Abstract

Background:

This study was carried out to evaluate the effect of two commercially available chemical disinfectants namely sodium hypochlorite and glutaraldehyde and a surface wetting agent on the wettability of three high precision elastomeric impression materials, addition silicone, condensation silicone and polyether.

Materials and Methods:

Three different types of elastomeric impression materials commonly used in prosthodontic practice were selected. The glutaraldehyde and sodium hypochloride solutions were employed to disinfect the impressions made with the above-mentioned elastomeric impression materials.

True Blue surface wetting agent was selected.

GBX contact angle analyzer was used to measure advancing and receding contact angle.

Results:

The results of this study have demonstrated that the polyether impression material was the most hydrophilic of all the materials, followed by hydrophilic addition silicone. Condensation silicone was least hydrophilic. All materials showed improvement in the wettability when a topical surfactant was used.

Conclusion:

The short term disinfection of the three elastomeric impression materials does not affect the wettability of these impression materials.

Keywords: Disinfectants, elastomeric impression materials, surface wetting agent

Introduction

Impressions play a vital role in the success of prosthesis because a prosthesis can be no more accurate than the impression from which it has been made. One of the most critical factors in the production of an accurate impression is the use of an appropriate impression material. There is a continuous effort to improve materials used to achieve dimensional stability, precision and fine tissue details.

The dimensional stability and surface detail obtained with elastomeric impression materials has made them the material of choice for recording impressions that require a high degree of accuracy. It is also necessary for the impression materials to allow easy flow of the stone as is being poured. Silicone impression materials, however are recognized as having poor surface wettability.1 Clinically, the topical use of a surface wetting agent has been demonstrated to improve wettability and significantly reduce the number of voids in dental casts poured in silicone impressions.2

The impressions are contaminated with saliva, plaque and sometimes blood, all of which may carry pathogenic micro-organisms. Mere washing of the impression as it is practiced does not clear away all the micro-organisms.3 These contaminated impressions may cause cross-infection from the patient to operator or dental assistant or laboratory technician.4 Hence, it is necessary that the disinfection of dental impressions be adopted as a mandatory procedure in dental practice.

In trying to achieve the goal of disinfection for the protection of the dental team, it is absolutely necessary that accuracy and surface details of impressions, not be compromised. Moreover currently available impression materials were never originally designed to undergo disinfection or sterilization and it is quite conceivable that available disinfecting solutions may adversely affect the impressions.5 Commonly used disinfecting agents like glutaraldehyde and sodium hypochlorite may alter the surface characteristics of impression materials, which may lead to dimensional changes in the impressions, along with changes in surface tension and wettability of the impression material.

Thus, the need arises to critically evaluate how these disinfecting solutions could affect the physical properties of elastomeric impression materials in order to ensure efficient, ethical and a consistent modern day prosthodontic practice.

Hence, this study was designed to evaluate the effect of two commercially available chemical disinfectants namely sodium hypochlorite and glutaraldehyde and a surface wetting agent on the physical property of three high precision elastomeric impression materials, viz. addition silicone, condensation silicone and polyether. Wettability was the physical property evaluated.

Aims and objectives

The study was conducted:

To determine the contact angle and the wettability of various elastomeric impression materials before and after immersion disinfection

To determine the contact angle and the wettability of various elastomeric impression materials before and after treatment with a surface wetting agent.

Materials and Methods

For the purpose of this study, three different types of elastomeric impression materials commonly used in prosthodontic practice were selected.

They are as follows:

-

Addition silicone impression material:

- Express STD

- Putty and light body syringeable (3M ESPE Dental Products U.S.A.)

-

Condensation silicone impression material:

- Zetaplus

- Putty and light body (Zhermack Italy)

-

Polyether impression material:

- Impregum F

- Hydrophilic medium consistency (3M ESPE Dental Products U.S.A.)

The glutaraldehyde and sodium hypochloride solutions were employed to disinfect the impressions made with the above mentioned elastomeric impression materials.

True Blue surface wetting agent was selected.

-

Glutaril

2% Glutaraldehyde (Glaxo India Ltd.)

-

Sodium hypochlorite sodium U.S.P.

4-6% sodium hypochlorite (Snow Chem Industries, Mumbai)

-

True Blue

Surface wetting agent (Georg Taub Products, U.S.A.)

Armamentarium

Aluminum model die,

Glass slide.

GBX contact angle analyzer to measure advancing and receding contact angle.

In vitro study Wettability

Three different types of elastomeric impression materials were selected as representative of the materials currently used. Each impression material was mixed according to manufacturer’s instructions. Specimens 20 mm × 10 mm × 2 mm were prepared by compressing the elastomeric material in a mold and glass slide. Five specimens were produced of each material for each test condition.

The test conditions were as follows:

Dry

Surface wetting agent (spray twice)

2% glutaraldehyde (10 min immersion)

2% glutaraldehyde (10 min immersion) and surface wetting agent

4% sodium hypochlorite (10 min immersion)

4% sodium hypochlorite (10 min immersion) and surface wetting agent.

Care was taken not to permit contamination of the surfaces.

Contact angle measurements

A contact angle analyzer linked to a compatible computer as used to measure the advancing and receding contact angles. Distilled water was used as the wetting medium.

In the technique used, the material was suspended in an electro balance while the wetting medium scans along at a constant speed via a computer-controlled stage. The meniscus at the interface is characterized by the dynamic contact angle (θ). Both the advancing and receding contact angles are measured as the stage moves up (the specimen) and then down. The difference between these two contact angles is called as contact angle hysteresis.

A simple equation relates the cosine of the contact angle (θ) to the magnitude of the wetting force recorded by the balance, the surface tension of the liquid, and the wetted perimeter of the solid specimen:

where,

F = force (dynes)

P = perimeter (cm)

v = surface tension (dyne/cm)

Observations and Results

Contact angle of Express 3M, Zetaplus and Impregum F (addition silicone, condensation silicone and polyether respectively) were evaluated after 10 min immersion disinfection in one of the two disinfectants namely sodium hypochlorite and glutaraldehyde and also after treatment with surface wetting agent.

For the evaluation of contact angle of impression materials, GBX contact angle analyzer instrument was used.

The contact angle measurements were conducted using each sample and each test solution only once before discarding.

The data were tabulated and subjected to statistical analysis.

The results of this study have been presented in Tables 1-5 with their standard deviations.

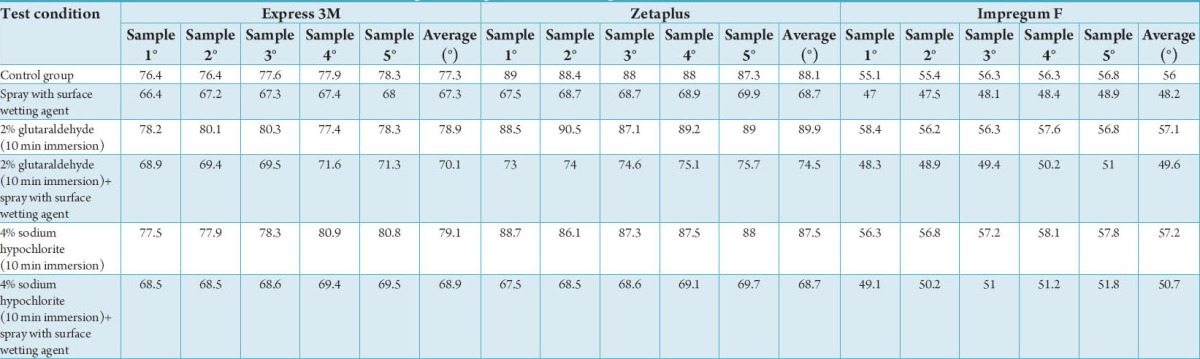

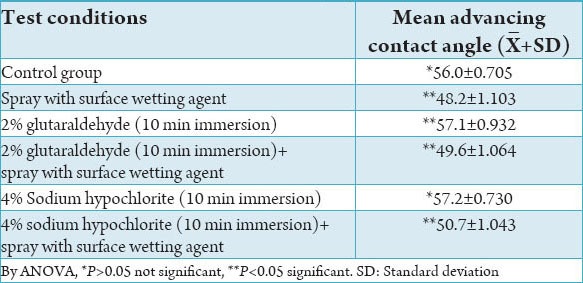

Table 1.

Advancing contact angle of elastometric impression materials after different test conditions.

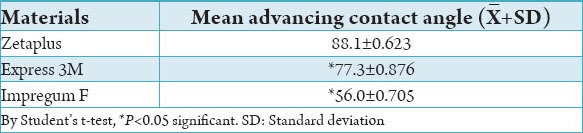

Table 2.

Comparison of advancing contact angle between three elestomeric impression materials (dry sample): Control group.

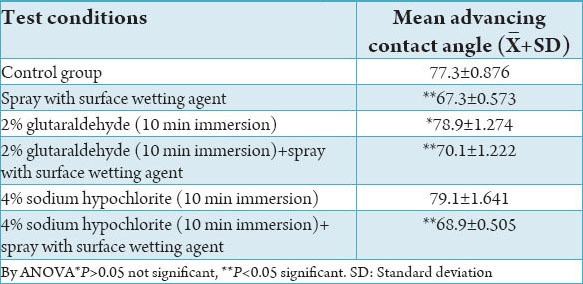

Table 3.

Comparison of advancing contact angle between different test conditions on Express 3M.

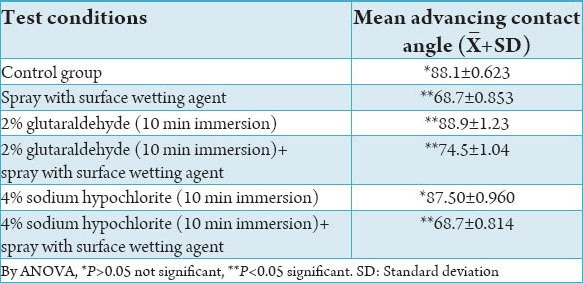

Table 4.

Comparison of advancing contact angle between different test conditions on Zetaplus.

Table 5.

Comparison of advancing contact angle between different test conditions on Impregum F.

Summary and Conclusion

Impressions play a vital role in the success of a prosthesis because a prosthesis can be no more accurate than the impression from which it has been made. The impressions are contaminated with saliva, plaque and sometimes blood all of which may carry pathogenic microorganisms. These contaminated impressions may cause cross-infection from the patient to operator or dental assistant. Immersion disinfection is an acceptable method of disinfecting dental impressions.

This study was designed to evaluate the wettability of the three commercially available elastomeric impression materials viz. addition silicone (Express 3M), condensation silicone (Zetaplus) and polyether (Impregum F) after immersion disinfection in two commercially available chemical disinfectants, 2% glutaraldehyde (glutaril), and 4% sodium hypochlorite for 10 min and after spraying with surface wetting agent (True Blue).

Wettability was assessed by measuring the contact angle of elastomeric impression materials with the help of GBX contact angle analyzer.

The data collected was tabulated and subjected to statistical analysis.

-

Considering the results of the study, following conclusions can be drawn.

- The polyether impression material was the most hydrophilic of all the materials, followed by hydrophilic addition silicone. Condensation silicone was least hydrophilic of the three materials.

- All the three elastomeric impression materials showed improvement in the wettability when a topical surfactant was used.

- The short term disinfection of the three elastomeric impression materials does not affect the wettability of these impression materials.

- The treatment with a topical surface wetting agent after short term disinfection resulted in an improvement in the wettability of the impression materials. Thus it is recommended that elastomeric impression materials be treated with a surface wetting agent after disinfection to obtain accurate and void free casts and dies.

- Thus the evaluated impression materials could be safely disinfected with any of the given chemical disinfectants for a short duration of 10 min, without compromising wettability.

From the results, it was observed that none of the disinfectants affect the physical properties of the impression materials beyond the acceptable limits.

Furthermore, it was observed that treatment with a surface wetting agent improved the wettability of elastomeric impression materials.

However, statistically significant differences were found in the wettability of the three types of impression materials used.

It should be kept in mind that the current in vitro study has certain limitations. Further long term in vivo studies with respect to these impression materials and disinfectants are suggested to enhance the conclusion obtained from the current study.

Footnotes

Conflicts of Interest: None

Source of Support: Nil

References

- 1.Pratten DH, Craig RG. Wettability of a hydrophilic addition silicone impression material. J Prosthet Dent. 1989;61(2):197–202. doi: 10.1016/0022-3913(89)90373-9. [DOI] [PubMed] [Google Scholar]

- 2.Johnson GH, Drennon DG, Powell GL. Accuracy of elastomeric impressions disinfected by immersion. J Am Dent Assoc. 1988;116(4):525–30. doi: 10.14219/jada.archive.1988.0307. [DOI] [PubMed] [Google Scholar]

- 3.Tan HK, Wolfaardt JF, Hooper PM, Busby B. Effects of disinfecting irreversible hydrocolloid impressions on the resultant gypsum casts: Part I– Surface quality. J Prosthet Dent. 1993;69(3):250–7. doi: 10.1016/0022-3913(93)90101-s. [DOI] [PubMed] [Google Scholar]

- 4.al-Omari WM, Jones JC, Wood DJ. The effect of disinfecting alginate and addition cured silicone rubber impression materials on the physical properties of impressions and resultant casts. Eur J Prosthodont Restor Dent. 1998;6(3):103–10. [PubMed] [Google Scholar]

- 5.Rios MP, Morgano SM, Stein RS, Rose L. Effects of chemical disinfectant solutions on the stability and accuracy of the dental impression complex. J Prosthet Dent. 1996;76(4):356–62. doi: 10.1016/s0022-3913(96)90538-7. [DOI] [PubMed] [Google Scholar]