Abstract

Gluten free biscuits, also suitable during fasting were developed utilizing different levels of fruits (water chestnut and makhana) and starchy vegetable (potato) powders. Biscuits were developed using creamery method and evaluated for physical properties, proximate composition, sensory characteristics and storability for 90 days at room temperature. Expansion in diameter of biscuits with different level of potato and makhana powder varied between 1.026 to 1.059 and 1.046 to 1.059, respectively as compared to 1.075 for biscuits prepared using water chestnut only. Breaking hardness and toughness of different biscuit was increased with increasing level of potato or makhana powder in flour blends and higher in potato powder incorporated biscuits. Whiteness (L values) of biscuits was decreased with increasing level of potato powder while a reverse trend was observed in case of makhana powder incorporated biscuits. Protein content in biscuits with makhana powder was higher than the biscuits prepared using potato powder in flour blends. Biscuits prepared using hundred percent water chestnut showed the maximum crude fibre content in them. Results indicated that gluten free biscuits for fasting people can be prepared using potato powder or makhana powder up to 50 % with water chestnut powder. The overall sensory acceptability of biscuits with makhana powder was better than for biscuits with potato powder with maximum overall acceptability scores for biscuits developed using 70:30 parts of water chestnut and makhana powders in flour blend, which were storable for 90 days period at room temperature.

Keywords: Water chestnut, Makhana, Potato powder, Gluten free biscuits, Fasting

Biscuit is the one of oldest bakery snack item, consumed by all age groups regularly. This is the product with good shelf life and one of the most liked bakery product by the urban as well as rural consumers. Biscuit industry in India is pegged at 3,000 crores of which the unorganized sector accounts as much as 35 %. India is one of the largest biscuit producers in the world and last few years have witnessed substantial increase in the consumption of ready-to-eat snacks including biscuits (Kar et al. 2012). The growth of bakery industry is about 10 % per annum and the products are increasingly becoming popular among all sections of people (Indrani et al. 1997). It is expected for the bakery industry to grow at a rate of 15 to 17 % in the coming years (www.indianmirror.com). Being faster in growth of biscuit industry, there is a huge scope of research on diversification of this baked product. Biscuit, which is one of the most commonly accepted snack foods amongst children and adult, may be considered as one of the good supplementary food for distributing to the undernourished children through developmental agencies.

Conventionally biscuits are made from cereals particularly refined wheat flour, which contains a protein called gluten. Gluten is responsible for flour processing characteristics in bakery industry. However, gluten must be eliminated from the diet of patients suffering from celiac disease because its ingestion causes serious intestinal damage (Sciarini et al. 2008). Coelic disease has been diagnosed in 26 to 49 % of Indian children presenting with chronic diarrhea at tertiary care hospitals (Yachha et al. 1993; Bhatnagar et al. 2005). A healthy gluten free flour formulation can be prepared from the combination of grains and other foods like brown or white rice, millets, maize, soy, chickpea, buckwheat, amaranth, tapioca flour, potato flour, water chestnut, makhana with a little amount of xanthan for enhancing the dough quality required for making the baked product (Mridula and Sharma 2012).

Potato has a huge potential for a beneficial role in world food production, owing to its status as a cheap and plentiful crop which can be raised in a wide variety of climates and locales (Wade 2008). The excess potato products, as well as the damaged tubercles from the commercial standard can be transformed into other products, such as potato flour (Oliveira et al. 2006). Potato flour is an inexpensive, nutritious, and ordinarily harmless source of carbohydrate calories and contains lower levels of phytic acid than other plant foods (Kulkarni et al. 1996). Being rich in starch, potato flour can be used in a variety of foods products to improve their functional properties. It has its own distinctive flavour and texture but can sufficiently bland easily into many food preparations. For making baked products, a strong gluten is not required but water absorption of the flour should be high (Kent 1984). So a substantial amount of potato flour can be used as a supplement to the wheat flour.

Water chestnut is a popular fruit in many parts of India, Pakistan, Sri Lanka, Indonesia and Southern China. Water chestnut or Water Caltrop also known as “Singhara” in India, posses a remarkable nutritional composition, good in protein content, very low in fat, rich in potassium and gluten free (Puste 2004). The white flesh of water chestnut makes them enable to utilize it in various food preparations. The fruit is used as a substitute for cereal in Indian subcontinent in many Indian religious rituals during fasting days. The fruit is dried and the flour prepared from it is easily digestible with negligible fat content (Puste 2004). Its flour can be a good replacement for wheat flour with respect the Celiac disease caused by indigestion of gluten (wheat protein) (Singh et al. 2011). Demand for the water chestnut flour rises during the Navratras and other fasting and sacred days when consumption of wheat flour is avoided (Puste 2004). Studies indicated an excellent scope for development of water chestnut based cookies to be used as a specialized product in Indian market (Singh et al. 2011).

Makhana, a popped kernel of gorgon nut (Euryale ferox) is considered a delicious food item in India. It is cultivated in several districts of North Bihar, and is a main support for livelihood of the poor people. It is commonly used in many Indian religious rituals. Being gluten free, it can be successfully utilize for making gluten free products and in the products intended for use during fasting.

During the fasting in India, people usually avoid eating cereal based food products while prefer food products prepared using selected vegetables and fruits. Being good source of starches and other nutrients and free from gluten, water chestnut, potato and makhana may be considered for making baked product that can be utilized not only by celiac patients but also during fasting days. In view of this, the present study was carried out to develop and evaluate gluten free biscuits utilizing fruits and starchy vegetable powders for fasting people.

Materials and methods

Raw materials

Dried water chestnut and makhana procured from the local market, Ludhiana were first crushed using domestic flour mill (Natraj Atta Maker, Scorpio Enterprises, India) followed by fine grinding using laboratory mill (Foss Tecator, Sweden) and passed through 85 mesh sieve of BSS standard to obtain a fine formulation (particle size 0.177 mm). Potato powder was prepared using good quality raw potato, purchased from local market, Ludhiana. Peeled potato was cut into thin slices of 4 to 5 mm, followed by steaming at atmospheric pressure for 6 min and drying in a tray dryer at 60 °C to 8–9 %. The dried potato slices were milled into flour using the laboratory mill and passed through 85 mesh sieve of BSS standard to obtain a fine formulation (particle size 0.177 mm). The potato flour thus obtained was packed in the air tight container and stored at room temperature for further use.

Preparation of biscuits

Eight flour blends, prepared using water chestnut flour, potato flour and makhana powder are given in Table 1. Biscuit samples were prepared, using creamery method for making biscuit dough. The ingredients (g) used in preparation of biscuits were flour blends 100, fat 25, sugar 25, baking powder 0.3, sodium bicarbonate 0.2, ammonium bicarbonate 0.5 and milk as desired to make dough softer. Edible gum, purchased from local market was also used (0.5 g/100 g of flour blend) to enhance the binding properties of the flour. Biscuit dough was prepared in a Spar Quart Mini Mixer (SP-800) and sheeted to a thickness of about 4.5 mm approximately, cut into round shape of 45 mm diameter, transferred to baking tray and baked at 180 °C for 15 min. The biscuits, after attaining the room temperature were packed in LDPE bags and evaluated for all different quality parameters.

Table 1.

Proportion of different fruits and starchy vegetable powders in flour blends

| Ingredients | Proportion of WP:PP/WP:MP |

|---|---|

| Biscuits with PP | |

| CW0P0a | 0:0 |

| WP0 | 100:0 |

| WP1 | 90:10 |

| WP2 | 70:30 |

| WP3 | 50:50 |

| Biscuits with MP | |

| CW0P0 | 0:0 |

| WM0 | 100:0 |

| WM1 | 90:10 |

| WM2 | 70:30 |

| WM3 | 50:50 |

W water chestnut, WP water chestnut powder, PP potato powder, MP Makhana powder

aControl prepared using refined wheat flour

Biscuit samples with 70:30 parts of water chestnut and makhana powder (WM2) were well accepted during sensory evaluation, hence they were considered for shelf life study. In order to compare them with refined wheat based (CW0P0, control), and hundred percent water chestnut based (WP0 or WM0); these samples have also been kept for shelf life study. Selected biscuit samples namely WP0/WM0, WM2 and CW0P0 (Control) were prepared and packed in commercially available Low density polyethylene (LDPE; thickness 65 μ) pouches and kept at room temperature for 90 days period during March to May 2013. The LDPE pouches before loading were wrapped in brown paper and kept in hot air oven at 60 °C for 4 h to reduce the any microbial loads (Mridula et al. 2010). The stored biscuit samples were evaluated for important quality parameters viz. moisture content, free fatty acids (FFA), microbial load, and sensory characteristics at 30 days interval.

Physical properties

Expansion in diameter and thickness was the ratio of biscuit diameter and thickness before and after baking. Spread ratio of biscuit samples was calculated as per standard AACC methods (AACC 1967). Fifteen biscuit samples were considered for determining the physical properties of different types of biscuits.

Proximate composition and microbial load

Moisture, crude fat, protein (using the factor 6.5 × N), ash and crude fibre content in different biscuit samples were determined as per standard methods (AOAC 2000). Total carbohydrates value was obtained by subtracting the total of moisture, protein, fat, crude fibre and ash content from 100. Total calories were calculated by multiplying protein, carbohydrates and fat content by the factor 4, 4 and 9, respectively. Free fatty acids (on whole sample basis) in fresh and stored energy bar, was determined as per Thapar et al. (1988) method. Microbial load i.e. viable bacterial count and yeast and mould (fungi) were determined by standard pour plating method.

Textural properties

Breaking test of biscuit samples was conducted using texture analyzer (TA-Hdi), Stable Micro systems (U.K.). The individual sample of biscuits was placed over two points of the blade. The blade HDP/BS was attached to the crosshead of the instrument. This test simulates the evaluation of hardness by consumer holding the biscuit in hands and breaking by bending. The peak force from the resulting curve was considered as breaking hardness of the biscuit and the area under the peak force on the graph was considered as breaking toughness. TA settings were kept as pre-test speed 1 mm/s, test speed 1 mm/s, post test speed 2 mm/s, distance 5 mm and 50 kg load cell.

Instrumental colour quality

L, a and b values of the biscuits was determined by using Hunter Colorimeter (model no. 45/0 L, made in U.S.A). L is known as the lightness and extends from 0 (black) to 100 (white). The other two coordinates a and b represents redness (+a values) to greenness (−a values) and yellowness (+b values) to blueness (−b values), respectively. h0 (Hue angle) is the attribute of the colour by means of which the colour is perceived. C (chroma) is the attribute of colour used to indicate the degree of departure of the colour from gray of the same lightness. h0 and C* are computed by using the following formula.

where b = b, a = a.

Sensory characteristics

Sensory characteristics of biscuits were evaluated for its different sensory attributes by a group of nine panelists. Sensory attributes like appearance and colour, texture, odour, flavour and taste and overall acceptability for all biscuit samples were assessed using nine point hedonic scale. Hedonic scale was in the following sequence: like extremely—9, like very much—8, like moderately—7, like slightly—6, neither like nor dislike—5, dislike slightly 4, dislike moderately,—3, dislike very much—2, dislike extremely—1 (BIS 1971).

Statistical analysis

Data pertaining to all the parameters of the present study were calculated for mean values using MS Excel 2003. ANOVA and least significant difference (LSD) was computed using AgRes statistical software (1994; Version 7.01; Pascal International Software Solution, Boston, MA, USA) to evaluate the interaction effect of different parameters. Linear regression and R2 values were computed using MS-Excel 2003 software.

Results and discussion

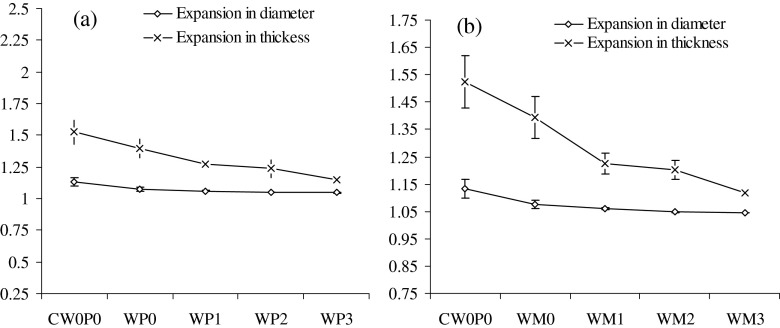

Effect of different proportion of fruits and starchy vegetable powders on selected baking characteristics of gluten free biscuits suitable fasting people biscuits is given Table 2 and Fig. 1. Expansion in diameter of refined wheat based control biscuits was higher than the biscuits with different levels of vegetable and fruit powders. Expansion in diameter and thickness of refined wheat based biscuits was 1.132 ± 0.04 and 1.523 ± 0.095, respectively, which was higher than the developed gluten free biscuits. Expansion in diameter of biscuits with different level of potato and makhana powders ranged between 1.026 ± 0.002 to 1.059 ± 0.005 and 1.046 ± 0.004 to 1.059 ± 0.003, respectively. Expansion in diameter of biscuits prepared using water chestnut only was 1.075 ± 0.02. The level of potato or makhana powder in flour blends significantly affected the expansion in diameter and thickness (p < 0.05) of biscuits. Studies also indicated the reduced expansion in diameter and thickness with increasing level of carrot as well as in beetroot powder incorporated biscuits (Mridula et al. 2009a; Mridula 2011).

Table 2.

Anova table for textural characteristics of fruits and starchy vegetable powders based gluten free biscuit

| Parameters | DF | SS | MS | F-value | P-value | |

|---|---|---|---|---|---|---|

| Expansion in diameter | T | 1 | 0.000900 | 0.000900 | 2.64ns | 0.180 |

| P | 4 | 0.109734 | 0.027434 | 80.48** | 0.000 | |

| TP | 4 | 0.002070 | 0.000517 | 1.52ns | 0.348 | |

| Expansion in thickness | T | 1 | 0.012544 | 0.012544 | 3.40ns | 0.139 |

| P | 4 | 1.927510 | 0.481877 | 130.62** | 0.000 | |

| TP | 4 | 0.009126 | 0.003689 | 0.62ns | 0.674 | |

| Breaking hardness | T | 1 | 357.255 | 357.255 | 157.30** | 0.000 |

| P | 4 | 6886.2 | 1721.55 | 758.01** | 0.000 | |

| TP | 4 | 384.54 | 96.137 | 42.33** | 0.002 | |

| Breaking toughness | T | 1 | 2.757 | 2.757 | 10.67* | 0.031 |

| P | 4 | 419.91 | 104.978 | 406.06** | 0.000 | |

| TP | 4 | 2.75 | 0.688 | 2.66ns | 0.183 | |

T type of biscuits, P level of potato or Makhana powder, TP interaction of T and P, ns non significant

*Significant at p ≤ 0.05

**Significant at p ≤ 0.01

Fig. 1.

Effect of different proportion of a water chestnut and potato powder and b water chestnut and makhana powder on baking quality of gluten free biscuits (n = 10)

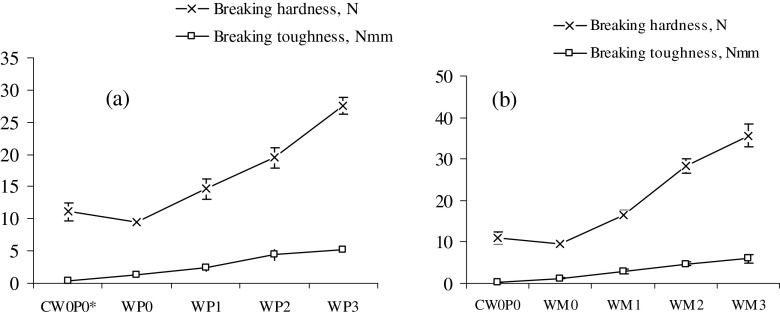

Effect of different proportion of fruits and starchy vegetable powders on breaking hardness and toughness of developed gluten free biscuits is given in Table 2 and Fig. 2. Breaking hardness of potato and makhana powder incorporated gluten free biscuits varied between 9.57 ± 0.49 N to 27.53 ± 1.26 N and 9.57 ± 0.49 N to 35.69 ± 2.64 N, respectively as against 11.08 ± 1.44 N for wheat based control biscuit samples. A linear increased in breaking hardness and toughness of different biscuit samples was observed with increasing level of potato or makhana powder in flour blends. Biscuits with potato powder were comparatively softer than makhana powder based biscuits as indicated by lower breaking hardness. Makhana powder, when absorbed water though not results in smooth dough due to absence of gluten but gives an elastic texture to dough. This might have ultimately resulted in the hard texture of makhana powder based biscuits as compared to potato powder incorporated gluten free biscuits. Hundred percent water chestnut based biscuits were softer than the refined wheat flour based control biscuit samples. This may be due to absence of gluten in the water chestnut that brought a structural variation in the crust and crumb as indicated by the fissure on the surface of water chestnut based biscuits. Although biscuit samples with different level of potato or makhana powder were harder and tougher as compared to hundred percent water chestnut and refined wheat based control samples biscuits but they were found acceptable on sensory evaluation. The relationship between the hardness/toughness and potato powder or makhana powder can be expressed by using the following regression equation.

| 1 |

| 2 |

| 3 |

| 4 |

Fig. 2.

Effect of different proportion of a water chestnut and potato powder and b water chestnut and makhana powder on texture of gluten free biscuit (n = 10)

Effect of different proportion of fruits and starchy vegetable powders on instrumental colour quality of biscuits is given in Table 3. The L, a and b values of water chestnut, potato and makhana powder, used for making biscuits were 79.61, 2.72, and 10.26; 81.4, 2.93 and 11.8; 85.43, 2.29 and 7.94, respectively. The results indicated that different levels of water chestnut, potato and makhana powder significantly affected the colour quality of the developed gluten free biscuits. L values were found decreased with increasing level of potato powder while increased with increasing level of makhana powder in developed biscuits. A reverse trend was observed in a values of developed gluten free biscuits with increasing level of potato or makhana powder in these biscuit samples. Minimum lightness and maximum redness i.e. a values were observed in the biscuits samples, developed using 50:50 parts of water chestnut and potato powder in flour blends. This may be possibly due to higher a, b values of potato powder as compared to makhana powder. At the same time, browning of starch molecules of potato powder during baking due to mallard reaction may be a reason of lower L and higher a values of biscuit with higher proportion of potato powder. Results indicated a significant variation in hue and chroma of the developed gluten free biscuit samples with the variable proportion of fruits and vegetable powders in flour blends. Although colour quality of the different gluten free biscuits was significantly affected due to variation in fruits and vegetable powders in flour blends but the sensory scores for appearance and colour were in the acceptable range of hedonic scale even at 30 % level of potato or makhana powder in flour blends.

Table 3.

Effect of different proportion of fruits and starchy vegetable powders on instrumental colour quality of gluten free biscuits

| Biscuit samples | L | a | b | Hue | Chroma | |

|---|---|---|---|---|---|---|

| Biscuits with PP | ||||||

| CW0P0a | 66.54 ± 1.74a | 8.70 ± 1.23b | 31.87 ± 1.00a | 74.77 ± 1.72a | 33.04 ± 1.24a | |

| WP0 | 46.89 ± 0.71d | 8.55 ± 0.45b | 25.82 ± 1.36c | 71.65 ± 1.36c | 27.20 ± 1.28c | |

| WP1 | 49.81 ± 1.02bc | 8.63 ± 0.52b | 28.06 ± 0.63b | 72.92 ± 0.80abc | 29.36 ± 0.70b | |

| WP2 | 45.28 ± 0.31e | 10.61 ± 0.71a | 25.91 ± 0.37c | 67.74 ± 1.45d | 28.00 ± 0.38bc | |

| WP3 | 42.93 ± 1.34f | 11.23 ± 0.60a | 25.12 ± 1.67cd | 65.87 ± 1.72d | 27.52 ± 1.57c | |

| Biscuits with MP | ||||||

| CW0P0 | 66.54 ± 1.74a | 8.70 ± 1.23b | 31.87 ± 1.00a | 74.77 ± 1.72a | 33.04 ± 1.24a | |

| WM0 | 46.89 ± 0.71d | 8.55 ± 0.45b | 25.82 ± 1.36c | 71.65 ± 1.36c | 27.20 ± 1.28c | |

| WM1 | 49.57 ± 0.93c | 7.72 ± 0.75bc | 23.67 ± 0.20de | 71.97 ± 1.47c | 24.90 ± 0.43d | |

| WM2 | 49.59 ± 0.29c | 7.02 ± 0.64cd | 22.19 ± 0.52e | 72.47 ± 1.13bc | 23.28 ± 0.67e | |

| WM3 | 51.20 ± 0.58b | 6.39 ± 0.20d | 22.33 ± 1.36e | 74.01 ± 0.84ab | 23.23 ± 1.34e | |

| F value | T | 54.0197** | 62.75** | 42.29** | 29.23** | 61.12** |

| P | 509.2237** | 1.02ns | 76.85** | 16.04** | 65.35** | |

| TP | 25.0670** | 17.7** | 7.63* | 15.70** | 10.23** | |

| CD (5 %) | T | 0.69 | 0.48 | 0.68 | 0.9 | 0.70 |

| P | 1.08 | 0.76 | 1.08 | 1.42 | 1.11 | |

| TP | 1.53 | 1.077 | 1.53 | 2.01 | 1.57 | |

W water chestnut, WP water chestnut powder, PP potato powder, MP Makhana powder, T type of biscuits, P level of potato or Makhana powder, TP interaction of T and P, ns non significant; n = 4

*Significant at p ≤ 0.05

**Significant at p ≤ 0.01

a–fControl prepared using refined wheat flour

The proximate composition of refined wheat flour, water chestnut, potato powder and makhana powder used for development of gluten free biscuits were protein 11.8, 7.50, 6.50 and 10.24 %; fat 1.18, 0.90, 0.68 and 0.16 %; ash 0.94, 2.59, 2.46 and 0.75 %; crude fibre 1.2, 6.75, 3.65 and 1.29 %; and carbohydrates (by difference) 71.2, 74.9, 79.9 and 77.76 %, respectively. Iron and calcium content in refined wheat flour, water chestnut, potato powder and makhana powder was 4.3 and 41, 3.15 and 82, 3.05 and 83.33 and 2.73 and 62.0 mg/100 g, respectively. No significant difference was observed in the moisture content of different gluten free biscuit samples, baked at the same temperature and time (p > 0.05). Protein content in biscuits with makhana powder was significantly higher than the biscuits prepared using potato powder in flour blends but lower than the wheat based control biscuits (Table 4). This might be due to lower protein content in the potato powder as compared to water chestnut and refined wheat flour. Though there was a slight variation in the fat content in different gluten free biscuits with potato or makhana powder but it was statistically similar. Mineral content in different gluten free biscuits was higher than wheat based control biscuits, which was decreased with increasing level of makhana powder in the flour blends. Water chestnut based biscuits (WP0 and WM0) showed the maximum crude fibre content while minimum in wheat based control biscuit sample. At the same time, crude fibre content was decreased with increasing level of potato or makhana powder in flour blends. The crude fibre content was higher in potato powder incorporated biscuits (p < 0.001) than other samples. Mineral content in water chestnut and potato powder was found at par, which resulted in the statistically similar mineral content in biscuits with different levels of potato powder. A slight variation was observed in the iron content in biscuit samples developed using potato or makhana powder but the calcium content in biscuits with potato powder was significantly higher than biscuits with makhana powder. This might be due to higher calcium content in the potato powder. The variation in the nutrients content in water chestnut, potato and makhana powder brought a significant difference in protein, fat, crude fibre and carbohydrates content in developed gluten free biscuits that ultimately affected the calorie content in the biscuit samples.

Table 4.

Proximate composition of different fruits and vegetable based gluten free biscuits

| Biscuit samples | Moisture, % | Protein, % | Fat, % | Mineral, % | Crude fibre, % | Iron, mg/100 g | Calcium, mg/100 g | Carbohydrates, % | Calorie, kcal/100 g | |

|---|---|---|---|---|---|---|---|---|---|---|

| Biscuits with PP | ||||||||||

| CW0P0a | 4.29 ± 0.12 | 7.87 ± 0.05 | 17.49 ± 0.17 | 0.86 ± 0.12 | 0.80 ± 0.01 | 3.54 ± 0.10 | 27.35 ± 0.04 | 68.69 ± 0.324 | 463.63 ± 0.41 | |

| WP0 | 4.20 ± 0.10 | 5.75 ± 0.00 | 17.31 ± 0.32 | 1.71 ± 0.088 | 4.56 ± 0.03 | 2.10 ± 0.00 | 54.69 ± 0.00 | 66.48 ± 0.396 | 444.68 ± 1.44 | |

| WP1 | 4.24 ± 0.02 | 4.92 ± 0.01 | 17.29 ± 0.04 | 1.70 ± 0.024 | 4.30 ± 0.02 | 2.08 ± 0.04 | 54.79 ± 0.03 | 67.53 ± 0.04 | 445.42 ± 0.14 | |

| WP2 | 4.28 ± 0.15 | 4.80 ± 0.02 | 17.24 ± 0.17 | 2.08 ± 0.01 | 3.88 ± 0.10 | 2.08 ± 0.01 | 54.93 ± 0.04 | 68.105 ± 0.22 | 446.76 ± 0.86 | |

| WP3 | 4.25 ± 0.13 | 4.67 ± 0.02 | 17.21 ± 0.10 | 2.068 ± 0.009 | 3.44 ± 0.14 | 2.07 ± 0.01 | 55.14 ± 0.01 | 68.80 ± 0.13 | 448.7 ± 1.35 | |

| Biscuits with MP | ||||||||||

| CW0P0 | 4.29 ± 0.12 | 7.87 ± 0.05 | 17.49 ± 0.17 | 0.86 ± 0.12 | 0.80 ± 0.01 | 3.54 ± 0.10 | 27.35 ± 0.04 | 68.69 ± 0.324 | 463.63 ± 0.41 | |

| WM0 | 4.20 ± 0.10 | 5.75 ± 0.00 | 17.31 ± 0.32 | 1.71 ± 0.088 | 4.56 ± 0.03 | 2.10 ± 0.00 | 54.69 ± 0.00 | 66.48 ± 0.396 | 444.68 ± 1.44 | |

| WM1 | 4.28 ± 0.03 | 5.19 ± 0.02 | 17.23 ± 0.09 | 1.60 ± 0.01 | 4.14 ± 0.01 | 2.07 ± 0.01 | 53.37 ± 0.04 | 67.56 ± 0.071 | 446.10 ± 0.47 | |

| WM2 | 4.21 ± 0.16 | 5.55 ± 0.02 | 17.13 ± 0.11 | 1.36 ± 0.01 | 3.40 ± 0.02 | 2.02 ± 0.01 | 50.69 ± 0.02 | 68.35 ± 0.18 | 449.77 ± 0.98 | |

| WM3 | 4.23 ± 0.02 | 5.91 ± 0.02 | 16.87 ± 0.36 | 1.11 ± 0.01 | 2.68 ± 0.02 | 1.96 ± 0.01 | 48.04 ± 0.05 | 69.19 ± 0.33 | 452.23 ± 1.85 | |

| F value | T | 0.055ns | 2070.7** | 1.697ns | 61.29** | 171.25** | 3.9ns | 49059.87** | 1.86ns | 13.39* |

| P | 0.506ns | 1133.6** | 3.63ns | 146.46** | 3846.5 | 1180.6** | 819057.1** | 81.74** | 301.4** | |

| TP | 0.204ns | 586.81** | 0.653ns | 16.99** | 47.48** | 1.55ns | 14260.38** | 0.65ns | 3.71ns | |

| CD (5 %) | T | 0.082ns | 0.020 | 0.161 | 0.052 | 0.043 | 0.034 | 0.023 | 0.207 | 0.822 |

| P | 0.13ns | 0.031 | 0.255 | 0.083 | 0.067 | 0.054 | 0.036 | 0.327 | 1.298 | |

| TP | 0.183ns | 0.044 | 0.360 | 0.117 | 0.095 | 0.077 | 0.051 | 0.462 | 1.84 | |

W water chestnut, WP water chestnut powder, PP potato powder, MP Makhana powder, T type of biscuits, P level of potato or Makhana powder, TP interaction of T and P, ns non significant; n = 3

*Significant at p ≤ 0.05

**Significant at p ≤ 0.01

aControl prepared using refined wheat flour

Mean sensory scores for different sensory characteristics of fruits and starchy vegetable powders based gluten free biscuits are presented in Table 5. The mean sensory scores, for different gluten free biscuit samples, for all the sensory characteristics were more than minimum acceptable score of 6. The result thus indicated that the biscuits prepared using different level of fruits and starchy vegetable powders were accepted by the panelists. Though the study revealed that gluten free biscuits for fasting people can be prepared using potato powder or makhana powder up to 50 % with water chestnut powder but mean comparison by LSD results indicated that overall sensory acceptability for water chestnut and makhana powders based biscuits was more than the biscuits with potato powder. This was due to slightly bitter aftertaste in water chestnut and potato powders based biscuits as reported by the sensory panel. The maximum mean scores (8.50) for different sensory characteristics of gluten free biscuits developed using 70:30 parts of water chestnut and makhana powders in flour blend indicated the commercial scope for manufacturing of good quality fruits and starchy vegetable powders based biscuits, which can be consumed during fasting and also by people with gluten allergy.

Table 5.

Effect of different proportion of fruits and starchy vegetable powders on sensory characteristics of gluten free biscuits

| Biscuit samples | Appearance and colour | Sensory texture | Odour | Flavour and taste | Mouth feel | Overall acceptability | |

|---|---|---|---|---|---|---|---|

| Biscuits with PP | |||||||

| CW0P0a | 8.56 ± 0.39a | 8.44 ± 0.17a | 8.56 ± 0.46a | 8.06 ± 0.30b | 8.09 ± 0.27b | 8.03 ± 0.32b | |

| WP0 | 7.56 ± 0.46bc | 7.50 ± 0.43c | 7.39 ± 0.33de | 7.56 ± 0.30c | 7.50 ± 0.35cd | 7.56 ± 0.39cd | |

| WP1 | 7.78 ± 0.51b | 7.87 ± 0.56b | 7.63 ± 0.38cd | 7.57 ± 0.40c | 7.56 ± 0.30cd | 7.56 ± 0.85cd | |

| WP2 | 7.39 ± 0.42c | 7.08 ± 0.34d | 7.54 ± 0.44cde | 6.78 ± 0.36e | 6.76 ± 0.35e | 6.78 ± 0.36ef | |

| WP3 | 7.22 ± 0.26c | 6.92 ± 0.36d | 7.22 ± 0.36e | 6.37 ± 0.29f | 6.28 ± 0.26f | 6.39 ± 0.55f | |

| Biscuits with MP | |||||||

| CW0P0 | 8.56 + 0.39a | 8.44 + 0.17a | 8.56 + 0.46a | 8.06 + 0.30b | 8.09 + 0.27b | 8.03 + 0.32b | |

| WM0 | 7.56 ± 0.46bc | 7.50 ± 0.43c | 7.39 ± 0.33de | 7.56 ± 0.30c | 7.50 ± 0.35cd | 7.56 ± 0.39cd | |

| WM1 | 7.83 ± 0.25b | 7.73 ± 0.36bc | 7.80 ± 0.26c | 7.72 ± 0.36c | 7.79 ± 0.78bc | 7.72 ± 0.26bc | |

| WM2 | 8.44 ± 0.53a | 8.22 ± 0.36a | 8.44 ± 0.30ab | 8.50 ± 0.38a | 8.52 ± 0.25a | 8.50 ± 0.35a | |

| WM3 | 7.89 ± 0.22b | 6.78 ± 0.26d | 8.17 ± 0.43b | 7.22 ± 0.26d | 7.28 ± 0.36d | 7.17 ± 0.25de | |

| F value | T | 17.50** | 5.14* | 24.67** | 62.40** | 55.20** | 33.51** |

| P | 18.66** | 45.01** | 23.53** | 35.19** | 27.75** | 19.74** | |

| TP | 6.44* | 10.24* | 7.02* | 23.26** | 18.21** | 12.82* | |

| CD (5 %) | T | 0.17 | 0.15 | 0.16 | 0.14 | 0.16 | 0.18 |

| P | 0.27 | 0.24 | 0.25 | 0.22 | 0.25 | 0.29 | |

| TP | 0.38 | 0.34 | 0.36 | 0.31 | 0.36 | 0.41 | |

W water chestnut, WP water chestnut powder, PP potato powder, MP Makhana powder, T type of biscuits, P level of potato or Makhana powder, TP interaction of T and P, ns non significant; n = 9

*Significant at p ≤ 0.05

**Significant at p ≤ 0.01

a–fControl prepared using refined wheat flour

Effect of storage on moisture content, FFA and sensory attributes of studied biscuit samples (CW0M0, WM0 and WM2) are presented in Table 6. Moisture content of control (CW0M0), WM0 and WM2 biscuit samples after 90 days storage was 4.31, 4.26 and 4.29 % (w.b.), respectively with an increment of 0.02, 0.06 and 0.08 %, respectively. Though storage brought an increment of 0.02 to 0.04 % in FFA content of all the studied three biscuit samples but this increment did not cause any rancid odour or off flavour as indicated by the panellists during sensory evaluation. Similar type of linearly, but little changes in FFA content with increasing storage period were also reported in fortified bengal gram sattu (Mridula et al. 2010). The increase in FFA content may be mainly from degradation products of hydroperoxide, which is directly related with relatively humidity and moisture content of the products (Thakur and Arya 1990; Sowbhagya and Bhattacharya 1976; Mridula et al. 2009b). Due to very little variation in the moisture content after 90 days storage of biscuit samples, FFA content of biscuit samples was also not changed much in the present study. The bacterial load in CW0M0, WM0 and WM2 biscuit samples was 1.3, 1.48 and 1.3 log cfu/g while no yeast and mould counts were observed in all three biscuit samples. No change in the microbial load has been observed in the biscuits samples due to storage for 3 months duration. The mean sensory scores for appearance and colour, sensory texture and odour for all the studied biscuit samples after 90 days storage were similar to the fresh biscuit samples. Results indicated no noticeable changes in the flavour and taste and overall acceptability of all the stored biscuit samples during 90 days storage period. This indicated that gluten free fruits and vegetable powders based biscuit can be successfully developed to satisfy the demands of fasting people as well as individuals suffering from celiac disease.

Table 6.

Effect of storage at room temperature on selected quality attributes of biscuits

| Parameters | Biscuits samples | Storage days | |||

|---|---|---|---|---|---|

| Fresh | 30 days | 60 days | 90 days | ||

| Moisture, % (n = 3) | Control | 4.29 | 4.28 | 4.27 | 4.31 |

| 100 | 4.20 | 4.22 | 4.25 | 4.26 | |

| 70:30 | 4.21 | 4.22 | 4.26 | 4.29 | |

| FFA, % (on whole sample basis), (n = 3) | Control | 0.14 | 0.14 | 0.16 | 0.18 |

| 100 | 0.14 | 0.14 | 0.15 | 0.18 | |

| 70:30 | 0.12 | 0.11 | 0.12 | 0.14 | |

| Sensory attributes (n = 9) | |||||

| Flavour and taste | Control | 8.06 | 8.11 | 8.10 | 8.09 |

| 100 | 7.56 | 7.62 | 7.58 | 7.60 | |

| 70:30 | 8.50 | 8.45 | 8.50 | 8.50 | |

| Overall acceptability | Control | 8.03 | 8.05 | 8.10 | 8.08 |

| 100 | 7.56 | 7.60 | 7.44 | 7.60 | |

| 70:30 | 8.50 | 8.40 | 8.60 | 8.50 | |

FFA free fatty acids

Conclusion

The study revealed that gluten free biscuits for fasting people can be prepared using potato powder or makhana powder up to 50 % with water chestnut powder. Biscuits with potato powder were comparatively softer than makhana powder based biscuits but the later showed better sensory acceptability. Biscuits with makhana powder were also better in protein content than biscuits with potato powder. Though all the levels of makhana powder in flour blends resulted in acceptable quality biscuits but the maximum mean scores for different sensory characteristics for biscuits developed utilizing 70:30 parts of water chestnut and makhana powders with good storability at room temperature for 90 days period indicated the commercial scope for manufacturing of good quality fruits and starchy vegetable powders based biscuits, which can be consumed during fasting and also by people with gluten allergy.

References

- AACC . Approved method of American Association of Cereal Chemists. St. Paul: Cereal Laboratory Methods; 1967. [Google Scholar]

- AOAC . Official methods of analysis. 17. Washington DC: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Bhatnagar S, Gupta SD, Mathur M, Phillips AD, Kumar R, Knutton S, Unsworth DJ, Lock RJ, Natchu UC, Mukhopadhyaya S, Saini S, Bhan MK. Celiac disease with mild to moderate histologic changes is a common cause of chronic diarrhea in Indian children. J Pediatr Gastroenterol Nutr. 2005;41:204–209. doi: 10.1097/01.mpg.0000172261.24115.29. [DOI] [PubMed] [Google Scholar]

- BIS . IS: 6273 part I and part II—1971. Guide for sensory evaluation of foods. Manak Bhawan: Indian Standard Institution; 1971. [Google Scholar]

- Indrani D, Savithri GD, Venkateswara Rao G. Effect of defatted soy flour on the quality of buns. J Food Sci Technol. 1997;34:440–442. [Google Scholar]

- Kar S, Roy P, Ghosh M, Bhattacharyya DK. Utilization of seed protein concentrates in making protein rich biscuits. Indian J Inf Sci Appl. 2012;2(1):7–14. [Google Scholar]

- Kent NL. Technology of cereals. An introduction for students of food science and agriculture. 3. Oxford: Pergamon Press; 1984. p. 86. [Google Scholar]

- Kulkarni KD, Govinden N, Kulkarni D. Production and use of raw potato flour in Mauritian traditional foods. Food Nutr Bull. 1996;17(2):148–156. [Google Scholar]

- Mridula D. Physico-chemical and sensory characteristics of β-carotene rich defatted soy fortified biscuits. Afr J Food Sci. 2011;5(5):305–312. [Google Scholar]

- Mridula D, Sharma M. Composite and fortified flours. In: Gupta RK, Bansal S, Mangal M, editors. Health foods: concepts, technology and scope—vol-I. New Delhi: Biotec Books; 2012. pp. 317–344. [Google Scholar]

- Mridula D, Naveen Kumar M, Jain D, Tyagi SK, Rai DR. Effect of addition of beetroot powder on physical properties and acceptability of defatted soya flour fortified biscuits. Indian J Nutr Diet. 2009;46(2):59–69. [Google Scholar]

- Mridula D, Jain R, Singh KK. Quality, acceptability and shelf life of micronutrient fortified Indian traditional sattu. J Agric Eng. 2009;46(2):26–32. [Google Scholar]

- Mridula D, Jain R, Singh KK. Effect of storage on quality of fortified bengal gram sattu. J Food Sci Technol. 2010;47(1):119–123. doi: 10.1007/s13197-010-0006-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oliveira DM, Reis KC, Pereira J, Graduacao EM. Agronomia/UFLA, Lavras, MG, Brazil. Rev Bras Armazenamento. 2006;31(2):125–135. [Google Scholar]

- Puste AM. Agronomic management of wetland crops. Ludhiana: Kalyani Publishers; 2004. [Google Scholar]

- Sciarini SL, Ribotta DP, León EA, Pérez TG. Influence of gluten-free flours and their mixtures on batter properties and bread quality. Food Bioprocess Technol. 2008 [Google Scholar]

- Singh GD, Riar CS, Saini C, Bawa AS, Sogi DS, Saxena DC. Indian water chestnut flour-method optimization for preparation, its physicochemical, morphological, pasting properties and its potential in cookies preparation. LWT Food Sci Technol. 2011;44:665–672. doi: 10.1016/j.lwt.2010.09.015. [DOI] [Google Scholar]

- Sowbhagya CM, Bhattacharya KR. Lipid autoxidation in rice. J Food Sci. 1976;41:1018–1023. doi: 10.1111/j.1365-2621.1976.tb14380.x. [DOI] [Google Scholar]

- Thakur BR, Arya SS. Packaging requirements and stability of fried wheat snacks (Trisnacks) J Food Sci Technol. 1990;27(2):76–81. [Google Scholar]

- Thapar VK, Sehgal VK, Shashi P. Post harvest quality analysis of foodgrains—research bulletin. Ludhiana: Department of Processing and Agricultural Structures, Punjab Agricultural University; 1988. pp. 13–14. [Google Scholar]

- Wade T (2008) As other staples soar, potatoes break new ground, reuters

- Yachha SK, Misra S, Malik AK, Nagi B, Mehta S. Spectrum of mal absorption syndrome in north Indian children. Indian J Gastroenterol. 1993;12:120–125. [PubMed] [Google Scholar]