Abstract

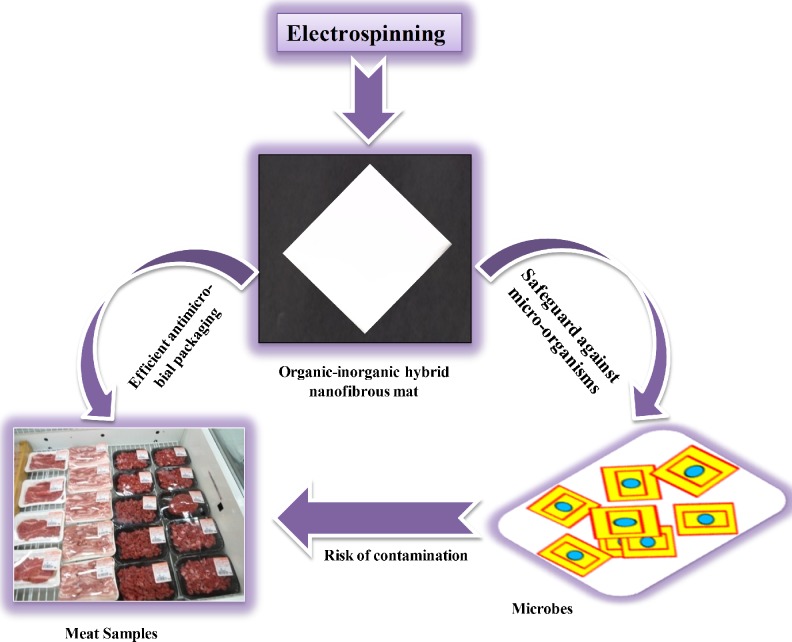

To prevent the development and spread of spoilage/pathogenic microorganisms via meat foodstuffs, antimicrobial nanocomposite packaging can serve as a potential alternative. The objective of this study was to develop a new class of antimicrobial hybrid packaging mat composed of biodegradable polyurethane supplemented with virgin olive oil and zinc oxide via electrospinning. Instead of mixing antimicrobial compounds directly with food, incorporation in packaging materials allows the functional effect at food surfaces where microbial activity is localized. The nanofibers were characterized by SEM, EDX, XRD and TEM. The antibacterial activity was tested against two common foodborne pathogens viz., Staphylococcus aureus and Salmonella typhimurium. The present results indicated that incorporation of olive oil in the polymer affected morphology of PU nanofibers and nanocomposite packaging were able to inhibit growth of pathogens. Thus; as-spun mat can be used as prospective antimicrobial packaging, which potentially reduces contamination of meat/meat-products. Moreover, introduced biodegradable packaging for meat products could serve to replace PVC films and simultaneously help to protect natural environment.

Keywords: Meat-products, Biodegradable packaging, Spoilage microbes, Polyurethane matrix, Olive oil

Introduction

Meat is one of the most perishable foods present in the food industry/or commerce. In fact, meat represents an ideal medium for the growth of spoilage or/pathogenic microorganisms. Contamination of food products by microbial growth can cause health hazards to human beings. It is particularly hazardous when the food is contaminated by pathogenic microorganisms. It is well known that tissues from healthy animals are mostly germ-free (Gill 1979). Microorganisms gain access into or onto the surface of meat from different sources during handling and processing of meat. In addition to the development of pathogens, microbial growth commonly induces undesirable organoleptic changes during the storage of meat. Food spoilage is the result of microbial activity in the food matrix causing decomposition of carbohydrates and proteins (Jay 1996; Ellis & Goodacre 2001). Meat and meat products are usually contaminated with Listeria monocytogenes, Salmonella typhimurium, Salmonella enteritidis, and Yersinia enterocolitica responsible for foodborne illnesses and in severe case deaths. Recent reports have shown that different types of food and environmental sources harbor bacteria that are resistant to one or more antimicrobial drugs (Anderson et al. 2003; Schroeder et al. 2004). The foodborne pathogens which were found to be resistant to a range of antibiotics are Escherichia coli, Staphylococcus aureus, Salmonella typhimurium, Bacillus cereus, Klebsiella pneumoniae, Enterobacter spp. (Tenover 2006). Among the predominant bacteria involved in foodborne diseases; Staphylococcus aureus is a leading cause of gastroenteritis resulting from the consumption of contaminated food. Likewise; Salmonella is a leading cause of bacterial food-borne diseases in both developed and developing countries (Carter et al. 2009). Thus it is given to understand that additional measures should be used to ensure the safety of food products. In recent years, much emphasis has been put on the safety aspect of foods owing to cross contamination caused by spoilage food microorganisms. To prevent the development and spread of spoilage and pathogenic microorganisms via meat foodstuffs, antimicrobial packaging, especially based on the natural substance and biodegradable polymer could be a potential alternative. Instead of mixing antimicrobial compounds directly with food, incorporating them in the packaging matrices/or mats allow the functional effect on the food surface. Recently, nanotechnology in food packaging has been an emerging area in which packaging materials can be manipulated for improving the barrier, mechanical and heat-resistance properties, biodegradability, and flame retardancy compared to normal polymer (Pereda et al. 2012; Huang et al. 2012). It also provides promising alternatives for developing active antimicrobial and antifungal surfaces and sensing as well as signaling microbiological and biochemical changes (ElAmin 2005). The goal of this work was to develop durable organic–inorganic hybrid antimicrobial nanofibers as packaging material for meat and meat based products. Nevertheless, to the best of our knowledge, there is no report on the fabrication of biodegradable polyurethane based packaging material supplemented with zinc oxide and virgin olive oil. Olive oil from olive fruit (Olea europaea L.; Family-Oleaceae) is of huge dietetic importance as it is rich in essential vitamins, fatty acids, and other natural nutrients. Olive oil is used from the ancient times as medicine and was valued highly in the Middle East. It was mentioned in the Holy Quran 1,400 years ago. Olive oil is a natural material and is loaded with antibacterial ingredients, flavonoids and antioxidants (Kiritsakis and Markakis 1987). Likewise, zinc oxide nanoparticles (ZnO) possess antibacterial activity and it is currently used in various materials (Chia et al. 2010; Jalal et al. 2010; Becheri et al. 2008; Alessio et al. 2008; Sawai 2003). The extensive use of ZnO nanomaterials is because of its low toxicity and biodegradability. Zn2+ is also among the essential trace element for adults (Approximately 9.5 and 7.0 mg of Zn2+ per day in any form is needed for men and women, respectively) (Su et al. 2013). Considering the unique properties of olive oil and zinc oxide, we herein report for the first time the fabrication of olive oil/polyurethane composite nanofibrous packaging mats decorated with ZnO nanoparticles by electrospinning. Electrospinning is one of the most successful methods to fabricate fibers from a broad range of materials such as polymers, ceramics, metals and so forth. In the present investigation, we opted biocompatible, biodegradable poly (urethane) (PU) as a driving source to support the spinning progression of olive oil. PU is thermoplastic polymer having outstanding mechanical properties and water insolubility (Kidoaki et al. 2006; Khlystalova et al. 1986). PU possesses good barrier properties and oxygen permeability and more to the point it is an FDA approved polymer. Generally, chilled meat is packaged in polystyrene trays and wrapped in plastic polyvinyl chloride (PVC) film. However, these films impose recycling issues. The present study explores the possibility of replacing PVC film with the introduced biodegradable packaging material in order to get rid of the microbial contamination and preserve the characteristic features (such as color, taste etc.) of meat.

Materials and methods

Materials

The oil (Spain extra virgin olive 100 %) was purchased from the local supermarket (Jeonju, South Korea). ZnO powder (particle size < 100 nm, 99.9 %) was purchased from Sigma-Aldrich. Polyurethane (PU: Mw = 110,000, Cardio Tech. Intern., Japan) was used for the fabrication of pristine and composite nanofiber membranes. Tetrahydrofuran (THF) and N,N-dimethylformamide (DMF) (analytical grade; Showa Chemicals Ltd.,Japan) were used as solvents without further purification. S. aureus and S. typhimurium were purchased from the Korean Culture Centre of Microorganisms (KCCM). Tryptone Soya Broth (TSB; Becton, Dickinson and Company, USA) was used as a growth medium.

Electrospinning of pristine and organic–inorganic hybrid mats

The fabrication of pristine PU and olive oil-ZnO/poly (urethane) hybrid nanofibrous mats was carried out by electrospinning process. PU solution (10 wt.%) was prepared by dissolving PU in DMF: THF (1:1 w/w) under magnetic stirring overnight at room temperature. Different weight% (5 % and 10 %) of virgin olive oil was added separately into the polymer solution and stirred for about 2 h at room temperature to get uniform olive/PU composite solution. For the preparation of olive oil-ZnO/poly (urethane) hybrid mat, 5 wt.% of virgin olive oil and 3 wt.% of ZnO were added together in the polymer solution and stirred for an hour prior to electrospinning. The obtained solutions were independently subjected to the electrospinning. Briefly, the obtained sol–gel was transferred with the help of micropipette to a 10 ml syringe (Shinchang medical Co. Ltd., Republic of Korea) fixed with a plastic micro-tip (internal diameter = 0.6 mm) as the spinning head. A high voltage power supply (SHV300 60 kV/2 mA, ACP Korea Co. Ltd., Republic of Korea) capable of generating voltage up to 60 KV was used as a source of electric field in the spinning process. A copper pin connected to high voltage power supply was inserted in the solution as a positive terminal whereas a ground iron drum covered by a polyethylene sheet served as counter electrode. The solution was kept in the capillary by adjusting the inclination angle. A voltage of 15 kV was applied to this solution. The distance between the syringe needle tip and collector was fixed at 10 cm. The electrospun mats were collected, dried in a vacuum oven overnight to remove the residual solvents and stored in desiccators for further analysis.

Characterization

The XRD patterns of pristine PU, and olive oil-ZnO poly (urethane) hybrid nanofibrous mats were recorded on X-ray diffractometer (D/MAX 2500, Rigaku Corporation, Tokyo, Japan) with copper Kα radiation (λ = 1.540 Å) over Bragg angles ranging from 10–80 °. The operating voltage and current were maintained at 30 kV and 40 mA, respectively. The morphological features of pristine PU, virgin olive oil encapsulated PU and olive oil-ZnO/PU hybrid nanofibrous mats were observed by a scanning electron microscope (SEM, S-7400, Hitachi High Technologies, Japan). Each specimen was uniformly spread on the carbon tape; Pt coating was applied for 10 s onto the synthesized nanofibers prior to SEM observation. The fiber diameter was measured directly from SEM images and the average was calculated. To get insight into topographical, compositional and morphological view of hybrid nanofibers; TEM was taken. The chemical composition of pristine and olive oil-ZnO/poly (urethane) hybrid nanofibrous mats was analyzed by energy dispersive X-ray spectrometer (EDX) equipped with SEM apparatus.

Antibacterial activity

The bactericidal activity of pristine PU, virgin olive oil encapsulated PU and olive oil-ZnO/PU hybrid nanofibers were tested using S. aureus and S. typhimurium as model organisms. Briefly, the inoculum was prepared from fresh overnight broth (TSB) cultures that were incubated at 37 °C. For antibacterial assay, the bacterial strains were first grown on agar medium and from the agar plates, fresh colonies were inoculated into broth (TSB-100 ml). Growth was monitored at every 4 h with UV-visible spectrophotometer (Shimadzu, UV- 2550), till the optical density reached 0.1 at 600 nm. Subsequently, 1 ml inocula from the above was further added to 100 ml of freshly prepared TSB supplemented with known weights of pristine PU, virgin olive oil encapsulated PU and olive oil/PU-ZnO composite mats respectively. All the flasks were incubated at 37 °C in a rotary shaker with shaking at 150 rpm. The growth rates and the bacterial concentrations were monitored by OD measurements as aforementioned at an interval of 4 h for 16 h. Furthermore, we also checked the changes in the pH and color of meat packed in the antimicrobial hybrid mat in the present study.

Results and discussion

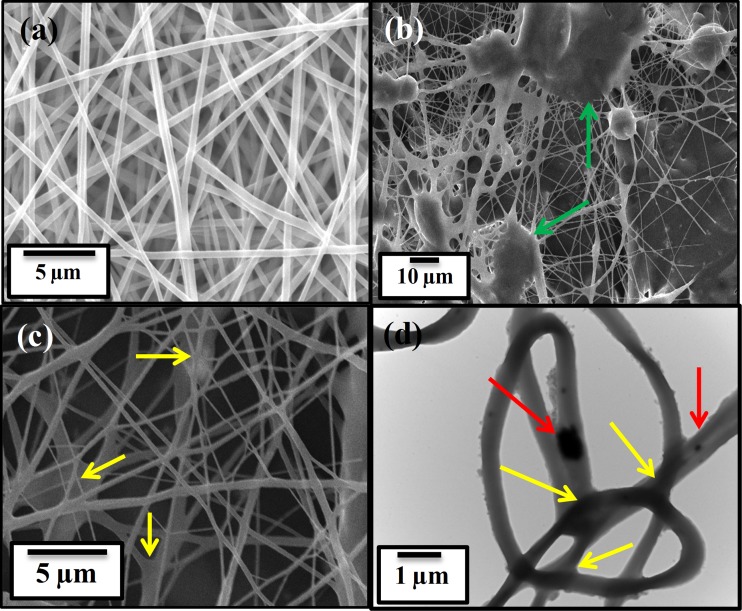

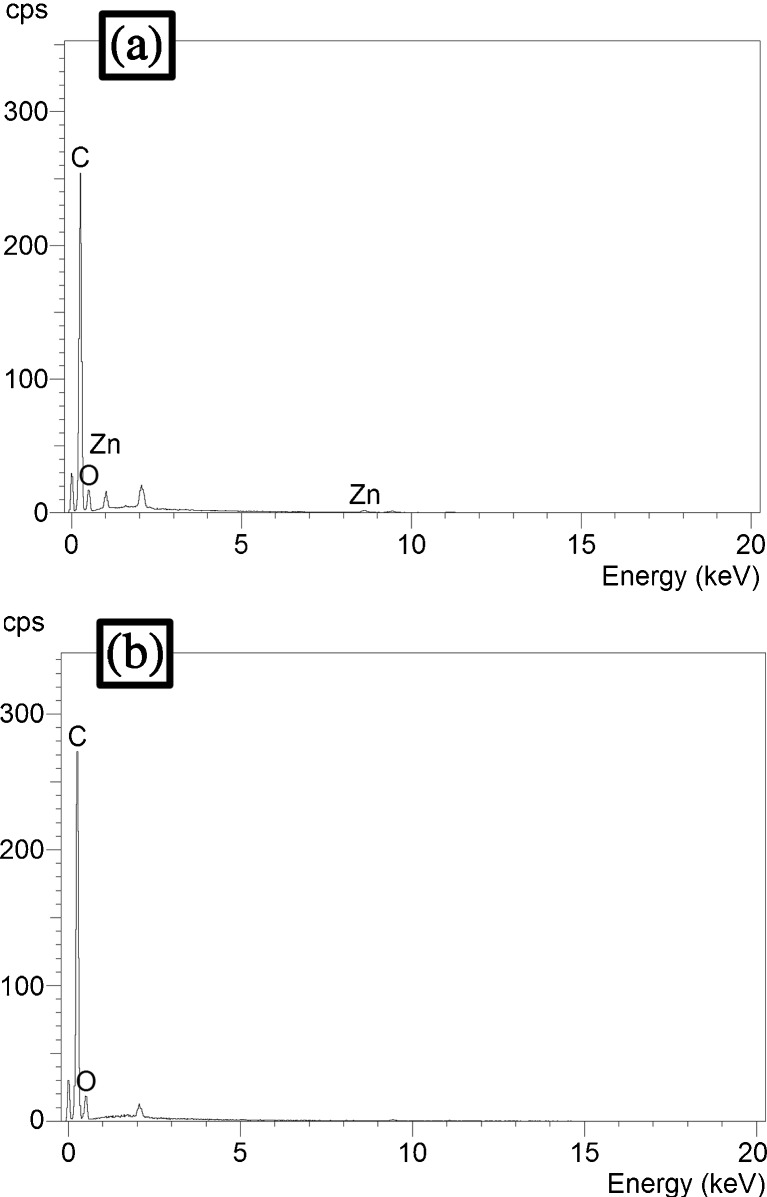

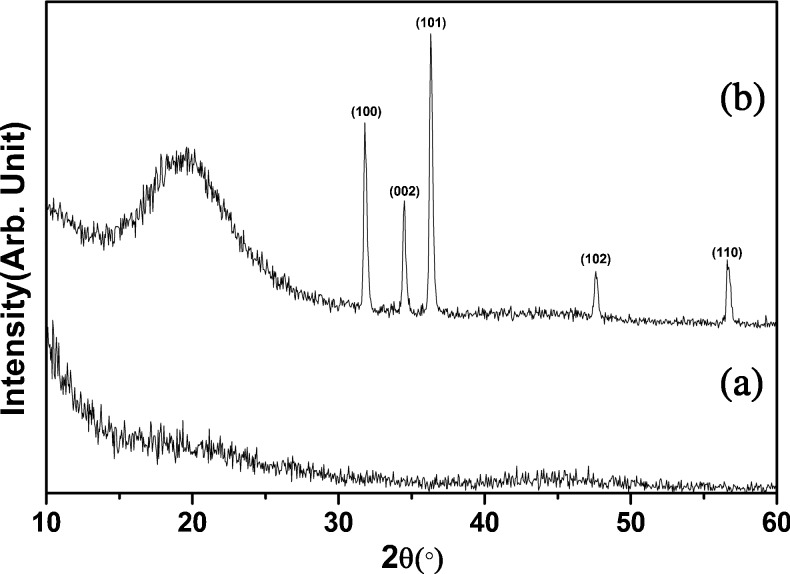

Since microbial contamination on the meat surface occurs primarily during the slaughter and post slaughter process. However, the efficient antimicrobial packaging can inhibit or/delay microbial spoilage on meat surfaces between packaging and consumption. To preserve the meat from possible contaminations from spoilage microbes during storage, it is generally packaged in polystyrene trays and PVC films. However, the use of PVC films upset the atmosphere and water ecosystems by creating problems in the recycling of such materials. The purpose of our investigation was to check the possibility of replacing PVC film with novel olive oil/ZnO doped biodegradable polyurethane polymer matrix in order to preserve the characteristic meat color as well as control the microbial contamination. Polyurethanes (PUs) are important and versatile class of man-made polymers used in a wide variety of products in the medical, automotive and industrial fields. PU is a general term used for a class of polymers derived from the condensation of polyisocyanates and polyalcohols. It is well known that the PUs properties depend both on the method of preparation and the monomers used. In general, PUs can be prepared in one shot process or more commonly by a two-step method, (especially for the case of segmented PUs). In spite of their good physicochemical and mechanical properties and acceptable biocompatibility they are prone to degradation under different conditions. These conditions range from hydrolysis, oxidation, metal induced oxidation, environmental stress cracking, enzyme-assisted degradation and so forth. As soon as the importance of recycling was recognized, due attention has been given to the studies on elucidation of the biodegradability of PUs. Despite its xenobiotic origins, PU has been found to be susceptible to biodegradation by naturally occurring microorganisms. Microbial degradation of PUs is dependent on the properties of the polymer such as molecular orientation, crystallinity, cross-linking and chemical groups present in the molecular chains which determine the accessibility to degrading-enzyme systems. Esterase activity (both membrane-bound and extracellular) has been noted in microbes which allow them to utilize PU. Microbial degradation of polyester polyurethane is hypothesized to be mainly due to the hydrolysis of ester bonds by these esterase enzymes (Gary 2002). We herein report for the first time the outcome of synergistic effect of virgin olive oil and zinc oxide for enhanced antimicrobial application. Fig. 1 shows the SEM images of the pristine PU and organic–inorganic hybrid matrix. PU solutions containing 5 wt.% of the polymer gives rise to well-defined nanofibers with diameters in the range of about 250–550 NM (±10 NM) as demonstrated in Fig. 1a. Plain electrospun nanofibers obtained had a smooth surface, bread free morphology and showed a relatively less diameter distribution. In the present study, we optimized the concentration of olive oil, which could let easily electrospinning. We initially tried 10 % of olive oil with respect to PU polymer, but this couldn’t yield very well defined nanofibers (fig. 1b). Then we gradually decreased the concentration of oil. The 5 % doping of olive oil in PU resulted good morphology (Fig. 1c). The incorporation of virgin olive oil into the spinning solution altered the fibrous morphology (Fig. 1b, c). From the images (Fig. 1b, c) merged fiber morphology is evident and this interconnection (cross linked fibers) between the fibers could be due to the low volatility of the olive oil. The shift from the non-bonded to the point-bonded fiber morphology of the mat significantly affects the mechanical strength and stability of the mat, which is desirable for packaging material. Fig. 1d shows the TEM image of the ZnO doped PU/Olive oil nanofibers after electrospinning. ZnO nanoparticles were observed as small particles and cluster in/on the surface of composite nanofibers. Fig. 2 shows the EDX analysis of the plain and olive oil/PU-ZnO bionanocomposite. The signals of carbon and oxygen were observed for pristine PU nanofibers (Fig. 2b). As revealed by the Fig. 2a, the fibers contained carbon, oxygen, and Zn; no other elemental impurity was detected. The presence of olive oil and ZnO NPs in the dispersed composite was further confirmed by XRD pattern (Fig. 3). In case of pristine PU (Fig. 3a), no peak appeared in spectrum except a low intensity broad peak at ~20° indicating the amorphous nature of the polymer (Silva et al. 2013). Presence of olive oil increases the peak intensity of the broad peak at ~20° of PU polymers used (Fig. 3b). This is an indication that the oil is dispersed in the matrix in microspheres form (Berger et al. 1976). Whereas in the XRD of olive oil/PU-ZnO (Fig. 3b), the sharp peak represents the presence of ZnO in the bionanocomposite. The ZnO crystals in the nanofibers have hexagonal structure (JCPDS no. 891397). Thus XRD spectrum clearly indicated the presence of ZnO particles in the composite nanofibrous mats. The results of XRD are consistent with the EDX.

Fig. 1.

SEM images of a pristine PU b Olive oil (10 wt.%)/PU blend system c Olive oil (5 wt.%)/ZnO-PU d TEM image of Olive oil (5 wt.%)/ZnO-PU hybrid nanofibers. The yellow arrows depict the Olive oil encapsulation region. The yellow arrows depict the point bonding region and the green arrows show the defective regions in nanofibers; whereas the red arrows show the ZnO nanoparticles

Fig. 2.

EDX spectra of a Olive oil/ZnO-PU hybrid packaging mat b pristine PU

Fig. 3.

XRD pattern of a pristine PU b Olive oil/ZnO-PU hybrid packaging mat

Relatively very few reports are published about the olive oil based blend systems. Mariana Pereda et al. (2012) reported the fabrication of the edible chitosan/olive oil emulsion films with increased stability and tensile properties. Likewise, Ma et al. (2012) demonstrated the fabrication of Gelatin/olive oil composite films which revealed that olive oil has a good potential to be incorporated into gelatin to make edible films or coating for food applications. On the other hand, Huang et al. (2012) utilized two step methodology, i.e. layer-by-layer self-assembly technique and electrospining method to fabricate the packaging material especially for pork preservation. However, in the present study, we utilized facile one way electrospinning approach for the fabrication of hybrid packaging material for meat and meat products. We have encapsulated olive oil in the nanofibrous matrix. The nanoencapsulation offers advantages such as immobilization efficiency due to the large surface area and greater protection. The nanoencapsulation enhances light stability of the olive oil and thus maintains its characteristics for longer time. In the previous studies the authors have mainly used the organic components, but in the present study, we have introduced hybrid packaging material concept. Composite materials formed by the combination of inorganic materials and organic polymers are attractive for the purpose of creating high-performance or/highly efficient materials. The combination of two different components of interest may lead to new composite materials generally referred as organic–inorganic hybrid materials. The hybrid materials composed of two different components are of great interest in the enhancement of the desired properties. This is because the mixing of two materials can improve the properties of the original single material and create a novel hybrid property. Thus; as-spun mat can be used as efficient antimicrobial packaging which potentially reduce contamination of meat/meat-products due to the synergistic effect of zinc and olive oil.

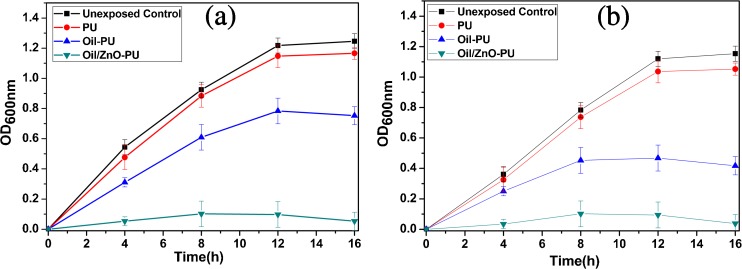

Antibacterial properties of the olive oil doped PU and olive oil/PU-ZnO hybrid nanofibers were tested using S. aureus and S. typhimurium as model organisms (Fig. 4). These are the predominant pathogenic bacteria responsible for spoilage of food and food-borne infections. PU nanofibers without olive oil/ZnO components showed a little antibacterial activity. Conversely, olive oil doped PU nanofibers showed significant activity. Nevertheless, olive oil/ZnO-PU packaging mat showed greater inhibition of testing microorganisms indicating that the packaging mats are endowed with excellent antibacterial properties due to the introduction of virgin olive oil and ZnO nanoparticles (Fig. 4). Olive Oil/ZnO-PU hybrid nanofibers have shown effective antibacterial activity against food/meat pathogens. Previously, Oussalah et al. (2004) evaluated the ability of a milk protein based edible film containing 1 % essential oils to control Pseudomonas spp. and E. coli H0157:H7 growth on surface inoculated beef muscle. The use of film containing essential oils significantly reduced the microorganism level in meat when compared to meat samples without film. Antibacterial nanofibers have attracted huge interests in recent years. In fact, with the emergence and increase of microbial resistant to multiple antibiotics, many researchers have tried to develop new antibiotics. The aim of our research was to develop novel virgin olive oil based ZnO decorated biodegradable PU packaging material with enhanced antibacterial activity. Olive oil is a natural material and is loaded with antibacterial ingredients (Kiritsakis and Markakis 1987). Nevertheless, the antibacterial activity of the ZnO is also eminent; therefore, it is expected that the electrospun nanofiberous mats will have enhanced antibacterial action. Earlier workers have also reported the antibacterial effect of ZnO. ZnO is a widely used in cosmetic products (Chia et al. 2010) and other materials (Jalal et al. 2010; Becheri et al. 2008; Alessio et al. 2008; Sawai 2003) as it possess broad spectrum antimicrobial activity but is non-toxic to human cells. The unique combination of olive oil and ZnO nanoparticles displayed potent bactericidal effect due to synergism. Besides, the electrospun mats can be sliced into any size depending upon the requirement for packaging. Moreover; no significant effect of as-spun hybrid mat on changes in pH and color parameters of meat were found in the present study. However, detailed investigation of shelf life and toxicity will be made in future study. Fig. 5 described the fabricated hybrid mat and its projected future applications as packaging material for meat and meat based products.

Fig. 4.

Growth curve of a S. aureus and b S. typhimurium cells exposed to pristine PU, live oil/PU and Olive oil/ZnO-PU hybrid mat.

Fig. 5.

Electrsospun hybrid mat; its antimicrobial concept and its projected future applications as packaging material for meat and meat based products

Nowadays; the electrospinning technique has gained much popularity due to its versatility in spinning a wide variety of polymeric fibers and also it is a simple and economic approach to produce the fibers in the nano-range with uniform morphology. Additionally, the electrospun polymeric nanofibers are rapidly replacing the conventional packaging materials such as glass, ceramics, metals, etc. due to significant interesting characteristics such as light weight, low cost and ease of processability etc. However, in spite of many interesting properties, their capability to resist deformation is lower as compared to metals and ceramics. To address the aforementioned shortcomings and to meet the increasing expectations of customers there have been extensive investigation of suitable packaging materials with desired qualities. In the present study we have designed a hybrid material which is made up of polymer as well as the ZnO nanoparticels. Nanoparticles have proportionally larger surface area and significant aspect ratio than their micro-scale counterparts, which promotes the development of mechanical and barrier properties. Thus, it is expected that the performance of designed mat could be improved for food packaging by adding ZnO nanoparticles. Moreover, the advantage of using PU as the polymer is that PUs have increased tensile strength and melting points making them more durable. Their resistance to degradation by water, oils, and solvents make them excellent for the replacement of plastics (Gary 2002; Kriegel et al., 2008). In summary, the results of our investigation suggest that the fabricated biodegradable nanofibrous mats are eco-friendly and could be used to replace PVC films for packaging fresh processed meat and meat based products. Some improvements of the properties or modifications of these materials can also be explored from the industrial application viewpoint. Now in future study these films can be modified by using the cheaper oil.

Conclusion

The aim of this work was to successfully develop novel organic–inorganic hybrid nanofibrous packaging material via facile electrospinning technique. The fabricated packaging mats were characterized in detail using sophisticated techniques and tested against the widespread spoilage organisms. The introduced biodegradable packaging material displayed potent antimicrobial activity against S. aureus and S. typhimurium. The outcome of our investigation clearly suggests that the fabricated biodegradable nanofibrous mats are promising materials and can be used for packaging fresh/or processed meat and meat based products. Thus, we can conclude here that the prepared antimicrobial organic–inorganic hybrid nanofibers provide another attractive solution for packaging material to be utilized in meat and food packaging industries. The as-synthesized nanofibers seem to be capable to replace non-degradable films and overcome the recycling complexity. However, a detailed study is needed to investigate toxicity issues before this material can be reliably used.

Acknowledgments

This research was fully supported by research funds of Chonbuk National University in 2013 and Grant from Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (Project no. 2014R1A1A2007175). This work has been partly supported by a grant from FTA strategy issues (No. PJ010170032014 and No. PJ008525), RDA Republic of Korea.

References

- Alessio B, Maximilian D, Pierandrea LN, Piero B. Synthesis and characterization of zinc oxide nanoparticles: application to textiles as UV-absorbers. J Nanoparticle Res. 2008;10:679–689. doi: 10.1007/s11051-007-9318-3. [DOI] [Google Scholar]

- Anderson AD, Nelson JM, Rossiter S, Angulo FJ. Public health consequences of use of antimicrobial agents in food animals in the United States. Microb Drug Resist. 2003;9:373–379. doi: 10.1089/107662903322762815. [DOI] [PubMed] [Google Scholar]

- Becheri A, Durr M, Nostro PL, Baglioni PJ. Synthesis and characterization of zinc oxide nanoparticles: application to textiles as UV-absorbers. J Nanoparticle Res. 2008;10:679–689. doi: 10.1007/s11051-007-9318-3. [DOI] [Google Scholar]

- Berger T, Spadaro J, Chapin S, Becker R. Electrically generated silver ions: quantitative effects on bacterial and mammalian cells. Antimicrob Agents Chemother. 1976;9(2):357–358. doi: 10.1128/AAC.9.2.357. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Carter AJ, Adams MR, Woodward MJ, La Ragione RM. Control strategies for Salmonella colonisation of poultry: the probiotic perspective. Food Science and Technology Bulletin: Functional Foods. 2009;5(9):103–115. [Google Scholar]

- Chia LK, Cheng LW, Horng HK, Weng SH, Kuo C, Wang LL. Synthesis of zinc oxide nanocrystalline powders for cosmetic applications. Ceram Int. 2010;36:693–698. doi: 10.1016/j.ceramint.2009.10.001. [DOI] [Google Scholar]

- ElAmin A (2005) Nanotechnology targets new food packaging products. http://www.foodproductiondaily.com/Packaging/Nanotechnology-targets-new-food- packagingproducts Accessed 22 Jan. 2010

- Ellis DI, Goodacre R. Rapid and quantitative detection of the microbial spoilage of muscle foods: current status and future trends. Trends Food Sci Technol. 2001;12:414–424. doi: 10.1016/S0924-2244(02)00019-5. [DOI] [Google Scholar]

- Gill CO. A review: intrinsic bacteria in meat. J Appl Bacteriol. 1979;47:1–12. doi: 10.1111/j.1365-2672.1979.tb01166.x. [DOI] [PubMed] [Google Scholar]

- Gary TH. Biodegradation of polyurethane: a review. International Biodeterioration &Biodegradation. 2002;49:245–252. doi: 10.1016/S0964-8305(02)00051-3. [DOI] [Google Scholar]

- Jalal R, Goharshadia EK, Abareshia M, Moosavic M, Yousefid A. ZnO nanofluids: Green synthesis, characterization, and antibacterial activity. Mater Chem Phys. 2010;121:198–201. doi: 10.1016/j.matchemphys.2010.01.020. [DOI] [Google Scholar]

- Jay JM (1996) Modern Food Microbiology. Chapman & Hall, London, 5th edn.

- Khlystalova TK, Kurganova MN, Demina AI, Petova MB, Tarakanov OG. Hydrolytic stability of polyurethanes in model biological media. Mech. Compos Mater Ser. 1986;21:763–767. doi: 10.1007/BF00605943. [DOI] [Google Scholar]

- Kidoaki S, Kwon IK, Matsuda T. Structural features and mechanical properties of in situ–bonded meshes of segmented polyurethane electrospun from mixed solvents. J Biomed Mater Res B Appl Biomater. 2006;76B:219–229. doi: 10.1002/jbm.b.30336. [DOI] [PubMed] [Google Scholar]

- Kiritsakis A, Markakis P. Olive oil–a review. Adv Food Res. 1987;31:453–482. doi: 10.1016/S0065-2628(08)60170-6. [DOI] [PubMed] [Google Scholar]

- Ma W, Tang C-H, Yin S-W, Yang X-Q, Wang Q, Liu F, Wei Z-H. Characterization of gelatin-based edible films incorporated with olive oil. Food Res Int. 2012;49:572–579. doi: 10.1016/j.foodres.2012.07.037. [DOI] [Google Scholar]

- Oussalah M, Caillet S, Salmieäri S, Saucier L, Lacroix M. Antimicrobial and Antioxidant Effects of Milk Protein-Based Film Containing Essential Oils for the Preservation of Whole Beef Muscle. J Agric Food Chem. 2004;52:5598–5605. doi: 10.1021/jf049389q. [DOI] [PubMed] [Google Scholar]

- Pereda M, Amica G, Marcovich NE. Development and characterization of edible chitosan/olive oil emulsion films. Carbohydr Polym. 2012;87:1318–1325. doi: 10.1016/j.carbpol.2011.09.019. [DOI] [Google Scholar]

- Sawai J. Quantitative evaluation of antibacterial activities of metallic oxide powders (ZnO, MgO and CaO) by conductimetric assay. J Microbiol Meth. 2003;54:177–182. doi: 10.1016/S0167-7012(03)00037-X. [DOI] [PubMed] [Google Scholar]

- Schroeder CM, White DG, Meng J. Retail meat and poultry as a reservoir of antimicrobial-resistant Escherichia coli. Food Microbiol. 2004;21:249–255. doi: 10.1016/S0740-0020(03)00074-1. [DOI] [Google Scholar]

- Silva KA, Coelho MAZ, Calado VMA, Rocha-Leão MHM. Olive oil and lemon salad dressing microencapsulated by freeze-drying. LWT Food Sci Technol. 2013;50:569–574. doi: 10.1016/j.lwt.2012.08.005. [DOI] [Google Scholar]

- Tenover FC. Mechanisms of antimicrobial resistance in bacteria. Am J Med. 2006;119:S3–S10. doi: 10.1016/j.amjmed.2006.03.011. [DOI] [PubMed] [Google Scholar]

- Huang W, Xu H, Xue Y, Huang R, Deng H, Pan S. Layer-by-layer immobilization of lysozyme–chitosan–organic rectorite composites on electrospun nanofibrous mats for pork preservation. Food Res Int. 2012;48:784–791. doi: 10.1016/j.foodres.2012.06.026. [DOI] [Google Scholar]

- Kriegel C, Arrechi A, Kit K, McClements DJ, Weiss J. Fabrication, functionalization, and application of electrospun biopolymer nanofibers. Crit Rev Food Sci Nutr. 2008;48:775–797. doi: 10.1080/10408390802241325. [DOI] [PubMed] [Google Scholar]

- Su KJ, Mi KK, Young-Hoon L, Dong HS, Min HS, Byung YC, Bo YC. Lower Zinc Bioavailability May Be Related to Higher Risk of Subclinical Atherosclerosis in Korean Adults. PLoS One. 2013;8:80115–80125. doi: 10.1371/journal.pone.0080115. [DOI] [PMC free article] [PubMed] [Google Scholar]