Abstract

This in vitro study assessed the marginal gap and marginal microleakage in zirconia copings fabricated using two computer aided techniques- CAD milling and Copy milling and cemented to respective tooth preparations using two resin bonding systems, light cure and self-cure resin bonding systems. 32 extracted premolars were prepared to receive zirconia copings fabricated using CAD/CAM and Copy milling techniques. Once the copings were fabricated, the samples were evaluated for marginal fit prior to cementation through microscopic observation. Evaluation of marginal gap was done again after cementation, in order to incorporate the influence of the resin bonding system on the marginal microgap. The specimens were evaluated under the stereomicroscope for micro-leakage using commercial software. A comparative statistical analysis was done following data collection using Mann–Whitney U test, Wilcoxon test and chi-square test. The data collected regarding marginal gap was well within 120 µ, which is in accordance with previous studies. However, Copy milled specimens showed statistically lesser marginal gap when compared to CAD milled specimens. While comparing microleakage, it was observed that the microleakage in Copy milled specimens bonded with light cure resin bonded cement was statistically lesser than that of specimens cemented with chemical cure resin cement.(P = 0.003). This in vitro study concluded that Copy milling technique fabricated zirconia restorations with lesser marginal gap and microleakage score in comparison to CAD milled samples. Light cure resin bonding system also proved to be more effective option compared to self cure resin bonding systems. However, the limitations of this study should be taken into concern and further research should be aimed at a larger sample size to validate the results.

Keywords: Marginal gap, Microleakage, Copy milling, CAD milling, Resin bonding systems

Introduction

Throughout the history of dentistry, prosthodontists, dental clinicians and dental technicians have always aimed to create esthetically and functionally ideal restorations. Various factors that determine the success of a restoration include—marginal adaptation, resistance to fracture and esthetic value. [1] The marginal fit of dental restorations plays a key role in its success. Failure to provide optimal marginal adaptation leads to plaque accumulation, microleakage, carious lesions, endodontic lesions and periodontal disease [2]. Minimizing the marginal gap is necessary as it results in a decrease in the cement dissolution, thus decreasing the potential for microleakage. Luting agents’ sealing ability and resistance to varying stresses are also important factors that influence the extent of leakage [3]. Computer aided technology has been incorporated in dentistry to produce restorations which provide a higher quality of rehabilitation to patients. Currently, it is known that these restorations have significantly lesser marginal gap and microleakage values as compared to restorations fabricated by conventional techniques [4]. However, the number of studies conducted to comparatively evaluate the marginal gap values of restorations fabricated between various computer aided techniques, are minimal. Therefore, the purpose of this in vitro study was to determine and evaluate the inaccuracies in marginal fit, microleakage and their combined effect on zirconia restorations, designed by Computer Aided Designing/Computer Aided Manufacturing (CAD/CAM) and Copy milling methods, luted to respective tooth preparations using two different resin bonding systems (light cure resin cement and chemical cure resin cement). The null hypotheses were as below:

There would be no significant differences in marginal gap values of restorations fabricated by two different computer aided techniques.(CAD/CAM and Copy Milling technique).

No significant differences in microleakage values is seen when restorations are luted using light cure resin bonding system or chemical cure resin bonding system.

Materials and Methodology

Materials

Normal Saline.

Dental Stone (Type 3, Kalrock).

Relyx U200 chemical cure self-adhesive resin cement.

Calibra light cure adhesive resin cement.

Methylene blue stain.

Pumice.

Amann Girbach Zirconia Blocks.

Lava Zirconia Blocks.

Armamentarium

32 extracted maxillary premolars.

Mixing bowl and spatula.

Dental surveyor.

High speed air turbine handpiece (NSK).

Crown preparation kit (Torpedo-preparation and finishing burs).

Ceramill touch probe system.

Lava Scan ST system.

Ceramill copy milling system.

Lava CAD milling system.

Optical microscope with magnification up to 10×.

Stereomicroscope with magnification up to 40×.

Image analysis software (Motik, USA).

Light cure unit (QLH75 curing light, Dentsply, India).

Methodology

Collection of Samples

32 recently extracted, similar sized maxillary 1st premolars were collected from the Department of Oral and Maxillofacial Surgery, A. B. Shetty Memorial Institute of Dental Sciences, Mangalore and stored in normal saline to prevent microbial growth.

Inclusion Criteria

Premolars extracted from patients aged between 12–25.

Teeth with no clinical and radiographic evidence of caries.

Appropriate crown root ratio.

Minimal crown length of 4 mm.

Exclusion Criteria

Teeth with developmental anomalies.

Presence of regressive alterations of teeth.

History of trauma to the teeth in concern.

Chemically treated teeth.

Preparation of Experimental Samples

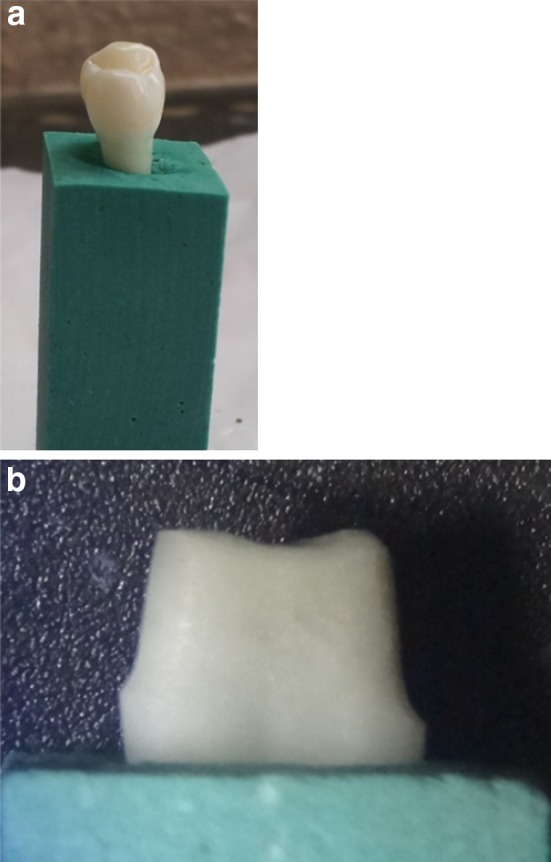

The teeth were mounted vertically in type III dental stone such that the coronal portion of the tooth was well above the dental stone block (Fig. 1a). Tooth preparation was accomplished on the mounted samples, to receive full veneer crowns, using a high speed air turbine hand piece. Using depth cutting diamond points and torpedo tapered fissure diamond points, a chamfer finish line of 1.5 mm and occlusal reduction of 2 mm was achieved on all the samples (Fig. 1b). The prepared samples were divided into two groups of 16- Group C1 and Group C2.

Fig. 1.

a Extracted tooth specimen mounted in Type III Dental Stone, b Prepared tooth specimen viewed under stereomicroscope

Fabrication of Zirconia Copings by CAD/CAM technology

The prepared models in Group C1 were directly scanned using an optical laser scanner (Lava ST Scan system) and zirconia copings were milled from pre-sintered zirconia blanks (Lava Zirconia, Lava, 3 M ESPE) using CAD/CAM technique (Lava, 3 M ESPE).The samples in Group C2 first received pattern resin copings of 2 mm uniform thickness standardized using a silicone index. These resin patterns were scanned using mechanical scanners (Touch probe scanner, Ceramill Copy milling system, Amann Girbach) and zirconia copings were milled from blanks by Copy milling method (Ceramill Copy milling system, Amann Girbach) (Fig. 2).

Fig. 2.

16 Zirconia copings fabricated by Copy milling technique

Evaluation of Marginal Gap

The copings were identified for the respective teeth and marginal adaptation was assessed at two points (mesial, distal) for every mounted model with an optical microscope of 10× magnification. An image analysis software (Motik, USA) was used to record magnified images of the copings on the respective prepared teeth. The copings were held in place using light finger pressure. On the image recorded by the software, a straight line connecting the lowest point on the coping margin to a point just axial to the finish line of the tooth was used to represent the marginal opening (Fig. 3). All the models were evaluated in the same manner for inaccuracies in marginal fit and the values obtained in microns were tabulated separately for statistical analysis.

Fig. 3.

Evaluation of marginal Gap

Cementation of Copings to Respective Models Using Light Cure and Self Cure Resin Bonding Systems

The values of inaccuracies in marginal fit were recorded and the teeth samples in each group were further divided into two groups of eight samples each - (Group 1 into Group 1A and Group 1B; Group 2 into Group 2A and Group 2 B).The prepared surfaces of the teeth in the aforementioned groups were cleaned with a mixture of pumice and water to remove any residual material and the inner surface of the zirconia coping was air abraded using 110 micron alumina particles at 40 Psi pressure (Renfert). The tooth surface and copings were washed and air dried gently in order to prevent dehydration. Following the manufacturer’s instructions, the copings in Group 1A and Group 2A were cemented onto respective prepared models using light cure resin cement (Calibra, Dentsply Caulk). The copings in Group 1B and 2B were bonded using chemical activated self-adhesive resin cement (Relyx U200, 3 M ESPE).

Evaluation of Marginal Microleakage

Once cementation of all the samples is complete, they are stored in water at 34° C in order to prevent oxidation of the resin cement for 24 h. After 24 h, the samples are immersed in Loeffler’s methylene blue stain for another 24 h. Care was taken to keep the dye bath away from sunlight in order to prevent disintegration of the stain. Following removal from the stain (Fig. 4), the samples are rinsed under tap water to eliminate any traces of excess stain solution and gently dried. Each sample was sectioned mesio- distally through the bonded restorations along the long axis, with a diamond disc (Fig. 5). It was intermittently placed in water in order to prevent heating of the tooth structure and restoration.

Fig. 4.

Stained specimen

Fig. 5.

Specimens sectioned mesio-distally

Once the sections were obtained, marginal gap opening and marginal microleakage was assessed on each of the specimens using digital photographs made at 10× magnification of the stereomicroscope (Fig. 6). Using commercially available softwares, the marginal opening and marginal microleakage was calculated. Marginal gap was determined as the distance between a point at the margin to the closest point on the margin of the restoration. Marginal microleakage was recorded as the ratio of penetration of the stain into the dentine to the length of the crown. It was scored according to a grading system given by Albert and Mowafy in 2004: [5].

-

0-

No leakage.

-

1-

Leakage up to one-third of the axial wall.

-

2-

Leakage up to two-thirds of the axial wall.

-

3-

Leakage along the entire length of the axial wall.

-

4-

Leakage extending onto the occlusal aspect.

Fig. 6.

Evaluation of marginal microleakage as a ratio of the length of stained section to the length of the crown

The data obtained was grouped and stored in the form of tabular columns to be analysed statistically.

Results

The results were analysed using Mann–Whitney U test for independent samples and Wilcoxon sign rank test for paired samples. Chi Square test was used to analyse categorical variables in case of comparison of grades. The results indicate that the minimum marginal gap, before cementation, is 12.34 µ, seen in CAD milled and Copy milled zirconia copings, and the maximum marginal gap before cementation is 142.8 µ, seen in CAD milled zirconia copings. The minimum marginal gap, after cementation, is 0 µ, seen in CAD milled and Copy milled specimens and the maximum marginal gap, after cementation, is 156.67 µ, seen in CAD milled specimens. (Table 1) All the data collected regarding marginal gap is well within 120 µ, which has been accepted as the clinically tolerable margin. The mean indicates a higher marginal gap with respect to CAD milled specimens as compared to Copy milled specimens when evaluated mesially as well as distally. However, there are no statistically significant differences observed from the comparison. The results also conclude that amongst the CAD milled and Copy milled specimens, the minimum microleakage is seen with respect to the zirconia specimens bonded with light cure bonding system when compared to the self-cure specimens.(Tables 2, 3) This difference was statistically significant(P = 0.003). Out of the 16 CAD milled specimens bonded, 14 presented microleakage grade of 0 whereas 1 specimen each presented microleakage scores of grade 2 and grade 1. Of the 16 Copy milled specimens bonded, 15 presented microleakage scores of grade 0 whereas 1 specimen presented microleakage score of grade 1(Table 4).

Table 1.

Comparison of marginal gap between CAD milled copings and Copy milled copings using Mann–Whitney U test

| N | Minimum | Maximum | 25th Percentile | Median | 75th | IQR | Sum of ranks | Mann–Whitney U | Wilcoxon W | Z | Asymp. Sig. (2-tailed) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Before cementation microgap -Mesial | CAD milled | 16 | 12.34 | 142.8 | 43.19 | 86.38 | 115.15 | 71.96 | 309.5 | 82.5 | 218.5 | −1.718 | 0.086 |

| Copy milled | 16 | 12.34 | 105.3 | 24.68 | 42.89 | 85.175 | 60.495 | 218.5 | |||||

| Before cementation microgap- Distal | CAD milled | 16 | 34.92 | 130.4 | 49.315 | 74.22 | 95.85 | 46.535 | 327.5 | 64.5 | 200.5 | −2.396 | 0.017 |

| Copy milled | 16 | 12.34 | 97.2 | 24.68 | 35.03 | 73.755 | 49.075 | 200.5 | |||||

| After cementation microgap - Mesial | CAD milled | 16 | 8.33 | 100 | 20.835 | 66.665 | 83.33 | 62.495 | 280 | 112 | 248 | −0.612 | 0.541 |

| Copy milled | 16 | 0 | 133.33 | 33.33 | 41.665 | 83.33 | 50 | 248 | |||||

| After cementation microgap - Distal | CAD milled | 16 | 0 | 166.67 | 10.415 | 25 | 62.5025 | 52.0875 | 247 | 111 | 247 | −0.648 | 0.517 |

| Copy milled | 16 | 0 | 116.67 | 6.25 | 50 | 83.33 | 77.08 | 281 |

a. Before cementation - Mesial marginal gap, Distal marginal gap b.After cementation - Mesial marginal gap, Distal marginal gap

Table 2.

Comparison of microleakage between (a) CAD milled copings cemented with light cure and self cure resin bonding systems and (b) copy milled copings cemented with light cure and self cure bonding systems

| CAD/COPY | Light/self | N | Mean Rank | Sum of Ranks | Mann–Whitney U | Wilcoxon W | Z | P Value | |

|---|---|---|---|---|---|---|---|---|---|

| CAD milled | L2/L1 | Light cure | 8 | 6.5 | 52 | 16 | 52 | −1.684 | 0.105 |

| Self cure | 8 | 10.5 | 84 | ||||||

| COPY milled | L2/L1 | Light cure | 8 | 5.19 | 41.5 | 5.5 | 41.5 | −2.86 | 0.003 |

| Self cure | 8 | 11.81 | 94.5 |

| Light/self | N | Minimum | Maximum | 25th Percentile | MEDIAN | 75th | IQR | ||

|---|---|---|---|---|---|---|---|---|---|

| CAD milled | L2/L1 | Light cured | 8 | 0 | 0.11 | 0.0075 | 0.06 | 0.09625 | 0.08875 |

| Self cured | 8 | 0.02 | 0.6 | 0.049 | 0.135 | 0.2475 | 0.1985 | ||

| COPY milled | L2/L1 | Light cured | 8 | 0 | 0.06 | 0 | 0 | 0.0225 | 0.0225 |

| Self cured | 8 | 0.02 | 0.31 | 0.03125 | 0.105 | 0.1775 | 0.14625 |

Table 3.

Comparison of microleakage seen in CAD milled and Copy milled samples when cemented using (a) light cure resin bonding system and (b) self cure resin bonding system

| Light/self | CAD/COPY | N | Mean Rank | Sum of Ranks | Mann–Whitney U | Wilcoxon W | Z | P value | |

|---|---|---|---|---|---|---|---|---|---|

| Light cured | L2/L1 | CAD milled | 8 | 10.94 | 87.5 | 12.5 | 48.5 | −2.189 | 0.038 |

| COPY milled | 8 | 6.06 | 48.5 | ||||||

| Self cured | L2/L1 | CAD milled | 8 | 9.25 | 74 | 26 | 62 | -0.631 | 0.574 |

| COPY milled | 8 | 7.75 | 62 |

| N | Minimum | Maximum | 25th Percentile | MEDIAN | 75th | IQR | |||

|---|---|---|---|---|---|---|---|---|---|

| Light cure | L2/L1 | CAD milled | 8 | 0 | 0.11 | 0.0075 | 0.06 | 0.09625 | 0.08875 |

| COPY milled | 8 | 0 | 0.06 | 0 | 0 | 0.0225 | 0.0225 | ||

| Self cure | L2/L1 | CAD milled | 8 | 0.02 | 0.6 | 0.049 | 0.135 | 0.2475 | 0.1985 |

| COPY milled | 8 | 0.02 | 0.31 | 0.03125 | 0.105 | 0.1775 | 0.14625 |

Table 4.

Comparison of Grades depicting the level of microleakage (Acc to Mowafy et al.) using Chi square test

| Crosstab | |||||

|---|---|---|---|---|---|

| CAD/Copy | Total | ||||

| CAD milled | Copy milled | ||||

| Grade | 0 | Count | 14 | 15 | 29 |

| % within Grade | 48.3 % | 51.7 % | 100.0 % | ||

| % within CAD/Copy | 87.5 % | 93.8 % | 90.6 % | ||

| 1 | Count | 1 | 1 | 2 | |

| % within Grade | 50.0 % | 50.0 % | 100.0 % | ||

| % within CAD/Copy | 6.2 % | 6.2 % | 6.2 % | ||

| 2 | Count | 1 | 0 | 1 | |

| % within Grade | 100.0 % | 0.0 % | 100.0 % | ||

| % within CAD/Copy | 6.2 % | 0.0 % | 3.1 % | ||

| Total | Count | 16 | 16 | 32 | |

| % within Grade | 50.0 % | 50.0 % | 100.0 % | ||

| % within CAD/Copy | 100.0 % | 100.0 % | 100.0 % | ||

| Chi Square tests | ||

|---|---|---|

| Value | Exact Sig. (2-sided) | |

| Fisher’s exact test | 1.211 | 1.000 |

| N of valid cases | 32 |

Discussion

The null hypotheses in regard to marginal microgap and microleakage was rejected, as Copy milled specimens showed significantly lesser marginal gap as compared to CAD milled specimens. Those specimens luted using light cure resin bonding agent showed lesser marginal microleakage values when compared to chemically cured resin bonding system.

Marginal discrepancies and micro leakage, in addition to fracture resistance are closely related to the longevity of Zirconia restorations [6]. This in vitro study has evaluated marginal adaptation and microleakage of zirconia copings using fabrication and cementation protocols that are technique sensitive yet clinically successful.

Zirconia and Computer Aided Dentistry

The interest in choosing zirconia as a biomaterial is based on its mechanical strength, as well as its chemical and dimensional stability and elastic modulus similar to steel. The theoretical density of zirconium dioxide is 6.51 g/cm2 which contributes to its optimal mechanical properties. [7] As far as aesthetic properties are concerned, zirconia has been known to have lesser translucency due to reduced light transmission. This property of light transmission is determined by the amount of light scattering, dictated by the voids, porosities, refractive indices and number and size of crystal particles. Baldissara et al. [8], however, concluded that Lava copings had high translucency and suggested that the reduction in grain size could lead to improved translucency. In an in vitro study conducted by Cekic- Nagas et al. [9], it was concluded that the translucency of zirconia reduced with the thickness of the restoration. However, the resin cement cured using quartz tungsten halogen and light emitting diode, under varying thickness of zirconia, showed adequate microhardness and setting.

The development of accurate scanning devices, expansion of software capabilities, precision milling in the use of CAD/CAM technologies makes dentistry one of the fastest changing disciplines. The marginal gap evaluated in this in vitro study indicated that Copy milled specimens had lesser marginal gap when compared to CAD milled specimens, the difference being statistically significant. This could be attributed to factors like scanning and fabrication technique. CAD milling involved a laser optical scanner whereas copy milling involved mechanical scanning using a touch probe scanner. In a three dimensional evaluation conducted by Person et al. in 2006 [10], it was concluded that optical scanning was comparable to mechanical digitization devices in terms of accuracy and repeatability. However, the drawbacks of laser optical scanning system included that the system is technique sensitive. Optical scanning functions by the mechanism of reflection of white light or laser from the prepared tooth surface. The optical properties of the object scanned may affect the accuracy of the scan data. It was also evaluated that the laser scanner technique tends to round off sharp edges, such as sharp line angles and margins, whereas the touch probe scanner reproduced sharp edges accurately, which leads to better margins in the restoration. Jeong [11] et al. had conducted a SEM analysis of the processes involved in CAD milling and Copy milling and concluded that CAD/CAM system led to increased chip outs in the marginal area. He concluded that these chip outs are responsible for the poorer marginal fit of CAD milled specimens.

Tooth Preparation Parameters

Most CAD softwares are highly sensitive to preparation discrepancies and offer very little flexibility by the computer technician. On the other hand Copy Milling allows for some flexibility to compensate for any discrepancies that may compromise the fabrication of the coping/framework [7]. Principles to be pertained to include a minimal incisal or occlusal reduction of 1.5–2.0 mm, a rounded shoulder margin or deep chamfer margin finish line and a minimal occlusal convergence angle of 6–10. However, these are minimal requirements and increasing the occlusal reduction to 2.5 mm in the posterior teeth would provide space to create natural, unworn anatomy [12]. In this study, an axial reduction of 1.5 mm has been maintained throughout with an occlusal reduction of 2 mm. Jeong [11] et al. had concluded from his study that cutting depth has a significant effect on the marginal gap and that a minimal cutting depth of 1 mm is necessary for recognition and scanning by the software. The axial preparation depth was maintained at 1.5 mm through the vestibular, oral, mesial and distal surfaces using a silicone index, as increasing differences in preparation depth influenced the size of the marginal gap significantly. An occlusal convergence angle of 10°–12° was chosen as specified by the system employed at the laboratory. An optical scanner requires a minimum of 6–10° to accurately read the margin of the prepared model or master die. Parallel walls confuse most scanners and had to be avoided. [12, 13].

Evaluation of Marginal Gap and Microleakage

Until the 1980s, investigators who evaluated marginal fit did not always measure the same distances. Holmes et al. [14] proposed a clear terminology in 1989, evaluating it by measuring the marginal gap or the absolute marginal discrepancy. In this particular study, the marginal fit evaluated is the absolute marginal discrepancy, which is a combination of vertical marginal misfit and extension error (overextension and underextension) [14]. In vitro results should be viewed cautiously because in vitro testing cannot completely simulate the clinical situation. However, an in vitro study has the advantage of providing standardized conditions with respect to preparation design, technique, and experimental performance, resulting in more repeatable performance. In the current study, marginal fit was initially assessed without cementing the specimens to the prepared tooth. When test specimens are cemented, they may lose the precision of primary adaptation, thereby allowing cement type, viscosity and cementation techniques to influence the result [2]. The precision of marginal fit was initially evaluated by direct viewing and external measurements as opposed to sectioning as direct viewing has the advantage of being non-destructive and, therefore applicable to clinical practice. The gold standard for inaccuracies in marginal fit has been established by McLean and von Fraunhofer [15], who, after examining more than 1,000 crowns, concluded that 120 µ is the maximum tolerable marginal gap. The current study supports the same as the mean marginal gap of CAD milled as well as Copy milled specimens is well within the clinically tolerable margin. Before cementation, the maximum marginal gap is 142.8 µ, which was seen in CAD milled specimens whereas a minimal marginal gap of 12.3 µ has been recorded in case of CAD milled and Copy milled specimens. However, Copy milled specimens demonstrated lesser marginal gap when compared to CAD milled specimens statistically. This could be attributed to the differences in the scanning and fabrication techniques. The evaluation of marginal fit was repeated after cementation of the zirconia copings to simulate the clinical scenario, where marginal fit is influenced by the luting agent used. However, marginal discrepancies were still seen with regard to both sets of specimens, indicating that luting agent cannot masque the effects of a compromised restoration.

In the current in vitro study, microleakage was evaluated by comparing the spread of dye in relation to the length of the crown. The studies carried out with dyes are considered stricter that those carried out in the oral cavity. This could be due to : (1) dye diffuses faster than bacteria and their by-products, (2) the build-up of proteins and debris that then calcify in the marginal opening may improve the seal, or (3) the dentinal fluid in viable teeth, which has a positive pressure, and the settling of fibrinogen inside the sectioned tubules may contrast molecular penetration. Accordingly, if a material responds positively to the dye test, it is likely to respond even better on a clinical level [16]. Microleakage is known to be a result of a combination of variables like inaccuracies in marginal fit, the mechanical properties of luting cement and adhesion between cement and tooth structure. Thermocycling done to simulate the oral conditions could increase the strains and microshifts causing the failure of the weakest link. However, as this study does not include thermocycling, it is considered that the evaluation of microleakage here, would give us a clear idea about the properties of luting agent and the influence of marginal microgap on microleakage.

According to the data obtained, all 16 specimens cemented with a light cure resin bonding system showed lesser microleakage values (Grade 0: 100 %) when compared to the specimens bonded using self- cure resin bonding system (Grade 0: 81.2 %, Grade 1: 12.5 %, Grade 2: 6.25 %.) The significant differences in the microleakage scores of the test samples does not subdue the fact that microleakage values scored are very minimal with respect to both CAD milled specimens as well as Copy milled specimens. In various comparative evaluations [3, 5, 6, 18, 19] between resin bonding systems, resin modified glass ionomer cements and zinc phosphate cement, the most clinically favourable results have been obtained with regard to resin bonding systems. A drawback, however, could be the polymerization shrinkage which could occur, which has been clinically evaluated by researchers. Resin bonding systems have the property of water absorption which helps the relaxation of internal stresses caused by polymerization shrinkage. This further decreases the potential of interfacial failure of resin cement in clinical scenarios during occlusal loading. Bonding with light cure cement involved a multi-step application which included etching of the tooth surface and restoration, application of a silane coupling agent and activation of the setting process by light emitting diode. Ceramic etching and silanization provide a good bond of restorations to the cement, that even exceeds the bond strength to the dentine [6]. Another reason for the significant success of the light activated system could be its short setting time as opposed to that of the self- cure resin bonding system [14, 20].

Previous studies [2, 4, 17] comparing the marginal fidelity of CAD milled and Copy milled zirconia copings reported variable results. However, the significant differences can be owed to the variations in the scanning and milling techniques. Procera all-ceram restorations, also manufactured by CAD/CAM technology have been extensively compared with conventionally fabricated all ceramic crowns, metal ceramic restorations etc., and have consistently shown superior results. However, it should be noted that Procera AllCeram (PAC; Nobel Biocare) employs mechanical scanning technique which was used for Copy milling technique in the current study. As of today, there is limited literature available on the comparison of parameters evaluated in the present study. The limitations in the present study include the minimal sample size in the subgroup. Also, direct human intervention in the manufacturing of a restoration could play a role according to the skill of the dental laboratory technician and the relative importance of his/her contribution. The finger pressure applied while cementation protocol and seating misfits could be other factors which could have caused errors due to human intervention. As the copings were fabricated in different laboratories, this could incorporate a small element of error in the data obtained. Limitations due to the data evaluation by the image analysis software and the commercial software could not be avoided. Further studies comparing similar parameters should take measures to avoid the shortcomings of this study and incorporate similar or better standardization protocols during the multi- step procedures, as this research is technique sensitive at every phase.

Conclusion

Within the conditions and limitations of this in vitro study, it was concluded that :

Zirconia copings fabricated by computer aided technology (CAD/CAM or Copy milling) had good marginal fidelity as the mean marginal gap was well within the clinically tolerable margin of 120 µ. This was in accordance with previous studies conducted by various authors comparing similar parameters.

Copy milled zirconia copings showed significantly lesser marginal gap compared to CAD milled zirconia copings before (P = 0.017) and after cementation using light cure and chemical cure resin bonding systems.

Light cure resin bonding system, though technique sensitive and multi-step, proved to be a better alternative to chemical cure resin bonding systems on evaluation of marginal microgap and microleakage values after cementation, owing to the procedures of silanization and etching involved.

Resin bonding systems proved to be an excellent choice in cementing zirconia copings on the basis of microleakage evaluated. Both systems showed impeccable microleakage scores of ‘Grade 0′ in more than 90 % of the samples.

With multiple parameters of marginal gap and microleakage taken into concern, Copy milled zirconia copings luted with light cure multistep resin bonding system proved to be the most successful combination with best in vitro results.

The clinical implication of the present study is that although computer aided manufacturing techniques promises excellent results, the technique and armamentarium used influences the marginal fit and hence the microleakage. Thus, the clinician should be aware of the same and make the choice with careful consideration.

References

- 1.Contrepois M, Soenen A, Bartela M, Laviole O. Marginal adaptation of ceramic crowns: a systematic review. J Prosthet Dent. 2013;110(6):447–454. doi: 10.1016/j.prosdent.2013.08.003. [DOI] [PubMed] [Google Scholar]

- 2.Hamza TA, Ezzat HA, El-Hossary MM, Katamish HA, Shokry TE, Rosensteil SF. Accuracy of ceramic restorations made with two CAD/CAM systems. J Prosthet Dent. 2013;109:83–87. doi: 10.1016/S0022-3913(13)60020-7. [DOI] [PubMed] [Google Scholar]

- 3.Yuksel E, Zaimoglu A. Influence of marginal fit and cement types on microleakage of all- ceramic crown systems. Braz Oral Res. 2011;25(3):261–266. doi: 10.1590/s1806-83242011000300012. [DOI] [PubMed] [Google Scholar]

- 4.Martinez-Ruz F, Suarez MJ, Rivera B, Pradies G. Evaluation of the absolute marginal discrepancy of zirconia based ceramic copings. J Prosthet Dent. 2011;105:108–114. doi: 10.1016/S0022-3913(11)60009-7. [DOI] [PubMed] [Google Scholar]

- 5.Albert FE, El-Mowafy OM. Marginal adaptation and microleakage of Procera All Ceram crowns with four cements. Int J Prosthodont. 2004;17:529–535. [PubMed] [Google Scholar]

- 6.Gu XH, Kern M. Marginal discrepancies and leakage of all ceramic crowns: Influence of luting agents and ageing conditions. Int J Prosthodont. 2003;16:109–116. [PubMed] [Google Scholar]

- 7.Helvey GA. Zirconia and computer aided design/CAM dentistry. Funct Aesthet Restor Dent. 2007;1(3):28–39. [Google Scholar]

- 8.Baldissara P, Llukacej A, Ciocca L, Valandro FL, Scotti R. Translucency of zirconia copings made with different CAD/CAM systems. J Prosthet Dent. 2010;104:6–12. doi: 10.1016/S0022-3913(10)60086-8. [DOI] [PubMed] [Google Scholar]

- 9.Cekic-Nagas I, Eglimez F, Ergun G, Kaya BM. Light transmittance of zirconia as a function of thickness and microhardness of resin cements under different thicknesses of zirconia. Med Oral Patol Oral Cir Bucal. 2013;18(2):e212–e218. doi: 10.4317/medoral.18181. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Person A, Anderson M, Oden A, Sandborgh G. A three dimensional evaluation of a laser scanner and a touch probe scanner. J Prosthet Dent. 2006;95:194–200. doi: 10.1016/j.prosdent.2006.01.003. [DOI] [PubMed] [Google Scholar]

- 11.Jeong S, Kang DW. Wolf C, Evaluation of marginal fidelity of Copy milled and CAD/CAM all ceramic crowns. J Korean Acad Prosthodont. 2001;39(3):243–249. [Google Scholar]

- 12.Raigrodski AJ. Clinical and Laboratory considerations for the use of CAD/CAM Y-TZP based restorations. Pract Proceed Aesthet Dent. 2003;15:469–476. [PubMed] [Google Scholar]

- 13.Doyle MG, et al. The effect of tooth preparation design on the breaking strength of Dicor crowns: 2. Int J Prosthodont. 1990;3:241–248. [PubMed] [Google Scholar]

- 14.Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989;62:405–408. doi: 10.1016/0022-3913(89)90170-4. [DOI] [PubMed] [Google Scholar]

- 15.McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971;131:107–111. doi: 10.1038/sj.bdj.4802708. [DOI] [PubMed] [Google Scholar]

- 16.Baldissara, et al. Comparitive study of marginal microleakage of 6 cements in provisional crowns. J Prosthet Dent. 1998;80:417–422. doi: 10.1016/S0022-3913(98)70005-8. [DOI] [PubMed] [Google Scholar]

- 17.Rinke S, Huls A, Jahn L. Marginal accuracy and fracture strength of conventional and copy milled all-ceramic crowns. Int J Prosthodont. 1995;8:303–310. [PubMed] [Google Scholar]

- 18.Palacios Johnson, Philips Raigrodski. Retention of Zirconium oxide ceramic crowns with three types of cement. JPD. 2006;96:104–114. doi: 10.1016/j.prosdent.2006.06.001. [DOI] [PubMed] [Google Scholar]

- 19.Mirza RB, Tan KCB, Nicholls JI. Evaluation of marginal fit of a zirconia ceramic computer- aided machined (CAM) crown system. J Prosthet Dent. 2010;104(4):216–227. doi: 10.1016/S0022-3913(10)60128-X. [DOI] [PubMed] [Google Scholar]

- 20.Badrawy El. Chemical versus dual curing of resin inlay cements. J Prosthet Dent. 1995;73:15–24. doi: 10.1016/s0022-3913(05)80109-x. [DOI] [PubMed] [Google Scholar]