYOMING OIL AND GAS INDUSTRY SAFETY ALLIANCE

Wyoming has a long history of extractive and energy industries, including oil and gas extraction, drilling, production and refining. Wyoming is the largest exporter of domestic energy in the US and ranks in the top 5 for natural gas production and “proved reserves” [Surdam, 2008]. Gas drilling and HVHF occur in several basins throughout the state. Wyoming also has a high workplace fatality rate, regularly ranking in the top 10, nationally. In 2007 and 2008, Wyoming had the highest occupational fatality rate in the nation, driven in part by fatal transportation incidents in the oil and gas industry (CFOI, 2014; Retzer et al., 2013).

Wyoming can serve as a “case study” for similarly impacted rural/frontier regions, illustrating both occupational risks and collaborative strategies to mitigate these risks. Wyoming has seen value in encouraging strong alliances between industry members to create safety councils. In response to the occupational fatality statistics, in 2009 the Governor’s office convened the Wyoming Workplace Fatality Prevention Task Force. Stakeholders included the major industries with high fatality rates, federal and state agencies (including NIOSH and Wyoming OSHA), safety and community organizations, education and training groups (the Mountain and Plains Education and Research Center), and others. The collaborative NIOSH-State “Alaska program” was used as a model [Conway et al., 1999]. The Task Force drew up a list of recommendations, one of which resulted in the creation of the new position of State Occupational Epidemiologist, initially housed in the Governor’s office. This individual was charged with gathering data and developing initiatives to reduce occupational fatalities. The position has been maintained with a new administration, and it is now housed in the Department of Workforce Services.

An additional outcome of the Task Force was the formation, in 2010, of the Wyoming Oil & Gas Industry Safety Alliance (WOGISA), funded in part by the oil and gas industry and working in association with Wyoming OSHA and other agencies and stakeholders [Wyoming Oil and Gas Industry Safety Alliance, 2014]. WOGISA’s goal is to promote a culture of safety and health improvement in the oil and gas industry by engaging members to share and discuss safety and health incidents, to develop best practices and to work with other organizations and agencies (OSHA, International Association of Drilling Contractors, American Petroleum Institute) to address specific issues [Wyoming Oil and Gas Industry Safety Alliance, 2014] WOGISA provides, at no cost, quarterly, standardized mandatory training for supervisors and group-level workers. It also conducts outreach and awareness throughout the state, hosts an annual Safety Summit (co-sponsored by Wyoming OSHA and other industry safety and related groups) [Wyoming Department of Workforce Services, 2013], and maintains a website (Wyomingsafety.org) as a resource for operators and subcontractors. Importantly, this training is open to workers from all oil and gas companies, including those from small-and medium-sized companies, which may not have extensive in-house training resources [Retzer et al., 2013]. With the backing of industry and private donations, the WOGISA executive council supports safety-oriented legislation, promotes safe driving practices, seatbelt use, and optimal use of flame-resistant clothing. WOGISA helped develop a “Stop-Work Authority” (SWA) award program to prevent accidents and near-misses. This program includes quarterly SWA WOGISA awards and the Governor’s annual SWA award. WOGISA membership has increased steadily and, as of 2013, included over 900 individual members representing over 320 companies and associations. This included 31% of the oil and gas operators working in Wyoming in 2013. Membership also represented 286 other companies and associations involved directly or indirectly with the oil and gas industry in Wyoming (service, equipment, drilling, pipeline, trucking, midstream, associations and government, downstream, roustabout, training, support, media, and field construction).

In 2012, the Wyoming State Legislature developed House Bill 089 (HB0089; Workplace safety-employer assistance) aimed at promoting workplace safety and adding up to eight additional Wyoming OSHA occupational health and safety consultants. The resulting statute [Wyoming Statute §9-2-2608, 2012] directly addresses incentives and supports for workplace safety, including “Safety Contract” grants up to $10,000 for employers to enhance or implement workplace safety programs or purchase safety equipment [Wyoming House of Representatives, 2012 Budget Session]. An additional 2013 bill (House Bill 0052) aims to offer discounts up to 10% in workers compensation premiums for employers who participate in the health and safety consultation program of the Wyoming OSHA division [Wyoming House of Representatives General Session, 2013].

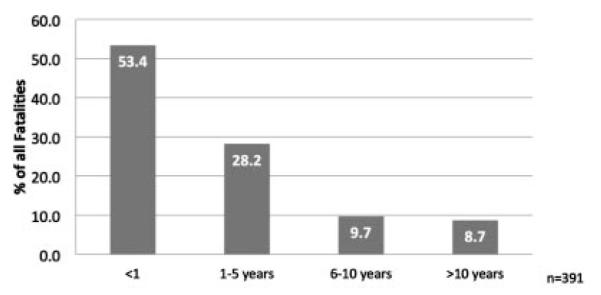

Occupational fatalities, including occupational transportation fatalities, have declined in Wyoming since 2008 [Bullard, 2014] (Fig. 5). It remains to be seen if this downward trend was due in part to the above initiatives, and whether the trend can be sustained. Nevertheless, the issue of workplace fatalities has now been in the forefront for several years, which may provide continued momentum for future initiatives.

FIGURE 5.

Wyoming occupational fatalities and transportation incidents, 2003–2011.

CONCLUSIONS

The oil and gas industry is rapidly expanding, providing many new jobs, but also increasing the risk for work-related fatality, injury and illness. New exposures related to the use of HVHF, as well as classic industrial safety hazards will challenge the industry to maintain a safe and healthy work environment. The industry, federal agencies and occupational health and safety researchers should work together to examine and improve health and safety for workers.

There are important topics that impact occupational safety and health in the oil and gas extraction industry that are not addressed in this paper, including important social factors such as availability of safe and affordable housing, family health and job stability, drug and substance abuse, mental health and long-term comorbidities. Further research and interventions are needed to address these health hazards associated with employment in this industry.

Political leaders should support injury and illness prevention research in the field of occupational health and safety in general and with respect to the oil and gas industry. Research partnerships between government agencies, academic research institutions and industry are essential in order to leverage research funds, improve worker health and safety, and minimize the business impact of injuries, illness and fatalities. Collaborative research approaches can benefit by (1) identification of the actual root-causes of injuries and fatalities and then (2) development of programs targeted towards the known root causes which are aimed to mitigate these causes, and (3) assessing the efficacy of mitigation programs.

Acknowledgments

Contract grant sponsor: NIOSH Mountain and Plains Education and Research Center (partial support).

Footnotes

Disclosure Statement: The authors report no conflicts of interests.

REFERENCES

- Azaroff LS, Levenstein C, Wegman DH. Occupational injury and illness suveillance: Conceptual filters explain underreporting. Am J Public Health. 2002;92(9):1421–1429. doi: 10.2105/ajph.92.9.1421. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Baker Hughes Incorporated . Rotary Rig Count. Baker Hughes Incorporated; Houston, TX: 2010. [Google Scholar]

- Bullard D. Wyoming Occupational Fatalities Decrease in 2011 [Internet] Wyoming Department of Workforce Services; Available from: http://doe.state.wy.us/lmi/trends/0912/a3.htm. [Google Scholar]

- Bureau of Labor Statistics . Census of Fatal Occupational Injuries. United States Department of Labor; Washington, DC: 2008. [Google Scholar]

- Bureau of Labor Statistics . In: Census of Fatal Occupational Injuries. Restricted Data under NIOSH MOU, editor. United States Department of Labor; Washington, DC: 2009. [Google Scholar]

- Census of Fatal Occupational Injuries (CFOI) Fatal occupational injuries [Internet] Wyoming CFOI unit, Research & Planning; Casper, WY: Available from: http://doe.state.wy.us/lmi/CFOI/toc.htm. [Google Scholar]

- Chemical Safety Board . Catastrophic vessel overpressurization. Chemical Safety and Hazard Investigation Board; Washington, DC: 1998. No. 1998-002-I-LA. [Google Scholar]

- Chemical Safety Board . Chemical Safety and Hazard Investigation Board Public Meeting. Chemical Safety Board; Washington, DC: 2003a. [Google Scholar]

- Chemical Safety Board . Vapor cloud deflagration and fire. U.S. Chemical Safety and Hazard Investigation Board; Washington, DC: 2003b. No. 2003-061-TX. [Google Scholar]

- Chemical Safety Board . Hot work control and safe work practices at oil and gas production wells. Chemical Safety and Hazard Identification Board; Washington, DC: 2006. No. 2006-07-I-MS. [Google Scholar]

- Committee on the Analysis of Causes of the Deepwater Horizon Explosion . Macondo Well Deepwater Horizon Blowout. National Academy of Engineering and National Research Council; Washington, DC: 2012. [Google Scholar]

- Conway G, Lincoln J, Husberg B, Manwaring J, Klatt M, Thomas T. Alaska’s model program for surveillance and prevention of occupational injury deaths. Public Health Rep. 1999;114:550–558. doi: 10.1093/phr/114.6.550. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Committee on Education and Labor . In: Hidden Tragedy: Under-reporting of Workplace Injuries and Illnesses. Education and Labor.110th Congress, editor. US Government Printing Office; Washington, DC: 2008. pp. 1–55. [Google Scholar]

- Esswein Eric J, Breitenstein M, Snawder J, Kiefer M, Sieber WK. Occupational exposures to respirable crystalline silica during hydraulic fracturing. J Occup Environ Hyg. 2013;10(7):347–356. doi: 10.1080/15459624.2013.788352. [DOI] [PubMed] [Google Scholar]

- Fan JZ, Bonauto DK, Foley MP, Silverstein BA. Underreporting of work-related injury or illness to workers’ compensation: individual and industry factors. J Occup Environ Med. 2006;48(9):914–922. doi: 10.1097/01.jom.0000226253.54138.1e. [DOI] [PubMed] [Google Scholar]

- Hamlat MS, Kadi H, Djeffal S, Brahimi H. Radon concentrations in Algerian oil and gas industry. Appl Radiat Isot. 2003;58:125–130. doi: 10.1016/s0969-8043(02)00257-9. [DOI] [PubMed] [Google Scholar]

- Hessel PA, Herbert A, Melenka LS, Yoshida K, Nakaza M. Lung health in relation to hydrogen sulfide exposure in oil and gas workers in Alberta, Canada. Am J Ind Med. 1997;31:554–557. doi: 10.1002/(sici)1097-0274(199705)31:5<554::aid-ajim9>3.0.co;2-t. [DOI] [PubMed] [Google Scholar]

- Khan F. Take home lead exposure in children of oil field workers. J Okla State Med Assoc. 2011;104:252–253. [PubMed] [Google Scholar]

- Marcellus Shale Education and Training Center . Pennsylvania Marcellus Shale Economic Impact Study. Pennsylavania College of Technology, Penn State Extension; 2011. [Google Scholar]

- Mine Safety and Health Administration . United States Department of Labor; Available from: http://www.msha.gov/ [Google Scholar]

- Minnesota Department of Natural Resources . Industrial Silica Sand Frequently Asked Questions and Answers [Internet] St. Paul, MN: Available from: http://www.dnr.state.mn.us/lands_minerals/silicasand.html. [Google Scholar]

- Mode NA, Conway G. Fatalites among oil and gas extraction workers—United States, 2003–2006. MMWR Wkly Rep. 2008;57(16):429–431. [PubMed] [Google Scholar]

- National Institute for Occupational Safety and Health . NIOSH Field Effort to Assess Chemical Exposure Risks to Gas and Oil Workers. Department of Health and Human Services; Centers for Disease Control and Prevention; Cincinnati, OH: 2010. [Google Scholar]

- National Institute for Occupational Safety and Health . NIOSH Program Portfolio: Oil and Gas Sector [Internet] Centers for Disease Control and Prevention; Atlanta, GA: Available from: http://www.cdc.gov/niosh/programs/oilgas/default.html. [Google Scholar]

- National Institute for Occupational Safety and Health . Roughnecks, Roustabouts, and Researchers: NIOSH’s Oil and Gas Extraction Safety and Health Program Protects Workers [Internet] Centers for Disease Control and Prevention; Available from: http://www.cdc.gov/niosh/programs/oilgas/risks.html. [Google Scholar]

- National Public Radio Natural Gas Extraction Creates A Boom for Sand [Internet] Available from: http://www.npr.org/2011/08/03/138710389/gas-extraction-creates-a-boom-for-sand.

- Occupational Safety and Health Administration Permissible Exposure limits for silica. 2002.

- Occupational Safety and Health Administration . In: OSHA fact sheet: Hydrogen sulfide. Labor USDo, editor. Washington, DC: 2006. [Google Scholar]

- Occupational Safety and Health Administration . In: Regional Emphasis Program for the Oil and Gas Well Industry: Region 6. Labor USDo, editor. Dallas, TX: 2010. [Google Scholar]

- Occupational Safety and Health Administration . Chemical Exposure Health Data. United States Department of Labor; Washington, DC: 2011a. [Google Scholar]

- Occupational Safety and Health Administration . Frequently Cited OSHA Standards. United States Department of Labor; Washington, DC: 2011b. [Google Scholar]

- Occupational Safety and Health Administration . Inspections by SIC. United States Department of Labor; Washington, DC: 2011c. [Google Scholar]

- Occupational Safety and Health Administration . In: Regional Emphasis Program for the Oil and Gas Industry; Region 8. Labor USDo, editor. Denver, CO: 2011d. [Google Scholar]

- Occupational Safety and Health Administration . In: Hazard Commummunication Standard. Labor USDo, editor. Washington, DC: 2012a. [Google Scholar]

- Occupational Safety and Health Administration . OSHA and NIOSH issue hazard alert on ensuring workers in hydraulic fracturing operations have appropriate protections from silica exposure. U.S. Department of Labor; Washington, DC: 2012b. [Google Scholar]

- Occupational Safety and Health Administration . In: Occupational Safety and Health Standards; Occupational Noise Exposure 1910.95. Labor USDo, editor. Washington, DC: [Google Scholar]

- Occupational Safety and Health Administration . In: Safety and Health Topics: Silica, Crystalline. Labor USDo, editor. Washington, DC: [Google Scholar]

- Occupational Safety and Health Administration . Oil and Gas Well Drilling and Servicing eTool [Internet] United States Department of Labor; Washington, DC: Available from: http://www.osha.gov/SLTC/etools/oilandgas/index.html. [Google Scholar]

- Occupational Safety and Health Administration. Department of Transportation . In: OSHA’s Distracted Driving Initiative. Labor USDo, editor. Washington, DC: 2010. [Google Scholar]

- Retzer KD, Hill R, Pratt SG. Motor vehicle fatalities among oil and gas extraction workers. Accid Anal Prev. 2013;51:168–174. doi: 10.1016/j.aap.2012.11.005. [DOI] [PubMed] [Google Scholar]

- Surdam RC. In: Wyoming energy development in the context of the global energy economy. Survey SoWG, editor. Cheyenne, Wyoming: 2008. [Google Scholar]

- United States Department of Labor. Bureau of Labor Statistics . Occupational Injuries and Illnesses: Industry Data. Washington, DC: 2010. [Google Scholar]

- United States Energy Information Administration . U.S. crude oil, natural gas, and ng liquids proved reserves [Internet] Energy Information Administration; Washington, DC: [cited 2010]. Available from: http://www.eia.gov/naturalgas/crudeoilreserves/index.cfm. [Google Scholar]

- United States Energy Information Administration . Annual Energy Outlook 2011 [Internet] Energy Information Administration; Washington, DC: 2012. Available from: http://www.eia.gov/oiaf/aeo/gas.html. [Google Scholar]

- United States Energy Information Administration . Annual Energy Outlook 2012 [Internet] Energy Information Adminstration; Washington, DC: Available from: http://www.eia.gov/oiaf/aeo/tablebrowser/#release=AEO2012&subject=0-AEO2012&table=11-AEO2012®ion=0-0&cases==ref2012-d020112c. [Google Scholar]

- United States Energy Information Administration . Frequently asked questions [Internet] Energy Information Administration; Washington, DC: Available from: http://www.eia.gov/tools/faqs/faq.cfm?id=46&t==8. [Google Scholar]

- United States Energy Information Administration . Natural Gas Summary [Internet] Energy Information Administration; Washington, DC: Available from: http://www.eia.gov/dnav/ng/ng_sum_lsum_a_EPG0_r20_Bcf_a.htm. [Google Scholar]

- United States Department of Commerce. United States Census Bureau . North American Industry Classification System. Washington, DC: 2011. [Google Scholar]

- van Netten C, Kan K, Anderson J, Morley D. Radon-222 and gamma ray levels associated with the collection, processing, transmission, and untilization of natural gas. Am Ind Hyg Assoc J. 1998;59(9):22–628. doi: 10.1080/15428119891010794. [DOI] [PubMed] [Google Scholar]

- Verma K, Johnson DM, McLean JD. Benzene and total hydrocarbon exposures in the upstream petroleum oil and gas industry. Am Ind Hyg Assoc J. 2000;61:255–263. doi: 10.1080/15298660008984534. [DOI] [PubMed] [Google Scholar]

- Wisconsin Department of Natural Resources . Silica Sand Mining in Wisconsin [Internet] Wisconsin Department of Natural Resources; Madison, WI: Available from: http://dnr.wi.gov/topic/Mines/Silica.html. [Google Scholar]

- World Economic Forum Energy for Economic Growth Energy Vision Update 2012 [Internet] Available from: http://www.weforum.org/reports.

- Wyoming Department of Workforce Services . Wyoming Safety & Workforce Summit [Internet] Larimer, WY: 2013. Available from: http://www.wyomingworkforce.org/employers-and-businesses/osha/Pages/2013-Wyoming-Safety--Workforce-Summit.aspx. [Google Scholar]

- Wyoming House of Representatives Budget Session. House Bill 0089: Workplace safety contract program. 2012.

- Wyoming House of Representatives General Session. House Bill 0052: Workplace safety initiatives. 2013.

- Wyoming Oil and Gas Industry Safety Alliance WOGISA [Internet] Available from: http://wyomingsafety.org/

- Wyoming Statute §9-2-2608 . In: Workplace Safety Program Contract. Legislature WS, editor. Cheyenne, Wyoming: 2012. [Google Scholar]