Abstract

The objectives of this investigation were to evaluate the degradation in fatigue strength of dentin by diamond bur preparations and to identify the importance of cutting direction. Three groups of coronal dentin specimens were prepared from unrestored 3rd molars, including a flaw free “control”, and two groups that received a diamond bur cutting treatment performed parallel or perpendicular to the specimen length. The specimens were subjected to static or cyclic flexural loading to failure and the results were compared with data for carbide bur cutting. Under static loading diamond bur cutting resulted in significantly flexure lower strength (p≤0.05) than the control for both cutting directions (from 154 MPa to approx. 124 MPa). However, there was no significant difference in the strength between the control and carbide bur treated specimens. Similarly, the fatigue strength of the diamond bur treated specimens was significantly lower (p≤0.0001) than that of the control for both cutting directions. Cutting in the perpendicular direction resulted in nearly 60% reduction to the endurance limit (from 44 MPa to 19 MPa). Based on the results, diamond bur cutting of cavity preparations causes a reduction in the fatigue strength of dentin, regardless of the cutting direction. To maintain the durability of dentin, cavity preparations introduced using diamond burs must be performed with appropriate cutting direction and followed by a finishing pass.

Keywords: cutting, dentin, diamond bur, fatigue, tooth fracture

1. INTRODUCTION

Cutting of tooth tissues is necessary in the removal of caries, in preparations preceding the placement of crowns and bridges, in the repair of failing restorations and in many other routine operations. The use of carbide and diamond burs operated with a high-speed handpiece is fundamental to the profession of dentistry. Perhaps by coincidence, those teeth that have been restored with methods involving cutting operations are also among the most likely to undergo failure. Next to secondary caries, tooth fracture is recognized as one of the most common forms of restored tooth failure.1,2 Are these fractures simply a result of the loss of tissue and reduction in tooth strength, or does the cutting process introduce damage that predisposes these teeth to fracture?

Kinney et al.3 reasoned that intrinsic defects within dentin and enamel, or those introduced by a cutting process, diminish the structural integrity of these tissues. Akin to the damage introduced in dental ceramics during cutting,4 damage introduced within the tooth tissues may facilitate restored tooth fracture. Earlier studies have sought to characterize the defects introduced during cutting of dentin and enamel,5,6 but their results were not conclusive. Though cracks have been found in enamel prepared with carbide and diamond burs,7 flaws are generally not found in dentin. Neither Banerjee et al.8 or Sehy and Drummond9 could identify visible cracks or microcracking in dentin after performing bur treatments and an evaluation by microscopy. Based on the results of these studies, it would appear that restored tooth fractures are primarily a result of the loss of tooth structure and not defects/flaws introduced by cutting.

Damage introduced within dentin has become an important topic in the field of endodontics, particularly with regards to its potential contribution to the incidence of Vertical Root Fracture (VRF). A number of studies have reported that damage is introduced during instrumentation of the canal during some methods of preparations [e.g. 10–12]. Nevertheless, a recent study involving a comparison of teeth from cadavers showed no difference in the presence of microcracks between instrumented teeth and controls (i.e. without instrumentation).13 Hence, there is controversy over whether the instrumentation process is responsible for the introduction of visible microcracks within root structure and their contribution to the incidence of VRF in root canal filled teeth.

As an alternative to microscopy, an exploration of damage or defects in tooth structure can be performed through an evaluation of strength. For instance, Staninec et al.14 showed that laser preparations reduced the strength of dentin but that only the most detrimental conditions resulted in visible flaws. Flaws introduced with dental burs may be too small to see by microscopic evaluations but could cause degradation in strength if sufficient in size. Majd et al.15 explored the influence of cutting on the durability of the dentin under both static and cyclic loading to failure. Although there was no influence of bur or airjet preparations on the strength of dentin under quasi-static loading, both treatments caused a significant reduction in the fatigue strength. One limitation of that study is that it considered cutting with carbide burs only and was limited to a single cutting direction. Flaws introduced within materials by cutting and grinding processes are often direction dependent [e.g. 16,17]. The reduction in strength is most severe when the direction of cutting and prominent lay of the surface is oriented transverse to the maximum normal stress. Despite its clinical relevance, no study has been reported on the contributions from cutting direction to the strength of dentin. While it is recognized that finishing is an important part of cavity preparations, there are essentially no guidelines for the direction of cutting.

Diamond burs are more commonly used today for cutting tooth tissues than in the past. Therefore, the primary objectives of this study were to evaluate the degradation in fatigue strength of coronal dentin resulting from cutting preparations with diamond burs, to compare that with results for carbide bur cutting and to determine the influence of cutting direction. The hypotheses to be tested were: 1) cutting with diamond burs reduces the fatigue strength of dentin, and 2) cutting direction has no effect on the fatigue strength.

2. MATERIALS AND METHODS

Caries-free third molars were obtained from participating dental practices in Maryland according to a protocol approved by the Institutional Review Board of the University of Maryland Baltimore County (Approval Y04DA23151). All teeth were from young donors between 17 and 25 years of age. The teeth were maintained in Hanks Balanced Salt Solution (HBSS) with 0.2% sodium azide as an antimicrobial agent at 4 °C, then cast in a polyester resin foundation, and sectioned using a highspeed grinder (Chevalier Smart-H818II, Chevalier Machinery, Santa Fe Springs, CA, USA) and diamond impregnated slicing wheels (#320 mesh abrasives) within a water coolant bath. Primary sections were made along the tooth’s axis, and secondary sectioning was performed to obtain rectangular beams (Figure 1(a)). A microscopic inspection was conducted to reject specimens with pulp horn intrusions, enamel end-caps or other non-uniformities.

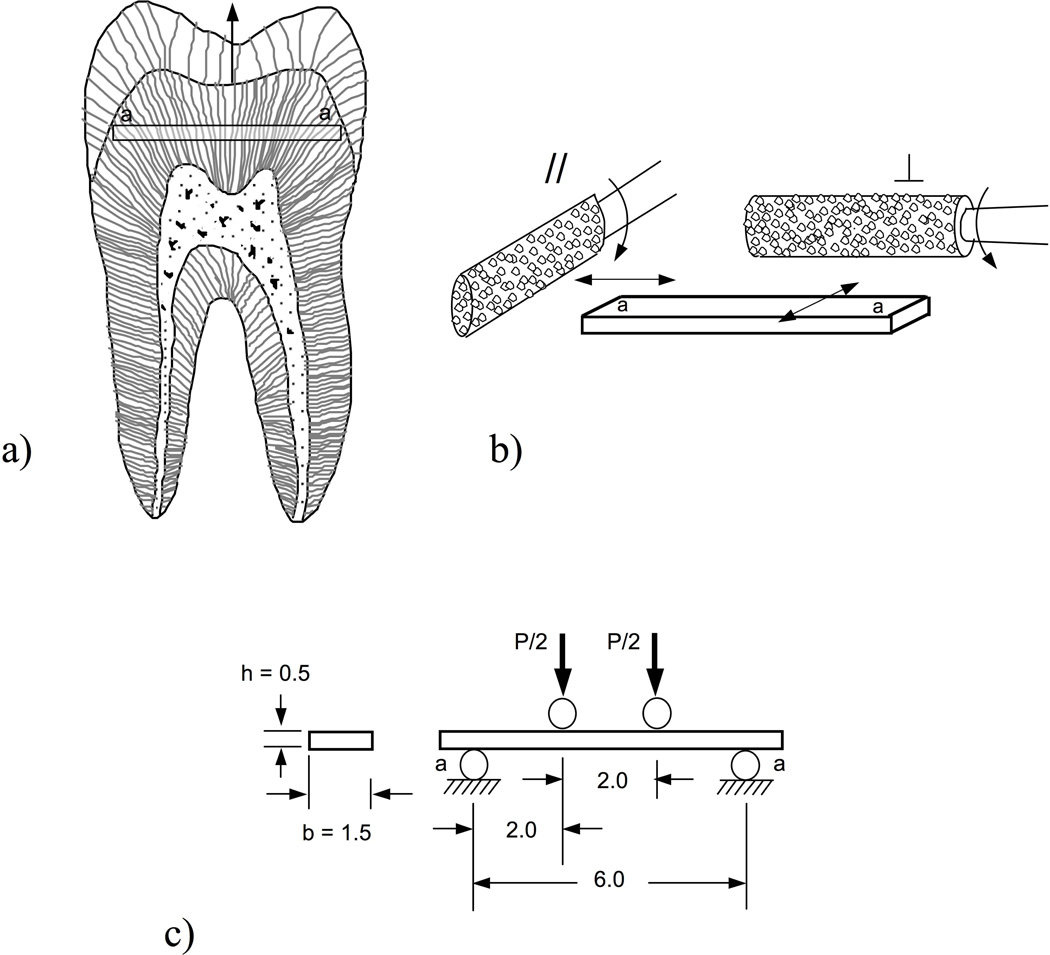

Figure 1.

Specimen preparation and flexure loading of the dentin specimens.

a) location of the crown in which the specimens were obtained. The dentin tubules are oriented perpendicular to the beam length and all beams were obtained from the central coronal region, equidistant from the pulp and DEJ. b) diamond abrasive bur treatments for the parallel (//) and perpendicular (⊥) cutting directions. Note that the surface receiving bur treatment (a-a) faces the DEJ. c) nominal specimen geometry and flexural loading configuration for both monotonic and cyclic loading. All dimensions are listed in millimeters. All of the specimens were loaded with the treated surfaces (a-a) subjected to tension.

The dentin beams were subdivided into a nominally flaw-free control group evaluated directly “as-sectioned” and two additional groups further modified by surface treatment. All of the control beams were sectioned using the slicer/grinder with final thickness of 0.5 mm. The two treated groups were sectioned to have an initial thickness of approximately 0.65 mm, and then further reduced in thickness by cutting using a flat-end taper commercial medium grit diamond bur (Model NS847018M 27AA, Premier, Plymouth Meeting PA, USA) with water spray irrigation. One group was processed with the cutting direction parallel to the beam length, and the second group treated by cutting in the perpendicular direction (Figure 1(b)). Results for the diamond bur treated specimens were also compared to specimens subjected to a surface treatment using a 6-flute tungsten carbide straight fissure bur (Model FG 57, SS White, Lakewood NJ, USA) as reported in Majd et al.15

Diamond bur cutting of the dentin beams was performed with hydration using a commercial air turbine (Midwest Quiet Air-L High Speed Handpiece, Dentsply, York, PA, USA). Hydration was maintained during cutting with water spray. Material was removed from one surface (denoted a-a in Figure 1(b)) in three equal passes for a total depth of material removal of 150 µm and a final specimen thickness of approximately 0.5 mm. The depth of cut was defined by preliminary tests in which a dentist made finishing passes on beams and controlled the depth of cut by tactile sense. Then the resulting depth of cut was measured and used in controlled cutting operations performed by attaching the handpiece with bur to a miniature milling machine (Dyna Mechtronics, Model Dynamyte 2400 CNC milling machine, San Jose, CA). Use of the milling machine provided controlled feed of the bur across the dentin specimens and ability to achieve a precise and uniform depth of cut that is clinically-relevant. The process also ensured that that the treated surface was uniform and would not have surface craters (resulting from inadvertent hand movements) that interfered with the flexure loading. A new bur was used after every 10 specimens to ensure that the bur was sharp. The total time involved in treatment (involving preparation and cutting) was less than five minutes. The procedures adopted for the diamond bur cutting are consistent with those used and reported in Majd et al.15 Following completion of the preparation, the specimens were returned to an HBSS bath prior to testing.

The average surface roughness (Ra) and peak to valley height (Ry) resulting from the treatments were assessed using contact profilometry (Model T8000, Hommelwerke, Jena, Germany). Profiles were obtained with direction parallel to the long axis of the beams using a 10 µm diameter contact probe. This profile orientation characterizes the apparent notches and surface defects that will promote a stress concentration under the tensile stresses that develop with flexural loading and directed along the length of the beam. The surface roughness parameters were calculated according to the standard ANSI B 48.1 using a traverse length and cutoff length of 4.8 mm and 0.8 mm, respectively.

Quasi-static and cyclic four-point flexure testing was conducted at room temperature (22 °C) within a HBSS bath using a universal testing system (Model 3200, BOSE ElectroForce, Eden Prairie, MN, USA) using routine methods utilized in previous studies.18,19 Quasi-static flexure was performed under displacement control loading at a rate of 0.06 mm/min (Figure 1(c)). The instantaneous load and load-line displacement were monitored at a frequency of 2 Hz to failure, with the average test requiring slightly less than five minutes. The cross-section geometry of each beam was measured and recorded for estimation of the bending stress that resulted from the flexure loading. The strength was determined using conventional beam theory20 according to 3Pl/bh2, where P is the maximum measured load, b and h (Figure 1(c)) define the beam geometry and l is the loading span (= 2 mm). The flexure strengths were compared using one-way ANOVA and the critical value (alpha) was set at 0.05. Overall, 35 specimens were evaluated by quasi-static loading and included ten specimens from each of the two diamond bur treated groups and fifteen specimens from the control group.

Cyclic loading experiments were conducted according to the same loading arrangement used for quasi-static evaluation (Fig. 1(c)) with a stress ratio (R=min load/max load) of 0.1 and frequency of 5 Hz. These conditions are in accordance with those used in previous studies.15,18,21 The cyclic loading experiments were initially performed using a maximum stress of approximately 90% of the average strength determined from the monotonic loading experiments. Subsequent tests were then conducted at a reduced level of maximum stress until reaching a value when the beams did not fail within a prescribed number of cycles. Specifically, each beam was subjected to cyclic loading until failure or up to 1,200 kcycles, a value distinguished to be near the apparent endurance limit after previous studies.21,22 The fatigue life distribution of the specimens that underwent fatigue failure in each group was modeled according to the Basquin-type model23

| (1) |

where A and B are the fatigue-life coefficient and exponent, respectively and were obtained from a regression of the fatigue responses plotted on a log-normal scale. The apparent endurance limit was estimated from the models developed for each group at a fatigue limit (N) defined as 1×107 cycles. Overall, 130 specimens were evaluated by cyclic loading and included 80 control specimens and 25 specimens from each of the two groups of diamond bur treatment. Some of the specimens from the “control” condition were also part of the specimens prepared and evaluated in a previously reported study.18 The fatigue life distributions were compared using the Wilcoxon Rank Sum test to establish significant differences with the critical value (alpha) set at 0.05.

Selected specimens from the control and treated groups were analyzed using a Scanning Electron Microscope (SEM: JEOL Model JSM 5600, Peabody MA, USA) in secondary electron imaging mode. Both the treated surfaces and the fracture surfaces were examined using the SEM and optical microscopy to distinguish distinct flaws or the origin of failure, if evident.

3. RESULTS

A comparison of surface profiles from the control and diamond bur treated specimens is shown in Figure 2(a). There are distinct differences evident in the surface height distributions between the three methods of preparation. Cutting with the diamond burs in the perpendicular direction clearly resulted in profile height variations with the largest amplitude. The average surface roughness and peak to valley height measurements obtained from the surface profiles from each group are shown in Figure 2(b). These values are also compared with the surface roughness parameters reported in Majd et al.15 for cutting of dentin with carbide burs. As evident in Figure 2(b), diamond bur cutting in the perpendicular direction resulted in an average surface roughness and peak to valley height nearly ten times greater than those values resulting from the control and the other two groups of prepared specimens. When comparing the magnitude of average surface roughness, there was no significant difference (p>0.05) in the surface quality between the control specimens and two treated groups (i.e. diamond and carbide bur) with parallel cutting direction. However, diamond bur cutting with perpendicular direction resulted in significantly greater average surface roughness (p≤0.0005) than that for the control and those specimens treated with either diamond or carbide bur with parallel cutting direction. Similarly, diamond bur cutting with perpendicular direction resulted in significantly greater peak to valley height (p≤0.0001) than for all of the other groups of specimens as well.

Figure 2.

The surface texture resulting from the methods of preparation.

a) surface profiles from representative control and treated specimens using the diamond abrasive burs, b) average surface roughness (Ra) and peak to valley height (Ry) of the control and specimens treated with diamond abrasive and carbide burs. Results for the carbide burs are from Majd et al.15

Scanning electron micrographs obtained from the surface of the control specimens and from diamond bur cutting are shown in Figure 3(a) and 3(b), respectively. Despite the differences in surface roughness parameters between specimens of these two groups, there was minimal difference in the characteristics of the cut surfaces. Both exhibit a smear layer and a distinct directionality that is associated with the direction of cutting. The surface for diamond bur preparation in Fig. 3(b) corresponds to cutting in the perpendicular direction and shows a combination of valleys and ridges related to the path of abrasive particles distributed about the body of the bur. Note that a micrograph is not shown for diamond bur cutting in the parallel direction since the surfaces resulting from the two directions were essentially identical. The only visible difference between the surface characteristics of these two groups was the direction of the lay marks, which correspond to the path of the abrasive particles with bur traverse movement. Their contact path is scored onto the surface during oscillation of the bur. Similar features are evident in the control specimens, yet with substantially smaller amplitude and with direction aligned with the beam length.

Figure 3.

Micrographs of treated surfaces from selected specimens. a) the surface from a control specimen. b) the surface after diamond bur cutting in the perpendicular direction. The specimen length extends from the left to right. Both of the surfaces in (a) and (b) show some degree of a smear layer, which obscures details of the microstructure beneath. Also note that the surface after diamond bur cutting in the parallel direction (not shown) is essentially identical to that in (b). The only difference is that the direction of the lay marks extends in the horizontal direction (rotated 90° with respect to that shown in (b)).

Results from quasi-static loading of the dentin specimens to failure provided measures of the strength in flexure. The average and standard deviation in strength of the control specimens was 154 ± 24 MPa. For those prepared using diamond burs, the average strength of specimens obtained for the parallel and perpendicular cutting directions, were 123 ± 21 MPa and 125 ± 25 MPa, respectively. For comparison, the average strength of the specimens receiving carbide bur treatment was 152 ± 22 MPa.15 Although there was no significant difference (p>0.05) in strength between the diamond bur treated specimens with parallel and perpendicular cutting directions, both groups were significantly weaker (p≤0.05) than the control group and those receiving treatment using the carbide burs.

Results obtained from fatigue testing of the dentin specimens provided measures of the fatigue life (i.e. number of cycles to failure) in terms of the applied stress amplitude. A comparison of the fatigue life distributions for the control dentin specimens and diamond bur treated specimens with parallel orientation is shown in Figure 4(a). As evident in this comparison, cutting of dentin with the diamond burs resulted in lower fatigue strength. Power-law models were developed for the fatigue life distributions using a least-squares error approach and are presented with the experimental data. A comparison of the fatigue life distributions for the two directions of diamond bur cutting is presented in Figure 4(b). Based on these two distributions, cutting in the perpendicular direction resulted in the lowest fatigue strength. A comparison of the results using the Wilcoxon Rank Sum test indicated that the fatigue strength of specimens treated using the diamond bur with parallel (Z = −5.7; p≤0.0001) and perpendicular (Z = −6.9; p≤0.0001) cutting directions were both significantly lower than the control. In addition, the fatigue strength from cutting with perpendicular direction was significantly lower (Z = −4.0; p≤0.0001) than that obtained with parallel direction.

Figure 4.

Fatigue life diagrams for the dentin specimens. a) comparison of the control and diamond bur specimens with parallel cutting direction. The fatigue strength of the specimens treated using the diamond burs with parallel cutting direction is significantly lower than the control group (Z = −5.7; p≤0.0001). b) comparison of the diamond bur treated specimens with parallel and perpendicular cutting directions. The fatigue strength of the specimens treated using the perpendicular cutting direction is significantly lower (Z = −4.0; p≤0.0001) than those treated with parallel cutting direction.

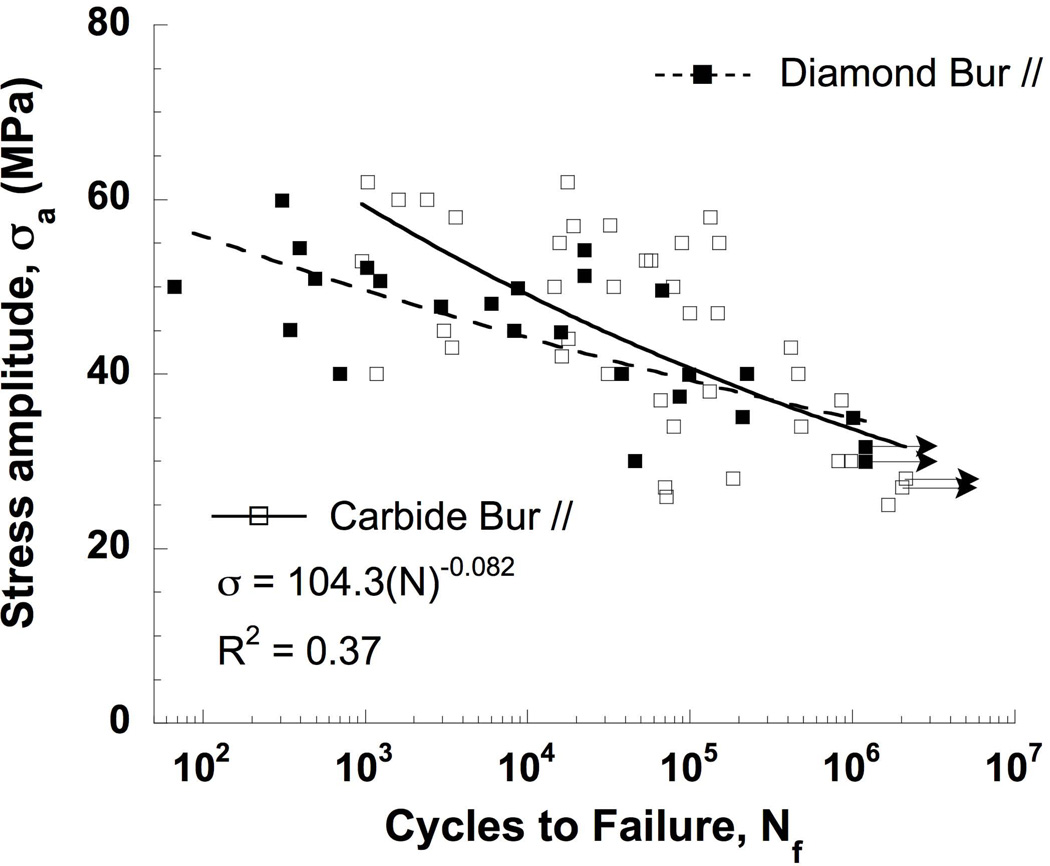

A comparison of the fatigue life distributions for the diamond bur treated specimens to those reported in Majd et al.15 for carbide bur treatment are shown in Figure 5; both of the cutting processes represented in this figure were performed in the parallel direction. There was no significant difference (Z = −0.2; p=0.88) in the fatigue strength distributions for the two methods of cutting. Hence, all three conditions of surface treatment caused a reduction in the fatigue strength of dentin with respect to that of the control. Although there was no difference in the mean response between these two groups, there is a difference in the degree of variation. The fatigue life distribution of specimens obtained by carbide bur treatment exhibits a larger degree of variability than that for diamond bur cutting (Figure 5), as evident from the lower coefficient of determination (R2=0.37) and the distribution of the data.

Figure 5.

A comparison of the fatigue life distributions for specimens receiving diamond bur and carbide bur cutting treatments. Cutting for both groups was in the perpendicular direction. There was no significant difference (Z = −0.2; p=0.88) in the fatigue strength distributions for the two methods of cutting.

The power-law models that were developed for each of the fatigue life distributions can be used for estimating an “apparent” endurance limit at a specific value of stress amplitude. Obtaining estimates in this manner provides an objective definition for each group. For the flaw-free control, the apparent endurance limit estimated at 1×107 cycles is approximately 44 MPa. Using this same approach for the treated specimens, the apparent endurance limits for diamond bur cutting with parallel and perpendicular directions are 29 and 19 MPa, respectively. According to results presented for carbide bur treatment,15 the reported apparent endurance limit is 28 MPa.

A fractographic analysis of the failed specimens was performed to search for the origin of failure and to detect potential differences in the failure characteristics. As noted from the presence of a compression curl on all the specimens examined, the initiation of failure occurred at the treated surface under tensile stress.24 However, the specific origin of failure could not be identified in either the control or treated groups. The fracture surfaces were also evaluated using scanning electron microscopy. Representative micrographs from each method of preparation are shown in Figure 6. Each of the micrographs in this figure was obtained just beneath the treated surface in the region of maximum tensile stress. The fracture surface from a representative control specimen is shown in Figure 6(a). Micrographs from the fracture surfaces of specimens receiving diamond bur treatments with parallel and perpendicular cutting directions are shown in Figures 6(b) and 6(c), respectively. In addition, an image from the fracture surface of a sample receiving carbide bur treatment is shown in Figure 6(d). It is important to note that a smear layer can be seen at the cut surface (top) of specimens obtained from each method of preparation. For the control and diamond bur treated surfaces there was no clear evidence of damage that resulted from the cutting process. However, those specimens subjected to carbide bur cutting (Figure 6(d)) exhibited a region of damage located just beneath the smear layer. The extent of damage was not uniformly distributed beneath the entire cut surface, nor was it of equivalent depth in all specimens. However, according to the estimates obtained from examined specimens, the maximum degree of damage extended to a depth (D) of approximately 10 µm beneath the smear layer, which is demarcated in the micrograph of Figure 6(d).

Figure 6.

Micrographs obtained from the fracture surfaces of selected dentin beams. The treated surface (i.e. the surface subjected to the maximum tensile stress) is at the top of these micrographs. Note the smear layer that is evident at the top of the fracture surface. a) control, b), and c) represent diamond abrasive bur treatments with parallel and perpendicular cutting directions. d) after carbide bur treatment from Majd et al.15 The damaged region (D) resulting from the cutting in is highlighted beneath the smear layer (S) in this micrograph.

4. DISCUSSION

Tooth fractures are one of the primary causes of restored tooth failures1,2 and serve as a major obstacle to lifelong oral health. Many fractures occur in teeth with pre-existing cracks. Despite the prominence of this problem, there is currently no treatment recommended for repairing cracked teeth with a clearly documented rate of success.25 Consequently, cracked teeth and those having suffered from incomplete fracture are more likely to result in extraction. Fatigue of dentin can contribute to the incidence of restored tooth fractures by facilitating the growth of small, essentially benign flaws, to a critical state.22,26 While intrinsic flaws within the tissue may serve as the origin of failure, cracks in restored teeth are much more likely to originate from damage introduced during the restorative process. Yet, the contribution of cutting preparations and defects resulting from material removal on the incidence of tooth fracture is rarely discussed.

A comparison of the specimens receiving diamond bur cutting treatment with the flaw-free control showed that the cutting process did not necessarily result in larger surface roughness. Only the perpendicular cutting direction caused significantly larger surface roughness than that of the control group (Figure 2(b)). In cutting with diamond burs, adjacent grooves are introduced via the path of the individual abrasive grains and the combined oscillation and traverse movement of the bur. The grooves promote a distribution of stress concentrations as shown in Figure 7(a). While the same tool type was used for the two cutting directions, the stress concentrations are greater in the specimens with transverse cutting direction because the series of grooves are oriented perpendicular to the direction of tensile stress resulting from flexure. There is an approach for estimating the stress concentration posed by the surface topography. The two deepest valleys of the profile in Figure 7(a) are highlighted in Figures 7(b) and 7(c), along with measures of the respective apparent profile valley radii (ρ) at these locations. Using a graphical radius gage for measurement, the values of ρ from surfaces prepared by diamond bur cutting with transverse direction ranged from roughly 15 µm to over 100 µm; the average was approximately 50 µm. The effective stress concentration (Kt) resulting from the surface texture can be obtained from the surface roughness parameters and measurements of ρ according to Arola and Ramulu.27 For the parallel and perpendicular directions of diamond bur cutting, the estimated Kt are 1.2 and 1.8, respectively. These values are far greater than the values recently reported for surfaces of dentin treated by acid etching (Kt = 1.02).28 For the control and carbide bur treated specimens the estimated Kt are both 1.0, which is substantially lower than those for diamond bur cutting due to the absence of dominant profile valleys. Therefore, one of the major differences between cutting with carbide and diamond burs is the magnitude of Kt posed by the surface texture.

Figure 7.

Profile height distribution for diamond bur cutting with transverse direction. a) surface profile and selected profile valleys for display. This profile is also shown in Figure 2(a). Both (b) and (c) represent the selected valleys with plotting aspect ratio of 1. A graphic radius gage is used in each of these figures to determine the profile valley radius (ρ).

Results from the quasi-static experiments showed that the flexure strength of the specimens treated by diamond bur cutting was lower than that of the control and statistically significant. But the strength of these two groups was approximately 15% lower than that of the control and those specimens prepared using the carbide burs, which may not be clinically significant. Nevertheless, the largest differences in strength were evident in the fatigue responses. The hypotheses to be tested were that cutting with diamond burs reduces the fatigue strength of dentin, but cutting direction with diamond burs is not important. Diamond bur cutting resulted in lower fatigue strength than the control for both directions, which requires that the first hypothesis is accepted. There was also a significant difference in the fatigue strength between the parallel and perpendicular cutting directions (Figure 4(b)). Diamond bur cutting performed in the parallel direction resulted in an apparent endurance limit (29 MPa) approximately 35% lower than that of the control (44 MPa). Cutting in the perpendicular direction resulted in an apparent endurance limit (19 MPa) nearly 35% lower than that obtained for the parallel cutting direction. Therefore, the second hypothesis must be rejected. Cutting direction is very important to the fatigue strength of dentin when using diamond burs. That discovery is not unexpected as the direction of cutting and grinding has been identified to be important to the mechanical behavior of engineering materials for some time.16,17,29,30 Nevertheless, results from the present study are the first to show that both the cutting process and the cutting direction are important to the durability of dentin. Both of these two factors should now be conveyed as being very important to the potential for tooth fracture.

The larger surface roughness and apparent surface stress concentration of the specimens treated by diamond bur cutting might be interpreted as the primary cause for the reduction in strength under static and cyclic loading. Indeed, the stress concentration is important but it is unlikely that surface texture reflects the true integrity of the surface and the degree of underlying surface damage due to the smear layer.31 Damage existing beneath the smear layer was identified in some of the specimens receiving carbide bur treatment (Fig. 6(d)), but to a depth limited to approximately 10 µm. That depth is substantially smaller than the subsurface flaw lengths reported in Majd et al.15 for carbide bur cutting estimated from the fatigue data and the Kitagawa-Takahashi approach;32 the average subsurface flaw length for carbide bur cutting was estimated to be 70 µm. According to the agreement of the apparent endurance limit of the carbide and diamond bur treated specimens with parallel direction, the estimated average subsurface flaw length should be identical. Therefore, in the case of diamond cutting in the perpendicular direction, the reduction in fatigue strength appears to result from the subsurface flaws introduced during material removal and the amplification of the surface stress by the apparent stress concentration.

It is important to comment on the variability in fatigue strength responses presented in Figure 5 for the carbide and diamond bur treated specimens. Both groups show quite extensive scatter in the fatigue life. Some of that variability is reflected by the lower coefficients of determination (R2 values) for these two groups. In fact, the variation in life at a single stress amplitude ranges over several tens of decades for both groups. One could interpret this behavior to reflect on the experimental methods and that it suggests poor repeatability. But the same experimental methods of assessment were used for all groups, and resulted in substantially lower variability for the control and diamond bur treatment with perpendicular cutting direction. That decreases the likelihood of experimental inconsistencies. An alternate interpretation of the scatter in fatigue distributions is that the material removal process in this cutting direction and potential for the introduction of flaws is highly dependent on the microstructure. Spatial variations in tubule density, tubule size, and peritubular cuff thickness illicit a local difference in the mineral to collagen ratio and brittleness. These regions would be more susceptible to the development of flaws during cutting and, for specimens with these microstructural variations, result in lower fatigue life. If material removal will continue to be a staple of restorative dentistry, the ideal process for introducing cavity preparations would maintain the durability of dentin and be independent of microstructure.

One concern in the aforementioned interpretation of results is that subsurface damage was not evident in evaluation of the specimens treated with diamond burs (e.g. Figures 6(b) and 4(c)). Neither were any discrete flaws identified in the fracture surfaces of these specimens. That could be a limitation of the experimental methods used in this study, indicating that conventional microscopy is possibly incapable of revealing the extent of damage that results from cutting of dentin. The limited success of visual examinations increases the necessity of assessing the apparent flaw sizes and their significance through the degradation in mechanical behavior. It also highlights the need for development and application of alternative approaches to identify defects and cracks in tooth tissues. Groth et al48 found value in using X-ray micro tomography in identifying damage in enamel as a result of laser irradiation. However, preliminary attempts at using micro computed tomography with micron resolution to identify bur-related cutting damage in dentin did not show clea evidence of discrete flaws. In fact, edge effects dominated the cut surfaces and post-process filtering was not successful at eliminating potential artifacts from damage. Yet, sub-micron resolution CT or alternative high resolution imaging techniques may prove valuable in this regard and future work appears warranted.

While studies aimed at the damage resulting from cavity preparations and cutting with either carbide or diamond burs are limited, there has been substantial work regarding flaws introduced by instrumentation of root canals. There is also evidence that some methods of endodontic preparation damage the root and induce dentinal defects [e.g. 10–12]. But not all methods cause damage. In comparing rotary files with hand files and self-adjusting files, Yoldas et al.33 reported that all rotary files created microcracks in the root dentin, whereas the other files did not. After instrumentation, the stresses introduced by lateral compaction appear to result in a larger number of defects,11 or an increase in size of existing defects and their visibility. Adorno et al.34 suggested that root canal procedures involving instrumentation and compaction facilitate the initiation and propagation of cracks in the apical region of the root. An in vitro study by Barreto et al.35 showed that while cyclic loading alone did not induce fracture in unprepared teeth, instrumented teeth followed by lateral compaction and mechanical cycling underwent a significantly higher incidence of root fractures. These findings imply that fatigue contributes to the growth of flaws caused by the cutting process and, in turn, reduces the durability of the tissue. That process is consistent with the findings in the present study, which showed that cutting with both carbide and diamond burs resulted in a reduction of fatigue strength of dentin.

Relevant to the discussion of tooth fracture is the importance of patient age and spatial variations in the properties of dentin. Due to changes in microstructure with age, dentin undergoes a decrease in fatigue strength,21,36 fatigue crack growth resistance37,38 and fracture toughness.39,40 This increase in “brittleness” of the tissue with age41 elevates the propensity for the introduction of flaws during the cutting process and an increase in their growth rate. Both are detrimental to the tooth’s durability. In addition, there is a reduction in both the fatigue crack growth resistance and fracture toughness of dentin with increasing distance from the dentin enamel junction.42,43 This spatial variation in properties increases the potential of flaws to be introduced in deep cavity preparations and to facilitate tooth fractures. Thus, diamond bur cutting and related damage resulting from the cavity preparation becomes increasingly detrimental with depth. From this perspective, finishing operations are essential in the placement of deep restorations and particularly in the treatment of seniors. Furthermore, the direction of cutting should be performed parallel to the expected direction of tensile stresses generated by mastication.

There are recognized limitations to this investigation that warrant discussion. For example, the influence of cutting was evaluated using medium grit diamond burs only. Cavity preparations should involve a finishing pass with a fine bur in an attempt to remove flaws introduced using the medium diamond and increase the overall surface quality. If successful, that step might facilitate a recovery in fatigue strength or an improvement in performance to a level more akin to the control. A complimentary investigation should explore the extent of material removal necessary using a finishing process, in subsequent steps, to remove the existing damage. Direction of cutting should also be considered as well as other factors related to the parameters involved in material removal (e.g. depth of cut, speed, etc). Future studies will address these issues.

There are additional limitations that should be highlighted as well. For instance, fatigue testing of the dentin specimens was conducted using a frequency of 5 Hz according to the methods adopted in earlier studies.15,18,21 But 5 Hz is higher than that expected in mastication (~2 Hz).44 The fatigue strength of dentin is susceptible to frequency effects,22,45 and there is an increase in fatigue strength with loading frequency. Thus, the estimated values of apparent endurance limit may be larger than those obtained under the loading rates of mastication, thereby resulting in an underestimate of the extent of degradation caused by the cutting process. Regardless of loading frequency, there is a reduction in fatigue strength of dentin with bur cutting.

Another limitation of this study is that the control specimens were considered to be “flaw free”. A true flaw-free control would require that the specimens be polished sufficiently to remove the smear layer and any damage introduced by the slicing process. While this finishing process is possible, it is not easily achieved due to the small specimen size and increasing potential for geometric errors in specimen profile. In addition, a measure of the true fatigue strength of dentin from a flaw free control would be difficult to obtain due to the influence of changes in the dentin tubule density in the tooth crown46 and their influence on the strength19,47 and fatigue resistance.42

Despite the aforementioned limitations, this study has provided new understanding regarding the cutting of cavity preparations and its importance to the durability of restored teeth. If cavity preparations will remain a staple of restorative dentistry, the development of improved methods and/or ancillary steps capable of maintaining the fatigue strength of dentin may be warranted.

5. CONCLUSION

Cutting of dentin is an integral component of restorative dentistry. According to the data collected in this study, cutting of coronal dentin with diamond abrasive burs resulted in statistically significant reductions in dentin strength under both static and cyclic loading conditions. The findings of most clinical relevance were that the largest degree of reduction occurred to the fatigue strength and that cutting with diamond burs can cause greater degradation than that resulted from cutting with tungsten carbide straight fissure burs. Furthermore, the direction of cutting was an important factor to the fatigue response. The largest reduction in fatigue strength occurred when the direction of cutting was perpendicular to the direction of maximum principal stress. The degradation in strength appears to have been caused by a combination of localized damage resulting from the cutting process, and the stress concentration posed by grooves that are formed by individual abrasive grains about the periphery of the bur.

Acknowledgments

Support for the following investigation was provided in part by the National Institutes of Dental and Craniofacial Research (DE016904).

REFERENCES

- 1.Deligeorgi V, Mjor IA, Wilson NH. An overview of reasons for the placement and replacement of restorations. Prim Dent Care. 2001;8(1):5–11. doi: 10.1308/135576101771799335. [DOI] [PubMed] [Google Scholar]

- 2.Brunthaler A, König F, Lucas T, Sperr W, Schedle A. Longevity of direct resin composite restorations in posterior teeth. Clin Oral Investig. 2003;7(2):63–70. doi: 10.1007/s00784-003-0206-7. [DOI] [PubMed] [Google Scholar]

- 3.Kinney JH, Marshall SJ, Marshall GW. The mechanical properties of human dentin: a critical review and re-evaluation of the dental literature. Crit Rev Oral Biol Med. 2003;14(1):13–29. doi: 10.1177/154411130301400103. [DOI] [PubMed] [Google Scholar]

- 4.Rekow D, Thompson VP. Engineering long term clinical success of advanced ceramic prostheses. J Mater Sci: Mater Med. 2007;18(1):47–56. doi: 10.1007/s10856-006-0661-1. [DOI] [PubMed] [Google Scholar]

- 5.Leidal TI, Tronstad L. Scanning electron microscopy of cavity margins finished with ultra high speed instruments. J Dent Res. 1975;54:152–159. doi: 10.1177/00220345750540011001. [DOI] [PubMed] [Google Scholar]

- 6.Watson T, Cook RJ. The influence of bur blade concentricity on high-Speed tooth-cutting interactions: A video-rate confocal microscopic study. J Dent Res. 1995;74:1749–1755. doi: 10.1177/00220345950740110601. [DOI] [PubMed] [Google Scholar]

- 7.Xu HHK, Kelly JR, Jahanmir S, Thompson VP, Rekow ED. Enamel subsurface damage due to tooth preparation with diamonds. J Dent Res. 1997;76(10):1698–1706. doi: 10.1177/00220345970760101201. [DOI] [PubMed] [Google Scholar]

- 8.Banerjee A, Kidd EA, Watson TF. Scanning electron microscope observations of human dentine after mechanical caries excavation. J Dent. 2000;28:179–186. doi: 10.1016/s0300-5712(99)00064-0. [DOI] [PubMed] [Google Scholar]

- 9.Sehy C, Drummond JL. Micro-cracking of tooth structure. Am J Dent. 2004;17(5):378–380. [PubMed] [Google Scholar]

- 10.Adorno CG, Yoshioka T, Jindan P, Kobayashi C, Suda H. The effect of endodontic procedures on apical crack initiation and propagation ex vivo. Int Endod J. 2013;46:763–768. doi: 10.1111/iej.12056. [DOI] [PubMed] [Google Scholar]

- 11.Shemesh H, Bier CA, Wu MK, Tanomaru-Filho M, Wesselink PR. The effects of canal preparation and filling on the incidence of dentinal defects. Int Endod J. 2009;42(3):208–213. doi: 10.1111/j.1365-2591.2008.01502.x. [DOI] [PubMed] [Google Scholar]

- 12.Bürklein S, Tsotsis P, Schäfer E. Incidence of dentinal defects after root canal preparation: reciprocating versus rotary instrumentation. J Endod. 2013;39(4):501–504. doi: 10.1016/j.joen.2012.11.045. [DOI] [PubMed] [Google Scholar]

- 13.Arias A, Lee YH, Peters CI, Gluskin AH, Peters OA. Comparison of 2 canal preparation techniques in the induction of microcracks: A pilot study with cadaver mandibles. J Endod. 2014;40(7):982–985. doi: 10.1016/j.joen.2013.12.003. [DOI] [PubMed] [Google Scholar]

- 14.Staninec M, Meshkin N, Manesh SK, Ritchie RO, Fried D. Weakening of dentin from cracks resulting from laser irradiation. Dent Mater. 2009;25(4):520–525. doi: 10.1016/j.dental.2008.10.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Majd H, Viray J, Porter JD, Romberg E, Arola D. Degradation in the fatigue resistance of dentin by burr and air jet preparations. J Dent Res. 2012;91(9):894–899. doi: 10.1177/0022034512455800. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Rice RW, Mecholsky JJ, Jr, Becher PF. The Effect of Grinding Direction on Flaw Character and Strength of Single Crystal and Polycrystalline Ceramics. J Mat Sci. 1981;16:853–862. [Google Scholar]

- 17.Quinn GD, Ives LK, Jahanmir S. On the nature of machining cracks in ground ceramics. Part I: SRBSN strengths and fractographic analysis. Mach Sci Tech. 2005;9(2):169–210. [Google Scholar]

- 18.Arola D, Reprogel R. Tubule orientation and the fatigue strength of human dentin. Biomaterials. 2006;27(9):2131–2140. doi: 10.1016/j.biomaterials.2005.10.005. [DOI] [PubMed] [Google Scholar]

- 19.Ryou H, Amin N, Ross A, Wang DH, Eidelman N, Romberg E, Arola D. Contributions of microstructure and chemical composition to the mechanical properties of dentin. J Mat Sci: Mater Med. 2011;22(5):1127–1135. doi: 10.1007/s10856-011-4293-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Popov EP. Mechanics of Materials. 2nd Edition. New Jersey: Prentic Hall Inc.; 1978. [Google Scholar]

- 21.Arola D, Reprogel R. Effects of aging on the mechanical behavior of human dentin. Biomaterials. 2005;26(18):4051–4061. doi: 10.1016/j.biomaterials.2004.10.029. [DOI] [PubMed] [Google Scholar]

- 22.Nalla RK, Imbeni V, Kinney JH, Staninec M, Marshall SJ, Ritchie RO. In vitro fatigue behavior of human dentin with implications for life prediction. J Biomed Mater Res. 2003;66(1):10–20. doi: 10.1002/jbm.a.10553. [DOI] [PubMed] [Google Scholar]

- 23.Basquin OH. The exponential law of endurance tests. Proceedings of the ASTM, 10(Part II): ASTM West Conshochoken, PA. 1910:625. [Google Scholar]

- 24.Quinn GD. Fractography of Ceramics and Glasses. NIST Special Publicagtion 960-16, US Government Printing Office. 2007:4–16.

- 25.Lubisich EB, Hilton TJ, Ferracane J. Cracked teeth: a review of the literature. J Esthet Restor Dent. 2010;22(3):158–167. doi: 10.1111/j.1708-8240.2010.00330.x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Arola D, Huang MP, Sultan MB. The failure of amalgam dental restorations due to cyclic fatigue crack growth. J Mater Sci Mater Med. 1999;10(6):319–327. doi: 10.1023/a:1026435821960. [DOI] [PubMed] [Google Scholar]

- 27.Arola D, Ramulu M. An examination of the effects from surface texture on the strength of fiber reinforced plastics. J Comp Mat. 1999;33(2):102–123. [Google Scholar]

- 28.Do D, Orrego S, Majd H, Ryou H, Mutluay MM, Xu HH, Arola DD. Accelerated fatigue of dentin with exposure to lactic acid. Biomaterials. 2013;34(34):8650–8659. doi: 10.1016/j.biomaterials.2013.07.090. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Mecholsky JJ, Jr, Freiman SW, Rice RW. Effect of grinding on flaw geometry and fracture of glass. J Am Ceram Soc. 1977;60(3–4):114–117. [Google Scholar]

- 30.Strakna TJ, Jahanmir S, Allor RL, Kumar KV. Influence of grinding direction on fracture strength of silicon nitride. ASME J Eng Mater Technol. 1996;118(3):335–342. [Google Scholar]

- 31.Bester SP, de Wet FA, Nel JC, Driessen CH. The effect of airborne particle abrasion on the dentin smear layer and dentin: an in vitro investigation. Int J Prosthodont. 1995;8(1):46–50. [PubMed] [Google Scholar]

- 32.Kitagawa H, Takahashi S. Applicability of fracture mechanics to very small cracks or the cracks in the early stages. Proceedings of the Second International Conference on Mechanical Behavior of Materials; ASM; Metals Park, OH. 1976. pp. 627–631. [Google Scholar]

- 33.Yoldas O, Yilmaz S, Atakan G, Kuden C, Kasan Z. Dentinal microcrack formation during root canal preparations by different NiTi rotary instruments and the self-adjusting file. J Endod. 2012;38(2):232–235. doi: 10.1016/j.joen.2011.10.011. [DOI] [PubMed] [Google Scholar]

- 34.Adorno CG, Yoshioka T, Suda H. The effect of root preparation technique and instrumentation length on the development of apical root cracks. J Endod. 2009;35:389–392. doi: 10.1016/j.joen.2008.12.008. [DOI] [PubMed] [Google Scholar]

- 35.Barreto MS, Moraes Rdo A, Rosa RA, Moreira CH, Só MV, Bier CA. Vertical root fractures and dentin defects: effects of root canal preparation, filling, and mechanical cycling. J Endod. 2012;38(8):1135–1139. doi: 10.1016/j.joen.2012.05.002. [DOI] [PubMed] [Google Scholar]

- 36.Kinney JH, Nalla RK, Pople JA, Breunig TM, Ritchie RO. Age-related transparent root dentin: mineral concentration, crystallite size, and mechanical properties. Biomaterials. 2005;26(16):3363–3376. doi: 10.1016/j.biomaterials.2004.09.004. [DOI] [PubMed] [Google Scholar]

- 37.Bajaj D, Nazari A, Sundaram N, Arola D. Aging, dehydration and fatigue crack growth in human dentin. Biomaterials. 2006;27(11):2507–2517. doi: 10.1016/j.biomaterials.2005.11.035. [DOI] [PubMed] [Google Scholar]

- 38.Ivancik J, Majd H, Bajaj D, Romberg E, Arola D. Contributions of aging to the fatigue crack growth resistance of human dentin. Acta Biomat. 2012;8(7):2737–2746. doi: 10.1016/j.actbio.2012.03.046. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Koester KJ, Ager JW, 3rd, Ritchie RO. The effect of aging on crack-growth resistance and toughening mechanisms in human dentin. Biomaterials. 2008;29(10):1318–1328. doi: 10.1016/j.biomaterials.2007.12.008. [DOI] [PubMed] [Google Scholar]

- 40.Nazari A, Bajaj D, Zhang D, Romberg E, Arola D. On the reduction in fracture toughness of human dentin with age. J Mech Behav Biomed Mat. 2009;2(5):550–559. doi: 10.1016/j.jmbbm.2009.01.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 41.Arola D. Fracture and Aging in Dentin. In: Curtis R, Watson T, editors. Dental Biomaterials: Imaging, Testing and Modeling. Cambridge, UK: Woodhead Publishing; 2007. [Google Scholar]

- 42.Ivancik J, Neerchal NK, Romberg E, Arola D. On the reduction in fatigue crack growth resistance of dentin with depth. J Dent Res. 2011;90(8):1031–1036. doi: 10.1177/0022034511408429. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 43.Ivancik J, Arola DD. The importance of microstructural variations on the fracture toughness of human dentin. Biomaterials. 2013;34(4):864–874. doi: 10.1016/j.biomaterials.2012.10.032. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 44.Po JM, Kieser JA, Gallo LM, Tésenyi AJ, Herbison P, Farella M. Time-frequency analysis of chewing activity in the natural environment. J Dent Res. 2011;90(10):1206–1210. doi: 10.1177/0022034511416669. [DOI] [PubMed] [Google Scholar]

- 45.Kruzic JJ, Nalla RK, Kinney JH, Ritchie RO. Mechanistic aspects of in vitro fatigue-crack growth in dentin. Biomaterials. 2005;26(10):1195–1204. doi: 10.1016/j.biomaterials.2004.04.051. [DOI] [PubMed] [Google Scholar]

- 46.Pashley D, Okabe A, Parham P. The relationship between dentin microhardness and tubule density. Endod Dent Traumatol. 1985;1(5):176–179. doi: 10.1111/j.1600-9657.1985.tb00653.x. [DOI] [PubMed] [Google Scholar]

- 47.Inoue S, Pereira PN, Kawamoto C, Nakajima M, Koshiro K, Tagami J, Carvalho RM, Pashley DH, Sano H. Effect of depth and tubule direction on ultimate tensile strength of human coronal dentin. Dent Mater J. 2003;22(1):39–47. doi: 10.4012/dmj.22.39. [DOI] [PubMed] [Google Scholar]

- 48.Groth EB, Mercer CE, Anderson P. Microtomographic analysis of subsurface enamel and dentine following Er:YAG laser and acid etching. Eur J Prosthodont Restor Dent. 2001;9(2):73–79. [PubMed] [Google Scholar]