Abstract

As the only fuel that is not chemically bound to carbon, hydrogen has gained interest as an energy carrier to face the current environmental issues of greenhouse gas emissions and to substitute the depleting non-renewable reserves. In the last years, there has been a significant increase in the number of publications about the bacterium Thermotoga neapolitana that is responsible for production yields of H2 that are among the highest achievements reported in the literature. Here we present an extensive overview of the most recent studies on this hyperthermophilic bacterium together with a critical discussion of the potential of fermentative production by this bacterium. The review article is organized into sections focused on biochemical, microbiological and technical issues, including the effect of substrate, reactor type, gas sparging, temperature, pH, hydraulic retention time and organic loading parameters on rate and yield of gas production.

Keywords: thermophilic bacteria, fermentation, hydrogen, lactic acid, carbon dioxide, biomass, renewable energy, process kinetics, energy carrier, green-house gas

1. Introduction

Anaerobic digestion of organic material is regarded as a potential method for hydrogen (H2) production from biomass [1,2]. Besides simple carbohydrates (e.g., glucose) or polymers such as starch and cellulose, the process utilizes a wide range of organic compounds as substrate, including organic wastes and agro-industrial matrices [3,4,5,6,7,8,9]. Considering that such residues are abundant, cheap, renewable and biodegradable, H2 production by fermentation of this material is potentially competitive over conventional process [5] and technically more feasible than other biological methods, including photofermentation and photobiolysis. Furthermore production of H2 from organic substrates is viewed as an environmentally friendly process because of its potential to yield clean energy while reducing waste and greenhouse gas emissions. Although a more detailed life cycle assessment of feedstock materials is required to fully understand the environmental impact of the whole process, the possible implications on climate change have prompted growing attention to the fermentative production of H2 in recent years [10].

Chemotrophic H2 production can be operated at mesophilic (25–40 °C), thermophilic (40–65 °C) or hyperthermophilic (>80 °C) temperatures [11,12,13], but the process in heated cultures benefits from thermodynamically favorable reactions [14,15]. Although metabolic activity sharply drops outside the optimum temperature range, increase of temperature accelerates reaction rates and offers a number of technical advantages including reduction of viscosity, improvement of mixing efficiency, reduced risk of contamination and no need for reactor cooling [16]. In addition, the high operating temperature enhances hydrolysis rate of complex substrates and, generally speaking, thermophiles can more effectively utilize complex sugars, e.g., cellulose, than mesophiles [17,18]. Furthermore, hyperthermophilic conditions suffer less from inhibition due to H2 partial pressure and, in the case of microbial consortia, are less sensitive to H2 consumers like methanogens [19,20].

In the last years, pure cultures of the hyperthermophilic eubacterium Thermotoga neapolitana has shown promising results for fermentative H2 production from several organic substrates [21]. In a recent paper [22], we have also shown that T. neapolitana can yield significant amounts of lactic acid without affecting H2 synthesis, thus offering novel applications for the fermentative process. Here we critically review the most recent data on H2 production by T. neapolitana and discuss the challenges and future prospects of H2 production using this bacterium.

2. Taxonomy of Thermotoga neapolitana

Originally isolated from shallow submarine hot spring nears Lucrino in the Bay of Naples in 1986 [23,24], T. neapolitana is a gram-negative bacterium that grows between 55 and 90 °C with an optimal growth temperature of 80 °C [23,24]. The species belongs to the order Thermotogales (Phylum Thermotogae, class Thermotogae) that have, until the recent report of Mesotoga prima [25], been exclusively comprised of thermophilic or hyperthermophilic organisms. The order includes an assembly of rod-shaped, non-sporulating bacteria that are characterized by an unconventional outer envelope called the “toga”, which forms a large periplasmic space at the poles of each rod [26,27,28]. Although it has been shown that these regions could be involved in the formation of multicellular rods [29], the physiological role of the large periplasm remains unknown. Thermotogales also synthesizes many polysaccharide hydrolases, some exposed on the cell surface, that allow utilization of diverse sources of carbon [30,31,32,33,34,35,36,37,38,39].

The phylogenetic position of Thermotogae is still unresolved, even if many studies agree to place members of this phylum among the deepest branches of bacteria, and, thus, as prime candidates for evolutionary studies [21,40]. Based upon different phylogenetic approaches, the class Thermotogae is divided into three orders (Thermotogales, Kosmotogales and Petrotogales) containing four families (Thermotogaceae, Fervidobacteriaceae, Kosmotogaceae and Petrotogaceae) and 10 genera (Thermotoga, Thermosipho, Fervidobacterium, Geotoga, Petrotoga, Marinitoga, Thermococcoides, Kosmotoga, Oceanotoga, and Defluviitoga). The genus Thermotoga currently includes eleven species, i.e., T. maritima, T. neapolitana, T. thermarum, T. elfii, T. subterranea, T. hypogea, T. petrophila, T. naphthophila, T. lettingae, T. caldifontis, and T. profunda, that thrive in marine hydrothermal vents, oil reservoir sites and volcanic springs [21]. Recently, Bandhari and Gupta [41] proposed to split the current genus Thermotoga into two evolutionary distinct groups. According to this last classification, the original genus Thermotoga retains only the species T. maritima, T. neapolitana, T. petrophila, T. naphthophila, Thermotoga sp. EMP, Thermotoga sp. A7A and Thermotoga sp. RQ2 while the other Thermotoga species (T. lettingae, T. thermarum, T. elfii, T. subterranea and T. hypogea) belong to the new genus Pseudothermotoga [41].

3. Dark Fermentation Pathway in Thermotoga neapolitana

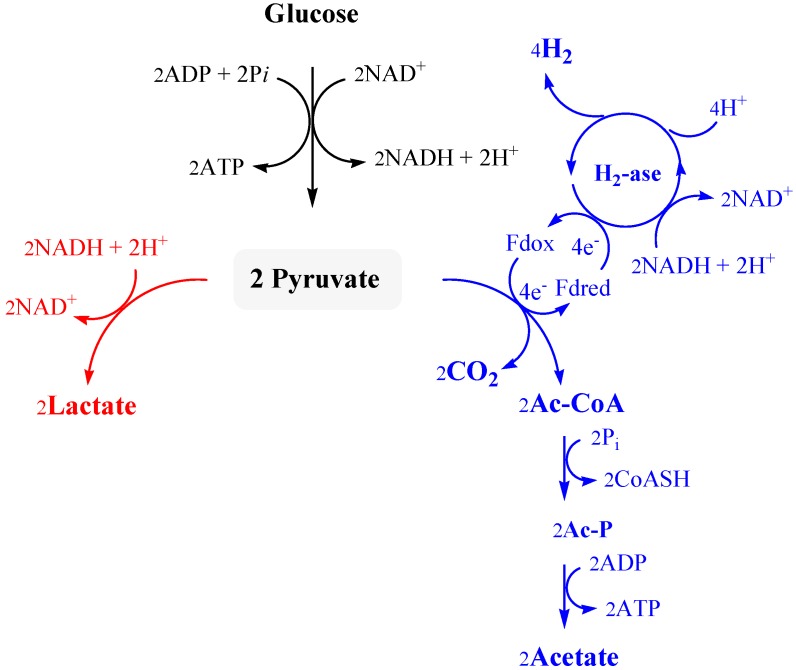

Chemotropic production of H2 is a respiration process using H+ as electron acceptor. The biochemical synthesis by bacteria of the genus Thermotoga entails catabolism of carbohydrates even if different members of the genus have the ability to use a large variety of substrates that, for example in T. elfii, include also sulfur compounds [42]. As in the related species T. maritima [43,44], T. neapolitana harvests energy mainly by glycolysis via the Embden-Meyerhoff pathway (EMP) [45]. EMP is the most common route for oxidation of glucose (and other hexoses) and supplies energy (ATP), reducing equivalents (NADH) and pyruvate, that undergoes terminal oxidation (acetate) or is used for biosynthesis (e.g., acetyl-CoA). According to the classical model of fermentation, generally referred to as Dark Fermentation (DF), 4 mol of H2 can be theoretically produced per mole of consumed glucose [46]. This molar ratio between H2 and glucose is usually referred to as the Thauer limit and represents the highest yield that can be achieved by a sugar-based fermentation by thermophilic bacteria. As fermentative H2 production is a mean to dispose of electrons, there is a direct relationship between the biogas yield and the type of the organic products that are concurrently released during the process. Yield is optimized only when all glucose is converted to acetate because NADH and electrons are fully consumed to produce the energy carrier (Equation (1)). On the other hand, in a redox neutral process, no H2 is produced when lactic acid is the organic product released in the medium (Equation (2)).

| (1) |

| (2) |

As shown in Figure 1, acetate production is driven by formation of additional ATP but, when H2 accumulates and consumption of NADH stops, pyruvate is diverted away for the synthesis of other organic substrates, mostly lactate that is produced by lactate dehydrogenase (LDH) with the concomitant oxidation of NADH. Lactate levels reported during fermentation by Thermotoga species vary from trace amounts up to levels rivaling those of acetate [44,47,48,49]. Low levels of alanine and ethanol have been also reported in T. neapolitana [21,45,50].

Figure 1.

Streamlined biochemical pathway for fermentative H2 production, adapted from Reference [22]. Water is omitted for simplicity.

The mechanism behind the high H2 yields achieved by T. neapolitana is likely related to the unique characteristic of the heterotrimeric [FeFe]-hydrogenase that is present in the bacterium. Hydrogenases (H2ase) constitute a family of enzymes that efficiently reduce protons to H2 in many anaerobic microorganisms. Sequence analysis on the three proteins that form the H2ase of T. maritima, which has more than 90% homology with that of T. neapolitana, suggests that the β subunit is a flavoprotein that accepts electrons from NADH, and the γ subunit transfers electrons from the β subunit to the catalytic α subunit. The catalytic site (the so-called H cluster) shows the most complex Fe-S structure characterized to date and requires the specific action of three highly conserved proteins to be assembled [51]. Despite the detailed knowledge of the active site, how the endergonic reaction of H2 production is accomplished under physiological conditions is not clear. In fact, the reduction of H2ase by NADH is an energetically unfavorable reaction and the reaction is typically influenced by environmental conditions such as pH, cell growth rate and H2 partial pressure. In many thermophilic bacteria and several Clostridium species, the transfer of electrons to proton ion by [FeFe]-H2ase requires the presence of NADH-Ferredoxin oxidoreductase (NFOR). In this reaction, it is suggested that the oxidized ferredoxin (Fd) is reduced by NADH, which is formed during carbon metabolism. Then, the electrons in Fd are transferred to protons by [FeFe]-H2ase to form molecular H2 (Figure 1) [52].

Recently Schut and Adams proposed a novel model for H2 production for Thermotoga species based on the synergistic effect of NADH and reduced Fd [44]. According to this study, H2ase of T. maritima concurrently oxidizes reduced Fd and NADH in a 1:1 ratio in order to reduce the H+ ions. Ferredoxin is cyclically produced by pyruvate Fd oxidoreductase (POR) during oxidation of pyruvate to acetyl coenzyme A (Figure 1). This mechanism that couples an exoergonic reduction with an endoergonic reduction has been called “bifurcating” [53] and it is proposed to correspond to a novel type of energy conservation. Thus, energy from the oxidation of Fd drives the unfavorable oxidation of NADH in T. maritima [44] and the hyperthermophilic bacterium has the ability to achieve H2 yields close to the Thauer limit. According to this mechanism, H2 production by H2ase of T. neapolitana is influenced by factors that affect either NADH or reduced Fd. Furthermore, the composite mechanism of this H2ase is consistent with the complexity of the trimeric structure, which is much greater than that of the typical Fd-dependent, single subunit [Fe-Fe]-H2ase found in Clostridium spp. [44].

4. Production of Lactic Acid and H2 by Capnophilic Lactic Fermentation

T. neapolitana and the other taxonomically-related species, such as T. maritima, T. petrophila, T. naphtophila, T. caldifontis, T. profunda, Pseudothermotoga thermarum, P. elfii, P. subterranea, P. hypogea and P. lettingae have been targeted for biological production of H2 because of yields approaching the theoretical maximum value (Thauer limit) of 4 mol H2/mol glucose [46]. According to Figure 1, this result can be achieved only if all of the reducing equivalents from glucose oxidation are used to reduce protons to H2. Nevertheless, as discussed above, in practice these reducing equivalents are also employed for biosynthetic purposes or formation of other fermentation products. Thus, the high H2 yields and low production of biomass that have been reported for T. neapolitana suggest that pyruvate is only partially used in other metabolic transformations under standard operating conditions [54].

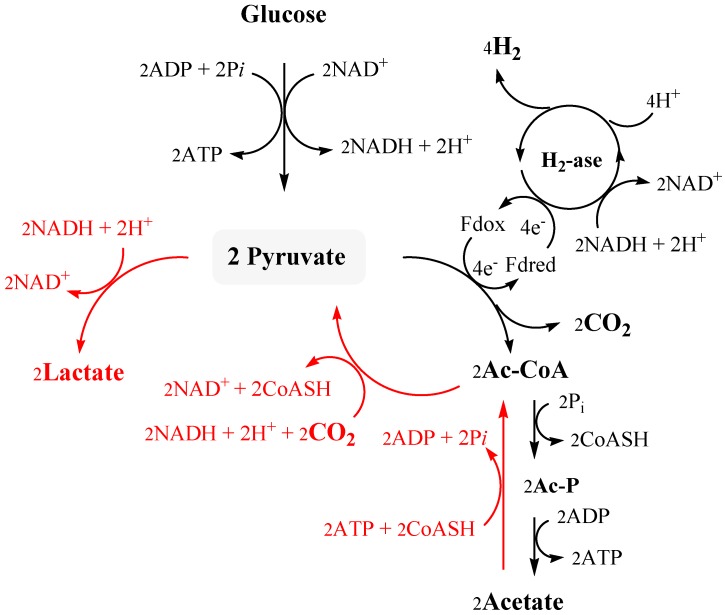

Inflow of gases is the most commonly reported method for removing oxygen and H2 from bacterial cultures in closed reactors [55,56]. Use of CO2 as gas sparging significantly increases the rate of both glucose consumption and hydrogen production even if there was no improvement of the overall productivity and molar yield that remained substantially unchanged in comparison with N2 [22]. Paradoxically, CO2 stimulated also synthesis of lactic acid. Feeding experiments with labeled precursors clearly proved that at least part of exogenous CO2 is biologically coupled with acetyl-CoA to give lactic acid when the cultures are stripped by CO2 gas or enriched in sodium bicarbonate. The process recycles glycolysis-derived acetyl-CoA or employs exogenous acetate with ATP consumption. In this latter case the overall outcome is a conversion of equimolar concentration of acetate and carbon dioxide into lactic acid according to reaction Equation (3).

| (3) |

The fermentative CO2-dependent synthesis of lactic acid and hydrogen was named capnophilic lactic fermentation (CLF) and, as suggested in Figure 2, it put forward the possibility to fully convert sugar to lactic acid (or other reduced derivatives of pyruvate) without affecting hydrogen synthesis by means of an additional consumption of reducing equivalents deriving from other cellular processes [57].

Figure 2.

Proposed model of capnophilic lactic fermentation, adapted from [57]. Water is omitted for simplicity.

To date, CLF has been described only in T. neapolitana but the pathway is likely to occur in other species of the order Thermotogales. The key enzyme of the process is a Pyruvate Synthase (also named Pyruvate Oxido-Reductase) that utilizes reduced ferredoxin as source of electrons [57]. In Thermotogales reductive carboxylation of Ac-CoA likely requires the pool of Fd that is also involved in hydrogen production. Role of Fd as efficient reductant in pyruvate synthesis has been demonstrated in vitro with Clostridium thermoaceticum [58] and suggested in vivo for methanogenic archaea, such as Methanosarcina barkeri [59]. It is noteworthy that the sequence of pyruvate oxido-reductase of this last organism has a good relation to those of T. neapolitana and T. maritima [57]. CLF is an example of biological sequestration of carbon dioxide by coupling with an exogenous substrate (acetate, glucose, etc.) and release of the end-product (lactic acid) outside of the cell. Since T. neapolitana does not convert CO2 to the reduced organic compounds required for cell metabolism, the above mechanism is not related to the autotrophic fixation known in other anaerobes. In fact, unlike known autotrophic [60,61] and heterotrophic [62,63] pathways for carbon dioxide assimilation, the capnophilic metabolism of T. neapolitana implies complete excretion of CO2 after fixation in lactic acid and no synthesis of reduced organic compounds required for cell metabolism.

5. Substrate Metabolism by Thermotoga neapolitana

As discussed above, extreme thermophiles are capable of producing H2 yields close to the theoretical Thauer limit of 4.0 mol H2/mol of glucose. In addition, the theoretical maximum yield for xylose, sucrose and glycerol are 3.33 mol H2/mol xylose, 8.0 mol H2/mol sucrose and 3.0 mol H2/mol glycerol under dark fermentation. Glucose is the substrate that gives the highest production of H2 with T. neapolitana. In batch experiments with this sugar, independent studies have reported H2 yield higher than 3.5 mol/mol and production rate ranging from 23 to 50 mL/L/h at pH of 7.5 and temperature of 80 °C [45,64]. As already mentioned above, the bacterium can also efficiently use a wide range of other substrates ranging from simple to complex sugars including ribose, xylose, fructose, sucrose, maltose, lactose, galactose, starch, and glycogen (Table 1) [21,24,50,65,66,67,68,69,70,71].

Table 1.

H2 production from various substrates by hyperthermophilic eubacterium T. neapolitana. B = batch; FB = fed-batch; AA = Acetic acid; LA = Lactic acid; EtOH = Ethanol.

| Carbon Source | Substrate Load (g/L) | Culture Type | T(°C)/Start pH | Mixing Speed (rpm) | Reactor Volume (mL) | Working Volume (mL) | H2 Yield | Byproducts | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Glucose | 5 | B | 80/7.5 | 250 | 3800 | 1000 | 2.8 mol H2/mol glucose | AA, LA, CO2 | [22] |

| Glucose | 5 | B | 80/7.1 | 250 | 2400 | 600 | 3.5 ± 0.1 mol H2/mol glucose a | AA, LA, CO2 | [45] |

| Glucose | 10 | B | 72/7.0 | 350 | 2000 | 1000 | 3.5 mol H2/mol glucose | AA, LA, CO2 | [50] |

| Glucose | 20 | B | 72/7.0 | 350 | 2000 | 1000 | 3.4 mol H2/mol glucose | AA, LA, CO2 | [50] |

| Glucose/Fructose 7:3 | 10 | B | 72/7.0 | 350 | 2000 | 1000 | 3.3 mol H2/mol glucose | AA, LA, CO2 | [50] |

| Glucose/Fructose 7:3 | 20 | B | 72/7.0 | 350 | 2000 | 1000 | 3.0 mol H2/mol glucose | AA, LA, CO2 | [50] |

| Fructose | 10 | B | 72/7.0 | 350 | 2000 | 1000 | 3.4 mol H2/mol fructose | AA, LA, CO2 | [50] |

| Fructose | 20 | B | 72/7.0 | 350 | 2000 | 1000 | 3.2 mol H2/mol fructose | AA, LA, CO2 | [50] |

| Carrot pulp hydrolysate | 10 | B | 72/7 | 350 | 2000 | 1000 | 2.7 mol H2/mol glucose | AA, LA, CO2, EtOH | [50] |

| Carrot pulp hydrolysate | 20 | B | 72/7 | 350 | 2000 | 1000 | 2.4 mol H2/mol glucose | AA, LA, CO2, EtOH | [50] |

| Glycerol | 5 | B | 75/7.5 | - | 120 | 40 | 2.7 ± 0.1 mol H2/mol glycerol | AA, LA, CO2 | [64] |

| Molasses | 20 | B | 77/8.5 | 100 | 116 | 40 | 2.6 ± 0.1 mol H2/mol glucose | AA, LA, CO2 | [65] |

| Cheese whey | 12.5 | B | 77/8.5 | 100 | 116 | 40 | 2.4 ± 0.1 mol H2/mol glucose | AA, LA, CO2 | [65] |

| Diatom b water soluble sugars | 2 | B | 80/7.5–8 | 250 | 3800 | 500 | 1.9 ± 0.1 mol H2/mol glucose | AA, LA, CO2 | [66] |

| Glucose | 5 | B | 80/8.0 | 200 | 120 | 60 | 3.8 ± 0.4 mol H2/mol glucose | AA, LA, CO2 | [67] |

| Arabinose | 5 | B | 80/8.0 | 200 | 120 | 60 | 3.8 ± 0.5 mol H2/mol arabinose | AA, LA, CO2 | [67] |

| Xylose | 5 | B | 80/8.0 | 200 | 120 | 60 | 3.4 ± 0.3 mol H2/mol xylose | AA, LA, CO2 | [67] |

| Potato steam peels | 10 | B | 75/6.9 | 350 | 2000 | 1000 | 3.8 mol H2/mol glucose | AA, LA, CO2 | [68] |

| Glycerol | 2.5 | B | 80/7.3 | 200 | 120/240 | 25/50 | 2.6 mol H2/mol glycerol | AA, LA, CO2 | [69] |

| Rice straw | 10 | B | 75/7.5 | 150 | 120 | 40 | 2.7 mmol H2/g straw | - | [70] |

| Algal c starch | 5 | B | 75/7–7.4 | 150 | 120 | 40 | 2.5 ± 0.3 mol H2/mol glucose | - | [71] |

| Glycerol | 1–10 | B | 75/7.5 | - | 120 | 40 | 620 ± 30 mL H2/L glycerol | AA, LA, CO2 | [72] |

| Xylose | 5 | B | 75/7.5 | 300 | 3000 | 1000 | 2.8 ± 0.1 mol H2/mol xylose | AA, LA, CO2 | [76] |

| Glucose/Xylose 7:3 | 10–28 | B | 80/6.8 | 350 | 2000 | 1000 | 2.5–3.3 mol H2/mol glucose | AA, LA, CO2 | [77] |

| Cellulose | 10–28 | B | 80/6.8 | 350 | 2000 | 1000 | 2.0–3.2 mol H2/mol glucose | AA, LA, CO2 | [77] |

| Xylose | 5 | B | 75/7.0 | 300 | 3000 | 1000 | 1.8 ± 0.1 mol H2/mol xylose | AA, LA, CO2 | [78] |

| Glucose | 7.5 | B | 77/8.5 | 100 | 119 | 40 | 1.3 ± 0.1 mmol H2/g glucose | AA, LA, CO2 | [79] |

| Molasses | 20 | B | 77/8.5 | 100 | 119 | 40 | 1.8 ± 0.1 mol H2/g glucose | AA, LA, CO2 | [79] |

| Cheese whey | 12.5 | B | 77/8.5 | 100 | 119 | 40 | 1.04 ± 0.05 mol H2/mol glucose | AA, LA, CO2 | [79] |

| Glucose | 5 | FB | 75/7.5 | 300 | 3000 | 1000 | 3.2 ± 0.2 mol H2/mol glucose | AA, LA, CO2 | [80] |

| Xylose | 5 | FB | 75/7.5 | 300 | 3000 | 1000 | 2.2 ± 0.1 mol H2/mol xylose | AA, LA, CO2 | [80] |

| Sucrose | 5 | FB | 75/7.5 | 300 | 3000 | 1000 | 4.9 ± 0.2 mol H2/mol sucrose | AA, LA, CO2 | [80] |

| Glucose | 2.5 | B | 77/7.5 | 75 | 160 | 50 | 3.8 ± 0.3 mol H2/mol glucose | AA, LA, CO2 | [81] |

| Glucose | 5 | B | 70/8.5 | 75 | 160 | 50 | 24% H2 (v/v) headspace d | CO2 | [82] |

| Glucose | 7 | B | 77/7.5 | 150 | 120 | 40 | 3.2 ± 0.1 mol H2/mol glucose | AA, LA, CO2 | [83] |

| Xylose | 4 | B | 77/7.5 | 150 | 120 | 40 | 2.2 ± 0.1 mol H2/mol xylose | AA, LA, CO2 | [83] |

| Glucose | 5 | B | 70/8.5 | - | 160 | 50 | 25%–30% H2 (v/v) headspace d | AA, LA, CO2 | [84] |

| Cellulose e | 5 | B | 75–80/7.5 | 150 | 120 | 50 | 0.25 ± 0.01 mol H2/mol glucose | AA, CO2 | [85] |

| Cellulose derivative | 5 | B | 75–80/7.5 | 150 | 120 | 50 | 0.77 ± 0.04 mol H2/g glucose | AA, CO2 | [85] |

| Cellulose | 5 | B | 80/7.5 | 150 | 120 | 40 | 2.2 mol H2/mol glucose | AA, CO2 | [85] |

| Starch | 5 | B | 75–80/7.5 | 150 | 120 | 50 | 1.4 ± 0.1 mL H2/g glucose | AA, CO2 | [85] |

a excluding the estimated contribution from protein; b Thalassiosira weissflogii; c Chlamydomonas reinhardtii; d yield not reported; e Miscanthus giganteus.

Waste glycerol from bio-diesel manufacturing is currently considered an attractive and abundant feedstock for fermentation process. Batch tests conducted by Maru et al. [69] have demonstrated that 2.65 mol of H2 can be produced per mole of glycerol by using the bacterium T. neapolitana at a glycerol concentration of 2.5 g/L. Ngo and Sim [72] also reported that the bacterium transforms pure glycerol and crude waste glycerol with approximately similar H2 production (447 ± 22 and 437 ± 21 mL/L, respectively). According to these authors, these yields are better than those reported with mesophilic bacteria [73,74] and addition of itaconic acid to buffer the culture medium further increased this productivity with both substrates. It is notable that a prediction model built on comparative analysis of the genomes of T. maritima and T. neapolitana put forward that this latter species should not be able to metabolize a number of sugars, including cellotetraose. However, experimental assessment proved that the bacterium grows on this substrate despite that the model predicted an incomplete cellotetraose transport complex. Proteomic analysis of glucose and cellotetraose revealed two possible new gene clusters that may be associated with transport of these sugars [75].

Cappelletti et al. [65] showed that T. neapolitana, T. maritima, T. petrophila and T. naphtophila produce about 2.95 mol of H2 per mol of glucose equivalent from molasses and 2.5 mol of H2 per mol of glucose equivalent from cheese whey, whereas 2.7–2.8 mol of H2 per mol of glucose equivalent were produced on carrot pulp hydrolysates containing glucose, fructose and sucrose as main sugars [50]. Enzymatic hydrolysis of the polysaccharide fraction prior to fermentation increased the H2 yield of almost 10% to 2.3 g/kg of hydrolyzed carrot pulp. Lignocellulosic substrates (e.g., crop residues) were tested for H2 production with some standard pretreatment to wash out lignin [70,76,77]. Thermo-chemical pretreatment (i.e., heat, ammonia soaking and dilute H2SO4 soaking) were found to be effective pretreatment techniques to remove lignin and enhance availability of simple sugars for H2 production. According to Ngo et al. [76] 2.8 mol of H2 per mol of xylose equivalent are produced by T. neapolitana in a pH-controlled continuously stirred anaerobic bioreactor sparged with N2 gas. Similar results have also been reported with rice straw pretreated with ammonia soaking and diluted sulfuric acid [70]. Algal biomass (Chlamydomonas reinhardtii) pretreated by heat-HCl or Termamyl® enzymatic hydrolysis has been also used as substrate of T. neapolitana to give 2.5 mol of H2 per mol of glucose equivalent [71]. Without pretreatment, a slightly lower yield (2.2 mol/mol of glucose equivalent) was produced by fermentation of laminarans derived from the marine diatom Thalassiosira weissflogii [66].

There are conflicting reports on the effect of protein lysates on growth and H2 production by T. neapolitana. Maru et al. [69] noticed that reduced level of yeast extract (YE) negatively affects H2 production but increasing concentration from 2 to 4 g/L did not induce significant change in gas evolution. On the contrary, increasing YE concentration from 1 to 4 g/L improved biomass and H2 production in cultures of T. neapolitana on glycerol as reported by other independent studies [72,73]. No effect is reported through increasing the concentration of protein lysates above 5 g/L. Cappelletti et al. [65] reported that partial production of H2 can be due to metabolism of tryptone soy broth (TSB) whereas the contribution of YE is null. On the other hand, transformation of peptone, tryptone and YE yields 10%–15% to the total H2 production according to d’Ippolito et al. [45] and Eriksen et al. [67].

6. Systems Integration

According to Levin et al. [86], H2 production by dark fermentation is considered the most practically applicable process for production of the energy carrier. However, as shown in Figure 1, only 2 mol of carbon from the substrate (i.e., glucose) are fully oxidized to CO2 and only 4 mol H2 are formed. Thus, according to the dark fermentation model, a fermentative H2 production can only convert, even in an optimal condition, less than 33% of the energy from the substrate (e.g., glucose). On the other hand, the transformation efficiency can be significantly improved (theoretically up to 12 mol H2 per mol of glucose) if a second biological process allows for the complete oxidation of the residual products released by the thermophilic process. In particular, photo-heterotrophic fermentation of organic acids produced by T. neapolitana is hypothetically entitled to produce a further 8 mol of H2, thus reaching the maximum possible yield of 12 mol of H2.

Purple nonsulphur (PNS) bacteria are a non-taxonomic group of microorganisms that are attractive for the biological production of H2 from biomass (reviewed in [87]). A few studies have also demonstrated that these microorganisms can be successfully integrated into a two-step process to produce H2 in combination with dark fermentation. The first report of a two-stage process with T. neapolitana by Uyar and coworkers [88] showed that Rhodobacter capsulatus effectively produces hydrogen when the concentration of acetate is lower than 60 mM in the spent medium of the thermophilic bacterium. Interestingly these authors also noticed that addition of iron II in the range of 0–29 µM to the culture medium (i.e., to the spent medium of thermophilic bacterium) of R. capsulatus increased the hydrogen production in a significant manner (1.37 L H2/L culture in effluent media supplemented with iron and vitamins; 0.30 L H2/L culture in effluent media supplemented only with vitamins). More recently, we have repeated the experiment with T. neapolitana and Rhodopseudomonas palustris by replacing the traditional conditions of DF (dark fermentation) with those of CLF (capnophilic lactic fermentation) [89]. To achieve photo-fermentation by a mutant strain of R. palustris [90], T. neapolitana was grown under reduced level of NaCl and nitrogen-containing compounds. According to Uyar et al. [88], the spent broths of the thermophilic bacterium were only supplemented with Fe-citrate and phosphate buffer. The combined microbial system gave 9.4 mol of hydrogen per mole of glucose consumed during the anaerobic process, which is the best production yield so far reported for conventional two-stage batch cultivations [89]. The results also proved that CLF can be used for inducing a metabolic switch in T. neapolitana that brings actual improvements of hydrogen yields in combination with photofermentation.

The advantages of using biomass for H2 production range from the mitigation of CO2 and other pollutant emissions, to reduction of environmental and economical costs for disposing wastes. Limitations in use of biomass are mainly due to the seasonal availability of agro wastes, costs of their collection and incomplete use of the organic matter. In this view, microalgal biomass is an attractive alternative since algal cultivation can theoretically run continuously with no restriction due to seasonal cycle and can yield large amounts of biomass of constant composition. Furthermore, fermentation of algal feedstock can be associated with production of biofuels or by-products of high value. T. neapolitana directly produces H2 by fermentation of the biomass of the green alga Chlamydomonas reinhardtii with molar yields (1.8–2.2 mol/mol glucose equivalent) depending on pretreatment methods [71]. T. neapolitana possesses genes encoding both for a 1,3-β-glucosidase BglB (laminaribiase) and a 1,3-β-glucanase LamA (laminarinase) that are able to completely degrade chrysolaminarin, the storage polysaccharides of diatoms, to glucose with a synergic action [91,92]. Accordingly, the bacterium fermented the water-soluble fraction of the marine diatom Thalassiosira weissflogii without any pretreatment [66]. Production (434 mL/L in 24 h; 18.1 mL/L/h) and yield (2.2 mol H2/mol glu. eq) of H2 on diatom extracts containing 2 g/L of sugar equivalent were just slightly lower than those achieved by fermentation of glucose (809 mL/L in 24 h; 33.7 mL/L/h; 3.0 mol H2/mol glu) and pure chrysolaminarin (643 mL/L in 24 h; 26.8 mL/L/h; 3.2 mol H2/mol glu. eq).

7. Bioreactor Configuration

Several bioreactor configurations such as continuously stirred tank reactors (CSTRs), fluidized bed reactors (FBRs), packed bed reactors (PBRs), up-flow anaerobic sludge blanket (UASB) reactors, anaerobic sequencing batch reactors (AnSBRs), high rate/hybrid reactors, and membrane biological reactors (MBRs) have promising prospects for dark fermentation processes [14]. Table 2 reports the CSTR used for fed-batch and continuous reactors studied for H2 production by suspended and immobilized cells of T. neapolitana. CSTRs operate continuously and the bulk inside the reactor is mixed uniformly. However the mixing rate depends on the reactor geometry and power input [93]. CSTRs favor mass transfer among biomass, substrates and gases, and are effective in temperature and pH bulk control. However, CSTR can experience biomass washout, when the loading and the dilution rate increases.

Table 2.

Continuous and fed-batch operation in CSTRs for T. neapolitana.

| Substrate | Reactor Volume (L) | Working Volume (L) | Temp. (°C) | Culture Type | Culture Condition | H2 Yield | References |

|---|---|---|---|---|---|---|---|

| Glucose/Xylose/Arabinose | 3.0 | 2.75 | 80 | Suspended cells | Fed-batch | 3.8 ± 0.4 mol H2/mol glucose; 3.4 ± 0.3 mol H2/mol xylose; 3.8 ± 0.5 mol H2/mol arabinose | [67] |

| Glucose/Sucrose/Xylose | 3.0 | 1.0 | 75 | Suspended cells | Fed-batch | 3.2 ± 0.16 mol H2/mol glucose; 4.95 ± 0.25 mol H2/mol sucrose; 2.2 ± 0.11 mol H2/mol xylose | [80] |

| Xylose | 3.0 | 1.0 | 75 | Immobilized cells | Fed-batch | 1.84 ± 0.1 mol H2/mol xylose | [78] |

| Glucose/Cheese whey/Molasses | 19.0 | 15.0 | 77 | Suspended cells | Continuous | 1.2 mmol H2/L/h for glucose; 0.42 mmol/L/h for cheese whey; 1.3 mmol/L/h for molasses | [79] |

| Glucose | - | - | 80 | Immobilized cells | Fed-batch | 3.3 mol H2/mol glucose | [96] |

The biomass washout is less probable in attached biomass reactors (e.g., FBRs, PBRs, UASB) where inert material is used to support and contain the bacteria, thus providing a high concentration of cells and, consequently high solids retention time, high organic load, high mass transfer efficiency and high tolerance for shock loads [78,94,95]. Several inert materials have been used successfully as support for T. neapolitana growth, i.e., coir, bagasse, loofah sponge, expanded clay, diatomaceous clay, activated carbon, polysaccharide gels (e.g., alginate, k-carrageenan, agar, chitosan), synthesized materials (e.g., polyvinyl alcohol (PVA), silicone, polyacrylamide, urethane foam and polymethyl methacrylate) [26,96,97,98,99], ceramic porous carries (i.e., biomax) [65,79], and porous glass beads [78]. The batch fermentation tests conducted by Ngo and Bui have shown that the H2 production rate and H2 yield of the immobilized cells reached the highest values of 5.64 ± 0.19 mmol H2/L/h and 1.84 ± 0.1 mol H2/mol xylose, respectively, which were 1.7- and 1.3-fold higher than those with free cells [78]. Synthetic hydrogels based on methacrylate derivatives with buffer capacity also effectively supported cell growth and hydrogen production [96,100]. In particular, the use of hydrogel with positive charge and amine groups doubled hydrogen production rate compared with suspension cultures. Both sugar metabolism and hydrogen synthesis were affected positively by neutralization of the acidic side-products of the fermentation, i.e., acetate and lactate. The presence of positively charged groups on the inert support proved to be critical to promote the colonization of the polymeric material by a great number of T. neapolitana cells laying in a biofilm-like arrangement.

8. Operating Conditions and Kinetics of Thermotoga neapolitana Fermentation

8.1. Hydraulic Retention Time (HRT)

In the dark fermentative H2 production, hydraulic retention time (HRT), organic loading rate (OLR) and pH are coupled variables since short HRT and high OLR generally correspond to low pH condition that affects the biomass metabolism. Both high OLR and low HRT represent favorable conditions for H2 production as such operating conditions inhibit other slow growing bacteria, such as methanogens [101]. A HRT in the range of 0.25–60 h (lower HRT for attached/immobilized biomass and higher HRT for suspended growth biomass) is proved to be suitable for hyperthermophilic dark fermentative H2 production by T. neapolitana in batch, fed-batch and continuous bioreactors using a wide range of substrates such as glucose, sucrose, starch, lignocellulose, organic waste and algal starch [102]. T. neapolitana is an exceptionally robust microorganism for H2 production because of its efficient hydrolytic abilities and adaptability to different culture conditions [77]. Nevertheless, production of H2 is optimal only in very restricted range of operating conditions. In particular, the bacterium grows in a wide interval of temperatures (i.e., 55–90 °C) but the highest H2 production occurs between 75 and 80 °C [76].

8.2. Working pH

As reported above, culture pH is directly affected by the acidogenic activity. Consequently, pH control by base addition (e.g., NaOH) is critically important to maximize both H2 production and substrate consumption [45,80,81]. Growth of T. neapolitana is inhibited at pH of 4.5 [82], whereas change from 4.0 to 5.5 induces an increase of H2 content in the headspace from 42% to 64% [103]. Nguyen et al. demonstrated that variation of pH in T. neapolitana cultures from 5.5 to 7.0 enhances cumulative H2 production from 125 to 198 mL H2/L medium, but further increase to 8.0–9.0 leads to total decline in the biogas evolution [83]. At laboratory scale, the strict control of pH has also suggested the use of compounds with increased buffer capacity such as diacid/monoacid phosphate (HPO4−2/H2PO4−), tris (hydroxymethyl) aminomethane (TRIS), 3-(N-morpholino) propanesulfonic acid (MOPS), piperazine-N,N′-bis(2-ethanesulfonic) acid (PIPES), and 4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid (HEPES) [77,81,82,84]. For large scale application the use of these chemicals is probably economically prohibitive but similar effects could be achieved by use of more convenient products (e.g., CO2).

8.3. Temperature

The primary fermentation products for T. neapolitana across the permissive growth temperature range are H2, CO2, acetate and small amounts of lactate. Two independent studies on the influence of temperature on H2 production of T. neapolitana and T. maritima support a direct correlation with H2 production and bacterial growth [81,85]. Munro et al. reported that rate and amount of glucose consumption and H2 formation increased by arising the operating temperature from 60 to 77 °C, but there was no significant difference from 77 to 85 °C [81]. Although production of acetate and lactate indicated a difference between 77 and 85 °C, a comparison of the molar yields acetate/glucose and lactate/glucose for the operating temperatures between 65 and 85 °C suggested no significant change in molar yield for the two organic acids.

8.4. Partial Pressure

The total and partial pressure of gas inside the reactor influences the biomass growth and product formation. According to Schonheit and Schafer [104], H2 itself inhibits the process in a batch reactor. Van Niel et al. reported that H2 partial pressure less than 20 kPa is required for reactor operating at high temperature (>70 °C) [20]. Partial pressure of H2 above 20 kPa reverses the metabolic pathway, thereby facilitating the production of more reduced products such as acetone, ethanol, lactate, butanol and alanine [11,50,105]. Experimental data show that use of pure nitrogen as gas sparging and high ratio between headspace volume/culture volume can contain the partial pressure of H2 below the critical limit in cultures of T. neapolitana [45,67,81]. Increase in yield and production of H2 are reported by N2 sparging compared to no sparging condition [45,83]. The tolerance of T. neapolitana to oxygen is matter of debate. Van Ooteghem et al. described significant improvement of H2 production under microaerobic condition [82,84], whereas Eriksen et al., in line with other studies, reported that T. neapolitana can tolerate only low oxygen partial pressure (1% or 1.2 kPa) and found that 6% O2 (7.2 kPa) inside the reactor completely inhibits H2 production and reduces glucose consumption from 12 to 4 µmol/h [106].

8.5. Mathematical Modeling and Kinetics

Metabolic transformation of glucose by T. neapolitana can be effectively described with the Equation (4).

| (4) |

where m is a stoichiometric coefficient [22].

A majority of studies have either adapted or modified exiting mathematical (or empirical) models to describe the experimental results [107]. Gompertz empirical model (Equaton (5)) and International Water Association (IWA) anaerobic digestion model No. 1 (ADM1) are the most popular models to simulate dark fermentation. The Gompertz model is particularly used to estimate the maximum hydrogen production potential and to determine the lag phase for H2 production [108] but it does not allow the process kinetics to be addressed because of the exclusion of operating conditions (e.g., substrate type and concentration, pH, temperature, and partial pressure of gas mixture) that regulate the fermentation reaction [108].

| (5) |

where

H (t) = Cumulative H2 production (mL/L)

P = H2 production potential (mL H2)

Rm= Maximum H2 production rate (mL H2/h)

t = Incubation/cultivation time (h)

λ = Duration of the lag phase (h)

On the other hand, ADM1 is a complete and comprehensive kinetic model based on Monod kinetic Equations (6) [109,110,111,112] and has been used often to model DF reactions [79,113,114].

| (6) |

where

μ = specific growth rate of biomass (h−1)

μmax = maximum specific growth rate of biomass (h−1)

ks = semi saturation constant (g/L); ks equals the substrate concentration at which μ equals ½ μmax

S = substrate concentration (g/L)

The ADM1-based model and Gompertz empirical model have been extensively used to study H2 production by fermentative process, but to date there are only two studies with T. neapolitana. In pure culture on glucose at 77 °C, Yu and Drapcho [114] reported maximum specific maximum growth rate (µmax) of 0.94 h−1 and semi saturation constant (ks) of 0.57 g sugar/L when H2 and biomass product yields were 0.0286 g H2/g glucose and 0.248 g biomass/g glucose, respectively. More recently, Frascari et al. [79] have studied the kinetic parameters for T. neapolitana grown on glucose, molasses and cheese whey by suspended or immobilized cells. The µmax value with immobilized bacteria (0.09 ± 0.05 h−1 for glucose, 0.19 ± 0.02 h−1 for molasses and 0.042 ± 0.007 h−1 for cheese whey) was found to be significantly higher than with suspended cells (0.024 ± 0.005 h−1 for glucose, 0.055 ± 0.005 h−1 for molasses and 0.033 ± 0.006 h−1 for cheese whey). On the contrary, the semi saturation constant (ks) was 0.09 ± 0.05 g sugar/L for glucose, 0.6 ± 0.2 g sugar/L for molasses and 1.2 ± 0.3 g sugar/L for cheese whey in the immobilized systems and 1.1 ± 0.3 g sugar/L for glucose, 0.2 ± 0.05 g sugar/L for molasses and 1.5 ± 0.5 g sugar/L for cheese whey with bacterial suspensions [79].

9. Conclusions

Among the various technologies, fermentation has many advantages for the biological production of H2 and is theoretically feasible for large-scale application particularly from the fermentation of solid wastes [115,116]. Extensive research in the last decades has shown the promising prospect of using pure cultures of the bacterium T. neapolitana. Like other hyperthermophilic process, the technology is readily used at laboratory scale with high production rate, low energy demand, easy operation and sustainability. On the contrary little has been done in terms of comparison of cost and effectiveness between T. neapolitana and traditional processes that use fossil fuel for production of hydrogen.

T. neapolitana has also shown great potential for other applications such as recovery of byproducts with potential economic value in the market i.e., lactic acid. Introduction of capnophilic process for the simultaneous production of H2 and lactic acid is very promising and could significantly influence the future of agro-waste management. Clearly, further research is needed to optimize the operating parameters and reactor configurations and more experiments are needed to verify process kinetics and full-scale applicability. Nevertheless, fermentation of organic material by the thermophilic bacterium could be the beachhead of a complete conversion process that generates H2 only as a first step.

Agro-food wastes and algal biomass seem to be attractive substrates for fermentation by T. neapolitana and thus are considered as feedstock for comprehensive development of biorefineries. Moreover, coupling of T. neapolitana-based transformation with other biological processes also seems very promising. In this view, chemotrophic production of hydrogen by hyperthermophilic bacteria has already shown great potential in association with both microalgal cultivations and photofermentation by purple nonsulphur bacteria. Finally, considerable enhancement of the fermentative capacity of T. neapolitana can be also expected by metabolic engineering and physiological manipulations of strains, as well as by improvement in reactor configurations [1,117]. In fact, for example the unexpected success of CLF suggests that a huge unexplored gene pool available in nature, with great potential for H2 production, is yet to be discovered [118].

Acknowledgments

This work was funded by the Italian Ministry of Education, University and Research (MIUR) through the project “Integrated exploitation of algal biomass in the energy supply chain (SIBAFEQ)” (PON01_02740) and by CNR through the project “Energy from Renewable Sources (EFOR)”. The authors also acknowledge the assistance and support of the Erasmus Mundus Joint Doctorate program ETeCoS3 (Environmental Technologies for Contaminated Solids, Soils and Sediments) under the EU grant agreement FPA No 2010-0009.

Author Contributions

Nirakar Pradhan and Laura Dipasquale carried out bibliographic search; Nirakar Pradhan, Laura Dipasquale and Angelo Fontana carried out data analysis; Laura Dipasquale and Angelo Fontana wrote the manuscript; Giuliana d’Ippolito, Antonio Panico, Piet N. L. Lens and Giovanni Esposito corrected the manuscript and improved the discussion.

Conflicts of Interest

The authors declare no conflict of interest.

References

- 1.Hallenbeck P.C., Benemann J.R. Biological H2 production; fundamentals and limiting processes. Int. J. Hydrog. Energy. 2002;27:1185–1193. doi: 10.1016/S0360-3199(02)00131-3. [DOI] [Google Scholar]

- 2.Nath K., Das D. Improvement of fermentative hydrogen production: Various approaches. Appl. Microbiol. Biotechnol. 2004;65:520–529. doi: 10.1007/s00253-004-1644-0. [DOI] [PubMed] [Google Scholar]

- 3.Fan Y., Zhang Y., Zhang S., Hou H., Ren B. Efficient conversion of wheat straw wastes into biohydrogen gas by cow dung compost. Bioresour. Technol. 2006;97:500–505. doi: 10.1016/j.biortech.2005.02.049. [DOI] [PubMed] [Google Scholar]

- 4.Ghimire A., Frunzo L., Pirozzi F., Trably E., Escudie R., Lens P.N.L., Esposito G. A review on dark fermentative biohydrogen production from organic biomass: Process parameters and use of by-products. Appl. Energy. 2015;144:73–95. doi: 10.1016/j.apenergy.2015.01.045. [DOI] [Google Scholar]

- 5.Guo X.M., Trably E., Angenent L.T., Karim K., al-Dahhan M.H., Wrenn B., Latrille E., Carrère H., Steyer J. Hydrogen production from agricultural waste by dark fermentation: A review. Int. J. Hydrog. Energy. 2010;35:10660–10673. doi: 10.1016/j.ijhydene.2010.03.008. [DOI] [Google Scholar]

- 6.Kotsopoulos T.A., Fotidis I.A., Tsolakis N., Martzopoulos G.G. BioH2 production from pig slurry in a CSTR reactor system with mixed cultures under hyperthermophilic temperature (70 °C) Biomass Bioenergy. 2009;33:1168–1174. doi: 10.1016/j.biombioe.2009.05.001. [DOI] [Google Scholar]

- 7.Sinha P., Pandey A. An evaluative report and challenges for fermentative bioH2 production. Int. J. Hydrog. Energy. 2011;36:7460–7478. doi: 10.1016/j.ijhydene.2011.03.077. [DOI] [Google Scholar]

- 8.Vijayaraghavan K., Ahmad D. Biohydrogen generation from palm oil mill effluent using anaerobic contact filter. Int. J. Hydrog. Energy. 2006;31:1284–1291. doi: 10.1016/j.ijhydene.2005.12.002. [DOI] [Google Scholar]

- 9.Wukovits W., Drljo A., Hilby E., Friedl A. Integration of biohydrogen production with heat and power generation from biomass residues. Chem. Eng. Trans. 2013;35:1003–1008. [Google Scholar]

- 10.Djomo S.N., Blumberga D. Comparative life cycle assessment of three biohydrogen pathways. Bioresour. Technol. 2011;102:2684–2694. doi: 10.1016/j.biortech.2010.10.139. [DOI] [PubMed] [Google Scholar]

- 11.Angenenta L.T., Karima K., Al-Dahhana M.H., Brian A., Wrennb B.A., Domíguez-Espinosad R. Production of bioengineering and biochemical’s from industrial and agricultural wastewater. Trends Biotechnol. 2004;22:477–485. doi: 10.1016/j.tibtech.2004.07.001. [DOI] [PubMed] [Google Scholar]

- 12.Elsharnouby O., Hafez H., Nakhla G., el Naggar M.H. A critical literature review on bioH2 production by pure cultures. Int. J. Hydrog. Energy. 2013;38:4945–4966. doi: 10.1016/j.ijhydene.2013.02.032. [DOI] [Google Scholar]

- 13.Amend J.P., Shock E.L. Energetics of overall metabolic reactions of thermophilic and hyperthermophilic Archea and Bacteria. Microbiol. Rev. 2001;25:175–243. doi: 10.1111/j.1574-6976.2001.tb00576.x. [DOI] [PubMed] [Google Scholar]

- 14.Krishna R.H. Review of research on bioreactors used in wastewater treatment for production of bioH2: Future fuel. Int. J. Sci. Invent. Today. 2013;2:302–310. [Google Scholar]

- 15.Hafez H., Nakhla G., el Naggar H. Biological H2 production. In: Sherif S.A., editor. Handbook of H2 Energy. CRC Press; Boca Raton, FL, USA: 2012. [Google Scholar]

- 16.Verhaart M.R., Bielen A.A., Oost J.V.D., Stams A.J., Kengen S.W. Hydrogen production by hyperthermophilic and extremely thermophilic bacteria and archaea: Mechanisms for reductant disposal. Environ. Technol. 2010;31:993–1003. doi: 10.1080/09593331003710244. [DOI] [PubMed] [Google Scholar]

- 17.Zhang T., Liu H., Fang H.H.P. Biohydrogen production from starch in wastewater under thermophilic condition. J. Environ. Manag. 2003;69:149–156. doi: 10.1016/S0301-4797(03)00141-5. [DOI] [PubMed] [Google Scholar]

- 18.Islam R., Cicek N., Sparling R., Levin D. Influence of initial cellulose concentration on the carbon flow distribution during batch fermentation by Clostridium thermocellum ATCC 27405. Appl. Microbiol. Biotechnol. 2009;82:141–148. doi: 10.1007/s00253-008-1763-0. [DOI] [PubMed] [Google Scholar]

- 19.Liu Y., Yu P., Song X., Qu Y. H2 production from cellulose by co-culture of Clostridium thermocellum JN4 and Thermoanaerobacterium thermosaccharolyticum GD17. Int. J. Hydrog. Energy. 2008;33:2927–2933. doi: 10.1016/j.ijhydene.2008.04.004. [DOI] [Google Scholar]

- 20.Van Niel E.W.J., Claassen P.A.M., Stams A.J.M. Substrate and product inhibition of H2 production by the extreme thermophile, Caldicellulosiruptor saccharolyticus. Biotech. Bioeng. 2003;81:255–262. doi: 10.1002/bit.10463. [DOI] [PubMed] [Google Scholar]

- 21.Cappelletti M., Zannoni D., Postec A., Ollivier B. Members of the order Thermotogales: From microbiology to hydrogen production. In: Zannoni D., de Philippis R., editors. Microbial BioEnergy: Hydrogen Production. Volume 38. Springer; New York, NY, USA: 2014. pp. 197–224. [Google Scholar]

- 22.Dipasquale L., d’Ippolito G., Fontana A. Capnophilic lactic fermentation and hydrogen synthesis by Thermotoga neapolitana: An unexpected deviation from the dark fermentation model. Int. J. Hydrog. Energy. 2014;39:4857–4862. doi: 10.1016/j.ijhydene.2013.12.183. [DOI] [Google Scholar]

- 23.Belkin S., Wirsen C.O., Jannasch H.W. A new sulfur-reducing, extremely thermophilic eubacterium from a submarine thermal vent. Appl. Environ. Microbiol. 1986;51:1180–1185. doi: 10.1128/aem.51.6.1180-1185.1986. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Jannasch H.W., Huber R., Belkin S., Stetter K.O. Thermotoga neapolitana sp. nov. of the extremely thermophilic, eubacterial genus Thermotoga. Arch. Microbiol. 1988;150:103–104. doi: 10.1007/BF00409725. [DOI] [Google Scholar]

- 25.Nesbo C.L., Bradnan D.N., Adebusuyi A., Dlutek M., Petrus A.K., Foght J., Doolittle W.F., Noll K.M. Mesotoga prima gen. nov., sp. nov., the first described mesophilic species of the Thermotogales. Extremophiles. 2012;16:387–393. doi: 10.1007/s00792-012-0437-0. [DOI] [PubMed] [Google Scholar]

- 26.Angel A.M., Brunene M., Baumeister W. The functional properties of Ompβ, the regularly arrayed porin of the hyperthermophilic bacterium Thermotoga neapolitana. FEMS Microbiol. Lett. 1993;109:231–236. [Google Scholar]

- 27.Huber R., Langworthy T.A., Konig H., Thomm M., Woese C.R., Sleytr U.B., Stetter K.O. Thermotoga maritima sp. nov. represents a new genus of unique extremely thermophilic eubacteria growing up to 90 °C. Arch. Microbiol. 1986;144:324–333. doi: 10.1007/BF00409880. [DOI] [Google Scholar]

- 28.Rachel R., Engel A.M., Huber R., Stetter K.O., Baumeister W. A porin-type protein is the main constituent of the cell envelope of the ancestral bacterium Thermotoga maritima. FEBS Lett. 1990;262:64–68. doi: 10.1016/0014-5793(90)80155-C. [DOI] [Google Scholar]

- 29.Kuwabara T., Igarashi K. Microscopic studies on Thermosipho globiformans implicate a role of the large periplasm of Thermotogales. Extremophiles. 2012;16:863–870. doi: 10.1007/s00792-012-0481-9. [DOI] [PubMed] [Google Scholar]

- 30.Choi K.-W., Seo J.Y., Park K.-M., Park C.-S., Cha J. Characterization of glycosyl hydrolase family 3 β-N-acetylglucosaminidases from Thermotoga maritima and Thermotoga neapolitana. J. Biosci. Bioeng. 2009;108:455–459. doi: 10.1016/j.jbiosc.2009.06.003. [DOI] [PubMed] [Google Scholar]

- 31.Choi K.-H., Hwang S., Lee H.-S., Cha J. Identification of an extracellular thermostable glicosyl hydrolase family 13 a-amylase from Thermotoga neapolitana. J. Microbiol. 2011;49:628–634. doi: 10.1007/s12275-011-0432-7. [DOI] [PubMed] [Google Scholar]

- 32.Dipasquale L., Gambacorta A., Siciliano R.A., Mazzeo M.F., Lama L. Purification and biochemical characterization of a native invertase from the hydrogen-producing Thermotoga neapolitana. Extremophiles. 2009;13:345–354. doi: 10.1007/s00792-008-0222-2. [DOI] [PubMed] [Google Scholar]

- 33.Kang L., Park K.M., Choi K.H., Park C.S., Kim G.E., Kim D., Cha J. Molecular cloning and biochemical characterization of a heat-stable pullulanase type I from Thermotoga neapolitana. Enzym. Microb. Technol. 2011;48:260–266. doi: 10.1016/j.enzmictec.2010.11.006. [DOI] [PubMed] [Google Scholar]

- 34.Lama L., Tramice A., Finore I., Anzelmo G., Calandrelli V., Pagnotta E., Tommonaro G., Poli A., di Donato P., Nicolaus B., et al. Degradative actions of microbial xylanolytic activities on hemicelluloses from rhizome of Arundo donax. AMB Express. 2014;4:55. doi: 10.1186/s13568-014-0055-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Liebl W.G., Winterhalter C., Baumeister W., Armbrech M., Valdez M. Xylanase attachment to the cell wall of the hyperthermophilic bacterium Thermotoga maritima. J. Bacteriol. 2008;190:1350–1358. doi: 10.1128/JB.01149-07. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Okazaki F., Nakashima N., Ogino C., Tamaru Y., Kondo A. Biochemical characterization of a thermostable β-1,3-xylanase from the hyperthermophilic Eubacterium, Thermotoga neapolitana strain DSM 4359. Appl. Microbiol. Biotechnol. 2013;97:6749–6757. doi: 10.1007/s00253-012-4555-5. [DOI] [PubMed] [Google Scholar]

- 37.Pozzo T., Pasten J.L., Karlsson E.N., Logan D.T. Structural and functional analyses of β-glucosidase 3B from Thermotoga neapolitana: A thermostable three-domain representative of glycoside hydrolase 3. J. Mol. Biol. 2010;397:724–739. doi: 10.1016/j.jmb.2010.01.072. [DOI] [PubMed] [Google Scholar]

- 38.Schumann J., Wrba A., Jaenicke R., Stetter K.O. Topographical and enzymatic characterization of amylases from the extremely thermophilic eubacterium Thermotoga maritima. FEBS Lett. 1991;282:122–126. doi: 10.1016/0014-5793(91)80459-G. [DOI] [PubMed] [Google Scholar]

- 39.Yun B.Y., Jun S.Y., Kim N.A., Yoom B.Y., Piao S., Park S.H., Jeong S.H., Lee H., Ha N.C. Crystal structure and thermostability of a putative a-glucosidase from Thermotoga neapolitana. Biochem. Biophys. Res. Commun. 2011;416:92–98. doi: 10.1016/j.bbrc.2011.11.002. [DOI] [PubMed] [Google Scholar]

- 40.Latif H., Lerman J.A., Portnoy V.A., Tarasova Y., Nagarajan H. The Genome Organization of Thermotoga maritima reflects its lifestyle. PLoS Genet. 2013;9:e1003485. doi: 10.1371/journal.pgen.1003485. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Bhandari V., Gupta R.S. Molecular signatures for the phylum (class) Thermotogae and a proposal for its division into three orders (Thermotogales, Kosmotogales ord. nov. and Petrotogales ord. nov.) containing four families (Thermotogaceae, Fervidobacteriaceae fam.nov., Kosmotogaceae fam. nov. and Petrotogaceae fam. nov.) and a new genus Pseudothermotoga gen. nov. with five new combinations. Antonie Leeuwenhoek. 2014;105:143–168. doi: 10.1007/s10482-013-0062-7. [DOI] [PubMed] [Google Scholar]

- 42.Ravot G., Magot M., Fardeau M.L., Patel B.K.C., Prensier G., Egan A., Garcia J.L., Ollivier B. Thermotoga elfii Sp-Nov, a novel thermophilic bacterium from an african oil-producing well. Int. J. Syst. Bacteriol. 1995;45:308–314. doi: 10.1099/00207713-45-2-308. [DOI] [PubMed] [Google Scholar]

- 43.Schroder C., Selig M., Schonheit P. Glucose fermentation to acetate, CO2 and H2 in the anaerobic hyperthermophilic eubacterium Thermotoga maritima-involvement of the Embden-Meyerhof pathway. Arch. Microbiol. 1994;161:460–470. [Google Scholar]

- 44.Schut G.J., Adams M.W. The iron-H2ase of Thermotoga maritima utilizes ferredoxin and NADH synergistically: A new perspective on anaerobic H2 production. J. Bacteriol. 2009;191:4451–4457. doi: 10.1128/JB.01582-08. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 45.D’Ippolito G., Dipasquale L., Vella F.M., Romano I., Gambacorta A., Cutignano A., Fontana A. H2 metabolism in the extreme thermophile Thermotoga neapolitana. Int. J. Hydrog. Energy. 2010;35:2290–2295. doi: 10.1016/j.ijhydene.2009.12.044. [DOI] [Google Scholar]

- 46.Thauer R.K., Jungerman K., Decker K. Energy conservation in chemotrophic anaerobic bacteria. Bacteriol. Rev. 1977;41:100–180. doi: 10.1128/br.41.1.100-180.1977. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Anshuman K., Mike M., Brenda J. H2: The energy source for the 21st century. Technovation. 2005;25:569–585. [Google Scholar]

- 48.Khanna N., Das D. BioH2 production by dark fermentation. WIREs Energy Environ. 2013;2:401–421. doi: 10.1002/wene.15. [DOI] [Google Scholar]

- 49.Wu S.Y., Hung C.H., Lin C.N., Chen H.W., Lee A.S., Chang J.S. Fermentative H2 production and bacterial community structure in high-rate anaerobic bioreactors containing silicone immobilized and self-flocculated sludge. Biotechnol. Bioeng. 2006;93:934–946. doi: 10.1002/bit.20800. [DOI] [PubMed] [Google Scholar]

- 50.De Vrije T., Budde M.A.W., Lips S.J., Bakker R.R., Mars A.E., Claassen P.A.M. H2 production from carrot pulp by the extreme thermophiles Caldicellulosiruptor saccharolyticus and Thermotoga neapolitana. Int. J. Hydrog. Energy. 2010;35:13206–13213. doi: 10.1016/j.ijhydene.2010.09.014. [DOI] [Google Scholar]

- 51.Albertini M., Vallese F., Valentin M., Berto P., Giacometti G.M., Costantini P., Carbonera D. The proton iron-sulfur cluster environment of the [FeFe]-hydrogenase maturation protein HydF from Thermotoga neapolitana. Int. J. Hydrog. Energy. 2014;39:18574–18582. doi: 10.1016/j.ijhydene.2013.12.164. [DOI] [Google Scholar]

- 52.Oh Y.K., Raj S.M., Jung G.Y., Park S. Current status of the metabolic engineering of microorganisms for bioH2 production. Bioresour. Technol. 2011;102:8357–8367. doi: 10.1016/j.biortech.2011.04.054. [DOI] [PubMed] [Google Scholar]

- 53.Li F., Hinderberger J., Seedorf H., Zhang J., Buckel W., Thauer R.K. Coupled ferredoxin and crotonyl coenzyme A (CoA) reduction with NADH catalyzed by the butyryl-CoA deH2ase/Etf complex from Clostridium kluyveri. J. Bacteriol. 2008;190:843–850. doi: 10.1128/JB.01417-07. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 54.Frock A.D., Notey J.S., Kelly R.M. The genus Thermotoga: Recent developments. Environ. Tech. 2010;31:1169–1181. doi: 10.1080/09593330.2010.484076. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 55.Mizuno O., Dinsdale R., Hawkes F., Hawkes D., Noike T. Enhancement of hydrogen production from glucose by nitrogen gas sparging. Bioresour. Technol. 2000;73:59–65. doi: 10.1016/S0960-8524(99)00130-3. [DOI] [Google Scholar]

- 56.Valdez I., Rios E., Carmona A., Muñoz K., Poggi H. Improvement of biohydrogen production from solid wastes by intermittent venting and gas flushing of batch reactors headspace. Environ. Sci. Technol. 2006;40:3409–3415. doi: 10.1021/es052119j. [DOI] [PubMed] [Google Scholar]

- 57.D’Ippolito G., Dipasquale L., Fontana A. Recycling of carbon dioxide and acetate as lactic acid by the hydrogen-producing bacterium Thermotoga neapolitana. ChemSusChem. 2014;7:2678–2683. doi: 10.1002/cssc.201402155. [DOI] [PubMed] [Google Scholar]

- 58.Furdui C., Ragsdale S.W. The role of pyruvate ferredoxin oxidoreductase in pyruvate synthesis during autotrophic growth by the Wood-Ljungdahl pathway. J. Biol. Chem. 2000;275:28494–28499. doi: 10.1074/jbc.M003291200. [DOI] [PubMed] [Google Scholar]

- 59.Bock A.K., Kunow J., Glasemacher J., Schönheit P. Catalytic properties, molecular composition and sequence alignments of pyruvate: Ferredoxin oxidoreductase from the methanogenic archaeon Methanosarcina barkeri (strain Fusaro) Eur. J. Biochem. 1996;237:35–44. doi: 10.1111/j.1432-1033.1996.0035n.x. [DOI] [PubMed] [Google Scholar]

- 60.Berg I.A., Kockelkorn D., Ramos-vera W.H., Say R.F., Zarzychi J., Hugler M., Alber B.E., Fuchs G. Autotrophic carbon fixation in archaea. Nat. Rev. Microbial. 2010;8:447–460. doi: 10.1038/nrmicro2365. [DOI] [PubMed] [Google Scholar]

- 61.Braakman R., Smith E. The emergence and early evolution of biological carbon-fixation. PLoS Comput. Biol. 2012;8:e1002455. doi: 10.1371/journal.pcbi.1002455. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Krebs H.A. Carbon dioxide assimilation in heterotrophic organisms. Nature. 1941;147:560–563. doi: 10.1038/147560a0. [DOI] [Google Scholar]

- 63.Werkman C.H., Wood H.G. Heterotrophic assimilation of carbon dioxide. Adv. Enzymol. Relat. Areas Mol. Biol. 2006;2:135–179. [PubMed] [Google Scholar]

- 64.Ngo T.A., Kim M.S., Sim S.J. High-yield bioH2 production from biodiesel manufacturing waste by Thermotoga neapolitana. Int. J. Hydrog. Energy. 2011;36:5636–5642. doi: 10.1016/j.ijhydene.2010.11.057. [DOI] [Google Scholar]

- 65.Cappelletti M., Bucchi G., Mendes J.D.S., Alberini A., Fedi S., Bertin L., Frascari D. BioH2 production from glucose, molasses and cheese whey by suspended and attached cells of four hyperthermophilic Thermotoga strains. J. Chem. Technol. Biotechnol. 2012;87:1291–1301. doi: 10.1002/jctb.3782. [DOI] [Google Scholar]

- 66.Dipasquale L., d’Ippolito G., Gallo C., Vella F.M., Gambacorta A., Picariello G., Fontana A. H2 production by the thermophilic eubacterium Thermotoga neapolitana from storage polysaccharides of the CO2-fixing diatom Thalassiosira weissflogii. Int. J. Hydrog. Energy. 2012;37:12250–12257. doi: 10.1016/j.ijhydene.2012.05.160. [DOI] [Google Scholar]

- 67.Eriksen N.T., Leegaard Riis M., Kyndby Holm N., Iversen N. H2 synthesis from pentose and biomass in Thermotoga spp. Biotechnol. Lett. 2011;33:293–300. doi: 10.1007/s10529-010-0439-x. [DOI] [PubMed] [Google Scholar]

- 68.Mars A.E., Veuskens T., Budde M.A.W., van Doeveren P.F.N.M., Lips S.J., Bakker R.R., de Vrije T., Claassen P.A.M. BioH2 production from untreated and hydrolyzed potato steam peels by the extreme thermophiles Caldicellulosiruptor saccharolyticus and Thermotoga neapolitana. Int. J. Hydrog. Energy. 2010;35:7730–7737. doi: 10.1016/j.ijhydene.2010.05.063. [DOI] [Google Scholar]

- 69.Maru B.T., Bielen A.A.M., Kengen S.W.M., Constanti M., Medina F. BioH2 production from glycerol using Thermotoga spp. Energy Procedia. 2012;29:300–307. doi: 10.1016/j.egypro.2012.09.036. [DOI] [Google Scholar]

- 70.Nguyen T.A.D., Kim K.R., Kim M.S., Sim S.J. Thermophilic H2 fermentation from Korean rice straw by Thermotoga neapolitana. Int. J. Hydrog. Energy. 2010;35:13392–13398. doi: 10.1016/j.ijhydene.2009.11.112. [DOI] [Google Scholar]

- 71.Nguyen T.A.D., Kim K.R., Nguyen M.T., Kim M.S., Kim D., Sim S.J. Enhancement of fermentative H2 production from green algal biomass of Thermotoga neapolitana by various pretreatment methods. Int. J. Hydrog. Energy. 2010;35:13035–13040. doi: 10.1016/j.ijhydene.2010.04.062. [DOI] [Google Scholar]

- 72.Ngo T.N., Sim S.J. Dark fermentation of H2 from waste glycerol using hyperthermophilic eubacterium Thermotoga neapolitana. Environ. Prog. Sustain. Energy. 2012;31:466–473. doi: 10.1002/ep.10578. [DOI] [Google Scholar]

- 73.Ito T., Nakashimada Y., Senba K., Matsui T., Nishio N. H2 and ethanol production from Glycerol-containing wastes discharged after biodiesel manufacturing process. J. Biosci. Bioeng. 2005;100:260–265. doi: 10.1263/jbb.100.260. [DOI] [PubMed] [Google Scholar]

- 74.Pott R.W.M., Howe C.J., Dennis J.S. Photofermentation of crude glycerol from biodiesel using Rhodopseudomonas palustris: Comparison with organic acids and the identification of inhibitory compounds. Bioresour. Technol. 2013;130:725–730. doi: 10.1016/j.biortech.2012.11.126. [DOI] [PubMed] [Google Scholar]

- 75.Munro S.A., Choe L., Zinder S.H., Lee K.H., Walker L.P. Proteomic and physiological experiments to test Thermotoga neapolitana constraint-based model hypotheses of carbon source utilization. Biotechnol. Prog. 2012;28:312–318. doi: 10.1002/btpr.735. [DOI] [PubMed] [Google Scholar]

- 76.Ngo T.A., Nguyen T.H., Bui H.T.V. Thermophilic fermentative H2 production from xylose by Thermotoga neapolitana DSM 4359. Renew. Energy. 2012;37:174–179. doi: 10.1016/j.renene.2011.06.015. [DOI] [Google Scholar]

- 77.De Vrije T., Bakker R.R., Budde M.A.W., Lai M.H., Mars A.E., Claassen P.A.M. Efficient H2 production from the lignocellulosic energy crop miscanthus by the extreme thermophilic bacteria Caldicellulosiruptor saccharolyticus and Thermotoga neapolitana. Biotechnol. Biofuels. 2009;2:12. doi: 10.1186/1754-6834-2-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 78.Ngo T.A., Bui H.T.V. BioH2 Production using immobilized cells of hyperthermophilic eubacterium Thermotoga neapolitana on porous glass beads. J. Technol. Innov. Renew. Energy. 2013;2:231–238. [Google Scholar]

- 79.Frascari D., Cappelletti M., Mendes J.D.S., Alberini A., Scimonelli F., Manfreda C., Longanesi L., Zannoni D., Pinelli D., Fedi S. A kinetic study of bioH2 production from glucose, molasses and cheese whey by suspended and attached cells of Thermotoga neapolitana. Bioresour. Technol. 2013;147:553–561. doi: 10.1016/j.biortech.2013.08.047. [DOI] [PubMed] [Google Scholar]

- 80.Ngo T.A., Kim M.S., Sim S.J. Thermophilic H2 fermentation using Thermotoga neapolitana DSM 4359 by fed-batch culture. Int. J. Hydrog. Energy. 2011;36:14014–14023. doi: 10.1016/j.ijhydene.2011.04.058. [DOI] [Google Scholar]

- 81.Munro S.A., Zinder S.H., Walker L.P. The fermentation stoichiometry of Thermotoga neapolitana and influence of temperature, oxygen, and pH on H2 production. Biotechnol. Progress. 2009;25:1035–1042. doi: 10.1002/btpr.201. [DOI] [PubMed] [Google Scholar]

- 82.Van Ooteghem S.A., Jones A., van der Lelie D., Dong B., Mahajan D. H2 production and carbon utilization by Thermotoga neapolitana under anaerobic and microaerobic growth conditions. Biotechnol. Lett. 2004;26:1223–1232. doi: 10.1023/B:BILE.0000036602.75427.88. [DOI] [PubMed] [Google Scholar]

- 83.Nguyen T.A.D., Han S.J., Kim J.P., Kim M.S., Oh Y.K., Sim S.J. H2 production by the hyperthermophilic eubacterium, Thermotoga neapolitana, using cellulose pretreated by ionic liquid. Int. J. Hydrog. Energy. 2008;33:5161–5168. doi: 10.1016/j.ijhydene.2008.05.019. [DOI] [Google Scholar]

- 84.Van Ooteghem S.A., Beer S.K., Yue P.C. H2 production by the thermophilic bacterium Thermotoga neapolitana. Appl. Biochem. Biotechnol. 2002;98:177–189. doi: 10.1385/ABAB:98-100:1-9:177. [DOI] [PubMed] [Google Scholar]

- 85.Nguyen T.A.D., Kim J.P., Kim M.S., Oh Y.K., Sim S.J. Optimization of H2 production by hyperthermophilic eubacteria, Thermotoga maritima and Thermotoga neapolitana in batch fermentation. Int. J. Hydrog. Energy. 2008;33:1483–1488. doi: 10.1016/j.ijhydene.2007.09.033. [DOI] [Google Scholar]

- 86.Levin D.B., Pitt L., Love M. BioH2 production: Prospects and limitations to practical application. Int. J. Hydrog. Energy. 2004;29:173–185. doi: 10.1016/S0360-3199(03)00094-6. [DOI] [Google Scholar]

- 87.Basak N., Das D. The prospect of purple non-sulfur (PNS) photosynthetic bacteria for hydrogen production: The present state of the art. World J. Microbiol. Biotechnol. 2006;23:31–42. doi: 10.1007/s11274-006-9190-9. [DOI] [Google Scholar]

- 88.Uyar B., Schumacher M., Gebicki J., Modigell M. Photoproduction of hydrogen by Rhodobacter capsulatus from thermophilic fermentation effluent. Bioprocess Biosyst. Eng. 2009;32:603–606. doi: 10.1007/s00449-008-0282-9. [DOI] [PubMed] [Google Scholar]

- 89.Dipasquale L., Adessi A., d’Ippolito G., Rossi F., Fontana A., de Philippis R. Introducing capnophilic lactic fermentation in a combined dark-photo fermentation process: A route to unparalleled H2 yields. Appl. Microbiol. Biotechnol. 2015;99:1001–1010. doi: 10.1007/s00253-014-6231-4. [DOI] [PubMed] [Google Scholar]

- 90.Adessi A., McKinlay J.B., Harwood C.S., de Philippis R. A Rhodopseudomonas palustris nifA* mutant produces H2 from NH4+-containing vegetable wastes. Int. J. Hydrog. Energy. 2012;37:15893–15900. doi: 10.1016/j.ijhydene.2012.08.009. [DOI] [Google Scholar]

- 91.Zverlov V.V., Volkov I.Y., Velikodvorskaya T.V., Schwarz W.H. Highly thermostable endo-1,3-b-glucanase (chrysolaminaranase) LamA from Thermotoga neapolitana: Nucleotide sequence of the gene and characterization of the recombinant gene product. Microbiology. 1997;143:1701–1708. doi: 10.1099/00221287-143-5-1701. [DOI] [PubMed] [Google Scholar]

- 92.Zverlov V.V., Volkov I.Y., Velikodvorskaya T.V., Schwarz W.H. Thermotoga neapolitana bglB gene, upstream of lamA, encodes a highly thermostable β-glucosidase that is a laminaribiase. Microbiology. 1997;143:3537–3542. doi: 10.1099/00221287-143-11-3537. [DOI] [PubMed] [Google Scholar]

- 93.Li R.Y., Zhang T., Fang H.H.P. Characteristics of a phototrophic sludge producing H2 from acetate and butyrate. Int. J. Hydrog. Energy. 2008;33:2147–2155. [Google Scholar]

- 94.Malina J.F., Poland F.G. Design of Anaerobic Processes for Treatment of Industrial and Municipal Wastes. Technomic Publishing Co., Inc.; Lanchester, UK: 1992. [Google Scholar]

- 95.Mohan S.V., Rao N.C., Prasad K.K., Madhavi B.T.V., Sarma P.N. Treatment of complex chemical effluents by sequencing batch reactor (SBR) with aerobic suspended growth configuration. Process Biochem. 2005;40:1501–1508. doi: 10.1016/j.procbio.2003.02.001. [DOI] [Google Scholar]

- 96.Basile M.A., Carfagna C., Cerruti P., d’Avala G.G., Fontana A., Gambacorta A., Malinconico M., Dipasquale L. Continuous hydrogen production by immobilized cultures of Thermotoga neapolitana on an acrylic hydrogel with pH-buffering properties. RSC Adv. 2012;2:3611–3614. doi: 10.1039/c2ra01025a. [DOI] [Google Scholar]

- 97.Chang J.S., Lee K.S., Lin P.J. BioH2 production with fixed-bed bioreactors. Int. J. Hydrog. Energy. 2002;27:1167–1174. doi: 10.1016/S0360-3199(02)00130-1. [DOI] [Google Scholar]

- 98.Kumar N., Das D. Continuous H2 production by immobilized Enterobacter cloacae IIT-BT 08 using lignocellulosic materials as solid matrices. Enzym. Microb. Technol. 2001;29:280–287. doi: 10.1016/S0141-0229(01)00394-5. [DOI] [Google Scholar]

- 99.Wu K.J., Chang J.S. Batch and continuous fermentative production of H2 with anaerobic sludge entrapped in a composite polymeric matrix. Process Biochem. 2007;42:279–284. doi: 10.1016/j.procbio.2006.07.021. [DOI] [Google Scholar]

- 100.Basile M.A., Carfagna C., Dipasquale L., Fontana A., Gambacorta A., d’Ayala G.G., Malinconico M., Cerruti P. Hydrogen Production: Prospects and Processes. Volume 13. Nova Science Publishers Inc.; Hauppauge, NY, USA: 2011. Development of novel immobilizing hydrogels for thermophilic hydrogen production; pp. 401–411. [Google Scholar]

- 101.Yang P., Zhang R., McGarvey J.A., Benemann J.R. BioH2 production from cheese processing wastewater by anaerobic fermentation using mixed microbial communities. Int. J. Hydrog. Energy. 2007;32:4761–4771. doi: 10.1016/j.ijhydene.2007.07.038. [DOI] [Google Scholar]

- 102.Kim S.H., Han S.K., Shin H.S. Optimization of continuous H2 fermentation of food waste as a function of solids retention time independent of hydraulic retention time. Process Biochem. 2008;43:213–218. doi: 10.1016/j.procbio.2007.11.007. [DOI] [Google Scholar]

- 103.Fang H.H.P., Liu H. Granulation of H2-producing acidogenic sludge; Proceeding of the 9th World Congress Anaerobic Digestion Part 2; Antwerp, Belgium. 2–6 September 2001; pp. 527–532. [Google Scholar]

- 104.Schonheit P., Schafer T. Metabolism of hyperthermophiles. World J. Microbiol. Biotechnol. 1995;11:26–57. doi: 10.1007/BF00339135. [DOI] [PubMed] [Google Scholar]

- 105.Hawkes F.R., Hussy I., Kyazza G., Dinsdale R., Hawkes D.L. Continuous dark fermentative H2 production by mesophilic microflora: Principles and progress. Int. J. Hydrog. Energy. 2007;32:172–184. doi: 10.1016/j.ijhydene.2006.08.014. [DOI] [Google Scholar]

- 106.Eriksen T.N., Niels N.T., Iversen N. H2 production in anaerobic and microaerobic Thermotoga neapolitana. Biotechnol. Lett. 2008;30:103–109. doi: 10.1007/s10529-007-9520-5. [DOI] [PubMed] [Google Scholar]

- 107.Gadhe A., Sonawane S.S., Varma M.N. Optimization of conditions for H2 production from complex dairy wastewater by anaerobic sludge using desirability function approach. Int. J. Hydrog. Energy. 2013;38:6607. doi: 10.1016/j.ijhydene.2013.03.078. [DOI] [Google Scholar]

- 108.Gadhamshetty V., Arudchelvam Y., Nirmalakhandan N., Johnson D.C. Modeling dark fermentation for bioH2 production: ADM1-based model vs. Gompertz model. Int. J. Hydrog. Energy. 2010;35:470–490. doi: 10.1016/j.ijhydene.2009.11.007. [DOI] [Google Scholar]

- 109.Batstone D.J., Keller J., Angelidaki I., Kalyuzhnyi S.V. IWA Task Group for Mathematical Modeling of Anaerobic Digestion Processes. IWA Publishing; London, UK: 2002. Anaerobic Digestion Model No. 1 (ADM1) [Google Scholar]

- 110.Castello E., García C., Santos Y., Iglesias T., Paolino G., Wenzel J., Borzacconi L. Feasibility of bioH2 production from cheese whey using a UASB reactor: Links between microbial community and reactor performance. Int. J. Hydrog. Energy. 2009;34:5674–5682. doi: 10.1016/j.ijhydene.2009.05.060. [DOI] [Google Scholar]

- 111.Fuentes M., Scenna N.J., Aguirre P.A. Modeling of H2 production in biofilm reactors: Application of the Anaerobic Digestion Model 1. Hyfusen. 2011:01-223. [Google Scholar]

- 112.Paulo C.I., Maggio J.A.D., Diaz M.S., Ruggeri B. Modeling and parameter estimation in biofuel discontinuous production by H2 forming bacteria (HFB) Chem. Eng. Trans. 2013;32:1033–1038. [Google Scholar]

- 113.Wang J., Wan W. Kinetic models for fermentative H2 production: A review. Int. J. Hydrog. Energy. 2009;34:3313. doi: 10.1016/j.ijhydene.2009.02.031. [DOI] [Google Scholar]

- 114.Yu X., Drapcho C. H2 production by the hyperthermophilic bacterium Thermotoga neapolitana using agricultural-based carbon and nitrogen sources. Biol. Eng. Trans. 2011;4:101–112. doi: 10.13031/2013.38506. [DOI] [Google Scholar]

- 115.Kovacs K.L., Maróti G., Rákhelya G. A novel approach for biohydrogen production. Int. J. Hydrog. Energy. 2006;31:1460–1468. doi: 10.1016/j.ijhydene.2006.06.011. [DOI] [Google Scholar]

- 116.Munoz-Páez K.M., Ríos-Leal E., Valdez-Vazquez I. Re-fermentation of washed spent solids from batch hydrogenogenic fermentation for additional production of biohydrogen from the organic fraction of municipal solid waste. J. Environ. Manag. 2012;95:S355–S359. doi: 10.1016/j.jenvman.2011.01.017. [DOI] [PubMed] [Google Scholar]

- 117.Mathews J., Wang G. Metabolic pathway engineering for enhanced bioH2 production. Int. J. Hydrog. Energy. 2009;34:7404–7416. doi: 10.1016/j.ijhydene.2009.05.078. [DOI] [Google Scholar]

- 118.Show K.Y., Lee D.J., Tay J.H., Lin C.Y., Chang J.S. BioH2 production: Current perspectives and the way forward. Int. J. Hydrog. Energy. 2012;37:15616–15631. doi: 10.1016/j.ijhydene.2012.04.109. [DOI] [Google Scholar]