Abstract

The biologically active compounds raphasatin and sulforaphene are formed during the hydrolysis of radishes by an endogenous myrosinase. Raphasatin is very unstable, and it is generated and simultaneously degraded to less active compounds during hydrolysis in aqueous media. This study determined the hydrolysis conditions to maximize the formation of raphasatin and sulforaphene by an endogenous myrosinase and minimize their degradation during the hydrolysis of radish roots. The reaction parameters, such as the reaction medium, reaction time, type of mixing, and reaction temperature were optimized. A stability test for raphasatin and sulforaphene was also performed during storage of the hydrolyzed products at 25°C for 10 days. The formation and breakdown of raphasatin and sulforaphene in radish roots by endogenous enzymolysis was strongly influenced by the reaction medium, reaction time, and type of mixing. The production and stabilization of raphasatin in radishes was efficient in water and dichloromethane with shaking for 15 min at 25°C. For sulforaphene, the favorable condition was water as the reaction medium without shaking for 10 min at 25°C. The maximum yields of raphasatin and sulforaphene were achieved in a concurrent hydrolysis reaction without shaking in water for 10 min and then with shaking in dichloromethane for 15 min at 25°C. Under these conditions, the yields of raphasatin and sulforaphene were maximized at 12.89 and 1.93 μmol/g of dry radish, respectively. The stabilities of raphasatin and sulforaphene in the hydrolyzed products were 56.4% and 86.5% after 10 days of storage in water and dichloromethane at 25°C.

Keywords: radish roots, endogenous enzymolysis, raphasatin, sulforaphene, formation and stabilization

INTRODUCTION

Radishes (Raphanus sativus L.) belong to the family Brassicaceae, and they are cultivated and consumed throughout the world. Radishes are a good source of vitamin C, dietary fiber, minerals, polysaccharides, gibberellins, alkaloids, and nitrogenous compounds, as well as a large variety of phytochemicals, namely glucosinolates (GLs) and phenols (1). The primary glucosinolates in radishes are thio-functionalized GLs, glucoraphasatin (4-methyl thio-3-butenyl GL) and glucoraphenin (4-methyl sulfinyl-3-butenyl GL). Glucoraphasatin is the predominant GL accounting for about 80% of the total GLs while glucoraphenin is the second most common GL and accounts for less than 10% of the total GLs in mature radishes (2). In their original forms, these compounds do not have any direct biological activities, but their derivatives, i.e., isothiocyanates (ITCs), raphasatin (4-methyl thio-3-butenyl ITC) and sulforaphene (4-methyl sulfin-yl-3-butenyl ITC) may have potential health benefits.

Raphasatin is an antioxidant (3,4), a potent inducer of phase II enzymes in precision-cut rat liver slices (5), cytotoxic to multiple cancer cell lines (6–9), and has anti-mutagenic properties (10). Sulforaphene has antimicrobial, antiviral, and antioxidant properties (4,10,11). Sulforaphene is 1.3~1.5-fold more active than sulforaphane with regard to in vitro antimutagenic activities in Salmonella Typhimurium in the presence of Aroclor 1254-induced rat liver S9 (12). Sulforaphene has greater cancer preventive properties (IC50=10.67 μg/mL) against the human colon cancer (HCT116) cell line than the chemotherapeutic drug, mitomycin C (IC50=19.12 μg/mL), via both cytotoxicity and the induction of apoptosis (13).

Radishes are generally utilized as raw vegetables and as components of salads. They may be more beneficial than other cruciferous vegetables, which are consumed after cooking, because heating inactivates myrosinase, which is essential for producing active ITCs from their GL precursors (12). Glucoraphasatin and glucoraphenin in raw radish roots are converted to raphasatin and sulforaphene in water by endogenous myrosinase (thioglucoside glucohydrolase, EC 3.2.1.147) when plant tissues and cells are damaged. The capability of myrosinase in the degradation of GLs could be influenced by a number of processing factors such as reaction temperature, reaction time, solid-liquid ratio, pH, reaction medium, type of mixing, and vitamin C levels (14). The stability of the hydrolyzed products, which are critical for their development as functional agents or as dietary foods, is particularly affected by the reaction medium.

Sulforaphene is slightly soluble in water, and thus it is produced and stabilized during the hydrolysis of radishes in an aqueous medium. However, raphasatin is hydrophobic, highly unstable in an aqueous environment, and spontaneously changes to less active compounds during the hydrolysis of radishes in water (15,16). Therefore, there is a need to optimize a processing method to maximize the formation and minimize the degradation of raphasatin and sulforaphene by the endogenous enzymolysis of radishes.

Shen et al. (14) investigated the conversion of glucoraphanin to sulforaphane using an endogenous myrosinase from broccoli seed powder under various enzymolysis conditions such as reaction temperature, reaction time, solid-liquid ratio, pH, and the addition of vitamin C. However, to our knowledge, a systematic study of endogenous enzymatic hydrolysis with radishes under various enzymolysis conditions has not been reported. Previous studies have been performed on the hydrolysis of radishes in water or in 0.1 M phosphate buffer (pH 6.5) for a certain length of time, and the resulting mixture was then centrifuged with the addition of ethanol or dichloromethane to recover the hydrolyzed products (2,5,13,16–18). The formation and degradation of the hydrolyzed products in aqueous media were not considered during the hydrolysis and centrifugation processes. Therefore, the reported yields of ITCs from GLs could be underestimated.

The objective of this study was to optimize the hydrolysis conditions to increase yields and minimize the degradation of raphasatin and sulforaphene from glucoraphasatin and glucoraphenin by an endogenous myrosinase in radish roots during hydrolysis.

MATERIALS AND METHODS

Materials and chemicals

Radish (Raphanus sativus L.) roots were obtained from a local store in Jeju, Korea. They were washed, sliced, and freeze-dried. Radish root powder was stored in a cooler at 4°C until needed. Sulforaphene, erucin, and benzyl ITC (BITC) standards were purchased from Santa Cruz Biotechnology Inc. (Santa Cruz, CA, USA). HPLC-grade dichloromethane was purchased from Daejung Chemical & Metals Co., Ltd. (Seoul, Korea).

Analysis of isothiocyanates in radishes

The intrinsic ITC content of the radish roots before hydrolysis was measured. Ten milliliters of dichloromethane were added to 0.5 g of freeze-dried radish root powder in a 50 mL centrifuge tube. The tube was left undisturbed at 25°C for 30 min, then centrifuged at 7,000 g at 4°C for 5 min after which the dichloromethane layer was collected. After triplicate extractions, the combined extracts were filtered through a No. 5A filter paper (Advantec, Kashiwa, Japan) with 2 g of anhydrous sodium sulfate. The filtrate was evaporated to remove the solvent using a rotary vacuum evaporator (Rotavapor R-124, BÜCHI Labortechnik AG, Flawil, Switzerland) at 25°C. The dried residue was dissolved in 2 mL of dichloromethane and filtered using a 0.50 μm syringe filter (Advantec). A 200 μL aliquot of a 75 μg/mL solution of BITC (internal standard) was added to 400 μL of this solution, and the sample was then analyzed for ITCs by gas chromatography/mass spectrometry (GC/MS).

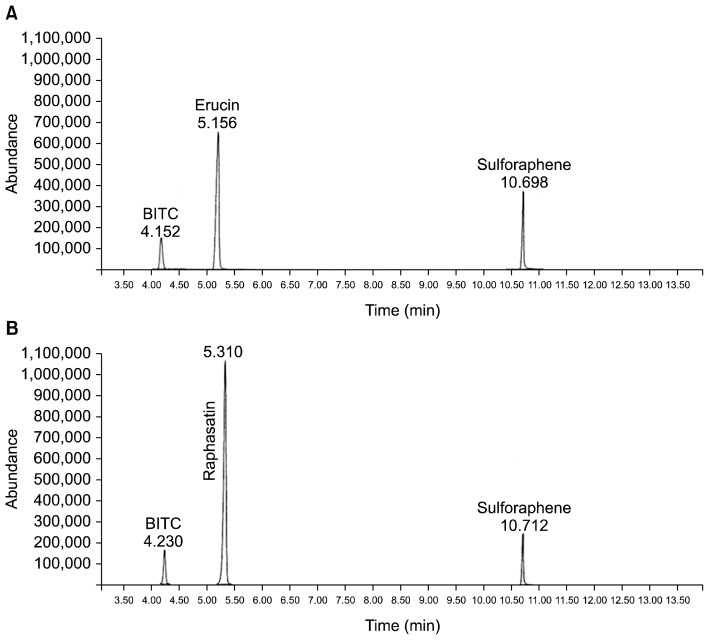

Raphasatin and sulforaphene were analyzed using an Agilent 6890N GC/5973 MSD (Agilent Technologies, Santa Clara, CA, USA). A HP-5 MS capillary column (30 m×0.25 mm i.d., 0.25 μm film thickness, J&W Scientific, Folsom, CA, USA) was used for separation. Helium was used as the carrier gas at a constant flow of 0.8 mL/min. The column temperature was maintained at 150°C for 8 min, and then programmed at 25°C/min to 250°C where it remained for 2 min. The GC injector temperature was 200°C, and the transfer line temperature was 280°C. The injection volume was 2 μL, with a split ratio of 1:20. Mass spectra were obtained by electron-impact ionization over the mass range of 50~500 amu at a scan rate of 2 scans/s. Typical GC/MS chromatograms of standards and the sample extract are shown in Fig. 1.

Fig. 1.

Chromatograms of standards (A) and sample extract (B).

The concentration of raphasatin was calculated using erucin as the standard, which is similar to raphasatin in structure and is commercially available (16). The concentration of sulforaphene was calculated using a sulforaphene standard. Standard solutions were prepared with dichloromethane for a set of erucin solutions at concentrations of 150, 175, 200, 225, and 250 μg/mL and a set of sulforaphene solutions at concentrations of 40, 50, 60, 70, and 80 μg/mL. A 100 μL aliquot of a 75 μg/mL solution of BITC (internal standard) was added to 200 μL of each standard solution, and the mixed standard solutions were then analyzed by GC/MS. The ratios of the peak area of erucin or sulforaphene to BITC for each solution were recorded and plotted against the various concentrations to obtain the standard curves.

Endogenous enzymatic hydrolysis of radish roots under various conditions

Eight milliliters of distilled water and/or dichloromethane were added gently to 0.5 g of freeze-dried radish root powder in a 50 mL centrifuge tube. The endogenous enzymatic hydrolysis was performed at a controlled temperature for a certain length of time with and without shaking. The enzymatic reaction was stopped by the addition of 1.8 mL of 6 M HCl. The resulting mixture was added to 10 mL of dichloromethane and centrifuged at 7,000 g at 4°C for 5 min after which the dichloromethane layer was collected. The rest of the experimental method was followed as described above in the analysis of isothiocyanates in radishes.

The endogenous enzymatic hydrolysis was conducted under various controlled conditions including different reaction media [distilled water (hydrophilic) and dichloromethane (hydrophobic)], reaction times (5, 10, 15, 20, and 25 min), type of mixing (with and without shaking), and reaction temperatures (10, 25, and 37°C). A stability test for raphasatin and sulforaphene produced by enzymatic hydrolysis was also performed during storage of the hydrolysis products at 25°C for 2, 4, 6, 8, and 10 days.

Statistical analysis

Three replicate experiments were conducted and the data presented here represent the average of three experiments±standard deviation. Statistical analysis was performed using SPSS version 18.0 software (SPSS Inc., Chicago, IL, USA). Significant differences (P<0.05) among the treatment means were determined by Duncan’s multiple range test.

RESULTS AND DISCUSSION

Intrinsic isothiocyanate concentrations in radish roots

The intrinsic ITC contents in freeze-dried radish roots before endogenous enzymatic hydrolysis in water were measured with GC/MS by extracting freeze-dried radishes three times with dichloromethane. Only a small amount of raphasatin was detected (1.97±0.01 μmol/g of dry radish), while sulforaphene was not detected. Therefore, to improve the health benefits of radishes, they should be hydrolyzed by the endogenous enzyme to maximize the yield of functional ITCs such as raphasatin and sulforaphene.

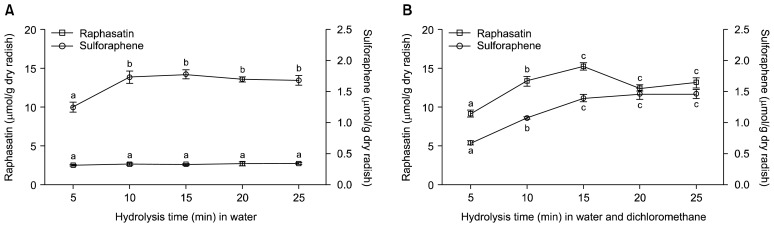

Formation of raphasatin and sulforaphene by hydrolysis in water without shaking

Radish powder and distilled water were mixed and incubated without shaking at 25°C for 5~25 min and then the amount of ITC was measured at various time points (Fig. 2A). For 25 min the amount of raphasatin was almost constant at about 2.52 μmol/g of dry radish regardless of the hydrolysis time, while the amount of sulforaphene increased from 1.25 μmol/g of dry radish at 5 min to 1.73 μmol/g of dry radish at 10 min and then remained unchanged.

Fig. 2.

Raphasatin and sulforaphene yields in radishes during hydrolysis in water (A), and in water and dichloromethane (B) without shaking during hydrolysis. Different letters (a–c) within the same compound are significantly different (P<0.05).

Production of sulforaphene from glucoraphenin, present in small amount in radishes, was completed within 10 min at 25°C. However, glucoraphasatin was not completely hydrolyzed into raphasatin from the large amount of glucoraphasatin present in radishes or produced and degraded simultaneously during hydrolysis in water because the yield of raphasatin was low (2.52 μmol/g of dry radish). Raphasatin is hydrophobic and unstable in aqueous or methanolic environments (15). Therefore, for maximum raphasatin production, a polar and non-polar medium should be used during hydrolysis.

Minimization of the degradation of raphasatin during hydrolysis

To increase the yield of raphasatin by minimizing its degradation during hydrolysis, a non-polar solvent (dichloromethane) (10 mL) was added to the radish powder (0.5 g) together with distilled water (8 mL), and the mixture was incubated without shaking at 25°C; the amount of ITC was measured after the indicated times (Fig. 2B). The amount of raphasatin gradually increased from 9.17 μmol/g of dry radish after 5 min to 12.72 μmol/g of dry radish after 15 min and remained unchanged thereafter. The amount of sulforaphene also gradually increased from 0.67 μmol/g of dry radish at 5 min to 1.39 μmol/g of dry radish at 15 min and then remained constant thereafter.

We found that due to the presence of dichloromethane in water during hydrolysis, the amount of raphasatin in radishes (12.72 μmol/g of dry radish) (Fig. 2B) was increased 5-fold compared to that in water alone (2.52 μmol/g of dry radish) (Fig. 2A). Therefore, the non-polar raphasatin produced by hydrolysis in water migrated to the non-polar dichloromethane medium and was protected.

The yield of sulforaphene due to hydrolysis in a water and dichloromethane mixture (1.39 μmol/g of dry radish) decreased by about 20% compared to that in water alone (1.73 μmol/g of dry radish) due to the use of a mixture of polar and non-polar solvent as a reaction medium, which did not favor the sulforaphene. Therefore, to increase the formation and to minimize the degradation of non-polar raphasatin in an aqueous medium, hydrolysis should be performed in a mixture of polar and non-polar medium to obtain the maximum yield of raphasatin.

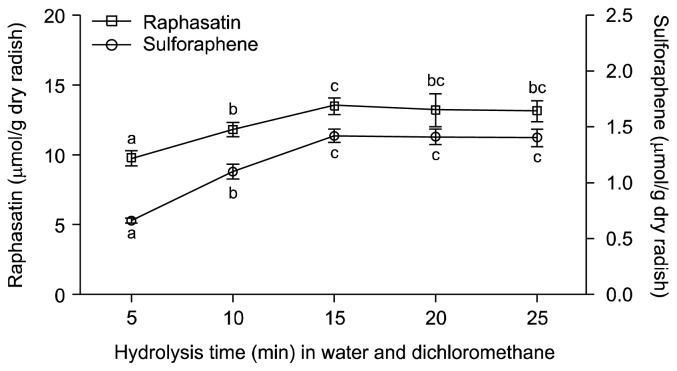

Maximization of raphasatin production by hydrolysis

To provide more favorable conditions for migration of the raphasatin produced during hydrolysis into a non-polar medium, radish powder, distilled water, and dichloromethane were mixed and hydrolyzed with shaking in a water bath at 25°C for a controlled length of time; the amount of ITC was then measured (Fig. 3). The amount of raphasatin after 15 min of hydrolysis was increased by about 7% with shaking (13.57 μmol/g of dry radish) compared to that without shaking (12.72 μmol/g of dry radish) (Fig. 2B). This was because during hydrolysis with shaking, the non-polar raphasatin produced moved easily into a non-polar medium (dichloromethane) and retained its stability, and/or the shaking during hydrolysis provided a greater opportunity for endogenous myrosinase to come into contact with glucoraphasatin in radishes. The sulforaphene yield was not changed regardless of the use of shaking.

Fig. 3.

Raphasatin and sulforaphene yields in radishes during hydrolysis in water and dichloromethane with shaking. Different letters (a–c) within the same compound are significantly different (P<0.05).

Based on the above experiments, the formation and minimization of the degradation of the non-polar raphasatin was favored in the hydrolysis reaction with the mixed polar and non-polar medium and shaking for 15 min. In contrast, for the sulforaphene, the optimal hydrolysis reaction conditions were the use of water as a reaction medium for 10 min without shaking.

Maximization of raphasatin and sulforaphene production by concurrent hydrolysis in water and dichloromethane

To simultaneously maximize the formation and maintain the stability of raphasatin and sulforaphene, radish powder and distilled water were mixed and hydrolyzed without shaking at 25°C for 10 min. Dichloromethane was then added and the mixture was further hydrolyzed with shaking in a water bath at 25°C for 15 min before the amount of ITC was measured (Table 1).

Table 1.

Raphasatin and sulforaphene yields in radishes during concurrent hydrolysis in water without shaking and in dichloromethane with shaking (unit: μmol/g of dry radish)

| Hydrolysis method | Yield | |

|---|---|---|

|

| ||

| Raphasatin | Sulforaphene | |

| Without shaking for 10 min in water and with shaking for 15 min in dichloromethane | 12.89±0.66A | 1.93±0.07a |

| Without shaking for 10 min in water and without shaking for 15 min in dichloromethane | 12.46±0.19A | 1.93±0.00a |

Values followed by the same letters are not significantly different (P<0.05).

The yield of raphasatin in the hydrolysis without shaking in water for 10 min and then with shaking in dichloromethane for 15 min (12.89 μmol/g of dry radish) was not significantly different from that in the hydrolysis with only water and then in dichloromethane with shaking for 15 min (13.57 μmol/g of dry radish, Fig. 2B). However, the yield of sulforaphene in the hydrolysis without shaking in water for 10 min and then with shaking in dichloromethane for 15 min (1.93 μmol/g of dry radish) was about 12% greater than that of the hydrolysis with only water without shaking for 10 min (1.73 μmol/g of dry radish, Fig. 2A). The yields of raphasatin and sulforaphene were not significantly different with and without shaking (12.46 μmol/g and 1.93 μmol/g of dry radish, respectively) in dichloromethane in the second hydrolysis process.

Based on the above experiments, it was concluded that to maximize the formation and minimize the degradation of raphasatin and sulforaphene, the endogenous enzyme hydrolysis of radishes should be performed in water for 10 min without shaking and then in dichloromethane for 15 min with or without shaking.

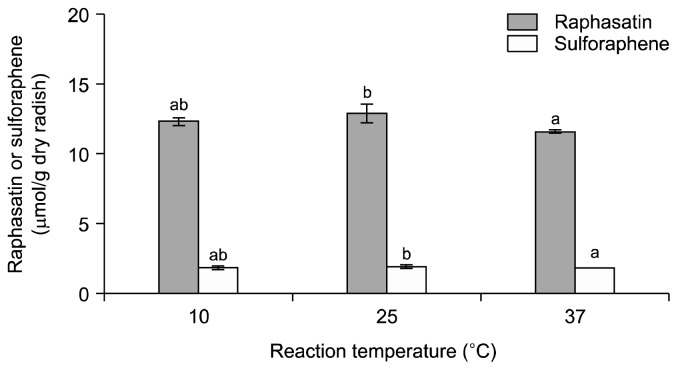

Effect of hydrolysis temperature on the formation of raphasatin and sulforaphene

The yields of raphasatin and sulforaphene at 25°C were slightly higher than those at 37°C but not significantly different from those at 10°C (Fig. 4). Generally, a temperature too low or too high is not beneficial for enzymatic activity. In our particular case, the optimum temperature for endogenous enzyme activity appeared to be 25°C, where the maximum yields of 12.89 μmol/g of dry radish for raphasatin and 1.93 μmol/g of dry radish for sulforaphene were observed for the enzymolysis of GLs in radishes. Shen et al. (14) investigated the conversion of glucoraphanin to sulforaphane using an endogenous myrosinase from broccoli seed powder over a temperature range between 5 and 55°C, with the maximum transformation achieved at 25°C.

Fig. 4.

Effects of hydrolysis temperature on raphasatin and sulforaphene yields in radishes during hydrolysis. Different letters (a,b) within the same compound are significantly different (P<0.05).

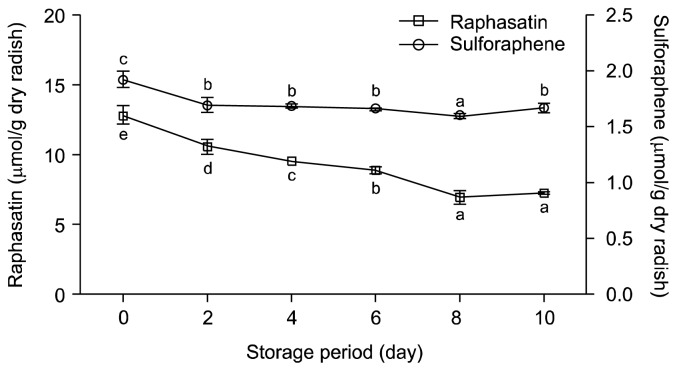

Stability of raphasatin and sulforaphene during storage at 25°C

Because raphasatin is a significantly more potent activator of detoxification enzymes than its degradation products (16), the stability of raphasatin and sulforaphene in radishes is crucial to their health effects during dietary consumption.

The hydrolyzed products of radishes were stored at 25°C for 10 days and ITC concentrations were measured at 2 day intervals (Fig. 5). The raphasatin content decreased gradually as the storage period increased. After 2 days of storage at 25°C, the raphasatin content was decreased by only 17.6% but after 10 days the content had decreased by 43.5%.

Fig. 5.

Stability of raphasatin and sulforaphene formed by endogenous enzyme hydrolysis during storage at 25°C. Different letters (a–c) within the same compound are significantly different (P<0.05).

Scholl et al. (16) found that the transformation of glucoraphasatin into raphasatin was initiated by the addition of water to freeze-dried radish powder, and after 24 h, raphasatin was degraded completely. In our experiment, more than 56% of the raphasatin remained after 10 days of storage at 25°C because the storage medium was the mixed hydrophilic and hydrophobic medium (water and dichloromethane) compared to the use of only water reported by Scholl et al. (16). Therefore, to minimize the breakdown of raphasatin produced by hydrolysis, the hydrolyzed radishes need to be stored in a mixed polar and non-polar medium (e.g., water and oil).

For sulforaphene, after 2 days of storage at 25°C, the content decreased by only 11.9% and then remained unchanged for 10 days. Scholl et al. (16) found that upto 24 h after the initial hydrolysis, 77.6% of sulforaphene produced by the hydrolysis of radishes in water was remained. Matera et al. (19) also found that under refrigerated conditions, only about 7% of the original ITCs content in radish sprout juices were lost after 12 months, although the stability tests were not performed at 25°C.

In conclusion, the formation and breakdown of raphasatin and sulforaphene in radish roots by endogenous enzymolysis was strongly influenced by the reaction medium, reaction time, and type of mixing. The production and stabilization of raphasatin in radishes was efficient in a mixture of water and dichloromethane with shaking for 15 min at 25°C. For sulforaphene in radishes, the favorable conditions were water as a reaction medium without shaking for 10 min at 25°C. The maximum yields of raphasatin and sulforaphene were achieved in a concurrent hydrolysis reaction without shaking in water for 10 min and with shaking in dichloromethane for 15 min at 25°C.

ACKNOWLEDGEMENTS

This research was supported by the Ministry of Trade, Industry and Energy (MOTIE) and the Korea Institute for the Advancement of Technology (KIAT) through the Research and Development for Regional Industry.

Footnotes

AUTHOR DISCLOSURE STATEMENT

The authors declare no conflict of interest.

REFERENCES

- 1.Gutiérrez RMP, Perez RL. Raphanus sativus (radish): their chemistry and biology. Sci World J. 2004;4:811–837. doi: 10.1100/tsw.2004.131. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Hanlon PR, Barnes DM. Phytochemical composition and biological activity of 8 varieties of radish (Raphanus sativus L.) sprouts and mature taproots. J Food Sci. 2011;76:C185–C192. doi: 10.1111/j.1750-3841.2010.01972.x. [DOI] [PubMed] [Google Scholar]

- 3.Papi A, Orlandi M, Bartolini G, Barillari J, Iori R, Paolini M, Ferroni F, Grazia Fumo M, Pedulli GF, Valgimigli L. Cytotoxic and antioxidant activity of 4-methylthio-3-butenyl isothiocyanate from Raphanus sativus L. (kaiware daikon) sprouts. J Agric Food Chem. 2008;56:875–883. doi: 10.1021/jf073123c. [DOI] [PubMed] [Google Scholar]

- 4.Yuan G, Wang X, Guo R, Wang Q. Effect of salt stress on phenolic compounds, glucosinolates, myrosinase and antioxidant activity in radish sprouts. Food Chem. 2010;121:1014–1019. doi: 10.1016/j.foodchem.2010.01.040. [DOI] [Google Scholar]

- 5.Abdull Razis AF, De Nicola GR, Pagnotta E, Iori R, Ioannides C. 4-Methylsulfanyl-3-butenyl isothiocyanate derived from glucoraphasatin is a potent inducer of rat hepatic phase II enzymes and a potential chemopreventive agent. Arch Toxicol. 2012;86:183–194. doi: 10.1007/s00204-011-0750-x. [DOI] [PubMed] [Google Scholar]

- 6.Hanlon PR, Webber DM, Barnes DM. Aqueous extract from spanish black radish (Raphanus sativus L. var. niger) induces detoxification enzymes in the HepG2 human hepatoma cell line. J Agric Food Chem. 2007;55:6439–6446. doi: 10.1021/jf070530f. [DOI] [PubMed] [Google Scholar]

- 7.Barillari J, Iori R, Papi A, Orlandi M, Bartolini G, Gabbanini S, Pedulli GF, Valgimigli L. Kaiware Daikon (Raphanus sativus L.) extract: a naturally multipotent chemopreventive agent. J Agric Food Chem. 2008;56:7823–7830. doi: 10.1021/jf8011213. [DOI] [PubMed] [Google Scholar]

- 8.Yamasaki M, Omi Y, Fujii N, Ozaki A, Nakama A, Sakakibara Y, Suiko M, Nishiyama K. Mustard oil in “Shibori Daikon” a variety of Japanese radish, selectively inhibits the proliferation of H-ras-transformed 3Y1 cells. Biosci Biotechnol Biochem. 2009;73:2217–2221. doi: 10.1271/bbb.90322. [DOI] [PubMed] [Google Scholar]

- 9.Beevi SS, Mangamoori LN, Subathra M, Edula JR. Hexane extract of Raphanus sativus L. roots inhibits cell proliferation and induces apoptosis in human cancer cells by modulating genes related to apoptotic pathway. Plant Foods Hum Nutr. 2010;65:200–209. doi: 10.1007/s11130-010-0178-0. [DOI] [PubMed] [Google Scholar]

- 10.Nakamura Y, Iwahashi T, Tanaka A, Koutani J, Matsuo T, Okamoto S, Sato K, Ohtsuki K. 4-(Methylthio)-3-butenyl isothiocyanate, a principal antimutagen in daikon (Raphanus sativus; Japanese white radish) J Agric Food Chem. 2001;49:5755–5760. doi: 10.1021/jf0108415. [DOI] [PubMed] [Google Scholar]

- 11.Ippoushi K, Takeuchi A, Ito H, Horie H, Azuma K. Antioxidative effects of daikon sprout (Raphanus sativus L.) and ginger (Zingiber officinale Roscoe) in rats. Food Chem. 2007;102:237–242. doi: 10.1016/j.foodchem.2006.04.046. [DOI] [Google Scholar]

- 12.Shishu, Kaur IP. Inhibition of cooked food-induced mutagenesis by dietary constituents: comparison of two natural isothiocyanates. Food Chem. 2009;112:977–981. doi: 10.1016/j.foodchem.2008.07.019. [DOI] [Google Scholar]

- 13.Pocasap P, Weerapreeyakul N, Barusrux S. Cancer preventive effect of Thai rat-tailed radish (Raphanus sativus L. var. caudatus Alef) J Funct Foods. 2013;5:1372–1381. doi: 10.1016/j.jff.2013.05.005. [DOI] [Google Scholar]

- 14.Shen L, Su G, Wang X, Du Q, Wang K. Endogenous and exogenous enzymolysis of vegetable-sourced glucosinolates and influencing factors. Food Chem. 2010;119:987–994. doi: 10.1016/j.foodchem.2009.08.003. [DOI] [Google Scholar]

- 15.Montaut S, Barillari J, Iori R, Rollin P. Glucoraphasatin: chemistry, occurrence, and biological properties. Phytochemistry. 2010;71:6–12. doi: 10.1016/j.phytochem.2009.09.021. [DOI] [PubMed] [Google Scholar]

- 16.Scholl C, Eshelman BD, Barnes DM, Hanlon PR. Raphasatin is a more potent inducer of the detoxification enzymes than its degradation products. J Food Sci. 2011;76:C504–C511. doi: 10.1111/j.1750-3841.2011.02078.x. [DOI] [PubMed] [Google Scholar]

- 17.Hanlon PR, Robbins MG, Hammon LD, Barnes DM. Aqueous extract from the vegetative portion of Spanish black radish (Raphanus sativus L. var. niger) induces detoxification enzyme expression in HepG2 cells. J Funct Foods. 2009;1:356–365. doi: 10.1016/j.jff.2009.08.001. [DOI] [Google Scholar]

- 18.Li J, Xie B, Yan S, Li H, Wang Q. Extraction and determination of 4-methylthio-3-butenyl isothiocyanate in Chinese radish (Raphanus sativus L.) roots. LWT–Food Sci Technol. 2015;60:1080–1087. doi: 10.1016/j.lwt.2014.10.014. [DOI] [Google Scholar]

- 19.Matera R, Gabbanini S, De Nicola GR, Iori R, Petrillo G, Valgimigli L. Identification and analysis of isothiocyanates and new acylated anthocyanins in the juice of Raphanus sativus cv. Sango sprouts. Food Chem. 2012;133:563–572. doi: 10.1016/j.foodchem.2012.01.050. [DOI] [PubMed] [Google Scholar]