Abstract

An experimental oil refining unit has been developed and tested for sunflower oil. Crude pressed sunflower oil obtained from a local oil mill was refined using chemical method by degumming, neutralization, bleaching and dewaxing. The quality and composition of crude and refined oil were analysed compared. Reduction in phosphorous content from 6.15 ppm to 0, FFA content from 1.1 to 0.24 % (oleic acid), peroxide value from 22.5 to 7.9 meq/kg, wax content from 1,420 to 200 ppm and colour absorbance value from 0.149 to 0.079 (in spectrophotometer at 460 nm) were observed from crude to refined oil. It was observed that refining did not have significant effect on fatty acid compositions as found in the percentage peak area in the GC-MS chromatogram. The percentage of unsaturated fatty acid in both the oils were recorded to be about 95 % containing 9-Octadecenoic acid (Oleic acid) and 11,14-Eicosadienoic acid (elongated form of linoleic acid). The research results will be useful to small entrepreneurs and farmers for refining of sunflower oil for better marketability.

Keywords: Crude, Refined, Sunflower oil, Fatty acid profile, FFA content, GC-MS

Introduction

Sunflower oil is used as a premium salad oil due to the presence of high ratio of polyunsaturated-to-saturated fatty acids. Refined sunflower oil has found wide acceptance because of its high polyunsaturated fatty acid content, bland flavour, good storage stability and low viscosity (Semwal et al. 1996). Refined sunflower oil has emerged as one of the most popular cooking oil in India. Sunflower seed produced a highly desirable polyunsaturated oil for human consumption. Its high proportion of valuable linoleic acid has steadily increased the importance of sunflower oil in recent decades.

Crude sunflower oil is obtained from partially dehulled seeds by mechanical pressing followed by hexane extraction and water degumming. Quality and stability are the major factors in the production, acceptance and marketing of vegetables oil products. These properties depend mainly on seed quality, seed treatment prior to extraction, extraction method and processing conditions. They are influenced by the presence of some minor components, such as free fatty acids, tocopherols, phospholipids, trace metals and waxes which have pro or anti oxidant properties. The stability and quality of vegetable oils are influenced by the presence of minor constituents such as phosphatides (Carelli et al. 1997) and waxes (Carelli et al. 2002). Processing of oils causes alterations in their chemical composition, affecting their quality and oxidative stability (Brevedan et al. 2000).

Vegetable oils are refined in order to remove the non-glyceride impurities that are present in the crude oil. Some of these impurities are naturally present in the seeds or formed during harvesting and storage of seeds or during extraction of crude oil and subsequently during its refining. Oil refining processes for vegetable oils are designed to remove these impurities from the oil or reduce them to a level where their deleterious effects on oil stability are minimum and made suitable for human consumption. Vegetable oil undergoes degradation almost immediately after the seed is crushed. The oil starts to show the sign of primary oxidation as measured by its peroxide value. Under certain circumstances the oil may develop a darker colour or higher free fatty acids and eventually an unpleasant flavour. Gums, phosphatides and mucilaginous substances act as emulsifier increasing loss of oil and decompose at high temperature, increasing colour of the refined oil. Free fatty acids increase foaming, reduce smoke point and diminish keeping properties of oil.

Presence of compounds such as phosphatides, free fatty acids, odiferous volatiles, colourant, waxes and metal compounds in oil negatively affect taste, smell, appearance and storage stability of the refined oil and hence must be removed to yield a stable product with a bland or pleasant taste (Aluyor et al. 2009). In modern society, consumers can not use crude oil directly without proper processing due to the unacceptable colour and odour. This has led to efficient refining process which involves removing these unpleasant impurities with the least possible effect on the desired components (tocopherols, phenols, sterols) with the minimum losses of oil (Verhe et al. 2006).

Chemical refining includes degumming, neutralizing, bleaching, winterizing and deodourising stages (Tasan and Demicri 2005). When used for salad oil, the refined oil was winterized for wax removal and then deodorized. Though chemical refining decreased yield, higher investment cost, high chemicals used and higher waste, but has less effect on oil desirable components and oil stability (Suliman et al. 2013). The objective of refining is to remove the objectionable impurities with the least possible damage to the neutral oil and minimum loss of oil during processing.

Several authors have investigated the influence of industrial processing, especially the refining process on quality and stability of different vegetable oils. Effect of pressing conditions on nonrefined sunflower oil has been presented by Turkulov et al. (1998) and the influence of water degumming in phosphatide content has been discussed by Crapiste et al. (1998).

The aim of the present work was to develop a mini oil refining unit and investigate the effect of chemical refining process on composition and quality characteristics of refined oil as compared to crude oil.

Materials and methods

Development of oil refining unit

An experimental oil refining unit has been developed for minimal refining of sunflower oil. The unit consists of (i) one open mild steel tank with conical bottom for degumming/neutralization, (ii) one closed oval tank for vacuum drying/bleaching and (iii) one filter for filtration of oil. The oil dewaxing section consists of a well insulated oil tank, cooling coil, water cooler and filtration unit. The helical pipe is immersed in the oil in the tank and the cold water from the cooler is recirculated for cooling the oil to crystallize the wax. The centrifugal pump is connected to the tank outlet to force the oil through the pressure leaf filtration unit to filter the wax.

Testing of the refining unit

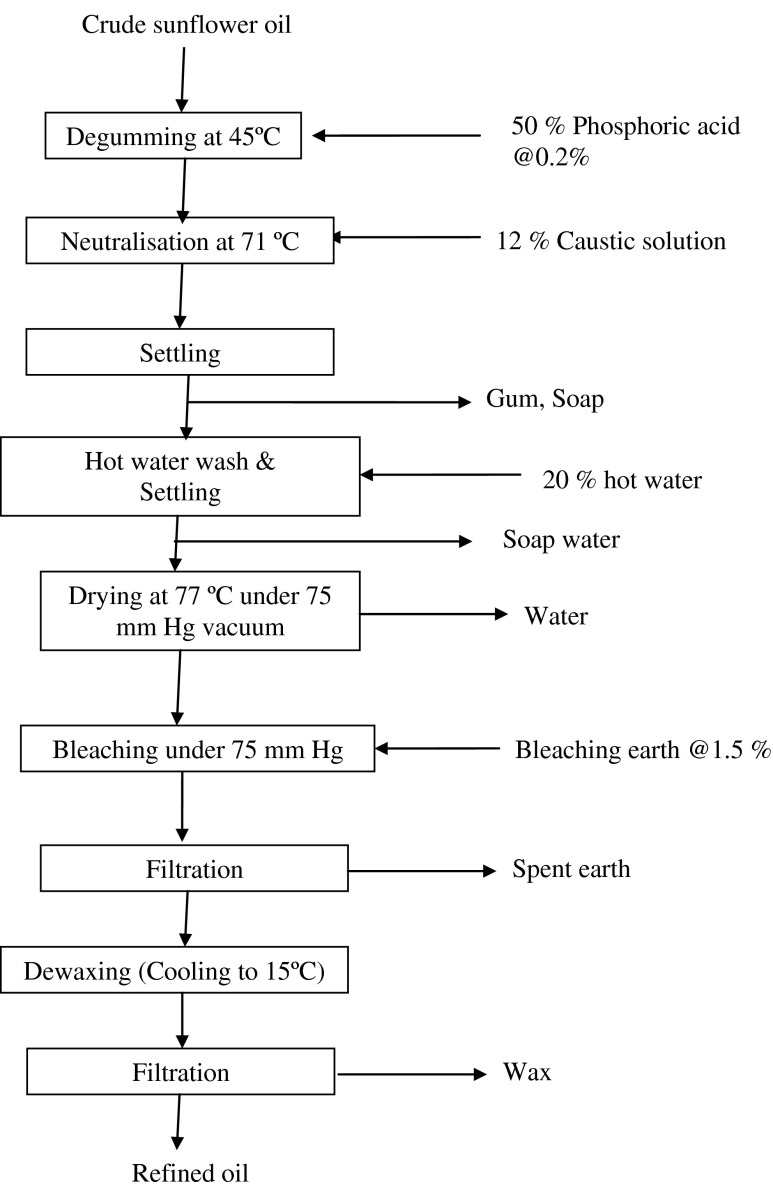

Mechanically pressed crude sunflower oil was obtained from a local oil mill. The crude oil was kept in tin container away from the light, high temperature and oxygen to avoid auto oxidation. The oil was refined in the developed experimental unit as per the process flow diagramme shown in Fig. 1.

Fig. 1.

Process flow diagramme for refining of sunflower oil

Degumming

The crude oil in the open conical tank was heated to 45 °C and degummed by adding 0.2 % phosphoric acid (50 % w/w strength) with slow agitation for 30 min. Then the oil was settled for 30 min and the water with dissolved gum was drained out.

Neutralisation

The temperature of oil was further increased to 71 °C and mixed with desired quantity of sodium hydroxide solution (12 %) as per FFA content of the oil with slow agitation for 15 min followed by settling for 30 min. The soap stock with residual gum was removed by draining. The neutralized oil was washed with 20 % hot soft water at 75 °C and residual soap was removed by settling.

Vacuum drying and bleaching

The washed oil was heated at 77 °C under 75 mmHg vacuum for 30 min to remove the moisture traces. The oil was next mixed with 1.5 % bleaching earth (w/w) with vigorous stirring for 30 min under vacuum for bleaching. Then oil was cooled to 60 °C and filtered to obtain the bleached oil.

Dewaxing

The bleached oil was cooled gradually at 15 °C for 4 h for crystallization of wax and filtered to remove the wax.

Quality analysis of sunflower oil

The crude oil, refined oil obtained from the experimental refining unit and commercially available refined sunflower oil sample were analysed for moisture content, specific gravity, kinematic viscosity, total phosphorous content (indication of phospholipids), Free Fatty Acid (FFA) content, peroxide value, colour value and wax content using standard procedure (Ranganna 2004) as given below for comparison with the Bureau of Indian standards (BIS) specifications.

The specific gravity of oil samples were measured by pycnometer method and viscosity by Kinematic Viscometer at 40 °C. Moisture content was determined by oven drying at 105 °C for 24 h.

The free fatty acid content was measured using the titration method with 0.1 Normal sodium hydroxide solution and phenopthaline indicator and expressed as % oleic acid. The absorbance of oil was measured at wavelength of 460 nm in a spectrophotometer using Carbon tetrachloride as blank which was taken as an indicator for colour comparison. Peroxide value was determined by Sodium Thiosulphate titration method.

Phosphorus content (an indicator of phospholipid content) of oil was determined by wet digestion using di-acid mixture (nitric acid and perchloric acid @ 3;2). Phosphorus content in the digest was estimated spetrophotometrically at 470 nm wavelength after developing yellow colour with vanado-molybdate reagent. The standard curve was prepared using 0 to 20 ppm phosphorus prepared with analytical grade KH2PO4.

The wax content was determined gravimetrically by dissolving oil in acetone, cooling at 0 ºC for 24 h and filtering through Gooch crucible as per American Bureau of Shipping (ABS 227) method.

Fatty acid profile by GC-MS Analysis

The fatty acid profile of both crude and refined sunflower oil was determined by Gas Chromatography. The given samples were methylated with sodium methoxide and the fatty acid methyl esters (FAME) were analyzed in GC-MS for identification of different components.

GC Programme

Column: Elite-5MS (5 % Diphenyl/95 % Dimethyl poly siloxane), 30 × 0.25 mm × 0.25 m df

Equipment: GC Clarus 500 Perkin Elmer

Carrier gas: 1 ml per min, Split: 10:1

Detector: Mass detector Turbo mass gold-Perkin Elmer

Software: Turbomass 5.2

Sample injected: 2μl

Oven temperature Programme

110 ° C −2 min hold

Up to 200 ° C at the rate of 10 ° C/min-No hold

Up to 280 ° C at the rate of 5 ° C/min-9 min hold

Injector temperature 250 ° C

Total GC running time 36 min

MS Programme

Library used NIST Version-Year 2005

Inlet line temperature 200 ° C

Source temperature 200 ° C

Electron energy: 70 eV

Mass scan (m/z): 45–450

Solvent Delay: 0–2 min

Total MS running time: 36 min

Results and discussion

Quality of sunflower oil

The physico-chemical parameters of crude sunflower oil, refined oil obtained from the experimental unit and commercial refined oil sample is given in Table 1. The oil samples were found to be completely moisture free after refining and less than the maximum limit of 0.1 %. The specific gravity of crude and refined oil at 20 °C were found to be same (0.92) with the commercial sample. The kinematic viscosity of oil decreased from 38.8 to 36.2 cs after refining which was as par with the commercial sample. The reduction in viscosity was probably due to the removal of impurities during refining.

Table 1.

Physico-chemical parameters of crude, refined and commercial oil (n = 3)

| Quality parameters | Crude oil | Refined oil (from the developed unit) | Commercial sample | BIS standard value |

|---|---|---|---|---|

| Specific gravity (20 °C) | 0.92 | 0.92 | 0.92 | 0.92 |

| Kinetic viscosity (40 °C) in cs | 38.8 | 36.2 | 36.5 | – |

| Moisture content, % | 0 | 0 | 0 | 0.1 |

| Phosphorous content, ppm | 6.15 | Trace | Trace | – |

| FFA content, (% Oleic acid) | 1.10 | 0.24 | 0.13 | 0.25 |

| Peroxide value, meq/kg oil | 22.5 | 7.9 | 23.9 | 10 |

| Wax content, ppm | 1420 | 200 | 20 | – |

| Colour absorbance value (in Spectrophotometer at 460 nm) | 0.149 | 0.079 | 0.050 | – |

The crude oil under experiment was found to have 6.15 ppm of total phosphorous content (0.019 % phospholipids) which was reduced almost to zero as most of the phospholipids were removed by degumming and neutralization process during refining. The phospholipids content of pressed and pressed-degummed sunflower oil were reported to be 0.737 and 0.132 % indicating a decrease in phopspholipid content during degumming operation (Carelli et al. 1997). Brevedan et al. (2000) also reported decrease in phospholipids content from 0.39 to 0.10 % during degumming of pressed sunflower oil.

Free Fatty Acid content of crude sunflower oil was found to be reduced from 1.1 to 0.24 (% Oleic acid) after neutralization. The residual FFA content of the refined oil was less than the maximum specified value of 0.25 % in the BIS standard for pressed refined sunflower oil. During the chemical refining process, most of the FFA content was eliminated during the neutralization stage as soap because of the alkali treatment which improved the quality of oil. Suliman et al. (2013) reported similar results of reduction in FFA content from 0.5 to 0.1 % during neutralization of crude oil. According to Demian (1990), the FFA content is used to measure the extent to which triglycerides in oil has been decomposed by lipase and other actions such as light and heat and its determination is often used as general indication of the condition and edibility of oils. The presence of free fatty acid and other fatty materials in oil bring about the offensive odour and taste in oil on long storage (Kirk and Sawyer 1991). The low FFA content of refined oil makes the oil edible and of higher quality. The odour of the refined oil was agreeable and had no offensive smell which might be due to low FFA content of the oil.

The peroxide value reduced from 22.5 to 7.9 meq/kg during refining which was less than the standard specified value of 10 meq/kg. The reduction is probably due to the absorbance of peroxide compounds by bleaching earth. However, the peroxide value of commercial oil sample was observed to be more than freshly obtained refined oil from the developed unit which might be due to oxidative reactions in market sample during storage before marketing.

Reduction in wax content from 1,420 to 200 ppm was observed from crude to refined oil. The reduction in wax content was due to the separation of crystallized wax from cold oil by filtration. Carelli et al. (2002) reported that total wax content of commercial refined oil varied between 360 and 620 ppm, indicating a strong dependence on variety, condition of seed and refining process. Wax content of sunflower seed oil are reported to be in the range of 200 to 350 ppm (Martini and Anon 2000).

The colour absorbance value of refined oil measured at 460 nm in spectrophotometer was observed to be lower (0.079) than crude oil (0.149) which might be due to the removal of colouring pigments during bleaching operation. The decrease in colour pigments after bleaching step due to the effect of activated bleaching earth was also reported by Suliman et al. (2013).

The FFA content, wax content and absorbance value of commercial refined oil sample were found to be less than the oil obtained from the experimental refining unit which might be due to the precise control of process parameters and large scale operations in the commercial refining unit.

Fatty acid profile of sunflower oil by GC-MS analysis

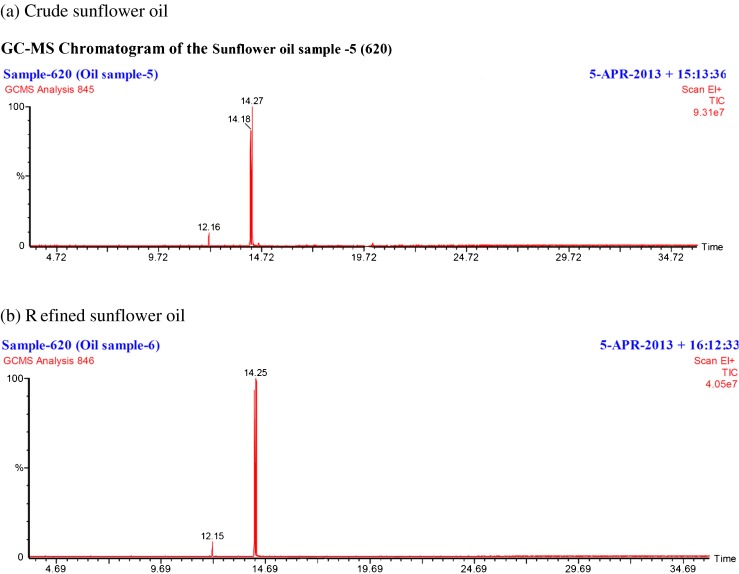

From the fatty acid profile analysis of both crude and refined oil, it was observed that there was no significant difference in fatty acid composition of both the samples as shown in the percentage peak area in the GC-MS chromatogram (Fig. 2). This indicated that refining did not have much effect on fatty acid composition which was also reported by Achinewhu and Akpapunam (2005) and Aluyor et al. (2009). It was concluded that there was no undesirable polymerization of oil during the refining process in the experimental refined unit. 11,14-Eicosadienoic acid, methyl ester and 9-Octadecenoic acid (Z)-, methyl ester were the major compounds found in the GC-MS analysis (Table 2). The percentage of unsaturated fatty acid in both the oils were recorded to be about 95 % containing 9-Octadecenoic acid (Oleic acid) and 11,14-Eicosadienoic acid (elongated form of linoleic acid). Oleic acid (52 %) is the major unsaturated fatty acid followed by Eicosadienoic acid (43 %) in both crude and refined oil.

Fig. 2.

GC-MS Chromatogram of (a) crude and (b) refined sunflower oil

Table 2.

Fatty acid profile of crude and refined sunflower oil sample [GC MS study] (n = 3)

| No. | Name of the compound | Molecular formula | MW | Crude oil | Refined oil | ||

|---|---|---|---|---|---|---|---|

| RT | Peak Area % | RT | Peak Area % | ||||

| 1 | Tridecanoic acid, methyl ester | C14H28O2 | 228 | 12.16 | 3.8 | 12.16 | 3.7 |

| 2 | 11,14-Eicosadienoic acid, methyl ester | C21H38O2 | 322 | 14.18 | 43.3 | 14.17 | 43.5 |

| 3 | 9-Octadecenoic acid (Z)-, methyl ester | C19H36O2 | 296 | 14.27 | 51.9 | 14.25 | 52.3 |

| 4 | Octadecanoic Acid, 11-Methyl-, Methyl Ester | C20H40O2 | 312 | 14.57 | 1.0 | 14.57 | 0.5 |

MW: Molecular weight, RT: Retention time

Conclusion

An experimental oil refining unit has been developed and tested for refining of sunflower oil. Crude pressed sunflower oil obtained from a local oil mill was refined using chemical method by degumming, neutralization, bleaching and dewaxing. The quality and composition of crude and refined oil were compared. The phosphorous content, FFA content, peroxide value and wax content decreased during the refining process. There was no significant difference in fatty acid profile of both crude and refined oil. Oleic acid is the major unsaturated fatty acid followed by Eicosadienoic acid in both crude and refined sunflower oil. Further studies on storage stability of the refined oil obtained from the developed unit may give more information for its adoptability.

Acknowledgments

Authors are thankful to the Indian Council of Agricultural Research, New Delhi and Orissa University of Agricultural and Technology, Bhubaneswar for providing financial assistance and infrastructure.

References

- Achinewhu SC, Akpapunam MA. Physical and chemical characteristics of refined vegetable oils from rubber seed and bread fruit. J Plant Food. 2005;35:103–107. doi: 10.1007/BF01092125. [DOI] [Google Scholar]

- Aluyor EO, Aluyor P, Ozigagu CE. Effect of refining on the quality and composition of groundnut oil. Afr J of Food Sci. 2009;3(8):201–205. [Google Scholar]

- Brevedan MIV, Carelli AA, Crapiste GH. Changes in composition and quality of sunflower oils during extraction and degumming. Grasas y Aceites. 2000;51(6):417–423. [Google Scholar]

- Carelli AA, Brevedan MIV, Crapiste GH. Quantitative determination of phospholipids in sunflower oil. JAOCS. 1997;74(5):511–514. [Google Scholar]

- Carelli AA, Frizzera LM, Forbito PR, Crapiste GH. Wax composition of sunflower seed oils. JAOCS. 2002;79(8):763–768. [Google Scholar]

- Crapiste GH, Brevedan MIV, Carelli AA (1998) “Water degumming of sunflower oils”- In World Conference on Oilseed and Edible Oil Processing. Vol II, pp 32–35, S.S. Koseoglu, K.C. Rhee and R. F. Wilson (Ed.). AOCS Press, Champaign, IL

- Demian MJ (1990) Principles of Food Chemistry. 2nd Ed. Van Nostrond Reinhold International Company Limited, London England. 37–38

- Kirk RS, Sawyer R (1991) Pearson’s Composition and Analysis of Foods. 9th Ed. Longmand Sci. Tech. England pp. 607–617

- Martini S, Anon MC. Determination of wax concentration in sunflower seed oil. JAOCS. 2000;77(10):1087–1092. [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products 2nd Ed. New Delhi: Tata McGraw-Hill Publishing Company Limited; 2004. [Google Scholar]

- Semwal AD, Murthy MCN, Sharama GK, Arya SS. Studies on storage stability of commercially marketed refined sunflower oil in plastic film packs. J Food Sci Technol. 1996;33(4):352–354. [Google Scholar]

- Suliman TMA, Jiang J, Liu Y. Chemical refining of sunflower oil: effect on oil stability, total tocopherol, free fatty acids and colour. Int J of Eng Sci and Technol. 2013;5(2):449–454. [Google Scholar]

- Tasan M, Demicri M. Total and indivisual tocopherol contents of sunflower oil at different steps of refining. J of Eur Food Res and Technol. 2005;220:251–254. doi: 10.1007/s00217-004-1045-8. [DOI] [Google Scholar]

- Turkulov J, Dimic E, Karlovic D, Vuksa V (1998) “Effect of hydrothermal treatment on the quality of nonrefined edible sunflower oil”- In World Conference on Oilseed and Edible Oil Processing. Vol I, pp 185–187, S.S. Koseoglu, K.C. Rhee and R. F. Wilson (Ed.). AOCS Press, Champaign, IL

- Verhe R, Verleyen T, Van Hoed V, De Greyt W. (2006) Influence of refining of vegetable oils on minor components. J. of Oil Palm research 168–179