Abstract

The contribution of heavy-duty haulage trucks to the concentrations of aerosols and criteria gases in underground mine air and the physical properties of those aerosols were assessed for three fuel blends made with fatty acid methyl esters biodiesel and petroleum-based ultra-low-sulfur diesel (ULSD). The contributions of blends with 20, 50, and 57% of biodiesel as well as neat ULSD were assessed using a 30-ton truck operated over a simulated production cycle in an isolated zone of an operating underground metal mine. When fueled with the B20 (blend of biodiesel with ULSD with 20% of biodiesel content), B50 (blend of biodiesel with ULSD with 50% of biodiesel content), and B57 (blend of biodiesel with ULSD with 57% of biodiesel content) blends in place of ULSD, the truck’s contribution to mass concentrations of elemental and total carbon was reduced by 20, 50, and 61%, respectively. Size distribution measurements showed that the aerosols produced by the engine fueled with these blends were characterized by smaller median electrical mobility diameter and lower peak concentrations than the aerosols produced by the same engine fueled with ULSD. The use of the blends resulted in number concentrations of aerosols that were 13–29% lower than those when ULSD was used. Depending on the content of biodiesel in the blends, the average reductions in the surface area concentrations of aerosol which could be deposited in the alveolar region of the lung (as measured by a nanoparticle surface area monitor) ranged between 6 and 37%. The use of blends also resulted in slight but measurable reductions in CO emissions, as well as an increase in NOX emissions. All of the above changes in concentrations and physical properties were found to be correlated with the proportion of biodiesel in the blends.

Keywords: alternative fuels, diesel aerosols, FAME biodiesel, nitrogen oxides, number concentrations, size distributions, underground mining

INTRODUCTION

Changing the fuel supply from petroleum diesel to neat or blended biodiesel is considered by a number of underground metal and nonmetal mine operators in the USA to be a viable method for controlling diesel particulate matter (DPM) emissions (Tomko et al., 2010) and complying with current US Mine Safety and Health Administration (MSHA) regulations that limit the exposure of underground metal/nonmetal mines to DPM (30 CFR 57.5060). Currently, underground mines in the USA using biodiesel fuels are exclusively using fatty acid methyl ester (FAME) biodiesels, which are made from various vegetable oils and animal fats through the process of transesterifcation (Graboski and McCormick, 1998).

The effects of FAME biodiesel and FAME biodiesel blends with petroleum diesel on regulated and non-regulated emissions from heavy-duty diesel engines have been previously extensive evaluated in the laboratory (Tsolakis, 2006; Mueller et al., 2009; Tsai et al., 2010; Hajbabaei et al., 2012) and in on-road environments (Durbin et al., 2007; Walkowicz et al., 2009). Very few studies were conducted in occupational settings to examine impact of those fuels on quality of air and risks associated with exposure of workers to aerosols and gases emitted by in-use diesel-powered vehicles (National Institute for Occupational Safety and Health [NIOSH], 2006a,b; Bugarski et al., 2010; Traviss et al., 2010).

When compared to low-sulfur and ultra-low-sulfur petroleum diesels (LSD and ULSD), FAME biodiesels reduce emissions of total DPM and nonvolatile fractions of DPM (Williams et al., 2006; Yuan et al., 2007; Sappok and Wong, 2008; Bugarski et al., 2010) and, under certain engine operating conditions, can increase the particle-bound volatile organic fraction of DPM (Purcell et al., 1996; Stackpole, 2009; Bugarski et al., 2010).

In-use studies have shown the potential of neat soy methyl ester (SME) FAME (McDonald et al., 1997; Bugarski et al., 2010) and SME biodiesel blends (NIOSH, 2006a,b; Bugarski et al., 2010) to reduce the exposures of underground miners to elemental carbon (EC), total carbon (TC), and total DPM. The relatively low particulate mass emissions of FAME biodiesel fuels have been attributed to certain properties of these fuels such as the presence of fuel-bound oxygen, increased Cetane number, and increased flame temperature (less soot-radiative heat transfer) (Schönborn et al., 2009). Substantial increases in emissions of the organic carbon (OC) fractions of DPM were observed when the engine was fueled with SME FAME fuels and operated at light-load conditions (McDonald et al., 1995; Schönborn et al., 2009; Bugarski et al., 2010). At these conditions, during the late stages of the expansion stroke when temperatures in the cylinder drop below the boiling point of the fuel, the unburned fuel condenses into nucleation mode particles primarily composed of OC (Schönborn et al., 2009).

Several researchers have studied the impact of rapeseed methyl ester (RME) (Tsolakis, 2006) and SME (Jung et al., 2006; Chung et al., 2008; Bugarski et al., 2010) FAME fuels on the size distribution of aerosols emitted by diesel engines. Relative to ULSD, FAME fuels produced smaller particles (Jung et al., 2006; Tsolakis, 2006; Bugarski et al., 2010). Increases in the concentration of nucleation mode aerosols and reductions in the concentration of accumulation mode aerosols relative to LSD (Jung et al., 2006) and ULSD (Chung et al., 2008; Zhu et al., 2010) were also reported. However, this increase in nucleation particles was not observed for the conditions in an underground mine environment (Bugarski et al., 2010).

A number of studies found a relatively modest increase in emissions of nitrogen oxides (NOX = NO + NO2) associated with the use of biodiesel in place of ULSD (Monyem and Van Gerpen, 2001; Tsolakis, 2006; Durbin et al., 2007; Kawano et al., 2007; Verbeek et al., 2009; Hajbabaei et al., 2012; Hoekman and Robbins, 2012). The differences in chemical composition (e.g. oxygen content) and physical properties (e.g. bulk modulus of compressibility, Cetane number) between biodiesel and petroleum-based fuels were found to affect a number of complex coupled mechanisms controlling combustion behavior of those fuels (Kawano et al., 2007; Mueller et al., 2009; Schönborn et al., 2009; Bittle et al., 2010; Hoekman and Robbins, 2012). FAME biodiesel was shown to reduce CO and hydrocarbon (HC) emissions (Monyem and Van Gerpen, 2001; Yuan et al., 2007; Cheung et al., 2009). These reductions in CO and HC emissions were explained primarily by the presence of fuel-bound oxygen in the biodiesel (Schönborn et al., 2009).

Additionally, RME and SME FAME biofuels have been found to reduce total monocyclic aromatic hydrocarbons (MAHs), polycyclic aromatic hydrocarbons (PAHs), and benzo(a)pyrene equivalent emissions (Correa and Arbilla, 2006; Yuan et al., 2007; Verbeek et al., 2009). The biodiesel fuels were reported to have both favorable (Ratcliff et al., 2010; Traviss et al., 2010) and adverse (Cheung et al., 2009; Liu et al., 2009; Karavalakis et al., 2010) effects on carbonyl emissions. The impact of FAME on the emissions of individual MAHs and PAHs is not clear, however. Lower emissions of unburned HCs are generally attributed to a higher ignition quality of FAME fuels (Schönborn et al., 2009).

Limited information is available on the effects of FAME emissions on health (McCormick, 2007; Swanson et al., 2007). Aerosols generated by engines operated on biodiesel are not necessarily less toxic than those generated by the same engine operated on ULSD (Liu et al., 2009; Verbeek et al., 2009). In one study, B100 (neat FAME biodiesel fuel) RME FAME was found to produce a significant increase in cytotoxicity and mutagenicity/genotoxicity and a reduction in oxidative stress potential (Verbeek et al., 2009). Liu et al. (2009) showed that an engine without a diesel oxidation catalytic converter (DOC) produced emissions with higher acute toxicity and cytotoxicity when fueled with 10% RME FAME biodiesel blend rather than ULSD fuel. A study by Yanamala et al. (2013) showed elevated magnitude of phagocytic immune cell responses, higher lung permeability, higher pulmonary cytotoxicity, and elevated inflammatory response when the mice were exposed to B100 aerosols rather than to ULSD aerosols.

The potential increase in OC emissions due to the use of biodiesel is commonly counteracted by DOCs. Those were shown to be effective in controlling the emissions of organic compounds emitted by the mining engines operated on FAME blends (Bagley et al., 1998; Stackpole, 2009). Jalava et al. (2010) showed that DOC decreased oxidative potential of diesel particulate samples generated by nonroad diesel engine operated with RME fuel. However, the effects of DOCs on OC emissions depend upon the catalyst formulation, fuel formulation, and the engine operating conditions. Some DOCs were shown to be effective in reducing the number and mass concentrations of aerosol emitted by engines fueled with SME FAME fuel (Bugarski et al., 2010). For these reasons, the use of a DOC is an excellent control strategy for reducing OC exposures at light-load conditions, when higher concentrations of OC are emitted. The drawback of using a DOC to control OC emissions is the potential for an increase in NO2 emissions, particularly at high-load conditions (Bagley et al., 1998; Stackpole, 2009; Bugarski et al., 2010).

The effects of FAME biodiesel fuels on diesel engine emissions are not consistent over the range of possible applications. These effects have been found to vary widely with FAME type, usage conditions, and engine type and age (Durbin et al., 2007; Bugarski et al., 2010). Some engine technologies are more responsive to the biodiesel blends than others (Durbin et al., 2007). In addition, engine operating conditions play a major role in defining the characteristics of the emissions when using FAME fuels as a control strategy (Bugarski et al., 2010).

The primary objective of the study described in this manuscript was to investigate the effects that three fuel blends produced from FAME biodiesel and petroleum-based ULSD have on the physical properties and overall concentrations of aerosols exhausted in a production-like setting in the underground mine. Additional efforts were made to assess the effects of tested fuels on the in-use gaseous emissions. The experimental part of the study was designed to compromise between the genuineness of in situ measurements of contributions of the vehicle to concentrations of submicron aerosols and the repeatability and accuracy of the emission measurements obtained under research laboratory conditions. The intention was to complement already available knowledge gained on FAME biodiesel through numerous emissions laboratory studies with information needed to advance the efforts on reducing workers exposure to diesel pollutants. In order to accomplish this, the effects of FAME biodiesel were studied on the results of testing performed with a haulage truck (powered by a late model heavy-duty diesel engine) that was operated over a simulated heavy-duty transient production cycle in an isolated section of a working underground mine. The effects of the blends were then compared with the corresponding effects of ULSD fuel. The results of this study should help the industry to understand benefits and limitations of biodiesel as strategy used to curtail exposure of underground miners to diesel aerosols and gases.

MATERIAL AND METHODS

Vehicle and fuels

The testing took place in the Newmont USA Ltd Leeville underground mining operation close to Carlin, NV, USA. At the time of the study, the host mine was using 50% FAME biodiesel blend to fuel its entire fleet of diesel-powered underground heavy- and light-duty engines. The test vehicle used in this study, a 30-ton haulage truck, was powered by a 6-cylinder liquid-cooled, turbocharged, and electronically controlled EPA Tier 3 nonroad engine. The engine was equipped with a DOC and a closed crankcase ventilation system.

The biodiesel fuels evaluated in this study were blended using B100 supplied by the Renewable Energy Group (REG9000-10; Ames, IA, USA) and petroleum-based ULSD supplied by Thomas Petroleum (Carlin, NV, USA). The primary source of the oils for the biodiesel was soy. Blends with 20% (B20), 50% (B50), and 57% (B57) of biodiesel content were evaluated. Supplementary Table S1 in Supplementary Material, available at Annals of Occupational Hygiene online, summarizes the results of a fuel property analysis performed on these test fuels by Bentley Tribology Services (Minden, NV, USA).

Isolated zone and vehicle duty cycle

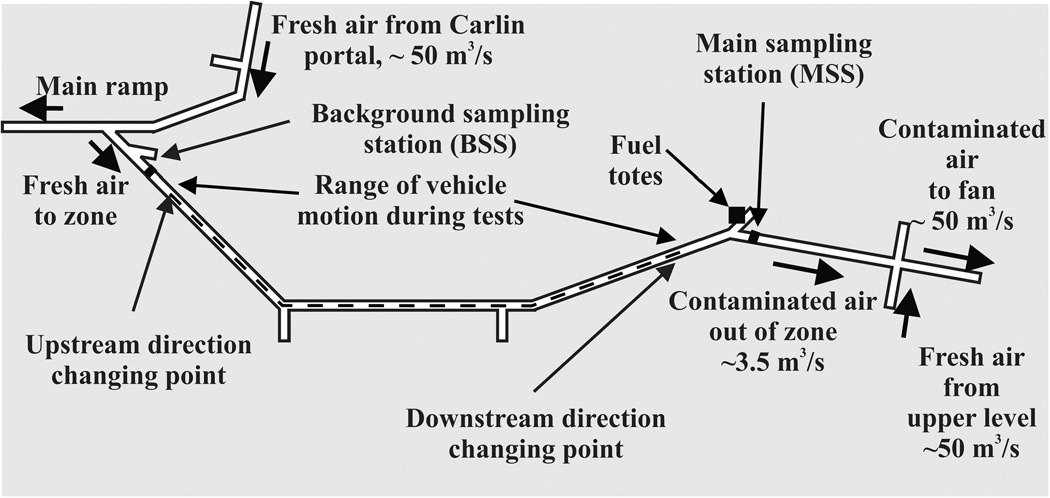

The contribution of the test engine to the concentration of aerosols and criteria gases in the mine air was assessed under simulated production conditions using an isolated zone methodology (NIOSH, 2006a,b). The test zone (Fig. 1) was established in a development drift situated ~1500 m above sea level. The zone was selected, so that the contribution from other diesel-powered vehicles concurrently operated in the mine was absent or minimized in intensity and duration. The only source of aerosols and gasses was the tested vehicle.

1.

Layout of isolated zone (not in scale).

For all tests, a single, experienced worker operated the truck within a 200-m-long section of the main drift (Fig. 1). During all of the tests, the truck bed was loaded with ~30 tons of ore. The vehicle was operated over a series of repetitions of a 300-s duty cycle which was developed specifically for this study (Supplementary Figure S1, available at Annals of Occupational Hygiene online).

Measurement, sampling, and analysis

Due to the complex physical and chemical nature of DPM, as well as the changing nature of the aerosol or of the environment, the measurement and characterization methodology plays important role in linking DPM to health (Russell and Brunekreef, 2009; Bugarski et al., 2012; Cauda et al., 2012; Giechaskiel et al., 2014). In this study, several metrics were used to characterize primary and secondary submicron aerosols in the underground environment directly resulting from the contributions of a diesel-powered vehicle, including potentially some of those that were non-exhaust related. The traditionally used measurements of mass concentrations of total DPM and EC were complemented with measurements of number and surface concentrations and size distribution. A large number of studies have shown that size, number, and surface area are aerosol attributes essential for assessing risk associated with exposure to nanometer and ultrafine aerosols (Donaldson et al., 2005; Cauda et al., 2012).

Two ambient measurement and sampling stations were established in the isolated zone: (i) the background sampling station (BSS) at the upstream end of the zone and (ii) the main sampling station (MSS) at the downstream end of the zone (Fig. 1). The BSS was located at the upstream end of the isolated zone ~20 m beyond the upstream vehicle direction changing point. The MSS was established at the downstream end of the isolated zone ~30 m beyond the downstream vehicle direction changing point. The net contribution of the test vehicle to concentrations of aerosols and criteria gases was determined by subtracting the results of measurements performed at the BSS from the results of measurements performed at the MSS.

At the BSS, all sampling and measurements were performed from a single point that was centrally located in the cross section of the drift. At the MSS, in order to minimize the effects of thermal stratification, the measurements were performed using a sampling train positioned on a structure that was rotated in a vertical plane around a centrally located point in a cross section of the drift. A geared motor was used to revolve this structure on a 1-m-long arm at a radial speed of 1 r.p.m.

At the BSS, triplicates of background DPM samples for EC, OC, and TC analysis were collected on DPM cassettes (SKC, Eighty Four, PA, USA) using standard MSHA compliance sampling procedures as well as standard MSHA compliance sampling train components (30 CFR 57.5060). Concurrently, number concentrations and size distributions of submicron aerosols in background air were measured using a fast mobility particle spectrometer (FMPS) (FMPS 3091; TSI) ( Johnson et al., 2004).

An infrared analyzer (Carboncap GM70IR; Vaisala) was used to continuously measure background concentrations of CO2; an electrochemical cell-based multi-gas monitor (iTX; Industrial Scientific) was used at the same location to continuously measure background concentrations of CO, NO, and NO2. The ventilation flow rate at the BSS was calculated from the results of periodic measurements of air velocity across the opening using a mechanical vane anemometer (Davis Instruments, A2/4”) and a traverse method. A continuous ventilation flow rate was also estimated from the results of an air velocity measurement obtained at a single point (centrally located in a cross section of the drift and ~20 m downstream of the BSS) using an electronic vane anemometer that was recording throughout each test (Alnor RVA501; TSI).

DPM samples for carbon analysis were collected in triplicate at the MSS using a methodology identical to the one used to collect background DPM samples for carbon analysis. The number concentrations and size distributions of the submicrometer aerosols were measured using an FMPS (FMPS 3091; TSI) and a scanning mobility particle size (SMPS) spectrometer (SMPS 3936; TSI) (Wang and Flagan, 1990). Concurrently, a nanoparticle surface area monitor (NSAM) (NSAM 3550; TSI) was used to measure the surface area of aerosols which could be deposited in the alveolar region of the lungs (Fissan et al., 2007; Asbach et al., 2009). The concentrations of CO2 and CO, NO, and NO2 and ventilation flow rate at the MSS were determined using the same methodology and instrumentation used at the BSS.

Carbon analysis on DPM samples collected at the BSS and the MSS was performed using the thermal optical transmittance-evolve gas analysis (TOT-EGA) known as NIOSH Method 5040 (Birch and Cary, 1996; NIOSH, 1999).

In addition, concentrations of CO, CO2, NO, and NO2 were measured in the exhaust upstream and downstream of the DOC using a SEMTECH DS mobile emissions analyzer from Sensors Inc., Saline, MI, USA. The data acquisition system of the SEMTECH DS was used to record pertinent parameters available from the engine control unit of the tested engine.

Ventilation and ambient parameters

Fresh air (from the Carlin Portal and main ramp) was pulled through the isolated zone by a fan located in an exhaust shaft downstream of the test area (Fig. 1). The same fan was pulling additional quantities of air from the upper level of the mine. These two flows merged downwind from the tested section. In order to prevent contamination of dilution air by other diesel-powered vehicles, the main ramp was closed to all traffic during the tests. The average ventilation flow rates were between 3.02 and 3.54 m3 s−1. CO2 concentration measurements taken in the vehicle exhaust (downstream of the DOC) and in mine air (at the MSS) were used to normalize all measured aerosol and gas concentrations to the average ventilation conditions observed during the ULSD test.

The time-weighted averages for barometric pressure and ambient temperature measured on the vehicle were 83.9 ± 2.6 kPa and 27.4 ± 3.9°C. The corresponding time-weighted average ambient temperature at MSS was 20.9 ± 1.3°C.

RESULTS AND DISCUSSION

Background aerosol concentrations

The results of total aerosol number concentration measurements performed with condensation particle counters at the BSS and the MSS were used to assess the contribution of background air to the total aerosol concentrations. For all test cases, the background concentrations contributed <1% to the total time-weighted average number concentrations measured at the MSS. Since the TOT-EGA analysis for DPM samples collected at the BSS and MSS confirmed that the contribution of background air to the total EC, OC, and TC concentrations at the MSS was negligible, the contribution from the background aerosols was not considered in the analysis.

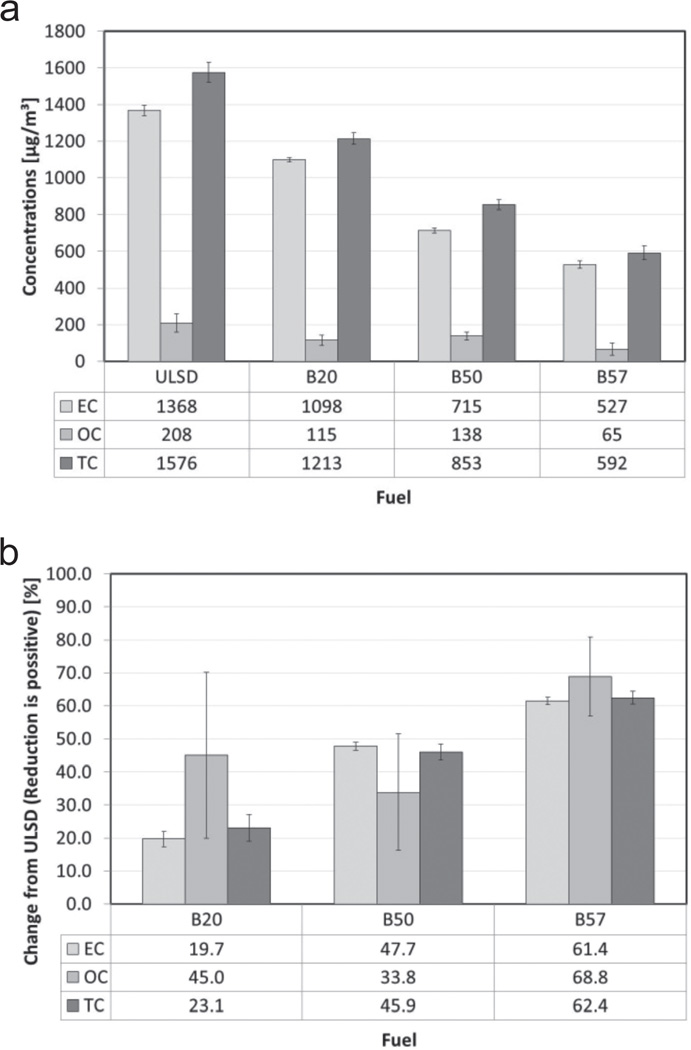

EC, OC, and TC concentrations

The results of the TOT-EGA analysis performed on the time-integrated DPM samples collected at the MSS are shown in Fig. 2a. Those results were used to calculate changes in the concentrations from the baseline (ULSD) case (Fig. 2b). The positive and negative error bars shown on top of the average values in Fig. 2 represent the single standard deviations from the mean. The EC and TC concentrations at the MSS were substantially lower for B20, B50, and B57 blends than for ULSD (Fig. 2). The reductions in EC and TC (dominated by EC) concentrations were directly related to biodiesel content in the blends. The relation between biodiesel content and OC concentrations was less certain (Fig. 2). This can potentially be explained by the higher uncertainty of the OC results.

2.

EC, OC, and TC: (a) concentrations at the MSS and (b) changes in concentrations with respect to ULSD case.

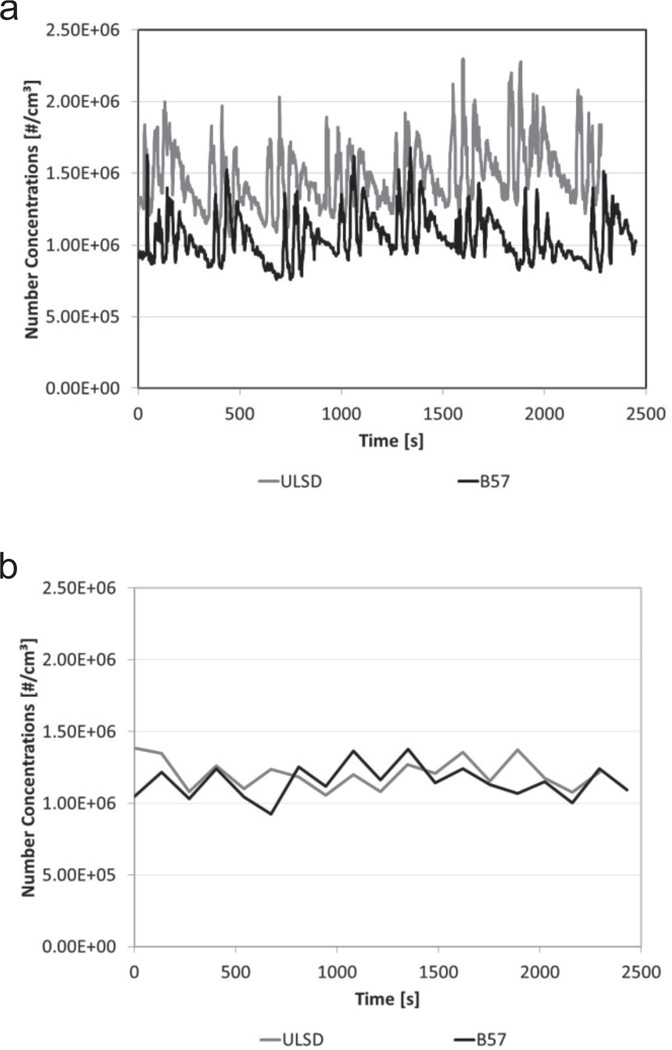

Total number concentrations of aerosols

The total aerosol number concentrations were measured with the FMPS (one measurement per second from the rotating platform) and the SMPS (one measurement per 120 s from a fixed location in the center of the drift). As shown for the ULSD and B57 tests in Fig. 3, the combination of the effects of continuously changing engine operating conditions, the movement of the vehicle within the zone, and a number of processes controlling the formation and transformation of diesel aerosols in mine air resulted in transient and cyclic traces. The data clearly show the 300-s vehicle duty cycle. Although quantitative comparison of the FMPS and SMPS results is not possible due to differences in the measurement principles, a general agreement is still apparent (Fig. 3). The higher peak concentration values and larger value ranges that are shown in the FMPS data are explained by the increased measurement frequency and the radial movement of the FMPS sampling inlet throughout the tunnel opening.

3.

Number concentrations of aerosols at the MSS for ULSD and B57 tests: (a) FMPS and (b) SMPS.

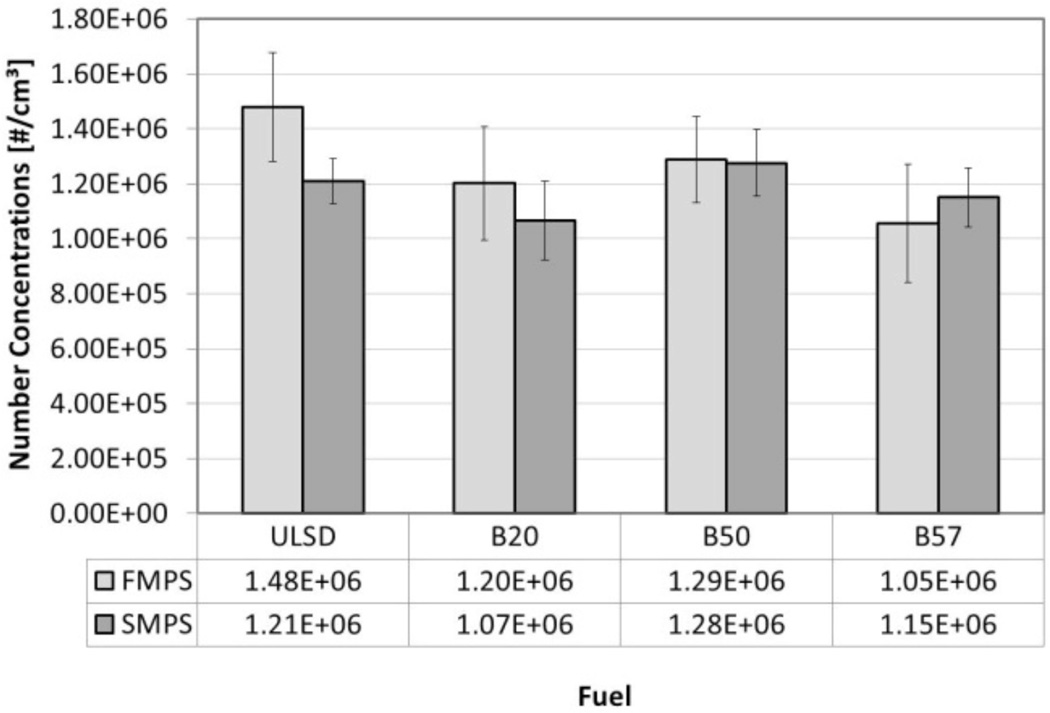

The results of continuous measurements were used to calculate the contributions to the average total number concentrations of aerosols (Fig. 4). The error bars represent 1 SD from the respective means. According to the FMPS results, the biodiesel blends (when compared with ULSD) produced 13–29% lower number concentrations of aerosols in the air at the MSS. The SMPS measurements showed that in B20 and B57 cases number concentrations were 12 and 5%, respectively, lower than in ULSD case. In the case of B50, the concentrations were 6% higher than those for ULSD. The results did not exhibit a clear linear relationship between FAME biodiesel content in the fuels and a change in total number concentrations.

4.

Average number concentrations of aerosols at the MSS for the ULSD and three biodiesel blends.

Size distribution of aerosols

The effects of the fuel type used on the aerosol size distributions were therefore examined using measurements made at selected instances throughout these cycles. In order to enhance the clarity of the figures, the aerosol size distributions were fitted with log-normal curves using DistFit software from Chimera Technologies (Forest Lake, MN, USA). For reasons of brevity, only the results of FMPS measurements were used in further discussion. Five of those distributions were examined for each of the tests. The example of size distributions measured for selected instances of the ULSD and B57 tests are shown in Supplementary Figure S2 in the Supplementary Material, available at Annals of Occupational Hygiene online.

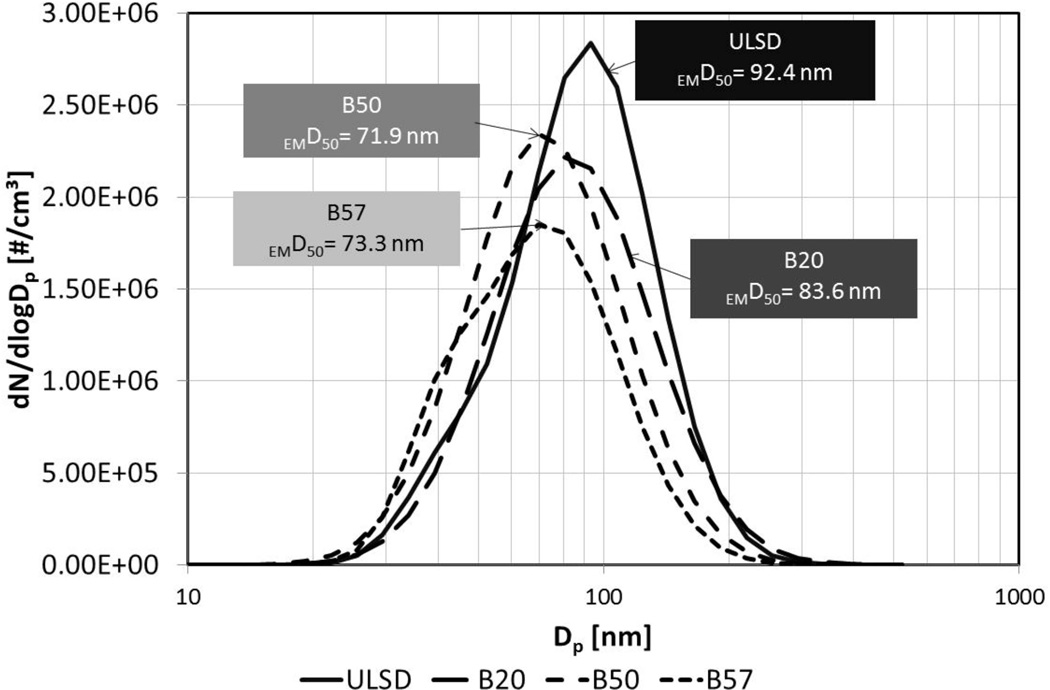

The majority of aerosols generated by the engine for each of the tested fuels were distributed in single accumulation mode. For each of the evaluated fuels, the distributions were characterized by almost identical geometric mean electrical mobility diameters (EMD50) of accumulation mode and peak concentrations dependent on the stage of vehicle/engine duty cycle. Depending on the fuel, EMD50 of accumulation modes were between 70 and 92 nm.

The effects of fuels on EMD50 of aerosols are illustrated on the example shown in Fig. 5. In general, the size distributions of aerosols observed for the biodiesel blends were found to be characterized by smaller EMD50 and lower peak concentrations than the corresponding size distributions observed for ULSD. For B50, B20, and ULSD, the EMD50 of aerosols decreased with the amount of biodiesel in the blends. The same trend was not apparent for the blend with highest biodiesel content. The EMD50 for B57 was slightly larger than the one for B50.

5.

Effects of fuel on electrical mobility median diameter of aerosols measured using FMPS at the MSS.

Surface area concentrations measured by NSAM

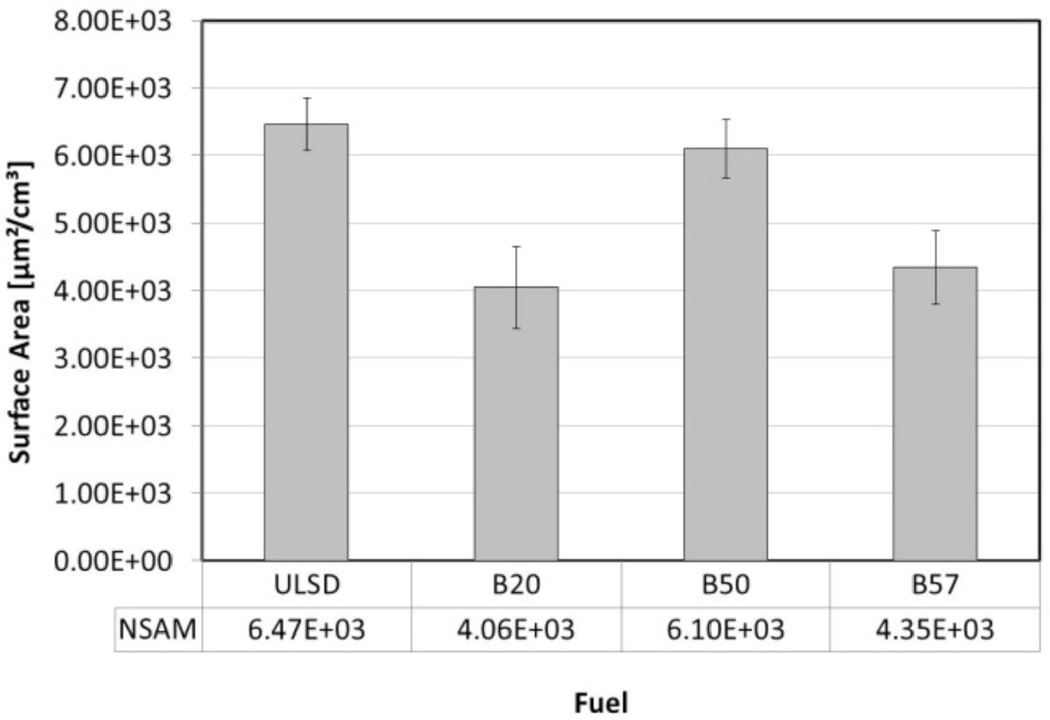

The surface area concentrations (SAC) of aerosols which could be deposited in the alveolar region of the lungs were measured by NSAM at the MSS. Similar to the other measured parameters, the SAC measured by NSAM were also transient and cyclic in nature.

The effects of fuel formulations on SAC were examined on the averages calculated for each of the tests (Fig. 6). The error bars represent the standard deviation from the means. The results showed that the use of biodiesel blends produced measurable reductions in average SAC in the air at the MSS. Depending on the content of biodiesel in the blends, the average reductions ranged between 6 and 37%. However, a direct correlation between biodiesel content and changes in average SAC was not evident in the results of those measurements.

6.

Average surface area concentrations of aerosols deposited in the alveolar region of lungs as measured by NSAM at the MSS.

Tailpipe concentrations of CO, NO, and NO2

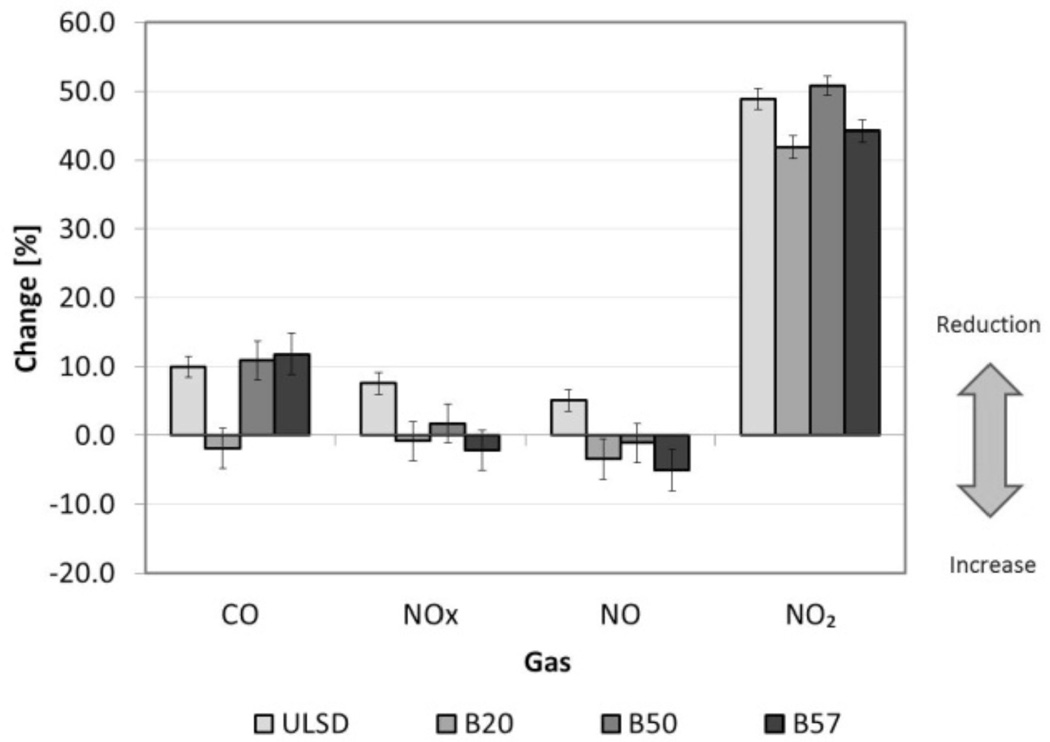

The results of measurements acquired in the vehicle exhaust stream both upstream and downstream of the DOC were used to assess the effects of the DOC on CO, NOX, NO, and NO2 (Fig. 7). Minor reductions in CO emissions and major reductions in NO2 concentrations indicated that, at the time of the tests, the catalyst in this vintage DOC was most likely completely deactivated. Reductions in NO2 concentrations were, therefore, probably a result of reaction of that gas with soot deposited on the walls of the DOC.

7.

Effects of the DOC on CO, NOX, NO, and NO2 emissions.

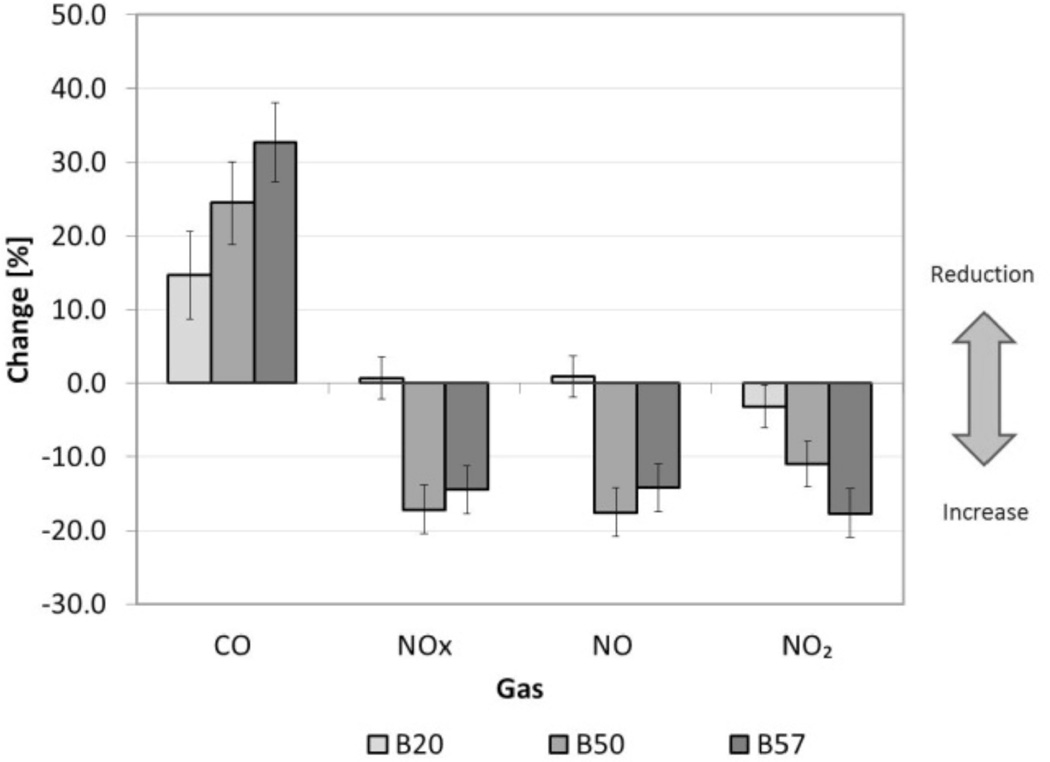

The results of continuous measurements of CO, NOX, NO, and NO2 concentrations in the exhaust of the test engine downstream of the practically deactivated DOC showed that, in general, when compared to measurements made with ULSD, the biodiesel fuels reduced CO emissions and increased NO and NO2 emissions (Fig. 8). The data for CO and NO2 emissions in Fig. 8 demonstrate a direct correlation with biodiesel content in the blends. The relation between biodiesel content and the effects on NO emissions is not clear.

8.

Effects of biodiesel fuels when compared to ULSD on CO, NOX, NO, and NO2 emissions from deactivated DOC.

CONCLUSIONS

The effects of three fuel blends produced from FAME biodiesel and petroleum-based ULSD on aerosols and criteria gases emitted by heavy-duty diesel haulage truck equipped with a most likely deactivated DOC in underground mine air were assessed in the simulated production conditions. The use of FAME biodiesel blends in place of ULSD resulted in substantial reductions in the contribution of a truck to EC and TC mass concentrations in an underground mine environment. Those reductions were found to be correlated with changes to biodiesel content in the blends. Size distribution measurement showed that the aerosols produced by the engine fueled with those biodiesel blends were characterized by smaller EMD50 and lower peak number concentrations than the aerosols produced by the same engine fueled with ULSD. The changes in number concentrations and the SAC of aerosols that could be deposited in the alveolar region of the lungs (as measured by NSAM) were found to be relatively moderate compared to the changes in EC and TC mass concentrations. Therefore, the reductions in EC and TC mass concentrations can be primarily attributed to the changes in the size of the generated aerosols. The results emphasize necessity for use of several metrics to assess the effects of control technologies and strategies on submicron aerosols in the occupational settings.

The use of FAME blends, when compared to ULSD, also resulted in slight but measurable reductions in CO emissions and a slight increase in NOX emissions. Both of those were found to be directly related to the content of biodiesel in the blends. The fraction of NO2 in NOX increased slightly with biodiesel content.

In general, the results of this study corroborate with the results of a study previously conducted by the authors in an experimental mine using a naturally aspirated mechanically controlled engine operated over steady-state conditions (Bugarski et al., 2010). This study confirmed that fueling diesel-powered vehicles with neat or blended FAME biodiesel is a viable strategy for reducing DPM mass emissions. However, substantial changes in physical and chemical properties of aerosols emitted by diesel engines fueled with FAME fuels warrant further investigations on the effectiveness of this strategy in reducing health risk associated with exposure to those aerosols.

ACKNOWLEDGEMENTS

We acknowledge support from Benjamin Rader (Newmont USA Ltd), Louie Moret (Sensors Inc.), and Chris Darby (Sensors Inc.) for their help and assistance in the experimental phase of this study. Special thanks go to James Noll and Shawn Vanderslice of the NIOSH Office of Mine Safety and Health Research for providing results of the carbon analysis.

FUNDING

This work was funded by National Institute for Occupational Safety and Health under Project 927ZJGH. Newmont USA Limited provided in-kind access to test site, vehicle, operator, and fuels.

Footnotes

SUPPLEMENTARY DATA

Supplementary data can be found at http://annhyg.oxfordjournals.org/.

DISCLAIMER

The findings and conclusions of this publication are those of the authors and do not necessarily represent the views of the National Institute for Occupational Safety and Health. Mention of company names or products does not constitute endorsement by NIOSH.

REFERENCES

- 30 CFR 57.5060. Diesel particulate matter exposure of underground metal and nonmetal miners. Limit on concentration of diesel particulate matter. Code of Federal Regulations. Washington, DC: US Government Printing Office, Office of the Federal Register; [Google Scholar]

- Asbach C, Fissan H, Stahlmecke B, et al. Conceptual limitations and extensions of lung-deposited nanoparticle surface area monitor (NSAM) J Nanopart Res. 2009;11:101–109. [Google Scholar]

- Bagley ST, Gratz LD, Johnson JH, et al. Effects of oxidation catalytic converter and a biodiesel fuel on chemical, mutagenic, and particle size characteristics of emissions from a diesel engine. Environ Sci Techol. 1998;32:1183–1191. [Google Scholar]

- Birch ME, Cary R. Elemental carbon-based method for occupational monitoring of particulate diesel exhaust: methodology and exposure issues. Analyst. 1996;121:1183–1190. doi: 10.1039/an9962101183. [DOI] [PubMed] [Google Scholar]

- Bittle J, Knight B, Jacobs T. Interesting behaviour of biodiesel ignition delay and combustion duration. Energy Fuels. 2010;24:4166–4177. [Google Scholar]

- Bugarski AD, Cauda EG, Janisko SJ, et al. Aerosols emitted in underground mine air by diesel engine fueled with biodiesel. J Air Waste Manag Assoc. 2010;60:237–244. doi: 10.3155/1047-3289.60.2.237. [DOI] [PubMed] [Google Scholar]

- Bugarski AD, Janisko S, Cauda EG, et al. Controlling exposure to diesel emissions in underground mines. Englewood, CO: Society for Mining, Metallurgy, and Exploration; 2012. pp. 361–362. ISBN-13: 9780873353601. [Google Scholar]

- Cauda EG, Ku BK, Miller AL, et al. Toward developing a new occupational metric approach for characterization of diesel aerosols. Aerosol Sci Technol. 2012;46:1370–1381. doi: 10.1080/02786826.2012.715781. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cheung CS, Zhu L, Huang Z. Regulated and unregulated emissions from a diesel engine fueled with biodiesel and biodiesel blend with methanol. Atmos Environ. 2009;43:4865–4872. [Google Scholar]

- Chung A, Lall AA, Paulson SE. Particulate emissions by a small non-road diesel engine: biodiesel and diesel characterization and mass measurements using the extended idealized aggregates theory. Atmos Environ. 2008;42:2129–2140. [Google Scholar]

- Correa SM, Arbilla G. Aromatic hydrocarbons emissions in diesel and biodiesel exhaust. Atmos Environ. 2006;40:6821–6826. [Google Scholar]

- Donaldson K, Tran L, Jimenez LA, et al. Combustion-derived nanoparticles: a review of their toxicology following inhalation exposure. Part Fibre Toxicol. 2005;2:10. doi: 10.1186/1743-8977-2-10. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Durbin DT, Cocker DR, III, Sawant AA, et al. Regulated emissions from biodiesel fuels from on/off-road applications. Atmos Environ. 2007;41:5647–5658. [Google Scholar]

- Fissan H, Neumann S, Trampe A, et al. Rationale and principle of an instrument measuring lung deposited nanoparticle surface area. J Nanopart Res. 2007;9:53–59. [Google Scholar]

- Giechaskiel B, Maricq M, Ntziachristos L, et al. Review of motor vehicle particulate emissions sampling and measurements: from smoke and filter mass to particle number. J Aerosol Sci. 2014;67:48–86. [Google Scholar]

- Graboski MS, McCormick RL. Combustion of fat and vegetable oils derived fuels in diesel engines. Prog Energy Combust Sci. 1998;24:125–164. [Google Scholar]

- Hajbabaei M, Johnson KC, Okamoto R, et al. Evaluation of the impacts of biodiesel and second generation biofuels on NO(x) emissions for CARB diesel fuels. Environ Sci Technol. 2012;46:9163–9173. doi: 10.1021/es300739r. [DOI] [PubMed] [Google Scholar]

- Hoekman SK, Robbins C. Review of the effects of biodiesel on NOX emissions. Fuel Process Tech. 2012;96:237–249. [Google Scholar]

- Jalava PI, Tapanainen M, Kuuspalo K, et al. Toxicological effects of emission particles from fossil- and biodiesel-fueled diesel engine with and without DOC/POC catalytic converter. Inhal Toxicol. 2010;22(Suppl. 2):48–58. doi: 10.3109/08958378.2010.519009. [DOI] [PubMed] [Google Scholar]

- Johnson T, Caldow R, Pöcher A, et al. A new electrical mobility particle sizer spectrometer for engine exhaust particle measurements. SAE Technical Paper 2004-01-1341. 2004 [Google Scholar]

- Jung H, Kittelson DB, Zachariah MR. Characteristics of SME biodiesel-fueled diesel particle emissions and the kinetics of oxidation. Environ Sci Technol. 2006;40:4949–4955. doi: 10.1021/es0515452. [DOI] [PubMed] [Google Scholar]

- Karavalakis G, Bakeas E, Stournas S. Influence of oxidized biodiesel blends on regulated and unregulated emissions from a diesel passenger car. Environ Sci Technol. 2010;44:5306–5312. doi: 10.1021/es100831j. [DOI] [PubMed] [Google Scholar]

- Kawano D, Ishil H, Goto Y, et al. Optimization of engine system for application of biodiesel fuel. SAE Technical Paper 2007-01-2028. 2007 [Google Scholar]

- Liu YY, Lin TC, Wang YJ, et al. Carbonyl compounds and toxicity assessments of emissions from a diesel engine running on biodiesels. J Air Waste Manage Assoc. 2009;59:163–171. doi: 10.3155/1047-3289.59.2.163. [DOI] [PubMed] [Google Scholar]

- McCormick RL. The impact of biodiesel on pollutant emissions and public health. Inhal Toxicol. 2007;19:1033–9. doi: 10.1080/08958370701533509. [DOI] [PubMed] [Google Scholar]

- McDonald JF, Cantrell BK, Watts WF, et al. Evaluation of a soybean oil based diesel fuel in an underground gold mine. CIM Bull. 1997;91:91–95. [Google Scholar]

- McDonald JF, Purcell DL, McClure BT, et al. Emissions characteristics of soy methyl ester fuels in an IDI compressions ignition engine. SAE Technical Paper 950400. 1995 [Google Scholar]

- Monyem A, Van Gerpen JH. The effects of biodiesel oxidation on engine performance and emissions. Biomass Bioenergy. 2001;20:317–325. [Google Scholar]

- Mueller CJ, Boehman AL, Martin GC. An experimental investigation of the origins of increased NOX emissions when fueling a heavy-duty compression-ignition engine with soy biodiesel. SAE Technical Paper 2009-01-1792. 2009 [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH) NIOSH manual of analytical methods. 5th edn. Cincinnati, OH: US Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; 1999. Elemental carbon (diesel exhaust). Method 5040. [Google Scholar]

- Bugarski AD, Schnakenberg GH, Noll JD, et al., editors. National Institute for Occupational Safety and Health (NIOSH) Effectiveness of selected diesel particulate matter control technologies for underground mining applications: isolated zone study, 2003. Pittsburgh, PA: US Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH); 2006a. pp. 14–78. Publication No. 2006-126, Report of Investigations 9667. [Google Scholar]

- Bugarski AD, Schnakenberg GH, Mischler SE, et al., editors. National Institute for Occupational Safety and Health (NIOSH) Effectiveness of selected diesel particulate matter control technologies for underground mining applications: isolated zone study, 2004. Pittsburgh, PA: US Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH); 2006b. pp. 6–67. Publication No. 2006-138, Report of Investigations 9668. [Google Scholar]

- Purcell DJ, McClure BT, McDonald J, et al. Transient testing of soy methyl ester fuels in an indirect injection, compression ignition engine. J Am Oil Chem Soc. 1996;73:381–388. [Google Scholar]

- Ratcliff MA, Dane AJ, Williams A, et al. Diesel particle filter and fuel effects on heavy-duty diesel engine emissions. Environ Sci Technol. 2010;44:8343–8349. doi: 10.1021/es1008032. [DOI] [PubMed] [Google Scholar]

- Russell AG, Brunekreef B. A focus on particulate matter and health. Environ Sci Technol. 2009;43:4620–4625. doi: 10.1021/es9005459. [DOI] [PubMed] [Google Scholar]

- Sappok AG, Wong VW. Impact of biodiesel on ash emissions and lubricant properties affecting fuel economy and engine wear: comparison with conventional diesel fuel. SAE Technical Paper 2008-01-1395. 2008 [Google Scholar]

- Schönborn A, Ladommatos N, Williams J, et al. The influence of molecular structure of fatty acid monoalkyl esters on diesel combustion. Combust Flame. 2009;156:1396–1412. [Google Scholar]

- Stackpole RP., II Diesel fuel testing on an Isuzu 4JG1T engine with and without a diesel oxidation catalyst. Final Report. [Accessed 30 June 2014];US Department of Labor, Mine Safety and Health Administration. 2009 Available at www.msha.gov/REGS/COMPLIAN/Pib/2009/P09-38MSHAFuelTestReport.pdf].

- Swanson KJ, Madden MC, Ghio AJ. Biodiesel exhaust: the need for health effects research. Environ Health Perspect. 2007;115:496–499. doi: 10.1289/ehp.9631. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tomko DM, Stackpole RP, Findlay CD, et al. Metal/nonmetal diesel particulate matter rule. In: Hardcastle S, McKinnon DL, editors. Proceedings of the 13th US/North American Mine Ventilation Symposium. Sudbury, Ontario, Canada: MIRRCO—Mining Innovation; 2010. pp. 143–148. [Google Scholar]

- Traviss N, Telen BA, Ingalls JK, et al. Biodiesel versus diesel: a pilot study comparing exhaust exposures for employees at a rural municipal facility. J Air Waste Manag Assoc. 2010;60:1026–1033. doi: 10.3155/1047-3289.60.9.1026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tsai J-H, Chen S-J, Huang K-L, Lin Y-C, Lee W-J, Lin C-C, Lin W-Y. PM, carbon, and PAH emissions from a diesel generator fuelled with soy-biodiesel blends. J Hazard Mater. 2010;179:237–243. doi: 10.1016/j.jhazmat.2010.02.085. [DOI] [PubMed] [Google Scholar]

- Tsolakis A. Effects on particles size distribution from the diesel engine operating on RME-biodiesel with EGR. Energy Fuels. 2006;20:1418–1424. [Google Scholar]

- Verbeek RP, Kooter IM, Houtzager MMG, et al. 13th ETH Conference on Combustion Generated Nanoparticles–June. Zurich, Switzerland: 2009. Health effects of biofuels and diesel particulate filter with a Euro III truck engine. [Google Scholar]

- Walkowicz K, Na K, Robertson W, et al. On-road and in-laboratory testing to demonstrate effects of ULSD, B20, and B99 on a retrofit urea-scr after treatment system. SAE Technical Paper 2009-01-2733. 2009 [Google Scholar]

- Wang CS, Flagan RC. Scanning electrical mobility spectrometer. Aerosol Sci Technol. 1990;13:230–240. [Google Scholar]

- Williams A, McCormick RL, Hayes R, et al. Effects of biodiesel on diesel particulate filter performance. SAE Technical Paper 2006-01-3280. 2006 [Google Scholar]

- Yanamala N, Hatfield MK, Farcas MT, et al. Biodiesel versus diesel exposure: enhanced pulmonary inflammation, oxidative stress, and differential morphological changes in the mouse lung. Toxicol Appl Pharmacol. 2013;272:373–383. doi: 10.1016/j.taap.2013.07.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Yuan CS, Lin HY, Lee WJ, et al. A new alternative fuel for reduction of polycyclic aromatic hydrocarbon and particulate matter emissions from diesel engines. J Air Waste Manag Assoc. 2007;57:465–471. doi: 10.3155/1047-3289.57.4.465. [DOI] [PubMed] [Google Scholar]

- Zhu L, Cheung CS, Zhang WG, Huang Z. Emissions characteristics of a diesel engine operating on biodiesel and biodiesel blend with ethanol and methanol. Sci Total Environ. 2010;408:914–921. doi: 10.1016/j.scitotenv.2009.10.078. [DOI] [PubMed] [Google Scholar]