Abstract

In the United States, total carbon (TC) is used as a surrogate for determining diesel particulate matter (DPM) compliance exposures in underground metal/nonmetal mines. Since TC can be affected by interferences and elemental carbon (EC) is not, one method used to estimate the TC concentration is to multiply the EC concentration from the personal sample by a conversion factor to avoid the influence of potential interferences. Since there is no accepted single conversion factor for all metal/nonmetal mines, one is determined every time an exposure sample is taken by collecting an area sample that represents the TC/EC ratio in the miner's breathing zone and is away from potential interferences. As an alternative to this procedure, this article investigates the relationship between TC and EC from DPM samples to determine if a single conversion factor can be used for all metal/nonmetal mines. In addition, this article also investigates how well EC represents DPM concentrations in Australian coal mines since the recommended exposure limit for DPM in Australia is an EC value. When TC was predicted from EC values using a single conversion factor of 1.27 in 14 US metal/nonmetal mines, 95% of the predicted values were within 18% of the measured value, even at the permissible exposure limit (PEL) concentration of 160 μg/m3 TC. A strong correlation between TC and EC was also found in nine underground coal mines in Australia.

Keywords: diesel, elemental carbon, measurement

Introduction

The Mine Safety and Health Administration (MSHA) has promulgated rules to limit the exposure of underground metal/nonmetal miners to diesel particulate matter (DPM). (1,2) Initially, mines had to comply with an interim permissible exposure limit (PEL) of 400 μg/m3 total carbon (TC) and then, in 2008, to a final limit of 160 μg/m3 TC. Direct mass measurement was not used to determine DPM exposures because it was neither sensitive nor selective enough. (1,3) Initially, MSHA employed TC as the surrogate because it consistently represented over 80% of DPM and could be measured at concentrations well below the final limit. (1,4) However, a 31-mine joint study by industry and government revealed that aerosols such as dust, cigarette smoke, and oil mist as well as sampling artifacts could interfere with the TC measurements. (2) Dust and some sampling artifacts were addressed by using an impactor and a dynamic blank (a quartz filter in tandem with the sampling filter). However, interferences from cigarette smoke and oil mist could not be eliminated.(5–7) Therefore, MSHA evaluated elemental carbon (EC) as a possible surrogate because interferences or artifacts do not affect EC. One shortcoming of using EC as a surrogate was that the relationship between EC and DPM varied, with engine load in laboratory testing, resulting in a concern about the correlation between DPM (or TC) and EC in underground mines.(1)

In 2002, MSHA investigated the relationship among EC, TC, and DPM in underground metal/nonmetal mines. The investigation centered on comparing EC to TC instead of EC directly to DPM mass for two reasons: the complications of measuring DPM mass in underground mines and the desire to convert the already TC-based exposure limits to an EC value. There was a correlation between EC and TC for concentrations around the interim limit of 400 μg/m3 TC. (8) Therefore, MSHA converted the interim TC PEL to an equivalent EC PEL, using a conversion factor of 1.3 derived from the MSHA data. However, the MSHA data were too variable at the final PEL (160 μg/m3 TC) to determine an equivalent EC PEL. One possible reason for this variability was that the data did not take into account sampling artifacts and some interferences, both of which have a larger influence on the final limit compared to the interim limit.

In 2007, the National Institute for Occupational Safety and Health (NIOSH) built on the MSHA findings by publishing data from four underground metal/nonmetal mines and an isolated zone (section in a mine closed off to perform testing) on the relationship between EC and TC(9) This study concluded that EC and DPM demonstrated a good correlation (R2 of 0.99, equation of linear regression: TC = 1.12 EC × +39.85) in underground metal/nonmetal mines for most of the samples collected, but an accurate TC/EC ratio at the final limit could not be recommended. This conclusion was based upon the increased variability of the data around the final limit and a concern about the effects of newly implemented control technologies on the relationship between TC and EC. Due to these issues, the study suggested that additional data near the final limit needed to be collected before a conversion factor could be determined for the following reasons:

There were limited data at the concentrations near the final limit, and additional data at these concentrations would provide a more reliable curve to evaluate the trend. As mines decrease their concentrations, these data may be obtained.

More than four mines would be a better representation of the overall metal/nonmetal underground mining industry.

There was some information on control technologies from an isolated zone study, but there were no data on the effects of many control technologies, such as diesel particulate filters (DPFs), operating under actual mining conditions.

Notes used to identify and avoid potential interferences could be more precise and be improved for future studies.

After evaluating these findings, MSHA decided to determine DPM exposures in two ways by the following procedure. First, a personal sample is collected and analyzed for EC and TC. Second, if the TC concentration of this sample is above the PEL, the EC is converted to TC using a conversion factor to avoid the influence of potential interferences. (10) The conversion factor is developed by dividing the TC minus a dynamic blank by the EC from an area sample. The area sample is collected downstream of the miner in a location which is intended to represent the TC/EC ratio from the miner's breathing zone without the influence of interferences. If both the TC from the personal sample and the TC calculated from EC are above the final PEL, the sample is considered to be out of compliance. A conversion factor is established for each measurement because at this time, no single reliable conversion factor could be determined.

The problem with this method is that in addition to the personal sample, an area sample must be collected and that it can be difficult to ensure that the sample used to determine the conversion factor is not affected by any interferences. Using a single conversion factor could reduce the number of samples taken and eliminate the potential difficult step of collecting a sample in an area that is not only uninfluenced by interferences but is also representative of the air in the miner's breathing zone. A single conversion factor would also help a mine to determine if personal samples are in compliance without trying to replicate the MSHA sampling protocol.

In this article, researchers evaluate some new data from several mine surveys to determine a single EC to TC conversion method. These current data have several advantages over previous samples collected. They represent more mines, represent many different types of control technologies, do a better job at blank correction, and, most importantly, include more samples near or below the final PEL.

In addition to the relationship between EC and TC in metal/nonmetal mines, the correlation between TC and EC is also of interest in coal mines for some countries. The United States does not measure DPM exposures via NIOSH Method 5040 in coal mines due to the potential interference to TC from coal dust, but instead regulates the emissions from the engine. (11) However, based on research demonstrating that DPM can be measured in the presence of coal dust using an impactor and EC as a surrogate,(12,13) DPM exposures using EC as a surrogate are measured in coal mines in Australia. (14) Therefore, there is an interest in how well EC correlates to DPM. Because total DPM can be difficult to measure, and TC accounts for over 80% of DPM in this study, the correlation between TC and EC was investigated in nine coal mines in Australia.

Methods

Metal/Nonmetal Underground Mines

Sample Collection

During the past several years, NIOSH collected field samples in many areas of 14 mines. Both TC and EC samples were collected using the standard sampling train described in previous publications, (15,16) and analyzed using NIOSH Method 5040. (17) A subset of these data was selected using the following criteria:

- The samples were not taken in the vicinity of oil mist, ammonium nitrate/fuel oil (ANFO), or cigarette smoke.

- As much as possible, the samples were not collected downstream of oil mist.

- A dynamic blank was used to correct for sampling artifacts.

- It was observed that the dynamic blank in SKC DPM cassettes can be contaminated. Therefore, if the dynamic blank was out of the normal range determined in previous studies, the sample was not used.(6)

At least 3 μg/cm2 EC was collected onto the filter.

Samples were collected for at least 200 min.

This data set has some benefits over the previous data used to evaluate the TC and EC relationship, as follows:(9)

Fourteen mines instead of four provide better representation of the mining community and of the types of control technologies being used.

More data points are available.

More care was taken to record and avoid potential interferences.

More data near the final limit are present. Twenty-five percent of the 2007 data were at or below 160 μg/m3 TC, while about 40 percent of the new data set is at or below 160 μg/m3 TC.

- More control technologies are represented:

- Diesel particulate filters

- Flow-through filters

- Biodiesel (35-70%)

- Emission-based maintenance

- Newer engines

There is a better understanding of the dynamic blank correction. (6) One important discovery is the identification of when the dynamic blank is contaminated

Data Analysis

Two different methods for estimating TC concentrations from EC were evaluated. The first method consisted of using a regression model to predict TC from EC. A linear regression analysis was performed on the data using SPSS software Version 21 (IBM Corporation, Armonk, NY). However, the data failed to meet the normality and constant variance assumptions. One method commonly used to overcome these assumptions is to apply a weighted least squares regression. (18,19) A weighted least squares regression was performed in the SPSS Version 21 computer program with a commonly used weighting factor of 1/y to determine the slope, intercept, and 95% prediction intervals. Since the data were non-normal, the Spearman correlation coefficient (rs) was performed using Sigma Plot 12.0 to determine the correlation between TC and EC.

The second method used to convert EC values to TC was to determine a single TC/EC conversion factor for all mines. This analysis was performed in two ways. The average TC/EC ratio was first calculated from all the data to establish an overall conversion factor. Then, each observed value of EC was multiplied by the conversion factor to compute an estimate of TC as demonstrated in the equation below:

| (1) |

To evaluate the accuracy of the estimate, the % bias was determined using the following equation:

| (2) |

Since the data were non-normal, instead of determining 95% confidence or prediction intervals, the value where 95% of the % biases (absolute values) were below was determined. The approach was based on the premise that the size of the sample (222 observations) was large enough for the distribution of values in the sample to provide a reasonable approximation of the distribution of the values in the population. The main shortcoming with this method is that the same data were used to both establish and validate the model. Therefore, a method sometimes employed to validate linear regression models was adapted. (20) The data set was randomly divided in half. One-half of the data set was used to produce the model (in our case establish a single TC/EC conversion factor), and the model was applied to the other half of the data for validation. This random division was performed five times. The average TC/EC ratio with 95% confidence range was calculated from the five sets. Then, the % bias between predicted and measured TC values and the range where 95% of the biases (absolute value) were below was calculated.

Coal Mines

Sample Collection

It is difficult to determine the relationship between TC and EC in coal mines since even with an impactor certain concentrations of coal dust may cause an interference to TC. (12,13) Therefore, DPM measurements were collected in areas where concentrations of coal dust would not interfere significantly with the TC measurement. As with the metal/nonmetal data set, only samples containing at least 3 μg/cm2 EC were used in the coal data set.

During the past several years, DPM samples have been collected in nine coal mines in Australia. The SKC impactor apparatus described in previous publications(15,16) was placed in several areas of the mine during longwall moves to collect NIOSH Method 5040 samples. During the longwall moves, the amount of dust was limited because there was no production in those areas at the time of sampling. A field blank—a cassette exposed to the same elements as the samplers but not used for sampling—was used instead of the dynamic blank. While DPFs are not commonly employed in Australian coal mines, one of the mines included in the sample set of this study did implement DPFs.

Data Analysis

Because the data from the coal mines also failed the tests for normality and constant variance, the same weighted regression analysis performed on the data for the metal/nonmetal mines was applied to the data from the coal mines.

As with the metal/nonmetal data, an universal conversion factor model was applied to the data. It was discovered in this data set that there was higher variability in the TC/EC ratios for concentrations below 50 μg/m3 EC. Therefore, the same data analysis was repeated for data only containing concentrations of EC above 50 μg/m3.

Results and Discussion

Metal/Nonmetal Mines

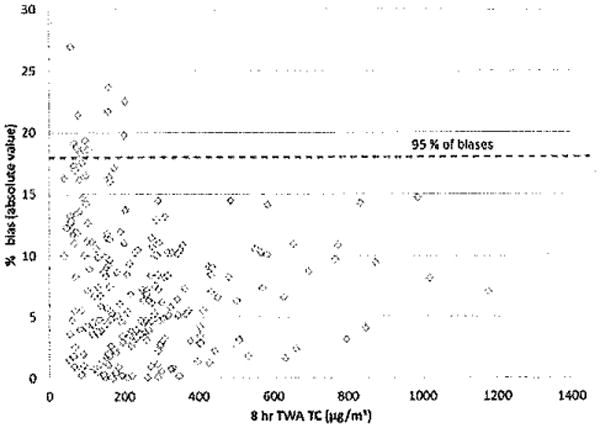

The results of this study demonstrate that 95% of EC concentrations in DPM samples across at least 14 mines can be converted to TC concentrations within 18% of measured values via a single conversion factor. This conclusion is supported through a combination of statistical analyses. The weighted least squares regression model presented in Figure 1 and the Spearman rank correlation coefficient (0.99 with p < 0.05) reveal a strong relationship between TC and EC concentrations from DPM samples across 14 different mines. By using the regression equation to solve for x instead of y, an EC value of 127 μg/m3 corresponds to a TC concentration of 160 μg/m3 with the width of the prediction interval being ±25 μg/m3. Therefore, one is 95% confident that the predicted TC at the PEL is within 18% of the measured value. The weighted regression analysis demonstrated similar results to the linear regression analysis in the 2007 data for the higher DPM concentrations. For example, 321μg/m3 EC represented 400 μg/m3 TC in the 2007 study while 331 μg/m3 EC corresponds to 400 μg/m3 TC in this study (less than a 3% difference).

Figure 1.

The weighted regression of the 8-hr TWA of TC concentration vs. EC concentration of DPM samples from 14 metal/nonmetal mines.

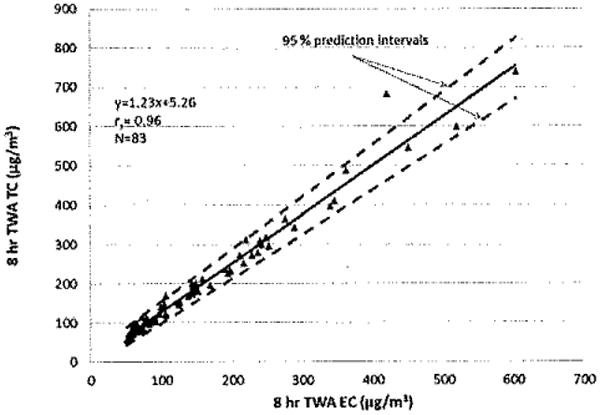

The universal conversion factor approach shows similar results. Table I lists the mines and the average TC/EC ratio for each mine. The average ratio for the whole data set is 1.27; application of this ratio shows 126 μg/m3 EC corresponding to 160 μg/m3 TC. When each EC value is multiplied by this ratio and the % bias between the calculated and measured TC value is determined, Figure 2 shows that 95% of the biases are below ±18%. Therefore, for these 14 mines in this survey, a conversion factor of 1.27 results in TC concentrations within 18% of the measured value 95% of the time. One could argue that the use of the same data to develop and validate the model may skew the results. To address this concern, the data set is randomly divided in half; half of the data are used to establish the model and the other half is used to validate it. After repeating this random division of the total data set five times, the average TC/EC ratio across the five repetitions is 1.28 ± 0.01. After calculating the % biases between the estimated and measured TC values using the single conversion factor five times, 95% of all biases are within 18% of the measured value.

Table I. TC/EC Ratios of Several Metal/Nonmetal Mines in the United States.

| Mine | Engine controls | Type | Other control technologies used | N | TC/EC | Standard deviation |

|---|---|---|---|---|---|---|

| A | none | limestone | cabs, ventilation | 15 | 1.24 | 0.09 |

| B | DPFs | metal | ventilation | 17 | 1.39 | 0.15 |

| C | DPF/biodiesel (70%) | metal | cabs, ventilation | 14 | 1.29 | 0.16 |

| D | Biodiesel (50%)-DPF | metal | cabs, ventilation | 8 | 1.34 | 0.16 |

| E | emission-based maintenance | limestone | cabs, ventilation | 15 | 1.24 | 0.07 |

| F | none | limestone | cabs, ventilation | 9 | 1.25 | 0.09 |

| G | none | limestone | cabs, ventilation | 9 | 1.44 | 0.1 |

| H | none | limestone | cabs, newer engines, ventilation | 11 | 1.23 | 0.07 |

| I | none | metal | cabs and ventilation | 3 | 1.22 | 0.08 |

| J | 50% biodiesel/doc | limestone | cabs and ventilation | 11 | 1.4 | 0.12 |

| K | 35% biodiesel/doc | limestone | cabs and ventilation | 6 | 1.19 | 0.03 |

| L | flow-through filters | metal | ventilation | 13 | 1.21 | 0.06 |

| M | cabs ventilation | granite | cabs and ventilation | 53 | 1.23 | 0.09 |

| N | newer engines | limestone | cabs and ventilation | 38 | 1.26 | 0.12 |

Figure 2.

The absolute value of the % bias of the calculated TC from the TC/EC ratio when compared to the measure TC value from 14 metal/nonmetal mines.

The weighted regression and universal conversion factor models resulted in a similar relationship being revealed between TC and EC from DPM samples and with similar errors. The errors or biases represent the overall error in the method, including errors from the analytical method, pump, sampling, and conversion technique. The errors of both models are less than the current error for determining compliance results from the TC of the personal sample (error of 19%) or when converting EC to TC using a single area sample to determine conversion factor (error of 26%).(21) Therefore, using a single conversion factor could potentially be better than the current MSHA compliance method while eliminating the need for additional area samples.

Though the number of mines (14) used in this research study does not represent all mines, the number of points is substantial. The control technologies in this data set represent most of what is used currently in underground mines. (No data were collected for mines using 100% biodiesel).

Australian Coal Mines

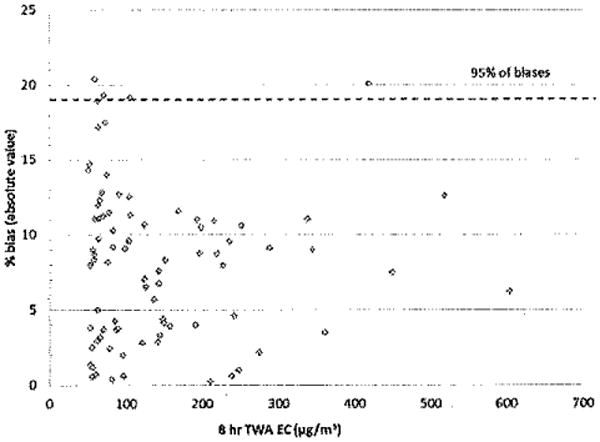

For Australian coal mines, the results demonstrate that 95% of the time TC will be within about 19% of the measured value when predicted from the EC values above 50 μg/m3. Out of a total sample of 120 cases, 83 cases were included in the analysis because there is some evidence that there is higher variability between the relationship between TC or DPM and EC at concentrations of EC below 50 μg/m3. The range used in the analysis incorporates the recommended exposure limit (100 μg/m3 EC) for the state of New South Wales in Australia. (14) Again, these results were supported using a combination of statistical analyses. For concentrations of EC above 50 μg/m3, a strong relationship between TC and EC in the nine coal mines is demonstrated in the weighted regression (see Figure 3) and the Spearman rank correlation coefficient (0.96 with p < 0.05). Application of the regression equation shows that a TC value of 128 μg/m3 would be predicted from an EC value of 100 μg/m3. The margin of error in the 95% prediction interval is found to be ±27.7. This margin would be equivalent to a 21.6% error in the predicted value at 100 μg/m3 EC.

Figure 3.

The weighted regression of the 8-hr TWA of TC concentration vs. EC concentration of DPM samples from nine coal mines (for data of EC above 50 μg/m3).

The single conversion factor method for data with EC concentrations above 50 μg/m3 EC is able to calculate TC values within 19% of the measured value. Table II lists the mines and the average TC/EC ratio for each mine. The average ratio for the whole data set is 1.30 resulting in an EC value of 100 μg/m3 converting to a TC value of 130 μg/m3. When each EC is multiplied by this ratio and the % bias between the calculated and measured TC value is determined. 95% of the biases are within ±19% (see Figure 4). Therefore, for these nine mines in this survey, a conversion factor of 1.30 results in TC concentrations (when EC is above 50 μg/m3) within 19% of the measured value 95% of the time. After implementing a split model where half (randomly selected) the data are used to establish the model and the other half is used to validate five times the average ratio of the five random sets is 1.30 ± 0.01. After implementing this model on the other half of the data set and calculating the % biases, 95% of all biases are again found to be within 19% of the measured value.

Table II. TC/EC Ratios of Several Coal Mines in Australia.

| Mine | Engine controls | Type | Other control technologies used | Whole data set | EC > 50 μg/m3 | ||||

|---|---|---|---|---|---|---|---|---|---|

|

|

|

||||||||

| N | TC/EC | Standard deviation | N | TC/EC | Standard deviation | ||||

| CA | None | Coal, LW Punch mine | Diesel tag hoard, Electric mule at Recovery face | 6 | 1.10 | 0.05 | 4 | 1.11 | 0.06 |

| CB | None | Coal, LW mine | Diesel tag board, Electric mule at Recovery face | 10 | 1.46 | 0.18 | 7 | 1.36 | 0.07 |

| CC | None | Coal, LW Punch mine | Diesel tag board, Electric mule at Recovery face | 7 | 1.27 | 0.10 | 4 | 1.21 | 0.02 |

| CD | None | Coal, LW mine | Diesel tag board, Electric Loader at Recovery face | 16 | 1.27 | 0.08 | 10 | 1.26 | 0.07 |

| CE | Exhaust Filters | Coal, LW mine | Diesel tag board, Electric dozer at Recovery face, special vent circuit design for LW move | 30 | 1.50 | 0.34 | 15 | 1.4 | 0.17 |

| CF | None | Coal, LW mine | Diesel tag board | 12 | 1.23 | 0.05 | 12 | 1.23 | 0.05 |

| CG | None | Coal, LW mine | Diesel tag board | 25 | 1.32 | 0.14 | 21 | 1.31 | 0.13 |

| CH | None | Coal, LW mine | Diesel tag board, Electric mule at Recovery face | 9 | 1.24 | 0.15 | 9 | 1.24 | 0.15 |

| CI | None | Coal, LW mine | Electric mule at Installation face | 5 | 1.32 | 0.07 | 4 | 1.33 | 0.08 |

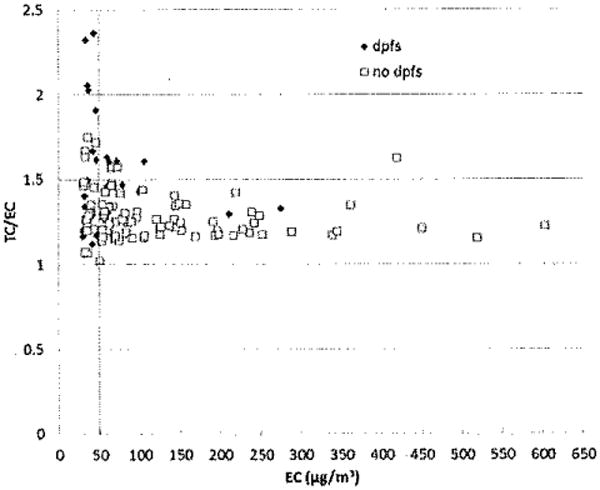

Figure 4.

The absolute value of the % bias of the calculated TC from the TC/EC ratio when compared to the measured TC value from nine Australian coal mines (for data of EC above 50 μgg/m3).

As mentioned earlier, only data with EC concentrations above 50 μg/m3 were included because as seen in Figure 5 the variability of TC/EC ratios increases at concentrations of EC below 50 μg/m3. One possible reason for this observation could be that DPFs can start to affect the relationship between TC or DPM and EC at concentrations of EC below 50 μg/m3. As seen in Table II and Figure 5, the data from the mine (Mine CE) using some DPFs on equipment result in the highest TC/EC ratios and more than twice the variability (standard deviation) of any other mine. In addition, as seen in Figure 5, TC/EC ratios start to become obviously greater below 50 μg/m3 EC at the mine using DPFs but not as much in the other mines. Since there are only data of DPFs for one mine, more data are needed to confirm this potential reason. In support of this finding, an isolated zone study shows that some DPFs can influence the TC and EC relationship.(9)

Figure 5.

TC/EC ratios vs. EC concentrations comparing mines that do and do not use DPFs.

With this data set, TC, and therefore DPM, can be predicted from EC concentrations within 21.6% (95% confidence) at 100 μg/m3 EC using a regression model and 19% (95% of the time) using a single conversion factor for EC concentrations greater than 50 μg/m3. It is important to note that the variability of the data could have been affected by not using a dynamic blank (a field blank does not correct for artifacts as well as a dynamic blank (6)) and by interferences not accounted for. Although nine mines were included, the data set may not be a statistical representation of all coal mines in Australia.

Conclusion

The data set from the metal/nonmetal mines sampled for this study demonstrates a strong relationship between TC and EC in 14 underground mines, even when using several different types of control technologies. TC is able to be predicted from the EC values with an overall conversion factor within 18% of measured values 95% of the time. Using this single conversion model for at least the 14 mines sampled in this study results in less error by comparison to compliance sampling, is less complicated, and requires fewer samples. Using the model derived from these data to determine an EC value for the PEL, an EC value of 127 or 128 μg/m3 would represent a TC value of 160 μg/m3. This data set does not represent all mines but contains many samples from 14 mines, and most control technologies in underground mines are represented (except for 100% biodiesel).

The data set from the coal mines in Australia also demonstrated a strong relationship between TC and EC in nine underground mines. It showed that TC, and therefore DPM, for these nine coal mines can be determined within 19% from using EC as a surrogate for at least concentrations of 50 μg/m3 EC and greater, even when using DPFs.

Footnotes

Disclaimer: Mention of a company name or product does not constitute endorsement by the National Institute for Occupational Safety and Health. The findings and conclusions in this report are those of the authors and do not necessarily represent the views of the National Institute for Occupational Safety and Health. This article is not subject to U.S. Copyright law.

References

- 1.Diesel Particulate Matter Exposure of Underground Metal and Nonmetal Miners. Federal Register. 2001 Jan 19;66:5706. 13. [Google Scholar]

- 2.Part II, Diesel Particulate Matter Exposure of Underground Metal and Nonmetal Miners. Federal Register. 2006 May 18;71:28924. 96. [Google Scholar]

- 3.Cantrell BK, Watts WF., Jr Diesel Exhaust Aerosol, Review of Measurement Technology. The Canadian Ad Hoc Committee Proceedings of the November 6—7, 1996, Plenary Conference in Toronto, Ontario, Diesel Emissions Exposure Reduction in Mines; Toronto, Ontario, Canada. Canada Centre for Mineral and Energy Technology (CANMET); 1996. pp. 7.1–7.9. [Google Scholar]

- 4.Kittelson DB. Engines and nanoparticles: A review. J Aerosol Sci. 1998;29:575–588. [Google Scholar]

- 5.Noll JD, Timko RJ, McWilliams L, et al. Sampling results of the improved SKC diesel particulate matter cassette. J Occu Environ Hyg. 2005;2:29–37. doi: 10.1080/15459620590900320. [DOI] [PubMed] [Google Scholar]

- 6.Noll JD, Birch ME. effects of sampling artifacts on occupational samples of diesel particulate matter. Environ Sci Technol. 2008;42:5223–5228. doi: 10.1021/es702883k. [DOI] [PubMed] [Google Scholar]

- 7.Noll JD, Mischler S, Schnakenberg GH, et al. Measuring Diesel Particulate Matter in Underground Mines Using Sub Micron Elemental Carbon as a Surrogate. In: Mutmansky J, Ramani R, editors. Proceedings for the 11th US North American Mine Ventilation Symposium. Vol. 2006. State College, Pennsylvania: 2006. pp. 105–110. [Google Scholar]

- 8.Diesel Particulate Matter Exposure of Underground Metal and Nonmetal Miners. Federal Register. 2002 Jul 18;67:47297. 138. [Google Scholar]

- 9.Noll JD, Bugarski AD, Patts LD, et al. Relationship between elemental carbon, total carbon, and diesel particulate matter in several underground metal/non-metal mines. Environ Sci and Technol. 2007;41(3):710–716. doi: 10.1021/es061556a. [DOI] [PubMed] [Google Scholar]

- 10.Diesel Particulate Matter Exposure of Underground Metal and Nonmetal Miners. Federal Register. 2008 May 20;73:29058. 98. [Google Scholar]

- 11.Diesel Particulate Matter Exposure of Coal Miners. Federal Register. 2001 Jan 19;66:5526. 3. [Google Scholar]

- 12.Noll JD, Birch ME. Evaluation of SKC DPM cassettes for monitoring diesel particulate matter in coal mines. J Environ Monit. 2004;6:973–978. doi: 10.1039/b410057c. [DOI] [PubMed] [Google Scholar]

- 13.Birch ME, Noll JD. Submicrometer elemental carbon as a selective measure of diesel particulate matter in coal mines. J Environ Monitor. 2004;6:799–806. doi: 10.1039/b407507b. [DOI] [PubMed] [Google Scholar]

- 14.New South Wales Department of Primary Industries. Guideline for the Management of Diesel Engine Pollutants in Underground Environments. [accessed November 24, 2014];MDG-29. 2008 Available at http://www.resources.nsw.gov.au/data/assets/pdf.file/0011/419465ZMDG-29.pdf.

- 15.Noll JD, Cecala AB, Organiscak JA. Transactions 2011. Vol. 330. Littleton, CO: Society for Mining, Metallurgy, and Exploration, Inc.; 2012. The Effectiveness of Several Enclosed Cab Filters and Systems for Reducing Diesel Particulate Matter; p. 408. [Google Scholar]

- 16.Noll JD, Patts L, Grau R. The Effects of Ventilation Controls and Environmental Cabs on Diesel Particulate Matter Concentrations in Some Limestone Mines. Proceedings of the 12th U.S./North American Mine Ventilation Symposium; Reno, NV. June 9–11, 2008; pp. 463–468. [Google Scholar]

- 17.Birch ME, Cary R. Elemental carbon-based method for occupational monitoring of particulate diesel exhaust: methodology and exposure issues. Analyst. 1996;121:1183–1190. doi: 10.1039/an9962101183. [DOI] [PubMed] [Google Scholar]

- 18.National Institute of Standards and Technology (NIST) Gaithersburg, MD: NIST; 2012. [accessed November 24, 2014]. NIST/SEMATECH e-Handbook of Statistical Methods. Available at http://www.itl.nist.gov/div898/handbook. [Google Scholar]

- 19.Neter J, Kutner MH, Wasserman W, Nachtscheim CJ. Applied Linear Regression Models. New York: McGraw-Hill College; 1996. [Google Scholar]

- 20.Meko DM, Graybill DA. Tree-ring reconstruction of Upper Gila River discharge. Water Resources Bull. 1995;31(4):605–616. [Google Scholar]

- 21.Mine Safety and Health Administration (MSHA) Use of Error Factors in Determining a Miner's Overexposure to DPM. [accessed November 24, 2014];Program Policy Letter No P0S-1V-01. 2008 Available at http://www.msha.gov/01-995/TotalCarbonPersonalExposureLimit.pdf.