Abstract

Phenolic content, antioxidant activity and sensory characteristics of vegetable-enriched extrudates were investigated as a result of extrusion conditions, including extrusion temperature (140–180 °C), screw rotation speed (150–250 rpm) and feed moisture content (14–19 % w.b.). Broccoli flour and olive paste was used in mixtures with corn flour at a ratio of 4 to 10 % (broccoli/corn) and 4 to 8 % (olive paste/corn). A simple power model was developed for the prediction of phenolic content and antioxidant activity of extrudates by extrusion conditions and feed composition. Phenolic content and antioxidant activity of broccoli enriched extrudates increased with extrusion temperature and broccoli addition and decreased with feed moisture content. The antioxidant activity of olive paste extrudates increased with material ratio and decreased with feed moisture content and screw rotation. Sensory porosity, homogenous structure, crispness, cohesiveness and melting decreased with feed moisture content, while the latter increased the mealy flavor and hardness of extrudates. Acceptable snacks containing broccoli flour or olive paste can be produced by selecting the appropriate process conditions.

Keywords: Broccoli, Extrusion cooking, Olive paste, Phenolics, Sensory evaluation

Introduction

Cereals and especially corn grits/flour, constitute the basic raw ingredient for extruded snack food production, while their structure is affected and determined by the contained starch and protein (Guy 1994). As being low in protein content with poor biological value, an enhancement of both product matrix and nutritional value could be achieved by using mixtures of cereals and other raw materials such as legumes, vegetables and dietary fibres (Altan et al. 2009; Anton et al. 2009; Lazou and Krokida 2010b; Stojceska et al. 2008).

Brassica vegetables belong to Cruciferous family, including a number of widely consumed species such as cabbage, cauliflower, broccoli, Brussels sprouts and kale, which exhibit both antioxidant and anticarcinogenic properties (Bisharat et al. 2013; Nayak et al. 2011; Sarawong et al. 2014; Verhoeven et al. 1997). In addition to antioxidant vitamins, carotenoids, and polyphenols, Brassica vegetables provide a large group of glucosinolates, which possess rather low antioxidant activity (Plumb et al. 1996), but the products of their hydrolysis can protect against cancer (Keum et al. 2004). Among brassica vegetables broccoli contains the highest proportion of phenolic and nutraceutical compounds.

Olives and their products are one of the basic components of the Mediterranean diet, containing besides nutrients a variety of phenolic constituents. The olive phenols impart antioxidant and antimicrobial properties to different parts of the plant and are also responsible for the extent of browning in the fruit (Ghanbari et al. 2012). These phenolic components also contribute towards the sensory and aromatic characteristics of the olive as well as impart pharmaceutical and physiological benefits (Bianchi 2003; Covas 2007). Both lipophilic and hydrophilic phenolics are distributed in olive (Ghanbari et al. 2012).

Extruded snacks occupy a great part of worldwide consumed snacks, which have the characteristics of easiness to use and of the high nutritional quality. This fact led to the production of new food products that contain high nutritional values’ compounds, which include health promoting characteristics (such as antioxidant activity) (Ozer et al. 2006; Stojceska et al. 2008). Processing affects content, composition and antioxidant activity of bioactive compounds in vegetables. Extrusion cooking is a process that applies short processing times, which favors the retention of nutrient and bioactive compounds otherwise destroyed by thermal processing, and also enables the processing of various mixtures leading to a variety of final food products (Moore 1994). Vegetable incorporation in extruded snacks fortifies the food with health promoting bioactive compounds. Generally the production of extruded snacks with vegetable ingredients rich in nutraceutical components is a new area not fully investigated and existing information is very limited.

Sensory characteristics of extruded snacks are critical for consumer acceptance. Among them are crisp and well expanded texture, homogeneous structure, good taste, attractive appearance, color and aroma, all dependent on extrusion conditions and raw material composition. The formation of extruded food products with desired structural, textural and sensory characteristics can be achieved by selecting accordingly the extrusion conditions (Lazou and Krokida 2010b; Lazou et al. 2010). The effect of extrusion conditions and raw material properties on sensory properties has been reported for various cereal-based products (corn and wheat) (Chen et al. 1991; Onwulata and Heymann 1994), while the effect of vegetables incorporation on quality characteristics of extrudates has not been investigated widely in past.

The objective of the present work was to investigate the phenolic content, antioxidant activity and sensory characteristics of vegetable-corn extrudates as affected by extrusion conditions (extrusion temperature and screw speed) and raw material characteristics (moisture content and vegetable to corn ratio). Simple power models were developed for the prediction of phenolic content and antioxidant activity as a function of process conditions and feed composition.

Materials and methods

Sample preparation

Yellow corn flour was obtained from Marra Bros Mills S.A. (Korinthos, Greece), broccoli and olive paste (Minerva SA, Viotia, Greece) were obtained from the local market. Broccoli chopped and then was frozen at −30 °C in a biomedical freezer (SANYO, MDF-236, Osaka, Japan). The broccoli pieces were then dehydrated for 48 h using a laboratory freeze-dryer (Leybold-Heraeus GT 2A, Koln, Germany), under vacuum. The freeze dried broccoli was grinded in order to obtain broccoli flour. Olive paste was also freeze dried under the same conditions.

Raw materials with different characteristics and sensory attributes were used in order to produce added-value extruded products, which expected to lead in final products exhibiting different characteristics as well. Olive paste has dark colour and definitely higher phenolic content as well as bitter taste, than broccoli. In order to select material ratios, preliminary tests were run based on these facts. Hence, corn and broccoli flours were mixed to the desired broccoli/corn ratios of 4, 7, and 10 %, while the desired ratios for olive and corn mixtures were 4, 6 and 8 %.

Feed mixtures were adjusted to desired moisture content by spraying calculated amounts of distilled water and mixing thoroughly for 15 min, in a mixer. The feed moisture content levels were 14, 16.5 and 19 % wb. These moisture levels were selected based on our previous experience in order to obtain a puffed and crunchy extruded product (Lazou and Krokida 2010b; Lazou et al. 2010; Lazou et al. 2007). The samples were packed in polyethylene bags and kept in the refrigerator overnight to equilibrate the moisture. Sample moisture content was determined in an oven at 75 °C under a vacuum of 50 mm Hg to constant weight. Corrections in moisture content were performed in cases of deviation from the set values. Before extrusion cooking the samples were brought to room temperature.

Extrusion cooking

A co-rotating twin screw extruder (Prism Eurolab, model KX-16HC, Staffordshire, UK) was used. The screw geometry was: length 40 cm, diameter 16 mm, with maximum rotation speed 500 rpm. It was used a cylindrical die with diameter 3 mm and length 17.5 mm. The extruder screws consisted of forward pitch screw elements, reverse screw elements, and two kneading blocks. Details of screw configuration are presented in Table 1. The material was fed into the extruder using a volumetric feeder. The extruder had five temperature control zones. The temperature during extrusion was adjusted by varying the temperature in the barrel, and die using electric heaters. The extrusion conditions are shown on Table 2. Steady-state conditions were reached after 20 min, after which samples were collected. Samples were stored in laminated bags for further analysis.

Table 1.

Screw profile used for extrusion runs

| Configuration | Length (mm) |

|---|---|

| 15 × D feed screw | 240 |

| 1 × D/2 half feed screw | 8 |

| R60/R45 × 1.5D reversing screw | 24 |

| 3 × D feed screw | 48 |

| R60/R45 × 1.5D reversing screw | 24 |

| 2 × D | 32 |

| 1.5 × D extrusion screw | 24 |

Table 2.

Extrusion runs

| Feed moisture Χ % w.b. |

Vegetable/corn ratio C % |

Extrusion Temperature T (°C) |

Screw speed R (rpm) |

|---|---|---|---|

| 14 | 4 | 140 | 150 |

| 14 | 4 | 140 | 250 |

| 14 | 10 | 140 | 150 |

| 14 | 10 | 140 | 250 |

| 16.5 | 7 | 140 | 200 |

| 19 | 4 | 140 | 150 |

| 19 | 4 | 140 | 250 |

| 19 | 10 | 140 | 150 |

| 19 | 10 | 140 | 250 |

| 14 | 7 | 160 | 200 |

| 16.5 | 4 | 160 | 200 |

| 16.5 | 7 | 160 | 150 |

| 16.5 | 7 | 160 | 200 |

| 16.5 | 7 | 160 | 200 |

| 16.5 | 7 | 160 | 250 |

| 16.5 | 10 | 160 | 200 |

| 19 | 7 | 160 | 200 |

| 14 | 4 | 180 | 150 |

| 14 | 4 | 180 | 250 |

| 14 | 10 | 180 | 150 |

| 14 | 10 | 180 | 250 |

| 16.5 | 7 | 180 | 200 |

| 19 | 4 | 180 | 150 |

| 19 | 4 | 180 | 250 |

| 19 | 10 | 180 | 150 |

| 19 | 10 | 180 | 250 |

| 14 | 4 | 140 | 150 |

| 14 | 4 | 140 | 250 |

| 14 | 8 | 140 | 150 |

| 14 | 8 | 140 | 250 |

| 16.5 | 6 | 140 | 200 |

| 19 | 4 | 140 | 150 |

| 19 | 4 | 140 | 250 |

| 19 | 8 | 140 | 150 |

| 19 | 8 | 140 | 250 |

| 14 | 6 | 160 | 200 |

| 16.5 | 4 | 160 | 200 |

| 16.5 | 6 | 160 | 150 |

| 16.5 | 6 | 160 | 200 |

| 16.5 | 6 | 160 | 200 |

| 16.5 | 8 | 160 | 250 |

| 16.5 | 8 | 160 | 200 |

| 19 | 6 | 160 | 200 |

| 14 | 4 | 180 | 150 |

| 14 | 4 | 180 | 250 |

| 14 | 8 | 180 | 150 |

| 14 | 8 | 180 | 250 |

| 16.5 | 6 | 180 | 200 |

| 19 | 4 | 180 | 150 |

| 19 | 4 | 180 | 250 |

| 19 | 8 | 180 | 150 |

| 19 | 8 | 180 | 250 |

Extraction of phenolic compounds

The extraction of phenolic compounds, from both the raw material mixtures and extruded products, was performed using methanol as a solvent; this is because methanol is generally recognized as the solvent extracting almost all phenolics. The samples were extracted for 1 h with n-hexane at a ratio of 5:1 by continuous extraction, in an orbital shaker (Orbital Shaker SO1, Stuart Scientific, UK), at ambient temperature, for fat removal. The extract was filtered using GF/F filter paper Buchner funnel, and the filtrate, which contained the lipids, was removed. Then, the residue was extracted continuously with methanol for 24 h in an orbital shaker, at ambient temperature. The new extract was filtrated using a GF/F filter paper Buchner funnel, and the filtrate was obtained. The combined filtrates were evaporated to dryness in a rotary evaporator (Ika-Werke RV06-ML, Germany). In order to obtain the extracted phenolics from rotary flasks quantitatively, the residue was redissolved in methanol and kept at −20 °C until subsequent analyses.

Phenol content determination

The total phenol content of the extrudates was determined colourimetrically at 725 nm using the Folin-Ciocalteau reagent according to a modification of Lafka et al. (2011) method. The methanolic solution of extrudates extract (0.1–0.3 ml), 20 ml of deionised water and 0.625 ml of the Folin–Ciocalteau reagent were added in a 25 ml volumetric flask. After 3 min, 2.5 ml of saturated solution of Na2CO3 (35 %) were added. The content was mixed and diluted to volume with deionised water. After 1 h, the absorbance of the sample was measured at 725 nm against a blank using a single-beam ultraviolet–visible spectrophotometer (UVmini 1240, Shimadzu Ltd., Hong Kong). Gallic acid served as a standard for preparing the calibration curve, and ranged from 60 to 140 μg/25 ml of assay solution.

Antioxidant activity

The antioxidant activity of the phenol extracts was evaluated by using the stable 2,2-diphenyl-1-picryl-hydrazyl radical (DPPH) according to a modification of the method of Bandoniene et al. (2002). Methanolic solutions of phenol extracts (0.1 ml) and 3.9 ml methanolic solution of DPPH (0.0025 g/100 ml CH3OH) were added in a cuvette and the absorbance at 515 nm (till stabilization) was measured against methanol using a single-beam ultraviolet–visible spectrophotometer (UVmini 1240, Shimadzu, Ltd., Hong Kong). Simultaneously, the absorbance at 515 nm of the blank sample (0.1 ml methanol + 3.9 ml methanolic solution of DPPH) was measured against methanol. The radical scavenging activities of the tested samples, expressed as percentage inhibition of DPPH, were calculated according to the following formula proposed by Yen and Duh (1994):

| 1 |

where Αο the absorbance at 515 nm of the blank sample at the time t = 0 min and A is the final absorbance of the test sample at 515 nm.

Sensory evaluation

A ten-member trained panel, comprising of staff members and PhD students (4 males and 6 females), participated in descriptive analysis of extrudates. They had been trained in the lexicon and methodology of sensory analysis (ISO 1998) and had experience in accessing snack foods. The samples were presented monadically and in a random sequence as pieces, 4 cm length, in three-digit coded dishes. The evaluation was conducted in a climate-controlled sensory evaluation laboratory equipped with separately partitioned booths. The panelists cleansed their palates between samples with water. Samples were served at room temperature (25 ± 1 °C) and analyses were performed under normal lighting conditions. Sensory characteristics were divided into three main categories: appearance, flavour and texture. Table 3 summarizes the sensory attributes, definitions and ancors (Dijksterhuis et al. 2007; Liu et al. 2000). Panelists were asked to score each attribute from 1 (low) to 9 (high), with the exception of colour characteristic, in which 1 referred to dark samples and 9 referred to light samples. The experiment was designed so that three replicates were obtained for each extrudate. Five samples were served at one session and there were 5 sessions of 45 min each one.

Table 3.

Attributes, definitions and anchors used in descriptive analysis

| Attributes | Definition | Ancor | |

|---|---|---|---|

| Appearance | Appearance | Homogeneous structure | Low to high |

| Porosity | Amount of open air cell at the cross section of the sample | Few to many | |

| Diameter | Cross section size of sample | Low to high | |

| Colour | From dark brown to light yellow | Dark to light | |

| Flavor | Mealy | Raw flour | Low to high |

| Burnt and bitter | Burnt sample | Low to high | |

| Texture | Crunchiness | Degree of grinding noise when chewing with molar teeth | Low to high |

| Crispness | Cracks, you can force your teeth through the sample slowly, more airy than crackling | Low to high | |

| Hardness | Force required to bite through sample | Low to high | |

| Cohesiveness | Degree to which particles of a sample stick together | Low to high | |

| Melting (Hydration and solution) | Amount of dissolving | Low to high |

Hedonic sensory tests were conducted by 50 untrained panelists (20 males and 30 females) recruited among staff and graduate students of the Faculty of Chemical Engineering. The criteria for recruitment of the participants were that they ate snack food at least one a week, were from 18 to 65 years of age, had no food allergies and were available and willing to participate on the test. The experiment was designed so that three replicates were obtained for each extrudate. The laboratory was equipped with individual partitioned booths. Drinking water was provided to clean and rinse the mouth between samples. Samples were placed on white plates and were coded with random three-digit numbers and served under normal lighting conditions at room temperature. Extrudates were evaluated for overall acceptance using a nine-point hedonic scale ranging from 1 (dislike extremely) to 9 (like extremely). Extrudates were considered acceptable if their mean score for overall acceptance was above 6 (like slightly) (Choi et al. 2007; Lazou et al. 2010).

Experimental design

The design of experiments was a three level central composite design resulting in 26 extrusion runs, with two replications. The independent variables were material ratios (4, 7, and 10 % - broccoli/corn and 4, 6, 8 % - olive paste/corn); feed moisture content (14, 16.5, and 19 % wet basis); extrusion temperature (140, 160, and 180 °C) and screw speed (150, 200, and 250 rpm). The experimental design is presented in Table 4.

Table 4.

Experimental design

| Independent variables | Levels | Coding | ||||

|---|---|---|---|---|---|---|

| −1 | 0 | 1 | −1 | 0 | 1 | |

| Feed Moisture (% w.b.), Χ | 14 | 16.5 | 19 | 1 | 2 | 3 |

| Material ratio (%), C | ||||||

| Broccoli/corn % | 4 | 7 | 10 | 1 | 2 | 3 |

| Olive paste/corn ratio % | 4 | 6 | 8 | 1 | 2 | 3 |

| Extrusion temperature (°C), Τ | 140 | 160 | 180 | 1 | 2 | 3 |

| Screw speed (rpm), R | 150 | 200 | 250 | 1 | 2 | 3 |

Coding example Β1233: broccoli extrudate sample containing 14 % feed moisture, 7 % broccoli/corn ratio extruded at 180 °C with 250 rpm

Mathematical modeling and statistical analysis

A simple power model was used for the prediction of phenolic content and antioxidant activity of the extrudates from independent variables. The proposed equation has the form (Lazou and Krokida 2010b):

| 2 |

where M is the property, M0 is the property at reference conditions, T is the extrusion temperature, R is the screw rotation speed, X is the feed moisture content and C is the vegetable to corn ratio. The symbols with zero indexes indicate the respective values at reference conditions. The values of central point were used as reference conditions, which are 160 °C temperature, 200 rpm screw speed, 16.5 % w.b. feed moisture content and material ratio 6 and 7 %, for broccoli and olive paste respectively.

The model involve five parameters: the property at reference conditions (M0), the exponent for extrusion temperature (aT,M), the exponent for screw speed (aR,M), the exponent for feed moisture content (aX,M), and the exponent for vegetable to corn ratio (aC,M). The influence of process conditions on phenolic content and antioxidant activity, such as, extrusion temperature and screw speed is expressed by the aT,M, aR,M exponents, respectively, while the influence of material characteristics such as feed moisture content and vegetable to corn ratio is expressed by the ax,M, and ac,M exponents, respectively. The parameters that influence the phenolic content and antioxidant activity were estimated by regression analysis.

The influence of independent variables (extrusion conditions and material ratios) on sensory characteristics of extrudates was analyzed using analysis of variance. Significant differences were defined at p < 0.05. All analysis was performed using Statistica software (Statistica Release 7, Statsoft Inc. Tulsa, OK, USA).

Results

Phenolic content of extrudates

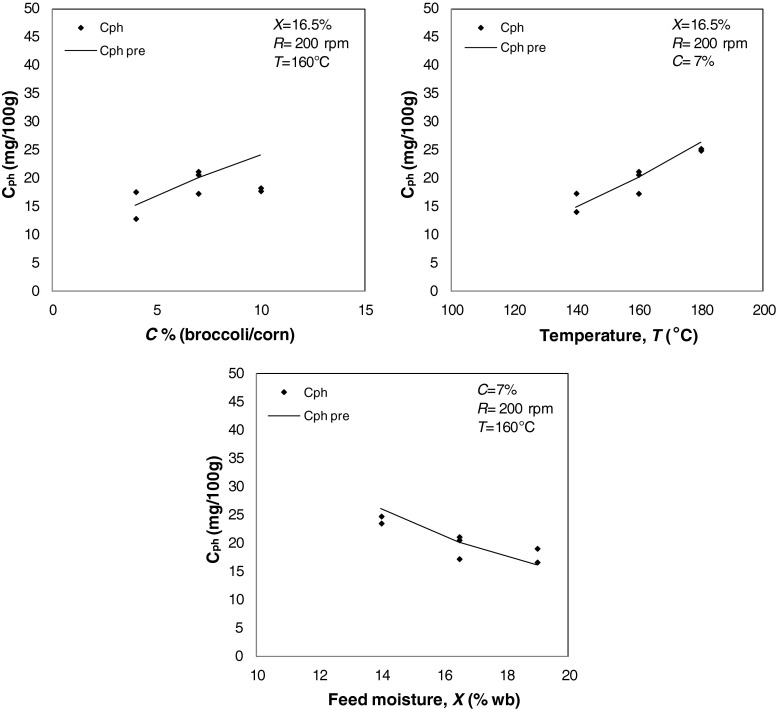

The application of regression analysis showed that not all of the five parameters of the proposed model had a significant effect on the phenolic content of extrudates. The significant parameters affecting phenolic content of broccoli enriched extrudates (p < 0.001) are Cph0, aT,Cph,br, nX,Cph,br and nC,Cph,br. The parameter estimates are summarized in Table 5. Figure 1 shows the variation of phenolic content of extrudates with process conditions and raw material characteristics. Phenolic content increased with extrusion temperature and broccoli flour addition and decreased with feed moisture content. Phenolic content of extrudates was not significantly affected by screw rotation speed.

Table 5.

Results of parameter estimation for phenolic content and antioxidant activity of broccoli enriched extrudates

| C ph,br (mg/100 g) | AA br (%) | |

|---|---|---|

| M 0 | 20.162 ± 0.568 | 32.802 ± 1.216 |

| p-value | ≤0.0001 | ≤0.0001 |

| α T,M,br | 2.288 ± 0.271 | 1.446 ± 0.357 |

| p-value | ≤0.0001 | ≤0.0001 |

| α R,M,br | −0.069 ± 0.121 | 0.097 ± 0.168 |

| p-value | 0.570 | 0.567 |

| α X,M,br | −1.567 ± 0.211 | −1.632 ± 0.292 |

| p-value | ≤0.001 | ≤0.0001 |

| α C,M,br | 0.498 ± 0.074 | 0.407 ± 0.100 |

| p-value | ≤0.0001 | ≤0.0001 |

| R 2 | 0.915 | 0.825 |

Fig. 1.

Phenolic content of broccoli enriched extrudates as a function of process conditions and raw material characteristics

Increasing barrel temperature could have a destructive effect on phenolic compounds, which would be easily damaged from high temperature environment (Kalt 2005). The reduction in phenolic content by extrusion temperature has also been reported for extruded bean, oat cereals and oat extrudates by 19–21, 24–46 and 50 %, respectively (Korus et al. 2007; Viscidi et al. 2004; Zadernowskl et al. 1999). In this study extrusion temperature exhibited an opposite effect. The increase of extrusion temperature increased the phenolic content of extruded broccoli-enriched snacks. The increasing effect of extrusion temperature has been observed for barley-tomato-grape pomace extrudates processed in a twin screw extruder at temperatures ranging from 140 to 160 °C and for barley extrudates extruded in temperature range from 150 to 180 °C. (Altan et al. 2009; Sharma et al. 2012). Apart from vegetable flour addition, antioxidant compounds as well as antioxidant activity change in extruded products could also be attributed to the release of phenolic compounds from cell walls (e.g., breaking complex polyphenols into low molecular weight phenolic compounds), to interaction of phenolics with protein, and to formation of Maillard reaction products as a result of high extrusion temperatures especially at higher temperatures (Nayak et al. 2011; Stojceska et al. 2009).

The phenolic content of broccoli enriched extrudates decreased with the feed moisture content rise. This variation can be explained by the fact that phenolics can be modified as their solubility and functional group properties are altered (Yağci and Göğϋş 2009). Phenolics can also suffer decarboxylation during processing of food (Pokorný 2001). The higher moisture content presumably promoted phenolic polymerization, which affected extractability of phenols and reduced antioxidant activity (Brennan et al. 2011; Pokorný and Schmidt Š 2003). Yağci and Göğϋş (2009) found for extrudates containing orange peel and grape seed by-products (using rice as a base flour) extruded with single screw extruder, ranging feed moisture content from 12 to 18 %, a reduction in phenolic content. A reduction in phenolic content with feed moisture content was also observed for cereal-based extrudates containing carrot powder (Ozer et al. 2006).

The increase in broccoli flour addition increased the phenolic content of extruded products. This fact may be explained by the increased initial phenolic content of the raw material. Extrusion cooking has been found to increase the total phenolic content in cauliflower and red cabbage extrudates (Stojceska et al. 2008; Stojceska et al. 2009). This increase seems likely a normal consequence of the high temperature, water-stress and wounding (Reyes et al. 2007) that could induce the synthesis of enzymes in the metabolic pathway that are responsible for increased production of phenolic compounds (Saltveit 1998). It has been shown that wounding increase antioxidant capacity and total phenolic compounds in lettuce, celery, carrot, parnships and sweetpotato (Reyes et al. 2007; Saltveit 1998) depending on the type of vegetable tissue.

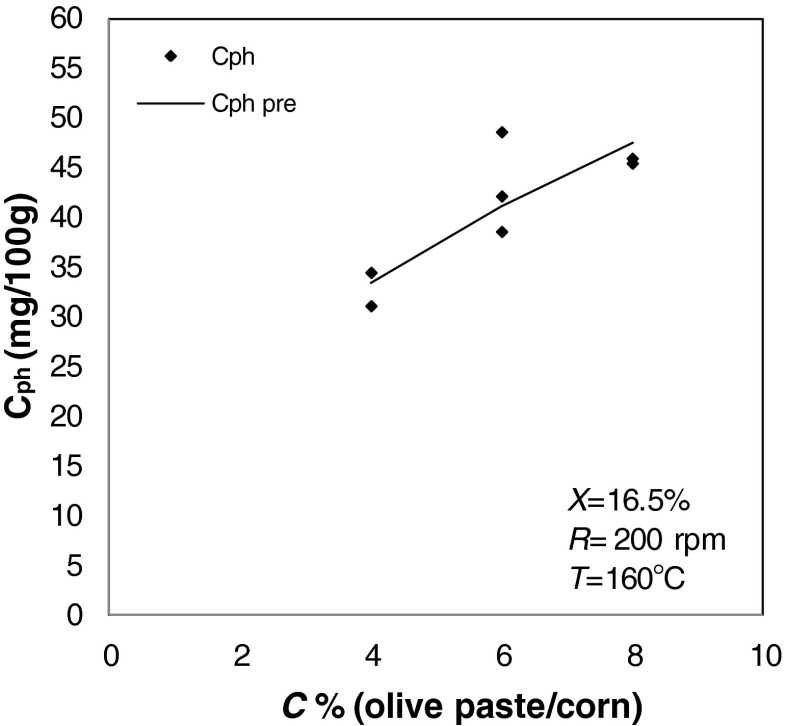

The application of regression analysis showed that the significant parameters affecting phenolic content of olive paste extrudates (p < 0.001) are Cph0,ol and aC,Cph,ol. The parameter estimates are summarized in Table 6. Figure 2 shows the variation of phenolic content of olive paste extrudates with olive paste/corn ratio. Phenolic content increased with olive paste addition in the initial mixture. The increasing olive paste content induced an increase in initial phenolic content of the raw material, which results to increased phenolic contents of the products.

Table 6.

Results of parameter estimation for phenolic content and antioxidant activity of olive paste enriched extrudates

| C ph,ol (mg/100 g) | AA ol (%) | |

|---|---|---|

| M 0 | 41.109 ± 0.430 | 38.600 ± 0.581 |

| p-value | ≤ 0.0001 | ≤ 0.0001 |

| α T,M,ol | 0.044 ± 0.108 | −0.062 ± 0.153 |

| p-value | 0.686 | 0.688 |

| α αN,M,ol | −0.084 ± 0.053 | −0.195 ± 0.074 |

| p-value | 0.124 | ≤ 0,05 |

| α X,M,ol | −0.016 ± 0.094 | −0.454 ± 0.130 |

| p-value | 0.864 | ≤ 0.05 |

| α C,M,ol | 0.510 ± 0.041 | 0.442 ± 0.060 |

| p-value | ≤ 0.0001 | ≤ 0.0001 |

| R 2 | 0.929 | 0.871 |

Fig. 2.

Phenolic content of olive paste extrudates as a function of olive paste/corn ratio

Antioxidant activity of extrudates

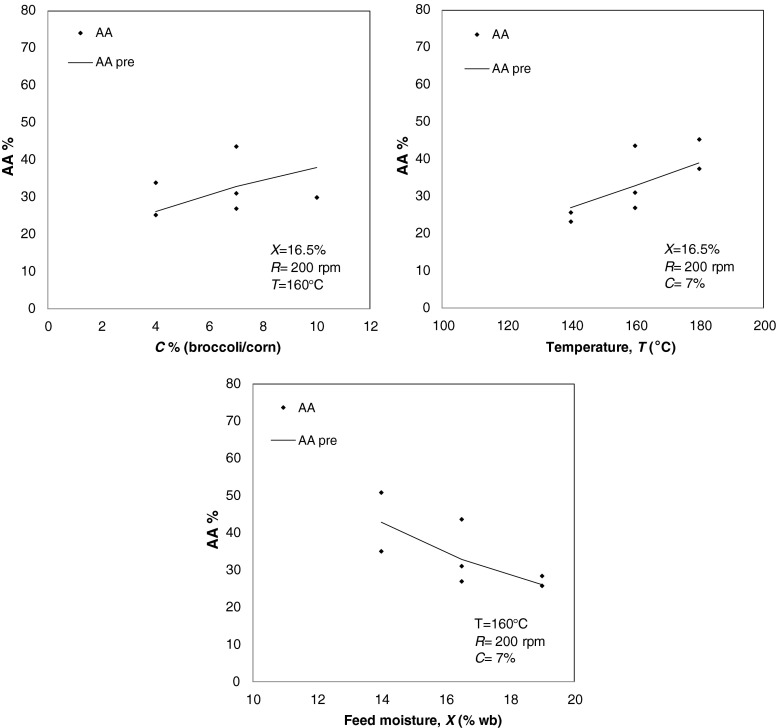

Regression analysis showed that the parameters which affect antioxidant activity of broccoli enriched extrudates significantly (p < 0.001) are AA0,br, aT,AA,br, aX,AA,br, ac,AA,br (Table 5). Fig. 3 shows the variation of antioxidant activity of broccoli extrudates with process conditions and raw material characteristics. Antioxidant activity increased with the increase of extrusion temperature and broccoli flour addition and decreased with increasing feed moisture content. Antioxidant activity was not affected significantly by screw speed.

Fig. 3.

Antoxidant activity of broccoli enriched extrudates as a function of process conditions and raw material characteristics

Antioxidant activity of broccoli enriched extruded snacks increased with extrusion temperature rise. Thermal treatment changes the antioxidants compounds profile and can bring out the production of more antioxidants, which can contribute to the overall antioxidant capacity (Brennan et al. 2011). The increase of antioxidant activity upon thermal treatment has been reported in past for tomato products (Dewanto et al. 2002; Nicoli et al. 1997). The increasing effect of extrusion temperature on antioxidant activity (determined with the ORAC method) has been found for twin screw extruded starch-cranberry pomace products processed at a temperature range between 150 and 190 °C (White et al. 2009).

Feed moisture content was found to decrease the antioxidant activity of broccoli enriched extrudates. It was stated earlier that the higher moisture content presumably promoted phenolic polymerization, which affected extractability of phenols and reduced antioxidant activity (Brennan et al. 2011; Pokorný and Schmidt Š 2003). This fact probably explains the antioxidant activity reduction.

The regression analysis results for antioxidant activity of olive paste extrudates are summarized in Table 6. The parameters which affect antioxidant activity of olive paste extrudates significantly (p < 0.001) are AA0,ol, aR,AA,ol, aX,AA,ol, aC,AA,ol.. Antioxidant activity variations of olive paste extrudates with extrusion conditions and raw material content are presented in Fig. 4. The increase of olive paste/corn ratio raised antioxidant activity, while the increase of feed moisture content and screw speed resulted to antioxidant activity decrease.

Fig. 4.

Antoxidant activity of olive paste extrudates as a function of process conditions and raw material characteristics

The antioxidant activity of olive paste extrudates decreased with the increase of screw rotation speed. The screw speed can increase the mechanical energy dissipated in the material during extrusion cooking (Liang et al. 2002). The fact can contribute to the degradation of bioactive compounds, decreasing the antioxidant activity of the extrudates. Similar variations have been found for barley based extruded products (Altan et al. 2009). The variations of antioxidant activity of olive paste extrudates with feed moisture and material ratio are similar with those of broccoli extrudates.

A positive correlation (R2 = 0.796) was found between phenolic content and antioxidant activity of broccoli extrudates. This finding suggests that the antioxidant activity of produced broccoli-enriched snack is due to a great extent to its phenolic content and is in line with observations of Yağci and Göğϋş (2009) and Repo-Carrasco-Valencia et al. (2001) who reported a high correlation between DPPH and Folin-Ciocalteau assays in rice-based and kiwicha extruded products respectively. In addition, it should be noted that not such a correlation was observed for olive paste extrudates.

Sensory evaluation

Appearance

The analysis of variance showed that the number of open cells (sensory porosity) of broccoli and olive paste extrudates affected significantly (p < 0.05) from feed moisture content and extrusion temperature. The sensory porosity decreased with feed moisture content and increased with extrusion temperature (Figs. 5 and 6). The increased levels of temperature favor the bubble formation (Wang et al. 2005). Furthermore, increasing the feed moisture content leads to the formation of more rigid structures with increased apparent density, resulting in decreased number of open cells in extrudates cellular matrix (Lazou and Krokida 2010b).

Fig. 5.

Appearance characteristics of broccoli enriched extruded snacks as affected by extrusion conditions and raw material characteristics

Fig. 6.

Appearance characteristics of olive paste extruded snacks as affected by extrusion conditions and raw material characteristics

The sensory diameter of broccoli-enriched extrudates affected significantly by extrusion temperature (p < 0.01). The temperature rise led to the reduction of extrudates sensory diameter. The number of open cells and the diameter of extrudates are correlated with the product expansion (Chen et al. 1991). The severity of thermal treatment affects the macromolecular degradation during extrusion cooking, which influences the degree of cooking. Generally, the degree of cooking can affect the pore size formation during extrusion cooking and, consequently the degree of expansion of starch based extrudates (Wang et al. 2005). In contrast, the sensory diameter of olive paste extrudates affected significantly by material ratio and screw rotation speed (p < 0.01). The increase in screw speed increased the sensory diameter of extrudates.

The sensory colour of extrudates affected significantly (p < 0.05) by the vegetable/corn ratio. It was found to decrease with the addition of broccoli flour or olive paste. Colour is an important quality characteristic of extruded foods and its changes during extrusion cooking due to ingredients decomposition and physicochemical reactions that take place during processing and final product expansion. In addition the sensory colour of olive paste extrudates increased with extrusion temperature (p < 0.001). The formation of more air cells (porosity increases) at elevated levels of temperature induce the production of lighter extrudates.

The appearance (homogenous structure) of broccoli enriched extrudates was affected significantly (p < 0.05) by feed moisture content (reduction), while appearance of olive paste extrudates affected (p < 0.001) by extrusion temperature (increase). The perception of homogeneous structure of the products can be affected by their geometrical characteristics and their colour. The observed variations may be attributed to the respective impact of this independent variable in the expansion of the products.

Flavour

The extrudates flavor changes are represented in Figs. 7 and 8. The analysis of variance showed that mealy flavour was affected significantly (p < 0.05) by feed moisture content and extrusion temperature, while burnt flavor affected (p < 0.05) by extrusion temperature. Mealy flavour increased with feed moisture and decreased with extrusion temperature. The burnt flavour increased with extrusion temperature. This fact indicates that the increased levels of temperature enhanced chemical reactions leading to the generation of roasted flavour of extrudates, increasing burnt flavour. Recently it has been found that as the feed moisture content during extrusion increases, the degree of cooking (evaluated by the change of water solubility index because of protein denaturation) of extrudates decreases (Drago et al. 2007; Lazou and Krokida 2010a). So, the lower degree of macromolecular degradation at higher values of feed moisture contents may be a possible explanation of the increased mealy flavour of the extrudates. Feed moisture content has also been found to increase mealy flavour of lentil-based extruded snacks (Lazou et al. 2010).

Fig. 7.

Flavour of broccoli enriched extruded snacks as affected by extrusion conditions and raw material characteristics

Fig. 8.

Flavour of olive paste extruded snacks as affected by extrusion conditions and raw material characteristics

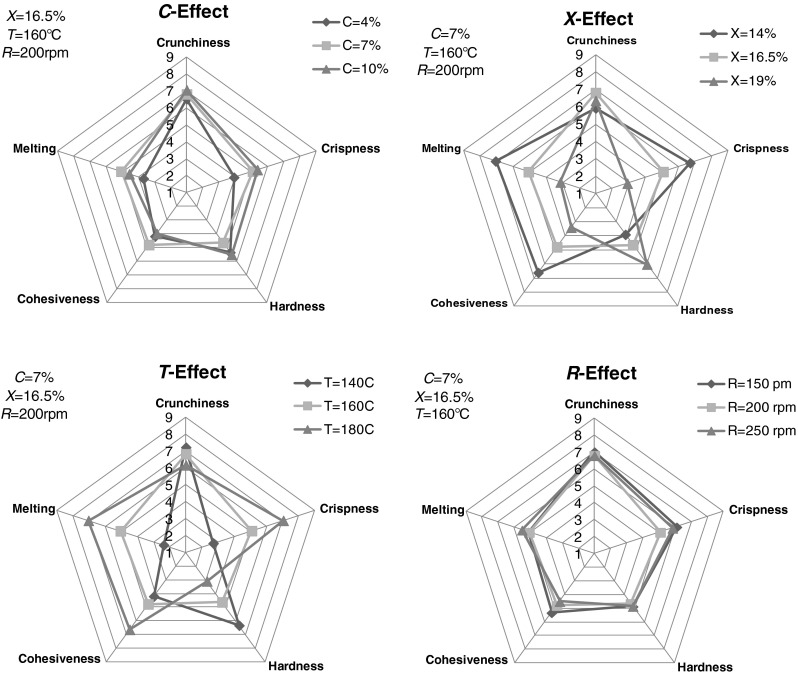

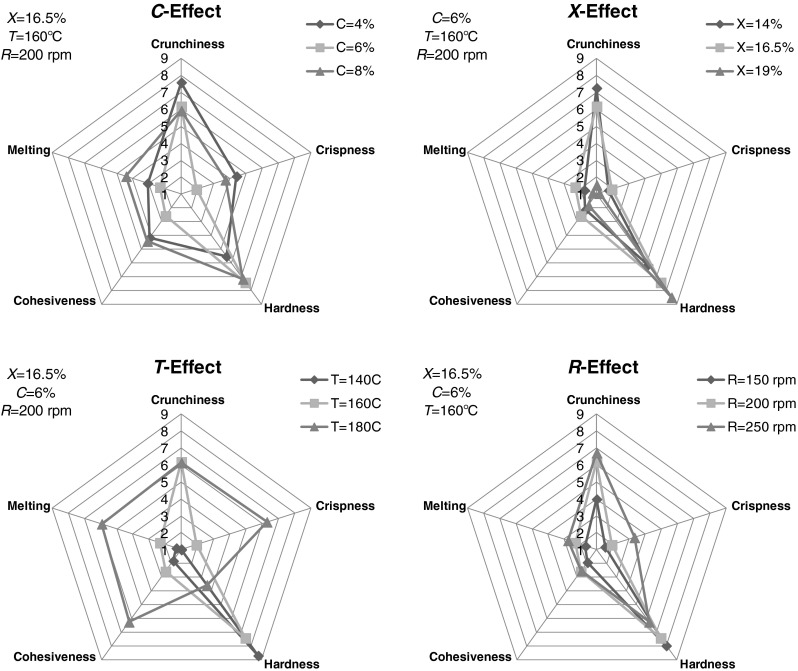

Texture

The variations of the texture of extruded products are shown in Figs. 9 and 10. The crunchiness of olive paste extrudates was affected significantly (p < 0.05) from extrusion temperature. The increased of extrusion temperature led to an increase of extrudates’ crunchiness. At high temperature levels the formation cell walls of extrudates is favoured and as a result the porosity of the product increases and the sound during mastication becomes more intense, increasing the perception of crunchiness (Lazou et al. 2010).

Fig. 9.

Textural characteristics of broccoli enriched extruded snacks as affected by extrusion conditions and feed composition

Fig. 10.

Textural characteristics of olive paste extruded snacks as affected by extrusion conditions and feed composition

Crispness of extrudates was affected significantly (p < 0.01) from feed moisture content. Moisture content had a depressing effect on crispness of both broccoli and olive paste extrudates. This fact may be ascribed to the reduction of expansion of extruded dough, which results by the higher feed moisture (Lazou et al. 2010). Moreover, crispness of extrudates increased with extrusion temperature. The increase of temperature is able to increase the degree of superheating of water, before extruded melt is forced to pass through the die. This may increase the bubble radius, which simultaneously caused the increase in matrix radius and decrease in shell wall thickness (Wang et al. 2005). The thinner shell wall is probably responsible for the improvement of the perception of crispness of snacks.

Hardness of extrudates affected significantly (p < 0.01) by feed moisture content. It increased with feed moisture content. The apparent density of extrudates increases with feed moisture. The denser product exhibit more resistant on fracture. Similar results have been reported in past for soya and lentil based extrudates (Lazou et al. 2010; Li et al. 2005). The extrusion temperature decreased hardness of extruded snacks. The rise in extrusion temperature favours the production of more expanded product which becomes crispier and as a result has softer texture.

The cohesiveness and melting of all extruded products affected significantly (p < 0.05) by feed moisture content. Both of these sensory properties decreased with the feed moisture content rise. The degree of dissolving of the samples can be related with their functionality. It has been proven that the higher levels of moisture content result in lower values of water solubility indexes of corn, bean and lentil extrudates (Hernandez-Diaz et al. 2007; Lazou and Krokida 2010a). This fact is responsible for the reduction of hydration and melting of extruded products. Extrusion temperature was found to improve the melting perception of the samples (p < 0.05). This trend may be expected, because the increase of extrusion temperature ameliorates the degree of cooking during extrusion processing.

Overall acceptability

The overall acceptability of vegetable enriched products is presented in Fig. 11. Samples containing 10 % broccoli to corn ratio were not acceptable (score <6), expect samples with initial moisture content 14 % w.b., processed at extrusion temperature 140 °C with screw speed 150 rpm and 250 rpm and the sample processed at 180 °C and 250 rpm. Acceptable broccoli snacks were produced using feed moisture content 14 %w.b. and 4 % broccoli/corn ratio, processed at 140 °C and 250 rpm and at 180 °C and 150 rpm. The sample containing 16.5 % w.b. feed moisture and 7 % broccoli/corn ratio extruded at 180 °C and 200 rpm was also acceptable.

Fig. 11.

Overall acceptability of broccoli and olive paste extruded products. Sample coding according to Table 4

Acceptable olive paste snacks were produced at 180 °C using screw rotation speed 150 rpm and 250 rpm. These samples had initial moisture content 14 % w.b. and olive paste/corn ratio 4 and 8 %. Most of the acceptable extrudates (both broccoli and olive paste enriched) had fairly homogeneous structure (score > 5), were crunchy, crispy and were relatively soft.

Conclusions

Phenolic content and antioxidant activity of vegetable enriched extruded snacks produced on a twin screw extruder were both depended on process conditions and raw material characteristics. Simple power models were developed in order to examine the effect of extrusion conditions and feed composition on phenolic content and antioxidant activity of extrudates. Phenolic content and antioxidant activity of broccoli enriched extrudates increased with extrusion temperature and broccoli flour addition and decreased with feed moisture content. Phenolic content of olive paste extrudates increased with olive paste addition, while their antioxidant activity increased with material ratio and decreased with feed moisture content and screw rotation speed. Moreover, the sensory properties of extrudates affected by extrusion conditions and raw material characteristics. The extrusion temperature decreased the extrudates diameter and crunchiness, while improved their porosity and hydration. The increase of feed moisture content deteriorated sensory properties of extrudates. The feed moisture content decreased extrudates porosity, homogenous structure, crispness, cohesiveness and melting and increased hardness and mealy flavour. The addition of broccoli flour and olive paste decreased colour of extruded snacks. Acceptable snacks with dehydrated broccoli flour can be produced using 14 % w.b. feed moisture content, extruded at 140 °C and 150–250 rpm or at 180 °C and 250 rpm. The acceptable olive paste extrudates can be produced using 14 % feed moisture content, material ratio 4 and 8 % processed at 180 °C using screw rotation speed 150 and 250 rpm.

Acknowledgments

This work has been performed under the framework of Basic Research Project 2010, funded by National Technical University of Athens.

We also thank Mr. Panagiotis Michailidis for technical assistance and Ms Theodora Lafka for helpful advice and guidance in phenolics and antioxidants analysis.

Contributor Information

G. I. Bisharat, Email: Gibish@ahu.edu.jo

A. E. Lazou, Email: alazou259@gmail.com

N. M. Panagiotou, Email: nickpan@central.ntua.gr

M. K. Krokida, Email: mkrok@central.ntua.gr

Z. B. Maroulis, Email: maroulis@mail.ntua.gr

References

- Altan A, McCarthy KL, Maskan M. Effect of extrusion process on antioxidant activity, total phenolics and β-glucan content of extrudates developed from barley-fruit and vegetable by-products. Int J Food Sci Technol. 2009;44:1263–1271. doi: 10.1111/j.1365-2621.2009.01956.x. [DOI] [Google Scholar]

- Anton AA, Gary Fulcher R, Arntfield SD. Physical and nutritional impact of fortification of corn starch-based extruded snacks with common bean (Phaseolus vulgaris L.) flour: Effects of bean addition and extrusion cooking. Food Chem. 2009;113:989–996. doi: 10.1016/j.foodchem.2008.08.050. [DOI] [Google Scholar]

- Bandoniene D, Murkovic M, Pfannhauser W, Venskutonis PR, Gruzdiene D. Detection and activity evaluation of radical scavenging compounds by using DPPH free radical and on-line HPLC-DPPH methods. Eur Food Res Technol. 2002;214:143–147. doi: 10.1007/s00217-001-0430-9. [DOI] [Google Scholar]

- Bianchi G. Lipids and phenols in table olives. Eur J Lipid Sci Technol. 2003;105:229–242. doi: 10.1002/ejlt.200390046. [DOI] [Google Scholar]

- Bisharat GI, Oikonomopoulou VP, Panagiotou NM, Krokida MK, Maroulis ZB. Effect of extrusion conditions on the structural properties of corn extrudates enriched with dehydrated vegetables. Food Res Int. 2013;53:1–14. doi: 10.1016/j.foodres.2013.03.043. [DOI] [Google Scholar]

- Brennan C, Brennan M, Derbyshire E, Tiwari BK. Effects of extrusion on the polyphenols, vitamins and antioxidant activity of foods. Trends Food Sci Technol. 2011;22:570–575. doi: 10.1016/j.tifs.2011.05.007. [DOI] [Google Scholar]

- Chen J, Serafin FL, Pandya RN, Daun H. Effects of extrusion conditions on sensory properties of corn meal extrudates. J Food Sci. 1991;56:84–89. doi: 10.1111/j.1365-2621.1991.tb07981.x. [DOI] [Google Scholar]

- Choi I-D, Phillips RD, Resurreccion AVA. Consumer-based optimization of a third-generation product made from peanut and rice flour. J Food Sci. 2007;72:S443–S449. doi: 10.1111/j.1750-3841.2007.00457.x. [DOI] [PubMed] [Google Scholar]

- Covas M-I. Olive oil and the cardiovascular system. Pharmacol Res. 2007;55:175–186. doi: 10.1016/j.phrs.2007.01.010. [DOI] [PubMed] [Google Scholar]

- Dewanto V, Wu X, Adom KK, Liu RH. Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J Agric Food Chem. 2002;50:3010–3014. doi: 10.1021/jf0115589. [DOI] [PubMed] [Google Scholar]

- Dijksterhuis G, Luyten H, de Wijk R, Mojet J. A new sensory vocabulary for crisp and crunchy dry model foods. Food Qual Prefer. 2007;18:37–50. doi: 10.1016/j.foodqual.2005.07.012. [DOI] [Google Scholar]

- Drago S, Velasco-González O, Torres R, González R, Valencia M. Effect of the extrusion on functional properties and mineral dialyzability from phaseolus vulgaris bean flour. Plant Foods Hum Nutr. 2007;62:43–48. doi: 10.1007/s11130-006-0033-5. [DOI] [PubMed] [Google Scholar]

- Ghanbari R, Anwar F, Alkharfy KM, Gilani A-H, Saari N. Valuable nutrients and functional bioactives in different parts of olive (Olea europaea L.)—a review. Int J Mol Sci. 2012;13:3291–3340. doi: 10.3390/ijms13033291. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Guy RCE. Raw material for extrusion cooking processes. In: Frame ND, editor. The technology of extrusion cooking. London: Blakie Academic & Professional; 1994. pp. 52–72. [Google Scholar]

- Hernandez-Diaz JR, Quintero-Ramos A, Barnard J, Balandran-Quintana RR. Functional properties of extrudates prepared with blends of wheat flour/pinto bean meal with added wheat bran. Food Sci Technol Int. 2007;13:301–308. doi: 10.1177/1082013207082463. [DOI] [Google Scholar]

- ISO . General guidance for establishing a sensory profile - ISO 13299. Geneva: International Organisation for Standardisation; 1998. [Google Scholar]

- Kalt W. Effects of production and processing factors on major fruit and vegetable antioxidants. J Food Sci. 2005;70:R11–R19. doi: 10.1111/j.1365-2621.2005.tb09053.x. [DOI] [Google Scholar]

- Keum YS, Jeong WS, Tony Kong AN. Chemoprevention by isothiocyanates and their underlying molecular signaling mechanisms. Mutat Res Fundam Mol Mech Mutagen. 2004;555:191–202. doi: 10.1016/j.mrfmmm.2004.05.024. [DOI] [PubMed] [Google Scholar]

- Korus J, Gumul D, Czechowska K. Effect of extrusion on the phenolic composition and antioxidant activity of dry beans of Phaseolus vulgaris L. Food Technol Biotechnol. 2007;45:139–146. [Google Scholar]

- Lafka T-I, Lazou AE, Sinanoglou VJ, Lazos ES. Phenolic and antioxidant potential of olive oil mill wastes. Food Chem. 2011;125:92–98. doi: 10.1016/j.foodchem.2010.08.041. [DOI] [Google Scholar]

- Lazou A, Krokida M. Functional properties of corn and corn-lentil extrudates. Food Res Int. 2010;43:609–616. doi: 10.1016/j.foodres.2009.09.017. [DOI] [Google Scholar]

- Lazou A, Krokida M. Structural and textural characterization of corn-lentil extruded snacks. J Food Eng. 2010;100:392–408. doi: 10.1016/j.jfoodeng.2010.04.024. [DOI] [Google Scholar]

- Lazou AE, Michailidis PA, Thymi S, Krokida MK, Bisharat GI. Structural properties of corn-legume based extrudates as a function of processing conditions and raw material characteristics. Int J Food Prop. 2007;10:721–738. doi: 10.1080/10942910601154305. [DOI] [Google Scholar]

- Lazou A, Krokida M, Tzia C. Sensory properties and acceptability of corn and lentil extruded puffs. J Sens Stud. 2010;25:838–860. doi: 10.1111/j.1745-459X.2010.00308.x. [DOI] [Google Scholar]

- Li S-q, Zhang HQ, Tony Jin Z, Hsieh F-h. Textural modification of soya bean/corn extrudates as affected by moisture content, screw speed and soya bean concentration. Int J Food Sci Technol. 2005;40:731–741. doi: 10.1111/j.1365-2621.2005.00993.x. [DOI] [Google Scholar]

- Liang M, Huff HE, Hsieh FH. Evaluating energy consumption and efficiency of a twin-screw extruder. J Food Sci. 2002;67:1803–1807. doi: 10.1111/j.1365-2621.2002.tb08726.x. [DOI] [Google Scholar]

- Liu Y, Hsieh F, Heymann H, Huff HE. Effect of process conditions on the physical and sensory properties of extruded oat-corn puff. J Food Sci. 2000;65:1253–1259. doi: 10.1111/j.1365-2621.2000.tb10274.x. [DOI] [Google Scholar]

- Moore G. Snack food extrusion. In: Frame ND, editor. The technology of extrusion cooking. London: Blackie Academic and Professional; 1994. pp. 110–143. [Google Scholar]

- Nayak B, Berrios JDJ, Powers JR, Tang J. Effect of extrusion on the antioxidant capacity and color attributes of expanded extrudates prepared from purple potato and yellow pea flour mixes. J Food Sci. 2011;76:C874–C883. doi: 10.1111/j.1750-3841.2011.02279.x. [DOI] [PubMed] [Google Scholar]

- Nicoli MC, Anese M, Parpinel MT, Franceschi S, Lerici CR. Loss and/or formation of antioxidants during food processing and storage. Cancer Lett. 1997;114:71–74. doi: 10.1016/S0304-3835(97)04628-4. [DOI] [PubMed] [Google Scholar]

- Onwulata C, Heymann H. Sensory properties of extruded corn meal related to the spatial distribution of process conditions. J Sens Stud. 1994;9:101–112. doi: 10.1111/j.1745-459X.1994.tb00233.x. [DOI] [Google Scholar]

- Ozer EA, Herken EN, Güzel S, Ainsworth P, İbanoğlu Ş. Effect of extrusion process on the antioxidant activity and total phenolics in a nutritious snack food. Int J Food Sci Technol. 2006;41:289–293. doi: 10.1111/j.1365-2621.2005.01062.x. [DOI] [Google Scholar]

- Plumb GW, et al. Are whole extracts and purified glucosinolates from cruciferous vegetables antioxidants? Free Radic Res. 1996;25:75–86. doi: 10.3109/10715769609145657. [DOI] [PubMed] [Google Scholar]

- Pokorný J (2001) 14 - Natural antioxidant functionality during food processing. In Pokorny J, Yanishlieva N, Gordon M (eds) Antioxidants in food. Woodhead publishing, pp 331–354. doi:http://dx.doi.org/10.1016/9781855736160.4.331

- Pokorný J, Schmidt Š (2003) 15 - The impact of food processing in phytochemicals: the case of antioxidants. In Johnson I, Williamson G (eds) Phytochemical Functional Foods. Woodhead Publishing, pp 298–314. doi:http://dx.doi.org/10.1533/9781855736986.2.298

- Reyes LF, Villarreal JE, Cisneros-Zevallos L. The increase in antioxidant capacity after wounding depends on the type of fruit or vegetable tissue. Food Chem. 2007;101:1254–1262. doi: 10.1016/j.foodchem.2006.03.032. [DOI] [Google Scholar]

- Saltveit ME (1998) Heat-shock and fresh cut lettuce perishables handling quarterly:5–6

- Sarawong C, Schoenlechner R, Sekiguchi K, Berghofer E, Ng PKW. Effect of extrusion cooking on the physicochemical properties, resistant starch, phenolic content and antioxidant capacities of green banana flour. Food Chem. 2014;143:33–39. doi: 10.1016/j.foodchem.2013.07.081. [DOI] [PubMed] [Google Scholar]

- Sharma P, Gujral HS, Singh B. Antioxidant activity of barley as affected by extrusion cooking. Food Chem. 2012;131:1406–1413. doi: 10.1016/j.foodchem.2011.10.009. [DOI] [Google Scholar]

- Stojceska V, Ainsworth P, Plunkett A, Ibanoglu E, Ibanoglu S. Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready-to-eat expanded snacks. J Food Eng. 2008;87:554–563. doi: 10.1016/j.jfoodeng.2008.01.009. [DOI] [Google Scholar]

- Stojceska V, Ainsworth P, Plunkett A, Ibanoglu S. The effect of extrusion cooking using different water feed rates on the quality of ready-to-eat snacks made from food by-products. Food Chem. 2009;114:226–232. doi: 10.1016/j.foodchem.2008.09.043. [DOI] [Google Scholar]

- Verhoeven DTH, Verhagen H, Goldbohm RA, Van Den Brandt PA, Van Poppel G. A review of mechanisms underlying anticarcinogenicity by brassica vegetables. Chem Biol Interact. 1997;103:79–129. doi: 10.1016/S0009-2797(96)03745-3. [DOI] [PubMed] [Google Scholar]

- Viscidi KA, Dougherty MP, Briggs J, Camire ME. Complex phenolic compounds reduce lipid oxidation in extruded oat cereals. LWT Food Sci Technol. 2004;37:789–796. doi: 10.1016/j.lwt.2004.03.005. [DOI] [Google Scholar]

- Wang L, Ganjyal GM, Jones DD, Weller CL, Hanna MA. Modeling of bubble growth dynamics and nonisothermal expansion in starch-based foams during extrusion. Adv Polym Technol. 2005;24:29–45. doi: 10.1002/adv.20030. [DOI] [Google Scholar]

- White BL, Howard LR, Prior RL. Polyphenolic composition and antioxidant capacity of extruded cranberry Pomace†. J Agric Food Chem. 2009;58:4037–4042. doi: 10.1021/jf902838b. [DOI] [PubMed] [Google Scholar]

- Yağci S, Göğϋş F. Effect of incorporation of various food by-products on some nutritional properties of rice-based extruded foods. Food Sci Technol Int. 2009;15:571–581. doi: 10.1177/1082013209353078. [DOI] [Google Scholar]

- Yen GC, Duh PD. Scavenging effect of methanolic extracts of peanut hulls on free-radical and active-oxygen species. J Agric Food Chem. 1994;42:629–632. doi: 10.1021/jf00039a005. [DOI] [Google Scholar]

- Zadernowskl R, Nowak-Polakowska H, Rashed AA. The influence of heat treatment on the activity of lipo and hydrophilic components of oat grain. J Food Process Preserv. 1999;23:177–191. doi: 10.1111/j.1745-4549.1999.tb00378.x. [DOI] [Google Scholar]