Abstract

Statement of Problem: Wear of complete denture teeth results in compromise in denture esthetics and functions. To counteract this problem, artificial teeth with increased wear resistance had been introduced in the market such as nanocomposite teeth. Purpose: The purpose of this study was to compare the amount of wear between nanocomposite teeth and acrylic teeth. Materials and methods: Fifteen specimens were chosen from each group namely the nanocomposite teeth (SR_-PHONARES) and the acrylic teeth (ACRY PLUS). Maxillary premolar was only chosen for testing and the samples were customized according to the specifications of the pin on disc machine. Pin on disc machine is a two body tribometer which quantifies the amount of wear under a specific load and time. Test samples were mounted on to the receptacle of the pin on disc machine and tested under a load of 0.3 kg for 1,000 cycles of rotation against a 600 grit emery paper. The amount of wear is displayed from the digital reading obtained from the pin on disc machine. Results: After statistical analysis, it was found that, the amount of wear is more in four layered acrylic teeth. The p value obtained is 0.002 (<0.005) thus implies that the difference in wear between nanocomposite teeth and acrylic teeth is statistically significant. Conclusion: Though the nanocomposite teeth has less amount of wear than the four layered acrylic teeth, the difference is very less and adds only to a little clinical significance but the cost of the nanocomposite is four times that of the acrylic teeth. Further clinical studies must be performed to confirm our results.

Electronic supplementary material

The online version of this article (doi:10.1007/s13191-014-0381-z) contains supplementary material, which is available to authorized users.

Keywords: Wear, Nanocomposite teeth, Four layered acrylic teeth or In-vitro study

Introduction

The prosthetic teeth restore the form, function and esthetics of a completely edentulous patient thereby enhance the quality of mastication, speech and provide psychological comfort for them [1]. Denture teeth wear is a complex process which occurs due to multiple factors namely: chewing habits, diet, parafunctional habits, anatomy of the supporting residual ridges and material of the prosthetic teeth [1, 2]. Among the above factors enlisted, the operator can control the wear by selecting the prosthetic teeth which has less wear. Prosthetic teeth with less wear increases the longevity of the denture as stated by Reis et al. [3]. Early literature on artificial teeth stated that stone, wood, ivory and even human teeth were used for teeth replacements [1]. Modern Prosthodontics commonly utilizes acrylic, porcelain, and composite teeth for denture fabrication [4–6]. Acrylic teeth are usually made of Polymethyl methacrylate resin (PMMA) which is highly elastic, and have good chemical bond with the denture base. To improve the esthetic qualities of the denture teeth, chromatic layers are incorporated. They have been named based on the number of chromatic layers as, single layered; double layered, triple and four layered acrylic teeth. To improve the mechanical properties of PMMA resin teeth, cross linking agent was incorporated in the chemical structure and henceforth it was marketed as cross linked acrylic teeth [7]. Highly cross linked teeth were of two types one with double cross linked (DCL) and another one with interpenetrating network (IPN) [8]. The other material that has emerged over the years for manufacturing prosthetic teeth is composite resin. Mixing Bis-GMA with diluting monomers and adding glass or silica powder initiated the era of composites. Initially introduced composite teeth are microfilled composites which did not meet the esthetic requirements of prosthetic teeth because of poor polishability, but nanocomposite teeth which was refined by controlling the size of the filler particles was highly polishable thus improving the esthetics [9]. Composite denture teeth gained its fame over few decades and stated to have superior wear resistance. With the advancement in the field of nanotechnology, researchers developed the sialinized silicon inorganic nanofillers of less than 50 nm, for the composite matrix of Urethane dimethyl methaacrylate (UDMA) and PMMA which thereby led to the introduction of nanocomposite teeth without much compromise in the mechanical properties and superior esthetics [9, 10].

Among the mechanical properties of the prosthetic teeth, the most discussed entity is the wear resistance, as it is directly related to its applications in prosthetic dentistry [11]. The effect of excessive artificial tooth wear includes loss of vertical dimension leading to decrease in masticatory efficiency, improper occlusal relationship which may end up in increased horizontal stresses and result in compromise of esthetics and function [12].

Various studies had been done comparing the property of wear resistance of artificial teeth. Ghazal and Kern evaluated the wear resistance of four artificial denture teeth namely feldspathic ceramic, nano-filled composite resin, experimental acrylic resin with UDMA/PMMA, and IPN acrylic resin (AR) teeth [13]. In this study, composite teeth exhibited less wear than that of acrylic teeth. Composite teeth with nanofillers were stated to have more amount of wear compared to composite teeth with traditional microfillers in the same experiment.

Four layered acrylic teeth were new to the market and literature does not exist on the direct comparison of the same with nanocomposite teeth. To find the strategic difference between the properties of both the prosthetic denture teeth, an in vitro study was planned. Research question for our study was “Do nanofilled composite denture teeth has less wear than that of four layered acrylic teeth?”. The objective of our study was to compare the amount of wear of four layered acrylic teeth and newly introduced nanofilled composite teeth. It was hypothesized that the wear of nanocomposite teeth is less than acrylic teeth. The parameter intended to check was the amount of wear in micrometers and both the groups were tested under same laboratory conditions. Though studies exist in relation to test of hardness and two body wear of acrylic and composite resin teeth, the comparison of wear resistance between four layered acrylic and nanocomposite teeth have not yet been reported in the literature. Null hypothesis set for the in vitro study was that the nanocomposite teeth have no difference in wear when compared with four layered acrylic teeth.

Materials and Methods

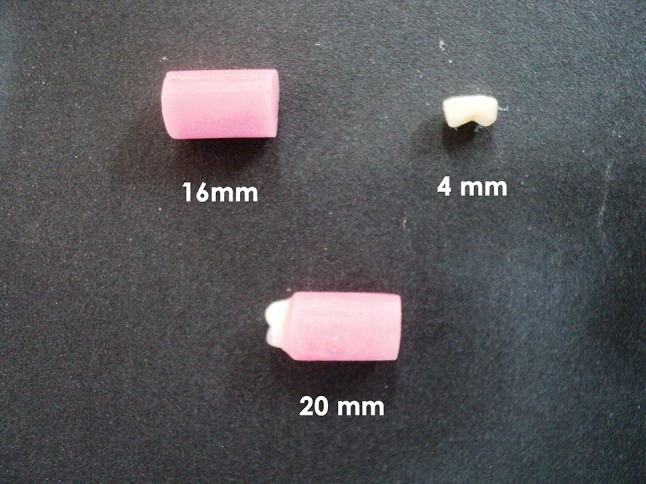

Two brands of prosthetic teeth were compared in this study, one is a four layered acrylic teeth ACRY PLUS (Ruthinium Group, Italy); another is a nanocomposite teeth called SR Phonares (Ivoclar Vivadent) (Fig. 1). The teeth were assigned into two groups: The nanocomposite teeth as group A and the ACRY PLUS teeth as group B. Sample size was determined based on the previous studies using statistical formulae and determined as 15 samples per group and the power of the study was set as 80 with 95 % confidence interval [3]. The statistical p-value was set less than 0.05 apriori. Maxillary premolars were only chosen in each group (n = 15) for two reasons: (1) standardization of the samples for comparison (2) the complete denture patients have more preference for chewing in the premolar region [14]. Pin on disc tribometer which simulates two body wear was chosen for the study [15, 16].

Fig. 1.

Nanocomposite and acrylic teeth

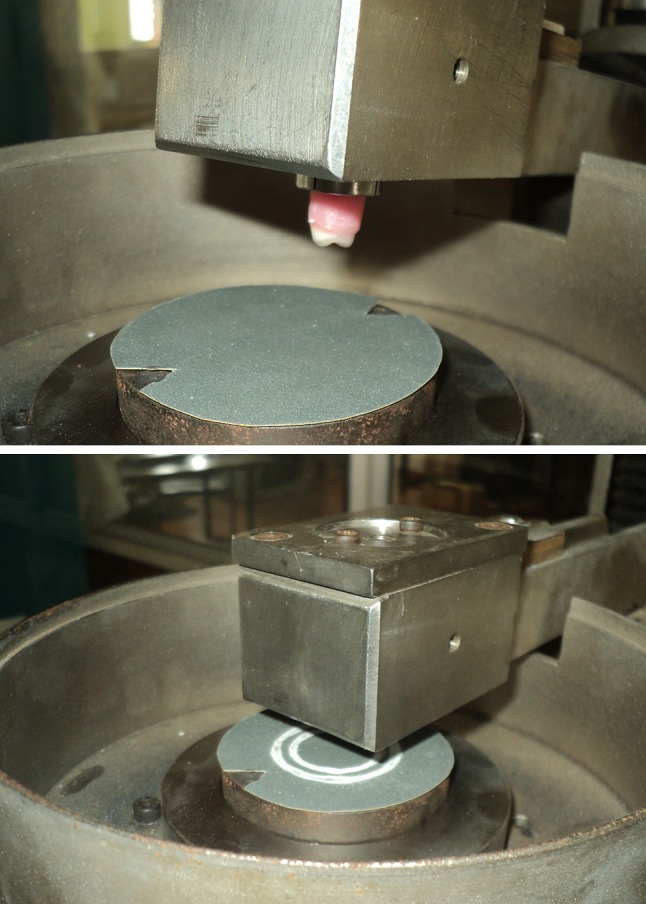

Die Making

The sample to be tested with the pin on disc tribometer must have a prescribed dimension recommended by the manufacturer for that machine. Pin on disc machine has a receptacle into which the sample can be mounted and tightened by screw. A model of the metal analog which fits into the pin on disc receptacle was obtained and duplicated with acrylic. Putty impression of a metal analog which is cylindrical in shape with the dimensions of 16 mm height and 10 mm in diameter was made. Cold cure acrylic resin was packed in the mold space and acrylic cylinder were formed. The ridge lap area of the teeth was trimmed with Tungsten Carbide bur (Edenta no: 5610.045HP) and the thicknesses of the teeth were brought down to 4 mm with a heavy duty lab micromotor (Mighty, Confident). Care was taken to preserve the occlusal morphology as the aim of our study was to test the occlusal wear and excessive trimming was avoided. Occlusal surface of the test specimens were not modified in our experiment as it is important layer to have contact with the masticating units. Thickness was measured with Evan’s gauge (GDC, Germany). The acrylic teeth were bonded to the acrylic cylinder with cyanoacrylate. The entire setup after bonding measured 20 mm in height and 10 mm in diameter (Fig. 2). The same process was followed for fabricating all the 30 samples. Samples were labeled according to their groups (Eg: Acry plus tooth as AP-01; Phonares as PH-01).

Fig. 2.

Sample preparation

Loading of the Specimens

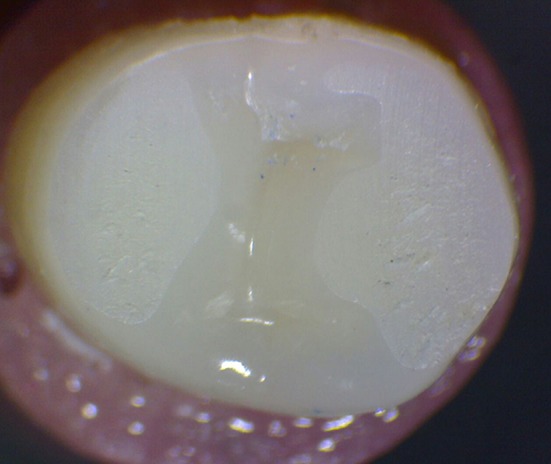

One by one, samples were mounted on the metal receptacle present in the pin on disc tribometer [17]. All the samples were tested under standard conditions in which 600 grit sandpaper was used as antagonist material on the disc of the apparatus (Fig. 3). Our study compared the wear under similar laboratory parameters against 600 grit sand paper as antagonist based on previous research studies [18]. The sample was positioned on the machine in such a way that both the cusps of the premolars were in point contact with the sand paper. Load of 300 g was given for the apparatus and the teeth were subjected to a revolution of 1,000 cycles which ran approximately for 1.2 min [19, 20]. The amount of wear in micrometers was obtained from the digital reading of the pin on disc machine (Fig. 4). The type of wear was of abrasive type without any chipping or discoloration of the samples. None of the samples failed; Wear of both the buccal and lingual cusps occurred evenly. The stereomicroscope image (Dee winter, Italy) of a nanocomposite teeth and acrylic teeth were examined at 3X magnification (Figs. 5, 6).

Fig. 3.

Samples at test setup

Fig. 4.

Reading acquired from digital reading

Fig. 5.

Photomicrograph of nanocomposite teeth after wear

Fig. 6.

Photomicrograph of cross linked four layered acrylic teeth after wear

The readings for both the groups were tabulated in Table 1 and statistical tests are performed for the data obtained by using the statistical software STATISTICS ver5.0. The normality of the data was checked by Kolmogrov Smirov test; Means and Standard deviations of amount of wear in each group were calculated. Data was analyzed using independent group unpaired t-test at p < 0.05.

Table 1.

Group statistics

| Group | N | Min | Max | Mean | SD | Standard error | 95 % CI | |

|---|---|---|---|---|---|---|---|---|

| Lower | Upper | |||||||

| ACRY PLUS | 15 | 475 | 766 | 627.80 | 87.07 | 22.5 | 579.58 | 676.02 |

| Phonares | 15 | 395 | 767 | 507.07 | 101.98 | 26.35 | 450.59 | 563.54 |

Results

The results obtained after 1,000 wear cycles of all materials are presented in Table 2. Mean value of wear occurred were 627.80 and 507.07 μm for ACRY PLUS and PHONARES respectively with a mean difference of 120.73 μm. The p value obtained is 0.002 (<0.005) thus implies that the difference in wear between nanocomposite teeth and acrylic teeth is statistically significant.

Table 2.

Independent group unpaired t-test results comparing Mean scores

| Group | Mean | Mean difference | t-value | df | p Value |

|---|---|---|---|---|---|

| ACRY PLUS | 627.80 | 120.73 | 3.487 | 28 | 0.002 |

| Phonares | 507.07 |

p < 0.05: means that the result is statistically significant

Discussion

This in vitro study compared the amount of wear which occurred under same laboratory conditions between nanocomposite and four layered acrylic teeth. The results of our study revealed the fact that nanocomposite teeth have less wear than the four layered acrylic teeth as hypothesized before and the null hypothesis was rejected. This implies that the wear resistance is better for the nanocomposite teeth. The difference in resin chemistry and variation in the density of the pyrogenic inorganic silica filler particles between both the groups may be responsible for a significantly different wear behavior. The decreased wear of nanocomposite teeth may be due to the presence of nanofillers which is incorporated in them [21]. Various in vitro studies have been performed previously to compare the wear characteristics. Ghazal et al. [22], evaluated the wear in three types of denture teeth: feldspathic ceramic, nano-filled composite resin (NCR), and experimental AR teeth. They stated that NCR teeth seemed to be more suitable for complete dentures and partial dentures because of their good wear resistance. On the other side, acrylic teeth used in prosthetic dentistry can be categorized into non cross linked, cross linked, highly cross linked with DCL teeth and highly cross linked with interpenetrating network (IPN). The later types were introduced to solve the issue of increased wear of the acrylic teeth. Reis et al. [23] compared the wear of three different PMMA teeth. The results confirmed the fact that high strength PMMA teeth have good wear resistance. The mechanical and physical properties of PMMA teeth will be increased by cross-linking and IPN- Interpenetrating network. As the teeth used in our study was highly cross linked, minimal difference (120.73 micrometers) in wear was present between both the groups. Loyaga–Rendon et al. [24] compared the compositional characteristics of hardness of acrylic and composite teeth and stated that prosthetic teeth had good wear resistance, when the filler content were increased in the peripheral layers of the artificial teeth. Our study tested the peripheral layer of the occlusal surface of the samples without morphological modification, to quantify the occlusal wear which was an added advantage. Ghazal and Kern performed an invitro study to evaluate the wear resistance of artificial denture teeth and their human enamel antagonists in a dual-axis chewing simulator, in which four artificial teeth were compared namely: feldspathic ceramic, nanofilled composite resin, experimental acrylic resin with UDMA/PMMA, and IPN acrylic resin teeth. Results of this study showed that the nanofilled composite teeth had comparatively more wear resistance among the four groups, when human enamel is used as antagonist material [25]. Ghazal and Kern performed another study where direct comparison of the wear resistance of the nanofilled composite teeth with human enamel was done which reflected the fact that enamel showed less wear among the two [26]. In our study, the difference in the amount of wear between the two groups was 120.73 μm which is statistically significant but not clinically significant. When comparing the cost difference between the two groups tested in our study, the nanocomposite teeth is four times costlier than acrylic teeth for such a small difference in wear; only a randomized control trial comparing the nanocomposite and four layered teeth in real life clinical scenario could further confirm our findings. Moreover studies can be performed comparing the hardness of the highly cross linked acrylic teeth and the nanocomposite teeth; those results can be correlated with the amount of the wear produced. The limitation of our study is that the test specimens itself can be used as antagonist and wear would have been simulated under saliva like medium to obtain accurate simulation of wear in both the materials with high end wear simulators.

Conclusion

In this in vitro study, the occlusal surface of the teeth were not modified so as to evaluate the amount of occlusal wear. Nanofilled composite teeth and four layered cross linked acrylic teeth had been rarely compared in the literature. This study confirmed the fact that the nanocomposite teeth had more wear resistance than newly developed acrylic teeth, but the difference was very minimal. Further developments in the material science must give birth to much more wear resistant artificial teeth which could stand equally to human enamel and thus can solve the issue of denture wear.

Electronic supplementary material

References

- 1.Winkler S. Essentials of complete denture Prosthodontics. 2. Delhi: ATIBS; 2012. p. 222. [Google Scholar]

- 2.Kim SK, Kim KN, Chang IT, Heo SJ. A study of the effects of chewing patterns on occlusal wear. J Oral Rehabil. 2001;28:1048–1055. doi: 10.1046/j.1365-2842.2001.00761.x. [DOI] [PubMed] [Google Scholar]

- 3.Reis KR, Bonfante G, Pegoraro LF, Conti PC, Oliveira PC, Kaizer OB. In vitro wear resistance of three types of polymethyl methacrylate denture teeth. J Appl Oral Sci. 2008;16(3):176–180. doi: 10.1590/S1678-77572008000300003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.CANDULOR. Porcelain teeth is still available! (2011). http://www.candulor.us/fileadmin/produktbilder/C. Accessed 16 Feb 2014

- 5.Ohlmann B. Influences on clinical wear of acrylic denture teeth: a Pilot study. Int J Prosthodont. 2007;20:496–498. [PubMed] [Google Scholar]

- 6.Chang JC, Katz ST. Composite denture teeth made on a removable partial metal framework. J Prosthet Dent. 1994;71(4):409–412. doi: 10.1016/0022-3913(94)90105-8. [DOI] [PubMed] [Google Scholar]

- 7.Craig RG, Powers JM. Restorative dental materials. 11. Missouri: Mosby; 2002. p. 672. [Google Scholar]

- 8.Heintze SD, et al. Laboratory methods for evaluating the wear of denture teeth and their correlation with clinical results. Dent Mater. 2012;28:261–272. doi: 10.1016/j.dental.2011.10.012. [DOI] [PubMed] [Google Scholar]

- 9.Suzuki S. In vitro wear of nano-composite denture teeth. J Prosthodont. 2004;13:238–243. doi: 10.1111/j.1532-849X.2004.04043.x. [DOI] [PubMed] [Google Scholar]

- 10.Hahnel S, Behr M, Handel G, Rosentritt M. Two- body wear of artificial acrylic and composite resin teeth in relation to antagonist material. J Prosthet Dent. 2009;101:269–278. doi: 10.1016/S0022-3913(09)60051-2. [DOI] [PubMed] [Google Scholar]

- 11.Coffey JP, Goodkind RJ, DeLong R, Douglas WH. In vitro study of wear characteristics of natural and artificial teeth. J Prosthet Dent. 1985;54:273–280. doi: 10.1016/0022-3913(85)90304-X. [DOI] [PubMed] [Google Scholar]

- 12.Ogle RE, Davis EL. Clinical wear of three commercially available artificial tooth materials: thirty-six month results. J Prosthet Dent. 1998;79:145–151. doi: 10.1016/S0022-3913(98)70208-2. [DOI] [PubMed] [Google Scholar]

- 13.Ghazal M, Kern M. Wear of denture teeth and their human enamel antagonists. Quintessence Int. 2010;41(2):157–163. [PubMed] [Google Scholar]

- 14.Zarb GA. Prosthodontic Treatment for edentulous patients. 12. Missouri: Mosby; 2004. p. 16. [Google Scholar]

- 15.Zhou ZR, Zheng J. Tribology of dental materials: a review. J Phys D Appl Phys. 2008;41(11):1–22. doi: 10.1088/0022-3727/41/11/113001. [DOI] [Google Scholar]

- 16.Heintze SD, Faouzi M, Rousson V, Ozcan M. Correlation of wear in vivo and six laboratory wear methods. Dent Mater. 2012;28(9):961–973. doi: 10.1016/j.dental.2012.04.006. [DOI] [PubMed] [Google Scholar]

- 17.Lambrechts P, Debels E, Landuyt KV, Pneumans M, Meerbeek BV. How to simulate wear? Overview of existing methods. Dent Mater. 2006;22:693–701. doi: 10.1016/j.dental.2006.02.004. [DOI] [PubMed] [Google Scholar]

- 18.Powers JM, Fan PL, Craig RG. Wear of dental restorative resins. Biomed Dent Appl Polym. 1981;14:453–457. doi: 10.1007/978-1-4757-9510-3_34. [DOI] [Google Scholar]

- 19.Heintze SD. How to qualify and validate wear simulation devices and methods. Dent Mater. 2006;22(8):712–734. doi: 10.1016/j.dental.2006.02.002. [DOI] [PubMed] [Google Scholar]

- 20.Harrison A, Lewis TT. The development of an abrasion testing machine for dental materials. J Biomed Mater Res. 1975;9(3):341–353. doi: 10.1002/jbm.820090309. [DOI] [PubMed] [Google Scholar]

- 21.Stober, et al. Three body wear of resin denture teeth with and without nanofillers. J Prosthet Dent. 2010;103:108–117. doi: 10.1016/S0022-3913(10)60014-5. [DOI] [PubMed] [Google Scholar]

- 22.Ghazal M, Hedderich J, Kern M. Wear of feldspathic ceramic, nano-filled composite resin and acrylic resin artificial teeth when opposed to different antagonists. Eur J Oral Sci. 2008;116(6):585–592. doi: 10.1111/j.1600-0722.2008.00573.x. [DOI] [PubMed] [Google Scholar]

- 23.Reis KR, Bonfante G, Pegoraro LF, Conti PC, Oliveira PC, Kaizer OB. In vitro wear resistance of three types of polymethyl methacrylate denture teeth. J Appl Oral Sci. 2008;16(3):176–180. doi: 10.1590/S1678-77572008000300003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 24.Loyaga-Rendon PG, Takahashi H, Hayakawa I, Iwasaki N. Compositional characteristics and hardness of acrylic and composite resin artificial teeth. J Prosthet Dent. 2007;98(2):141–149. doi: 10.1016/S0022-3913(07)60047-X. [DOI] [PubMed] [Google Scholar]

- 25.Ghazal M, Kern M. Wear of human enamel and nano-filled composite resin denture teeth under different loading forces. J Oral Rehabil. 2009;36(1):58–64. doi: 10.1111/j.1365-2842.2008.01904.x. [DOI] [PubMed] [Google Scholar]

- 26.Ghazal M, Kern M. The influence of antagonistic surface roughness on the wear of human enamel and nanofilled composite resin artificial teeth. J Prosthet Dent. 2009;101(5):342–349. doi: 10.1016/S0022-3913(09)60068-8. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.