Abstract

Traditional packaging systems are refused since these systems do not provide any information about the quality of food products to the consumers and manufacturers at any stage of supply chain. The essence of a new technology to monitor the food spoilage from farm to fork is emerged to reduce hazards such as food borne diseases. Moreover, the food quality monitoring systems clarify the main factors in food wastage during supply chain. Intelligent packaging is employed to provide information about the history of food handling and storage to enhance food products quality and meet consumer satisfactions. Meat is one of the most perishable foods which causes sever illnesses in the case of spoilage. Variety of indicators and sensors have been proposed to warn about meat spoilage in meat industry. In this paper an overview of proposed approaches as well as commercial technologies to monitor the quality of meat during storage and transportation is presented. Furthermore, the existing technologies are compared in the sense of advantages and disadvantages in meat packaging applications.

Keywords: Intelligent packaging, Meat industry, Sensors, Indicators, Food spoilage

Introduction

Recently the demand for strategies to increase the food products shelf-lives and real time quality monitoring is increased by consumers and manufacturers. Such food products are included but not limited to frozen products, processed foods and take-out foods. Active packaging methods have been used to change the condition of the packed food to improve the safety and sensory properties and extend it’s shelf-life. Active packaging refers to the active materials, such as moisture absorbent, scavengers, antimicrobial and antioxidants releasing systems, that are used in the food surrounding environment to enhance the performance of packaging system. One of the most popular active packaging technologies is modified atmosphere packaging (MAP) (McMillin 2008), which acts as a barrier against contaminants and plays a crucial role in the selection of spoilage micro-organisms by increasing the shelf life of foods. MAP packages do not provide any individual knowledge of freshness by visual inspection to alert contamination in the packages during packaging process or eventual alterations in the cooling chain. Unfortunately, the active packing neither records nor presents any information about the food quality before or at the point of consumption. The essence of monitoring or checking the quality of food from farm to fork is increased due to the consumer satisfactions, reduction of food wastage and food poisoning. Intelligent packaging or “smart packaging” is proposed to carry out such tasks. Intelligent packaging is a packaging system to detect, sense and record any deterioration inside the food package to enhance the safety, improve quality and warn about possible problems during food transport and storage (Yam et al. 2005).

Many smart packaging technologies based on sensors have been proposed during last decades (Avella et al. 2011; Mukhopadhyay et al. 2006; Watanabe et al. 1984; Abad et al. 2007; Along et al. 2010; Kuswandi et al. 2012a; Borchert et al. 2013; O’Farrell and Sheridan 2007; O’Grady and Kerry 2008; Duncan 2014; García-gonzález et al. 2014; Huang et al. 2011; Murkovic et al. 2014 2014; Salinas et al. 2014; Xiao et al. 2014; Xiao-wei et al. 2014). The term sensor is defined as a device including control and processing electronics and software to measure physical or chemical quantity (Kuswandi et al. 2011). Smart packaging utilizes chemical sensor or biosensor to monitor the quality and safety of food from the producers to the costumers. This technology can lead to a variety of sensor designs, which are suitable for monitoring food quality and safety, such as freshness indication, pathogens, leakage, carbon dioxide, oxygen and pH detection as well as temperature fluctuations. Thus, a real time quality control and safety system is introduced, which has great potential in the development of new sensing systems integrated in the food packaging systems to be beneficial to both consumers and food manufactures (Hernndez-Czares et al. 2010).

Among the vast category of food products, meat is one of the highly perishable foods, which unless properly stored, processed and packaged, spoils quickly. The meat products are decomposed naturally and contain high fat and water. Such products are susceptible to spoilage by both lipid oxidation and microbial contamination. The spoiled meat is hazardous due to microbial growth and consequently distribution of food borne illness. Conventionally, sensory evaluation, chemical experiments including microbial growth evaluation are two key techniques to check the meat quality degradation. The meat sensory evaluation is usually based on color, flavor, stickiness and elasticity of it’s texture (Bejerholm and Aaslyng 2004). This traditional method is refused due to human errors that may arise from expert panels. Moreover, this method is destructive and suffers from low efficiency and precision. Traditional microbiological tests including bacterial counts or concerning microbial population are very time consuming and far from real time monitoring, where costumers are interested to get information on the quality of on-shelf meat products. Therefore, a real time system integrated into the packaging system would be highly desired.

The combination of knowledge in electrochemistry, biochemistry, physics leads to the development of sensors as new analytical tools for meat quality monitoring. These sensors have been proven to be fast, reliable and generating sensitive measurements with lower cost than that of using traditional methods (Vernat-Rossi et al. 1996, Yano et al. 2001). However, most of the sensors which have been developed for biological laboratory and environmental applications are quite different from those required for meat packaging systems.

The aim of this paper is to highlight an overview of existing commercial sensors for monitoring meat stability and it’s shelf-life. We discuss about sensors that have been applied to monitor different kinds of meat, such as pork, fish, beef and shrimp. In addition, we also review the integration of these sensors to the meat packaging technology and compare their advantages and disadvantages in meat industry.

Sensors for meat quality monitoring

Odor is one of the most important parameters for evaluating the freshness of meat. The characteristics of volatile compounds in each meat product is different therefore each meat has its own characteristic odor. Studies show that the biogenic amines, such as tyramine, tryptamine, putrescine, cadaverine, were significantly related to traditional quality indices (total bacterial counts, pH, and TVBN1) in meat products (Xiao et al. 2014).

Sensing the gaseous metabolites can give information on the status of the stored meat products. This forms the hypothesis of developing electronic nose sensing systems, which shows promises for developing rapid and nondestructive sensors for meat safety applications (Balasubramanian et al. 2012). Electronic nose (e-nose), also known as artificial olfactory, is a simulation of biological functions to identify some simple or complex odor (Gardner and Bartlett 1994). A typical e-nose system contains a selective chemical sensor array, a signal processing and a pattern recognition subsystem. The sensors in the sensor array are sensitive to different substances, therefore an e-nose can extracts the whole information of substances for identification (Hong et al. 2012). The colorimetric sensor array (e-nose) is designed based on two fundamental requirements: First, the chemoresponsive pigment, which must contain center (functional group) to interact strongly with analytes, and then this interaction center must be strongly coupled to an intense chromophore. The first requirement implies that the interaction must not be simple physical adsorption, but rather must involve other, stronger chemical interactions (Xiao et al. 2014). Chemoresponsive pigments are those pigments that change color, in either reflected or absorbed light, upon changes in their chemical environment. In this section an overview of sensors/e-nose, which have been developed for quality monitoring of meat products is presented.

The freshness of beef degrades because microbial spoilage and biochemical reactions occur during storage. The main ingredients like protein, fat and carbohydrates are decomposed by enzymes and bacteria, producing odor: the protein will be decomposed into ammonia, hydrogen sulfide, ethyl mercaptan; the fat will be decomposed into aldehydes and aldehyde acids; the carbohydrates will be decomposed into alcohols, ketones, aldehydes, and carboxylic acid gases (Kong and Ma 2003).

Image processing is used to assess the fish freshness. Images are taken from fish muscles to identify regions of interest. Based on the color of the fish muscles, these regions processed to produce a RGB color index (N 2008, Muhamad et al. 2009). One of the drawbacks of this method is that the relationship between color processing and the degree of freshness can not be determined accurately. E-noses are shown to be a proper choice for fish freshness assessment and a variety of integrations of e-nose systems with data mining methods have been proposed for olfactory detection in fishery products (Li and Olafsdottir 2002, Barbri et al. 2007). The major cause of spoilage in most seafood products are microorganisms. The specific spoilage organisms, which are a small group in microbial community, lead to the offensive off-flavors associated with seafood spoilage (Olafsdottir et al. 2004). Volatile compounds such as ammonia, dimethylamine, and trimethylamine, which are also known as TVBN, are products of microbial degradation and are considered as potential indicators of fish spoilage (Hamada-Sato et al. 2005).

Optoelectronic sensors

An optoelectronic array of sensors is developed for monitoring fresh pork inside MAP (Salinas et al. 2014). The array is based on the combination of pH indicators and selective chromogenic reagents supported on inorganic materials with diverse acidities and topologies. This approach results in a final array containing seven materials as a suitable system capable of monitoring meat spoilage of fresh pork under MAP atmosphere via simple color changes. Moreover, freshness over time is assessed via microbial counts and sensory analyses. The optoelectronic array is able to differentiate samples with a 7-day difference in storage time offering characteristic colorimetric fingerprints. This sensor array is not economical to be commercialize into packages, since its coupled with microbial counts and sensory analysis, which are not easy to implement in real time.

A novel optoelectronic nose to monitor chicken meat aging is developed by (Salinas et al. 2012). It is based on 16 pigments prepared by the incorporation of different dyes (pH indicators, Lewis acids, hydrogen-bonding derivatives, selective probes and natural dyes) into inorganic materials (UVM-7, silica and alumina). The color changes of the sensor array were characteristic of chicken aging in a modified packaging atmosphere (30 % CO(2)-70 % N(2)). The chromogenic array data were processed with qualitative (PCA) and quantitative (PLS) tools. The PCA statistical analysis showed a high degree of dispersion, with nine dimensions required to explain 95 % of variance. Despite this high dimensionality, a tridimensional representation of the three principal components was able to differentiate aging with 2-day intervals. Moreover, the PLS statistical analysis allows the creation of a model to correlate the chromogenic data with chicken meat aging. The model offers a PLS prediction model for aging with values of 0.9937, 0.0389 and 0.994 for the slope, the intercept and the regression coefficient, respectively, and is in agreement with the perfect fit between the predicted and measured values observed. The results suggest the feasibility of this system to help develop optoelectronic noses that monitor food freshness

Colorimetric sensors

The employment of natural pigments in colorimetric sensors is advantageous, because such sensors do not have chemical effect on the packaged meat. Xiao et al. (2014) developed a colorimetric sensor array based on four natural pigments, that are extracted from spinach, red radish, winter jasmine, and black rice for the sensitive detection of amines generated in pork meat during its gradual abiotic decomposition. Based on the investigation into the structure and properties of pigment molecules, they discover that black rice extract is the most sensitive of the extracts. This is due to the better interaction between the carbonyl and hydroxyl groups of anthocyanin molecules in the black rice extract with the amines generated during spoilage.

The fish spoilage on the basis of the presence of total volatile basic nitrogen (TVBN) is monitored by a colorimetric dye-based sensor and indicator (Byrne et al. 2002, Pacquit et al. 2007). The system is deigned to be as on-package sensor which, contains a pH sensitive dye, bromocresol green, entrapped within a polymer matrix. However, one of the short comings is leaching of the dye that may occur over time, which resulted in inaccurate responses or false-positive indications as a fish freshness sensor. Consequently, the occurrence of dye leaching needs to be investigated when this sensor system is used.

An improvement to the problem of leaching in colorimetric dye-based sensor is proposed by Kuswandi et al. (2012b) for fish freshness monitoring using polyaniline. Polyaniline (PANI) is a polymer that changes conductivity and color with change in pH as a result of changes in the degree of protonation of the polymer backbone, making it useful as a leach-free visual sensor for volatile bases such as TVBN. As the pH increases, due to the basic spoilage volatiles amines produced gradually in the package headspace, the color of PANI film or sensor changes from green to blue, which is easily visible to the naked eye.

Zaragozá et al. (2012) evaluate a new optoelectronic nose composed by eight sensing materials prepared by the incorporation of pH indicators and chromogenic reagents selective to metabolites into inorganic materials (aluminum oxide and silica gel) in the shelf-life assessment of fresh sea bream in cold storage. Physicochemical and microbial analyses were carried out periodically throughout the cold storage, as well as color measurements on the colorimetric array. The results obtained using the chromogenic array were in accordance with those obtained from physicochemical and microbial analyses, which showed a clear loss of freshness from day 4 to day 7. The authors show that the potential usefulness of colorimetric reagents for detection of sea bream spoilage.

Enzyme sensors

A very first enzyme sensor specific for hypoxanthine (Hx) using immobilized xanthine oxidase-membrane and an oxygen probe is developed by Watanabe et al. (1983). Xanthine oxidase (E.C. 1.2.3.2.) was covalently immobilized on a membrane prepared from cellulose triacetate, 1,8-diamino-4-aminomethyloctane, and glutaraldehyde. Hx is oxidized to uric acid by the immobilized enzyme, the output current of the oxygen probe decreasing due to oxygen consumption. A linear relationship was obtained between current decrease and Hx concentration in the range 0.061.5 mM. The enzyme sensor could be used for more than 100 assays without decrease of output current After 30-day-storage at 5C, no remarkable decrease of output current was observed. The enzyme sensor system was applicable to the simple, rapid, and economical determination of Hx in several fish meats including sea bass, saurel, mackerel, yellowfish, and flounder.

An enzyme sensor based on combination of an oxygen electrode and xanthine oxidase (XO) is developed to measure the pork freshness by determining the hypoxanthine (Hx) content in pork meat at different time sequences (Hernndez-Czares et al. 2010). enzyme sensors demonstrate a good sensitivity to the detection of Hx, in comparison with those obtained by high performance liquid chromatography (HPLC). Furthermore, the easy preparation and operation of both enzyme sensors suggest them as a reliable, rapid and economical alternative to the simple or multiple Hx measurements in a short time.

E-noses

E-noses vary in sensitivity to volatile compounds, therefore a low sensitive e-nose might not detect the spoilage in fish products with low concentration of contamination. A sensitive e-nose comprising a colorimetric sensor array is developed for fish freshness evaluation (Huang et al. 2011). Nine chemically responsive dyes are chosen according to their sensitivity to volatile compounds, which occurs during spoilage in fish. The colorimetric sensor array was made by printing selected dyes on a reverse phase silica gel plate. A color change profile for each sample was obtained by differentiating the images of the sensor array before and after exposure to the odor of sample. Huang et al. (2011) employed principal component analysis to analyze the digital data representing the color change profiles for the fish samples. Then the samples were classified into three freshness groups using a radial basis function neural network, with an overall classification accuracy of 87.5 %. This research demonstrates that the system is useful for early detection of spoilage in fish and perhaps other food containing high protein.

An e-nose instrument combined with chemometrics is developed to predict the physical and chemical indexes (sensory scores, TVBN and microbial population) of beef (Hong et al. 2012). The generated data by e-nose, which are analyzed by chemometrics and pattern recognition methods, indicate that it is possible to use the proposed e-nose to discriminate and predict physical and chemical indexes of beef freshness. Furthermore, the results show that the e-nose has a great qualitative distinguish ability (with an accuracy of 96.19 %) of the beef samples, which have been stored at 2∘C in different time periods. However, the structure of the proposed e-nose is not suitable to be applied to the packaging systems.

Blixt and Borch (1999) proposed an e-nose to analyze the composition of the volatile compounds of vacuum-packaged beef to determine spoilage. The results demonstrate that the degree of spoilage could be determined quantitatively. However, no information about specific compounds is obtained by this method. The analysis of volatile compounds using this electronic nose provides a pattern, which is composed of the signals from the different sensors, that reflects the spoilage odor. The authors show that possible variation in the spoilage odor can happen due to different bacterial populations, which has been taken into account by using meat samples originating from different slaughterhouses. In fact, it is shown that the e-nose can distinguish between spoiled meat from different slaughterhouses.

A fast e-nose is developed to detect bacteria and microbes in beef and sausage samples efficiently (Abdallah et al. 2013). In the first phase, the standard microbiological method is employed to consider total viable counts (TVC) in fresh and frozen beef samples using the e-nose. In the second phase, the e-nose is applied to beef before and after contamination with different bacterial pathogens separately. The results show that the proposed e-nose can detect the TVC in different beef and sausage samples and quantify the volatile organic compounds rapidly. Although, the validity of results obtained by this e-nose must be checked by further experiments.

The beef samples, which are stored at two different temperatures are classified by a metal oxide sensor-based e-nose system (Panigrahi et al. 2006). The collection of signals from the e-nose are pre-processed to reduce the noise and then processed to build statistical-based classification models. The classification models classified meat samples based on the microbial population into “unspoiled” (microbial counts ) and “spoiled” (microbial counts ). The highest classification accuracy of 96 % for the beef sample stored at 4 ∘C is reported in the experimental results. Despite of its accuracy, this e-nose is design in a such way that makes it to be applicable in food and safety laboratories, where the processing time is far from online applications.

Oxygen sensors

Oxygen sensors are less complicated than e-noses and easy to be adopted into the meat packaging industry. These sensors are employed to compare the oxygen content in MAP and vacuum packed beef as a non-destructive method to check the impact of oxygen content on lipid oxidation (Smiddy et al. 2002a). The oxygen sensors monitor the changes in oxygen levels in all samples, which have been stored at 4 ∘C for 15 to 35 days. The initial oxygen content of 1.15 % in MAP and 0.07 % in vacuum beef samples is reported, which increased to 1.26 % in MAP and 0.55 % in vacuum beef samples. The results demonstrate that the samples containing greatest levels of oxygen are the most oxidized. Moreover, it suggests that a certain level of oxygen is required for lipid oxidation and the extra oxygen has no effect on further lipid oxidation. The commercialized version of oxygen sensors is cheap and suitable for large scale production to be used in each individual meat package.

Dye-based sensors

A chemical sensor based on natural dyes of curcumin is introduced to recognize volatile inorganic amines, which are produced during bacterial growth in shrimp samples (Kuswandi et al. 2012a). The major yellow pigment are extracted from turmeric, curcumin, which is used as a natural sensing reagent. This reagent is immobilized on bacterial cellulose membrane (biopolymers) using absorption as a simple method that enables the mass production of low-cost sensors. Thus, all the sensing materials are edible and suitable for food applications. The curcumin/bacterial cellulose membrane is used as an on-package sticker sensor for a visual detection of shrimp spoilage. The proposed sticker sensors could offer an extra analytical device to both the fish industries and retailers who are interested in approaches and devices that are safe, commercially affordable, simple, rapid, disposable, non-destructive, and with real time applications.

A novel sticker sensor has been fabricated based on methyl red, and tests have been conducted by Kuswandi et al. (2014) to detect the freshness of broiler chicken cuts. Methyl red was immobilized onto a bacterial cellulose membrane via absorption method. The methyl red/cellulose membrane as a freshness sensor worked based on pH increase as the basic spoilage volatile amines produced gradually in the package headspace, and subsequently, the color of the sensor will change from red to yellow for spoilage indication, which is easily visible to the naked eye. The results show that the sticker sensor could be used to determine the degree of chicken cut freshness, as the relationship between the color change of methyl red as a sensor response and the chicken cut freshness follows a similar trend. Therefore, the spoilage of the chicken cut could be detected visually. A sticker sensor indicates the chicken cut freshness by its color change in real time. Thus, the sticker sensor can be used as an effective tool for monitoring the microbial quality of packaged fresh poultry meat. The methyl red/cellulose membrane was successfully used as a sticker sensor for the real-time monitoring of chicken cut freshness in ambient and chiller conditions.

Smart packaging in meat industry

The mentioned intelligent sensing methods are accurate in determining meat degradation (microbiological, sensorial and detection of metabolite concentrations), however, they are time-consuming, employ expensive instrumentation, require qualified panels and are not suitable to be used in meat packaging systems. These procedures are generally suitable for food safety agencies, but not to be used in supermarkets, at consumer’s homes or individually in each piece of meat (Salinas et al. 2014). Therefore, easy-to-handle disposable systems, which are usually economical, versatile and can be integrated into the package are the most promising ones. Moreover, using the colorimetric sensors, which can be printed on the package, where the changes in color can be easily measured using cameras or other image-capturing systems, or in some cases by the naked eye (Kuswandi et al. 2011).

Application of sensors to food packaging systems has been caught the manufacturers attention for a long time, but unfortunately its commercialization is still in the beginning stages. Although many benefits of this innovative technology are well known in the food industry, those in the industry are still reluctant to apply these technologies. Some regulations should be considered in food packaging for instance, the materials or articles which are used in food packaging should not transfer their constituents to food, which might cause a danger to human health, moreover, they should not cause an unacceptable change in food composition or cause deterioration of the organoleptic characteristics.

Although intelligent packaging technology is already being successfully implemented in some countries such as Australia, but its development and implementation have been delayed due to legislative restrictions, a lack of consumer acceptance, and the possible economic and environmental impact (Kuswandi et al. 2011). Some sensors in food packaging industries, which are recently commercialized, are discussed in this section.

Indicators

Indicators are devices that give some information about the presence or absence of a substance or the degree of interaction between two substances by changing in characteristics, like color. The difference between sensors and indicators is that the latter do not have receptor and transducer components and instead communicate information through direct visual changes (Kuswandi et al. 2011). Three categories of well known indicators are time temperature, gas and freshness indicators.

Time temperature indicators

One of the most substantial environmental factors, which its fluctuations lead to deterioration of meat quality and safety is temperature. The loss of hygienic, nutritional, and sensory qualities or spoilage of meat significantly depend on both time and temperature. Therefore, time temperature indicators are proposed to monitor and record the time in which the temperature is fluctuated during supply chain.

A time temperature indicator is a device that can show an easily measurable, time temperature-dependent change that reflects the full or partial temperature history of a product to which it is attached. TTIs, which are places within or outside of the meat package, should indicate whether the package had been improperly exposed to high temperatures, as well as the effect of this exposure, based on its duration, and usually does not provide information about the quality of the product within the package. TTIs are design based on the storage temperature, which is required for a particular product, thus record the time in which the product has been stored beyond a threshold temperature (Vaikousi et al. 2009). This allows one to measure an estimation of microbial growth inside the package.

TTIs usually are small, low cost, reliable, and can be easily integrated into packaging system, and they should not themselves reduce the shelf life of the product by exposing it to environmental factors (light, air pollutants and humidity) or mechanical stresses (pressure and friction). They should also provide simple, continuous, and understandable indications for producers, wholesalers, retailers and consumers, which can be measured both visually and electronically, furthermore they should have no deleterious effects on health and environment (Taoukis 2010).

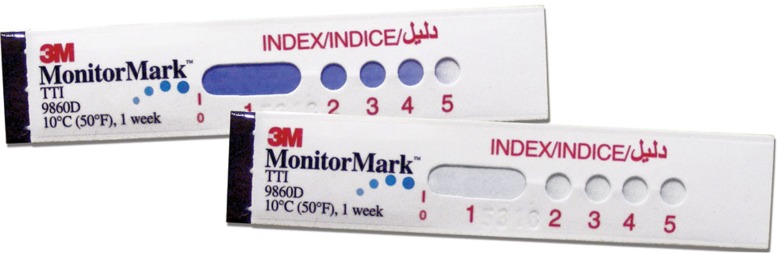

3M company (founded in 1902, US) has developed Monitor Mark time temperature indicator to monitor the storage conditions of foods in supply chain. The device is a non-reversible record of temperature exposure that is accurate and easy to interpret (see Fig. 1).

Fig. 1.

Monitor Mark TM TTI

The product specifications are as follows:

Rectangular, flat laminate with layers of paper, film, adhesive and other components,

Blue compound run-out to estimate how long your product was above the threshold temperature,

Removable film activation strip,

Pressure-sensitive adhesive allows attachment to almost all clean, dry surfaces.

The device works based on the time temperature-dependent diffusion of a colored fatty acid ester through a porous wick indicator track strip made of high quality blotting paper (Taoukis and Labuza 1989).

To prevent premature response, MonitorMarkTime Temperature Indicators (including dual temperature indicators) must be conditioned prior to removing the activation strip and activating the indicators. This insures that the response chemical is solid and not liquid prior to removing the activation strip. Condition indicators for a minimum of two hours in a suitable refrigerator, freezer or chamber at or below the temperature shown in the product table. Once conditioned and ready for use, the indicators can be maintained at any temperature below their critical temperature.

The device is activated by simply pulling the side tab up and removing the activation strip. This allows contact between the reservoir pad and the end of the porous wick indicator track. At this point the indicator track (visible under the viewing windows) is a plain white color. Upon exposure to temperatures exceeding the critical response temperature, the chemical in the reservoir melts and begins to migrate along the track. Thus, blue coloring first appears at the left edge of the first viewing window and gradually moves left to right to the end of the track. The rate of the blue color movement is dependent on the temperature.

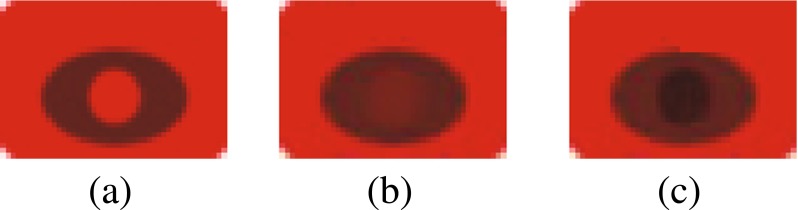

Fresh-Check®; time temperature indicator, produced by TEMPTIME Corporation, is a self-adhesive device that is specifically formulated to match the shelf life of the food products to which it is affixed. The active center circle of the Fresh-Check darkens irreversibly faster at higher temperatures and slower at lower temperatures, thus it is easy to see when to USE or NOT USE the food product within the product date codes. As the active center is exposed to temperature over time it gradually changes color to show the freshness of the food product, see Fig. 2.

Fig. 2.

Fresh-Check®;. a ready to use, b use as soon as possible and c expired

An intensely colored polymer is produced through 1, 4-polymerization of disubstituted diacetylene crystals. The changes in color can be measured as a decrease in reflectance using a laser optic scanning device supplied by the manufacturer. The collected data by the optical scanning device can be processed for further decision making. These types of indicators are self-activated and therefore must be stored at very low temperatures (Fig. 3).

Fig. 3.

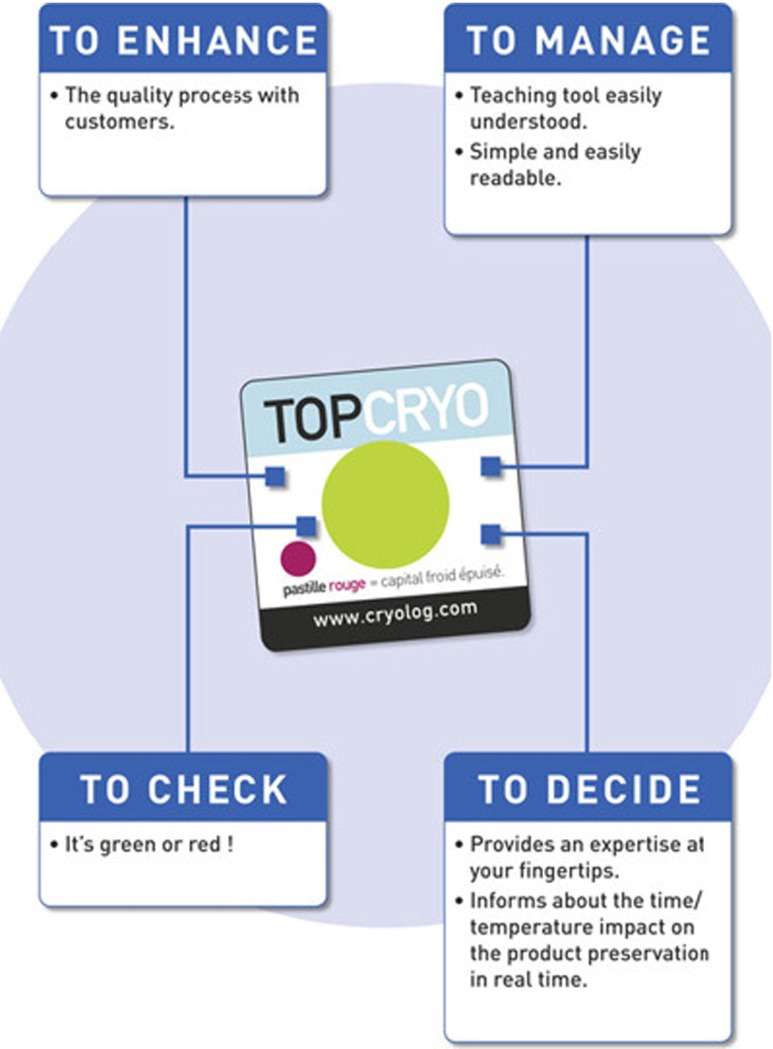

TopCryoTM properties

TRACEO company introduced TopCryo intelligent tracers as a time temperature indicator. This device is a microbiological, simple and affordable time temperature indicator that interprets the time/temperature impact on the food preservation by a visible, easily readable and irreversible change. Some of the benefits of TopCryo are:

Proof of the cold chain respect in real time,

Interpretation of the time/temperature impact on the foodstuffs preservation,

Quick information provided by a color code,

Teaching tool easily understood,

Affordable option compared to the usual cold chain monitoring means,

Self-adhesive label easy to implement.

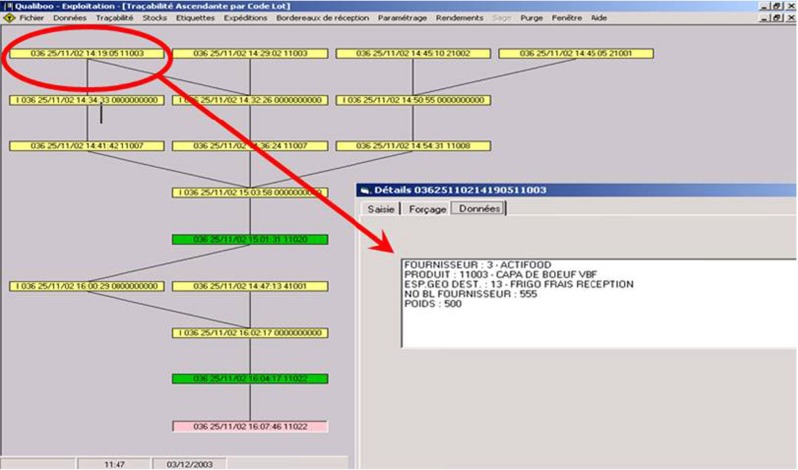

TopCryo device is determined by the user based on his time/temperature specifications. A wide range spanning of Integrators have been developed to cover temperatures between 2 ∘C and 12 ∘C from a few hours up to 12 days and integrating cold chain breaks at ambient temperature. Moreover, the device is communicating by QualiBoo®; system in real time. All information and data are recorded in real time on a computer system. All workstations identified as key station in terms of traceability are equipped with an interactive terminal, OualiBox, composed by a barcode reader and a printer (Fig. 4).

Fig. 4.

QualiBoo®; system

The QualiBox generates an event record in the form of a barcode label. The operator in charge of the next operation will only have to scan the barcodes of the previous ones to ensure traceability. This system allows to correlate events between one another. It enables to find history, use or location step by step, i.e. from delivery of raw materials up to shipment of end products.

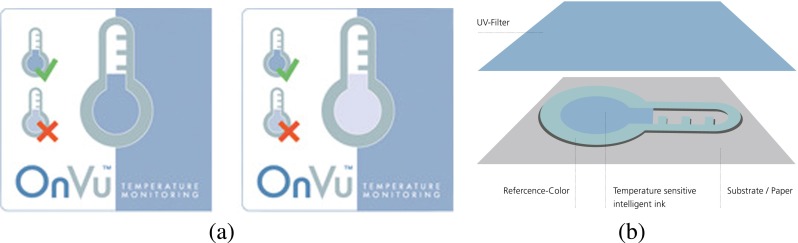

OnVu is a simple, intelligent indicator technology that alerts costumers weather food products have been exposed to unsafe temperature. This device can be used to monitor fresh or frozen products in cold supply chain from production line to retailers. OnVu is based on a printable, intelligent, temperature-sensitive ink technology. This offers a very low cost indicators, at only a few cents per unit. OnVu indicator is automatically applied to the inner or outer packaging on the production line at the point of packaging. Either a separate label is applied, or OnVu indicator is integrated into an existing label. Both approaches can be easily implemented since OnVu is based on a normal printing ink.

The indicator is activated by exposing it to UV light on the packaging line, causing it to turn dark-blue. From that moment on, the indicator monitors the chill or frozen chain. As time passes, if the cold chain is interrupted, the color pales (see Fig. 5a). The heart of OnVu is an intelligent temperature sensitive ink, which lies in the middle of the bulb. Then a very thin layer of UV filter is protecting the device from undesirable activation. The structure of OnVu is illustrated in Fig. 5b .

Fig. 5.

OnVuTM indicator. a color changes, b structure

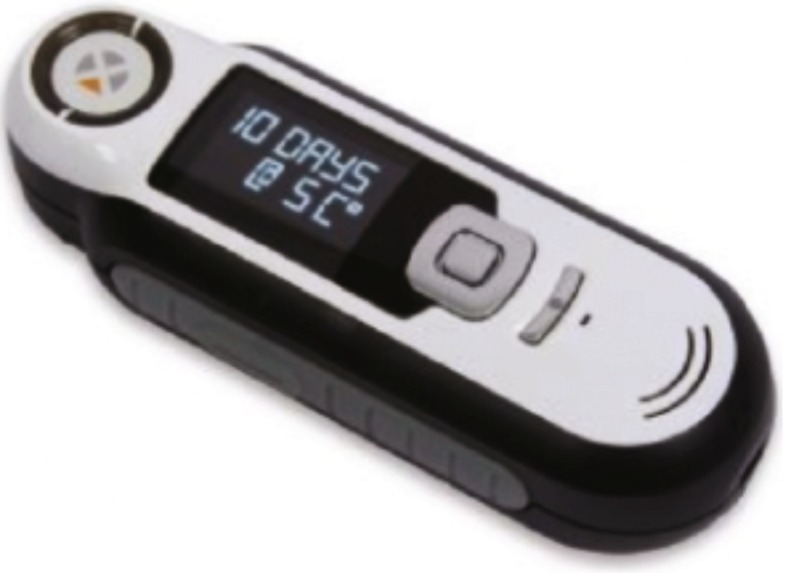

The status of the indicator can be checked by naked eye and without requiring any specialized or added equipment, however OnVu system can also be customized to deliver digitized information. A measurement device, see Fig. 6, has been specially developed for OnVu.

Fig. 6.

Measurement device for OnVuTM

Gas indicators

The gas which is produced due to lipid oxidation and microbial spoilage can change the gas composition in the package headspace. Therefore, gas indicators in the form of labels or printed on the packaging films can monitor the gaseous changes and warn about the safety and quality of the meat products. These indicators give information about the presence and absence of oxygen or carbon dioxide by changing in their color due to chemical or enzymatic reactions. The gas indicators usually printed or immobilized inside the package to have a direct contact with the gases which are produced during the spoilage.

Modified atmosphere packaging (MAP) has been defined as the replacement of air in a pack by a formulated mixture of gases, where the proportion of each component is fixed but no further control is exercised during storage. Oxygen and carbon dioxide are the major gases in MAP products, thus using gas indicators can contribute to have a controlled atmosphere packaging, where the composition of gases is continuously controlled throughout storage (Brody 2001).

A visual carbon dioxide indicator based on a chemical dye is developed to be integrated into polymeric films for packaging system. This non-destructive film not only gives information about the concentration of the CO 2 in the package but also detects the early spoilage. The system is based on a pH-dependent color change regardless of temperature. As the concentration of CO 2 changes it alters the pH, which consequently changes the color of the indicator (Hong and Park 2000).

Freshness indicators

A freshness indicator is an indicator in packaging system to show the quality of the products using microbial growth instead of indicating temperature deteriorations or package leaks (Smolander 2003). Microbial metabolites such as glucose, organic acids such as acetic or lactic acid, ethanol, volatile nitrogen compounds (e.g., trimethylamine in packed fish), biogenic amines, carbon dioxide, ATP degradation products, and sulfuric compounds are usually estimated to evaluate a product’s freshness.

To develop a freshness indicator successfully, it is vital to have the knowledge about the quality-indicating metabolites. The freshness indicator should be capable of reacting to these compounds with high sensitivity. Furthermore, the indicator system should comply with legislation since the indicator needs to be brought into contact either directly with the food product or with the package headspace (Smolander 2008). Hence the indicator generally needs to be placed inside the food package unless the packaging material is a breathable or gas-permeable wrap like that described by Miller et al. (2006). It is also essential to avoid false negatives, which are likely to dissuade producers from adopting indicators in real use (Kerry et al. 2006).

The Vanprob company developed Food freshTM indicators, which are a kind of timers that can be set to time out within a given “consume within” time frame, ranging from a few days to several weeks or months. They are a cost effective solution to the problem of storing food after opening (see Fig. 7). Food fresh indicator, which is illustrated in Fig. 7, can be applied to products such as jars, vacuum packed or cartons using a label applicator. The labels are made of PET and are less than 50 microns thick.

Fig. 7.

a Food fresh TM indicators, b Food fresh TM indicators color changes

An innovative label is produced by Insignia Technologies, NOVAS freshness indicator, which is easily incorporated into a film lid. This label is activated when the consumer opens the packet and triggers a timer to show a strong color change as the food within loses freshness.

Sensors

A sensor is a device that is capable of transmitting a continuous output signal. Most sensors consist of a receptor and a transducer. Receptors transform physical or chemical information into a form of energy, whereas a transducer converts this energy into a useful analytical signal i.e. electrical. Sensors have been widely used in biomedical and environmental applications, however these sensors are not applicable to food packaging due to restrictions such as food safety. High development costs and limited demand are some of the obstacles to extensive commercial production of such sensors and their adoption in food packaging industries.

Gas sensors

Gas sensors are devices that respond reversibly and quantitatively to the presence of a gaseous analyte by changing the physical parameters of the sensor, and are monitored by an external device (Kerry et al. 2006). An optochemical CO 2 sensor (Borchert et al. 2013) which uses a phosphorescent reporter dye and a colourimetric pH indicator showed robust optical responses to CO 2. The sensor is designed as a film coatings to be applicable in meat packaging. The results show that the sensor is stable for at least 14 days at 4 ∘C and 50 days at 20 ∘C, however they deteriorate within 7 days by loosing color and sensitivity to CO 2 at room temperature.

Most of the well known gas sensors such as carbon dioxide sensors are susceptible to consumption of analyte (oxygen) (Trettnak et al. 1995). Due to this fact, optical oxygen sensors are superior over conventional electrochemical sensors, such as metal oxide semiconductor field effect transistors, organic conducting polymers, and piezoelectric crystal sensors. The optical oxygen sensors do not consume oxygen, are not susceptible to stirring, are not affected by electromagnetic interference, have extremely high spatial resolution, are employed in hazardous areas, are capable of remote measurements, and are capable of measuring gas and liquids. The use of a reversible optical sensor incorporating a phosphorescent dye that is quenched by molecular oxygen has been well documented in meat packaging applications. These include, MAP and vacuum packed beef (Smiddy et al. 2002a), cooked meats (Smiddy et al. 2002c) and MAP and vacuum packed chicken (Smiddy et al. 2002b).

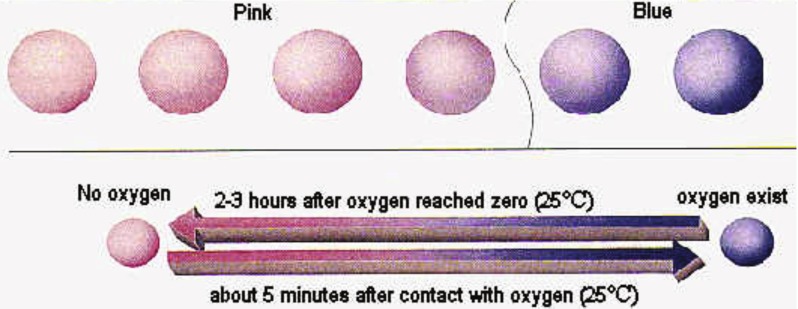

The IMPAK Corporation (Los Angeles, CA) developed a tablet as an oxygen indicator known as the Tell-Tab. The indicator is maintained in a cool, dark place free from oxygen, usually achieved by utilizing oxygen absorbing packets. Once the product is exposed to oxygen within the package, it turns from its original pink color to blue or purple, and as the level of oxygen is reduced a reversion of the color occurs. The changes in color can be detected by the naked eye, but there is no specific device to measure the degree of changes in color digitally, where the collected data can be stored for further investigations (Fig. 8).

Fig. 8.

Oxygen indicators tablets (Tell-Tab TM) color changes

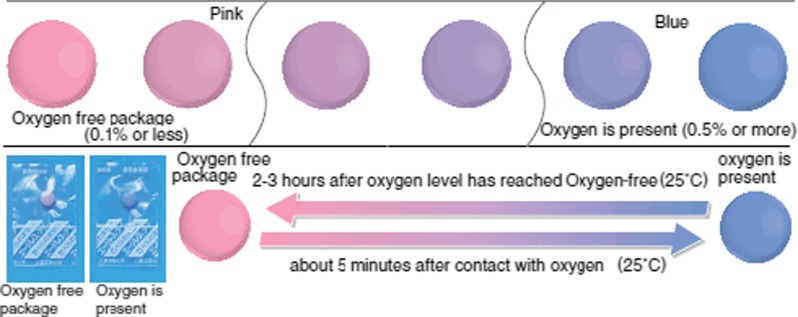

Ageless EyeTM, made by the Mitsubishi Gas Chemical Corporation, is also the producer of oxygen-scavenging sachets (Ageless). Ageless Eye sachets contain an oxygen indicator tablet in order to confirm the normal functioning of Ageless absorbers (see Fig. 9).

Fig. 9.

Ageless-eye TM oxygen indicator color changes

If the oxygen is absent in the headspace (≤0.1 %) the indicator displays a pink color. Once the oxygen is present to the system (≤0.5 %), it turns blue (Ahvenainen and Hurme 1997).

Specialized pigments are developed as CO 2 indicator by Insignia Technologies. These pigments, see Figure 10, can be used in plastic packaging which shows a clear color change when packaging has been damaged for products that are packed in a modified atmosphere or MAP. This allows manufacturers and retailers to remove those products from the supply chain before they even reach the supermarket shelf.

Fig. 10.

Pigments as CO 2 indicator

Biosensors

A biosensor comprises a biological recognition element (e.g. antibodies, enzymes, lectins, receptors and microbial cells) and a signal transduction element (e.g. optical amperometric, acoustic and electrochemical), which is connected to a data acquisition and processing system. Thus, the signal from the biological element is converted to an electrical signal. The transducer may be electrochemical (amperometric, potentiometric, or conductometric/impedimetric), optical, piezoelectric, or calorimetric. An ideal biosensor should have sensitivity, precisions, accuracy, as well as being economical, small and easy to understand and operate.

Biosensors have been applied in various fields such as food processing industries, environmental diagnostics, medical care (both clinical as well as laboratory use), security and defense, and biotechnology. Biosensors are applied to pathogen detection and safety systems in the food packaging industry (Alocilja and Radke 2003), particularly, they have been effectively used to indicate the freshness of fish and meat. Biosensors can be used as a small analytical tool integrated into the meat package to detect biogenic amines. The increase in diamines in poultry meat can be detected with a putrescine oxidase reactor combined with an amperometric hydrogen peroxide electrode (Ahvenainen 2003). This system can also be applied in the detection of histamine from rainbow trout meat and biogenic amines from fish muscles.

Toxin Guard TM is developed by Toxin Alert (Ontario, Canada) and the Food Sentinel Systems (SIRA Technologies, Pasadena, CA) as a visual sensor based on antibody-antigen reactions. The sensor is integrated into polymer packaging films that indicate the presence of pathogenic bacteria. The antibodies are secured to a thin layer of flexible polymer film and changes in its shape or color are brought about by reaction with the target pathogen. This immunoassay test has already been successfully applied commercially on a conventional food wrap.

The sensor requires spacial handling and its performance is not degraded due to environmental factors such as heat, cold or microwave treatments, moreover the sensor remains stable for at least nine months. However, the disadvantage of this system is that it only detects gross contamination and is insensitive in detecting very low levels of pathogens that can cause disease.

SIRA Technologies developed an economical barcode label, the so called Food Sentinel Systems to detect pathogens in meat packaging. The system consists of two barcodes, a SIRA and a normal product code. A specific-pathogen antibody is applied to a membrane forming part of the barcode system which, when exposed to contaminants such as Salmonella spp., Escherichia coli 0157:H7, or Listeria monocytogenes, form a localized dark bar on the membrane, rendering the UPC unscannable, see Fig. 11.

Fig. 11.

Food Sentinel Systems barcode. a ready to use b expired which can not be scanned

Fluorescence-base oxygen sensors

Special dye molecules display excited states and emit radiation at specific wavelengths (fluorescence or phosphorescence) when they absorb light. Quenching of this excited luminescent dye can occur during collision with oxygen molecules (Eggins 2002). Due to this energy transfer mechanism, luminescence intensity is decreased over time and the degree of quenching is proportional to the concentration of oxygen within the system. This brought the inspirations of fluorescence-based oxygen sensor.

Fluorescence-based oxygen sensor consists of a fluorescent or phosphorescent dye which is immobilized in a solid polymer matrix. A dye-polymer coating is applied as a thin film on a device such as an optical fiber (Wang and Wolfbeis 2013) after immobilization to create the sensor. The existence of molecular oxygen in the packaging headspace influences into the sensitive coating by simple diffusion and quenches luminescence in a dynamic fashion. The concentration of oxygen is then estimated based on the degree of alteration in luminescence parameters, using a predetermined calibration (Papkovsky et al. 2002). The process is reversible and clean, and there is no consumption of either dye or oxygen in the photochemical reactions involved, as well as no generation of byproducts.

The sensing materials, which are using a thin film coatings, are low diffusion barrier and very fast in sensing responses where the oxygen concentration is changed. The responding time is usually as low as tenths of milliseconds (Kolle et al. 1997). This feature is important for real-time, on-line quality control of large volume throughput of packages. Such rapid screening allows for immediate identification of improperly sealed units and their removal.

Fluorescence-base oxygen sensors are well suited to be integrated into meat packages since they should remain in operation and be reliable through the supply chain until the point of opening. Exposure to light, including UV/retail display lighting can cause gradual photobleaching of certain dyes or aging of polymers. In the case of phase fluorimetric oxygen sensors this is not important but can be problematical for other sensor types.

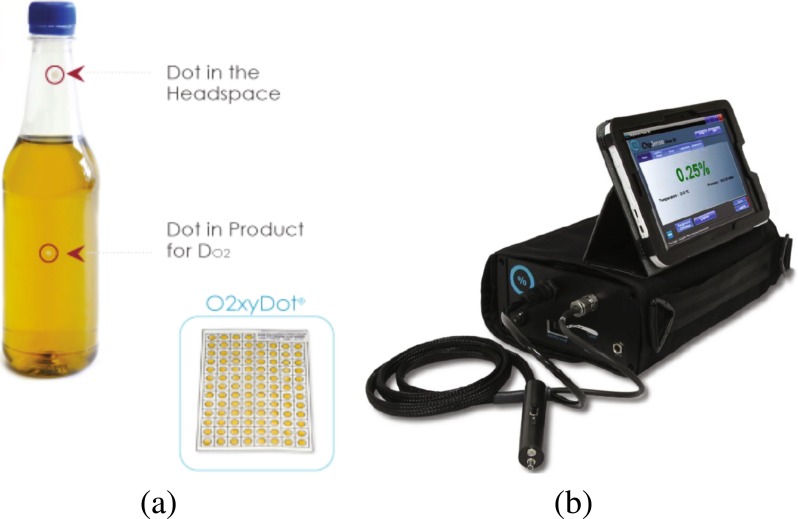

O2xyDot is one of the commercial fluorescence-base oxygen sensors, which is developed by OxySense. This sensor is attached inside the packaging system prior to filling and can be read from outside of the package nondestructively. The sensor can be used in the headspace or in contact with the products such as liquids (see Figure 12a). The dot is illuminated with a pulsed blue light from a LED. The blue light is absorbed by the dot and the emitted red light is detected by a photo-detector to measure characteristics of the fluorescence lifetime, which is illustrated in Fig. 12b. Different lifetime characteristics indicate different levels of oxygen within the package.

Fig. 12.

O2xyDot. a the sensor b the portable optical reader

The oxygen measurement technique is based upon the fluorescence quenching of a metal organic fluorescent dye immobilized in a gas permeable hydrophobic polymer. The dye absorbs light in the blue region and fluoresces within the red region of the spectrum. The presence of oxygen quenches the fluorescent light from the dye as well as its lifetime. The quenching process is a purely collisional dynamic where the energy from the excited fluorescent dye is transferred to the oxygen molecule during a collision, hence, reducing the emission intensity as well as the fluorescent lifetime of the dye. Thus, the oxygen content of the enclosed space is not changed by the measurement process.

RFID tags

Radiofrequency identification (RFID) tags are electronic information-based systems that uses radio frequency electromagnetic fields to transfer data from a tag attached to an object to trace and identify the object automatically. RFID is an improvement to the previous manual tracking systems or barcodes. Furthermore, it has a longer reading range, it is very strong and can work under extreme temperatures and different pressures, it can be detected at distances of more than 100 m, and many tags can be read simultaneously (Abad et al. 2009). RFID tags can be affixed to foods, automobiles, livestock, garments, or possessions, or even implanted within pets. This system has already been used for temperature monitoring of perishable foods such as meat (Montanari 2008, Liu et al. 2010).

A real time monitoring and online decisions support system with RFID is developed to improve the delivery system for perishable products (Wang et al. 2010). Mathematical models based on degeneration values are proposed to handle different aspects of spoilage using the data from RFID and sensor network. Then, the quality of the goods can be predicted by the forecast module. In the case of any deterioration the warning function will send an alarm signal to the users, then, a rule-based decision module will provide the user with suggestions as how to cope with the abnormality. The results from the simulation have shown that the monitoring and decision support system is an efficient tool for reducing the transportation losses of perishable products, such as meat, for the enterprises in cold chain.

Despite of the several advantages of RFID technology over traditional technologies such as barcodes, there are shortcomings in real-world applications. The main obstacle for the slow uptake of this technology is their high cost, thus, it is not economical to use these within each individual package (Roberts 2006). Moreover, the application of RFID tags is limited in some products, where contain a large amount of moisture such as meat products. The water molecules can absorb microwave signals leading to signal loss or in some cases, metals can cause the signals to be reflected. Although the implementation of intelligent packaging of meat products using RFID technology is still largely hypothetical, indications suggest it is unlikely to remain so for very much longer.

Comparison of meat quality control technologies

In this section we compare the existing technologies in meat quality control and packaging system. The advantages and dis-advantages of the mentioned meat quality monitoring techniques are discussed in Table 1. From Table 1 one can see that most of the devices, except e-nose, are commercialized which can be employed in meat packaging industries.

Table 1.

Comparison of meat quality control technologies

| Sensor/Indicator | Advantages | Dis-advantages |

|---|---|---|

| Time temperature indicator | Easy to be integrated into packaging | No information about quality of |

| system, can be checked by naked eye, | food, must be conditioned before use. | |

| cheap and economical, can be measured | no contact with food | |

| by electronic devices | ||

| Gas indicator | Can be integrated into the packaging | No information about gas concentration |

| films, can be checked by naked eye, | attached inside the package | |

| cheap and economical, | and its chemical dye may | |

| can be measured by electronic devices. | interfere in food quality. | |

| Freshness indicator | Sensitive, can be checked by naked eye, | False negatives results, attached |

| cheap and economical, can be | inside the package which may | |

| measured by electronic devices. | interfere in food quality. | |

| Biosensors | Can be integrated into the packaging films, | Can not detect low concentrated contamination, |

| can be checked by naked eye, | may have chemical effect on the food. | |

| cheap and economical, can be measured by | ||

| electronic devices, pathogen | ||

| and microbial detection. | ||

| Gas sensors | Sensitive, Can be integrated into the | Nil |

| packaging films, high spatial resolution, | ||

| can be checked by naked eye and optical devices, | ||

| not affected by heat, electromagnetic and stirring. | ||

| E-nose | Accurate since uses an array of | Expensive for packaging and |

| sensors, can detect many kind of | commercial purpose. | |

| volatile compounds, can be integrated | ||

| into pattern recognition and | ||

| decision making systems. | ||

| Fluorescence-base (oxygen) | Sensitive, concentration of oxygen | can not be checked by naked eye. |

| can be checked by optical device, can | ||

| be used in headspace or in liquid, fast | ||

| and reliable. | ||

| RFID tags | Accurate, Can be integrated into barcodes, | The signal can be lost, expensive to |

| wireless technology, reading multiple | be commercialized. | |

| products at once, fast. |

E-noses, which usually consist of an array of sensors, are the most accurate devices in meat spoilage detection. Moreover, they are fast, reliable, and can detect different gaseous combinations at once. These devices have been widely used in food laboratories to monitor meat product spoilage rather than food packaging systems.

The indicators, TTI and gas indicators, simply can be checked by the naked eye which are economical to be commercialized. However, they do not provide additional information about the quality of the food in real time. The accuracy of gas sensors is higher than biosensors, moreover the latter are fast and reliable with low chemical effect on food quality. The e-noses and RFID tags are expensive to be used in each individual meat package. However, they are accurate and can be integrated with pattern recognition and data mining techniques for further investigations. The Fluorescence-base (oxygen) sensors are fast, reliable which can be used in various environments such as liquids. Furthermore they required an optical device to measure the level of gas concentration.

The compatibility of commercialize devices for meat quality monitoring are compared in Table 2. In this table TTI stands for time temperature indicator, FI for freshness indicator, GS for gas sensor, BS for biosensor and FLOS for Fluorescence-base (oxygen) sensor. From Comparison of TTIs, one can see that the Monitor Mar TM is the simplest device which is available in the market with no additional measurement electronic device. TopCryo TM and OnVu TM are most advanced TTIs, where the collected data by the measurement device can be stored and analyzed for further decision making. The level of contamination using commercialized gas sensors and biosensors can be checked by naked eye which is not really accurate and precise. The TopCryo TM and OnVu TM, and O2xyDot seems to be suitable for application in meat industry since the device is accurate and fast with the ability of recording the results electronically. Thus, the collected results can be further analyzed by employing pattern recognition techniques.

Table 2.

Comparison of commercialized technologies

| Device | Type | Meat quality monitoring application | Digital measurement device compatibility | Measurement device compatibility |

|---|---|---|---|---|

| Monitor Mark TM | TTI | Yes | No | No |

| Fresh-Check | TTI | Yes | Yes | No |

| TopCryo TM | TTI | Yes | Yes | Yes |

| OnVu TM | TTI | Yes | Yes | Yes |

| Food fresh TM | FI | No | No | No |

| Tell-Tab TM | GS | Yes | No | No |

| Ageless Eye TM | GS | Yes | No | No |

| Toxin Guard TM | BS | Yes | No | No |

| Food Sentinel | BS | Yes | No | No |

| O2xyDot | FLOS | Yes | Yes | Yes |

The presented devices in Table 2 have been used in meat quality monitoring except Food fresh, which has been developed to be used in monitoring the freshness of vegetables only. Monitor mark, Fresh-check, TopCryo and OnVu are very suitable in monitoring the temperature fluctuations of meat products in the supply chain. Tell-Tab, Ageless Eye and O2xyDot are designed to monitor the oxygen consumption of the meat product from the head space of the package. Those meat products with significant changes in the oxygen amount are considered as low quality products. Toxin Guard and Food Sentinel are biosensors, which are developed to be integrated into the barcodes of the meat products.

Among the mentioned technologies in the this paper, the TTIs are the simplest and most affordable technologies in the meat products quality monitoring. However, the TTIs are susceptible to incorrect indication due to damages, which are involved in the handling process. On the other hand the e-noses are sophisticated and expensive to be used in industrial environments. These technologies are likely to be employed in laboratories and food agency departments. The biosensors such as Toxin Guard and Food Sentinel are economical and require less maintenance in quality monitoring of meat products compared to gas sensors.

Conclusion and future work

In this paper an overview of intelligent packaging methods for meat quality monitoring are discussed. Devices, such as TTI, chemical and gas indicators are affordable, simple and easy to be integrated into the packaging systems. Some indicators are suitable for data mining and decision making purpose, where the level of changes in the indicator color can be measured by an electronic/optical device and stored for further investigations. However, the simplicity of indicators makes them to be susceptible to errors in measurements moreover, they do not provide any further information about the meat quality.

Sensors, such as biosensors, gas sensor, fluorescence-based sensors are the most advanced technologies in intelligent packaging. In comparison with indicators, sensors are fast, accurate and reliable but their application in packaging systems is more complicated. Biosensors suffer from failure in detection of low contamination in meat packages and their chemical effect on meat quality should be more studied. E-noses consist of an array of chemical or gas sensors are the most complicated ones. These devices are very accurate and suitable to be used in food quality laboratories rather than in supermarkets. Among the mentioned devices, gas and fluorescence-based sensors are sensitive, fast and easy to be implement into food packages.

The integration of RFID tags and sensors is one of the promising technologies in food quality monitoring, since the quality history of the products can be stored and retrieved efficiently for further investigations such as data mining and decision making. Developing a model for RFID monitoring of meat products in cool chain is a part of the future works.

Acknowledgments

The authors are grateful to anonymous referees for their comments and criticism that significantly improved the quality of the paper.

Footnotes

Total volatile basic nitrogen

Contributor Information

Ehsan Mohebi, Email: e.mohebi@federation.edu.au.

Leorey Marquez, Email: leorey.marquez@csiro.au.

References

- Abad E, Zampolli S, Marco S. Flexible tag microlab development: gas sensors integration in RFID flexible tags for food logistic. Sensors Actuators B Chem. 2007;127(1):2–7. doi: 10.1016/j.snb.2007.07.007. [DOI] [Google Scholar]

- Abad E, Palacio F, Nuin M, De Zárate AG, Juarros A, Gómez J, Marco S. Rfid smart tag for traceability and cold chain monitoring of foods: demonstration in an intercontinental fresh fish logistic chain. J Food Eng. 2009;93(4):394–399. doi: 10.1016/j.jfoodeng.2009.02.004. [DOI] [Google Scholar]

- Abdallah S, Al-Shatti L, Alhajraf A, Al-Hammad N, Al-Awadi B. The detection of foodborne bacteria on beef: the application of the electronic nose. SpringerPlus. 2013;2(1):1–9. doi: 10.1186/2193-1801-2-687. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ahvenainen R (2003) Novel Food Packaging Techniques. Woodhead Publishing in food science and technology, CRC Press

- Ahvenainen R, Hurme E. Active and smart packaging for meeting consumer demands for quality and safety. Food Addit Contam. 1997;14(6–7):753–763. doi: 10.1080/02652039709374586. [DOI] [PubMed] [Google Scholar]

- Alocilja EC, Radke SM. Market analysis of biosensors for food safety. Biosens Bioelectron. 2003;18(56):841–846. doi: 10.1016/S0956-5663(03)00009-5. [DOI] [PubMed] [Google Scholar]

- Along K, Chenrui Z, Luo Z, Xiaozheng L, Tao H (2010) Saw rfid enabled multi-functional sensors for food safety applications pp 200–204

- Avella M, Errico M, Gentile G, Volpe M (2011) Nanocomposite sensors for food packaging pp 501–510

- Balasubramanian S, Amamcharla J, Panigrahi S, Logue C, Marchello M, Sherwood J. Investigation of different gas sensor-based artificial olfactory systems for screening salmonella typhimurium contamination in beef. Food Bioprocess Technol. 2012;5(4):1206–1219. doi: 10.1007/s11947-010-0444-z. [DOI] [Google Scholar]

- Barbri NE, Amari A, Vinaixa M, Bouchikhi B, Correig X, Llobet E. Building of a metal oxide gas sensor-based electronic nose to assess the freshness of sardines under cold storage. Sensors Actuators B Chem. 2007;128(1):235–244. doi: 10.1016/j.snb.2007.06.007. [DOI] [Google Scholar]

- Bejerholm C, Aaslyng MD. The influence of cooking technique and core temperature on results of a sensory analysis of pork-depending on the raw meat quality. Food Qual Prefer. 2004;15(1):19–30. doi: 10.1016/S0950-3293(03)00018-1. [DOI] [Google Scholar]

- Blixt Y, Borch E. Using an electronic nose for determining the spoilage of vacuum-packaged beef. Int J Food Microbiol. 1999;46(2):123–134. doi: 10.1016/S0168-1605(98)00192-5. [DOI] [PubMed] [Google Scholar]

- Borchert NB, Kerry JP, Papkovsky DB. A CO2 sensor based on Pt-porphyrin dye and FRET scheme for food packaging applications. Sensors Actuators B Chem. 2013;176:157–165. doi: 10.1016/j.snb.2012.09.043. [DOI] [Google Scholar]

- Brody A. What’s active about intelligent packaging. Food Technol. 2001;55(6):75. [Google Scholar]

- Byrne L, Lau KT, Diamond D. Monitoring of headspace total volatile basic nitrogen from selected fish species using reflectance spectroscopic measurements of ph sensitive films. Analyst. 2002;127:1338–1341. doi: 10.1039/b206149j. [DOI] [PubMed] [Google Scholar]

- Duncan TV. Journal of colloid and interface science applications of nanotechnology in food packaging and food safety: Barrier materials, antimicrobials and sensors. J Colloid Interface Sci. 2014;363(1):1–24. doi: 10.1016/j.jcis.2011.07.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Eggins B (2002) Chemical Sensors and Biosensors. Analytical Techniques in the Sciences (AnTs)*, Wiley

- García-gonzález DL, Tena N, Aparicio-ruiz R, Aparicio R. Talanta Sensor responses to fat food aroma : a comprehensive study of dry-cured ham typicality. Talanta. 2014;120:342–348. doi: 10.1016/j.talanta.2013.12.013. [DOI] [PubMed] [Google Scholar]

- Gardner JW, Bartlett PN. A brief history of electronic noses. Sensors Actuators B Chem. 1994;18(13):210–211. doi: 10.1016/0925-4005(94)87085-3. [DOI] [Google Scholar]

- Hamada-Sato N, Usui K, Kobayashi T, Imada C, Watanabe E. Quality assurance of raw fish based on haccp concept. Food Control. 2005;16(4):301–307. doi: 10.1016/j.foodcont.2004.02.001. [DOI] [Google Scholar]

- Hernndez-Czares AS, Aristoy MC, Toldr F. Hypoxanthine-based enzymatic sensor for determination of pork meat freshness. Food Chem. 2010;123(3):949–954. doi: 10.1016/j.foodchem.2010.04.066. [DOI] [Google Scholar]

- Hong SI, Park WS. Use of color indicators as an active packaging system for evaluating kimchi fermentation. J Food Eng. 2000;46(1):67–72. doi: 10.1016/S0308-8146(00)00141-2. [DOI] [Google Scholar]

- Hong X, Wang J, Hai Z. Discrimination and prediction of multiple beef freshness indexes based on electronic nose. Sensors Actuators B Chem. 2012;161(1):381–389. doi: 10.1016/j.snb.2011.10.048. [DOI] [Google Scholar]

- Huang X, Xin J, Zhao J. A novel technique for rapid evaluation of fish freshness using colorimetric sensor array. J Food Eng. 2011;105(4):632–637. doi: 10.1016/j.jfoodeng.2011.03.034. [DOI] [Google Scholar]

- Kerry J, OGrady M, Hogan S. Past, current and potential utilisation of active and intelligent packaging systems for meat and muscle-based products: a review. Meat Sci. 2006;74(1):113–130. doi: 10.1016/j.meatsci.2006.04.024. [DOI] [PubMed] [Google Scholar]

- Kolle C, Gruber W, Trettnak W, Biebernik K, Dolezal C, Reininger F, O’Leary P. Fast optochemical sensor for continuous monitoring of oxygen in breath-gas analysis. Sensors Actuators B Chem. 1997;38(13):141–149. doi: 10.1016/S0925-4005(97)80184-0. [DOI] [Google Scholar]

- Kong BH, Ma LZ. Meat science and technology. Beijing, China: Chinese Light Industry Press; 2003. pp. 97–99. [Google Scholar]

- Kuswandi B, Wicaksono Y, Jayus AbdullahA, Heng L, Ahmad M. Smart packaging: sensors for monitoring of food quality and safety. Sens Instrum Food Qual Saf. 2011;5(3–4):137–146. doi: 10.1007/s11694-011-9120-x. [DOI] [Google Scholar]

- Kuswandi B, Jayus LarasatiT, Abdullah A, Heng L. Real-time monitoring of shrimp spoilage using on-package sticker sensor based on natural dye of curcumin. Food Anal Methods. 2012;5(4):881–889. doi: 10.1007/s12161-011-9326-x. [DOI] [Google Scholar]

- Kuswandi B, Jayus RestyanaA, Abdullah A, Heng LY, Ahmad M. A novel colorimetric food package label for fish spoilage based on polyaniline film. Food Control. 2012;25(1):184–189. doi: 10.1016/j.foodcont.2011.10.008. [DOI] [Google Scholar]

- Kuswandi B, Jayus OktavianaR, Abdullah A, Heng LY. A novel on-package sticker sensor based on methyl red for real-time monitoring of broiler chicken cut freshness. Packag Technol Sci. 2014;27(1):69–81. doi: 10.1002/pts.2016. [DOI] [Google Scholar]

- Li XC, Olafsdottir G. Development and application of electronic noses in freshness assessment of fishery products. J Fish China. 2002;26(3):275–280. [Google Scholar]

- Liu L, Hu J, Zhang J, Fu Z, Zhang J. Development of time-temperature data collection program for frozen fish in the cold chain. Sensor Lett. 2010;8(1):47–51. doi: 10.1166/sl.2010.1198. [DOI] [Google Scholar]

- McMillin KW. Where is MAP going? a review and future potential of modified atmosphere packaging for meat. Meat Sci. 2008;80(1):43–65. doi: 10.1016/j.meatsci.2008.05.028. [DOI] [PubMed] [Google Scholar]

- Miller D, Wilkes J, Conte E (2006) With indicator calorimetrically responsive at freezing temperatures to volatile bases generated by food decomposition. US Patent 7,014, 816

- Montanari R. Cold chain tracking: a managerial perspective. Trends Food Sci Technol. 2008;19(8):425–431. doi: 10.1016/j.tifs.2008.03.009. [DOI] [Google Scholar]

- Muhamad F, Hashim H, Jarmin R, Ahmad A (2009) Fish freshness classification based on image processing and fuzzy logic. In: Proceedings of the 8th WSEAS International Conference on Circuits, Systems, Electronics, Control &; Signal Processing, World Scientific and Engineering Academy and Society (WSEAS), Stevens Point, Wisconsin, USA, CSECS’09, pp 109–115

- Mukhopadhyay S, Karunanayaka SD, Suri V, Gupta G (2006) A novel bio-sensor for non-invasive meat inspection pp 931–934

- Murkovic I, Steinberg MD, Ivan Z. Wireless smart tag with on-board conductometric chemical sensor. Sensors Actuators B Chem. 2014;196:208–214. doi: 10.1016/j.snb.2014.02.012. [DOI] [Google Scholar]

- Yasin NM. Identification of color index for fish freshness. In: Proc. 4th International Colloquium on Signal Processing & Its Application. Malaysia: Kuala Lumpur; 2008. pp. 255–262. [Google Scholar]

- O’Farrell M, Sheridan C. Online optical fiber sensor for etecting premature browning in ground beef using pattern recognition techniques and reflection spectroscopy. IEEE Sensors J. 2007;7(12):1685–1692. doi: 10.1109/JSEN.2007.908441. [DOI] [Google Scholar]

- O’Grady M, Kerry J (2008) Smart packaging technologies and their application in conventional meat packaging systems. Meat Biotechnol:425–451

- Olafsdottir G, Nesvadba P, Natale CD, Careche M, Oehlenschloger J, Tryggvadottir SV, Schubring R, Kroeger M, Heia K, Esaiassen M, Macagnano A, Jorgensen BM. Multisensor for fish quality determination. Trends Food Sci Technol. 2004;15(2):86–93. doi: 10.1016/j.tifs.2003.08.006. [DOI] [Google Scholar]

- Pacquit A, Frisby J, Diamond D, Lau KT, Farrell A, Quilty B, Diamond D. Development of a smart packaging for the monitoring of fish spoilage. Food Chem. 2007;102(2):466–470. doi: 10.1016/j.foodchem.2006.05.052. [DOI] [Google Scholar]

- Panigrahi S, Balasubramanian S, Gu H, Logue C, Marchello M. Design and development of a metal oxide based electronic nose for spoilage classification of beef. Sensors Actuators B Chem. 2006;119(1):2–14. doi: 10.1016/j.snb.2005.03.120. [DOI] [Google Scholar]

- Papkovsky D, Smiddy M, Papkovskaia N, Kerry J. Nondestructive measurement of oxygen in modified atmosphere packaged hams using a phase-fluorimetric sensor system. J Food Sci. 2002;67(8):3164–3169. doi: 10.1111/j.1365-2621.2002.tb08877.x. [DOI] [Google Scholar]

- Roberts C. Radio frequency identification (RFID) Comput Secur. 2006;25(1):18–26. doi: 10.1016/j.cose.2005.12.003. [DOI] [Google Scholar]

- Salinas Y, Ros-Lis J, Vivancos J, Martinez-Máñez R, Marcos M, Aucejo S, Herranz N, Lorente I. Monitoring of chicken meat freshness by means of a colorimetric sensor array. Analyst. 2012;137(16):3635–43. doi: 10.1039/c2an35211g. [DOI] [PubMed] [Google Scholar]

- Salinas Y, Ros-lis JV, Vivancos Jl, Martínez-má nez R, Marcos MD, Aucejo S, Herranz N, Lorente I, Garcia E (2014) A novel colorimetric sensor array for monitoring fresh pork sausages spoilage. Food Control 35(1):166–176

- Smiddy M, Fitzgerald M, Kerry J, Papkovsky D, Sullivan CO, Guilbault G. Use of oxygen sensors to non-destructively measure the oxygen content in modified atmosphere and vacuum packed beef: impact of oxygen content on lipid oxidation. Meat Sci. 2002;61(3):285–290. doi: 10.1016/S0309-1740(01)00194-2. [DOI] [PubMed] [Google Scholar]

- Smiddy M, Papkovskaia N, Papkovsky D, Kerry J. Use of oxygen sensors for the non-destructive measurement of the oxygen content in modified atmosphere and vacuum packs of cooked chicken patties; impact of oxygen content on lipid oxidation. Food Res Int. 2002;35(6):577–584. doi: 10.1016/S0963-9969(01)00160-0. [DOI] [Google Scholar]

- Smiddy M, Papkovsky D, Kerry J. Evaluation of oxygen content in commercial modified atmosphere packs (map) of processed cooked meats. Food Res Int. 2002;35(6):571–575. doi: 10.1016/S0963-9969(01)00159-4. [DOI] [Google Scholar]

- Smolander M (2003) The use of freshness indicators in packaging. Novel Food Packaging Techniques pp 128–143, cited By (since 1996)18

- Smolander M (2008) Freshness indicators for food packaging. Wiley, Ltd, pp 111–127

- Taoukis P (2010) 14-commercialization of time-temperature integrators for foods. In: Doona CJ, Kustin K, Feeherry FE (eds) Case Studies in Novel Food Processing Technologies, Woodhead Publishing Series in Food Science, Technology and Nutrition. Woodhead Publishing, pp 351–366

- Taoukis PS, Labuza TP. Applicability of time-temperature indicators as shelf life monitors of food products. J Food Sci. 1989;54(4):783–788. doi: 10.1111/j.1365-2621.1989.tb07882.x. [DOI] [Google Scholar]

- Trettnak W, Gruber W, Reininger F, Klimant I (1995) Recent progress in optical oxygen sensor instrumentation. Sensors Actuators B Chem 29(13):219–225. proceedings of the 2nd European Conference on Optical Chemical Sensors and Biosensors

- Vaikousi H, Biliaderis CG, Koutsoumanis KP. Applicability of a microbial time temperature indicator (tti) for monitoring spoilage of modified atmosphere packed minced meat. Int J Food Microbiol. 2009;133(3):272–278. doi: 10.1016/j.ijfoodmicro.2009.05.030. [DOI] [PubMed] [Google Scholar]

- Vernat-Rossi V, Garcia C, Talon R, Denoyer C, Berdagu JL. Rapid discrimination of meat products and bacterial strains using semiconductor gas sensors. Sensors Actuators B Chem. 1996;37(1–2):43–48. doi: 10.1016/S0925-4005(97)80070-6. [DOI] [Google Scholar]

- Wang L, Kwok S, Ip W. A radio frequency identification and sensor-based system for the transportation of food. J Food Eng. 2010;101(1):120–129. doi: 10.1016/j.jfoodeng.2010.06.020. [DOI] [Google Scholar]

- Wang XD, Wolfbeis OS. Fiber-optic chemical sensors and biosensors (20082012) Anal Chem. 2013;85(2):487–508. doi: 10.1021/ac303159b. [DOI] [PubMed] [Google Scholar]

- Watanabe E, Ando K, Karube I, Suzuki MSH. Determination of hypoxanthine in fish meat with an enzyme sensor. J Food Sci. 1983;48(2):496–500. doi: 10.1111/j.1365-2621.1983.tb10775.x. [DOI] [Google Scholar]

- Watanabe E, Toyama K, Karube I. Enzyme sensor for hypoxanthine and inosine determination in edible fish. Appl Microbiol. 1984;38:127–134. [Google Scholar]

- Xiao Y, Jiaojiao J, Guohua H, Fangyuan Y, Minmin W, Jie H, Xiaoguo Y, Shanggui D (2014) Determination of the freshness of beef strip loins (m. longissimus lumborum) using electronic nose pp 1–7

- Xiao-wei H, Xiao-bo Z, Ji-yong S, Yanin G, Jie-wen Z, Jianchun Z, Limin H. Determination of pork spoilage by colorimetric gas sensor array based on natural pigments. Food Chem. 2014;145:549–554. doi: 10.1016/j.foodchem.2013.08.101. [DOI] [PubMed] [Google Scholar]

- Yam KL, Takhistov PT, Miltz J. Intelligent packaging: Concepts and applications. J Food Sci. 2005;70(1):R1–R10. doi: 10.1111/j.1365-2621.2005.tb09052.x. [DOI] [Google Scholar]

- Yano Y, Numata M, Hachiya H, Ito S, Masadome T, Ohkubo S, Asano Y, Imato T. Application of a microbial sensor to the quality control of meat freshness. Talanta. 2001;54(2):255–262. doi: 10.1016/S0039-9140(00)00637-8. [DOI] [PubMed] [Google Scholar]

- Zaragozá P, Ribes S, Fuentes A, Vivancos JL, Fernńdez-Segovia I, Ros-Lis JV, Barat JM, Nez RMM (2012) Fish freshness decay measurement with a colorimetric array. Procedia Engineering 47:1362–1365, 26th European Conference on Solid-State Transducers, EUROSENSOR